Abstract

Microfluidic systems have shown unequivocal performance improvements over conventional bench-top assays across a range of performance metrics. For example, specific advances have been made in reagent consumption, throughput, integration of multiple assay steps, assay automation, and multiplexing capability. For heterogeneous systems, controlled immobilization of reactants is essential for reliable, sensitive detection of analytes. In most cases, protein immobilization densities are maximized, while native activity and conformation are maintained. Immobilization methods and chemistries vary significantly depending on immobilization surface, protein properties, and specific assay goals. In this review, we present trade-offs considerations for common immobilization surface materials. We overview immobilization methods and chemistries, and discuss studies exemplar of key approaches—here with a specific emphasis on immunoassays and enzymatic reactors. Recent “smart immobilization” methods including the use of light, electrochemical, thermal, and chemical stimuli to attach and detach proteins on demand with precise spatial control are highlighted. Spatially encoded protein immobilization using DNA hybridization for multiplexed assays and reversible protein immobilization surfaces for repeatable assay are introduced as immobilization methods. We also describe multifunctional surface coatings that can perform tasks that were, until recently, relegated to multiple functional coatings. We consider the microfluidics literature from 1997 to present and close with a perspective on future approaches to protein immobilization.

INTRODUCTION

Proteins are biomacromolecules that play essential roles in life processes spanning from metabolic process regulation, cellular information exchange, cell-cycle control, and molecular transport to protection from the environment.1 In biomedicine, for example, proteins are of great interest as disease biomarkers. In biotechnology, as another example, the role of enzymes as biocatalysts is a topic of much study. Owing to functional involvement in physiological processes, protein state (expression levels and modifications) may be effective indicators of a disease state and/or response to therapeutic treatment.2 Biomarker detection using immunoassays has been a widely used disease diagnostic tool.3 Promising protein biomarkers benefit from further characterization by immunoassays and similar analytical tools.4 Immunoassays exploiting specific recognition of protein biomarkers by cognate antibodies have been optimized for high analytical performance (e.g., rapid assays, label-free detection, improved limits of detection, and multiplexing capability). Enzymes are a specific class of proteins that catalyze biochemical reactions. Enzymes display selectivity, accelerate reactions, provide environmentally friendly means to organic synthesis, and effectively synthesize complicated biomolecules such as DNA and RNA.5 As enzymes are selective and effective proteinaceous biocatalysts that convert substrates into products, the enzyme is actively used across agricultural feeds, polymer synthesis, biofuels production, food processing, and the paper industry.6 Enzymes are also used widely in biosciences and biotechnology such as genetic engineering (e.g., oligonucleotide manipulation) and the pharmaceutical industry (e.g., production of pharmaceutical ingredients).6, 7 In addition, enzyme-mediated fluorescence or colorimetric detection of proteins, i.e., ELISA (Enzyme-Linked Immunosorbent Assay), is a standard immunoassay technique.

In analysis of proteins and enzymes, microfluidic design has proven to be a powerful technological tool to improve performance of immunoassays,8, 9, 10 enzymatic reactors,11, 12, 13 and other biological assays.14 Importantly, manipulation of liquid inside microscale fluidic networks enables reduced consumption of reagents, compared to macroscale instruments.8, 9, 10, 13, 14 Decreased liquid volume and short diffusion lengths allow facile reactions between analyte and antibody or enzyme and substrate, resulting in reduced assay times.8, 9, 11 Using design strategies pioneered by the semiconductor industry, microfluidic integration offers a “sample-in, answer-out” capability.9, 10, 12, 14, 15, 16, 17 Microfluidic technologies make possible monolithic integration of disjoint assay steps, further underpinning automation of those steps.15, 16, 17, 18, 19, 20, 21, 22, 23, 24 As discussed in depth in this review, the fine spatial control in immobilizing proteins and biomolecules inside microchannels allows multiplexed21, 22, 25 and multiparameter assays.26 The overall form factor of self-contained microfluidic devices (and automation) reduces human errors and risks of exposure to dangerous and toxic bio-/chemical reagents.

Analytical immunoassays in microfluidic formats are designed for rapid and sensitive detection of one or several targeted antigens in clinical diagnostics,27, 28, 29, 30, 31, 32, 33 as protein sensors,34, 35, 36, 37 or in environmental analysis.38, 39, 40, 41, 42 Laboratory-grade assays such as polyacrylamide gel electrophoresis (PAGE) based immunoassays,43, 44, 45 isoelectric focusing (IEF),21 and Western blotting18, 19, 20, 22, 24, 46 provide qualitative and/or quantitative information on multiple proteins, even in complex biological fluids. Questions spanning from protein-protein interactions,47, 48 and protein binding kinetics,49, 50 to post-translational modifications23, 51 have all been pursued using analytical technologies in microfluidic formats. Recent reviews by Hanares et al.,9 Bange et al.,10 and Ng et al.8 are recommended as excellent overviews of immunoassay advances. Microfluidic enzyme reactors find use in analysis and optimization of biocatalytic process. For more detailed information on microfluidic enzyme reactors, recent reviews by Křenková et al.,11 Asanomi et al.,12 and Miyazaki et al.13 are recommended. Here, before scaling up to a large-scale batch process, the throughput and appreciable assay sensitivity of a microfluidic format can expedite candidate-enzyme screening process from mutant libraries.52 Enzyme-kinetic study has been performed in microfluidic formats.53, 54, 55, 56, 57, 58 Important to proteomics, enzymatic digestion before MALDI-TOF/MS (Matrix-assisted laser desorption-ionization time-of-fly/mass spectrometry) peptide mapping of a protein has been explored in microfluidic devices.59, 60, 61, 62, 63, 64, 65, 66 Compared to conventional in-solution enzyme digestion, which is time consuming and offers limited sensitivity, microfluidic formats have shown high conversion rates, facile replacement of inactivated enzyme, and long-term stability.54, 55, 63, 67 Enzymatic production of fluorescent and colored products for protein analysis (e.g., alkaline phosphatase (ALP) production of chemiluminescence or colorimetric product) enhances detection limits of immunoassays.

Heterogeneous assay formats where one binding or reaction partner is immobilized to a surface are widely employed and are the focus of this review. Consequently, surface immobilization is a primary design and performance consideration.8, 9, 10, 11, 12, 13 In contrast to heterogeneous formats are homogeneous approaches, where reactants are reacted in solution. This review focuses on the former category of reactions. Two examples of heterogeneous assays that are popular in microfluidic formats are immunoassays8, 9, 10 and enzyme reactors.11, 12, 13 For microfluidic immunoassays, antigen or antibody is immobilized inside microchannels. Key immunoassay performance metrics include analytical sensitivity, analytical specificity, and reproducibility. The immunoassay performance depends on the quality of protein immobilization, and thus on the immobilization surface, immobilization chemistry, and surface passivation technique (i.e., antibiofouling).68 In microfluidic enzymatic reactors where enzyme is immobilized inside microchannels, the enzyme conversion rate, long-term stability, and reusability depend on similar immobilization factors.63 We will cover the design and operation of these two canonical heterogeneous formats—the immunoassay and enzyme reactors—as we detail design and operational considerations for protein immobilization in microfluidic systems.

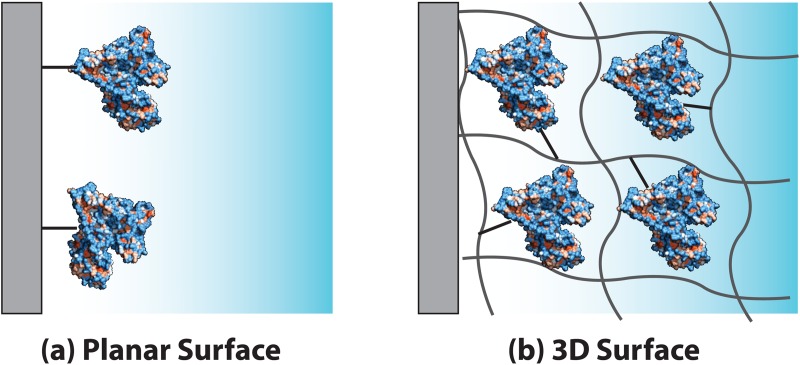

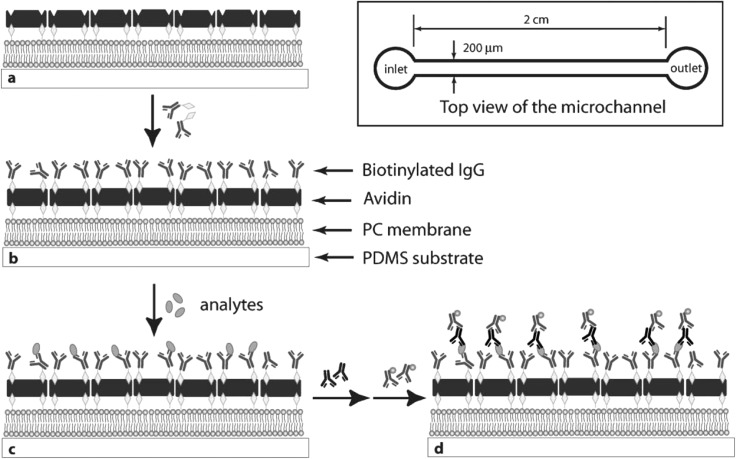

IMMOBILIZATION SURFACE

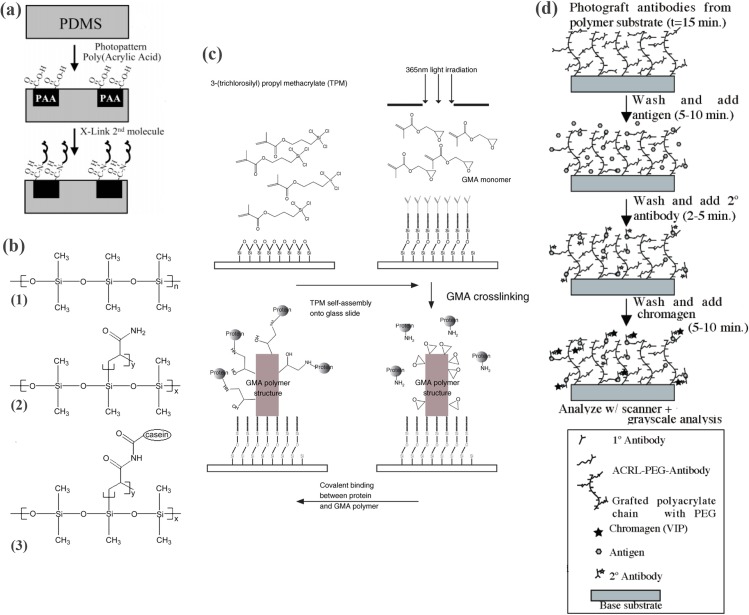

Immobilization methods vary largely with immobilization surface, protein properties, and the goals of the immunoassay or enzyme reactor. A major factor to consider is immobilization surface properties. One of the simplest surfaces on which protein is immobilized is the inner surface of microfluidic channels (Figure 1a). Traditional inorganic microfluidic device substrates are glass and silicon, which originated from the semiconductor industry and benefit from mature microfabrication techniques. For specialized detection methods such as surface plasmon resonance (SPR),8, 9, 49 Raman spectroscopy,69 and electrochemical analysis,35, 36, 70 protein is immobilized on metal films deposited on a glass or silicon surface. Silicon and glass share a similar surface chemistry, thus the route to immobilization is similar. Typically, the approach includes surface silanization followed by anchoring to a functional group of a silanizing agent. PDMS (polydimethylsiloxane), a silicon-based organic polymer, attained widespread use because of the low cost, rapid and prototype-friendly fabrication, as well as optical transparency, malleability, and gas permeability (appropriate for some applications).10, 71, 72, 73 Recently, plastic substrates such as PMMA [Poly(methyl methacrylate)], PS (polystyrene), and COC (cyclic olefin copolymer) have gained attention owing to low cost of fabrication (e.g., injection molding or hot embossing), a chemical resistance superior to PDMS, optical transparency, and low autofluorescence.74, 75, 76 PDMS and plastic surfaces are relatively inert and lack functional groups (i.e., sites for protein attachment). Thus, involved chemical surface preparation is generally required to induce surface functional groups for protein immobilization.9, 35, 77, 78, 79, 80 As immobilization on planar surfaces yields limited protein density, three dimensional (3-D) structures have been employed inside microfluidic channels for higher protein capture capacity,21, 22, 81 resulting in improved immunoassay sensitivity or enzyme conversion rates (Figure 1b). 3-D structures have been created by patterning microstructures (e.g., microposts29, 82, 83 and micropits60) or through insertion of porous membranes67, 84, 85 before assembly of microfluidic chips. In post-assembly approaches, microbeads54, 62, 86, 87, 88, 89, 90, 91, 92, 93 can be packed into enclosed channels or various polymers such as hydrogels,18, 19, 20, 21, 22, 23, 24, 57, 94, 95, 96, 97 sol-gels,64, 98, 99 polymer monoliths,61 or membranes100 can be polymerized in situ. For silica-based 3-D structures such as silica beads91 and alkoxysilane-based sol-gels,63 a similar glass/silicon surface immobilization strategy can be used. For polymer-based 3-D structures like agarose beads, hydrogels, and polymer monoliths, various immobilization methods including copolymerization of protein,18, 19, 20, 23, 94 graft polymerization,101 and oxidative activation of functional groups29, 54 can be used. Among these 3-D structures, hydrogels such as polyacrylamide gel and polyethylene glycol (PEG) gel provide hydrophilic environments conducive to good protein stability and retained protein activity.102 Paper has recently gained momentum as a 3-D substrate material for POC (point-of-care) diagnostics for low-resource settings owing to low cost, simple assay visualization, and simple reagent immobilization.103, 104, 105 In this section, we provide more detail on the most popular immobilization surfaces.

