Abstract

The worldwide incidence of bone disorders and conditions has trended steeply upward and is expected to double by 2020, especially in populations where aging is coupled with increased obesity and poor physical activity. Engineered bone tissue has been viewed as a potential alternative to the conventional use of bone grafts, due to their limitless supply and no disease transmission. However, bone tissue engineering practices have not proceeded to clinical practice due to several limitations or challenges. Bone tissue engineering aims to induce new functional bone regeneration via the synergistic combination of biomaterials, cells, and factor therapy. In this review, we discuss the fundamentals of bone tissue engineering, highlighting the current state of this field. Further, we review the recent advances of biomaterial and cell-based research, as well as approaches used to enhance bone regeneration. Specifically, we discuss widely investigated biomaterial scaffolds, micro- and nano-structural properties of these scaffolds, and the incorporation of biomimetic properties and/or growth factors. In addition, we examine various cellular approaches, including the use of mesenchymal stem cells (MSCs), embryonic stem cells (ESCs), adult stem cells, induced pluripotent stem cells (iPSCs), and platelet-rich plasma (PRP), and their clinical application strengths and limitations. We conclude by overviewing the challenges that face the bone tissue engineering field, such as the lack of sufficient vascularization at the defect site, and the research aimed at functional bone tissue engineering. These challenges will drive future research in the field.

Keywords: bone tissue engineering stem cells, scaffolds, vascularization, immunomodulation, cell homing, clinical challenges

I. INTRODUCTION

Bone grafts are utilized in a wide array of clinical settings to augment bone repair and regeneration. Bone defect repair using the tissue engineering approach is perceived as a better approach because the repair process may proceed with the patient’s own tissue by the time the regeneration is complete.1–3 Currently, the United States, as well as other countries worldwide, is experiencing an exceedingly high demand for functional bone grafts. Annually in the United States, more than half a million patients receive bone defect repairs, with a cost greater than $2.5 billion. This figure is expected to double by 2020 in the United States and globally due to a variety of factors, including the growing neeeds of the baby-boomer population and increased life expectancy.4

Extensive studies have reported the considerable shortcomings, limitations, and complications of current clinical treatments for bone repair and regeneration; these include autologous and allogeneic transplantations using autografts and allografts.4–10 To date, autografts serve as the gold standard for bone grafts because they are histocompatible and non-immunogenic, and they offer all of the imperative properties required of a bone graft material. Specifically, autografts possess the essential components to achieve osteoinduction (i.e., bone morphogenetic proteins (BMPs) and other growth factors), osteogenesis (i.e., osteoprogenitor cells) and osteoconduction (i.e., three-dimensional and porous matrix). However, autografts involve harvesting bone from the patient’s iliac crest, and thus, requires a second operation at the site of tissue harvest.11 Autologous bone transplants are very expensive procedures, and they may result in significant donor site injury and morbidity, deformity, scarring and they are associated with surgical risks as well: bleeding, inflammation, infection, and chronic pain.12–14 Autografts, further, may be a null treatment option in cases where the defect site requires larger volumes of bone than is feasible or available. Allografts represent the second most common bone-grafting technique; they involve transplanting donor bone tissue, often from a cadaver. Allogeneic bone is also likely histocompatible, and is available in various forms, including demineralized bone matrix (DBM), morcellised and cancellous chips, cortico-cancel-lous and cortical grafts, and osteochondral and whole-bone segments, depending on the host-site requirements. In comparison to autografts, allografts are associated with risks of immunoreactions and transmission of infections. They have reduced osteoinductive properties and no cellular component, because donor grafts are devitalized via irradiation or freeze-drying processing.15–17 Although less than autografts, allogenic grafts come with substantial cost issues. Furthermore, the bone grafting market is experiencing an obvious unmet supply and great demand; there is currently a shortage in allograft bone graft ma-terial.18 Other commonly used bone repair techniques may involve distraction osteogenesis, bone cement fillers, and bone morphogenic proteins. Although the previously mentioned clinical interventions have been shown to improve repair of bone, none possess all of the ideal characteristics: high osteoinductive and angiogenic potentials, biological safety, low patient morbidity, no size restrictions, ready access to surgeons, long shelf life, and reasonable cost.

