Abstract

Background:

Conventional heat cure poly methyl methacrylate (PMMA) is the most commonly used denture base resin despite having some short comings. Lengthy polymerization time being one of them and in order to overcome this fact microwave curing method was recommended. Unavailability of specially designed microwavable acrylic resin made it unpopular. Therefore, in this study, conventional heat cure PMMA was polymerized by microwave energy.

Aim and Objectives:

This study was designed to evaluate the surface porosities in PMMA cured by conventional water bath and microwave energy and compare it with microwavable acrylic resin cured by microwave energy.

Materials and Methods:

Wax samples were obtained by pouring molten wax into a metal mold of 25 mm × 12 mm × 3 mm dimensions. These samples were divided into three groups namely C, CM, and M. Group C denotes conventional heat cure PMMA cured by water bath method, CM denotes conventional heat cure PMMA cured by microwave energy, M denotes specially designed microwavable acrylic denture base resin cured by microwave energy. After polymerization, each sample was scanned in three pre-marked areas for surface porosities using the optical microscope. As per the literature available, this instrument is being used for the first time to measure the porosity in acrylic resin. It is a reliable method of measuring area of surface pores. Portion of the sample being scanned is displayed on the computer and with the help of software area of each pore was measured and data were analyzed.

Results:

Conventional heat cure PMMA samples cured by microwave energy showed maximum porosities than the samples cured by conventional water bath method and microwavable acrylic resin cured by microwave energy. Higher percentage of porosities was statistically significant, but well within the range to be clinically acceptable.

Conclusion:

Within the limitations of this in-vitro study, conventional heat cure PMMA can be cured by microwave energy without compromising on its property such as surface porosity.

Keywords: Denture base resin, microwave polymerization, poly methyl methacrylate

Introduction

The year 1937 saw a milestone in the dentistry with the invention of poly methyl methacrylate (PMMA). The virtue of acrylic resins consists, not merely in its acceptable aesthetic value, but also in comparative ease of manipulation and easy availability at low cost. Acrylic resins have their own shortcomings such as dimensional instability, residual monomer content, weak strength, water absorption, and color instability. It can be concluded that though acrylic resin is the most popular and widely used denture base material for over 60 years and it is still not the ideal one. In past few years, acrylic resin polymers and monomers have been modified not only to improve physical and mechanical properties, but also to improve the working properties that facilitate laboratory techniques such as microwave curing, visible light curing, and vacuum plus pressure at low temperature curing systems.

Since the introduction of acrylic resins for denture construction, there has been a continual search for modified procedures to process resins faster. Nishii first reported the use of microwave energy to polymerize denture base materials in 1968. Kimura et al., reported that it was possible to cure acrylic resin in a very short time using the same technique.[1] In 1984 and 1985, the fiber reinforced flask was substituted for heavy brass flask and the water-bath curing task gave way to microwave ovens.

Microwave heating is independent of thermal conductivity. The advantages of curing denture base resin by microwave energy include greatly reduced curing time, less cumbersome equipment, and a cleaner method of processing.[2] In 1983 Kimura et al., found that curing of denture bases by microwave energy resulted in good resin adaptation to dental cast. Other advantages claimed, but not substantiated, include a shortened dough forming time, more homogeneous resin dough, and minimal color changes in resin base.[3] In spite of advantages of microwave cured acrylic resins, it is not commonly used because of difficult availability and cost of material. In order to overcome that curing of conventional heat cured acrylic resin (PMMA) by microwave energy has been tried.

Porosity in heat processed denture base resins is one of the undesirable characteristics of PMMA. It can compromise physical, esthetic and hygienic properties of processed denture base. It can result in high internal stresses and vulnerability to distortion and warpage of denture base. It can occur through many factors such as air entrapment during mixing, presence of residual monomer, monomer contraction during the polymerization, monomer vaporization associated with exothermic reaction resulting in porosities.[4]

Jerolimov et al. reported that occurrence of porosity is dependent on the rate of polymerization and the efficiency of heat dissipation. Depending on polymerization conditions more than 11% of porosities have been observed associated with decreased mechanical properties, poor esthetics, harboring of organisms and retention of fluids. Thus, it can be concluded that porosities less than 11% are clinically acceptable.