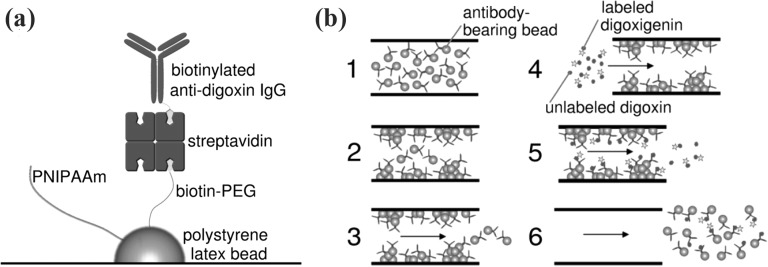

Figure 1.

Role of surface geometry in binding site density. Schematic drawing of (a) planar and (b) high surface-area-to-volume ratio three-dimensional immobilization surfaces.

Planar microchannel surface

In a large body of literature, protein is immobilized on microchannel surfaces made from silicon, glass, PDMS, plastic, or metal film deposited on channel surfaces. A protein monolayer can be formed on the surface after immobilization. The planar channel surface is a natural choice because of simplicity, a surface-to-volume ratio of microchannel surface larger than macroscopic counterparts, and the fact that fluids contact the surface. Random surface immobilization relying on multiple anchoring points can cause a protein to be denatured and lose native activity.106, 107 Also, active sites can orient towards the immobilization surface, resulting in reduced activity.106 Even though the diffusion length within microfluidic channel is short and thus the overall reaction can be faster than macroscopic counterparts, a single monolayer of protein may not provide sufficiently high analytical signal in immunoassays or a sufficiently high conversion rate in enzyme reactors. An ideal immobilization surface should have a large surface-area-to-volume ratio, a protein-friendly environment, minimal nonspecific protein adsorption, mechanical and chemical stability, and a reactive moiety for protein coupling.11

Silicon

Silicon is a most widely used and well-characterized substrate originating from integrated circuit development in the semiconductor industry. Silicon was adapted as a mechanical material with the advent of microelectromechanical systems (MEMS)108 and, subsequently, employed in the first microfluidic analytical system.109 Owing to high-resolution microfabrication technique development (feature size as low as 22 nm are attainable with mass fabrication110), fine fluidic channels and microfluidic components can be created on a silicon substrate. Naturally or artificially grown oxide on the silicon surface makes silanol-based chemistries compatible with for protein immobilization on silicon.40, 111, 112 While powerful, silicon has, however, three major drawbacks for microfluidic design: (1) opaqueness of silicon in the visible spectrum renders various optical imaging techniques irrelevant; (2) incompatibility of silicon with electrokinetic methods owing to the electrical conductivity of the silicon substrate, and (3) expense associated with the sophisticated microfabrication techniques used to micromachine silicon in a cleanroom environment. Therefore, silicon is not as widely used as initially with the exceptions of continued widespread application in electrochemical analysis113 and SPR.65

Glass

Besides silicon, glass (e.g., fused silica, soda lime, borosilicate glass), and quartz are another widely used substrate for microfluidic devices.114 Glass substrates were initially used in microfluidic electrophoresis systems, building on the earlier successes of glass capillaries as a format of choice among the electrophoresis community.115 Glass is transparent across a wide spectrum, with negligible autofluorescence.74 Therefore, glass is well-suited for fluorescence-based microfluidic assay readouts. Glass is robust, being resistant to solvents and acids and bases.10 Several commercially successful microfluidic devices use glass substrates.116 However, glass is not without disadvantages. Glass can fracture, so it must be handled with a care. Glass microfabrication can be costly, since much of the process requires a cleanroom facility. Microfabrication processes similar to those used for silicon result in patterned microchannels but acid wet etching of glass does not yield high-aspect-ratio anisotropic microchannels unlike silicon (e.g., deep reactive-ion etching process). Glass substrates benefit from immobilization chemistries including various silanol chemistries for covalent linking of proteins.117

PDMS

PDMS is currently one of the most frequently used and studied substrates in microfluidics, owing to a rapid design-fabricate-test cycle and low cost. PDMS is a rubber-like flexible polymer (i.e., elastomer) and is transparent making optical imaging possible. In contrast to rigid substrates such as silicon and glass, microfluidic actuators such as valves and pumps can be readily formed in a microdevice.118 Owing to rapid casting-based soft lithography processing, fabrication of microfluidic networks in PDMS is inexpensive, requiring low investment in infrastructure. Overall, PDMS is an excellent material for rapid prototyping of research device. After treating with oxygen plasma, PDMS can be irreversibly sealed with glass, plastic substrates, or PDMS slabs to form enclosed microchannels. Multiple layers of PDMS can be stacked yielding multifunctional microfluidic devices.118 This fabrication process stands in stark contrast to complex and time-consuming silicon or glass bonding processes.89, 93 Nevertheless, no material is well suited to every application. Drawbacks of PDMS are as follows: limited resistance to organic solvents, gas permeability, compliant characteristics and thus often inappropriate for harsh environments needing robust packaging.10 As related to protein immobilization, PDMS is hydrophobic in native form, so proteins tend to readily and nonspecifically bind to the surface. Therefore, blocking of the adsorptive surface must be done before an assay is completed. PDMS lacks functional groups for covalent derivatization. Silanol groups can be introduced after oxygen plasma treatment but these groups do not offer long-term stability.119 Therefore, immobilization methods are generally complex and require multiple steps to implement.97, 120 Because a large numbers of microfluidic devices are made by sealing microchannel-patterned PDMS slabs to glass slides, consideration of glass and PDMS surface properties is often required (e.g., care to avoid nonspecific adsorption to PDMS surfaces when protein is immobilized on glass surface).

Plastic

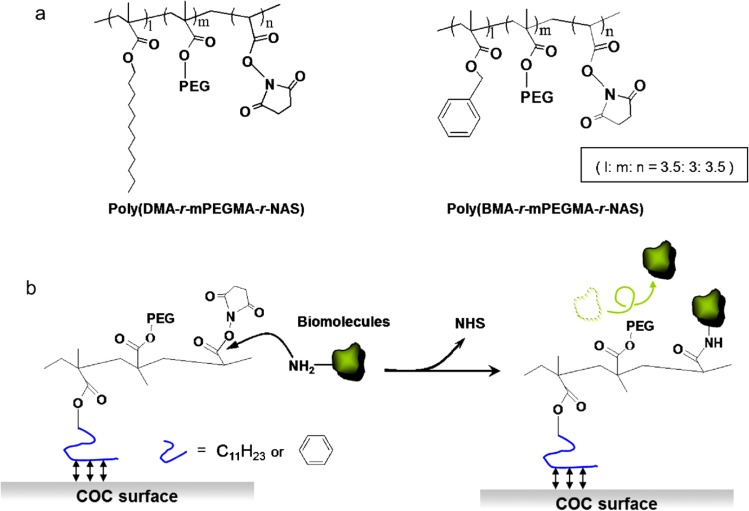

With a relevance to mass fabrication, cost effective, robust, and reliable substrates for microfluidics are of great interest. Microfluidic chips fabricated from plastics such as PMMA, PS, and COC are extremely cheap to mass produce when using mold-based techniques such as injection molding or hot embossing.76 Moreover, plastic is generally resistant to solvents and acids/bases, rigid but not fragile, common in the marketplace, and optically transparent.74, 75, 76 Owing to these attributes, numerous groups have investigated plastic as a material of a choice for commercial microfluidic devices.121, 122 Indeed, a few commercial microfluidic devices are made of plastic.123 Plastics share the disadvantages of PDMS, being hydrophobic in native form making hydrophobic nonspecific protein adsorption a concern. Inert plastic surfaces lack functional groups, so chemistry is employed to prepare the surface to immobilize proteins.29, 80, 124 Oxygen plasma77, 79 or strong bases/oxidizers35, 77, 78 are often used to introduce functional groups.

Metal

Metals films are sometimes deposited on silicon or glass surface. Protein is immobilized on the metal surface for detection methods other than fluorescence or colorimetric detection. Several assay readout modes are appropriate, including electrochemical sensing,35, 36, 69 Raman spectroscopy,69 and SPR.8, 9, 49 Thiol-based chemistry, although not as strong as covalent linkages, is available for protein immobilization on noble metal surfaces including gold, silver, and platinum.125

Three-dimensional materials in microchannels

In contrast to planar immobilization surfaces, three-dimensional (3-D) surfaces are often advantageous. Common formats include micro/nanostructures created using microposts, microbeads, hydrogels, sol-gels, polymer monoliths, and membranes. Fabrication approaches for these 3-D structures vary greatly, depending on the material choice and properties needed. The design rationale underpinning exploration and selection of 3-D structures stems from the increased surface-area-to-volume ratio offered (as compared to a planar surface). The increased effective surface area found in the 3-D material offers a larger number of immobilization sites, as compared to channel wall (2-D) systems.21, 22, 81 Back-of-the-envelope estimates suggest that three-dimensional gel structures provide about 100 ∼ 1000 fold increase in binding sites, as compared to immobilization sites on capillary or microchannel walls alone.21 Importantly, the diffusion length between reaction partners (e.g., antibody and antigen, or enzyme and substrate) is reduced when the immobilized partner is in a 3-D material, as opposed to patterned on a microchannel or even nanochannel wall. Therefore, high analytical sensitivity or fast conversion rates can be realized when 3-D materials are utilized in reacting systems and transport conditions are optimized.63, 70 For immobilization of proteins, structures with nanoscale features (e.g., sol-gels and nanoporous hydrogels) can physically encapsulate protein without chemically activating surfaces.64, 98 Packed bead beds can be dynamically introduced and eluted from the microchannel for quick surface regeneration.70 Clearly, 3-D structures need to be transparent for optical detection methods. For more information, the readers is referred to an excellent review on 3-D solid supports for microfluidic systems from Peterson.85

Packed bead beds

Monodisperse beads comprised of a wide-range of bead materials (i.e., PS,31, 86 silica,91 agarose,54, 126 ferromagnetic materials30, 62, 88) are a workhorse of conventional macroscale analytical chemistry, including chromatography85 and enzyme reactors.126 Bead packing inside microchannels has been accomplished using size-exclusion structures including microposts, dam, and weirs. High-sensitivity immunoassays are possible with the packed beads.93 As mentioned, the diffusion length from the solution phase to the bead surface is short in a packed bed, so enzyme conversion rates are also high.63 Magnetic beads are attractive, as these reactive 3-D surfaces can be immobilized by applying a magnetic field from outside of the microchannel (using a magnet). Regeneration after assay completion is facile, with beads flushed out of the channel after removing the magnetic field and applying a bulk flow (i.e., pressure driven).70 Protein immobilization strategies are diverse and vary with the bead material. For example, silanol chemistry can be exploited for glass or silica beads. More involved immobilization protocols are required for polymer beads such as polystyrene127 and agarose beads128 to induce functional groups on the polymeric surfaces.

