Abstract

Objective

To test the hypothesis that step-stress analysis is effective to predict the reliability of an alumina-based dental ceramic (VITA In-Ceram AL blocks) subjected to a mechanical aging test.

Methods

Bar-shaped ceramic specimens were fabricated, polished to 1µm finish and divided into 3 groups (n=10): (1) step-stress accelerating test; (2) flexural strength- control; (3) flexural strength- mechanical aging. Specimens from group 1 were tested in an electromagnetic actuator (MTS Evolution) using a three-point flexure fixture (frequency: 2Hz; R=0.1) in 37°C water bath. Each specimen was subjected to an individual stress profile, and the number of cycles to failure was recorded. A cumulative damage model with an inverse power law lifetime-stress relation and Weibull lifetime distribution were used to fit the fatigue data. The data were used to predict the stress level and number of cycles for mechanical aging (group 3). Groups 2 and 3 were tested for three-point flexural strength (σ) in a universal testing machine with 1.0 s in 37°C water. Data were statistically analyzed using Mann-Whitney Rank Sum test.

Results

Step-stress data analysis showed that the profile most likely to weaken the specimens without causing fracture during aging (95% CI: 0–14% failures) was: 80 MPa stress amplitude and 105 cycles. The median σ values (MPa) for groups 2 (493±54) and 3 (423±103) were statistically different (p=0.009).

Significance

The aging profile determined by step-stress analysis was effective to reduce alumina ceramic strength as predicted by the reliability estimate, confirming the study hypothesis.

Keywords: ceramics, aging, fatigue

Introduction

Dental ceramics with high crystalline content were developed with the objective to provide materials with superior mechanical properties to produce all-ceramic restorations [1]. Although the literature reports for alumina and zirconia-based systems fracture stress values well above the stresses estimated for the posterior areas of the mouth [2], there are reports of clinical failures [3–5]. This behavior may be attributed to the fact that the prognosis of ceramic restorations is not only related to their high initial mechanical strength but also to a phenomenon called “subcritical crack growth” (SCG) [6]. Ceramic components are susceptible to a stress-corrosion process that involves the stable growth of pre-existing flaws. The stress field at the crack tip can be described by the stress intensity factor in the opening mode (KI) and the flaw will propagate when it reaches the critical condition, KIc (fracture toughness or critical stress intensity factor) [7]

When a ceramic material is subjected to a long period of stresses below the critical stress intensity factor (KIc) but above the threshold level (KI0), pre-existing flaws may grow slowly until reaching critical size, that triggers catastrophic failure [7, 8]. The SCG behavior results from a combination of stress concentration at the crack tip and the presence of water or body fluids molecules that chemically react with the strained atomic bonds [9]. Many external factors that contribute to the SCG of ceramic materials are present in the oral environment such as humidity, pH and temperature fluctuations and stresses induced by loading (i.e. chewing) [10–12].

There is plethora of ceramic studies reporting only fast fracture data and neglecting the effect of the SCG phenomenon and cyclic fatigue in the reliability of these materials [6]. This is explained by the fact that cyclic fatigue testing has a high cost due to the large number of specimens and long time required [12]. To overcome these drawbacks, one possibility is to use accelerated lifetime tests in which specimens are subjected to stress levels lower than those used in fast fracture test but higher than those found during mastication so as to decrease the test duration to an acceptable period of time. However, the stress level used in these in vitro tests should ideally accelerate failure without adding new unrealistic failure modes that would not occur in clinical conditions [13]. Among these methods are the staircase or up-and-down method [14], the boundary technique [15] and the step-stress method [13]. These tests were designed to analyze long lasting materials such as dental ceramics since it is impractical to obtain use level condition lifetime data because of the long time to failure [13, 16].

The staircase method allows the researcher to precisely estimate the fatigue strength at 50% failure probability and to reduce the sample size. Yet, this method is not adequate to estimate low or high points of probability of failure (1% or 99%) [14], which is a disadvantage since the lifetime prediction in these extreme points is more important for engineering and biomedical materials. In the boundary technique, it is possible to estimate low or high points of failure probability with greater precision compared with the staircase method [15]. In this technique, the critical points are the lack of criteria to choose some parameters used in the method and to assume a normal distribution of the data since fatigue lifetimes fit more properly to the two-parameter Weibull distribution.