The purpose of this study was to evaluate the surface porosities of conventional heat cured acrylic resin cured by conventional water bath method and by using the microwave energy and microwave curable acrylic resin cured by microwave energy.

Materials and Methods

A total of 21 samples were obtained by pouring molten wax into metal mold [Figure 1] with engraving of three squares (2 mm × 2 mm), one at the center and two at the corners 1 mm away from the border. The samples were 25 mm × 12 mm × 3 mm in dimensions.

Figure 1.

Photograph of brass metal mold

Two heat activated denture base resins, one conventional DPI heat cure-denture base polymer resin (Dental Products of India, Mumbai, India) and one specially designed acrylic resin for microwave polymerization (Acron MC, GC Corporation Japan) were used to prepare test samples. Wax samples were divided into three groups:

Group (C): Conventional.

Group (CM): Conventional in microwave.

Group (M): Microwavable in microwave.

Group C: Conventional heat polymerized acrylic resin cured by water bath method

C: Curing cycle 74°C for 2 hrs, followed by 1 hr of terminal boiling for 3 mm thickness having seven sample blocks each.

Group CM: Conventional heat polymerized acrylic resin cured by microwave energy

CM: 500 W for 3 min for 3 mm thickness having seven sample blocks each.

Group M: Microwave polymerized acrylic resin cured by microwave energy

M: 500 W for 3 min for 3 mm thickness having seven sample blocks each.

The acrylic was mixed strictly as instructed by the manufacturers. Special care was taken during the mixing and processing of the polymer and thereby eliminating their effect on porosity. For the microwave polymerization method, a domestic microwave oven with a rotating table was used (Onida, India).

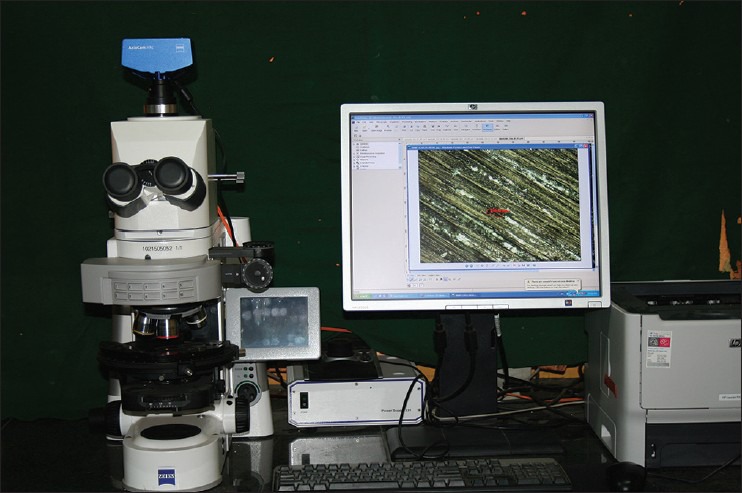

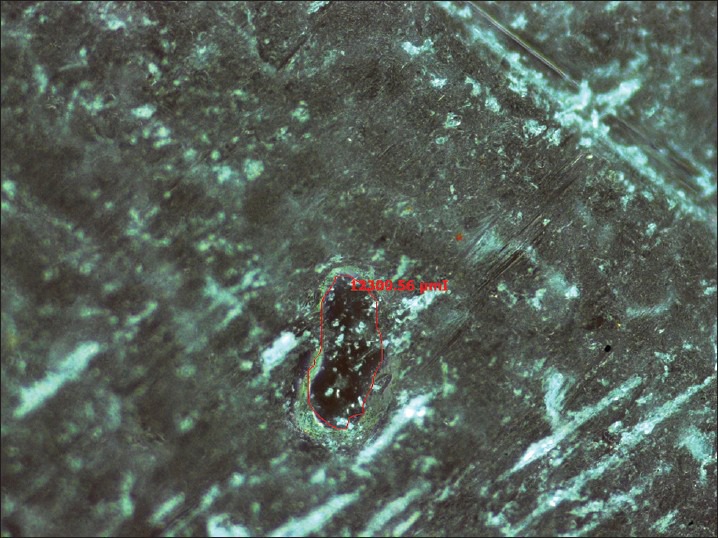

After undergoing its assigned polymerization treatment, each specimen was only polished and the three engraved portions of each specimen were observed under an optical microscope [Figure 2] (Zeiss Imager, model no. Z1, Carl Zeiss, Germany) and photographed using its camera. The perimeter of each surface pore [Figure 3] evident in the engraved square was outlined and area of each pore was measured with the help of software attached to the microscope. Total area of surface pores in engraved areas were calculated and expressed in percentage form.