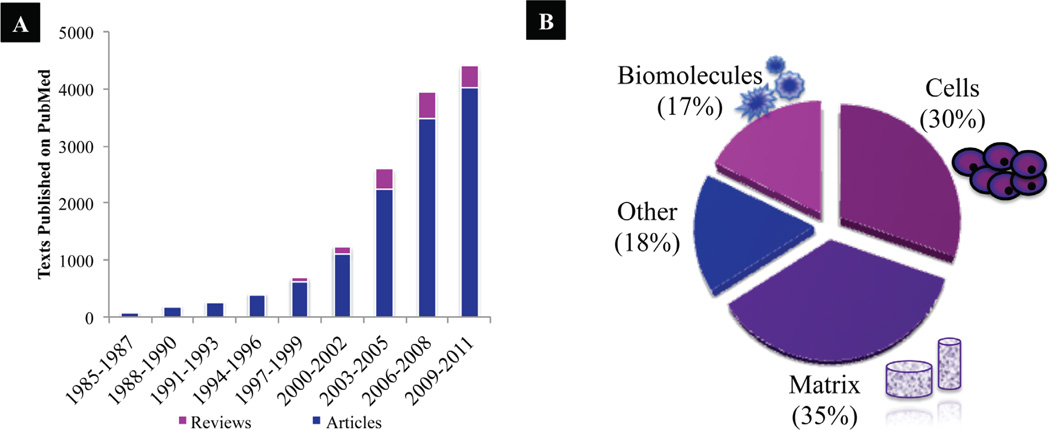

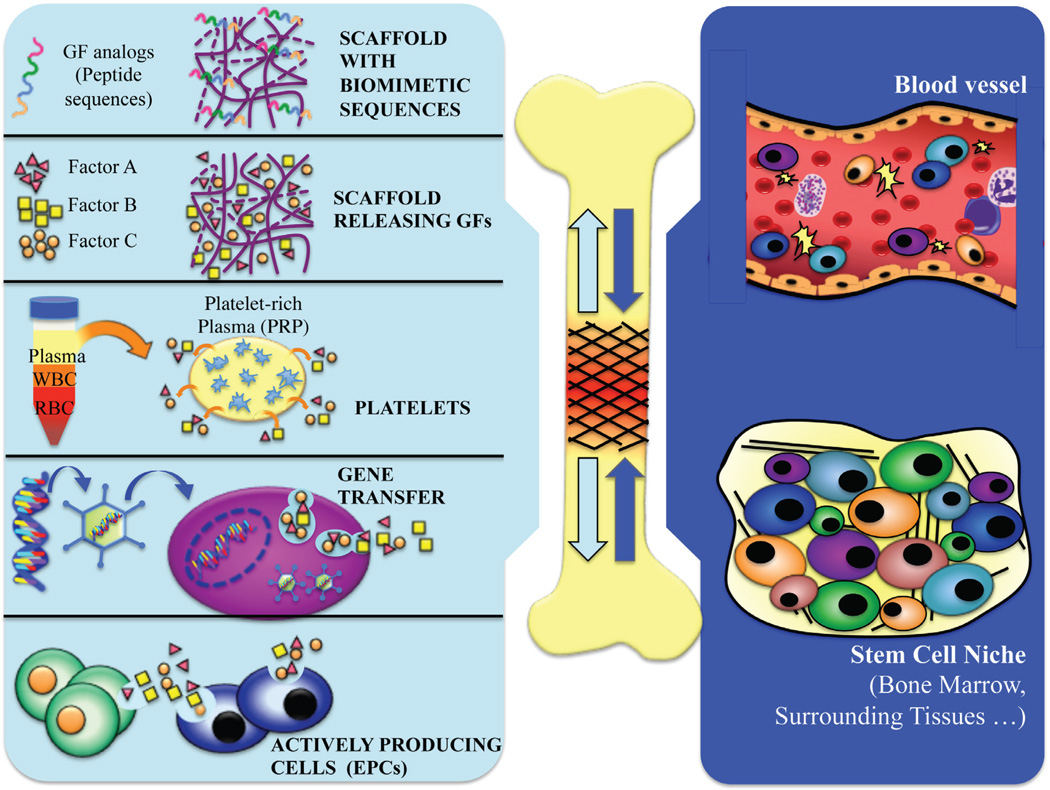

The field of bone tissue engineering (BTE) was initiated nearly three decades ago. Interest and progress in the BTE field has seen tremendous growth over the years, with an exponentially increasing number of studies and reviews published on the PubMed database since the mid-1980s (Fig. 1). The field of BTE focuses on alternative treatment options that will ideally eliminate the previously described issues of current clinically used treatments (i.e., donor site morbidity, limited availability, immune rejection, and pathogen transfer). BTE requires the collaborative efforts of scientists, engineers, and surgeons to achieve this ultimate goal of creating bone grafts that enhance bone repair and regeneration.19 The classic BTE paradigm highlights several key players: (1) a biocompatible scaffold that closely mimics the natural bone extracellular matrix niche, (2) osteo-genic cells to lay down the bone tissue matrix, (3) morphogenic signals that help to direct the cells to the phenotypically desirable type, and (4) sufficient vascularization to meet the growing tissue nutrient supply and clearance needs. Specifically, upon implantation, the construct may influence the host by releasing osteogenic and/or vasculo-genic growth factors (i.e., growth factor-releasing scaffold, scaffold with growth factor analogs, or seeding with platelet-enriched plasma), or by housing cells that are genetically engineered to or naturally release growth factors (Fig. 2). In turn, accelerated cell homing, vascularization, and bone regeneration of the defect site results. Although much progress has been made, many crucial hurdles remain to be cleared on the way to BTE becoming a true clinical reality. The following review critically considers advances and obstacles for functional BTE.

FIGURE 1.

(A) Published articles on BTE since mid-1980s on PubMed.