Hydrogel

Hydrogels have been actively used in tissue engineering129 and protein microarray81 owing to the hydrophilic, protein-friendly microenvironment offered. Hydrogels are flexible materials with a well-ordered fibrous structure. Synthetic PEGDA (PEG diacrylate) gel57, 83 and polyacrylamide gel18, 19, 20, 21, 22, 23, 24, 94, 95, 96 are popular with natural gels like chitosan130 or agarose gel also used. Porogen is sometimes employed to further increase the surface area by inclusion of macropores.82, 83 Hydrogel is usually transparent so that sensitive fluorescence imaging is appropriate. Polyacrylamide gel can also act as a biomolecular sieve without significant nonspecific adsorption, so protein can be separated based on charge and/or size (e.g., SDS-PAGE or sodium-dodecyl-sulfate polyacrylamide gel electrophoresis) before a detection step.22, 23, 24, 131, 132 With suitable surface modification, gel regions offering different assay functions can be integrated on a single chip using fabrication via photopatterning.18, 19, 20, 23, 24, 46, 94 The swelling property of hydrogels allows integration of actuators such as valves, allowing integration of sophisticated fluid handling functions.133 A wide range of immobilization methods are available to hydrogels, including copolymerization of proteins,18, 19, 23, 94, 132 activation for covalent linking of proteins,134 or electrostatic capture on charged hydrogel.20, 24 Even with a 3-D microchannel-filling hydrogel, the microchannel surface should be functionalized for covalent anchoring of the hydrogel structure within the channel, so that the gel will not drift out of the channel under hydrodynamic pressure or applied electric field.46, 82, 83 Hydrogels provide a hydrated environment for proteins so that native activity or functionality can often be maintained.102 A disadvantage of hydrogels is the fragility of some gel structures (i.e., application of shear forces or high electric fields can damage the structure135). Once formed, a stationary hydrogel is difficult to remove from the channel if regeneration of the assay system is needed.46

Sol-gel

Sol-gels are a condensation polymerization of colloids in aqueous media. After preparation of the “sol” (i.e., metal alkoxide monomer in acid and organic/aqueous solvent), the “gel” is formed by polymerization during evaporation of the solvent. By simply adding proteins to the “sol” before gelation, proteins are encapsulated in optical transparent 3-D nanostructure. Silica sol-gels made from silicon alkoxide colloids98 are the most common, but titania64 or zeolite99 colloids are also used. Immobilization of proteins proceeds under mild conditions,64 thus proteins can retain near-native activity.

Porous polymer monolith

Rigid polymer monoliths are a porous polymer frit formed inside microfluidic chips (or capillaries) using polymerization of monomers such as ethylene dimethacrylate, acrylamide, or 2-hydroxyethyl methacrylate in the presence of porogens, such as dodecanol, decanol, and cyclohenxanol.61, 85 Whereas packed beads require an immobilizing structure like a weir or micropost array, polymer monoliths can be photopolymerized at any location in the channel without said retaining structures.61 Owing to pores throughout the monolith, a large surface area is available for protein immobilization, and a low back pressure allows pressure driven flow for fluidic control.61 A disadvantage of polymer monoliths lies in the difficulty of reproducible operation owing to batch-to-batch variability.85

Membrane

Membranes are porous (planar) sheets that can provide a large surface area for protein immobilization. Commercial membrane comprised of polycarbonate (PC), nitrocellulose (NC), and PVDF (polyvinylidene fluoride) have been inserted and physically clamped between a microfluidic chip patterned with channels and a blank cover chip.67, 84, 85 However, resolving fluid leakage issues from the clamped membrane can be challenging.84 Membranes can also be formed in situ by condensation100 or electrospinning.33, 136 Membranes have been extensively used in biochemistry or analytical chemistry to adsorb proteins. Such protein immobilization strategies rely on intermolecular forces137 (i.e., hydrophobic, electrostatic, and van der Waals) and simple adsorption without complicated chemical activation of the solid supports. Membranes also have additional useful properties such as ion selectivity and selected transport of small molecules such as enzyme substrate (i.e., size exclusion)100 and ions.

Paper

Paper, a cellulose membrane, offers a versatile, low-cost material for immobilization.103, 104, 105 Originated from disposable lateral-flow immunoassays, paper microfluidic devices have the potential to be more cost-effective than plastics or PDMS.138 Fluid and material transport in and through paper can be accomplished passively (without power consumption) using capillary action.103, 138 Even though paper is macroscopically planar, the material has microscopic 3-D pores. Immobilization strategies on paper are rather simple. Much like NC membrane, paper adsorbs proteins via a combination of intermolecular forces making simple reagent spotting effective for protein immobilization. Paper is optically opaque, so that sensitive detection using fluorescence imaging could be difficult. Therefore, the limit of detection is rather poor compared to immunoassays based on transparent substrates.138

Porous silicon

Porous silicon is produced by anodic electrochemical or photochemical etching of silicon in hydrofluoric acid (HF).139 Nanopores in porous silicon are usually straight (unidirectional), and perpendicular to the silicon surface. Porous silicon offers the advantage that that porosity and pore size are exquisitely controllable. Owing to sensitive refractive index change, porous silicon offers exceptional performance an optical biosensor.139 Proteins can be immobilized on the porous silicon using covalent chemistries similar to those used for planar silicon substrates.40, 60, 68

IMMOBILIZATION STRATEGY

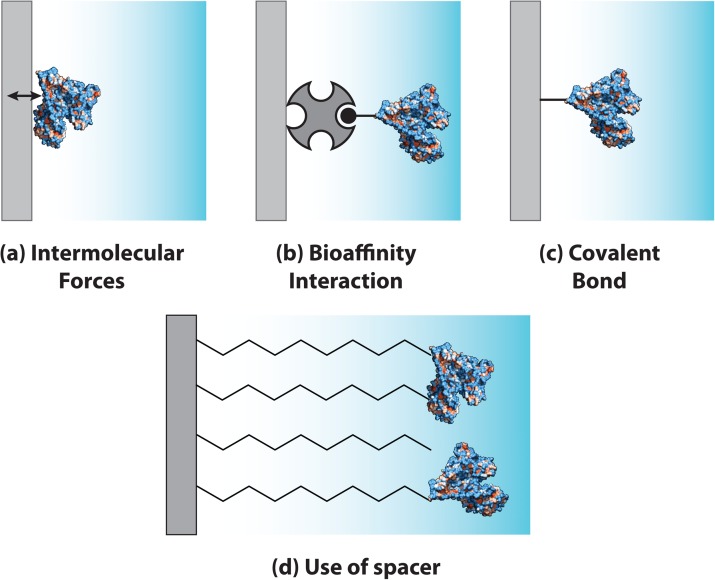

A wide variety of immobilization methods are employed to attach proteins to the immobilization surface. A specific immobilization method relies on a variety of factors including immobilization surface, sample matrix, protein property, buffer constituents, and assay performance metrics (e.g., sensitivity, reusability, selectivity, and reproducibility). Ideally, active sites for antibody binding or enzymatic conversion should be accessible to reaction partners (i.e., proteins face away from the immobilization surface to mitigate steric hindrance and are not sterically blocked by neighboring immobilized proteins). After immobilization, protein conformation should be intact so that protein functions are retained for a high-performance, reproducible assay.106 An excellent review on immobilization strategies for protein microarrays is provided by Rusmini et al.106 Useful information on enzyme immobilization inside microfluidic chips can be found in reviews by Křenková and Foret,11 Asanomi et al.,12 Miyazaki and Maeda.13 For protein immobilization in microfluidic immunoassays, readers are directed to reviews by Bange et al.,10 Ng et al.,8 and Křenková and Foret.11 Molecular mechanism of protein immobilization methods can be categorized into physisorption, bioaffinity interaction, covalent bond (Figures 2a, 2b, 2c), and combinations of the three mechanisms. The following sections detail specific aspects of the most widely used immobilization methods.

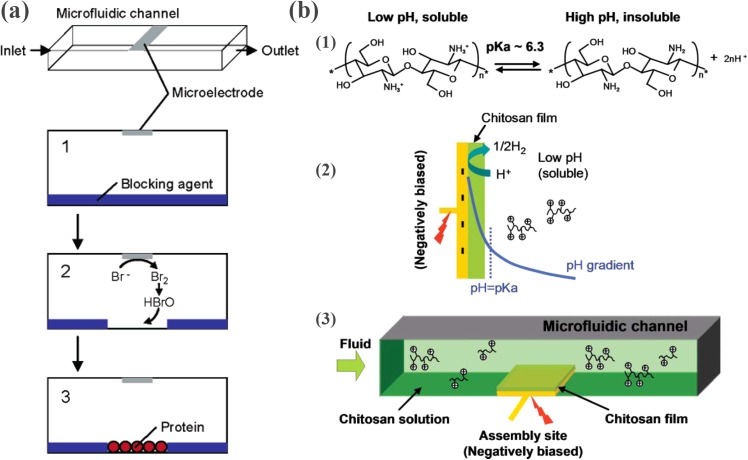

Figure 2.

Common surface immobilization methods for heterogeneous assays. Schematic of immobilization mechanisms: (a) physisorption, (b) bioaffinity interaction, and (c) covalent bond. The surface immobilization methods are often used in conjunction with (d) spacer for improved protein activity.

Physisorption

The simplest approach to immobilizing a protein on a surface is physisorption (i.e., physical adsorption). Protein can be conveniently adsorbed to various surfaces via intermolecular forces such as electrostatic, hydrophobic, van der Waals, hydrogen bonding interactions, or combination of those (Figure 2a).140 Incubation of protein in solution contacting the immobilization surface or continuous flow of solution will achieve attachment of protein without complicated chemistry or reagents. Physisorption is generally weak, and thus an adsorbed layer of proteins is not as stable as one formed by covalent or bioaffinity binding. The intermolecular forces are highly dependent on environmental condition such as pH, ionic strength, temperature, and surface condition.107 Therefore, immobilization of proteins—in a reproducible manner—can be difficult using physisorption. As protein immobilization is randomly oriented on the surface, some fraction of the binding sites within a population of immobilized proteins are likely not accessible.106 Further, protein can be immobilized to the surface via multiple binding sites, which may result in conformational change and reduction of protein activity.106, 107 Immobilization density depends on protein size, as well as physicochemical surface properties. If the immobilization density is too high, active sites could be sterically blocked.106 Therefore, the use of a spacer (e.g., PEG) with a surface-attaching head group and a protein-binding tail group has been widely adopted to reduce steric hindrance (Figure 2d).40 Blocking of uncoated surface should be performed after protein immobilization (e.g., BSA or bovine serum albumin) in order to minimize nonspecific adsorption of off-target biomolecules. Even given the low degree of control, many studies have employed physisorption of protein to a microfluidic-device surface. Popularity of the approach stems from several advantages including simple assay procedure, no toxic reagents and no sophisticated chemical protocols.125 For plastic and PDMS, proteins are often adsorbed onto the bare surface owing to the hydrophobic nature of these substrates. In such systems, intermediate molecules are frequently used in order to attach to surface by covalent linkage on one end and provide hydrophobic or charged functional group on the other end for protein physisorption. Surfaces are modified to have stronger charge or hydrophobicity to adsorb protein better than the native surface, with reports of such physisorption as practically irreversible.92 In some cases, physisorption happens instantaneously (i.e., high kon) compared to covalent or bioaffinity bonds that usually requires a substantial incubation time, and thus physisorption can be used as an intermediate immobilization step of a multistep assay sequence (e.g., Western blot).20, 24 Physisorption has a wider choice of buffer system, compared to widely used covalent bonding through primary amines where popular amine-based buffers (e.g., Tris, glycine) cannot be used.20

