Abstract

Several methods and techniques are potentially useful for the preparation of microparticles in the field of controlled drug delivery. The type and the size of the microparticles, the entrapment, release characteristics and stability of drug in microparticles in the formulations are dependent on the method used. One of the most common methods of preparing microparticles is the single emulsion technique. Poorly soluble, lipophilic drugs are successfully retained within the microparticles prepared by this method. However, the encapsulation of highly water soluble compounds including protein and peptides presents formidable challenges to the researchers. The successful encapsulation of such compounds requires high drug loading in the microparticles, prevention of protein and peptide degradation by the encapsulation method involved and predictable release, both rate and extent, of the drug compound from the microparticles. The above mentioned problems can be overcome by using the double emulsion technique, alternatively called as multiple emulsion technique. Aiming to achieve this various techniques have been examined to prepare stable formulations utilizing w/o/w, s/o/w, w/o/o, and s/o/o type double emulsion methods. This article reviews the current state of the art in double emulsion based technologies for the preparation of microparticles including the investigation of various classes of substances that are pharmaceutically and biopharmaceutically active.

Keywords: Microparticles, Double emulsion, Solvent evaporation, Protein drug, Controlled release

1. Introduction

The goal of any drug delivery system is to deliver a therapeutic amount of drug to the proper site in the body and then maintain the therapeutic concentration over a desired period of time. Various conventional drug delivery systems are being used widely to achieve systemic action of drugs. However, in some cases conventional drug delivery manifests toxic side effects. Following, a relatively short period at the therapeutic level, drug concentration eventually drops until re-administered. Novel drug delivery systems have overcome the above mentioned limitations of conventional drug delivery systems. Many efforts in developing novel drug delivery system have been focused on controlled release and sustained release dosage forms. There are various approaches in delivering a therapeutic substance to the target site in a sustained or controlled release fashion. One such approach is using microparticles as carrier for drugs. Microparticles offer greater effectiveness, lower toxicity and better stability than conventional dosage forms (Naha et al., 2008). Microparticulate drug delivery systems are used to prolong the delivery of the drug, to improve bioavailability, to enhance stability and, to target drug to specific site (Barakat and Ahmad, 2008). Microparticles have been prepared by a judicious blend of polymers with different coat core ratios utilizing various methods such as o/w single emulsion solvent evaporation (Dai et al., 2011; Khaled et al., 2010; Yang and Gao, 2010), spray drying (Ramtoola et al., 2011; Yan et al., 2010; Zhang et al., 2010; Khan and Kumar, 2011), ionotropic gelation (Li et al., 2010; Chakraborty et al., 2010; Ma and Liu, 2010; Sriamornsak et al., 2008), coacervation (Ilina et al., 2008; Dong et al., 2007; Celik and Akbuga, 2007; Bayomi, 2004), air suspension, and polymerization (Farook et al., 2008; Lu and Zhang, 2006; Chen et al., 2011; He et al., 2011; Hao et al., 2011; Shi et al., 2011).

The o/w single emulsion solvent evaporation method is the widely used one among various microencapsulation techniques. Water insoluble drugs are successfully retained within microparticles prepared by this method. However, the method is not efficient for the entrapment of hydrophilic drugs because of rapid dissolution of the compounds into the aqueous continuous phase. The problem of efficient encapsulation of hydrophilic drugs can be overcome by using the double emulsion technique. Many types of pharmaceuticals and biopharmaceuticals with different physico-chemical properties have been formulated into microparticles by double emulsion method (Chang et al., 2011; Lu et al., 2011; Karal-Ylmaz et al., 2011; Oh et al., 2011; Liu et al., 2010; Dalmoro et al., 2010; Blatsios et al., 2010). Many review articles have been published on controlled release microparticulate drug delivery system using single emulsion technique. However, no comprehensive review has yet been published on preparation of microparticles using double emulsion technique. This article after extensive survey of literatures presents a report on the advances in the double emulsion technique and the characteristics of microparticles produced by this method. This review also includes the investigation of various classes of pharmaceutical and biopharmaceutical active components used for preparing microparticles by double emulsion technique.

2. Limitations of the single emulsion method for the preparation of microparticles

The main limitation of this method is its limited ability to encapsulate water soluble drugs for their partitioning into the aqueous phase of the emulsion (Bodmeier and McGinity, 1987a,b). A further effect of partitioning is the accumulation of drug crystals on the surface of microparticles, which produces a burst release of the drug upon administration. The partitioning effect of the drug can be reduced by chemically modifying it to a lipophilic prodrug prior to its incorporation into the organic phase (Seki et al., 1990). Otherwise modification of the continuous phase of the emulsion to reduce leakage of the drug from the oily droplets can be employed. Several researchers have therefore suggested replacement of the continuous phase with a less hydrophilic one, as in the case of the non-aqueous emulsion of o/o type (Sturesson et al., 1993; Bodmeier and McGinity, 1987c; Spenlehauer et al., 1988). However, the mineral oil or vegetable oil used as an external oil phase in o/o emulsion is difficult to collect or to remove from the resulting microparticles.

3. Advantages of the double emulsion method for the preparation of microparticles

The double emulsion method has been considered better since the method is relatively simple, convenient in controlling process parameters, and has the ability to produce with simple instrument. The process can efficiently encapsulate highly water soluble compounds including proteins and peptides.

4. Preparation of microparticles using double emulsion technique

4.1. W/O/W double emulsion solvent evaporation technique

In the water in oil in water (w/o/w) double emulsions, the internal and external aqueous phases are separated by an oil layer. For their formation and stability, at least two surfactants, one having a low HLB to form the primary water in oil (w/o) emulsion and the other of higher HLB to achieve secondary emulsification are required to emulsify water in oil emulsion into water. These emulsion (w/o/w) systems being less viscous are excellent candidates for controlled release of hydrophilic drugs due to the existence of a middle oil layer that acts as a liquid membrane.

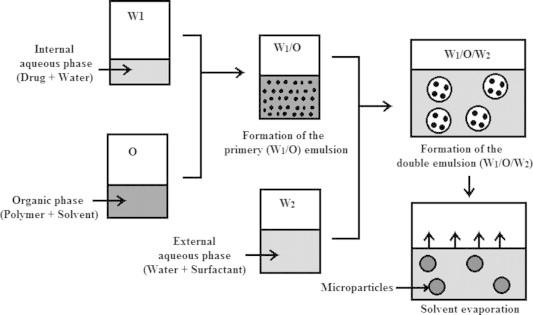

In water/oil/water double emulsion solvent evaporation method, an aqueous solution or suspension of the drug (internal aqueous phase, W1) is emulsified in a solution of polymer in organic solvent. The resulting primary emulsion (W1/O) is then dispersed in a second aqueous phase (external aqueous phase, W2) containing suitable emulsifier(s) to form double emulsion (W1/O/W2). Removal of the volatile organic solvent leads to the formation of solid microparticles (Fig. 1). The solid microparticles are separated by filtration or centrifugation, washed several times in order to eliminate the residual emulsifier and dried under vacuum or freeze-dried. The volatile organic solvent used in the preparation of the microparticles by the double emulsion solvent evaporation method should be of low boiling point to facilitate the removal of residual solvent. Various solvents that can be used for the preparation of microparticles are acetonitrile, ethyl acetate, chloroform, and benzene and methylene chloride. Uchida et al. (1995) prepared ovalbumin loaded poly(lactide-co-glycolide) (PLGA) microparticles by a w/o/w emulsion solvent evaporation technique using NaCl for protection of the internal aqueous droplets. PLGA is a copolymer of lactic acid and glycolic acid. It has been most widely used since their degradation rate and mechanical properties can be precisely controlled by varying the lactic acid/glycolic acid ratio and by altering the molecular weight of the polymers. Author tried to improve the loading efficiency and release of protein of the PLGA microspheres. Using a smaller volume of an internal aqueous phase resulted in a comparatively high loading efficiency than a large volume of the internal aqueous phase. The addition of NaCl into the external aqueous phase also improved ovalbumin loading efficiency. Microscopic examination suggested that in the presence of NaCl in the external aqueous phase, the internal aqueous droplets were stable and were not expelled during the second emulsification. Molecular weight of PLGA is a factor for release characteristics of the prepared microparticles of ovalbumin. The rate of release of ovalbumin from microparticles decreased with an increase in molecular weight of PLGA. Graves et al. (2004) investigated the effect of blending of low molecular weight (Mw) and high molecular weight (Mw) PLGA on the characteristics of microparticles prepared by double emulsion solvent evaporation technique. The drug entrapment efficiency increased significantly when high Mw PLGA (RG 506) was mixed with low Mw PLGA (RG 502) at a ratio of 1:7. However, this formulation also showed significantly high burst release which implies that a major portion of the encapsulated drug was deposited near the surface. The water soluble peptide, pBC 264, was encapsulated in PLGA microparticles using double emulsion solvent evaporation method (Blanco-Prieto et al., 1997). The encapsulation efficiency of pBC 264 in microparticles was very low (<20%) when the inner aqueous phase did not contain any stabilizing agent. However, the encapsulation efficiency was improved to about 41% by the addition of ovalbumin used as stabilizer of the inner emulsion. An additional and significant improvement of the encapsulation efficiency (90%) was observed when pH of the internal aqueous phase was basic (pH 8 corresponding to the optimal solubility of the pBC 264) and when the pH of the external aqueous phase was acid (pH 2.5 corresponding to a lower solubility of pBC 264). In vitro release experiments showed that more than 60% of the peptide released after 10 min. However, the extent of release of the peptide slowed down when the microparticles were prepared with the higher Mw copolymer.