(B) Break-down of the articles published in 2011 according to bone tissue engineering focus (i.e., biomolecules, cells, matrices, and other, including vascularization approaches and bioreactors).

FIGURE 2.

Schematic illustration of bone tissue engineering paradigm. Factors from the implanted graft at the defect site that influence the host response may include growth factors (or their analogs, or from platelet-enriched plasma), and cells (genetically modified to release factors, or naturally produce factors). In response, cell homing and enhanced vascularization and bone regeneration will occur.

II. FUNDAMENTALS OF BONE AND DEVELOPMENTAL BIOLOGY

Bone tissue engineering (BTE) is based on the understanding of bone structure, bone mechanics, and tissue formation as it aims to induce new functional bone tissues. In other words, to successfully regenerate or repair bone, knowledge of the bone biology and its development is quite essential.

Bone possesses the ability to perform a wide array functions, and bone responds to a variety of metabolic, physical and endocrine stimuli. Bones (1) represent the foundation for our bodily locomotion, (2) provide load-bearing capacity to our skeleton and protection to our internal organs, (3) house the biological elements required for hematopoiesis, (4) trap dangerous metals (i.e., lead), and (5) maintain the homeo-stasis of key electrolytes via calcium and phosphate ion storage. In addition, bone is engaged in a constant cycle of resorption and renewal, undergoing continual chemical exchange and structural remodeling due to both internal mediators and external mechanical demands. Bone has been previously, and most appropriately, referred to as the ultimate smart material for its scar-less regenerative capacity. Functional bone tissue engineering requires the newly restored bone to be fully integrated with the neighboring host bone, and importantly, to perform the previously mentioned functions of native bone.