Figure 2.

Photograph of optical microscope with its attachments

Figure 3.

Photomicrograph showing porosity in one of the samples of Group M under optical microscope

Results

Results were obtained and analyzed on the basis of occurrence of porosities in material and method of polymerization. Areas of surface pores were expressed in percentage form.

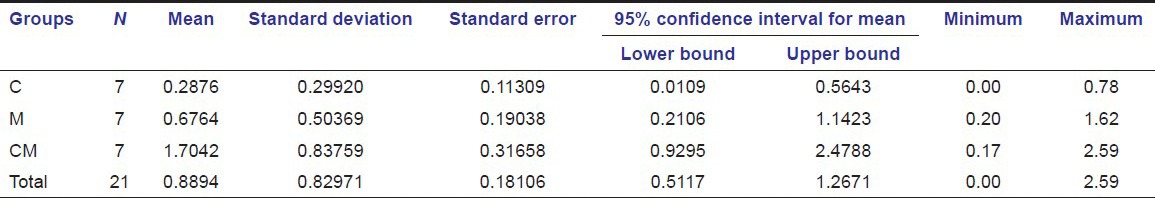

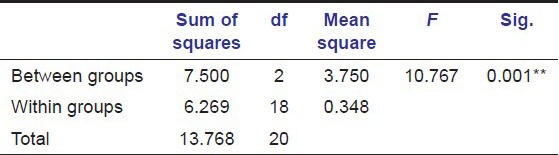

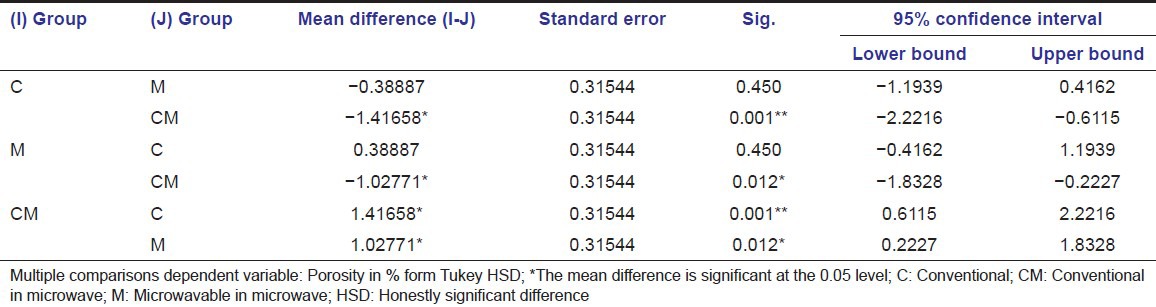

Statistical comparison (by ANOVA test) of porosity in % form of all the groups (C, CM, M) on the basis of materials, i.e., heat cured acrylic resin and specially designed acrylic resin for microwave curing [Tables 1 and 1a] showed statistically significant difference between the groups (0.001). Porosity in conventional heat cured acrylic resin cured by water bath (Group C) showed minimum porosity (0.2876%), specially designed acrylic resin for microwave curing and cured by microwave energy (Group M) showed moderate porosity (0.6764%), heat cured acrylic resin cured by microwave (Group CM) showed maximum porosity (1.7042). Post hoc tests (multiple comparisons) on the basis of materials [Table 2] showed that porosity of C was less than M and CM and it is statistically significant with CM. Porosity of M was more than C, but less than CM and it is statistically significant with CM. Porosity of CM was more than C and M and it is statistically significant with C and also with M.

Table 1.

Descriptive porosities in % form in different groups

Table 1a.

ANOVA analysis of porosity in % form between the groups and within the groups

Table 2.