Figure 1.

Preparation of microparticles by the double emulsion solvent evaporation method.

Ovalbumin loaded PLGA microparticles were prepared using w/o/w double emulsion solvent evaporation method by varying the external aqueous phase surfactant (Coombes et al., 1998). PVP stabilized microparticles exhibited higher protein loading, about 8.2%w/w, compared to PVA stabilized microparticles, about 4%w/w. The use of PVP instead of PVA to prepare microparticles also resulted in reduction in the initial burst release of ovalbumin. The former polymer resulted the sustained protein release over 28 days with an increase in the protein delivery capacity from 35 to 45 μg/mg particles. The PVP is more soluble in organic polymer solution than PVA. Therefore, PVA stabilizer molecules can be expected to be confined to the surface of the microparticles formed in the w/o/w technique. However, extensive diffusion of PVP molecules into the dispersed droplets of polymer solution can be envisaged. The diffusion of PVP(stabilizer) molecules from the external aqueous phase increased the viscosity of the droplets of polymer solution and consequently improved the protein loading and delivery characteristics. The effect of molecular weight and morphological structure of the copolymer on size, yield, degradation rate, bovine serum albumin (BSA) loading efficiency and BSA release profile of the microparticles prepared by w/o/w double emulsion method were studied by (Porjazoska et al., 2004). The microparticles prepared from poly(dl-lactide–coglycolide) showed biphasic profile for BSA release. However, microparticles prepared from poly(l-lactide–coglycolide) showed triphasic profile for BSA release. Blanco-Prieto et al. (2002) prepared gentamicin loaded PLGA microparticles using a double emulsion solvent evaporation technique. The encapsulation efficiency was found to vary from 34% to 90% depending on the formulation. Moreover, encapsulation efficiency depended on the pH values of the internal aqueous phase and the highest value was achieved when the internal aqueous phase was maintained at pH 6. Theophylline loaded enteric coated microparticles were prepared using a w/o/w solvent evaporation technique for targeted oral drug delivery (Dalmoro et al., 2010). Initially, the cellulose acetate phthalate (CAP) was used as a pH sensitive polymer for the preparation of microparticles. The desired release pattern was achieved but not the encapsulation efficiency. Then, the CAP was replaced by a novel synthesized pH sensitive poly(methyl methacrylate acrylic acid) copolymer. It has been observed that the encapsulation efficiency was directly related to the amount of emulsion stabilizer but inversely related to the stirring speed. By increasing the concentration of emulsion stabilizer (PVA) and by decreasing the stirring speed, a high stable double emulsion was obtained which increased the encapsulation efficiency. The use of polymethylmethacrylate (PMMA) polymers for controlled delivery of diclofenac sodium was investigated by Pal et al. (2011). PMMA coated microparticles were prepared by a modified w/o/w emulsion solvent evaporation method using sodium alginate as a matrix material in the internal aqueous phase. The microparticles were spherical with diameters ranging from 213.45 to 308.60 μm and entrapment efficiency from 28.71% to 72.16% was reported. Drug entrapment efficiency of the matrix microparticles was found to be considerably higher than that of non-matrix microparticles and increased with increase in the concentration of the matrix material. Release of the drug from all the microparticles appeared to be biphasic releasing less amount of drug in simulated gastric fluid and higher amount of drug in simulated intestinal fluid. Moreover, the release of the drug from most of the microparticles was observed to follow non-fickian model. Increase in the concentration of matrix material (sodium alginate) improved the viscosity of internal aqueous phase minimizing the leaching of the drug into external aqueous phase thus the drug entrapment efficiency increased consequently.

Cohen et al. (1991) prepared PLGA microspheres containing fluorescin isothiocyanate labeled BSA and horseradish peroxidase using a w/o/w double emulsion solvent evaporation method. The prepared microcapsules were spherical and more than 90% encapsulation efficiencies were reported. Unencapsulated horseradish peroxidase lost 80% of its activity in solution at 37 °C in a few days. However, the encapsulated enzyme retained more than 55% of its activity after 21 days incubation at 37 °C.

Insufficient solvent removal is likely to cause microparticles’ aggregation with decrease in the drug entrapment efficiency due to unsatisfactory speed of solvent removal from microparticles (Yamamoto et al., 1990; Takechi et al., 1998). The above mentioned problem was solved by Takechi et al. (2002) by developing a method to increase the speed of solvent removal from microparticles prepared from w/o/w double emulsion method. The drug entrapment efficiency in microparticles also improved markedly. The rate of solvent removal from the microparticles can be controlled by the temperature of the microsphere dispersion (Yang et al., 2000a,b). The characteristics of drug loaded microparticles prepared by the w/o/w solvent evaporation method are listed in Table 1.

Table 1.

Characteristics of drug loaded microparticles prepared by the w/o/w solvent evaporation method.

| Drug encapsulated | Polymer used | Organic solvent used | Stabilizing agent used | Drug entrapment efficiency | Drug release profile | Reference |

|---|---|---|---|---|---|---|

| Propranolol HCl, Nifedipine | Eudragit RL and Eudragit RS | Methylene chloride | Polyvinyl alcohol (PVA) | 51.7%, 88.1% |

The incorporated drugs were found to be controlled over periods of at least 8 h | Hombreiro-Perez et al. (2003) |

| MEP 421 | PLGA | Mixture of dichloromethane and ethyl acetate | PVA | 99.1% | Microparticles exhibited significant burst release followed by slow drug release for over one month | Yaju et al. (2008) |

| Bovine serum albumin | PLGA | Dichloromethane | PVA | 81% | Microparticles exhibited bi-exponential release with an initial burst release and a second sustained release phase | Igartua et al. (1997) |

| Acetaminophen | Poly(l-lactide) | Methylene chloride | PVA | 55.2% | Good controlled release behavior and fitted first order model | Lai and Tsiang (2005) |

| Pingyanmycin | PLGA | Dichloromethane | PVA | 65% | Microparticles sustainably release the drug over nearly 28 days | Han et al. (2010) |

| Insulin | Poly(lactic acid) and PEG | Dichloromethane | PVA | 42.74% | The release of insulin was approximately 75% with initial low burst release followed by a constant release over a period of one week. | Sheshala et al. (2009) |

| Phosphorothioate oligodeoxynucle-otide | PLGA | Methylene chloride | PVA | 2.63% drug loading | Initial rapid release followed by a slower release | Ahmed and Bodmeier (2009) |

| Melittin | Poly(dl-lactic acid) and PLGA | Dichloromethane | PVA | 90% | Melittin was released completely during the study period of 30 days | Cui et al. (2005) |

| Recombinant human epidermal growth factor | Poly(l-lactic acid) | Methylene chloride | PVA | 92% | Optimized formulation showed low initial release and 11-day sustained release pattern | Han et al. (2001) |

| Serratiopeptidase | Eudragit S100 | Dichloromethane, ethanol and isopropyl alcohol | Tween 80 | 81.32% | The release of enzyme from microparticles followed Higuchi kinetics | Rawat and Saraf (2009) |

| Ovalbumin | Poly(dl-lactide and polyethylene glycol-co-poly-dl-lactide) | Methylene chloride | PVA | 96.04% | Protein release was sustained with very low burst effect | Dorati et al. (2008) |

| Bovine serum albumin | PLGA | – | – | 71% | The release rate was fairly constant after an initial burst release | Ravi et al. (2008) |

| Plasmid DNA | PLGA | Dichloromethane | PVA | 8.9% loading efficiency | Generate the strongest transfection efficiency | Zhang et al., 2008a,b |

4.2. W/O/W double emulsion solvent extraction technique

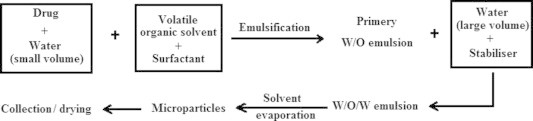

In this technique, the solvent can be removed from the microparticles through extraction of the solvent present in the internal phase. This can be achieved by the addition of w/o/w emulsion to a third solution, which is a non solvent of the polymer but miscible with both water and the organic solvent. Under these conditions the solvent contained in the polymer droplets is extracted into the aqueous medium. In this method, an aqueous solution or suspension of the drug is emulsified in a solution of polymer in organic solvent. The resulting primary emulsion is then dispersed in a second aqueous phase containing suitable emulsifier to form double emulsion. Removal of the solvent by extraction leads to the formation of solid microparticles (Fig. 2).

Figure 2.

Scheme of the preparation procedure for drug loaded microparticles by the double emulsion solvent evaporation method.