Bone is a highly dynamic and diverse tissue, both structurally and functionally. Macroscopic structure and mechanical properties of the more than 200 bones in the human skeletal system are largely influenced by distinct loading conditions. Skeletal structures range from long (i.e., tibia, ul-nar, etc.) to short (i.e., phalanges, etc.), flat (i.e., skull, sternum, etc.), and irregular (i.e., pelvic, vertebrae, etc.). Bone functions range from locomotion to vital organ protection. Bone tissue may also either take on a compact (i.e., cortical bone) or trabecular (i.e., cancellous bone) pattern arrangement, ranging in mechanical strength and modulus. Despite these complex features and forms, it has relative simplicity in terms of its microscopic, hierarchical architecture. Specifically, bone extracellular matrix (ECM) is composed of both a non-mineralized organic component (predominantly type-1 collagen) and a mineralized inorganic component (composed of 4-nm-thick plate-like carbonated apatite mineralites). The nano-composite structure (tough and flexible collagen fibers reinforced by hydroxyapatite crystals) is integral to the requisite compressive strength and high fracture toughness of bone.

A. Bone Development

Bone formation occurs via two very distinct pathways, intramembraneous and endochondral. In either case, mesenchymal cellular condensation first occurs and serves as a template for subsequent bone formation. Intramembraneous bone formation involves mesenchymal progenitor cells differentiating directly into osteoblasts and the subsequent development of parts of the mandible, clavicle, and many cranial bones. Most bones in the body (i.e., all long bones and vertebrae), however, are formed through endochondral bone formation. This process involves mesenchymal progenitor cells first differentiating into chondrocytes, which are responsible for depositing a cartilaginous template that is later mineralized and replaced by bone.

Although distinct differences in the bone composition and structure occur via endo-chondral and intramembranous ossification, several molecular regulators are shared.20,21 For instance, several key molecules, including Indian Hedgehog (Ihh), parathyroid hormone related peptide (PTHrP), bone morphogenetic proteins (BMPs), vascular endothelial growth factor (VEGF) and fibroblastic growth factors (FGFs), are critical regulators in both processes.22 In en-dochondral ossification, BMPs are responsible for the initiation of mesenchymal condensations, and Ihh and PTHrP form a critical feedback loop that mediate the balance between chondrocyte proliferation and hypertrophy and regulate the thickness of the growth plate. Likewise, during intramembranous bone formation, these key players are required to induce uncommitted mensenchymal progenitor cells along the osteogenic pathway as pre-osteoblasts, which co-express chondrocytic and osteoblastic markers simultaneously. Furthermore, in both processes, bone remodeling is required for the maintenance of all normal healthy bone, which involves a balance between osteoclastic bone resorption and osteoblastic bone formation.23

1. Bone Defect Repair

Interestingly, upon fracture, bone is repaired by a process that recapitulates many of the events of both intramembraneous and endochondral bone formation, and it uniquely heals without the formation of scar tissue.24,25 Initially, hema-toma formation is accompanied by an inflammatory response, and the recruitment of many of the signaling molecules involved in the regulation of new bone formation (i.e., ILs, TNF-α, FGFs, BMPs, PDGF, VEGF, etc.). At the cortex and periosteum, intramembranous bone formation immediately occurs. The external soft tissues stabilize the fracture by the formation of a callus, which subsequently undergoes chondrogenesis, and then a process highly similar to endochondral ossiflcation. More specifically, after the callus forms, chondrocyte proliferation decreases as the tissues begin to mature (i.e., hypertrophy) and calcify the matrix. In-growing blood vessels carry chondroclasts, which are responsible for resorbing the calcified cartilage and osteoblastic progenitors, which begin the process of new bone formation. The mechanical continuity of the cortex is achieved via subsequent remodeling of the newly formed bone.