In contrast to the constant stress amplitude used for the staircase method and for the boundary technique, in the step-stress method each specimen is subjected to time-varying stresses, which means that the magnitude of load changes after a period of time, for the same specimen, until failure occurs or the test is suspended. This technique assures that failure occurs quickly because it customizes the stress amplitude to the strength of the individual specimens, and different stress profiles can be used for each specimen [13, 16].

Data obtained with accelerated life testing are fitted to a life-stress model and extrapolated to normal use conditions. When time-varying stress is used, like in step-stress method, the cumulative damage model should be used. This model takes into consideration the cumulative effect of the stresses applied at each level of time-varying stress. Data on surviving specimens can be included in the analysis (censored data). It is possible to find the probability of failure over time and to predict the reliability for a specific period of time [13, 16]. Studies have used step-stress accelerated life testing in dental research to assess the reliability and failure modes of layered ceramic specimens, metal-ceramic and all-ceramic restorations and implants [17–21].

Different methodologies can be used to evaluate the SCG and cyclic fatigue behavior of dental ceramics. A popular methodology is to perform cyclic loading for a pre-determined period of time using a chewing simulator and to apply, subsequently, a static load until failure occurs. The objective of this methodology is to assess the strength degradation produced by aging in an environment that is similar to the human mouth. However, there is not a standard protocol for the stress amplitude, frequency and number of cycles used in these simulations [22]. Therefore, the objective of this study was to use the step-stress method to estimate the reliability of an alumina-based ceramic as to further design an aging mechanical test. To evaluate the accuracy of the reliability prediction, a group of specimens was aged using the optimum aging profile determined by the step-stress data and ALTA Pro 7 software. The hypothesis to be tested is that step-stress analysis is effective to predict alumina ceramic reliability. The results of this research can be used for efficient design of future accelerated lifetime ceramic studies.

Materials and Methods

Bar-shaped alumina specimens were obtained by cutting pre-sintered blocks (VITA In-Ceram AL, Vita-Zahnfabrik, Germany) using a diamond disc in a precision cutting machine (Isomet 1000, Buehler, Lake Buff, USA) at 275 rpm. Specimens were sintered in the Zyrcomat furnace (Vita Zahnfabrik, Germany). Sintering was carried out at 1530°C for 2 hours with a heating rate of 25°C/min. After sintering, the specimens were ground and polished to 1 µm finish to their final dimensions (2 mm × 4 mm × 16 mm). All edges were chamfered at a 0.1-mm wide chamfer, following ISO 6872:2008 [23]. Specimens were divided into 3 groups (n=10): (1) step-stress accelerating test; (2) flexural strength/fast fracture – control; (3) flexural strength/fast fracture after mechanical aging.

Group 1 was tested in an electromagnetic actuator (MTS Evolution, MTS Systems Corporation) using a three-point flexure fixture (span = 12 mm) at a frequency of 2 Hz (R=0.1) and in a 37°C deionized water bath. Each specimen was subjected to a different stress profile, and the number of cycles to failure was recorded. Each stress profile was designed considering data from all of the previous specimens and their individual lifetimes.

The three-point flexural strength equation used to calculate the stress value at failure is as follows:

| (1) |

where P is the fracture load (N), l is the span size (12 mm), w is the specimen width (4 mm) and b is the thickness of the specimen (2 mm).

A cumulative damage model with an inverse power law (IPL) lifetime-stress relation and a Weibull lifetime distribution were used to fit the fatigue data (ALTA Pro 7, Reliasoft).

The combined IPL-Weibull model is:

| (2) |

where Pf is the probability of failure at time t, σ is the stress level, β is the Weibull modulus, K and n are constants used to fit the model to the data set. The data was used to predict a safe stress level and number of cycles to perform a subsequent aging test (group 3) that could develop damage to the specimens without causing fracture.

Groups 2 (control) and 3 were tested for fast fracture in a three-point flexural strength (σ) design in a universal testing machine (Sintech 5G, MTS) at a constant stress rate of 1.0 MPa/s, in 37°C deionized water bath. Before testing for fast fracture, group 3 was subjected to a mechanical aging in a chewing simulator. Aging was performed in deionized water and the load was applied using a three-point flexure fixture, at 2 Hz frequency. The stress (80 MPa) and number of cycles (105) were determined by the step-stress analysis previously performed. The flexural strength results were statistically analyzed using Mann-Whitney Rank Sum test (α=0.05).

