Abstract

The paper describes the design, fabrication, and measurements of a high-frequency ultrasound kerfless linear array prepared from hydrothermal lead zirconate titanate (PZT) thick film. The 15-µm hydrothermal PZT thick film with an area of 1 × 1 cm, obtained through a self-separation process from Ti substrate, was used to fabricate a 32-element 100-MHz kerfless linear array with photolithography. The bandwidth at −6 dB without matching layer, insertion loss around center frequency, and crosstalk between adjacent elements were measured to be 39%, −30 dB, and −15 dB, respectively.

I. Introduction

Ultrasonic imaging is one of the most important diagnostic tools today and it is still growing. To obtain the desired spatial resolution images in clinical applications, the operating frequency of the medical ultrasound transducer has been driven higher and higher. To date, many efforts have been carried out to develop high-frequency ultrasound single-element transducers [1]–[8] and linear arrays [9]–[13]. Because of its relatively simple structure, the single-element transducer fabrication process is more convenient and its operating frequency can more easily reach over 100 MHz [3], [4], [6]–[8]. Meanwhile, following more than a decade of study, the fabrication of high-frequency (>30 MHz) linear arrays has remained a challenge. The element pitch of the array must be in inverse proportion to the operating frequency, leading to high difficulty in building linear arrays at a frequency greater than 100 MHz. Such arrays have the potential to provide a more detailed delineation of skin anatomy for early diagnosis of cancers such as melanoma or to image small structures in other parts of the body.

As indicated by the recent researches, piezoelectric films are good candidates for high-frequency transducer material [14] and micro-machining technology is a possible solution for high-frequency fabrication [15], [16], even though much improvement still must be made. Ito et al. have utilized sputtered ZnO film to build a novel 100-MHz linear array by wet etching [17]. However, the piezoelectric coefficient and electromechanical coupling coefficient of ZnO materials (d33 ~ 7.5 pm/V, kt ~ 0.24) is very low [18], [19], and moreover, the element pitch produced is large (approximately 7λ in water at 100 MHz), making this array unsuitable for medical imaging. In our previous works, with lead zirconate titanate (PZT) thick films prepared by modified sol-gel method, an 80-MHz kerfed array and a 120-MHz kerfless linear array with 32 elements were fabricated using dry etching and photolithography, respectively [9], [10]. Compared with bulk PZT ceramic (kt > 0.5), the obtained PZT thick film had a lower electromechanical coupling coefficient (kt = 0.34). As a result, the insertion loss of linear array element was only −41 dB, which was too poor and needed to be improved. The effective way to overcome this issue is to enhance the PZT thick film’s properties. Recently, we have found that self-separated hydrothermal PZT thick film after sol-gel filling and high-temperature annealing has high electromechanical coupling coefficient (kt = 0.52) which is comparable to that of bulk PZT 5H ceramic (0.53) [20] and over 1.5 times larger than that of PZT thick film prepared by the modified sol-gel method. In addition, a hydrothermal PZT thick-film single-element ultrasound transducer with a center frequency of 67 MHz and bandwidth at −6 dB of around 73% has been successfully fabricated [5]. Therefore, a higher-frequency linear array with this kind of film can be expected.

In this paper, the kerfless high-frequency (100-MHz) hydrothermal PZT thick-film linear array was developed as an alternative to kerfed arrays, because making fine kerfs at present is still a very expensive process [21], [22].

II. Experimental Procedure

Using a hydrothermal method, 15-µm PZT thick film was deposited on a 50-µm-thick Ti substrate with an area of 1 × 1 cm. Starting materials for the reaction were lead nitrate [Pb(NO3)2 99.0%], zirconium chloride oxide octahydrate (ZrOCl2·8H2O 99.0%), a powder of titanium oxide (TiO2 99.0%), deionized water, and potassium hydroxide (KOH) as the mineralizer [23]. The chemical reaction of nuclear and crystal growth was processed in hydrothermal environment using an autoclave. In this process, the temperature and the pressure inside of autoclave were 160°C and 0.55 MPa, respectively. For each process, the reaction time was about 12 h and the thickness of the film increased around 2 µm. The self-separation process and the treatments of sol-gel filling and high-temperature annealing were conducted according to [5]. The microstructure of the film was examined using a high-resolution field emission scanning electron microscope (SEM; S-3500N, Hitachi, Tokyo, Japan). Element analysis was characterized by energy dispersive spectrometer (EDS, EMAX 7593-H, Horiba, Ltd., England).

