Abstract

Both particulate matter (PM) and black carbon (BC) impact climate change and human health. Uncertainties in emission inventories of PM and BC are partially due to large variation of measured emission factors (EFs) and lack of EFs from developing countries. Although there is a debate whether thermal-optically measured elemental carbon (EC) may be referred to as BC, EC are often treated as the same mass of BC. In this study, EFs of PM (EFPM) and EC (EFEC) for 9 crop residues and 5 coals were measured in actual rural cooking and coal stoves using the carbon mass balance method. The dependence of the EFs on fuel properties and combustion conditions were investigated. It was found that the mean EFPM were 8.19 ± 4.27 and 3.17 ± 4.67 g/kg and the mean EFEC were 1.38 ± 0.70 and 0.23 ± 0.36 g/kg for crop residues and coals, respectively. PM with size less than 10 μm (PM10) from crop residues were dominated by particles of aerodynamic size ranging from 0.7 to 2.1 μm, while the most abundant size ranges of PM10 from coals were either from 0.7 to 2.1 μm or less than 0.7 μm. Of various fuel properties and combustion conditions tested, fuel moisture and modified combustion efficiency (MCE) were the most critical factors affecting EFPM and EFEC for crop residues. For coal combustion, EFPM were primarily affected by MCE and volatile matter, while EFEC were significantly influenced by ash content, volatile matter, heat value, and MCE. It was also found that EC emissions were significantly correlated with emissions of PM with size less than 0.4 μm.

Introduction

Exposure to particulate matter (PM), especially fine PM is associated with a wide range of diseases, including respiratory infection, lung cancer, and bronchus1. Smoke from household fuel combustion is a large risk factor for people, especially females in developing countries2. PM also impacts on global climate change and it was suggested that the Asian Brown Cloud was partly due to cook stove emission3. As an important component of PM, black carbon (BC) is the third largest warming agent, following CO2 and methane4. PM can be produced from direct combustion or atmospheric formation, while BC is mainly from combustion of carbon-based fuels5. It is believed that BC is dominated by elemental graphitic carbon6. Till now, many investigations on air quality or emission were based on thermal-optically measured elemental carbon (EC) instead of optically measured BC and treated them as the same mass5, 7. Emission inventories for PM and BC are critical in evaluation of how sources affect health and climate and have been continuously improved. Estimated emission of PM with size less than 10 μm (PM10) from Europe was 1823 Gg/year, of which 516 and 226 Gg/year were from households and non-combustion agricultural activities, respectively8. Global PM2.5 (PM with Da less than 2.5 μm) emission from biomass burning was 58.3 Tg/year, of which 19.4 Tg/year was from domestic biomass combustion9. BC emission was 2.54 Tg/year in Asian in 200010 and 8.0 Tg/year globally in 19965.

For emission inventory development, statistics such as medians or means for emission factors (EFs) from the literature were usually adopted. Since the measured EFs often varied over orders of magnitude, variation in EFs was the primary source of the overall uncertainty of emission inventories5, 10-11. In addition, most reported EFs were measured in developed countries potentially biasing the global EF databank and likely leading to considerable underestimation of emission in developing countries5, 10-12.

Combustion of solid fuels, including crop residues and coals, in cooking stoves is among the most important sources of PM and BC, particularly in developing countries5, 10-11. It was estimated that the total quantities of crop residue combusted in field and indoor in China were 151 and 333 Tg in 2003, respectively12. EFs of solid fuel varied widely due to variations in fuel types, fuel properties, and burning conditions, leading to large uncertainties in emission inventory5, 10-11. These tests were conducted either in stoves13-17, chambers18-21, or open-field21-23. It has been shown that emissions from cooking stoves, combustion chambers, or in open-field could be very different due to the differences in oxygen supply and circulation7, 21, 22-25. In addition, large difference in EFs among different kinds of solid fuels has been well documented13-14, 17. To improve process understanding and reduce uncertainty in emission estimation, it is necessary to quantify the influences of fuel properties and combustion conditions on the emission.

With the largest population and economy, China consumes the largest portion of energy among all developing countries. The main objectives of this study were to measure and characterize PM and EC emissions from combustion of commonly used crop residues and coals in traditional stoves in China and to quantitatively evaluate the key factors affecting the emissions so as to have a better understanding of the variations of EFs of PM (EFPM) and EC (EFEC). The information provided is useful for improving emission inventories for PM and EC. Particle size distribution of the PM emission was also addressed since it is important in terms of environmental and human health impacts1.