Fracture surfaces were examined using a stereomicroscope to determine the mode of failure based on the fracture origin and fractographic principles [24, 25]. Five specimens of each experimental group were randomly chosen and sputter-coated with gold-palladium and examined using a scanning electron microscope (SEM) to confirm and measure the critical flaw (c). The equivalent semi-circular flaw was determined using the following equation:

| (3) |

where, a is the crack depth and b is half crack width.

The critical flaw (c) values obtained for the experimental groups were statistically analyzed using ANOVA and Tukey’s test (α=0.05).

Results

The step-stress fatigue data (Group 1) were analyzed, and six aging profiles were simulated using ALTA Pro 7 software (Table 1).

Table 1.

Different aging profiles (number of cycles and stress amplitude), reliability and confidence bounds (CB).

| Profile | N Cycles | Stress (MPa) | Reliability (%)* | CB (95%)* |

|---|---|---|---|---|

| 1** | 105 | 80 | 100 | 86; 100 |

| 2 | 106 | 80 | 100 | 69; 100 |

| 3 | 105 | 60 | 100 | 90; 100 |

| 4 | 106 | 60 | 100 | 78; 100 |

| 5 | 105 | 100 | 100 | 81; 100 |

| 6 | 106 | 100 | 99 | 62; 100 |

95% confidence interval

optimal aging profile

Although most of the tested profiles showed 100 % reliability there were differences among the widths of the confidence intervals. Based on the comparison among different profiles, the aging profile number 1 was chosen to test the remaining specimens because it showed the best combination of reliability and precision. A lower confidence bound of 86%, as in profile 1, could guarantee some damage to the specimens without failure during the in vitro aging process. Profiles number 2, 4, 5 and 6 showed wide confidence bounds, meaning lower precision to the reliability estimate. Profile 3 showed high precision but the lower confidence bound of 90% is an indication that not enough damage will be generated in the specimens.

Table 2 shows the median, mean, standard deviation (SD), minimum and maximum flexural strength values, and coefficient of variation (CV) for groups 2 and 3. No specimen failed during the mechanical aging. There was statistically significant difference between group 2 (control) and group 3 (mechanical aging), since the aging condition used (105 cycles and 80 MPa) reduced significantly the median flexural strength of alumina ceramic material (p=0.009).

Table 2.

Median, mean, standard deviation (SD), minimum (Min) and maximum (Max) flexural strength values (MPa), and coefficient of variation (CV) for groups 2 and 3.

| Groups | Aging | Median* | Mean | SD | Min | Max | CV (%) |

|---|---|---|---|---|---|---|---|

| 2 | No | 493a | 489 | 54 | 384 | 567 | 11 |

| 3 | Yes | 423b | 389 | 103 | 135 | 505 | 26 |

Values followed by the same letter in the column are not statistically different (p>0.05).

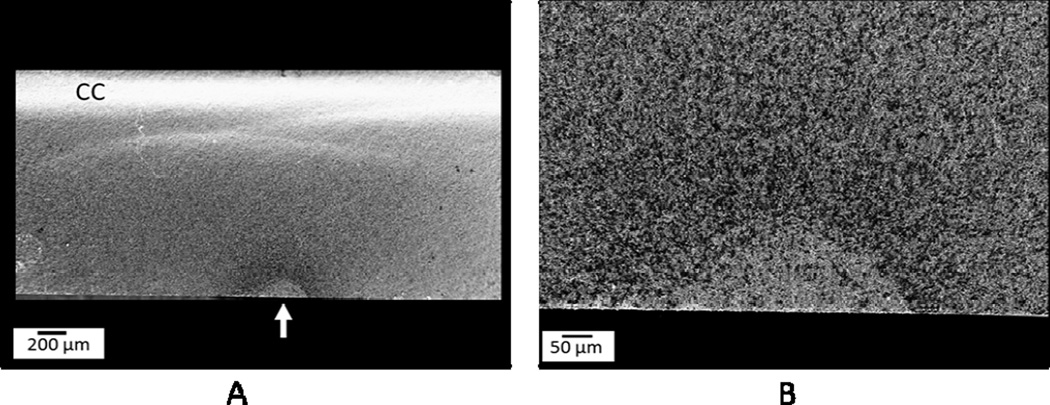

Through fractographic analysis it was possible to observe that the initial flaw was always located in the specimen surface subjected to tension during testing and propagated throughout the material. The fracture surfaces showed fractographic features such as hackle lines running in the direction of the fracture origin and compression curl on the opposite side of the critical flaw. It was also possible to identify in some specimens of groups 1 and 3 the presence of a SCG halo (Figure 1).