The question remains: What is the optimal method for bone regeneration? Should BTE focus more on bone development processes or on bone defect repair? In the opinion of the authors, BTE should not exclusively focus on one or the other, but both. In situations requiring bone regeneration, the initial events always involve he-matoma formation and an early inflammatory response, which is largely responsible for the recruitment of host cells and release of critical signaling molecules. From there, emulation of some aspects of normal bone tissue development and remodeling may hold the key to the future success of BTE. Seminal developmental biology principles that may help the future success of BTE include the following:

The use of pluri- or multipotent stem cells

The identification of critical genes, growth factors, and signal transduction cascades that mediate bone formation

The physical process of bone formation

Complex interactions between epithelium and mesenchyme within the underlying connective tissue

The understanding of mesenchyme encoding tissue-specific patterns

The understanding that normal tissue healing involves progressive remodeling and restructuring of pre-existing tissue structures

The importance of the tissue microenviron-ment’s physical properties (i.e., “mechanother-apy”) (8) Angiogenesis and neo-vascularization of the newly formed bone tissue

Incorporation of developmental biology insights will critically impact future tissue engineering approaches. For instance, future approaches may include appropriate extracellular matrix molecules or adhesive ligands that target stem cells mediating earlier stages of tissue remodeling and regeneration.26 And for the promotion of angiogenesis, BTE will aim to develop scaffolds that incorporate growth factors and possess the necessary porosity for vascular ingrowth.27 Furthermore, engineering featuring micro- and nano- meter surface topography of these scaffolds is critical for directing cellular adhesion, spreading, and proliferation. On a broader scale, for successful bone tissue engineering, it is critical to develop a scaffold that is inspired by the natural processes of developmental biology and promotes tissue remodeling, rather than simply supporting final tissue form and function.

III. RECENT ADVANCES IN BTE

Although bone is a highly vascularized tissue and has the ability to regenerate, beyond a critical point, clinical intervention measures are required. It is the hope that BTE will be the future treatment of choice, as it will likely eliminate many of the pitfalls of current treatments. In this section, we discuss the status and key issues for BTE components (i.e., biomaterials, cells, signaling molecules, and vascularization).

A. Biomaterials

1. Osteoinductive Materials

Osteoinductive or “smart” biomaterials have the ability to induce ectopic bone formation by instructing its surrounding in vivo environment to form bone.28–30 Although the biological mechanisms of this phenomenon have not been fully elucidated, it is well recognized that these materials hold great potential for bone tissue regeneration. An array of biomaterial families have demonstrated having osteoinductive properties, including natural and synthetic ceramics (i.e., hydroxyapatite (HA) and variouscalcium phosphate compositions, and their composites (i.e., HA/ poly(lactic-co-glycolic acid) (PLGA). A number of studies have illustrated osteoinduc-tion by calcium phosphate (CaP)-based bioma-terials in various physical forms.31 Specifically, osteoinductivity has been demonstrated with CaP-based biomaterials in the form of sintered ceramics,32–36 cements,37,38 coatings,39,40 and coral-derived ceramics41–43 in a variety of animal models. Other ceramics, such as alumina ceramic and porous bioglass, have also been recently identi-fied as being osteoconductive.44 In addition, polymer/ceramic composites, such as PLGA/ HA, have been shown to be osteoinductive and to induce bone formation ectopically.45–50 However, it is critical to note that other material properties play a critical role in osteoinduction, aside from the chemical composition of the biomaterial, which may include porosity of the biomaterial implant and its surface properties, such as nano/micro topography. To some extent, the level of osteoinductivity also depends on the species used for the study (i.e., interspecies variation). Two main theories have been proposed to explain the observed osteoinductivity. The first is based on the biomaterial surface features that absorb and present osteoinductive factors to the surrounding cells. The second hypothesis is that the calcium phosphate–based materials release calcium and phosphate ions, which later influence stem cell differentiation into bone cells. No conclusive evidence exists for either of these hypotheses.29