Methodology

Stoves and Fuels

Two types of stoves widely used in rural China are brick wok stoves designed for large-size round-bottom woks and movable cast-iron stoves for small woks, tea pot or other cookware. Both of them are fire enclosed and have been used for centuries26. During a period from 1980s to 1990s, a campaign of disseminating fuel-saving stoves in rural China have been undertaken to improve fuel efficiency of these stoves by using taller chimney, smaller firebox and fire door, and shorter distance between grid and cookware. It was estimated that the total numbers of the improved brick and cast-iron stoves used in China were 143 and 349 million in 2006, respectively26. In northern China, wok stoves used by 175 million rural residences are connected to heating beds, known as “Kang”27. In this study, a brick wok stove for crop residue burning was set up in a rural kitchen and a cast-iron stove for coal combustion was purchased from the local market in suburban Beijing. The exited smoke from the wok stove (passed a “Kang”) and cast-iron stove entered a mixing chamber (4.5 m3) with a build-in mixing fan. No further dilution was performed to avoid alterations in particulate mass loading and size distribution24. The photos of the stoves are shown in the Supporting Information (S1). Nine crop residues which contributed more than 90% of the total crop residue combusted in China (rice 17.5%, wheat 19.5%, corn 39.1%, beans including soybean and horsebean 5.4%, cotton 2.4%, oil crop including peanut, sesame, and rape 9.3%)28 and five coals (two honeycomb briquettes from Beijing and Taiyuan and three chunk coals from Taiyuan and Yulin) were tested. The two honeycomb briquettes (15 cm diameter and 11 cm thick with 16 holes) were made of either anthracite with 4% volatile matter (VM) (from Beijing) or low volatile bituminous with 15% VM (from Taiyuan). The three raw chunk coals (from Taiyuan and Yulin) were all medium volatile bituminous (MVB) with VM between 23 and 29 %. The fuel properties are listed in the Supporting Information (S2).

Combustion Experiments

Combustion experiments were conducted following traditional methods used by rural residents. For coal combustion, coal (ca. 800-1000 g) in the stove was first ignited outdoor using small wood chips. After the coal was ignited, the stove was moved into the kitchen and set up under a stainless hood. For crop residue burning, pre-weighed fuel (ca. 500-700 g) was inserted into the stove chamber in 8-10 batches, and the burning lasted for 20-30 minutes. The ash was collected, weighed, and analyzed for carbon content. The combustion experiment for each type of fuel was conducted twice as duplicates. CO2 and CO were measured every 2 seconds with an on-line detector equipped with non-dispersive infrared sensor. The equipment was calibrated before each experiment. Exact duration, fire temperature, smoke temperature, and relative humidity of smoke were recorded during the combustion (No significant difference among crop residues or among coals were observed). Emissions of PM and EC vary over the whole burning period of crop residues, which can be at least divided into flaming (with obvious fire) and smoldering (without observed fire) phases. Both CO and CO2 increased in the flaming phase and decreased during the smoldering phase24. The difference in PM and EC emissions between the two phases was expected. Therefore, in addition to the whole burning cycle experiment, the two phases were tested individually in duplicates for all crop residues.

Sample Collection and Measurement

Low-volume pumps (XQC-15E, Tianyue, China) with quartz fiber filters were used to collect PM (as total suspended particles) in the mixing chamber at a flow rate of 1.5 L/min. A nine stage cascade impactor (FA-3, Kangjie, China) with glass fiber filters was used to collect PM10 samples with different aerodynamic diameter (Da) (< 0.4, 0.4 - 0.7, 0.7 - 1.1, 1.1 - 2.1, 2.1 -3.3, 3.3 - 4.7, 4.7 - 5.8, 5.8 - 9.0, and 9.0 -10.0 μm) at a flow rate of 28.3 L/min. The filters were baked at 450 °C for 6 hours and stored in a desiccator for 24 hours prior to weighing and sampling. After sampling, particle-loaded filters were packed with aluminum foil and stored in a desiccator before further analysis. Gravimetric measurements were conducted using a high precision (0.00001g) digital balance. EC and organic carbon (OC) were analyzed using Sunset EC/OC analyzer (Sunset Lab, USA). Samples were also collected in the mixing chamber before the combustion experiment and measured for PM, EC, OC, CO, and CO2 using the same methods. The results were used as procedure blanks and subtracted from those measured during combustion.

Data analysis

EFs of CO2, CO, PM, EC, and OC were calculated using the carbon mass balance method13. As most of the released gaseous carbon was in the forms of CO2 or CO, the total hydrocarbon species in the gaseous phase were neglected which may lead to an error of less than 4%24. Several parameters including modified combustion efficiency (MCE), products of incomplete combustion (PIC), burning rate (Rb), and carbon release rate (Rc) were calculated to quantitatively describe the combustion conditions. The non-parametric Wilcoxon test for paired samples and Spearman correlation analysis were applied for data analysis using Statistica at a significant level of 0.05. To characterize the effects of various factors including fuel properties and combustion conditions, stepwise regression was applied. Calculation of the carbon balance method and various combustion conditions are provided in the Support Information (S3 and S4).