Figure 1.

Fracture surface of a specimen from Group 3 (mechanical aging) evidencing the presence of a slow crack growth halo. (A) General view - the white arrow point to the critical flaw that is surrounded by a darker halo (SCG halo), and it is also possible to observe a compression curl in the opposite side (CC). (B) Close view of the critical flaw and SCG halo.

The median, mean, SD, minimum and maximum critical flaw (c) values, and coefficient of variation (CV) for the experimental groups are shown in Table 3. The mean c value observed for group 1 (step-stress) was statistically higher than the result obtained for the control group (group 2) (p=0.004). There were no significant differences between the c values for groups 2 and 3, and groups 1 and 3. However, the coefficient of variation of group 3 (aging) was twice the value of group 2 (control).

Table 3.

Median, mean, minimum and maximum critical flaw (c) values (µm), standard deviation (SD) and coefficient of variation (CV) for the experimental groups.

| Groups | Aging | Median | Mean* | SD | Min | Max | CV (%) |

|---|---|---|---|---|---|---|---|

| 1 | Step-stress | 77 | 78a | 14 | 62 | 103 | 12 |

| 2 | No | 38 | 42b | 11 | 35 | 62 | 14 |

| 3 | Yes | 55 | 60ab | 22 | 42 | 89 | 35 |

Values followed by the same letter in the column are not statistically different (p>0.05).

Discussion

The study hypothesis was confirmed as the step-stress analysis was effective to predict alumina ceramic reliability. The step-stress fatigue test data and the reliability software were efficient in designing different aging profiles and in the estimation of its reliability, since the results of the laboratory aging and fast fracture test confirmed the software predictions. The aging profile chosen to test alumina ceramic significantly reduced the specimen’s flexural strength without causing failure during the aging process. These findings are in agreement with the 100% reliability and 86% lower confidence bound predicted by the step-stress analysis.

One of the challenges of the mechanical aging methodology is to determine which aging profile (stress amplitude and number of cycles) would properly simulate the oral environment and also induce degradation to the material in a reasonable period of time, without causing fracture during the process. The aging profile chosen to perform the mechanical cycling test combined both clinical relevance and testing efficiency. The stress amplitude (80 MPa) used in the aging process was within the range of the failure stresses reported for clinically failed all-ceramic restorations (60 to 100 MPa) [26], and the number of cycles (105 cycles) allowed for a non time-consuming test of approximately 14 hours. In addition, aging was performed in deionized water at 37°C to mimic the humidity and temperature of the oral cavity, and the frequency of 2 Hz is within the chewing frequency range (0.6 – 2.3 Hz) [27].

Step-stress fatigue testing is a relatively new method in dental research with few published studies available for comparison. Different step-stress profiles can be used to evaluate the reliability of dental materials. A series of studies distributed the specimens in the proportions of 4:2:1 or 3:2:1 across three test profiles (mild, moderate and aggressive), which requires a higher number of specimens [17–21]. In these studies, to decide the stress amplitude, the authors tested three specimens of each group for fast fracture strength and 30% of the mean load to failure was used as the first load in the stress profiles assigned to the remaining specimens. The difference in load application mode throughout the three different profiles was the magnitude of load increase during each step cycle, where the mild profile would cycle longer to reach the same load level as the aggressive profile [17]. In the present study there was no standard stress profile and specimens distribution. Each specimen was submitted to a different stress profile considering data from the previous specimen and its individual lifetime. The reason to use different stress profiles was based on the need to distribute failure across different step loads and allows better prediction statistics, narrowing confidence bounds [19].