The capacitance, dielectric loss, and electrical impedance of the array element were evaluated using an HP4294A impedance analyzer (Hewlett-Packard Company, Palo Alto, CA). The pulse–echo response of the array element was measured in deionized water bath at room temperature by reflecting the transmitted signal off a polished x-cut quartz target. A Panametrics 5900PR pulser/receiver (Panametrics Inc., Waltham, MA) was used to excite each element using 1-µJ, 50-Ω settings with 20 dB total gain on receiving. The reflected waveform received by the transducer was digitized using a 200-MHz oscilloscope (LC534, Lecroy Corp., Chestnut Ridge, NY). The 2-way insertion loss (IL) of the array element was tested using 20-cycle 5-V sinusoid high-frequency bursts generated by a Tektronix AFG2020 function generator (Tektronix Inc., Richardson, TX). The signal loss from the attenuation in water (2.2 × 10−4 dB·(mm·MHz2)−1) and transmission into the quartz target (1.9 dB) was compensated in the final IL calculation. The crosstalk between the adjacent elements was also measured using a Tektronix AFG2020 function generator according to [14].

III. Results and Discussion

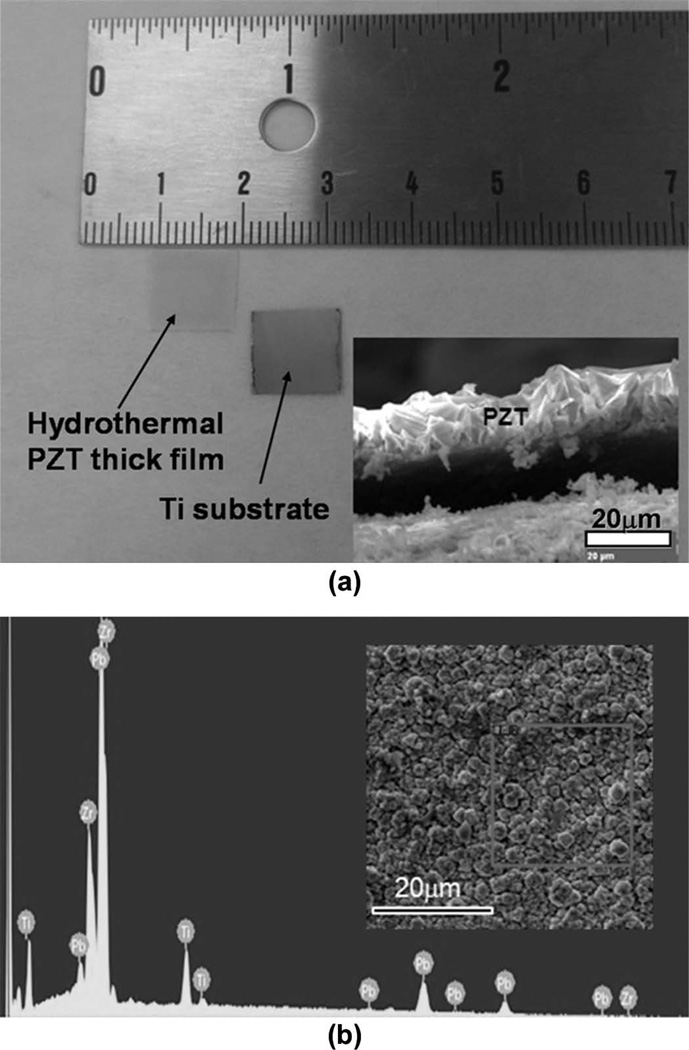

As described in the Fig. 1(a), the self-separated hydrothermal PZT thick film with an area of around 1 × 1 cm has been obtained and the thickness determined by SEM cross-sectional image is about 15 µm. In Fig. 1(b), the SEM surface image confirms that the free-standing film has no obvious physical damage; the EDS result of the film in pink square frame demonstrates the ratio of Zr and Ti is 53:47, suggesting that the composition of the PZT film is near morphotropic phase boundary (MPB).