Results

EFPM of Crop Residues and Coals

The measured EFs of PM, EC, OC, CO2, and CO for crop residues and coals are presented in the Supporting Information (S5). In brief, the means and standard deviations of EFs of CO2 (1380 ± 120 g/kg) and CO (126 ± 47 g/kg) for crop residue burning were comparable with the published data13-14. EFs of CO2 and CO for coal combustions varied between 291 and 2286 g/kg and between 35 and 288 g/kg, respectively, which also agreed with those previously reported13-14.

EFPM for crop residues varied from 3.41 ± 0.11 (cotton) to 16.8 ± 4.81 g/kg (rape) with a mean and a standard deviation of 8.19 ± 4.27 g/kg. Andreae and Merlet reviewed published EFPM data and came up with a similar value of 9.4 ± 6.0 g/kg for domestic biomass combustion9. The measured EFPM for coal combustion varied widely from 0.065 ± 0.002 for anthracite (honeycomb coals from Beijing) to 10.8 ± 0.55 g/kg for bituminous coals (raw chunk from Yulin) with a mean and a standard deviation of 3.17 ± 4.67 g/kg, depending on origin and type of the coals. Zhang et al. reported similar EFPM of 8.05 (1.12 - 29.0) and 1.30 (0.026 - 10.0) g/kg for crop residues and coals burned in stoves, respectively13. The differences in EFPM between anthracite and bituminous coals and between raw chunk and honeycomb coals are well recognized, and our results agreed well with those reported previously7, 29.

For the two phases of flaming and smoldering burning, the EFs of CO2 and CO for crop residues were not significantly different (p > 0.05), while EFPM of flaming phase (9.51 ± 3.02 g/kg) were significantly higher than those of smoldering one (7.09 ± 3.87 g/kg) (p < 0.05). In fact, smoke observed in smoldering phase was less thick than that in flaming phase. Although it was reported that PM number measured in flue gas during smoldering phase of biomass burning was lower than that of flaming phase, the fuel consumption rate was not measured for the two phases and the difference in EFPM between the two phases were not calculated by them15, 18. Taking high variability in burning conditions into consideration, the difference and the reasons causing such a difference should be further investigated.

EFEC for Crop Residues and Coals

EFEC and EFOC for crop residue burning were 1.38 ± 0.70 and 1.45 ± 0.62 g/kg, respectively. It is interesting to compare our results with those reported by the others for a better understanding of wide variation of EF measurements. In general, our results are more or less similar to those measured using cooking stoves in the literature25, 30. For example, Li et al. reported that EFEC and EFOC for crop residues in residential stoves were 0.09 - 0.94 and 0.85 - 3.21 g/kg, respectively25. It is noted that the EFEC, but not EFOC, measured for residential stoves (both our study and those reported in the literature) were often higher than those measured in laboratory chambers or open field. It was reported that EFEC and EFOC were 0.08 and 6.2 g/kg for rice residue20 and 0.35 and 1.9 g/kg for wheat23 burned in laboratory chambers. EFEC and EFOC of open fire burning for wheat were 0.16 - 0.17 and 0.29 - 2.81 g/kg, respectively23, 31. The difference is likely due to the restricted air supply and poor mixing in residential stoves compared with those in chambers and open field, resulting in relatively lower combustion efficiency and higher combustion temperature, which is favorable for EC formation5.

For coal combustion, EFEC varied from 0.006 for the anthracite coal (Beijing, honeycomb) to 0.83 ± 0.34 g/kg for the MVB chunk coals from Taiyuan. The mean and standard deviation of EFEC for coal was 0.23 ± 0.36 g/kg. Similarly, EFOC ranged from 0.007 to 1.00 g/kg for these coals. These results were comparable to those previously reported. For example, Chen et al. found EFEC measured in residential stoves ranged from 0.004 (anthracite) to 0.25 g/kg (MVB) for honeycomb briquette, and from 0.007 (anthracite) to 13.3 g/kg (MVB) for raw chunk coals7.

Size Distribution of PM10 from crop residue and coal combustion

For all crop residues tested in whole burning cycle, the distributions were similar and unimodal with the peak between 0.7 and 2.1 μm (S6). The similarity leads to small standard deviation of the overall distribution of all crop residues. On average, over 81% of the total mass of PM10 from crop residues was PM2.5 and approximately 12% were finer particles with Da less than 0.4 μm (PM0.4). Unlike crop residues, size distributions of PM10 from 5 coals fell into two distinguished categories (S6). For chunk coal from Taiyuan and chunk coal A from Yulin, size fraction between 0.7 and 2.1 μm contributed 49 ± 11% of the total mass of PM10, while the dominant fraction of two honeycomb coals and chunk coal B from Yulin was those with Da less than 0.7 μm, accounting for 52 ± 18 to 60 ± 1% of the total. For all coals tested, PM2.5 fractions were more than 77 ± 5% of the total. The domination of fine particles from coal combustion emissions was often reported7.