As ceramic fatigue strength data is highly scattered, precision in predicting probability of failure can be affected. In the present study, the step-stress analysis was effective to predict alumina ceramic reliability, even using a relatively small sample size (n=10). Therefore, this methodology can be considered a powerful toll to design future fatigue testing and perform ceramic life-time predictions.

To validate the results obtained using accelerated life testing it is essential to guarantee that the structure failure was accelerated without adding new fracture modes that would not occur in usual conditions [13]. A careful fractographic analysis was performed to show that the critical flaw was always located in the specimen surface subjected to tension, as previously shown for different dental ceramics [2, 28, 29]. The fracture pattern of the specimens subjected to the step-stress cyclic fatigue (Groups 1) and the mechanical aging process (Group 3) was similar, suggesting that the step-stress methodology used in the present study is valid. In addition, a SCG halo was identified in the fracture surface of some specimens subjected to cyclic load, which is a region or band around a flaw caused by stable crack extension [24].

The decrease in strength values and the presence of a SCG halo in the fracture surface of specimens after mechanical aging (Group 3) proves that the stress profile chosen was effective to produce damage in the alumina ceramic specimens. Although there was no significant difference in the critical flaw dimension (c) between the control group (Group 2) and the mechanical aging group (Group 3), it is important to consider two points. First, only 50% of the specimens was analyzed, which can affect the power of the statistical analysis. Second, an increase in the coefficient of variation was observed for the group subjected to aging when compared to the control group, suggesting presence of crack growth in some specimens (larger critical flaws).

There is not a consensus in the literature about the existence of true cyclic fatigue in ceramic materials mainly due to the absence of crack-tip plasticity. On the other hand, predictions based only on sustained load and fracture toughness data, that do not consider a cyclic fatigue effect, are said to overestimate ceramic lifetimes [7, 30, 31]. According to these studies, potential intrinsic mechanisms of fatigue include accumulated damage in material ahead of the crack tip in the form of localized microplasticity, or microcraking. Extrinsic mechanisms acts to diminish the effect of a crack-tip shielding process, thereby increasing the stress intensity factor compared to equivalent monotonic loading conditions [30]. In monolithic nontransforming ceramics, such as the polycrystalline alumina evaluated in the present study, the toughening is primarily due to grain bridging in the wake of the propagating crack, which shields the crack tip from the applied load [31]. Studies suggest that the cyclic fatigue mechanism in this ceramic is associated to the increase of the crack tip stress intensity factor due to a progressive degradation of this bridging zone [30, 31]. Thus, ceramic restorations may fail under a lower stress level than the one predicted by fast fracture and constant loading tests. Yet, the flexure strength reported in the present study is similar to the mean values previously reported for alumina-based dental ceramics [2, 32].

In addition to a good mechanical behavior [2, 9], which supports the application of polycrystalline alumina as framework for all-ceramic crowns and fixed partial dentures, this material is more translucent than zirconia-based ceramics and metal [33]. Thus, it can be chosen to produce anterior all-ceramic restorations that have a higher esthetic demand.

Extrapolation of the results to the clinical situation should be performed with caution since the effect of the restoration geometry and configuration (multi-layer structure) on the stress distribution was not considered [6]. Nevertheless it should be noted that the use of standardized tests and specimens is the first step to understand the behavior of materials and to develop new methodologies, such as the one proposed in this research. Therefore, the cycling mechanical tests used in the present study, step-stress fatigue and mechanical aging, can be considered important tools to study and predict the mechanical behavior of ceramic materials in vivo.

Conclusion

The aging profile determined by step-stress analysis was effective to reduce alumina ceramic strength as predicted by the reliability estimate, confirming the study hypothesis.

Acknowledgements

The authors acknowledge the Brazilian agencies FAPESP, CNPq and CAPES for the financial support of the present research.