Fig. 1.

(a) Photograph of self-separated hydrothermal lead zirconate titanate (PZT) thick film with area of around 1 × 1 cm; (inset) scanning electron microscope (SEM) cross-sectional image of the morphology of this PZT thick film. (b) Energy dispersive spectrometer (EDS) pattern of the self-separated hydrothermal PZT thick film; (inset) surface SEM image of this PZT thick film.

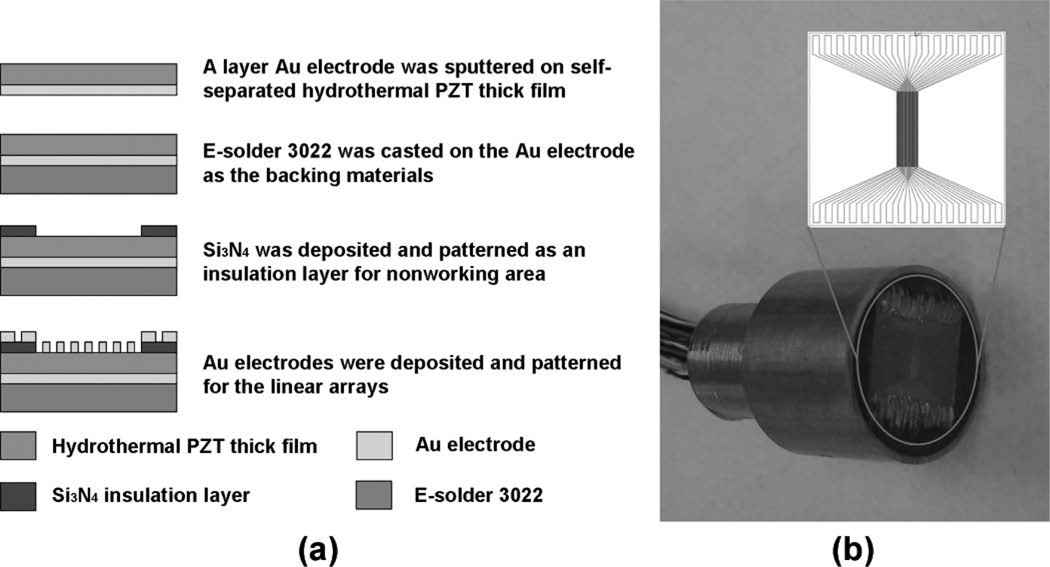

The fabrication process of the linear array is illustrated in Fig. 2(a). First, an Au/Cr (1000 Å/500 Å) layer was sputtered on one surface of the self-separated hydrothermal PZT film. Then, a conductive epoxy (E-solder 3022, Von Roll Isola Inc., New Haven, CT) was cast on the Au/Cr layer, acting as the backing material and providing the electric connection for the common electrode. On the other surface of the film, a 1-µm insulating layer of Si3N4 was deposited and patterned to leave an opening for the working area of the linear array; the Au/Cr layer was patterned with photolithography to serve as the top electrode of each element. The mask designed for patterning is shown in Fig. 2(b); the linear array has a kerf of 12 µm, an element width of 24 µm, and an element length of 4 mm. According to our experience, a reasonable thickness of the top electrode is 1000 Å/500 Å (Au/Cr), because it can provide good conduction and only damp ~1 MHz of the center frequency. Only in the working area are the top electrodes directly in contact with the film; all other areas are covered by the insulating layer of Si3N4. The 26-AWG 50-Ω miniature coaxial cables (Cooner Wire Inc., Chatsworth, CA) were connected with the top electrodes by conductive silver epoxy. Finally, the prototype array was encapsulated in the brass housing, as shown in Fig. 2(b). Note that no substrate needs to be etched in this fabrication process. In our previous works [9], [10], there is a crucial but expensive step to etch Si substrate under the working area by XeF2. Thus, the new fabrication process is much simpler and cheaper.

Fig. 2.