Discussion

Difference in EFPM among Crop Residues

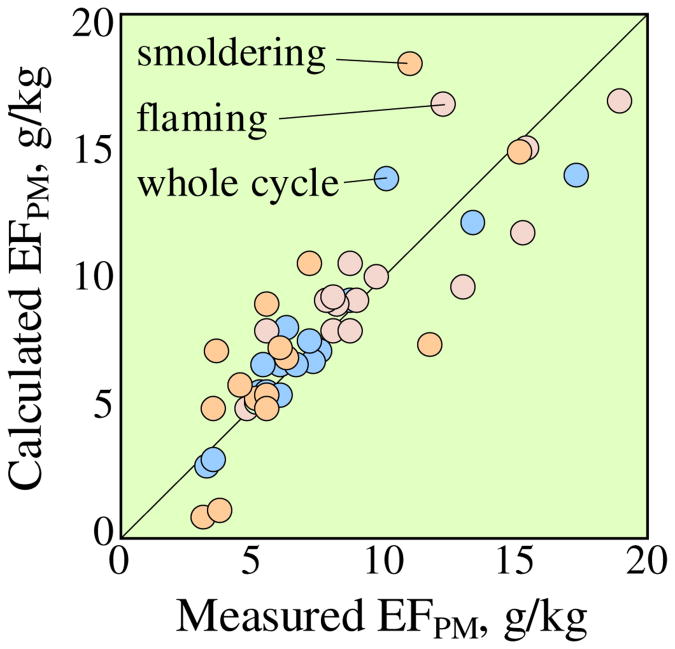

Like those reported in the literature, the measured EFPM varied widely among crops and coals. A number of factors including fuel property, stove type, oxygen supply, combustion temperature, and fire management have been investigated for their influences on EFPM13-23, 32-35. For example, EFPM for wheat and corn residues burned in household stoves ranged from 0.12 to 29.0 g/kg13. Dhammapala et al. found that PM2.5 emission from wheat stubble burning decreased from 4.7 ± 0.4 to 0.8 ± 0.4 g/kg when the combustion efficiency increased from 92.2 to 97.7%19. To address the factors affecting EFPM for crop residues, a number of factors including the measured contents of moisture, C, H, and N of the fuels as well as the calculated MCE, PIC, Rb, and Rc were assessed using a stepwise regression model. The detailed result is presented in S7. Of these parameters, moisture and MCE were significant (p < 0.05) in smoldering phase, flaming phase, and whole burning cycle and 63 - 83% of the total variations in EFPM can be explained by them. As such, the regression models can be applied to predict EFPM based on moisture and MCE and the predictions are plotted against the measurements for the three experiments in Figure 1.

Figure 1.

Comparison between the measured and calculated EFPM for crop residue burning. The calculation was based on regression models with two independent variables of moisture and MCE. Three experiments including smoldering phase, flaming phase, and whole burning cycle are presented together.

In smoldering phase, flaming phase, or whole burning cycle, moisture appeared to be the most important factor affecting PM emission. However, the influence of moisture on EFPM was complicated as documented in the literature. For example, it was found that PM concentrations were 34.2, 161, and 70.8 mg/m3 from combustion of firewood with moisture contents of < 25, 26 - 39, and > 40%, respectively35. The presence of water resulted in lower combustion efficiency, leading to a thick cloud of smoke particles33. Slower formation and hence lower PM emission rate can also occur due to lower combustion temperature under higher moisture content17. In addition, steam stripping or volatilization of organic compounds, which is fuel moisture dependent, can also result in the change of PM mass36. In this study, significantly negative correlation (p = 0.004) between moisture and EFPM was found. Since the crop residues were stored at the same condition for months prior to the experiment and the difference in moisture content was likely due to differences in fuel composition and texture. It will also be interesting to quantitatively test the influence of moisture on emission for the same crop residue in the future. The second important factor was MCE, which reflects the status of oxygen supply and combustion efficiency. It was found that similarly defined combustion efficiency explained more than 60% of variation in PM2.5 emission for wheat straw19. It was indicated that although MCE is affected by moisture and other fuel properties, it is also related to non-fuel factors, such as air supply and mixing during combustion20.

Difference in EFPM among Coals

Larger difference in EFPM was observed between the honeycomb and chunk coals and even among the three chunk coals tested. It was reported that PM2.5 emissions from chunk coal combustion were 1.4 to 4 times of those from combustion of honeycomb made from the same coal29. A number of parameters including moisture, ash content, VM, heat value, and MCE were tested for their influences on EFPM for coals using a stepwise regression. It was found that the two most significant factors affecting EFPM for coals were MCE (p = 7.0×10−7) and VM (p = 0.0003) and 92% of the variation was accountable (S7). Figure 2 presents the relationship between the model-predicted and measured EFPM. Higher EFPM were also reported for coals with higher VM previously7. It is also known that bituminous coal generally ranks first in both VM content and EFPM among various coals, followed by sub-bituminous and anthracite7, 29.