This investigation was also supported in part by Research Grant DE013358 and DE017991 from the NIH-NIDCR.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- 1.Della Bona A. Bonding to ceramics: scientific evidences for clinical dentistry. 1 ed. São Paulo: Artes Médicas; 2009. [Google Scholar]

- 2.Borba M, de Araujo MD, Fukushima KA, Yoshimura HN, Cesar PF, Griggs JA, et al. Effect of the microstructure on the lifetime of dental ceramics. Dent Mater. 2011 Apr 30;27:710–721. doi: 10.1016/j.dental.2011.04.003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Scherrer SS, Quinn GD, Quinn JB. Fractographic failure analysis of a Procera AllCeram crown using stereo and scanning electron microscopy. Dent Mater. 2008 Aug;24(8):1107–1113. doi: 10.1016/j.dental.2008.01.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Taskonak B, Yan J, Mecholsky JJ, Jr, Sertgoz A, Kocak A. Fractographic analyses of zirconia-based fixed partial dentures. Dent Mater. 2008 Aug;24(8):1077–1082. doi: 10.1016/j.dental.2007.12.006. [DOI] [PubMed] [Google Scholar]

- 5.Scherrer SS, Quinn JB, Quinn GD, Kelly JR. Failure analysis of ceramic clinical cases using qualitative fractography. Int J Prosthodont. 2006 Mar-Apr;19(2):185–192. [PubMed] [Google Scholar]

- 6.Kelly JR. Perspectives on strength. Dent Mater. 1995 Mar;11(2):103–110. doi: 10.1016/0109-5641(95)80043-3. [DOI] [PubMed] [Google Scholar]

- 7.Chevalier J, Olagnon C, Fantozzi G. Subcritical crack growth in 3Y–TZP ceramics: static and cyclic fatigue. J Am Ceram Soc. 1999;82(11):3129–3138. [Google Scholar]

- 8.Taskonak B, Griggs JA, Mecholsky JJ, Jr, Yan JH. Analysis of subcritical crack growth in dental ceramics using fracture mechanics and fractography. Dent Mater. 2008 May;24(5):700–707. doi: 10.1016/j.dental.2007.08.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.De Aza AH, Chevalier J, Fantozzi G, Schehl M, Torrecillas R. Crack growth resistance of alumina, zirconia and zirconia toughened alumina ceramics for joint prostheses. Biomaterials. 2002 Feb;23(3):937–945. doi: 10.1016/s0142-9612(01)00206-x. [DOI] [PubMed] [Google Scholar]

- 10.Studart AR, Filser F, Kocher P, Luthy H, Gauckler LJ. Cyclic fatigue in water of veneer-framework composites for all-ceramic dental bridges. Dent Mater. 2007 Feb;23(2):177–185. doi: 10.1016/j.dental.2006.01.011. [DOI] [PubMed] [Google Scholar]

- 11.Morena R, Beaudreau GM, Lockwood PE, Evans AL, Fairhurst CW. Fatigue of dental ceramics in a simulated oral environment. J Dent Res. 1986 Jul;65(7):993–997. doi: 10.1177/00220345860650071901. [DOI] [PubMed] [Google Scholar]

- 12.Salazar Marocho SM, Studart AR, Bottino MA, Bona AD. Mechanical strength and subcritical crack growth under wet cyclic loading of glass-infiltrated dental ceramics. Dent Mater. 2010 May;26(5):483–490. doi: 10.1016/j.dental.2010.01.007. [DOI] [PubMed] [Google Scholar]

- 13.Nelson W. Accelerated Life Testing - Step-Stress Models and Data Analyses. IEEE Transactions of Reliability. 1980 Jun;R-29(2):103–108. 1980. [Google Scholar]

- 14.Dixon WJ, Mood AM. A Method for Obtaining and Analyzing Sensitivity Data. Journal of American Statistical Association. 1948;43:109–126. [Google Scholar]

- 15.Maennig W. Statistical Planning and Evaluation of Fatigue Tests. A Survey of Recent Results. International Journal of Fracture. 1975;11(1):123–129. [Google Scholar]

- 16.Mettas A, Vassiliou P. Modeling and Analysis of Time-Dependent Stress Accelerated Life Data. IEEE Proc Ann Reliability Maintainability Symp. 2002:343–348. [Google Scholar]

- 17.Silva NR, Thompson VP, Valverde GB, Coelho PG, Powers JM, Farah JW, et al. Comparative reliability analyses of zirconium oxide and lithium disilicate restorations in vitro and in vivo. J Am Dent Assoc. 2011 Apr;142(Suppl 2):4S–9S. doi: 10.14219/jada.archive.2011.0336. [DOI] [PubMed] [Google Scholar]