Ruan et al. (2002) prepared human serum albumin loaded microparticles by the w/o/w solvent extraction method. They investigated the effects of different materials used for the preparation of microparticles: (a) PLGA (PLA-PGA) and PELA (PLA-PEG-PLA) as the polymers, (b) dichloromethane, ethyl acetate and acetone as the solvents, (c) PEG and d-α tocopheryl polyethylene glycol 1000 succinate (vitamin E TPGS) as additives. The encapsulation efficiency value of human serum albumin in PELA microparticles was about 10% higher than that in PLGA microparticles, may be due to improved stability of w/o emulsion by PELA. Dichloromethane mixed with 70% acetone or 100% ethyl acetate resulted in 69.09% and 65.33% of encapsulation efficiency, respectively. The encapsulation efficiency of using either low (2%) or high concentration (10%) of these two additives (PEG and vitamin E TPGS) was around 25% lower than that obtained without the use of additives. The displacement of the drug molecules from w/o emulsion interface by the surfactants (PEG or vitamin E TPGS) decreased the amount of drug located within the w/o emulsion resulting in lower entrapment efficiency. More than 90% of the encapsulated protein was released from PELA microparticles within 13 days. Higher PEG concentration (10%) resulted in more porous structure and slightly faster protein release. Recombinant human interleukin-2 loaded PLGA microparticles were prepared using modified w/o/w double emulsion solvent extraction method for pulmonary administration (Devrim et al., 2011). The encapsulation efficiency of drug was 99.22%. The in vitro release study exhibited a biphasic pattern, characterized by a fast release phase at first day, followed by a slower release on the subsequent days. Li et al. (1999) prepared leptospira interrogans antigens loaded PELA microparticles by solvent extraction method based on the formation of double w/o/w emulsion. By using a small volume of internal aqueous phase and intermediate volumes of organic phase and external aqueous phase, the microparticles with a size of 1–2 μm and encapsulation efficiency of 70–80% were achieved. The antigen release profiles from PELA microparticles consist of a small burst release followed by a gradual release phase.

A novel technique was used in double emulsion solvent extraction for the preparation of microparticles (Ereitas et al., 2005). In this technique, a flow through ultrasonic cell was used for the preparation of primary emulsion and a static micromixer was used for the preparation of double emulsion. The microparticles with a size range of 15–40 μm and 70% drug encapsulation efficiency were achieved. PELA microparticles containing Hepatitis B surface antigen were prepared by a solvent extraction method based on the formation of a double w/o/w emulsion (Zhou et al., 2004). The PELA microparticles displayed the highest encapsulation efficiency (80%) and improved stability of antigen molecules in the PELA microparticles during the preparation process.

4.3. S/O/W double emulsion technique

Using solids a double emulsion of solid in oil in water(s/o/w) can be prepared, in which the internal solid phase and external aqueous phase are separated by an oil layer. Initially the solid pharmaceuticals or biopharmaceuticals are dispersed in the polymer solution to form a primary emulsion. Then the dispersion is introduced into a large volume of aqueous solution containing emulsifying agent, such as PVA or PEG. The most commonly used encapsulation method for the preparation of microparticles is the w/o/w double emulsion technique. However, protein inactivation and aggregation are largely caused by protein adsorption on to the oil/water interface which is formed when the aqueous protein solution is emulsified under high shear with the organic solvent of choice (Crotts and Park, 1998; Weert Van De et al., 2000; Sah, 1999). The s/o/w technique has gained recognition since it improves protein stability during encapsulation because the first w/o emulsion step is avoided (Castellanos et al., 2001; Putney and burke, 1998). Morita and his coworkers (Morita et al., 2000) prepared protein loaded biodegradable microparticles by a novel s/o/w emulsion method using polyethylene glycol as a protein micronization adjuvant. They prepared monolithic type microparticles by a simple s/o/w emulsion method and reservoir type microparticles by the polymer alloys method. By this technology protein can be efficiently encapsulated into microparticles without any loss of activity. The protein release kinetics could be suitably modified by adjusting the loading amounts of PEG. If PEG is increased the entrapment of protein decreases and release would be faster. The reason for lower entrapment is partly because a large amount of PEG might enhance the leakage of protein particles into aqueous phase. The first release kinetics could be due to distribution of PEG in the polymer layer that enhances the water permeation, resulting in the prompt formation of aqueous channels through the shell. A novel stabilization strategy using polyethylene glycol as stabilizing excipient as well as emulsifying agent was developed by (Castellanos et al., 2003). They prepared PLGA microparticles for encapsulation of γ-chymotrypsin and horseradish peroxide by a s/o/w technique. The use of PEG as stabilizing excipient and emulsifier allowed encapsulation of γ-chymotrypsin in PLGA microparticles without causing aggregation and loss in the enzyme activity. Moreover, aggregation and inactivation of model proteins during encapsulation was prevented with increasing amounts of PEG co-encapsulated in the microparticles. Surface active PEG prevented the inactivation of the enzyme by protecting it upon exposure to two hydrophobic denaturing substances: Solvent (methylene chloride) and polymer (PLGA). Takada and his coworkers (Takada et al., 2003) prepared biodegradable microparticles by a s/o/w emulsion solvent evaporation technique using lyophilized protein microparticles for sustained release of recombinant human growth hormone (rhGH). High entrapment of rhGH in microparticles was achieved by incorporating rhGH powder of smaller particle size. It was observed that the incorporation of zinc oxide into microparticles resulted in higher serum levels than with those prepared without zinc oxide, after subcutaneous injection into rats. The microparticles prepared by using PLGA with molecular weight of 12600 demonstrated almost zero-order release profile resulting in constant serum rhGH levels for 2 weeks. Addition of zinc oxide into microparticles resulted in higher serum levels than with those prepared without zinc oxide, suggesting the stabilizing effect of zinc oxide after subcutaneous injection into rats. Similarly, γ-chymotrypsin has been encapsulated in PLGA microparticles using the s/o/w encapsulation technique (Castellanos et al., 2002). Three different γ-chymotrypsin formulations were employed to prepare microparticles: (a) lyophilized without excipient, (b) co-lyophilized with trehalose, (c) co-lyophilized with PEG at a 1:4 weight ratio (protein: excipient). The highest encapsulation efficiency (72%) was achieved with PEG as the excipient, while protein formulation with trehalose resulted in the lowest encapsulation efficiency (27%).

4.4. S/O/O double emulsion technique

Similarly, in the solid in oil in oil (s/o/o) double emulsions, the internal solid phase and external oil phase are separated by an oil phase. The s/o/o emulsion can be prepared by dispersing solid particles in an organic solvent, e.g. methylene chloride, and then mixed with a polymer solution. Alternatively the dispersion of solids in organic solvent can be coated with a suitable polymer using a coacervation technique. Carrasquillo and his coworkers (Carrasquillo et al., 2001) prepared BSA loaded PLGA microparticles by a non-aqueous s/o/o methodology. In this methodology, powder formulations of BSA obtained by spray-freeze drying were first suspended in methylene chloride containing PLGA followed by coacervation by adding silicon oil and microsphere hardening in heptanes. The release of BSA from PLGA microparticles was governed by an asymptotic profile in which > 80% of the protein was released rapidly within only 2 days. However, blending of PLGA with poloxamer had a dramatic effect on the in vitro release of BSA, specifically an increase in the release duration. Poloxamer is a triblock copolymer composed of polyoxyethylene and polyoxypropylene. The author suggested that the microsphere diameter was significantly increased by the presence of poloxamer in the o/o procedure. Leach and his coworkers (Leach et al., 2005) developed a method in which the coacervate droplets are introduced into a spinning cottonseed oil film at a controllable flow rate. So that the shear generated by the spinning film separates the droplets to produce uniform microparticles. The resultant microparticles showed higher encapsulation efficiency and lower initial burst release compared with microparticles produced by a conventional emulsification technique. Moreover, the optimized formulation showed slow release to 2.14% in 18 days and gradual release to 63% for next 55 days.

4.5. W/O/O double emulsion technique

In the water in oil in oil(w/o/o) double emulsions, the internal aqueous phase and external oil phase are separated by an oil phase. In the w/o/o method, water soluble compounds are first dissolved in the aqueous phase which is emulsified in an oil to form a stable emulsion. This primary emulsion is then dispersed in a solution of polymer in organic solvent to form a w/o/o emulsion. Water soluble compounds cannot diffuse into the processing medium since the oil is outer processing medium.

The total protein encapsulation efficiency is high in the microparticles produced by w/o/o emulsification technique since oil is the outer processing medium and protein cannot diffuse into the processing medium. PLGA microparticles were prepared by using a w/o/o double emulsification evaporation technique for the long term delivery of angiogenic inhibitors for the treatment of cancer (Wu et al., 2009). The mean particle size of endostatin microparticles was about 25 μm and the encapsulation efficiency was 100%. The in vitro release study showed that the microparticles allowed the sustained release of biologically active endostatin for 30 days. Moreover, in vitro studies on rats, endostatin microparticles produced a sustained release process in which the steady-state concentration was reached from 5th day to 27th day with the steady-state levels of endostatin between 174.8 and 351.3 mg/ml, respectively. Ciombor and his coworkers (Ciombor et al., 2006) prepared BSA loaded PLGA microparticles using a modified w/o/o emulsion solvent removal method. They studied various factors including composition of the suspension medium and the relative amounts of aqueous phase containing protein to polymer solution. High yields of microparticles were achieved by using silicon oil containing a mixture of methylene chloride and silicon oil, as a suspension medium, instead of pure silicon oil. When polymer solution and continuous phase at a ratio of 1:0.5 was used, a cake like polymer matrix of irregular shape was produced. However, at ratios of 1:1 to 1:9 spherical microparticles were produced.

5. Categories of pharmaceuticals and biopharmaceuticals used for encapsulation into microparticles prepared by double emulsion method

Encapsulation of certain pharmaceuticals and biopharmaceuticals in microparticles are reviewed with examples from the literature.