(a) Fabrication process of the self-separated hydrothermal lead zirconate titanate (PZT) high-frequency kerfless linear array. (b) Photograph of the self-separated hydrothermal PZT high-frequency kerfless linear array with 32 elements.

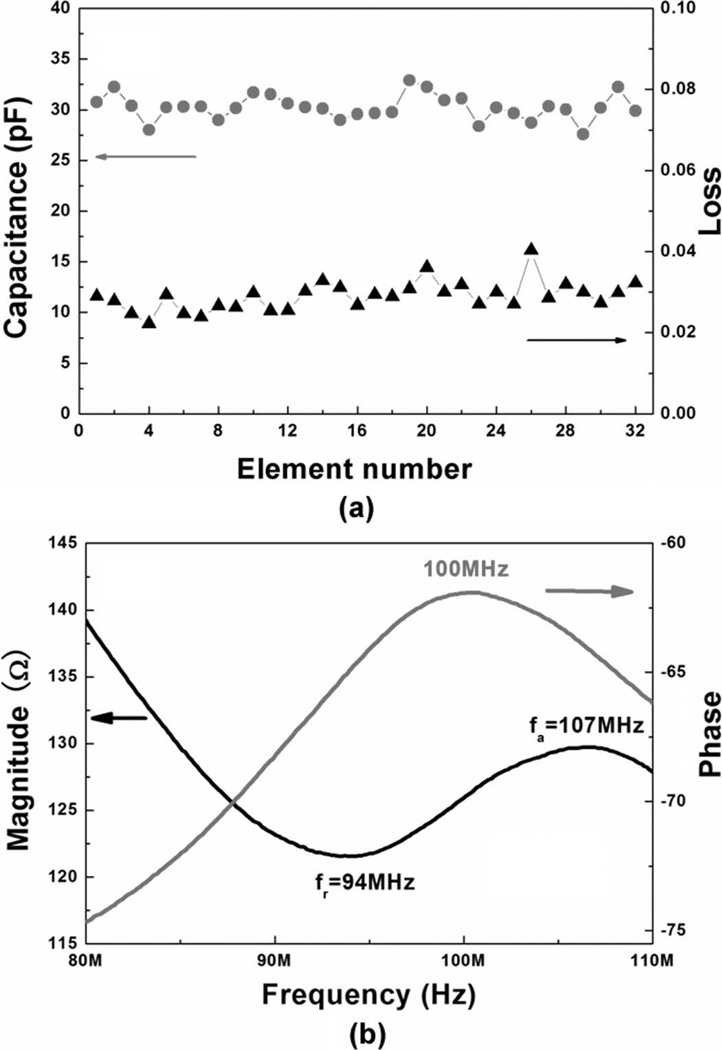

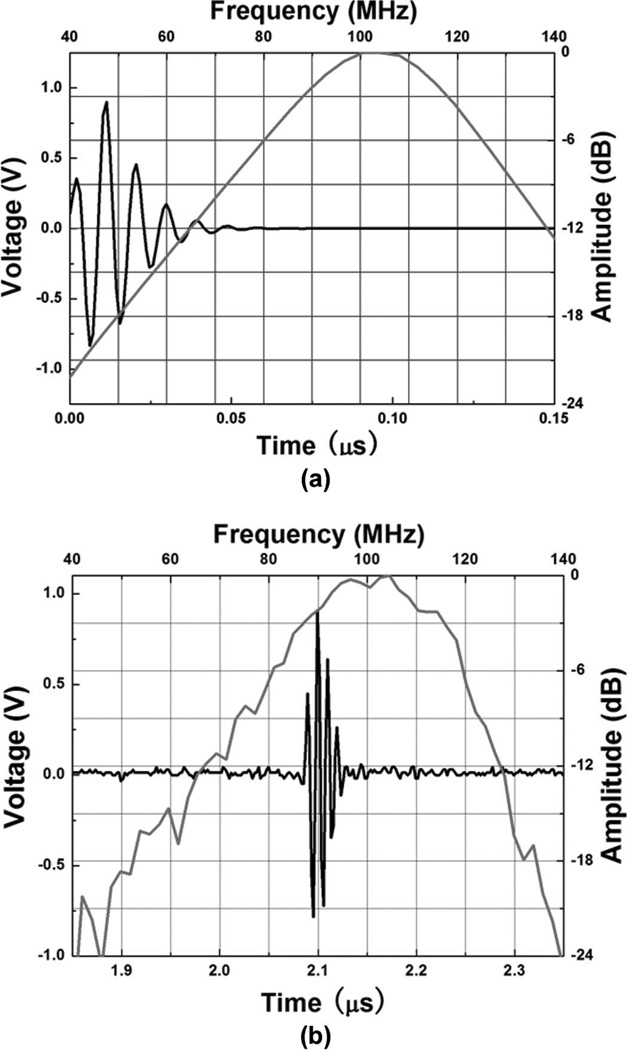

To acquire good pulse–echo signal and impedance peaks, the optimum poling condition for each element is 150 V at 150°C for 5 min. The poling electric field is 10 V/µm, which is much larger than that of PZT ceramics (normally ~2 to 3 V/µm) [24]. A similar phenomenon has been found in the poling process of PZT thick film prepared by modified sol-gel method [9]. Fig. 3(a) shows the uniformity of the array element behavior at 1 MHz and room temperature: the capacitance is located at around 30 pF and the dielectric loss is about 0.03. Most importantly, there are no broken elements observed. As shown in Fig. 3(b), there is a peak in the phase curve at 100 MHz, indicating the center frequency of the array element is around 100 MHz, where the impedance of array element is 126 Ω. PiezoCAD software (Sonic Concepts, Woodinville, WA) was used to predict the performance of the kerfless arrays. In the modeling, E-solder 3022 was selected as the backing material and no matching was added. The properties of the film and E-solder 3022 are listed in Table I. The modeled data, as shown in Fig. 4(a), suggests that the center frequency is 102 MHz and that the bandwidth at −6 dB may reach 43% without any matching layer. The measured result is shown in Fig. 4(b): the array element presents a bandwidth of 39% at −6 dB at central frequency of 100 MHz. Although the measured center frequency is in good agreement with the impedance result, it is still lower than the modeled one. This difference is mainly due to the ultrasound attenuation in the water at high frequency. After compensation for the attenuation caused by the