Represents post hoc tests (multiple comparisons) on the basis of materials

Discussion

Microwave oven is a device, in which electromagnetic waves are produced by a generator called as magnetron, which is used to generate heat. Microwaves do not pass through metal; thus, it is necessary to use specially designed flasks. Any material which can be heated by microwave has polarized molecules. This means that one end of each molecule has a slight positive charge while the other has a slight negative charge. In an electromagnetic field, which rapidly changes direction, polarized molecules are flipped over rapidly and generate heat due to molecular friction.[4]

Heat cured PMMA monomer has a high vapor pressure. Processing temperature much beyond 100.3°C causes vaporization of the monomer, which produces porosity in the final set material. The microwave liquid monomer material contains either a triethylene or a tetraethylene glycol, which are dimethylacrylates having a reactive group on each end. Dimethylacrylates have low vapor pressures even at a temperature of 100°C to 150°C; therefore, it has a high boiling point. The low vapor pressure would allow processing at elevated temperature without the danger of porosity.[5]

The major advantages of microwave heating over conventional heating are that in the microwave the polymer monomer mass is heated directly before the flask is heated, so whatever heat is generated gets dissipated to the investment and the flask where as in conventional water bath method the water gets heated first, which in turn heats the flask, then the investment and then the polymer monomer mass gets heated.[6] This is time consuming, which is one of the disadvantages over microwave processing. So, in this study, microwave processing was used as one of the methods to put into use all the advantages of microwave processing. Furthermore conventional heat cured acrylic resin was cured by conventional water bath method as a control group and it is one of the most common method of curing since many years in the field of dentistry. Conventional heat cured acrylic resin was also cured in microwave oven as microwave processing is time saving, clean, and easiest method of curing.

Porosity has been attributed to variety of factors that include the following; air entrapment during mixing, monomer contraction during the polymerization, monomer vaporization associated with exothermic reaction, the presence of residual monomer, insufficient mixing of monomer and polymer, processing temperature higher than 74°C, inadequate compression in the flask may also cause porosity in denture base resin.[7] Jerolimov et al.,[8] reported that occurrence of porosity is dependent on the concentration of the initiator, generally benzoyl peroxide in the polymer. Depending on the polymerization conditions, 11% porosities have been associated with decreased mechanical properties, poor esthetics, potential harboring of organisms, and retention of fluids.

A number of methods have been introduced for measuring porosity of polymerized acrylic resin including microscopic observation. One of the methods for calculating porosity is to measure the weight of the specimen before and after its immersion in water, the volume of the specimen and density of the acrylic resin, water and trapped air in the pores. Mercury porosimetry is also a method of routine measurement of porosity.[9]

The aim of this study is to investigate surface porosities in all the samples using the optical microscope. As per the literature available this instrument is being used for the first time to measure the porosity. It is the reliable method of measuring area of surface pores. Portion of the sample being scanned is displayed on the computer and with the help of software area of surface pores could be calculated.

When porosities in % form of different materials were compared, it showed that porosities of microwave cured acrylic resin were more than conventional resin polymerized in a water bath, but statistically it is insignificant.

Conventional resin specimen that underwent microwave curing showed maximum porosity and was statistically significant. These findings are in agreement with Sanders et al.,[10] Reitz et al.,[11] Bafile et al.,[3] and Al Doori et al.[4]

Yannikakis,[9] found that conventional resin specimen polymerized in a water bath exhibited no pores. Conventional resin specimen polymerized in microwave exhibited significant porosity. Specimen made from resin designed for microwave curing exhibited an extremely low percentage of pores of a clinically insignificant size.

Since, the percentage porosity of conventional resin specimen polymerized in microwave is 1.7042%, which is much less than 11%, it is clinically acceptable. This finding is in agreement with Jerolimov et al.[8]

Wolfaardt et al.[12] stated that the generation of porosity in PMMA denture base is apparently a complex phenomenon and which is multi-factorial in origin.

Clinical implication of the study

The complete denture prosthodontics means replacement of lost natural teeth to provide optimum function, esthetics, and comfort to the patient along with the preservation of the underlying tissues.