5.1. Pharmaceuticals

5.1.1. Anticancer drugs

5.1.1.1. Cisplastin

Cisplastin is a divalent inorganic water soluble platinum containing complex widely used as anticancer drugs. It is very effective in metastatic testicular and ovarian carcinoma. The usual intravenous dose of cisplastin is 20 mg/m2 per day for five days. Matsumoto et al. (1997) prepared cisplastin loaded multireservoir type microparticles by s/o/w double emulsion method using PLA and PLGA as polymers. The PLGA-PLA biphasic polymeric solution containing dispersed drug powders was emulsified, and then solidified by the solvent evaporation method. The resultant microparticles showed almost 100% encapsulation efficiency. The in vitro release study indicated that the release of cisplastin continued for 45 days without initial burst. Cisplastin loaded microparticles were prepared from d,l-lactic acid stereo copolymers and d,l-lactic acid/glycolic acid copolymers using a s/o/w double emulsion solvent evaporation process (Spenlehauer et al., 1988). It has been observed that the drug release depends on the amount of entrapped drug and polymer molecular weights. Moreover, the drug release mechanism was predominantly diffusional by either polymer matrices or dissolution in channels depending upon cisplastin crystal distribution in microparticles. Similarly, cisplastin loaded PLGA microparticles were prepared by s/o/w double emulsion method (Spenlehauer et al., 1986) for chemoembolization. The resultant microparticles showed high encapsulation efficiencies with little or no burst release.

5.1.1.2. 5-Fluorouracil

5-Fluorouracil is a pyrimidine whose analogs have varied applications like antineoplastic, antifungal and antipsoriatic agents. It is very effective in breast, colon, urinary bladder and liver carcinoma. The usual oral dose is 1 g on alternate days (6 days) then 1 g weekly. It has a half life of 10–20 min. 5-Fluorouracil loaded PLA microparticles were prepared by using double emulsion method for hepatic artery embolism treatment (Xin-Xia et al., 2010). The resultant microparticles showed 63.34% drug encapsulation efficiency and released the drug in a controlled manner. Chandy et al. (2000) developed chitosan coated PLA/PLGA injectable microparticles containing 5-fluorouracil using w/o/w double emulsion method for cerebral tumors. It has been observed that the drug release was initially much higher (25%), followed by a constant slow release profile for a 30 days period of study. In another study, 5-fluorouracil and antisense oligonucleotide were co-entrapped in single microparticles formulations and also entrapped individually using PLGA polymer by w/o/w double emulsion method (Hussain et al., 2002). Both types of formulation exhibited suitable entrapment and drug release over 35 days.

5.1.1.3. Doxorubicin

Doxorubicin is an antitumour antibiotic which is effective in many solid tumors. The recommended dose of doxorubicin is 60–75 mg/m2, administered as a single rapid intravenous infusion that is repeated after 21 days. Jiang et al. (2011) prepared PLGA microparticles loaded with doxorubin, PEGylated TNF-related apoptosis inducing ligand (PEG-TRAIL), and with doxorubicin plus PEG-TRAIL using a w/o/w double emulsion solvent extraction method for effective tumor combination therapy. The encapsulation efficiency of 69.4% for doxorubicin and 87.7% for PEG-TRAIL was observed. It has also been observed that the PLGA microparticles loaded with low amounts of doxorubicin, PEG-TRAIL, or dual agent resulted in 14.8%, 30.2%, and 63.6% reductions in human colon cancer tumor volume and 20.4%, 14.2%, and 67.7% reductions in human prostate cancer tumor volume at 5–35 days.

5.1.1.4. Epirubicin

Epirubicin is an anthracycline antibiotic used for chemotherapy. It has half life of 30–40 h. The recommended dose of epirubicin is 100–120 mg/m2 by intravenous infusion every 3–4 weeks. Zhou and his coworkers (Zhou et al., 2006) studied the effectiveness of treating hepatocellular carcinoma (HCC) in mice with locally administered epirubicin loaded PLA microparticles. They prepared microparticles by double emulsion solvent evaporation technique. The microparticles significantly prolonged the survival time of mice.

5.1.2. Anti-inflammatory drugs

5.1.2.1. Aceclofenac

Aceclofenac is an aryl-acetic acid derivative widely used as an analgesic. The usual oral dose is 100 mg twice daily. It has half life of 3–4 h. Aceclofenac loaded microparticles were prepared by an o/w/o double emulsion method (Nagda et al., 2008). The entrapment efficiency was in the range of 32–47%. Aceclofenac release from these microparticles was slow and extended over longer periods of time with fickian diffusion control. In another study, aceclofenac loaded bioadhesive microparticles were prepared by o/w/o double emulsion solvent evaporation method using polycarbophil as bioadhesive polymer (Nagda et al., 2009). The prepared polycarbophil microparticles showed reasonable drug entrapment, suitable size and relatively slow release of the drug.

5.1.2.2. Acetaminophen

Acetaminophen is a mild analgesic-antipyretic, with little anti-inflammatory properties. It has a biological half life of about 2 h. The usual adult dose is 0.5–1 g repeated 4–6 hourly to maintain analgesia. Lai and Tsiang (2005) prepared acetaminophen loaded PLA microparticles by three emulsion solvent evaporation methods: o/w emulsion method, o/w co-solvent method and w/o/w double emulsion method. The encapsulation efficiency in the w/o/w emulsion method was three times more compared to the o/w emulsion method. Moreover, the microparticles prepared by the w/o/w double emulsion method showed good controlled release characteristics.

5.1.2.3. Diclofenac sodium

Diclofenac sodium, a non steroidal anti-inflammatory drug, is widely used in rheumatoid arthritis, severe osteoarthritis and in ankylosing spondylitis. Its biological half life is 1–2 h and is administered 2–3 times a day. A novel poloxamer coated three-ply-walled microparticles were prepared based on the technique of multiple emulsion formation polymer at the interface followed by rigidization of the wall on evaporation of solvent for controlled delivery of diclofenac sodium (Bhatnagar et al., 1995). The microparticles were prepared by w/o/w double emulsion solvent evaporation method using ethyl cellulose as hydrophobic polymer. The resultant microparticles showed sustained release of the contained diclofenac. Similarly, Pal and his coworkers (Pal et al., 2011) prepared diclofenac sodium loaded polymethylmethacrylate microparticles by a modified w/o/w emulsion solvent evaporation method using sodium alginate as a matrix material in the internal aqueous phase. The resultant matrix microparticles appeared to be suitable for releasing lesser amounts of diclofenac sodium in simulated gastric fluids and providing extended release in simulated intestinal fluid.

5.1.2.4. Ketoprofen

Ketoprofen is a propionic acid derivative widely used as analgesic and antipyretic. It has a half life of about 2–2.5 h and is completely absorbed from the gut. The recommended daily dose is 100–150 mg per day in divided doses. Pavanetto et al. (1996) prepared ketoprofen loaded chitosan microparticles by the o/w/o double emulsion method. The double emulsion method produced well formed microparticles with high yield. The lowest theoretical drug/chitosan ratio showed the highest drug encapsulation efficiency.

5.1.3. Antibiotics

5.1.3.1. Gentamicin

Gentamicin is the most important aminoglycoside antibiotics and is used widely for the treatment of serious infections. The plasma half life is 2 h, and the minimum inhibitory concentration against pseudomonas should be between 6 and 10 μg/ml. Biodegradable PLA and/or PLA/PEG copolymer disk implants containing gentamicin sulfate were obtained by compression of microparticles prepared by a w/o/w double emulsion process for local treatment of bone infection (Huang and Chung, 2001). The PLA/PEG implant released the antibiotic faster and had a larger inhibitory zone based on the Boner-Kirby experiments used to assess the inhibitory activity of antimicrobial devices. It has been observed that the biodegradable PLA/PEG gentamicin delivery system had a potential for prophylaxis of post-operative injection.

5.1.3.2. Erythromycin

Erythromycin is a macrolide antibiotic and is administered as an alternative to the penicillin-allergic patient. The half life is 1.5–3 h. Only 20% of the drug is excreted by the kidneys; the remainder is metabolized by demethylation or appears in the bile, where it is highly concentrated. The usual dose for erythromycin stearate is between 250 and 500 mg every 6 hours. Erythromycin loaded gelatin microparticles were prepared using a w/o/w double emulsion solvent evaporation method for lung targeting (Fan et al., 2009). The drug loading and encapsulation efficiency of microparticles were 13.56% and 55.82%, respectively. The in vitro release study indicated an initial burst release and following a sustained release with a cumulative release of 80% at 4 h. The in vivo study in rabbits indicated the concentration of erythromycin in lung was 15.92 times higher than that in plasma and the drug targeting index of microparticles in lung was 6.65 times as compared to erythromycin lactobionate.

5.1.3.3. Cephalexin

Cephalexin is a first generation cephalosporin antibiotic. It is used for first line treatment for cellulitis. It has a half life of about 0.5–1.2 h. The oral dose is 0.25–1 g repeated 6–8 hourly. Chaisri et al. (2009) prepared cephalexin loaded PLGA microparticles using a w/o/w emulsion technology for the treatment of dairy mastitis. It has been observed that stirring during emulsification and a change in both the internal and external phase of the emulsion, influenced the size and the drug entrapment efficiency of the microparticles. The stirring rate of 8000–10,000 rpm gave high yield (>90%) microparticles with a desirable size and high drug entrapment efficiency.