water and reflection from the quartz, the insertion loss of the array element is determined to be −30 dB at 100 MHz, which is 11 dB better than that reported in [9] and [10]. At around the center frequency, the crosstalk of the adjacent elements was measured to be −15 dB. This relatively large cross talk is caused by the lack of isolation between elements, and we believe that it can be reduced by fabricating a kerfed array with a dry-etching process [10]. The performance of the transducer may be further improved by introducing matching layers to increase the bandwidth at the center frequency.

Fig. 3.

(a) Measured element uniformity of the kerfless linear array. (b) Electrical impedance magnitude and phase plots of the kerfless linear array element.

TABLE I.

The Properties of the Self-Separated Hydrothermal PZT Thick Film and E-Solder 3022.

| Material | Density (g/cm3) |

Velocity (m/s) |

Impedance (MRayls) |

|---|---|---|---|

| Self-separated hydrothermal PZT thick film | 6.5 | 3500 | 22.75 |

| E-Solder 3022 (centrifuged) | 3.20 | 1850 | 5.92 |

Fig. 4.

(a) Modeled pulse-echo signals of kerfless array elements. (b) Measured pulse echo response and spectrum of the kerfless linear-array element.

IV. Conclusions

In summary, based on a 15-µm freestanding hydrothermal Pb(Zr0.53Ti0.47)O3 thick film with an area of around 1 × 1 cm, a high-frequency (100-MHz) kerfless linear array with 32 elements has been fabricated. Without a matching layer, the central frequency of the array element is measured to be 100 MHz and the bandwidth at −6 dB is 39%. At the center frequency, the insertion loss of the array element is determined to be −30 dB. To reduce the crosstalk and enhance the bandwidth, the fabrication of a 100-MHz hydrothermal PZT thick film kerfed linear array with a matching layer is in progress; this will be a promising option for the development of high-frequency ultrasound transducer technology.