Electrostatic interaction

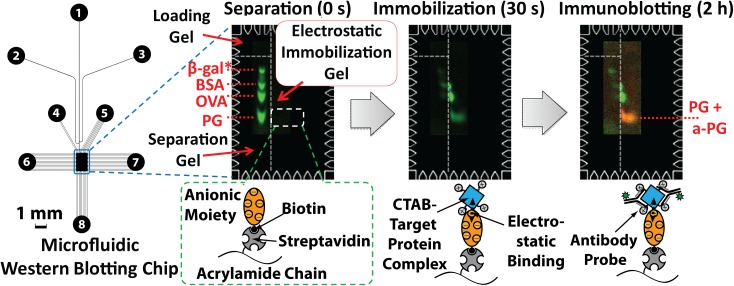

Electrostatic or ionic interaction is fundamental to biomolecular attraction (e.g., protein-protein interaction141 and DNA hybridization142). Thus, electrostatic interactions are exploited frequently in biochemical assays, for example, cell adherence to positively charged poly-L-lysine (PLL)-treated PS surfaces143 or protein blot to positively charge nylon membrane.144 Typical positively charged functional groups encountered in biochemistry are protonated amine (NH3+) and quaternary ammonium cations (NR4+). Negatively charged functional groups are carboxylic acid (—COO−) and sulfonic acid (—RSO3−). These functional groups are involved in the electrostatic interaction between protein and a surface. Complete isolation of contributions from other intermolecular forces may be difficult or impossible. However, electrostatic interactions can be studied by measuring the binding isotherm while changing the buffer ionic strength.141, 145 Electrostatic interactions find application in the protein immobilization in microfluidic assays. Protein friendly, gel-like hydrophilic environment have been created by electrostatic layering of polyelectrolytes such as PEI [poly(ethylene amine)], PDADMAC [poly(diallyldimethylammonium chloride)], PAA [poly(acrylic acid)], PAH [poly(allylamine hydrochloride)], and PSS [poly(styrene sulfonate)] on protein-unfriendly hydrophobic polymeric (e.g., PDMS, PMMA, and PS) surfaces35, 77, 78, 79, 124 or silicon surfaces.35, 40, 59, 68, 77, 79, 124 Proteins are immobilized on the composite layer directly by electrostatic interaction,146 covalent chemistry,40, 68 or bioaffinity interaction.35, 40, 68, 77, 79, 124 Electrostatic interaction has also been used to pack microbeads (with bead-surface immobilized proteins) into beds in microfluidic channels.92 Protein has also been directly immobilized inside hydrogels via electrostatic interaction. Kim et al. created negatively charge polyacrylamide (PA) gels to immobilize proteins after separation by electrophoresis to yield microfluidic Western blotting (Figure 3).20 Because of a high surface charge (−120 e) in electrophoresis buffer (pH 8.3), the enzyme β-gal (β-galactosidase) was copolymerized in PA gel to introduce a negative charge to the gel. CTAB (cetyltrimethylammonium bromide, cationic detergent) treated proteins were first separated in photopolymerized PA gel via electrophoresis then transferred to and instantaneously immobilized on the β-gal-conjugated PA gel. Immobilization was owing to strong electrostatic interaction between the positively charged protein-CTAB complex and the negatively charged PA gel. After the BSA blocking step, the immobilized target protein was detected by an antibody. In that study, the charge interaction was strong enough for immobilized antigens to sustain electrophoretic wash, blocking, and antibody introduction via electrophoresis. The role of electrostatic interaction was studied by the systematic changing of ionic strength and the associated characterizing of binding strength of the interaction.147, 148 As a follow up to this research, the same research group created a positively charged PA gel by copolymerizing PLL, thus allowing electrostatic immobilization of negatively charged SDS-treated proteins.24 Therefore, electrostatic protein immobilization after protein separation was used as a basis for automated microfluidic format SDS Western blotting.

Figure 3.

Charged PA gel allows electrostatic immobilization of CTAB-coated proteins in a microfluidic Western blotting. Negatively charged PA gel immobilizes separated proteins, followed by fluorescent detection (immunoblotting). Reprinted with permission from D. Kim et al., Anal. Chem. 84, 2533 (2012). Copyright 2012 American Chemical Society.

Hydrophobic interaction

As some designers of novel microfluidic devices aim for disposable point-of-care diagnostics applications, immobilization of biomolecules on polymeric hydrophobic materials has gained attention. COC, PMMA, and PS—transparent, hydrophobic thermoplastics—have gained attention recently for the POC application.121, 122 Bhattacharyya and Klapperich introduced a hot-embossed COC microfluidic chip for an immunoassay of CRP (C-reactive protein).28 Human CRP was introduced in the microfluidic channel and physisorbed by hydrophobic interaction, followed by BSA blocking, and chemiluminescence detection by horse radish peroxidase (HRP) conjugated antibody.

Tsougeni et al. recently presented an approach to increase protein adsorption on hydrophobic PMMA surfaces.149 Using directional O2 plasma etch and mask-based lithography, the researchers not only patterned microchannels but also roughened the channel surface. The roughened PMMA surface yielded stronger adsorption of protein (biotinylated BSA or IgG) compared to a smooth, hot-embossed PMMA surface (i.e., 120× poorer detection limit). Sia et al. reported a microfluidic device consisting of a PS lid mated to a PDMS substrate patterned with microchannels.150 HIV Env antigen (gp41) was adsorbed to the PS surface to assay antibodies in HIV-infected sera, with catalytic silver deposition using gold nanoparticle conjugated secondary antibodies. Xiang et al. designed an “H”-channel glass-covered PDMS chip.34 An Escherichia coli antigen was physisorbed to a PDMS surface and then later detected by primary and secondary antibodies. The authors used electrokinetic fluidic control.

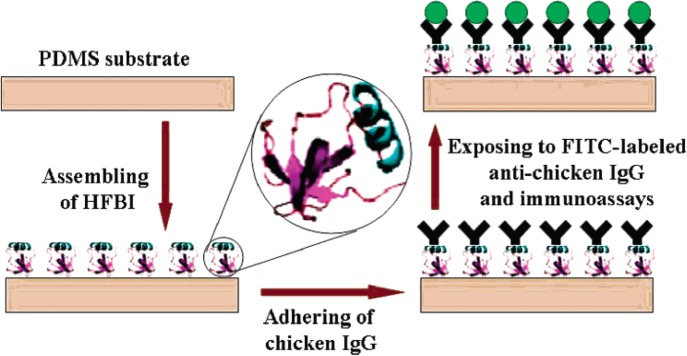

Kitamori's group published work on proteins absorbed to PS microbeads in a bead-based immunoassay.89, 93 Three glass substrates were patterned with channels using a CO2 laser and fast atom beam. Then, all the layers were thermally bonded to form a glass microfluidic device. Using a dam structure, analyte-adsorbed beads were pseudo-immobilized. Then, gold nanoparticle functionalized detection antibody was introduced for TLM (thermal lens microscopy). In a first study, secretory IgA was immobilized then analyzed by detection antibody.93 In a subsequent study, anti IFN-γ (interferon-r) capture antibody was immobilized, and IFN-γ was captured. Then biotinylated detection antibody was introduced, followed by injection of streptavidin conjugated with gold nanoparticle for improved detection limit.89 Feng's group published on a novel proteinaceous monolayer for antibody immobilization on a PDMS surface (Figure 4).151, 152 The authors used a copper TEM grid (i.e., stencil) to pattern hydrophobin, allowing conversion of the hydrophobic surface to a hydrophilic surface. Hydrophobin is a cysteine-rich small protein (∼100 amino acids) extracted from filamentous fungi. Hydrophobins can form self-assembled monolayer on hydrophilic-hydrophobic interface (e.g., air-water interface) owing to amphiphilic nature. Hydrophobic patches faced towards the PDMS while hydrophilic patches faced away. Chicken IgG was physisorbed via polar interaction to the hydrophobin SAM (self-assembled monolayer) creating a heterogeneous immunoassay format. Jo et al. reported a mass spectrometric (MS) imaging (spatially resolved MS information of attached polypeptides) modality using a PDMS microfluidic device.65 An Aplysia bag cell was attached to a PLL coated silicon surface through electrostatic interaction. Released neuropeptides were delivered through a PDMS microfluidic channel and physisorbed to another silicon surface rendered hydrophobic using octadecyltrichlorosilane (OTS) treatment. The peptides bradykinin, angiotensin II, substance P, renin substrate, and egg laying hormone were imaged by MALDI-TOF/MS.

Figure 4.

Immobilization process of chicken IgG on hydrophobin coated PDMS surface and immunoassay. Reprinted with permission from R. Wang et al., Chem. Mater. 19, 3227 (2007). Copyright 2007 American Chemical Society.

As described earlier, the simplicity of physisorption makes it a preferred method for immobilizing proteins in early, proof-of-concept experiments—a prototyping immobilization strategy. The Whitesides' group created a 3-D microfluidic stamp in PDMS as the basis for their technique called “3-D micromolding in capillaries (MIMIC),” which overcame limitations of conventional soft lithography.153 The micro contact printing can pattern complex protein patterns but requires multiple inking and stamping steps to have discrete pattern of multiple protein species.154 2-D MIMIC technique can deposit a discrete pattern of multiple protein species at a single “stamping,” but the pattern has to be continuous because the technique uses microfluidic channels that does not cross over.155 On the contrary, the 3-D MIMIC can put a discrete pattern of multiple proteins in a single stamping.153 BSA and fibrinogen were physisorbed to a PS substrate, and a complex protein pattern was created (Figure 5a). Following up on early work on “microfluidic networks (μFN),”156 Delamarche created a simple protein-microarray-like multiplexed immunoassay.157 The immunoassay was enabled by reversible sealing of silicon μFN to a PDMS slab, with simple physisorption of proteins resulting in a striped pattern on the PDMS. After patterning, the cover (housing a series of trenches) was rotated 90° and another reversible sealing of the μFN on the PDMS slab created enclosed microchannels for introduction of detection antibody and a multiplexed immunoassay was completed (Figure 5b). In later work, capillary action on wetting tissue was used to generate flow, and the silicon μFN was hydrophilized by gold-layer deposition, followed by PEG coating (HS-PEG) to reduce background signal resulting from nonspecific protein binding.27 CRP and cardiac markers (i.e., myoglobin and cardiac troponin I) were physisorbed on a PDMS slab and detected using the same sandwich immunoassay format. Nevertheless, preventing leakage of reagents through neighboring channels (i.e., cross-talk) has been a challenge for such reversible sealing. Finally, instead of a PDMS slab, Delamarche and colleagues used a gold-coated silicon μFN treated with HS-PEG for protein patterning (Figure 5c).158 The top surface of the μFN was coated with hexadecanethiol (HDT) to prevent nonspecific protein adsorption. Then, using deformable PDMS stamps, protein was microcontact-printed on the bottom surface, allowing subsequent antibody based detection. The authors observed that the HS-PEG coating promoted protein transfer from the PDMS stamp, as well as reduced nonspecific protein binding from solution. Stability of the transferred protein pattern on the hydrophilic HS-PEG surface could be an issue.

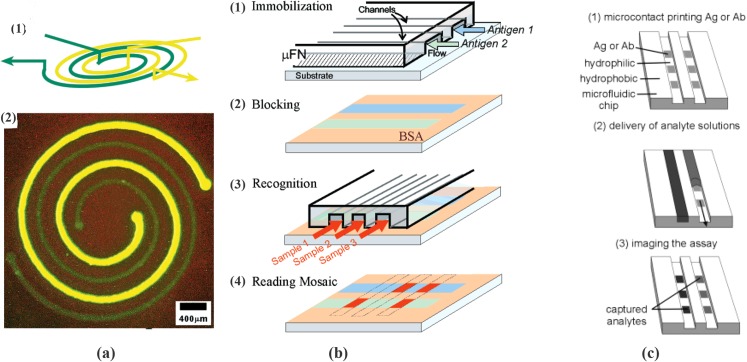

Figure 5.

Novel protein patterning methods using simple physisorption: (a) nested spirals of BSA (bright green) and fibrinogen (light green) on a PS surface using 3-D MIMIC technique. Reprinted with permission from D. T. Chiu et al., Proc. Natl. Acad. Sci. U.S.A. 97, 2408 (2000). Copyright 2000 National Academy of Science of USA. (b) Multiplexed immunoassay using μFN and reversible PDMS-to-PDMS sealing. Reprinted with permission from A. Bernard et al., Anal. Chem. 73, 8 (2001). Copyright 2001 American Chemical Society. (c) Protocol for an immunoassay in which the protein capture sites are patterned using microcontact printing and μFN. Reprinted with permission from J. Foley et al., Langmuir 21, 11296 (2005). Copyright 2005 American Chemical Society.