Figure 2.

Comparison between the measured and calculated EFPM for coals. The calculation was based on a stepwise regression model for predicting EFPM based on MCE and VM.

Difference in Particle Size Distributions

As discussed previously, size distributions of PM10 from burning of various crop residues were similar to one another (Figure S2). Still, it was found that the minor difference among crops was moisture dependent. Of the 9 size stages, correlation coefficients between moisture and relative fractions of 6 stages with Da larger than 1.1 μm were positive (5 out of the 6 were significant at p < 0.05), while correlation coefficients between moisture and relative fractions of the remained 3 stages with Da less than 1.1 μm were negative (p = 0.098, 0.041, and 0.054 for 0.7 - 1.1, 0.4 -0.7, and < 0.4 μm, respectively). Such a relationship was aggregately characterized by the significantly negative correlation between moisture and fine/coarse ratio (mass of PM smaller than 1.1 μm divided by that larger than 1.1 μm) (r = −0.651, p = 0.002). A similar linear correlation between fuel moisture and PM mean diameter was also found in residential wood combustion37. It is believed that the increase of moisture can reduce combustion temperature and efficiency33-35. Since larger particles are produced under lower combustion temperature17, higher moisture is favorable for emission of larger particles. Higher temperature may also shift mass distribution of particles to smaller diameter by limiting partitioning of organics on particles37. In addition, fuel moisture may also affect relative humidity of flue gas, subsequently particle condensation in flue gas, and the size of new emitted particles24. As EFPM was also negatively proportional to moisture as discussed above, a negative correlation between EFPM and PM size was expected. The same relationship was also revealed in sawdust combustion17.

The size distributions of PM10 from five coals can be divided into two categories with dominant size ranges of 0.7 - 2.1 μm or < 0.7 μm (Figure S2). Of all coal properties and combustion status determined in the study, the only one which distinguished the two categories was Char Residue Characteristics (CRC, an index describing caking property of combusted coal residue, the higher the CRC the tighter the combusted residue)38. The CRCs of the 2 coals emitted PM10 with dominant Da range of 0.7 - 2.1 μm were 5 and 6, while CRCs of the 3 coals emitted PM10 with dominant Da range of < 0.7 μm was 1 or 2. It appeared that the coals with higher CRC had stronger caking potential and tended to emit larger particles during the combustion, primarily due to decrease in particle surface area and increase in contact time between the volatiles and char38.

Difference in EFEC among Different Crop Residues and Coals

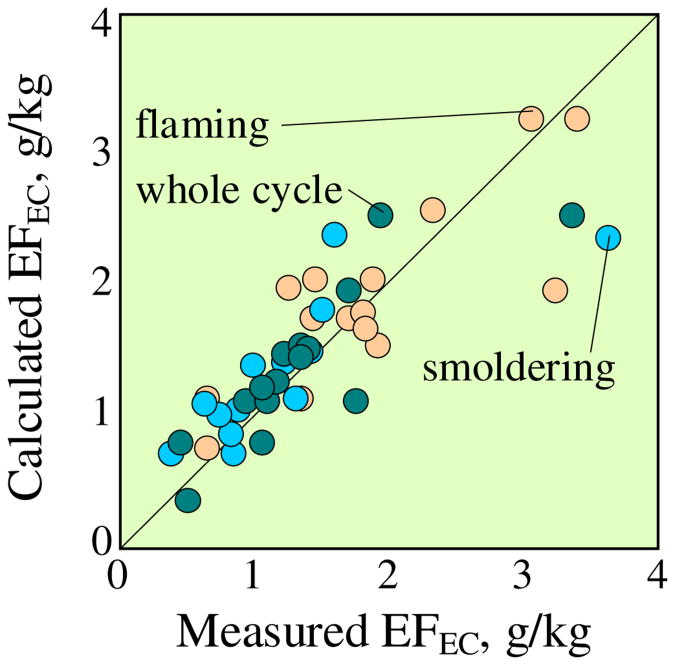

EFEC from crop residues varied widely from 0.493 (peanut) to 2.63 g/kg (wheat). A larger difference in EFEC among different crop residues with a coefficient of variation of 74% was also reported before25. Besides fuel type, many other factors including combustion efficiency, air flux, burning rates, and fuel loading can also affect EFEC 5, 25, 39. In this study, five factors of MCE, moisture, N, C, and H were evaluated using a stepwise regression model for their influences on EFEC. The details of the regression analysis can be found in S7. It was found that moisture and N were significant for EFEC (p < 0.05) and can explain 63 - 72% of the total variations in EFEC for whole burning cycle and two separated burning phases. A good agreement between the measured and predicted EFEC using a regression model with moisture and N as independent variables is shown in Figure 3. It appears that low moisture were favorable for EC emission, as high moisture content can suppress combustion temperature20. More studies are required for understanding the effect of N on EC emission, which can not be explained at this stage.