Acknowledgments

The authors thank C. Liu and R. Chen for their assistance with the transducer fabrication process.

This research was supported by the National Natural Science Foundation of China (grant number 51002055), the National Key Technology R&D Program in the 12th Five-year Plan of China (grant number 2012BAI13B02), the Electronic Materials Research Laboratory, Key Laboratory of The Ministry of Education of China, and National Institutes of Health grant P41-EB2182.

Contributor Information

Benpeng Zhu, School of Optical and Electronic Information, Huazhong University of Science and Technology, Wuhan, China, and Artificial Micro- and Nano-Structures, Ministry of Education; Department of Applied Physics and Materials Research Centre, The Hong Kong Polytechnic University, Hong Kong, China.

Ngai Yui Chan, Department of Applied Physics and Materials Research Centre, The Hong Kong Polytechnic University, Hong Kong, China.

Jiyan Dai, Email: jiyan.dai@polyu.edu.hk, Department of Applied Physics and Materials Research Centre, The Hong Kong Polytechnic University, Hong Kong, China.

K. Kirk Shung, National Institutes of Health Transducer Resource Center and the Department of Biomedical Engineering, University of Southern California, Los Angeles, CA.

Shinichi Takeuchi, Medical Engineering Course, Graduate School of Engineering, Toin University of Yokohama, Yokohama, Japan.

Qifa Zhou, Email: qifazhou@usc.edu, National Institutes of Health Transducer Resource Center and the Department of Biomedical Engineering, University of Southern California, Los Angeles, CA.

References

- 1.Lukacs M, Sayer M, Foster S. Single element high frequency (>50 MHz) PZT sol gel composite ultrasound transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2000;vol. 47(no. 1):148–159. doi: 10.1109/58.818757. [DOI] [PubMed] [Google Scholar]

- 2.Kim H, Griggio F, Kim IS, Choi K, Tutwiler RL, Jackson TN, Trolier-Mckinstry S. Piezoelectric thin films for a high frequency ultrasound transducer with integrated electronics. IEEE Sensors. 2010:2186–2188. [Google Scholar]

- 3.Lau ST, Ji HF, Li X, Ren W, Zhou QF, Shung KK. KNN/BNT composite lead free films for high frequency ultrasonic transducer applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2011;vol. 58(no. 1):249–254. doi: 10.1109/TUFFC.2011.1793. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Lau ST, Li X, Zhou QF, Shung KK, Ryu J, Park D-S. Aerosol-deposited KNN-LSO lead-free piezoelectric thick film for high frequency transducer applications. Sens. Actuators A. 2010;vol. 163(no. 1):226–230. [Google Scholar]

- 5.Zhu BP, Zhou QF, Shi J, Shung KK, Irisawa S, Takeuchi S. Self-separated hydrothermal lead zirconate titanate thick films for high frequency transducer applications. Appl. Phys. Lett. 2009;vol. 94(no. 10) doi: 10.1063/1.3095504. art no. 102901. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Zhu BP, Wu DW, Zhou QF, Shi J, Shung KK. Lead zirconate titanate thick film with enhanced electrical properties for high frequency transducer applications. Appl. Phys. Lett. 2008;vol. 93(no. 1) doi: 10.1063/1.3095504. art. no. 102905. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Zhu BP, Han JX, Shi J, Shung KK, Wei Q, Huang YH, Kosec M, Zhou QF. Lift-off PMN–PT thick film for high-frequency ultrasonic biomicroscopy. J. Am. Ceram. Soc. 2010;vol. 93(no. 10):2929–2931. doi: 10.1111/j.1551-2916.2010.03873.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Zhou QF, Sharp C, Cannata JM, Shung KK, Feng GH, Kim ES. Focused high frequency ZnO MEMS ultrasonic transducers for biomedical imaging. Appl. Phys. Lett. 2007 Mar.vol. 90 art. no. 113502. [Google Scholar]