- 18.Silva NR, Souza GMd, Coelho PG, Stappert CFJ, Clark EA, Rekow ED, et al. Effect of Water Storage Time and Composite Cement Thickness on Fatigue of a Glass-Ceramic Trilayer System. J Biomed Mat Res Part B: Appl Biomater. 2008;84B:117–123. doi: 10.1002/jbm.b.30851. [DOI] [PubMed] [Google Scholar]

- 19.Silva NR, Coelho PG, Fernandes CAO, Navarro JM, Dias RA, Thompson VP. Reliability of One-Piece Ceramic Implant. Biomed Mater Res Part B: Appl Biomater. 2009;88B:419–426. doi: 10.1002/jbm.b.31113. [DOI] [PubMed] [Google Scholar]

- 20.Coelho PG, Bonfante EA, Silva NR, Rekow ED, Thompson VP. Laboratory simulation of Y-TZP all-ceramic crown clinical failures. J Dent Res. 2009 Apr;88(4):382–386. doi: 10.1177/0022034509333968. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Silva NR, Bonfante EA, Rafferty BT, Zavanelli RA, Rekow ED, Thompson VP, et al. Modified Y-TZP core design improves all-ceramic crown reliability. J Dent Res. 2011 Jan;90(1):104–108. doi: 10.1177/0022034510384617. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Naumann M, Sterzenbach G, Proschel P. Evaluation of load testing of postendodontic restorations in vitro: linear compressive loading, gradual cycling loading and chewing simulation. J Biomed Mater Res B Appl Biomater. 2005 Aug;74(2):829–834. doi: 10.1002/jbm.b.30321. [DOI] [PubMed] [Google Scholar]

- 23.ISO/CD 6872 Dentistry - Ceramic Materials. 2008 [Google Scholar]

- 24.Quinn GD. Fractography of ceramics and glasses. Washington: National Institute of Standards and Technology; 2007. [Google Scholar]

- 25.C 1322-02a, Standard Practice for Fractography and Characterization of Fracture Origins in Advanced Ceramics. 2003 [Google Scholar]

- 26.Thompson JY, Anusavice KJ, Naman A, Morris HF. Fracture surface characterization of clinically failed all-ceramic crowns. J Dent Res. 1994 Dec;73(12):1824–1832. doi: 10.1177/00220345940730120601. [DOI] [PubMed] [Google Scholar]

- 27.DeLong R, Douglas WH. Development of an artificial oral environment for the testing of dental restoratives: bi-axial force and movement control. J Dent Res. 1983 Jan;62(1):32–36. doi: 10.1177/00220345830620010801. [DOI] [PubMed] [Google Scholar]

- 28.Della Bona A, Anusavice KJ, DeHoff PH. Weibull analysis and flexural strength of hot-pressed core and veneered ceramic structures. Dent Mater. 2003 Nov;19(7):662–669. doi: 10.1016/s0109-5641(03)00010-1. [DOI] [PubMed] [Google Scholar]

- 29.Della Bona A, Mecholsky JJ, Jr, Anusavice KJ. Fracture behavior of lithia disilicate- and leucite-based ceramics. Dent Mater. 2004 Dec;20(10):956–962. doi: 10.1016/j.dental.2004.02.004. [DOI] [PubMed] [Google Scholar]

- 30.Dauskardt RH, Marschall DB, Ritchie RO. Cyclic fatigue-crack propagation in magnesia-partially-stabilized zirconia ceramics. J Am Ceram Soc. 1990;73(4):893–903. [Google Scholar]

- 31.El Attaoui H, Saadaoui M. Quantitative analysis of crack shielding degradation during cyclic fatigue of alumina. J Am Ceram Soc. 2005;88(1):172–178. [Google Scholar]

- 32.Della Bona A, Mecholsky JJ, Barrett AA, Griggs JA. Characterization of glass-infiltrated alumina-based ceramics. Dent Mater. 2008 Nov;24(11):1568–1574. doi: 10.1016/j.dental.2008.06.005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Heffernan MJ, Aquilino SA, Diaz-Arnold AM, Haselton DR, Stanford CM, Vargas MA. Relative translucency of six all-ceramic systems. Part I: core materials. J Prosthet Dent. 2002 Jul;88(1):4–9. [PubMed] [Google Scholar]