Figure 3.

Comparison between the measured and calculated EFEC for crop residue burning. The prediction was based on two independent variables of moisture and N. Three sets of experiments presented include smoldering phase, flaming phase, and whole burning cycle.

In coal combustion, the four significant factors (p < 0.05) identified include ash content, VM, heat value, and MCE, which contributed 95% of the total variation of EFEC (S7). Of these factors, heat value was the most important one which can explain 48% of the total variation. The mechanisms of MCE and VM influence are similar to those for PM emission. Effects of VM and heat value on EC emission from coal combustion were also reported by other researchers5, 7 and it was suggested that VM in coal was associated with coal tar and hydrocarbons that serve as nuclei for EC formation5.

Relationship between EFEC and EFPM

Significant correlations among EFEC, EFOC, and EFPM were found in this study (p < 0.05) as well as in the literature7, 15. For various crop residues tested, EFEC/EFPM were 0.18 ± 0.06, 0.19 ± 0.11, and 0.19±0.09 for flaming, smoldering and whole cycle burning, respectively, showing relatively small variation among crops and no significant difference among the stages (p > 0.05). This is also true for EFOC/EFPM (0.17 ± 0.06, 0.19 ± 0.07, and 0.19 ± 0.07 for the three experiments, respectively). The results generally agree with those reported by the others21-23, 30. For the coals, EFOC/EFPM (0.18 ± 0.12) were similar to those of crop residues, while EFEC/EFPM (0.07 ± 0.06) were significantly lower than those of crop residues. Again, similar results have been reported previously7, 29. The similarity in influencing factors on EFEC and EFPM also suggests the correlation between them.

EC is usually associated with fine and ultrafine particles in air. For crop residues studied, six fractions with size larger than 1.1 μm were negatively correlated with EFEC (p < 0.05), while the coefficients between EFEC and the other three fractions were positive (p < 0.05). A significant linear relationship was revealed between log-transformed EFEC and EFPM0.4 and the details can be found in the S8.

Future Study

All above discussion was based on the data collected in this study under given circumstance and can not be simply extrapolated. For example, open-field burning may have very different results and stoves used in rural China can differ from those used in other developing countries.

Taking the large variations of EFEC and EFPM into consideration, more studies are preferred for a better characterization of the emissions and a better prediction of emission inventory. For laboratory studies, influences of various factors including type and condition of stoves, type and property of fuels, burning and environmental conditions, and the way of burning should be investigated systematically. The results should be compared and validated using filed observed data of relatively large sample size. Based on these results, emission models can be further improved. Globally, more studies on stove emission in developing countries other than China are also important.

Supplementary Material

Acknowledgments

Funding for this study was provided by the National Natural Science Foundation of China (40730737 and 140710019001), the National Basic Research Program (2007CB407301), the Ministry of Environmental Protection (200809101), and NIEHS (P42 ES016465).

Footnotes

Supporting Information available: The following materials, including design of the stoves, fuel properties, combustion conditions, the measured EFs, size distributions of PM10, the stepwise regression analysis, and the relationship between EFEC and EFPM0.4, are available free of charge via the Internet at http://pubs.acs.org.

References

- 1.Englert N. Fine particles and human health- a review of epidemiological studies. Toxicol Lett. 2004;149:235–242. doi: 10.1016/j.toxlet.2003.12.035. [DOI] [PubMed] [Google Scholar]

- 2.Zhang J, Smith KR. Household air pollution from coal and biomass fuels in China: Measurements, health impacts, and interventions. Environ Health Perspect. 2007;115:848–855. doi: 10.1289/ehp.9479. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Gustafsson Ö, Kruså M, Zencak Z, Sheesley RJ, Granat L, Engström E, Praveen PS, Rao PSP, Leck C, Rodhe H. Brown clouds over south asia: biomass or fossil fuel combustion? Science. 2009;323:495–498. doi: 10.1126/science.1164857. [DOI] [PubMed] [Google Scholar]

- 4.Sato M, Hansen J, Koch D, Lacis A, Ruedy R, Dubovik O, Holben B, Chin M, Novakov T. Global atmospheric black carbon inferred from AERONET. Proc Natl Acad Sci. 2003;100:6319–6324. doi: 10.1073/pnas.0731897100. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Bond TC, Streets DG, Yarber KF, Nelson SM, Woo J, Klimont Z. A technology-based global inventory of black and organic carbon emissions from combustion. J Geophys Res. 2004;109:D14203. doi: 10.1029/2003JD003697. [DOI] [Google Scholar]