5.1.3.4. Capreomycin

Capreomycin is a polypeptide antibiotic and widely used for the treatment of tuberculosis. The half life is about 3–6 h. The usual dose is 1 g intramuscularly daily. Giovagnoli et al. (2007) prepared capreomycin sulfate loaded microparticles using a simple emulsion solvent evaporation method for pulmonary delivery. PLGA microparticles were prepared using a w/o/w double emulsion solvent evaporation method. The homogenization method and the type of emulsifier employed strongly affected the microparticles size distribution. The double emulsion method allowed the preparation of microparticles having suitable characteristics of such respirability requirements.

5.1.3.5. Norfloxacin

Norfloxacin is a synthetic chemotherapeutic antibacterial agent occasionally used to treat common as well as complicated urinary tract infections. It has a half life of about 3–4 h. The usual oral dose is 800 mg per day. Norfloxacin is a fluoroquinoline derivative widely used as an antibiotic. Sindhuri and Purushotaman (2011) prepared norfloxacin loaded microparticles using various polymers like carbopol 934, sodium carboxymethyl cellulose by w/o/w double emulsion solvent evaporation technique. The prepared microparticles showed good flow properties with spherical shape and surface morphology. Moreover, microparticles showed sustained release of the drug from the formulation for a period of 12 h.

5.1.4. Steroidal drugs

5.1.4.1. Budesonide

Budesonide is a glucocorticoid and widely used for the treatment of asthma. The half life is about 2–3.6 h. The usual dose is 200–400 μg twice or thrice daily by inhalation in asthma. Budesonide is a corticosteroid widely used for the treatment of asthma. Budesonide loaded porous PLGA microparticles were prepared by a w/o/w double emulsion method with ammonium bicarbonate as the porogen (Oh et al., 2011). The drug loading efficiency in the microparticles was about 60%, and drug was released from the microparticles in a sustained manner for 24 h in vitro. It has been observed that the budesonide loaded microparticles significantly reduced bronchial hyper-responsiveness of asthmatic mice.

5.1.4.2. Triamcinolone acetonide

Triamcinolone acetonide is a synthetic corticosteroid used to treat various skin conditions and to relieve the discomfort of mouth sores. It has a half life of 88 minutes. The usual oral dose is 4–32 mg per day. Triamcinolone acetate loaded microparticles were prepared by a single or double emulsion solvent evaporation method (Blatsios et al., 2010). Then the microparticles compressed into mini-tablets. In vitro studies revealed a sustained release of drug over several hours. Triamcinolone acetate accumulated in the vitreous and aqueous humor of Cadaver rabbit eyes following scleral administration of the mini-tablets.

5.1.5. Anti HIV agents

5.1.5.1. Zidovudine

Zidovudine is an antiretroviral drug used for the treatment of HIV/AIDS. It has a half life of 0.5–3 h. The usual oral dose is 200 mg every 4 h continuously. Zidovudine encapsulated ethyl cellulose microparticles were prepared by w/o/o double emulsion solvent diffusion method (Das and Rao, 2006). The resultant microparticles showed 32–55% entrapment efficiency with free flowing properties. The drug release was found to be diffusion controlled.

5.1.5.2. Stavudine

Stavudine is a nucleoside analog and used in HIV infection. The usual oral dose is 30 mg every 12 h before one hour food. Sahoo and his coworkers (Sahoo et al., 2007) prepared stavudine loaded microparticles by w/o/o double emulsion solvent diffusion method using ethyl cellulose and a mixture of ethyl cellulose and polyvinyl pyrrolidone. The prepared microparticles were free flowing and spherical in shape with 41–65% of drug entrapment efficiency. The release of stavudine was influenced by the drug to polymer ratio, size of the microparticles and polymer combination.

5.1.6. Other drugs

5.1.6.1. Pseudoephedrine HCl

Pseudoephedrine HCl is a sympathomimetic drug. It has been orally administered as a decongestant of upper respiratory tract, nose and eustachian tubes. The half life is about 4.3–8 h. The usual oral dose is 240 mg per day. Pseudoephedrine HCl loaded carnauba wax microparticles were prepared by a w/o/w double emulsion melt dispersion technique (Bodmeier et al., 1992). The prepared microparticles showed above 80% drug encapsulation efficiency. The drug loading depended on the rate of cooling and the volume of the internal aqueous phase.

5.1.6.2. Sodium fusidate

Sodium fusidate is a bacteriostatic antibiotic. It has a half life of 5–6 h. The recommended oral dose is 250 mg twice daily. Cevher et al. (2007) prepared PLGA microparticles containing sodium fusidate using a w/o/w double emulsion solvent evaporation method with varying polymer to drug ratios. The resultant microparticles showed 19.8–34.3% encapsulation efficiency. The in vitro and in vivo studies indicated that the implanted sodium fusidate loaded microparticles were found to be effective for the treatment of chronic osteomyelitis in an animal experimental model.

5.1.6.3. Amifostine

Amifostine is a cytoprotective adjuvant used in cancer chemotherapy. It has a half life of 8 min. The usual intravenous dose is 910 mg/m2 once daily. Lu et al. (2011) prepared amifostine loaded PLGA microparticles using a modified double emulsion solvent evaporation technique. They also investigated its irradiation protective effect to mouse through oral administration. The prepared microparticles were spherical in shape with a mean diameter of 2.8 μm. In vitro release study showed a relatively large burst effect (50%) over the first 6 h, followed by a slower release phase, which sustained with 80% amifostine released in 48 h and almost 100% release till 6 days. In vivo study revealed that amifostine microparticles were more irradiation shielding to mouse than those of free amifostine under the same oral administration route.

5.1.6.4. Theophylline

Theophylline is a xanthine derivative widely used as an effective bronchodilator in the management of asthma. It has a half life of 5–8 h. The usual intravenous dose is 2.5–5 mg of anhydrous drug per kg body weight over a period of 20 min. Jelvehgari et al. (2011) encapsulated theophylline loaded poly(ε-caprolactone) nanoparticles in ethyl cellulose microparticles by using w/o/w double emulsion solvent diffusion/evaporation method. The prepared drug loaded composite microparticles showed minimum burst effect, satisfactory release and mean particle size of 17.696 μm.

5.2. Biopharmaceuticals

5.2.1. Bovine serum albumin (BSA)

Bovine serum albumin is a serum albumin protein derived from cows. It is often used as standard protein concentration standard. BSA loaded PLGA microparticles were prepared using a modified w/o/o double emulsion phase separation method (Zhang et al., 2005). Microparticles with high yield (>80%) and entrapment efficiency (>90%) were produced using petroleum ether containing 5% (w/v) span 80 as coacervating agent. A biphasic release behavior was observed for the microparticles prepared by this method. Pistel and Kissel (2000) investigated the effects of salt addition on the microencapsulation of BSA using w/o/w double emulsion solvent evaporation technique. For the preparation of microparticles poly(l-lactide) was used as performed polymer. Modification of the external water phase by adding salts produced microparticles with high encapsulation efficiency and excellent microparticles characteristics. Similarly, BSA was encapsulated in polyethylene glycol microparticles using a double emulsion technique (Thummala et al., 2003). It was observed that the production parameters significantly affected protein release rates.

5.2.2. Lysozyme

Lysozyme is glycoside hydrolase that damages the bacterial cell walls. The usual oral dose of lysozyme chloride is 60–270 mg thrice a day. Lysozyme loaded PLA microparticles were prepared by combining Shirasu porous glass (SPG) membrane emulsification technique and w/o/w double emulsion solvent evaporation method (Liu et al., 2005). The drug encapsulation efficiency of microparticles prepared by SPG membrane emulsification technique was much higher than that prepared by stirring method. The drug encapsulation efficiency was affected by PLA molecular weight, additive type and amount in the internal water phase, emulsifier type and amount in the oil phase, and NaCl concentration and pH value in the external water phase. In another study, the effect of emulsification of lysozyme solutions with methylene chloride on protein recovery and structural integrity was investigated (Weert Van de et al., 2000). The PLGA microparticles were prepared by w/o/w double emulsion method. Excipients competing for the water/organic solvent interface, such as BSA and partially polyvinyl alcohol significantly improved lysozyme recovery to >95%. Perez et al. (2002) prepared lysozyme loaded PLGA microparticles using a w/o/w double emulsion technique. It has been observed that the protein aggregation and inactivation were minimized by judiciously selecting excipients efficient in stabilizing lysozyme against the major stress factors of w/o/w encapsulation.

5.2.3. α-Chymotrypsin

α-Chymotrypsin is a digestive enzyme that can perform proteolysis. α-Chymotrypsin preferentially cleaves peptide amide bonds. α-Chymotrypsin loaded PLGA microparticles were prepared by using a w/o/w double emulsion technique for its stabilization toward the major stress factors during the encapsulation procedure (Perez-Rodriguez et al., 2003). It has been observed that co-dissolving the protein with maltose and polyethylene glycol in the first aqueous phase reduced interface induced protein aggregation and inactivation. Employing these excipients during encapsulation led to a reduction in α-chymotrypsin inactivation (10%) and aggregation (12%).