Unspecified combinations of intermolecular forces

Commercial NC and PVDF membranes are popular polymeric supports in molecular biology, being frequently used in Western blotting and dot blotting. These membranes now find use in microfluidic assays. While the exact immobilization mechanisms are not clear, protein immobilization on NC membranes is attributed primarily to hydrophobic interactions, hydrogen bonding, and electrostatic forces.137 For PVDF membranes, hydrophobic interaction is considered to play a major role.159 Gao et al. created an on-line protein digestion module in a PDMS microfluidic device.67 In this study, a commercial PVDF membrane (0.45 μm pore size) was clamped between two patterned PDMS substrates. Bovine pancreatic trypsin was adsorbed on a PVDF membrane by on-line injection. Denatured horse heart cytochrome C and ribonuclease A were passed through the trypsin-immobilized PVDF membrane, and then digested peptide was analyzed by ESI-MS (electrospray-ionization mass spectrometry). The authors observed that the microscopic surface area of the microporous PVDF membrane available for protein adsorption is 200 times larger than the macroscopic surface area of the membrane. Compared to solution-based trypsin digestion, the membrane reactor was 500–1000 times faster. The authors also reported that trypsin was active for more than 2 weeks. Lu et al. used wax-patterned NC membrane for their paper microfluidic device instead of pure cellulose (i.e., paper) owing to a higher binding capacity and more uniform binding patterns.160 Using a printer, a hydrophobic wax pattern was created on the NC membrane to confine antibody spots. Sandwich immunoassays using catalytic silver precipitation were demonstrated in the wax-patterned device.

Alternatively, porous membranes are fabricated in situ. These membranes benefit from tailored porosity and morphology, as well as localization in specific regions of a microfluidic channel. An NC membrane was created in situ on the glass surface by Park et al.66 After silanizing the glass surface with OTS to form a hydrophobic SAM, an NC membrane (dissolved in organic solvent) was spot-dried on the glass surface. Then, the glass was bonded to a patterned PDMS chip. The enzyme β-gal was physisorbed inside the membrane. The enzyme substrate di-β-D-galactopyranoside (FDG) was hydrolyzed to a fluorescent product and analyzed by electrophoresis. Jiang's group used an electrospinning (ES) technique to create a highly fibrous membrane as a protein-adsorption substrate in the PDMS microfluidic devices.33, 136 First, the researchers created a nanofibrous membrane using electrospinning of PC, and sandwiched the membrane between a glass substrate and a patterned PDMS chip.33 Then, HIV Env protein was physisorbed and detected by a primary antibody and a fluorescein isothiocyanate (FITC) conjugated secondary antibody. Compared with a track-etched polycarbonate (TEPC) membrane having a uniform pore size, the nanofiber membrane showed higher binding capacity. Similarly, a PVDF nanofibrous membrane was created for a similar PDMS-glass slide device.136 After adsorbing antibodies in the PVDF membrane, a multiplexed immunoassay was performed. The study reported that the protein adsorption capacity of the PVDF membrane was 8 times larger than that of TEPC membrane owing to an increased surface area.

Recently, paper (e.g., cellulose membrane) has drawn attention in the microfluidics community103, 104, 105, 138 owing to low chip material and manufacturing costs. Intermolecular forces including electrostatic and hydrophobic interactions are involved in protein adsorption to paper.161 Tan et al. reported a paper-PDMS glucose sensor.36 Enzyme GOx (glucose oxidase) was adsorbed to Whatman filter paper, then a glucose solution was flowed through a PDMS microfluidic channel to be converted into hydrogen peroxidase, which was later detected electrochemically. The stability of GOx observed in paper was excellent showing a 2.7% RSD (relative standard deviation) in repeatability and a one-month shelf life.

Physical encapsulation and entrapment

Alternately, a protein immobilization strategy that relies on physically encapsulating proteins in nanoporous structures has been employed. Compared to polymer monoliths or membranes having pore sizes on the order of a few hundred to thousands nanometers,84, 162 various nanoporous structures afford pore sizes of less than a few tens of nanometers.163 Owing to the small pore sizes, protein can be effectively encapsulated. A trade-off is seen in assays where an interaction with large binding partner (e.g., antibody or enzyme) could be hindered by slow diffusion through the nanoporous structure to the immobilized protein. Hydrogel has been used for protein encapsulation by using high monomer content and a suitable crosslinker to achieve small pore sizes.57, 95 Sol-gels are another popular material that can generate nanoporous structures. Some of the benefits of using sol-gels are the excellent enzymatic activity owing to high encapsulation concentration, mild immobilization conditions,64 and optical transparency for imaging.98 Common sol-gels are silica based, made by polycondensation of alkoxysilane monomers. Sakai-Kato et al. reported a PMMA microfluidic enzyme reactor based on silica sol-gel encapsulation of trypsin.98 The sol-gel was prepared with tetramethoxysilane (TMOS) in water and HCl. TMOS was hydrolyzed to form SiOH4−n(OMe)n. After addition of trypsin, a trypsin-entrapped sol-gel was formed inside the PMMA chip. On-chip digestion was characterized with electrophoresis of digested amino acids (ArgOEt, arginine ethyl ester) and proteins (bradykinin and casein). The immobilized trypsin was active for two days, whereas in-solution trypsin lost activity within a day. The enzyme reactor was stored for one week without loss in activity.

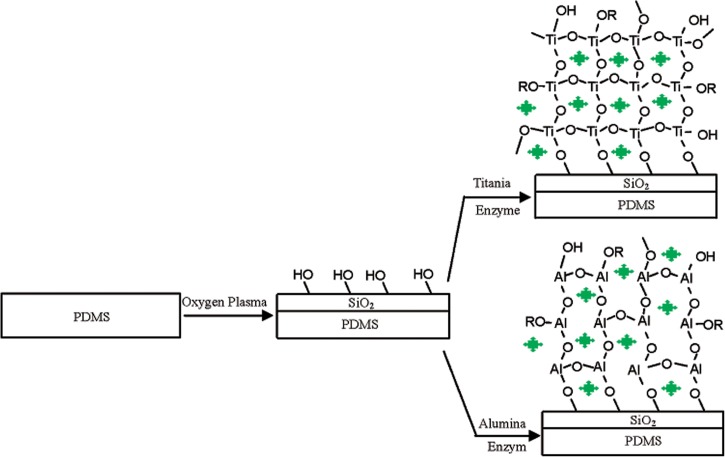

Common silica-based sol-gels are, however, fragile, experience pore shrinkage as well as pore collapse, and sometimes offer poor adhesion to the substrate.64 Consequently, new sol-gel materials have been explored. Wu et al. created titania and alumina sol-gels on a sandwiched PDMS microfluidic device (Figure 6).64 First, PDMS was treated with oxygen-plasma to generate silanol group. Then, titania sol and alumina sol were prepared by heating tetrabutyl titanate and aluminum isopropoxide in solvent. After adding trypsin to the sol, the PDMS microfluidic channel was filled with the sol. The silanol groups on the plasma-treated PDMS surface covalently anchored the hydroxyl group of the sol by condensation, such that a stable sol-gel formed on the PDMS surface with trypsin encapsulated within the sol-gel. BSA was digested, and peptides were analyzed by MS. A faster digestion time and longer enzyme lifetime were observed, as compared to those of a homogeneous (solution phase) reaction. Baohong Liu's group employed a similar strategy for enzyme encapsulation using nanozeolite.99 The Liu group's microfluidic device was fabricated using thermally laminated poly(ethylene terephthalate) (PET) sheets patterned via photoablation. Then, PSS polyelectrolyte was adsorbed to the PET surface yielding a negative surface charge. A layer-by-layer assembly technique59 was subsequently employed to build three layers of electrostatically combined polyelectrolyte PDADMAC (positively charged) and nanozeolite colloid crystal (negatively charged, 80 nm diameter). Finally, trypsin was adsorbed to the assembled nanozeolites in order to digest BSA and protein extract from mouse macrophage. After digestion, peptides were analyzed by MALDI-TOF MS. The zeolite encapsulated trypsin showed more stability and faster digestion compared to free-solution trypsin.

Figure 6.

Process of enzyme-encapsulated sol-gel inside microchannel of PDMS functionalized by oxidation in an oxygen plasma. Reprinted with permission from H. Wu et al., J. Proteome Res. 3, 1201 (2004). Copyright 2004 American Chemical Society.

Bioaffinity immobilization

The bioaffinity interaction or biospecific adsorption (Figure 2b) exploits specific binding phenomena existing in nature. The bioaffinity interaction has advantages over physisorption. A bioaffinity interaction yields relatively stronger, highly specific, and oriented protein immobilization.11, 106, 107 Therefore, protein leakage can be minimized and immobilized protein offers better accessibility to binding partners than random orientation strategies. Additionally, bioaffinity immobilization can be reversed using chemical treatment, pH change, or heat treatment.68, 77 In most of cases, bioaffinity interactions are used in conjunction with other immobilization mechanisms (i.e., physisorption and covalent bonding) with the bioaffinity reagent used as an intermediate binding molecule between the surface and proteins. Avidin-biotin, protein A/G-antibody, genetically engineered protein affinity ligands, DNA hybridization, and aptamers have been employed in microfluidic devices.

Avidin-biotin

One of the most widely employed immobilization partners is avidin (66–69 kDa tetrameric glycoprotein) and biotin (water-soluble vitamin B). Avidin binds to biotin via an exceptionally strong non-covalent interaction.164 The binding interaction is rapid and nearly insensitive to pH, temperature, proteolysis, and denaturing agents.106 Biotin is a small molecule and conjugation to proteins does not significantly affect protein functionality or conformation. One downside of using the avidin-biotin system is the high cost of the proteinaceous binding reagent. NHS (N-hydroxysuccinimide) ester is a popular commercial biotinylation reagent, which allows covalent linking of protein amine groups with biotin. Natural avidin or engineered avidin (e.g., streptavidin, neutravidin, and nitrividin) can be physisorbed or covalently linked to a surface for subsequent immobilization of biotinylated proteins. Sometimes, avidin is attached to surfaces functionalized with biotin, leaving available unoccupied biotin binding sites on the avidin for immobilization of two biotinylated proteins.38

Owing to the popularity of the avidin-biotin immobilization strategy, streptavidin coated PS, agarose, and glass beads are commercially available. These beads are used extensively in microfluidic assays. Typically, proteins are incubated with streptavidin-functionalized microbeads, then pseudo-immobilized in a microfluidic device using size-exclusion structures, such as dams, weirs, and microposts. Seong and Crooks packed enzyme functionalized PS beads on a PDMS microfluidic device with a weir structure.86 Biotinylated GOx and HRP were immobilized on the streptavidin-coated PS beads. The system was used to study the mixing efficiency of enzymatic substrate in a bead-packed microfluidic channel. Wang and Han adapted a nanofluidic pre-concentrator to concentration of the fluorescent proteins GFP (green fluorescent protein) and R-PE (R-phycoerythrin). A bead-based immunoassay was employed to detect the concentrated proteins.87 Biotinylated GFP and R-PE antibodies were attached to commercial streptavidin-coated PS beads. The bead was then pseudo-immobilized by a microfluidic weir. An impressive 50 pM to sub 100 fM detection limit was observed.