- 6.Bond TC, Charlson RJ, Heintzenberg J. Quantifying the emission of light-absorbing particles: measurements tailored to climate studies. Geophys Res Lett. 1998;25:337–340. [Google Scholar]

- 7.Chen Y, Sheng G, Bi X, Feng Y, Mai B, Fu J. Emission factors for carbonaceous particles and polycyclic hydrocarbons from residential coal combustion in China. Environ Sci Technol. 2005;39:1861–1867. doi: 10.1021/es0493650. [DOI] [PubMed] [Google Scholar]

- 8.Amann M, Bertok I, Cofala J, Gyarfas F, Heyes C, Klimont Z, Schöpp W, Winiwarter W. Final report: Baseline Scenarios for the Clean Air for Europe (CAFE) Programme. 2005 http://www.iiasa.ac.at/rains/CAFE_files/Cafe-Lot1_FINAL(Oct).pdf.

- 9.Andreae MO, Merlet P. Emission of trace gases and aerosols from biomass burning. Glob Biogeochem Cycle. 2001;15:955–966. [Google Scholar]

- 10.Streets DG, Bond TC, Carmichael GR, Fernandes SD, Fu Q, He D, Klimont Z, Nelson SM, Tsai NY, Wang MQ, Woo J, Yarber KF. An inventory of gaseous and primary aerosol emissions in Asia in the year 2000. J Geophys Res. 2003;108:D218809. doi: 10.1029/2002JD003093. [DOI] [Google Scholar]

- 11.Streets DG, Gupta S, Waldhoff ST, Wang MQ, Bond TC, Yiyun B. Black carbon emissions in China. Atmos Environ. 2001;35:4281–4296. [Google Scholar]

- 12.Zhang Y, Dou H, Chang B, Wei Z, Qiu W, Liu S, Liu W, Tao S. Emission of polycyclic aromatic hydrocarbons form indoor straw burning and emission inventory updating in China. Ann N Y Acad Sci. 2008;1140:218–227. doi: 10.1196/annals.1454.006. [DOI] [PubMed] [Google Scholar]

- 13.Zhang J, Smith KR, Ma Y, Ye S, Jiang F, Qi W, Liu P, Khalil MAK, Rasmussen RA, Thorneloe SA. Greenhouse gases and other airborne pollutants from household stoves in China: a database for emission factors. Atmos Environ. 2000;34:4537–4549. [Google Scholar]

- 14.Venkataraman C, Rao GUM. Emission factors of carbon monoxide and size-resolved aerosols from biofuel combustion. Environ Sci Technol. 2001;35:2100–2107. doi: 10.1021/es001603d. [DOI] [PubMed] [Google Scholar]

- 15.Li X, Duan L, Wang S, Duan J, Guo X, Yi H, Hu J, Li C, Hao J. Emission characteristics of particulate matter from rural household biofuel combustion in China. Energy Fuels. 2007;21:845–851. [Google Scholar]

- 16.Jetter JJ, Kariher P. Solid-fuel household cook stoves: characterization of performance and emission. Biomass Bioenerg. 2009;33:284–305. [Google Scholar]

- 17.Venkataraman C, Joshi P, Sethi V, Kohli S, Ravi MR. Aerosol and carbon monoxide emissions from low temperature combustion in a sawdust packed-bed stove. Aerosol Sci Technol. 2004;38:50–61. [Google Scholar]

- 18.Hays MD, Geron CC, Linna KJ, Smith ND. Speciation of gas-phase and fine particle emissions from burning of foliar fuels. Environ Sci Technol. 2002;36:2281–2295. doi: 10.1021/es0111683. [DOI] [PubMed] [Google Scholar]

- 19.Dhammapala R, Claiborn C, Corkill J, Gullett B. Particulate emissions from wheat and Kentucky bluegrass stubble burning in eastern Washington and northern Idaho. Atmos Environ. 2006;40:1007–1015. [Google Scholar]

- 20.McMeeking GR, Kreidenweis SM, Baker S, Carrico CM, Chow JC, Collett JL, Jr, Hao WM, Holden AS, Kirchstetter TW, Malm WC, Moosmüller H, Sullivan AP, Wold CE. Emission of trace gases and aerosols during the open combustion of biomass in the laboratory. J Geophys Res. 2009;114:D19210. doi: 10.1029/2009JD011836. [DOI] [Google Scholar]

- 21.Dhammapala R, Claiborn C, Simpson C, Jimenez J. Emission factor from wheat and Kentucky bluegrass stubble burning: comparison of field and simulated burn experiments. Atmos Environ. 2007;41:1512–1520. doi: 10.1021/es062039v. [DOI] [PubMed] [Google Scholar]

- 22.Li X, Wang S, Duan L, Hao J, Li C, Chen Y, Yang L. Particulate and trace gas emissions from open burning of wheat straw and corn stover in China. Environ Sci Technol. 2007;41:6052–6058. doi: 10.1021/es0705137. [DOI] [PubMed] [Google Scholar]