- 9.Wu DW, Zhou QF, Geng XC, Liu CG, Djuth F, Shung KK. Very high frequency (beyond 100 MHz) PZT kerfless linear arrays. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2009;vol. 56(no. 10):2304–2310. doi: 10.1109/TUFFC.2009.1311. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Zhou QF, Wu DW, Liu CG, Zhu BP, Djuth F, Shung KK. Micro-machined high-frequency (80 MHz) PZT thick film linear arrays. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2010;vol. 57(no. 10):2213–2220. doi: 10.1109/TUFFC.2010.1680. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Cannata JM, Williams JA, Zhou QF, Ritter TA, Shung KK. Development of a 35-MHz piezo-composite ultrasound array for medical imaging. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2006;vol. 53(no. 1):224–236. doi: 10.1109/tuffc.2006.1588408. [DOI] [PubMed] [Google Scholar]

- 12.Lukacs M, Yin J, Pang G, Garcia RC, Cherin E, Williams R, Mehi J, Foster FS. Performance and characterization of new micromachined high-frequency linear arrays. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2006;vol. 53(no. 10):1719–1729. doi: 10.1109/tuffc.2006.105. [DOI] [PubMed] [Google Scholar]

- 13.Liu CG, Zhou QF, Djuth FT, Shung KK. High-frequency (>50 MHz) medical ultrasound linear arrays produced by micromachining bulk PZT materials. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2012;vol. 59(no. 2):315–318. doi: 10.1109/TUFFC.2012.2193. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Zhou QF, Lau ST, Wu DW, Shung KK. Piezoelectric films for high frequency ultrasonic transducers in biomedical applications. Prog. Mater. Sci. 2011;vol. 56(no. 2):139–174. doi: 10.1016/j.pmatsci.2010.09.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Dauchy F, Dorey RA. Thickness mode high frequency MEMS piezoelectric micro ultrasound transducers. J. Electroceram. 2007;vol. 19(no. 4):383–386. [Google Scholar]

- 16.Pang G, Sayer M, Lockwood GR, Watt M. Fabrication of PZT sol gel composite ultrasonic transducers using batch fabrication micromolding. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2006;vol. 53(no. 9):1679–1684. doi: 10.1109/tuffc.2006.1678196. [DOI] [PubMed] [Google Scholar]

- 17.Ito Y, Kushida K, Sugawara K, Takeuchi H. A 100 MHz ultrasonic transducer array using ZnO thin films. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 1995;vol. 42(no. 2):316–324. [Google Scholar]

- 18.Cross LE, Trolier-Mckinstry S. Encyclopedia of Applied Physics. vol. 21. New York, NY: Wiley; 1997. Thin film integrated ferroelectrics; pp. 429–451. [Google Scholar]

- 19.Wu DW. Ph.D. thesis. Dept. of Biomedical Engineering, University of Southern California; 2009. Development of high frequency (~100MHz) PZT thick film ultrasound transducers and arrays. [Google Scholar]

- 20.Su Q, Zhu BP, Lee JH, Bi ZX, Shung KK, Takeuchi S, Zhou QF, Park BH, Jia QX, Wang HY. Self-separated PZT thick films with bulk-like piezoelectric and electromechanical properties. J. Mater. Res. 2011;vol. 26(no. 11):1431–1435. doi: 10.1557/jmr.2011.115. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Morton CE, Lockwood GR. Evaluation of kerfless linear arrays; Proc. IEEE Ultrasonics Symp; 2002. pp. 1257–1260. [Google Scholar]

- 22.Démoré CEM, Brown JA, Lockwood GR. Investigation of cross talk in kerfless annular arrays for high-frequency imaging. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2006;vol. 53(no. 5):1046–1056. doi: 10.1109/tuffc.2006.1632694. [DOI] [PubMed] [Google Scholar]

- 23.Ishikawa M, Kurosawa MK, Endoh A, Takeuchi S. Lead zirconate titanate thick-film ultrasonic transducer for 1 to 20 MHz frequency bands fabricated by hydrothermal polycrystal growth. Jpn. J. Appl. Phys. 2005;vol. 44(no. 6B):4342–4346. [Google Scholar]

- 24.Damjanovic D. Ferroelectric, dielectric and piezoelectric properties of ferroelectric thin films and ceramics. Rep. Prog. Phys. 1998;vol. 61(no. 9):1267–1324. [Google Scholar]