Protein A/G—antibody

Protein A and protein G are both popular antibody (IgG) immobilizing reagents, extracted from bacteria. Protein G is known to have a wider immunoreactivity to mammalian IgGs than protein A. Protein A or G specifically binds to the constant Fc region of IgG. Thus, the variable Fab region of IgG is accessible to antigen binding.11 A key consideration is the orientation of protein G or A, so that bound IgGs are away from the immobilization surface and accessible to antigen binding. Like the avidin-biotin system, a spacer that links proteins to the planar surface is frequently used in conjunction with protein A/G.106 An additional benefit of using protein A/G is that antibody can be detached by acid treatment and the surface made reusable.68

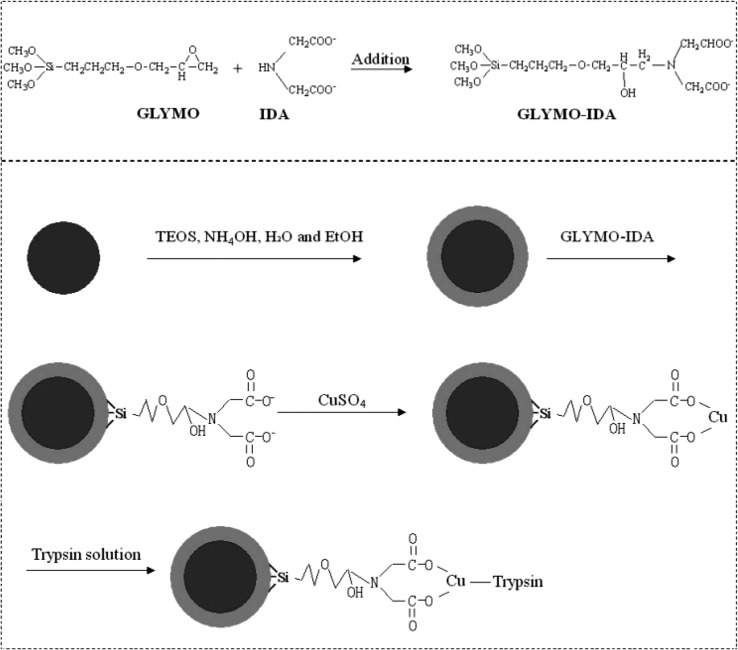

Affinity capture ligand

The C- or N-terminus of proteins can be genetically engineered to have an oligohistidine (His) segment that specifically chelates with metal ions (e.g., Ni2+).165 Ni2+ is then bound to another chelating agent such as NTA (nitriloacetic acid), which is typically covalently bound to an immobilization surface. Although the affinity of His tagged-NTA is much weaker than that of the streptavidin-biotin linkage, advantages include: (1) ready reversal of immobilization by adding completing chelating reagents such as EDTA (ethylenediaminetetraacetic acid), and (2) the controlled orientation of immobilized proteins is possible, as the His tag is on the C- or N-terminus of each protein. In a similar sense, GST (glutathione S-transferase) is tagged onto the N-terminus of proteins by genetic engineering. GST-fused target proteins are strongly attached to glutathione (GSH) functionalized surfaces,107 for example, GSH-coated agarose beads. By adding a high concentration of GST, GST-fused proteins can be released. Disadvantages of the GST tagging approach are: (1) cost and time associated with producing recombinant proteins and (2) irrelevance to endogenous proteins.

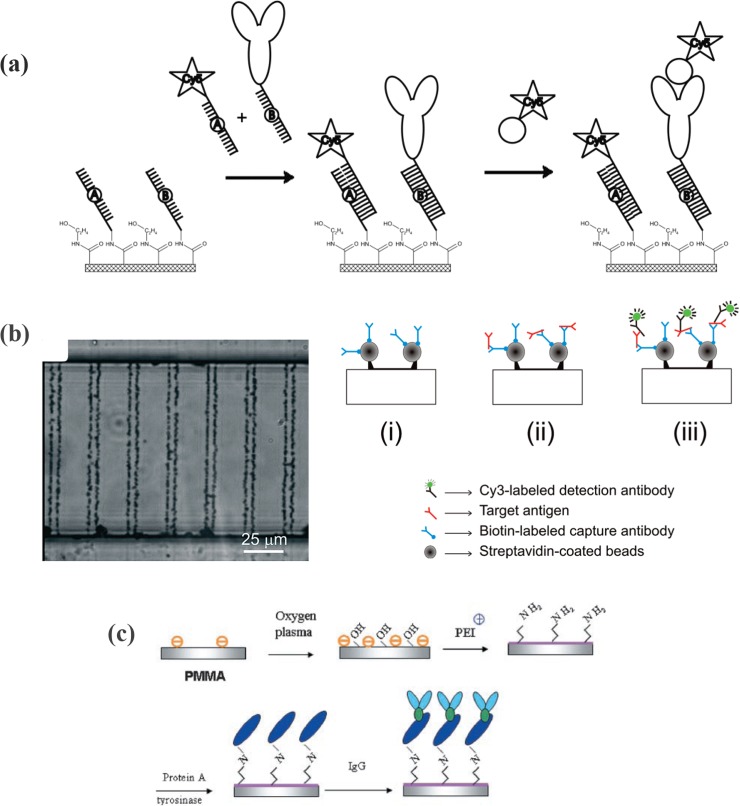

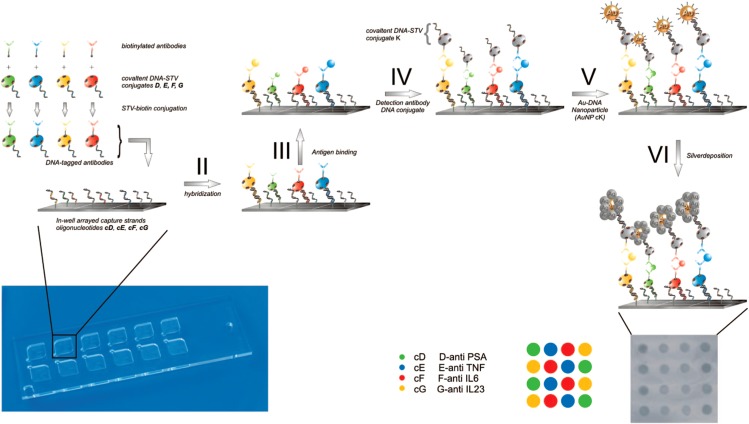

DNA hybridization

Specific hybridization of single-strand DNA (ssDNA) with the complementary DNA (cDNA) has been employed to immobilize proteins as well (i.e., DNA-directed protein immobilization).25, 26, 77 Oligonucleotide hybridization is exceptionally stable and selective.106 Protein is first coupled to ssDNA and then ssDNA that is linked to the protein is hybridized to the surface where complementary ssDNA are immobilized. An ssDNA tag may be attached to the protein via covalent linkage or a biotin-streptavidin linkage.106 The spatially encoded “DNA-directed” protein immobilization is originated from microarray technology.166, 167 Immobilization of multiple antibodies and multiplexed microfluidic immunoassays can be performed using the DNA-encoded immobilization method.25, 26 Additional advantages are (1) hybridized DNA acts as a spacer arm, and (2) immobilization is reversible by temperature control or alkaline denaturation.77

Antibody

Regardless of the high cost, variable affinity, and short shelf life, an antibody is a ubiquitous biomolecule for immobilizing proteins. The wide-spread use of antibodies arises from the exceptional specificity toward binding partner (i.e., immunoadsorption). Sandwich immunoassays in which immobilized antibody captures a target antigen are a workhorse bioanalytical assay.168 Microbeads coated with antibody having immunoreactivity toward an IgG of a specific animal species are commercially available. Shin et al. created a microfluidic SPE (solid phase extraction) device for improved immunoassay sensitivity.31 In this study, PS beads coated with goat anti-mouse IgG were incubated with mouse anti-CRP IgG. Then the beads were pseudo-immobilized onto a frit structure of a hybrid glass substrate–PDMS device. Immobilized CRP was eluted by an acidic 0.1 M glycine buffer (pH 1.8) treatment and the fluorescence signal was detected by a photodiode integrated in the microfluidic device. Competitive immunoassays were demonstrated.

Aptamers

Aptamers are oligonucleotide bioaffinity capture reagents that have drawn significant attention. Aptamers that show the highest affinity toward a target protein are selected from a synthetic, combinational nucleotide library called SELEX (systematic evolution of ligands by exponential enrichment).169 Aptamers are smaller than antibodies, thus a higher density of capture agents can be coated on surfaces to yield a large binding capacity for target proteins. Compared to antibodies, in particular polyclonal antibodies, aptamers are produced in vitro—eliminating the need for animals in production.170, 171 In addition, aptamers are touted to have a longer shelf life and less sensitivity to environmental change. For a detailed review of aptamers in microfluidics, readers are directed to the paper by Xu et al.170 and Mosing and Bowser.171 For aptamers for protein immobilization, readers are directed to the review by Nakanishi et al.107

Yang et al. used aptamer-functionalized magnetic beads in a multilayer PDMS microfluidic device to complete a CRP immunoassay.30 A CRP-specific aptamer sequence was screened using SELEX, followed by biotin conjugation. Aptamers were attached to commercial streptavidin-coated magnetic beads. After high-sensitivity, CRP (hs-CRP) was captured by aptamers, an acridinium-ester conjugated CRP antibody was introduced for chemiluminescence detection. Tennico et al. used a similar bead system (streptavidin-coated magnetic beads and biotinylated aptamer) to detect thrombin in a sandwich immunoassay format.90 They showed that aptamers have negligible affinity toward prothrombin and HSA, which are proteins similar to thrombin. The simple microfluidic device consisted of PMMA (or PC) top and bottom layers, which sandwiched an intermediate double-adhesive tape layer housing the microfluidic channel. Two aptamers having affinity toward different epitopes of thrombin were employed as detection and capture probes in the sandwich immunoassay, whereas antibody is commonly used as the detection probe in aptamer-based immunoassays.30

Covalent bond

Covalent bonds are a frequently used immobilization mechanism in microfluidic assays (Figure 2c).11 The immobilization surface is activated via reactive reagents. The activated surface reacts with amino acid residues on the protein exterior and forms an irreversible linkage. One tends to rely on covalent immobilization if high, stable protein coverage is required. Bifunctional spacer molecules are a common approach to forming an irreversible bond between proteins and the immobilization surface. In such an approach, one end of a spacer molecule is covalently linked to an activated surface, and then a protein is covalently linked to the other end of the spacer. Alternatively, another spacer or protein capture agent (e.g., streptavidin) is crosslinked on the other end. Unreacted active functional groups are blocked or deactivated (e.g., BSA,106 hydroxylamine,83 ethanolamine,172 or lysin40). Disadvantages of covalent linkage include reduced activity of proteins (by forming linkage on active sites),106 toxic reagents,125 and complicated chemistry.125 A covalent bond can be formed on active sites of proteins, resulting in reduced activity.11 The covalent attachment reaction is that the reaction is usually slow, so that the protein and surface require long incubation times of hours up to a full day (e.g., epoxide61). Therefore, covalent linking is usually performed as a preparatory step before performing microfluidic assays. An enormous variety of covalent conjugation chemistries are available. In this review, only a small subset of conjugation chemistries employed especially in microfluidic devices is introduced. For more information beyond the present scope, refer to a review by Feijen et al.106 and the excellent reference by Hermansson.125

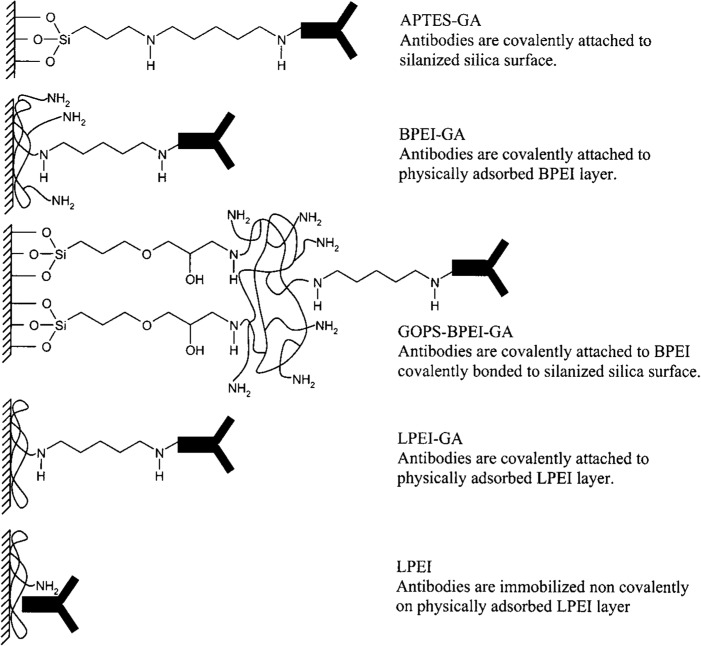

Amine—glutaraldehyde—amine

Amino groups (-NH2) of lysine are the most common covalent binding sites because lysine residues are usually present on the exterior of proteins. Aldehyde is a reactive compound that forms the labile Schiff base with the amine and can be further reduced to form a stable secondary amine bond using NaCNBH3 or NaBH4. Glutaraldehyde (GA) is a bis-aldehyde compound that has two reactive ends. GA can crosslink two amine functional groups, for example, between two proteins or between a protein and a surface-immobilized polymer with amine groups (e.g., PEI). The Schiff bases formed on proteins are stable without further reduction by NaCNBH3 or NaBH4;125 and indeed, a large number of protein immobilization strategies that rely on GA in microfluidic devices are completed without further reduction. When used with a glass or a silicon surface, aminosilane compounds like APTES [(3-aminopropyl)triethoxysilane] are used because they can bind to hydroxyl functional groups of glass at one end and possess an amine functional group to facilitate covalent linkage with proteins on the other end.117 GA had been extensively used to form stable protein microarrays on glass substrates.173 Regnier et al. used APTES to coat wet-etched glass microfluidic channels with aminosilane.174 Then, GA was electroosmotically injected for 2 h and the enzyme β-gal was covalently immobilized on the glass channel walls. Porous-silicon micropits were treated with APTES and GA for trypsin immobilization by Marko-Varga's group.60 The Schiff base was further reduced by NaCNBH3 for stable bonding. Digested proteins were analyzed by MALDI-TOF/MS. Wang et al. used a similar approach in immobilizing proteins and antibodies in a device consisting of a silicon substrate and a PDMS microfluidic array.111 Ellipsometry was used for label-free microarray immunoassays. Richter et al.91 used the same chemistry to immobilize enzymes xanthine oxidase (XOD) and HRP on porous silica beads. After trapping the silica beads behind a weir structure, they successfully detected hydrogen peroxide in a glass microfluidic device.