- 23.Jimenez JR, Claiborn CS, Dhammapala RS, Simpson CD. Methoxyphenols and levoglucosan ratios in PM2.5 from wheat and Kentucky bluegrass stubble burning in eastern Washington and northern Idaho. Environ Sci Technol. 2007;41:7824–7829. doi: 10.1021/es062039v. [DOI] [PubMed] [Google Scholar]

- 24.Roden CA, Bond TC, Conway S, Pinel ABO. Emission factors and real-time optical properties of particles emitted from traditional wood burning cookstoves. Environ Sci Technol. 2006;40:6750–6757. doi: 10.1021/es052080i. [DOI] [PubMed] [Google Scholar]

- 25.Li X, Wang S, Duan L, Hao J, Nie Y. Carbonaceous aerosol emissions from household biofuel combustion in China. Environ Sci Technol. 2009;43:6076–6081. doi: 10.1021/es803330j. [DOI] [PubMed] [Google Scholar]

- 26.Ministry of agriculture, P.R.C. China agriculture statistical report 2006. China agriculture press; 2007. [Google Scholar]

- 27.Zhuang Z, Li Y, Chen B, Guo J. Chinese kang as a domestic heating system in rural northern China- a review. Energy Build. 2009;41:111–119. [Google Scholar]

- 28.Zeng X, Ma Y, Ma L. Utilization of straw in biomass energy in China. Renew Sust Energ Rev. 2007;11:976–987. [Google Scholar]

- 29.Zhi G, Chen Y, Feng Y, Xiong S, Li J, Zhang G, Sheng G, Fu J. Emission characteristics of carbonaceous particles from various residential coal-stoves in China. Environ Sci Technol. 2008;42:3310–3315. doi: 10.1021/es702247q. [DOI] [PubMed] [Google Scholar]

- 30.Venkataraman C, Habib G, Eiguren-Fernandez A, Miguel AH, Friedlander SK. Residential biofuels in south Asia: carbonaceous aerosol emissions and climate impacts. Science. 2005;307:1454–1456. doi: 10.1126/science.1104359. [DOI] [PubMed] [Google Scholar]

- 31.Sahai S, Sharma C, Singh DP, Dixit CK, Singh N, Sharma P, Singh K, Bhatt S, Ghude S, Gupta V, Gupte RK, Tiwari MK, Garg SC, Mitra AP, Gupta PK. A study for development of emission factors for trace gases and carbonaceous particulate species from in situ burning of wheat straw in agricultural fields in india. Atmos Environ. 2007;41:9173–9186. [Google Scholar]

- 32.Ward DE, Susott RA, Kauffman JB, Babbitt RE, Cummings DL, Dias B, Holden BN, Kaufman YJ, Rasmussen RA, Setzer AW. Smoke and fire characteristics for cerrado and deforestation burns in Brazil: base-B experiment. J Geophys Res. 1992;97(D13):14601–14609. [Google Scholar]

- 33.Chomanee C, Tekasakul S, Tekasakul P, Furuuchi M, Otani Y. Effects of moisture content and burning period on concentration of smoke particles and particle-bound polycyclic aromatic hydrocarbons from rubber wood combustion. Aerosol Air Qual Res. 2009;9:404–411. [Google Scholar]

- 34.Purvis CR, Mccrillis RC, Kariher PH. Fine particulate matter (PM) and organic speciation of fireplace emissions. Environ Sci Technol. 2000;34:1653–1658. [Google Scholar]

- 35.Bignal KL, Langridge S, Zhou JL. Release of polycyclic aromatic hydrocarbons, carbon monoxide and particulate matter form biomass combustion in a wood-fired boiler under varying boiler conditions. Atmos Environ. 2008;42:8863–8871. [Google Scholar]

- 36.Simoneit BRT. Biomass burning-a review of organic tracers for smoke from incomplete combustion. Appl Geochem. 2002;17:129–162. [Google Scholar]

- 37.Hays MD, Smith ND, Kinsey J, Dong Y, Kariher P. Polycyclic aromatic hydrocarbon size distributions in aerosols from appliances of residential wood combustion as determined by direct thermal desorption-GC/MS. J Aerosol Sci. 2003;34:1061–1084. [Google Scholar]

- 38.Chang L, Feng Z, Xie K. Effect of coal properties on HCN and NH3 release during coal pyrolysis. Energy Sources Part A-Recovery Util Environ Eff. 2005;27:1399–1407. [Google Scholar]

- 39.McDonald JD, Zielinska B, Fujita EM, Sagebiel JC, Chow JC, Watson JG. Fine particle and gaseous emission rates from residential wood combustion. Environ Sci Technol. 2000;34:2080–2091. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.