2. Hybrid Materials

A number of synthetic and natural polymers, as well as ceramics have been developed and identified as biomaterials for BTE. Biomaterials for bone-scaffolding applications have to possess certain physical, chemical, and biological properties. Although great strides have been made, it is difficult for any biomaterial to satisfy all of the listed requirements. Recent efforts have been aimed, however, in the direction of developing hybrid biomaterials. These are nothing but the combination of two or more biomaterials, with enhanced functionalities, in the form of either co-polymers, polymer–polymer blends, or polymer–ceramic composites. These are considered an advanced class of biomaterials that are more optimal for bone scaffolding applications.

a. Co-polymers

Co-polymers are defined as being derived from two or more monomeric species. For example, poly (lactide-co-glycolide) (PLGA) co-polymer systems are derived from poly lactide, which displays a glass transition temperature (Tg) above room temperature with an unreasonably long degradation time, and polyglycolide, which displays Tg below room temperature and a shorter degradation time. The development of the PLGA co-polymer system allowed for the tuning of Tg and degradation based on the need. Similarly, other co-polymer systems have been developed, such as PLGA-PCL, PLGA co-polymerized with PLL, and PLA- co-polymerized PCL.54 In addition, DegraPol™ is another example of a co-polymer that was originally synthesized for bone regeneration.55

b. Polymer–polymer blends

Polymer blends involve a mixture of two polymers. By choosing polymers with required intermolecular or Van der Walls interactions, it is possible to design a miscible blend system with enhanced properties. PLGA blends with polyphosphazenes are a prime example. It is known that PLGA biomaterials produce acidic byproducts upon degradation, and this has been a major problem, because the long-term tissue exposure to acidic products may result in tissue necrosis and implant failure. On the other hand, polyphosphazenes release neutral or basic products in degradation.56 Therefore, PLGA has been blended with a wide variety of polyphosphazenes to achieve novel biomaterials with near-neutral degradation products.57–62

c. Polymer-ceramic composites

Composite materials represent attractive candidates for BTE applications because bone is, in fact, a composite material composed of a mix of inorganic hydroxyapatite crystals (HA) and organic collagen fibers.63 Furthermore, polymer-ceramic composites capitalize the advantages of each of its components (i.e., biodegradable polymer and ceramic materials), and have demonstrated success in bone regeneration that exceeds the results when these materials are used separately.64

Composites of HA and various polymers, including poly(lactic acid) (PLA),65 PLGA,66 gelatin,67 chitosan,68,69 and collagen70 have been successfully fabricated and have demonstrated enhanced bone formation in vitro and/or in vivo. These materials are considered to be biomimetic and to stimulate the formation, precipitation, and deposition of calcium phosphate from simulated body fluid (SBF), resulting in enhanced bone-matrix interface strength.62 Furthermore, Ma et al. demonstrated porous poly(L-lactic acid) (PLLA)/HA composite scaffolds to have superior osteoconductivity properties and to promote enhanced osteoblastic cell survival, proliferation, and expression of bone-specific markers (i.e., a bone sialoprotein and osteocalcin) in comparison to pure PLLA scaffolds during 6 weeks of in vitro cultivation.71

Upon implantation, the addition of HA to natural polymer scaffolds has been shown to improve the bioactivity and mechanical properties compared to polymer control scaffolds72 and to potentially reduce adverse effects associated with the degradation of some synthetic polymers.73 For instance, Higashi et al. observed accelerated and increased bone formation with composite PLA/HA scaffolds in a rat femur defect model, in comparison to pure PLA scaffolds.74 Overall, polymer/HA composites demonstrate osteoconductivity superior to their pure polymer counterparts.