5.2.4. Insulin

Insulin is poorly absorbed via the intestinal membrane because of extensive proteolytic degradation by intestinal enzymes and suffers from insufficient membrane permeability due to high molecular weight and low lipophilicity. Insulin loaded PLA-PEG microparticles were prepared using a w/o/w double emulsion solvent evaporation technique for controlled parenteral drug delivery (Sheshala et al., 2009). The prepared microparticles were spherical in structure with a mean particle size of 3.07 μm and entrapment efficiency of 42.74%. The in vitro insulin release profile was characterized by a bimodal behavior with an initial burst release followed by slower and continuous release. Kang and Singh, 2005 prepared insulin loaded PLGA microparticles by w/o/w and s/o/w double emulsion method for providing basal insulin level for an extended period of time. It has been observed that the insulin loaded PLGA microparticles controlled in vitro absorption of insulin to maintain the basal insulin level for a long period and the delivery system was biocompatible. In another study, insulin loaded PLGA microparticles were prepared by a novel s/o/w solvent evaporation process (Bao et al., 2006). Modified s/o/w process encapsulated more than 90% (w/w) insulin in the microparticles and the initial burst was much less than microparticles made by a w/o/w process.

5.2.5. Leuprolide

Leuprolide is a potent agonist of leutinizing hormone-releasing hormone currently used for the treatment of prostatic cancer, endometriosis and precocious puberty. The usual intramuscular dose is 1 mg daily. Leuprolide loaded PLA microparticles were prepared using a s/o/w double emulsion method (Woo et al., 2001). The prepared microparticles were spherical in shape with a mean diameter of 52 μm and 13.4% encapsulation efficiency. Ten percent of the peptide released within 24 h followed by a linear release for 150 days. Serum leuprolide levels increased immediately after administration to 45.6 ng/ml due to the initial burst release from the microparticles. Then the levels fall to 4.3 ng/ml at day 15 followed by a plateau level around 2 ng/ml or less over 120 days.

5.2.6. Hepatitis B surface antigen

Hepatitis B surface antigen is the most frequently used screening agent for HBV infection. It is the first detectable viral antigen to appear during infection. The usual adult dose is 1 ml intramuscularly and child dose is 0.5 ml intramuscularly. Hepatitis B surface antigen loaded PELA microparticles were prepared quickly by a novel method using w/o/w emulsion solvent extraction and premix membrane emulsification (Wei et al., 2008). It has been observed that the distribution pattern of PEG segment of polymers played an important role on the properties of microparticles. Diblock copolymer PLA-mPEG yielded a more stable interfacial layer at the interface of oil and water phase compared to triblock copolymer PLA-PEG-PLA and resulting in high encapsulation efficiency.

5.2.7. Recombinant human erythropoietin (rhEPO)

Recombinant human erythropoietin is widely used for the treatment of anemia associated with renal insufficiency and cancer. The administration of rhEPO is 300–600 IU/kg 3–4 times per week. Morlock et al. (1997) encapsulated rhEPO, a stimulating factor of red blood cell production, into PLGA microparticles using a w/o/w double emulsion technique. A distinct reduction of the formation of rhEPO aggregates was achieved by using excipients such as cyclodextrin, arginine, or BSA. Accelerated stability study demonstrated no change in drug content, release behavior and aggregate profile over 56 days at −20 °C, 8 °C or room temperature.

5.2.8. Tetanus toxoid

Tetanus toxoid is a sterile dispersion of toxoid in isotonic sodium chloride solution. It protects infants against the risks of tetanus neonatorum by immunizing pregnant mothers. The dose consists of 0.5 ml at least 4 weeks apart, at 18 months, 5 yrs, 10 yrs, 16 yrs and then every 10 yrs. Katare and Panda (2006) investigated the effect of serum albumin, sucrose and sodium bicarbonate on surface morphology, entrapment efficiency, in vitro release and in vivo performance of TT loaded PLA microparticles prepared by w/o/w double emulsion method. Maximum entrapment efficiency of TT was achieved when serum albumin, sucrose and sodium bicarbonate were used in internal aqueous phase and sucrose was used in the external aqueous phase. The optimized microparticles showed burst release of immunoreactive antigens (>40% in early period) and elicited high and sustained anti-TT antibody titers from single point intramuscular immunization.

5.2.9. Leutinizing hormone releasing hormone (LHRH) antagonist

Leutinizing hormone releasing hormone antagonist produces a competitive blockade of LHRH receptors and causes an immediate inhibition of the release of gonadotropins and sex steroids. Du et al. (2006) prepared LHRH antagonist loaded microparticles to treat prostate cancer. The microparticles were prepared by three methods: (a) double emulsion solvent extraction/evaporation technique, (b) single emulsion solvent extraction/evaporation technique, and (c) s/o/o double emulsion method. The prepared microparticles were smooth and with round surfaces. The drug encapsulation efficiency of microparticles was influenced by LA/GA ratio of PLGA, salt concentrations, solvent mixture and preparation methods. In another study, LHRH antagonist, orntide acetate was successfully incorporated into PLA and PLGA microparticles prepared by w/o/w double emulsion method (Kostanski et al., 2000). Peptide binding to microparticles was dependent upon pH and was markedly higher in phosphate buffer pH 7.4 than in acetate buffer pH 4.0. In vitro release of peptide in phosphate buffer varied from 0.5% to 26%/24 h but due to substantial binding of the peptide to the polymeric matrix the long term release in phosphate buffer could not be determined.

5.2.10. Staphylokinase variant K35R (DGR)

Staphylokinase variant K35R is a recombinant mutant of Staphylococcus aureus enzyme in which lysine (K) at position 35 is replaced by arginine (R). It is used to treat thrombotic disorders. He et al. (2006) prepared DGR loaded PLGA microparticles using a w/o/w double emulsion solvent extraction technique. It has been observed that the DGR encapsulation efficiency was significantly increased from 7.1% to 78%, when 2% polyvinyl alcohol was coencapsulated and 2.5% NaCl was added to the external water phase. In vitro release study revealed that DGR was released from PLGA microparticles in a sustained manner over 15 days.

5.2.11. Brain derived neurotrophic factor (BDNF)

Brain derived neurotrophic factor, a secreted protein, is encoded by the BDNF (member of neurotrophin) gene in human brain. BDNF helps to stimulate and control neurogenesis. Bertram et al. (2010) investigated the role of chemistry of the polymer played in loading and delivery of BDNF via microparticles. It was observed that a triblock polymer of PLGA, PLL, and PEG led to the delivery of BDNF for periods of time greater than 60 days. The released protein was active up to 65 days based on PCl2 cell morphology.

5.2.12. Interferon-alpha 26 (IFN-α26)

Interferon-alpha 26 has been widely used to treat chronic hepatitis C virus infection. It has terminal half life of about 4–5 h. IFN-α26 loaded biodegradable PLGA microparticles were prepared using a w/o/w double emulsion solvent evaporation method Zhang et al., 2008a,b. The prepared microparticles were spherical in shape with smooth surface. In vitro release study showed 63–84% IFN-α26 released in 30 days. In vivo study was conducted in rhesus monkeys by injecting intramuscularly with either commercial IFN-α26 lyophilized powder or IFN-α26 loaded PLGA microparticles. In vivo study revealed that the pharmacokinetic-pharmacodynamic properties between the IFN-α26 microparticles and IFN-α26 lyophilized powder were significantly different.

5.2.13. Glial cell-line derived neurotrophic factor (GDNF)

GDNF is a potent neurotrophic factor for dopaminergic neurons widely used for treating Parkinson’s disease. GDNF loaded PLGA microparticles were prepared using w/o/w double emulsion method (Garbayo et al., 2008). The prepared microparticles showed a mean diameter between 8 and 30 μm and drug entrapment efficiency ranged from 50% to 100%. Microparticles prepared using PLGA RG503H released 67% of the total protein content within 40 days.

5.2.14. Exenatide

Exenatide is a biopharmaceutical used for the treatment of diabetes mellitus type II. It has a half life of about 2.45 h. Its usual dose is 5 μg subcutaneously twice daily. Acetylated pullen microparticles were designed using w/o/w double emulsion method for delivery of type II diabetic drug (exenatide) (Yang et al., 2009). The prepared microparticles showed 68–90% encapsulation efficiency. The release of exenatide from the microparticles evidenced a sustained release profile for 21 days. Similarly, exenatide loaded PLGA microparticles were prepared using a w/o/w double emulsion solvent evaporation method (Liu et al., 2010). In vivo study in diabetic mice revealed that exenatide microparticles have a significant hypoglycemic activity within one month and its controlling of plasma glucose was similar to that of exenatide solution injected twice daily with identical exenatide amount.

5.2.15. Glucagon like peptide-1 (GLP-1)

GLP-1 is a gut hormone widely used for the treatment of type-II diabetes mellitus. GLP-1 loaded PLGA microparticles were prepared by w/o/o double emulsion solvent extraction method (Yin et al., 2008). GLP-1 was micronized or complexed with zinc, which was mixed with PLGA solution in acetonitrile. Mixture was dropped in cottonseed oil containing lecithin. GLP-1 zinc complexation significantly reduced initial burst release from 37.2% to 7.5%. The optimized formulation achieved controlled release in vivo for 28 days and exhibit sustained long term pharmacological efficacy to decrease blood glucose level in diabetic mice.