Based upon the methodology and results of the study, we found that microwave curing method is the easiest, cleanest, and a time saving method of curing denture base resins. The processing of microwavable acrylic resins using microwave energy also had very less porosity similar to conventional resin cured by water bath. The results indicated that porosities, in heat cured acrylic resin, were maximum when cured by microwave energy, but it was clinically acceptable. Microwave curing method can be considered as one of the methods for fabricating acrylic resin dental prostheses in routine practice in the field of dentistry.

Summary and Conclusion

Total 21 samples were made; they were divided into three groups namely C, CM, M, and each group containing seven samples. All samples were viewed under optical microscope. Based on the observations and results of this study following conclusions were made.

Conventional acrylic resin polymerized in water bath exhibited very less porosities. Microwavable acrylic resin cured by microwave energy exhibited insignificant increase in porosity when compared to conventionally cured acrylic resin by water bath method. Conventional acrylic resin polymerized in a microwave exhibited significant porosities, but they were clinically acceptable; so, it can be used for curing dentures without affecting its mechanical property such as surface porosity.

Footnotes

Source of Support: Nil

Conflict of Interest: None declared.

References

- 1.Kimura H, Teraoka F, Ohnishi H, Saito T, Yato M. Applications of microwave for dental technique (Part 1) dough forming and curing of acrylic resins. J Osaka Univ Dent Sch. 1983;23:43–9. [PubMed] [Google Scholar]

- 2.Hasan HR. Comparison of some physical properties of acrylic denture base material cured by water bath and microwave techniques. Al-Rafidain Dent J. 2003;3:143–7. [Google Scholar]

- 3.Bafile M, Graser GN, Myers ML, Li EK. Porosity of denture resin cured by microwave energy. J Prosthet Dent. 1991;66:269–74. doi: 10.1016/s0022-3913(05)80061-7. [DOI] [PubMed] [Google Scholar]

- 4.Compagnoni MA, Barbosa DB, de Souza RF, Pero AC. The effect of polymerization cycles on porosity of microwave-processed denture base resin. J Prosthet Dent. 2004;91:281–5. doi: 10.1016/j.prosdent.2004.01.006. [DOI] [PubMed] [Google Scholar]

- 5.Rizzatti-Barbosa CM, Ribeiro-Dasilva MC. Influence of double flask investing and microwave heating on the superficial porosity, surface roughness, and knoop hardness of acrylic resin. J Prosthodont. 2009;18:503–6. doi: 10.1111/j.1532-849X.2009.00469.x. [DOI] [PubMed] [Google Scholar]

- 6.De Clerck JP. Microwave polymerization of acrylic resins used in dental prostheses. J Prosthet Dent. 1987;57:650–8. doi: 10.1016/0022-3913(87)90353-2. [DOI] [PubMed] [Google Scholar]

- 7.Al Doori D, Huggett R, Bates JF, Brooks SC. A comparison of denture base acrylic resins polymerised by microwave irradiation and by conventional water bath curing systems. Dent Mater. 1988;4:25–32. doi: 10.1016/s0109-5641(88)80084-8. [DOI] [PubMed] [Google Scholar]

- 8.Jerolimov V, Brooks SC, Huggett R, Bates JF. Rapid curing of acrylic denture-base materials. Dent Mater. 1989;5:18–22. doi: 10.1016/0109-5641(89)90086-9. [DOI] [PubMed] [Google Scholar]

- 9.Yannikakis S, Zissis A, Polyzois, Andreopoulos A. Evaluation of porosity in microwave- processed acrylic resin using photographic method. J Prosthet Dent. 2002;87:613–9. doi: 10.1067/mpr.2002.124490. [DOI] [PubMed] [Google Scholar]

- 10.Saunders LJ, Levin B, Reitz PV. Porosity in denture acrylic resins cured by microwave energy. Quintessence. 1987;18:453–6. [PubMed] [Google Scholar]

- 11.Reitz PV, Sanders JL, Levin B. The curing of denture acrylic resins by microwave energy. Physical properties. Quintessence. 1985;8:547–551. [PubMed] [Google Scholar]

- 12.Wolfaardt F John, Jones Cleaton Peter, Fatti Paul. The occurrence of porosity in a heat cured poly methyl methacrylate denture base resin. J Prosthet dent. 1986;55:383–400. doi: 10.1016/0022-3913(86)90128-9. [DOI] [PubMed] [Google Scholar]