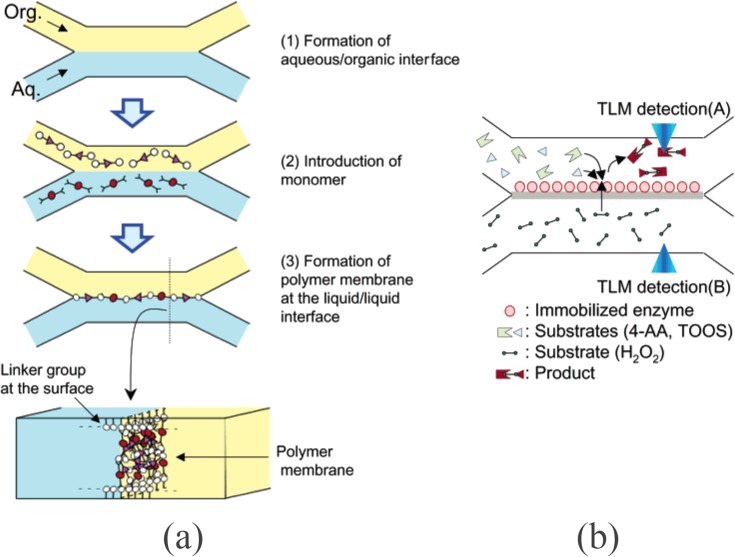

As described earlier, proteins are usually physisorbed to polymer membranes (e.g., NC, PS, and PVDF) clamped in a microfluidic device. Kitamori's group immobilized enzymes onto an in situ fabricated nylon membrane using covalent bonding (Figure 7).100 First, a glass microfluidic channel was treated with APTES and then a vertical nylon membrane was fabricated by interfacial polycondensation. Co-injecting immiscible laminar flows of adipoyl chloride in 1,2-dichloroethane and hexamethylenediamine (HMD) in 0.1 M NaOH created 10-μm thick nylon membrane. Amino groups on the membrane were activated by GA, followed by immobilization of HRP and further reduction of the Schiff base using NaBH4. The activity of HRP was tested by introducing substrate on one side and hydrogen peroxide on the other side of the membrane. Hydrogen peroxide diffused through the membrane and HRP generated a colored product.

Figure 7.

In situ polymerized nylon membrane for an enzyme assay. (a) In situ polymerization of nylon membrane using organic/aqueous two-phase flow in an X-shaped microfluidic chip, and (b) TLM (thermal-lens microscopy) was used to detect product and substrate. Reprinted with permission from H. Hisamoto et al., Anal. Chem. 75, 350 (2003). Copyright 2003 American Chemical Society.

Yu et al. used an intermediate PVA [poly(vinyl alcohol)] layer to minimize nonspecific protein adsorption to PDMS.175 The researchers silanized an oxygen-plasma-treated PDMS surface with APTES. In order to form the hydrophilic layer, the amine group on APTES was activated with GA to attach PVA (via hydroxyl group of PVA176) to PDMS. Then, GA was used once more to covalently link proteins such as IgM, BSA, and IgG to the PVA layer. A sandwich immunoassay was demonstrated. Compared to the native PDMS surface, the SNR (signal-to-noise ratio) was improved owing to low nonspecific adsorption and high antibody binding capacity. Thomsen et al. took an alternative approach to functionalizing a PDMS surface lacking functional groups. These authors applied pyrogenic silicic acid (i.e., silicon oxide powder prepared in oxyhydrogen flame) to PDMS, so that the PDMS surface exhibited hydroxyl groups.52 Using the added hydroxyl group and APTES, then activating with GA, the enzyme CelB (β-glycosidase) was immobilized to hydrolyze lactose to glucose and galactose.

Another aminosilane coupling reagent, 3-aminopropyl)trimethoxysilane (APTMS),120 is also popular because of better reactivity than APTES. Glass et al.117 provide a review of various organosilanes and deposition techniques of the organosilanes. A spacer of APTES or APTMS may be too short to properly immobilize large proteins (such as antibodies and enzymes) to planar channel surfaces in high capacity owing to steric hindrance. The scheme may also cause reduced activity owing to partial physisorption to channel surface.40 Therefore, a hydrophilic polymer matrix such as dextran (DEX),29, 68 chitosan,130 and PEG40, 120 are often used as longer spacers for improved assay sensitivity.

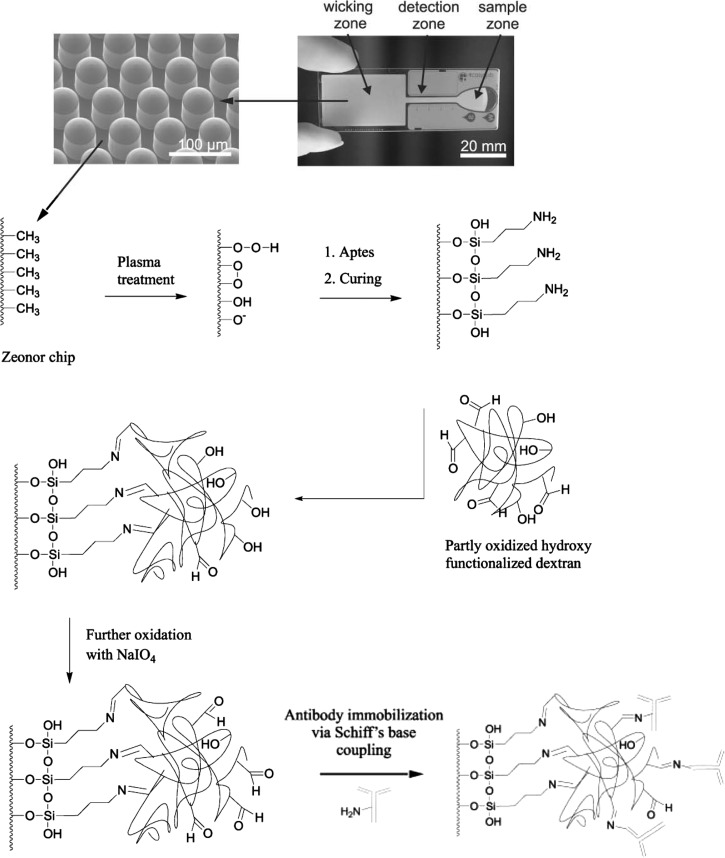

Amine—in situ generated aldehyde

Instead of adding GA, nucleophilic aldehyde groups can be generated in situ. While paper microfluidics is generally considered a low cost approach for diagnostic devices without external fluid handling systems (e.g., lateral-flow immunoassay), Jönsson et al. fabricated such a zero-powered device using a COC substrate (Figure 8).29 Their COC microfluidic chip has a capillary-action wicking zone consisting of a micropillar array. After oxygen-plasma treatment, the chip surface was amine-functionalized with APTES. They attached dextran (40 kDa), partly oxidized to have aldehyde groups, and the aldehyde groups formed the Schiff bases with the amine groups of the APTES. After dextran immobilization, dextran was further oxidized by NaIO4 adding more aldehyde groups for capture-antibody immobilization. A sandwich immunoassay of CRP was demonstrated with an improved detection limit (two orders of magnitude), as compared to a paper-based immunoassay. The authors reasoned that dextran improved assay performance by providing a hydrophilic surface for better capillary action, a hydrogel-like protein-friendly environment, and an enlarged surface area for a high antibody binding capacity. Baeza et al. took an in situ aldehyde generation approach in order to immobilize enzyme in LTCC (low temperature cofired ceramics) microfluidic device.54 A commercial agarose bead was activated to have a glyoxal functional group (agarose-O-CH2-CHO) by etherification with 2,3-epoxypropanol and oxidation with NaIO4.128 The aldehyde functional end of glyoxal agarose was used to immobilize β-gal after the Schiff-base reduction with NaBH4. The beads were pseudo-immobilized using microcolumns in a reaction chamber. The enzyme activity was measured colorimetrically with enzyme stability observed for 6 months.

Figure 8.

Zero-powered COC immunoassay chip with patterned micropillars for covalent antibody attachment. The COC surface is oxidized in oxygen plasma and silanized with APTES. The resultant amino terminated surface is subsequently functionalized with a dextran matrix. Finally, antibody is immobilized via Schiff's base coupling to the dextran matrix. Adapted from C. Jönsson et al., Lab Chip 8, 1191 (2008) with permission from The Royal Society of Chemistry.

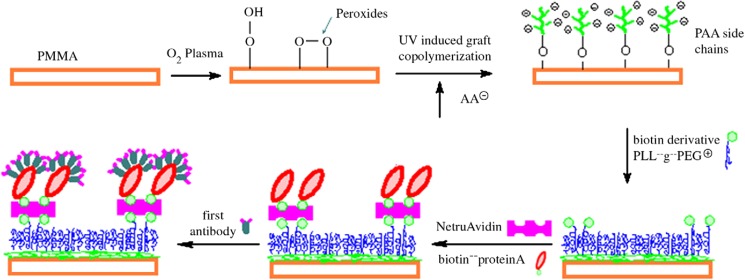

Amine—NHS (N-hydroxysuccinimide)

Probably, the most commonly used covalent linking agent is NHS ester.106 NHS ester reacts with amines on proteins and yield stable amide bonds while releasing NHS leaving groups.125 Sulfo-NHS (N-hydroxysulfosuccinimide) is preferred over NHS because sulfo-NHS is more water soluble while showing the same reactivity and specificity as NHS. Delamarche et al. provided an early report of protein immobilization in microfluidic device156 by introducing a PDMS microfluidic network (μFN) comprised of PDMS irreversibly bound to glass or silicon. The surface of the glass or silicon wafer was coated with aminosilane. Amine functional groups of the aminosilane were activated by the NHS ester for antibody immobilization. Palecek's group used PEG hydrogel micropillars copolymerized with an acryloyl-functionalized NHS ester for microfluidic kinase activity assays and immunoassays.82, 83 The microfluidic-chip fabrication process is rather interesting in that the authors fabricated a microfluidic channel using in situ polymerization of the monomer isobornyl acrylate (IBA) in an empty chamber made of a bottom glass slide, a polycarbonate top, and an intermediate adhesive rim, whereas typical microfluidic chip fabrication is done by etching bulk material.133 After the glass slide was silanized with (3-acryloxypropyl)-trimethoxysilane to provide an acryloyl group, macroporous PEG pillars were photopolymerized using PEGDA monomer. PEG porogens of various molecular masses were used to form macropores. A macroporous structure is favorable over a nanoporous gel for incorporating large proteins such as antibodies and kinase. The 6-((acryloyl)amino)hexanoic acid NHS ester was copolymerized in the hydrogel pillars for covalent immobilization of proteins such as GST-fused GFP and GST-fused CrkL (Crk-like) protein. GST antibody and kinase activity assays (phosphorylation) of K562 cell lysate were demonstrated.83 Characterization of diffusion of 250 kDa dextran and GST-GFP showed improved mass transport through the gel as compared to nanoporous PA or PEGDA hydrogels.82

Carboxylate—1-ethyl-3-(3-dimethylamonipropyl) carbodiimide (EDC)—amine

Carbodiimide is used to form amide linkage between carboxylates and amines. EDC is the most frequently used carbodiimide.125 Advantages of EDC include water solubility; EDC can be directly used with proteins in aqueous buffer unlike NHS, which is dissolved in organic solvent (e.g., DMSO). EDC reacts with carboxylic acid to form an o-acrylisourea intermediate, which subsequently reacts with primary amines to form amide bonds.119 Reaction of o-acrylisourea with amines is slow and can be hydrolyzed in aqueous solution. Thus, EDC is usually used with NHS.