5.2.16. Bovine hemoglobin

Bovine hemoglobin is the bovine blood obtained from hemoglobin. It acts as an oxygen transporter. Qiu et al. (2004) prepared bovine hemoglobin loaded PELA microparticles using a w/o/w double emulsion solvent diffusion process. They investigated the influence of wall polymer and preparation process on the particle size and encapsulation of microparticles. The prepared microparticles with PELA copolymer containing MPEG 2000 block showed encapsulation efficiency to 90% and the particle size range between 3 and 5 μm. Moreover, the encapsulation efficiency and particle size increased with the concentration of PELA. Other preparation process that influenced the encapsulation efficiency and particle size of microparticles is concentration of NaCl in outer aqueous solution, concentration of stabilizer in outer aqueous solution, and primary emulsion stirring rate.

5.2.17. Basic fibroblast growth factor (bFGF)

Basic fibroblast growth factor participates in the process of wound healing, tissue repair, proliferation, and differentiation of immature neural cells. It has mitogenic and angiogenic properties and is used to treat the inflammatory bowel disease. Shen et al. (2008) prepared bFGF loaded PLGA microparticles using a double emulsion method. They also studied the bioactivities of bFGF after release from microparticles on the cultured Schwann cells. The morphology and loading of prepared microparticles were good. The in vitro release rate of bFGF from microparticles was 72.47% in 11 days. The in vitro cellular study revealed that the prepared microparticles preserved the bioactivities of bFGF effectively and promote the proliferation of Schwann cells in a long period because of the controlled release of bFGF from the microparticles.

5.2.18. Vascular endothelial growth factor (VEGF)

Vascular endothelial growth factor is a signal protein produced by cells that stimulate vasculogenesis and angiogenesis. It restores the oxygen supply to tissue when blood circulation is inadequate. It is used in the treatment of breast cancer, and in rheumatoid arthritis. VEGF loaded PLGA microparticles were prepared using a modified w/o/w double emulsion solvent evaporation technique (Karal-Ylmaz et al., 2011). The prepared microparticles were spherical in shape with diameters of 10–60 μm and the encapsulation efficiency was between 46% and 60%. The microparticles containing 5 μg VEGF per 500 mg starting polymer showed an initial burst release followed by a higher steady-state release until 14 days.

5.2.19. Human immunoglobulin G (IgG)

Human immunoglobulin G is an antibody that constitutes 75% of serum immunoglobulin in humans. It provides protection to the fetus in uteri. Wang and his coworkers (Wang et al., 2004) studied the stabilizing effects of various excipients during the period of protein atomization using spray freeze drying and subsequent encapsulation into PLGA microparticles using a s/o/w double emulsion method. It was observed that ultrasonication did not change the primary structure of IgG significantly. However, subsequent double emulsion solvent evaporation process denatured nearly 80% of the total amount of IgG. Both mannitol and trehalose could stabilize IgG during spray freeze-drying with over 90% retention of its molecular integrity and immunoactivity.

5.2.20. SPf66 malarial antigen

SPf66 malarial antigen is a synthetic peptide vaccine containing antigens obtained from the blood at sporozoite stage of malaria infection. It is the first malaria vaccine which is used to prevent malaria. Igartua et al. (2008) investigated the effects of gamma-irradiation on biopharmaceutical properties of PLGA microparticles loaded with SPf66 malarial antigen. The microparticles were prepared by a w/o/w double emulsion solvent extraction method. First emulsion was formed by sonication and second emulsion was prepared by homogenization in 8% PVA aqueous solution. Two percent isopropanol in water was used to extract solvent. The in vitro results revealed that the gamma irradiation exposure had no apparent effect on SPf66 integrity and formulation properties such as morphology, size and peptide loading. Moreover, SPf66 malarial antigen retained in vivo activity up to week 27.

6. Conclusion

Microparticles made by the double emulsion technique are excellent reservoirs for the encapsulation of a variety of pharmaceutical and biopharmaceutical compounds. The physico-chemical properties of microparticles and its drug release characteristics are dependent on many factors like drug solubility, polymer composition and molecular weight, polymer to core ratio, polymer crystallinity, and rate of solvent evaporation and method of manufacture. Since last decade there has been a great deal of research focused on the controlled delivery of protein and peptide drug. Generally, the w/o/w double emulsion method has been extensively used for the encapsulation of protein and peptides. However, proteins and peptides are susceptible to denaturation, degradation and conformational changes during manufacturing w/o/w double emulsion method which may render them inactive. While by use of s/o/w, w/o/o, and s/o/o double emulsion method the problems associated with w/o/w double emulsion method could be avoided and stability of protein and peptide drugs loaded microparticles can be improved. Much progress has been made in recent years for the preparation of microparticles by double emulsion technique but more is needed. Thus, further development in the technology is still necessary for producing larger amounts of microparticles that are safe, economic, robust and well-controlled.

Footnotes

Peer review under the responsibility of King Saud University.

References

- Ahmed A.R., Bodmeier R. Preparation of performed porous PLGA microparticles and antisense oligonucleotides loading. Eur. J. Pharm. Biopharm. 2009;71(2):264–270. doi: 10.1016/j.ejpb.2008.09.007. [DOI] [PubMed] [Google Scholar]

- Bao W., Zhou J., Lui J., Wu D. PLGA microspheres with high drug loading and high encapsulation efficiency prepared by a novel solvent evaporation technique. J. Microencapsul. 2006;23(5):471–479. doi: 10.1080/02652040600687613. [DOI] [PubMed] [Google Scholar]

- Barakat N.S., Ahmad A.A.E. Diclofenac sodium loaded-cellulose acetate butyrate: effect of processing variables on microparticles properties, drug release kinetics and ulcerogenic activity. J. Microencapsul. 2008;25:31–45. doi: 10.1080/02652040701747928. [DOI] [PubMed] [Google Scholar]

- Bayomi M.A. Aqueous preparation and evaluation of albumin–chitosan microspheres containing indomethacin. Drug Dev. Ind. Pharm. 2004;30(4):329–339. doi: 10.1081/ddc-120030425. [DOI] [PubMed] [Google Scholar]

- Bertram J.P., Rauch M.F., Chang K., Lavik E.B. Using polymer chemistry to modulate the delivery of neurotrophic factors from degradable microspheres: delivery of BDNF. Pharm. Res. 2010;27(1):82–91. doi: 10.1007/s11095-009-0009-x. [DOI] [PubMed] [Google Scholar]

- Bhatnagar S., Nakhare S., Vyas S.P. Poloxamer coated three-ply-walled microcapsules for controlled delivery of diclofenac sodium. J. Microencapsul. 1995;12(1):13–22. doi: 10.3109/02652049509051123. [DOI] [PubMed] [Google Scholar]

- Blanco-Prieto M., Decaroz C., Renedo M., Kunkova J., Gamazo C. In vitro evaluation of gentamicin released from microparticles. Int. J. Pharm. 2002;242(1–2):203–206. doi: 10.1016/s0378-5173(02)00158-8. [DOI] [PubMed] [Google Scholar]

- Blanco-Prieto M.J., Fattal E., Gulik A., Dedieu J.C., Roques B.P., Couvreur P. Characterization and morphological analysis of a cholecystokinin derivative peptide-loaded poly(lactide-co-glycolide) microspheres prepared by a water-in-oil-in-water emulsion solvent evaporation method. J. Control. Release. 1997;43:81–87. [Google Scholar]

- Blatsios G., Tzimas A.S., Mattheolabakis G., Panagi Z., Avgoustakis K., Gartaganis S.P. Development of biodegradable controlled release scleral systems of triamcinolone acetonide. Curr. Eye Res. 2010;35(10):916–924. doi: 10.3109/02713683.2010.497599. [DOI] [PubMed] [Google Scholar]

- Bodmeier R., McGinity J.W. Polylactic acid microspheres containing quinidine base and quinidine sulphate prepared by the solvent evaporation technique. II. Some process parameters influencing the preparation and properties of microspheres. J. Microencapsul. 1987;4:289–297. doi: 10.3109/02652048709021821. [DOI] [PubMed] [Google Scholar]

- Bodmeier R., McGinity J.W. Polylactic acid microsphers containing quinidine base and quinidine sulphate prepared by the solvent evaporation technique: methods and morphology. J. Microencapsul. 1987;4:279–288. doi: 10.3109/02652048709021820. [DOI] [PubMed] [Google Scholar]

- Bodmeier R., McGinity J.W. The preparation and evaluation of drug containing poly(dl-lactide) microspheres formed by the solvent evaporation method. Pharm. Res. 1987;4:465–471. doi: 10.1023/a:1016419303727. [DOI] [PubMed] [Google Scholar]

- Bodmeier R., Wang J., Bhagwatwar H. Process and formulation variables in the preparation of wax microparticles by a melt dispersion technique. II. w/o/w multiple emulsion technique for water soluble drugs. J. Microencapsul. 1992;9(1):99–107. doi: 10.3109/02652049209021227. [DOI] [PubMed] [Google Scholar]

- Carrasquillo K.G., Stanley A.M., Aponte-Carro J.C., Jesus P.D., Costantino H.R., Bosques C.J., Griebenow K. Non-aqueous encapsulation of excipient stabilized spray freeze dried BSA into poly(lactide-co-glycolide) microspheres results in release of native protein. J. Control. Release. 2001;76:199–208. doi: 10.1016/s0168-3659(01)00430-8. [DOI] [PubMed] [Google Scholar]

- Castellanos I.J., Carasquillo K.G., Lopez J.D., Alvarez M., Griebenow K. Encapsulation of bovine serum albumin in poly(lactide-co-glycolide) microspheres by the solid-in-oil-in-water technique. J. Pharm. Pharmacol. 2001;53:167–178. doi: 10.1211/0022357011775361. [DOI] [PubMed] [Google Scholar]

- Castellanos I.J., Crespo R., Griebenow K. Poly(ethylene glycol) as stabilizer and emulsifying agent: a novel stabilization approach preventing aggregation and inactivation of proteins upon encapsulation in bioerodible polyester microspheres. J. Control. Release. 2003;88:135–145. doi: 10.1016/s0168-3659(02)00488-1. [DOI] [PubMed] [Google Scholar]

- Castellanos I.J., Cruz G., Crespo R., Griebenow K. Encapsulation induced aggregation and loss in activity of γ-chymotrypsin and their prevention. J. Control. Release. 2002;81:307–319. doi: 10.1016/s0168-3659(02)00073-1. [DOI] [PubMed] [Google Scholar]

- Celik O., Akbuga J. Preparation of superoxide dismutase loaded chitosan microspheres: characterization and release studies. Eur. J. Pharm. Biopharm. 2007;66(1):42–47. doi: 10.1016/j.ejpb.2006.08.016. [DOI] [PubMed] [Google Scholar]

- Cevher E., Orhan Z., Sensoy D., Ahiskali R., Kan P.L., Sagirli O., Mulazimoglu L. Sodium fusidate poly(dl-lactide-co-glycolide) microspheres: preparation, characterization and in vivo evaluation of their effectiveness in the treatment of chronic osteomyelitis. J. Microencapsul. 2007;24(6):577–595. doi: 10.1080/02652040701472584. [DOI] [PubMed] [Google Scholar]

- Chaisri W., Hennink W.E., Okonogi S. Preparation and characterization of cephalexin loaded PLGA microspheres. Curr. Drug. Deliv. 2009;6(1):69–75. doi: 10.2174/156720109787048186. [DOI] [PubMed] [Google Scholar]

- Chakraborty S., Khandai M., Sharma A., Khanzm N., Patra C.N., Dinda S.C., Sen K.K. Preparation, in vitro and in vivo evaluation of algino-pectinate bioadhesive microspheres: an investigation of the effects of polymers using multiple comparison analysis. Acta Pharm. 2010;60(3):255–266. doi: 10.2478/v10007-010-0026-7. [DOI] [PubMed] [Google Scholar]

- Chandy T., Das G.S., Rao G.H.R. 5-Fluorouracil loaded chitosan coated polylactic acid microspheres as biodegradable drug carriers for cerebral tumors. J. Microencapsul. 2000;17(5):625–638. doi: 10.1080/026520400417676. [DOI] [PubMed] [Google Scholar]

- Chang L.C., Yang C.Y., Chua A.C., Lin Y.J., Lai S.M. Sustained release of transgenic human factor IX: preparation, characterization, and in vivo efficacy. Mol. Pharm. 2011;8(5):1767–1774. doi: 10.1021/mp200133s. [DOI] [PubMed] [Google Scholar]

- Chen B., Song C., Luo X., Deng J., Yang W. Microspheres consisting of optically active helical substituted polyacetylenes: preparation via suspension polymerization and their chiral recognition/release properties. Macromol. Rapid Commun. 2011;32(24):1986–1992. doi: 10.1002/marc.201100557. [DOI] [PubMed] [Google Scholar]

- Ciombor D.M.C.K., Jaklenec A., Liu A.Z., Thanos C., Rahman N., Weston P., Aaron R., Mathiowitz E. Encapsulation of BSA using a modified W/O/O emulsion solvent removal method. J. Microencapsul. 2006;23(2):183–194. doi: 10.1080/02652040500435287. [DOI] [PubMed] [Google Scholar]

- Cohen S., Yoshioka T., Lucarelli M., Hwang L.H., Langer R. Controlled delivery systems for proteins based on poly(lactic/glycolic acid) microspheres. Pharm. Res. 1991;8:713–720. doi: 10.1023/a:1015841715384. [DOI] [PubMed] [Google Scholar]

- Coombes A.G.A., Yeh M.K., Lavelle E.C., Davis S.S. The control of protein release from poly(dl-lactide co-glycolide) microparticles by variation of the external aqueous phase surfactant in the water-in oil-in water method. J. Control. Release. 1998;52:311–320. doi: 10.1016/s0168-3659(98)00006-6. [DOI] [PubMed] [Google Scholar]

- Crotts G., Park T.G. Protein delivery from poly(lactic-co-glycolic acid) biodegradable microspheres: release kinetics and stability issues. J. Microencapsul. 1998;15:699–713. doi: 10.3109/02652049809008253. [DOI] [PubMed] [Google Scholar]

- Cui F., Cun D., Fao A., Yang M., Shi K., Zhao M., Guan Y. Preparation and characterization of melittin loaded poly(dl-lactic acid) or poly(dl-lactic-co-glycolic acid) microspheres made by the double emulsion method. J. Control. Release. 2005;107(2):310–319. doi: 10.1016/j.jconrel.2005.07.001. [DOI] [PubMed] [Google Scholar]

- Dai M., Xu X., Song J., Fu S., Gou M., Luo F., Qian Z. Preparation of camptothecin-loaded PCEC microspheres for the treatment of colorectal peritoneal carcinomatosis and tumor growth in mice. Cancer Lett. 2011;312(2):189–196. doi: 10.1016/j.canlet.2011.08.007. [DOI] [PubMed] [Google Scholar]

- Dalmoro A., Lamberti G., Titomanilo G., Barba A.A., Amore M. Enteric microparticles for targeted oral drug delivery. AAPS Pharm. Sci. Tech. 2010;11(4):1500–1507. doi: 10.1208/s12249-010-9528-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Das M.K., Rao K.R. Evaluation of zidovudine encapsulated ethyl cellulose microspheres prepared by water-in-oil-in-oil (w/o/o) double emulsion solvent diffusion technique. Acta Pol. Pharm. 2006;63(2):141–148. [PubMed] [Google Scholar]

- Devrim B., Bozkar A., Canefe K. Preparation and evaluation of PLGA microparticles as carrier for the pulmonary delivery of rhIL-2: I. Effects of some formulation parameters on microparticles characteristics. J. Microencapsul. 2011;28(6):582–594. doi: 10.3109/02652048.2011.599438. [DOI] [PubMed] [Google Scholar]

- Dong Z.J., Toure A., Jia C.S., Zhang X.M., Xu S.Y. Effect of processing parameters on the formation of spherical multinuclear microcapsules encapsulating peppermint oil by coacervation. J. Microencapsul. 2007;24(7):634–646. doi: 10.1080/02652040701500632. [DOI] [PubMed] [Google Scholar]

- Dorati R., Genta I., Tomasi C., Modena T., Colonna C., Pavanetto F., Perugini P., Conti B. Polyethyleneglycol-co-poly-dl-lactide copolymer based microspheres: preparation, characterization and delivery of a model protein. J. Microencapsul. 2008;25(5):330–338. doi: 10.1080/02652040801996763. [DOI] [PubMed] [Google Scholar]

- Du L., Cheng J., Chi Q., Qie J., Liu Y., Mei X. Biodegradable PLGA microspheres as a sustained release system for a new luteinizing hormone releasing hormone (LHRH) antagonist. Chem. Pharm. Bull. 2006;54(9):1259–1265. doi: 10.1248/cpb.54.1259. [DOI] [PubMed] [Google Scholar]

- Ereitas S., Rudolf B., Merkle H.P., Gander B. Flow through ultrasonic emulsification combined with static micromixing for aseptic production of microspheres by solvent extraction. Eur. J. Pharm. Biopharm. 2005;61(3):181–187. doi: 10.1016/j.ejpb.2005.05.004. [DOI] [PubMed] [Google Scholar]

- Fan Y., Shan-Guang W., Yu-Fang P., Feng-Lan S., Tao L. Preparation and characteristics of erythromycin microspheres for lung targeting. Drug. Dev. Ind. Pharm. 2009;35(6):639–645. doi: 10.1080/03639040802512243. [DOI] [PubMed] [Google Scholar]

- Farook U., Edirisinghe M.J., Stride E., Colombo P. Novel co-axial electrohydrodynamic in-situ preparation of liquid filled polymer shell microspheres for biomedical applications. J. Microencapsul. 2008;25(4):241–247. doi: 10.1080/02652040801896666. [DOI] [PubMed] [Google Scholar]

- Garbayo E., Ansorena E., Lanciego J.L., Aymerich M.S., Blanco-Prieto M.J. Sustained release of bioactive glycosylated glial cell-line derived neurotrophic factor from biodegradable polymeric microspheres. Eur. J. Pharm. Biopharm. 2008;69(3):844–851. doi: 10.1016/j.ejpb.2008.02.015. [DOI] [PubMed] [Google Scholar]

- Giovagnoli S., Blasi P., Schoubben A., Rossi C., Ricci M. Preparation of large porous biodegradable microspheres by using a simple double emulsion method for capreomycin sulfate pulmonary delivery. Int. J. Pharm. 2007;333(1–2):103–111. doi: 10.1016/j.ijpharm.2006.10.005. [DOI] [PubMed] [Google Scholar]