Carboxylate—EDC + NHS—amine

NHS esters can be formed on-demand using carbodiimide (e.g., EDC), NHS, and carboxylates to immobilize proteins.177 Didar et al. created multiplexed protein microarrays in a microfluidic device consisting of a glass substrate and PDMS microchannels after microcontact printing of APTES spots.177 NHS and EDC were used to covalently link proteins to the amine group of APTES. Carboxylate groups of antibodies were linked to the end of APTES after releasing the NHS leaving group. Antibodies for CD34, CD31, and CD36 proteins were immobilized on the patterned APTES spots and multiplexed sandwich immunoassays were demonstrated. Hu et al. used EDC and NHS chemistries to immobilize detection antibody to aqueous quantum dots (aqQD) for microfluidic sandwich immunoassays.178 Usually, high quantum-yield QDs are synthesized in an organic phase, which requires post treatment for water solubility. In contrast, the CdTe core/CdS shell QD was prepared in an aqueous phase.179 The QD was covered with 3-mercaptopropionic acid (MPA) in order to yield a carboxylic-acid functionalized surface. The carboxylic group was later activated with the NHS ester, and then covalently linked to the amine groups of antibodies. Capture antibody was covalently attached to commercial silanized glass slides, against which the PDMS microchannels were sealed. Sandwich immunoassays of the cancer biomarkers carcinoma embryonic antigen (CEA) and α-fetoprotein (AFP) were demonstrated using this approach.

Amine/sulfhydryl—epoxide

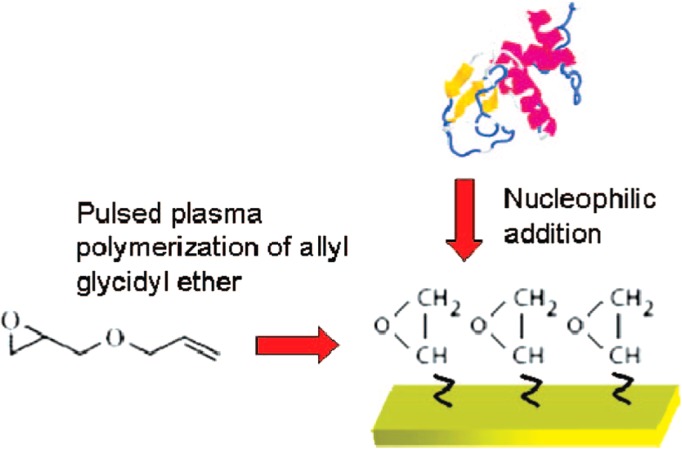

Epoxides form covalent bonds with primary amines at mild alkaline pH or with sulfhydryl groups (-SH) in the physiological pH range.125 The advantages of using epoxides include a simple protocol, a neutral pH range, and relevance to aqueous conditions. Due to slow kinetics, protocols suggest using high concentrations of epoxide and additional functional groups to promote the adsorption of proteins.106 A common epoxide functional group used in protein immobilization is glycidyl.96, 172, 180, 181 Thierry et al. reported epoxide-based capture of tyrosine-kinase human epidermal growth factor receptor (HER2) on PDMS microfluidic devices.181 They coated a PDMS microchannel and the surface of a glass substrate using a pulsed plasma polymerization of allyl glycidyl ether (AEG) monomer (Figure 9).172 The authors reasoned that a common epoxidation reagent GOPTS (3-glycidoxypropyltrimethoxysilane) was unstable owing to hydrolysis, but pulsed plasma yielded a conformal, adherent, defect-free glycidyl coatings on the surface.172 Herceptin, a commercial HER2 antibody, was attached to the coating via the epoxide group of the AEG polymer allowing capture of CTCs (circulating tumor cells). The authors also tested a multilayer coating consisting of AEG polymer and PEGDA deposited via epoxide crosslinking. The PEGDA layer was activated with NHS and EDC to immobilize Herceptin. In comparison to the AEG-only coating, reduced nonspecific protein adsorption was observed but lower Herceptin density was obtained.

Figure 9.

Pulsed plasma epoxidation of PDMS surfaces and bioconjugation of proteins. Reprinted with permission from B. Thierry et al., Langmuir 24, 10187 (2008). Copyright 2008 American Chemical Society.

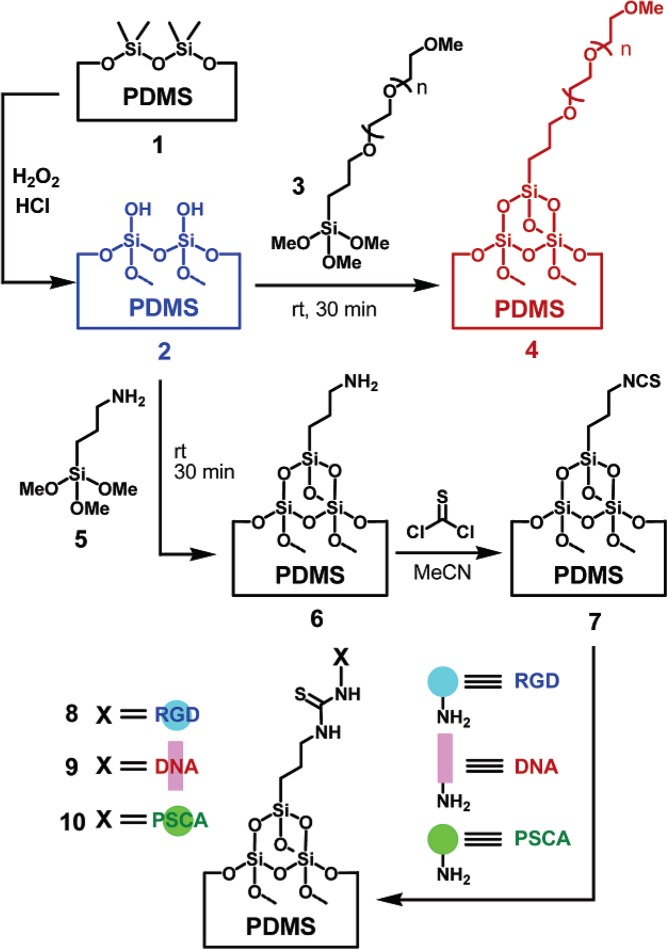

Amine—isothiocyanate

The reaction of an aromatic amine with thiophosgene (CSCl2) yields isothiocyanate (-NCS), which forms a stable bond with primary amine groups.125 Sui et al. used the isothiocyanate chemistry to immobilize proteins, peptides, and DNA on the PDMS surface of a glass-PDMS microfluidic device (Figure 10).120 The approach used solution-based oxidation of PDMS, not common plasma-based oxidation, owing to better stability of the oxidized surface. The PDMS channel was oxidized with H2O2 and HCl, then silanized with 2-[methoxy(polyethyleneoxy)propyl] trimethoxysilane to graft PEG onto the PDMS, followed by APTES treatment for amination. Subsequently, thiophosgene was introduced to convert amine groups to reactive isothiocynate groups. Later, in situ generated isothiocynate reacted with amine-terminated PSCA (prostate stem cell antigen) protein, tripeptide RGD (arginine-glycine-aspartic acid), and aminated DNA for immobilization. Sandwich immunoassays of PSCA, DNA hybridization, and RGD-mediated cell adhesion were demonstrated. The authors found that PEG was effective in repelling proteins from a surface for more than 2 months.

Figure 10.

PEG-grafted PDMS surface for biomolecule immobilization. (4) Preparation of the PEG-grafted PDMS microchannels and (6) amine-grafted PDMS microchannels. The amine-grafted microchannels can be activated by thiophosgene to obtain (7) the isothiocyanate-grafted PDMS microchannels as a precursor for (8) the RGD-grafted, (9) DNA-grafted, and (10) PSCA-grafted PDMS microchannels. Reprinted with permission from G. Sui et al., Anal. Chem. 78, 5543 (2006). Copyright 2006 American Chemical Society.

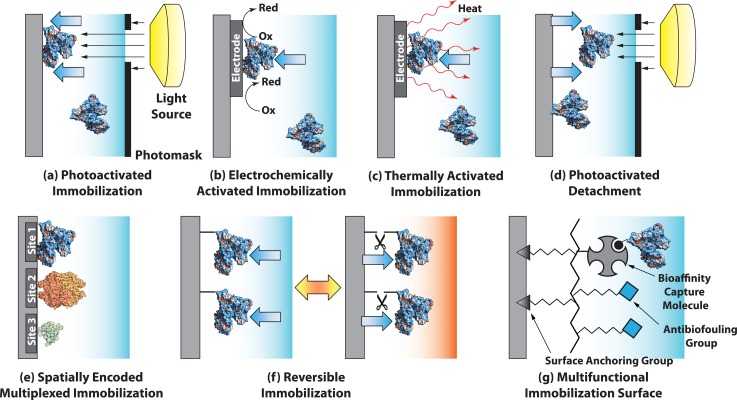

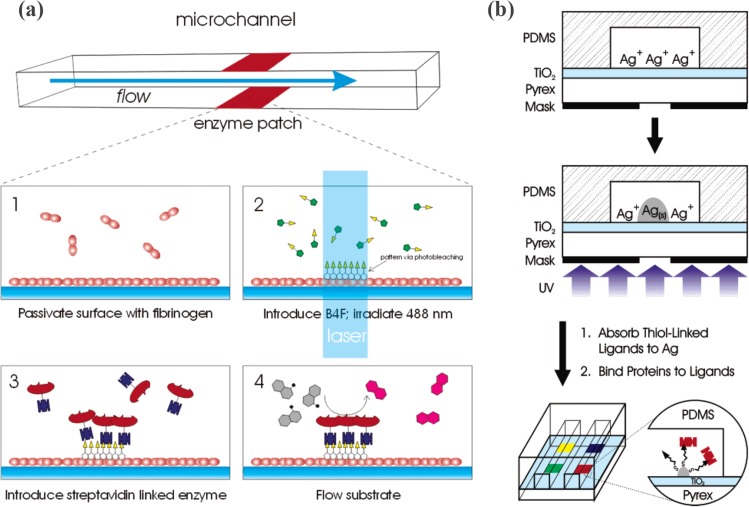

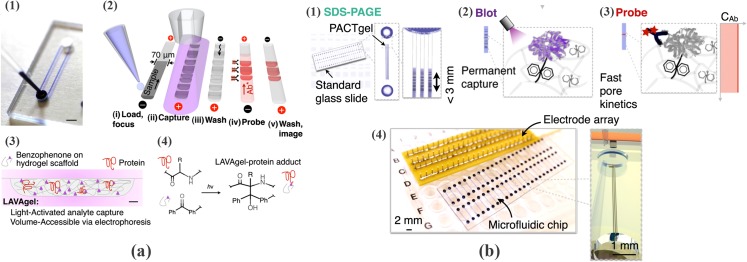

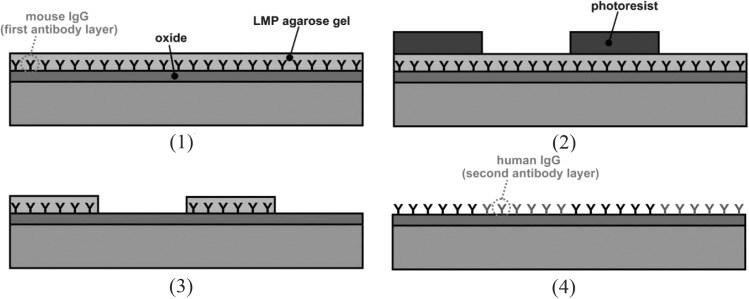

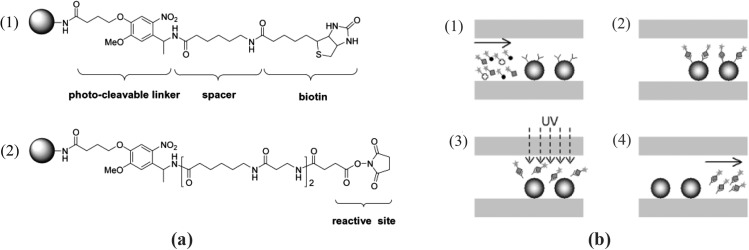

Amine—azlactone