3. Advanced Hydrogels

Hydrogels, due to their unique biocompatibility and desirable physical characteristics, have long been used as materials for tissue engineering. Hydrogels not only serve as matrices for tissue engineering and regenerative medicine but also are capable of mimicking extracellular matrix topography and delivering required bioactive agents that promote tissue regeneration.75,76 From the naturally derived collagen and gelatin gels to the synthetic poly(ethylene glycol) materials, poly(vinyl alcohol)-based hydrogel systems have been utilized for bone tissue engineering.76,77

Recently, self-assembling peptides have gained attention for forming scaffolds, as they are completely biological, biocompatible, and biodegradable.78,79 Self-assembling systems aim to mimic the natural extracellular matrix, and peptides, which may be readily synthesized chemically and biologically, conveniently serve as the starting material. For example, self-assembling RAD16-I (i.e., PuraMatrix™, Cambridge, MA) can form an injectable nanofiber network or hydrogel upon implantation. In other words, RAD16-I peptides may be injected, and via interactions with body fluids, they will gel and adopt the physical geometry of the tissue defect. Further, self-assembling RAD16-I, as well as other peptides such as P11-4, have been shown to support osteogenesis both in vitro and in vivo.80–83 For instance, Misawa et al. observed bony bridge formation after the injection of RAD16-I into small (i.e., 3 mm) bone defects of mice calvaria. Lastly, these self-assem-bling nano-featured biomaterials have been sown to be non-immunogenic and biodegradable, safely breaking down into amino acids that may be readily and easily cleared in vivo. Thus, SAPs represent a novel class of biomaterials that offers a promising option for BTE applications.

4. Immuno-modulatory Biomaterials

Immunobioengineering aims to design materials that have the ability to modulate or manipulate the immune system in a favorable manner for enhanced bone repair and regeneration.84 Typically, the host’s immune reaction to an implant begins with the initial acute response to the surgical injury and innate recognition of the foreign material, which is subsequently followed by adaptive immunity mediated chronic inflammation in response specific recognition of antigens. Novel strategies in immunobioengineering are highlighting the importance of incorporating rational control and modulation, and importantly not elimination, of host inflammation into the design of tissue engineering strategies methods. A list of immunomodulating biomate-rial strategies are presented in Table 1.

TABLE 1.

Immunomodulation Strategies for Biomaterials

| Biomaterial choice | Material type |

In vitro: Decreased dentritic cell maturation (decreased levels of CD40,CD80, and CD86, HLA-DQ HLA-DR, CD83); increased secretion of TNF–a (295,296) In vitro: Decreased natural killer cell activity, decreased T- and B-cell proliferation85 |

| Surface property modulation |

Surface treatments | |

| Hydrophilic surface |

In vitro: Increased apoptosis of adherent primary human macrophages; increased levels of anti-inflammatory cytokine IL-10 and decreased levels of inflammation-associated chemokine IL-8297,298 |

|

| Anti-fouling coating |

In vitro: Decreased passive cell attachment and cell activation (i.e., non-specific cell-material interaction)299, 300 |

|

| Surface topography | ||

| Aligned structures |

In vitro: Decreased initial monocyte adhesion In vivo: Increased cell infiltration; decreased fibrous capsule88 |

|

| Micro/Nano structures |

In vitro: Increased pro-inflammatory cytokines IL-1, IL-6, TNF-a301 In vivo: Decreased/ thinner fibrous capsule302 |

|

| Bioactive molecule incorporation |

Providing integrins adhesion sites |

In vitro and in vivo: RGD and PHSRN domains increased formation of FBGC303,304 |

| Coupling of anti- inflammatory drugs to biomaterials |

In vivo: Decreased anti-inflammatory cytokines, prostaglandins, proteolytic enzymes, free oxygen radicals and nitric oxide; Decreased T helper (Th)1-directed immunity305,306 |

|

| Delivery of growth factors/bioactive molecules |

In vivo: Increase macrophage chemotaxis and activation307 In vivo: Decreased capsule formation308 |

|

| Artificial ECM | Hydrogels |

In vivo: host response dependent on species of origin, tissue of origin, processing materials, method of terminal sterilization309 |

| Artificial ECM coatings for synthetic implants |

In vitro and in vivo: Increased cell adhesion and proliferation310,311 | |

Several specific strategies have been proposed in immunobioengineering, namely selection of appropriate material type, biomaterial surface modulate (i.e., surface treatments, surface topography), and incorporation of artificial extracellular matrix and/or bioactive molecules. Although traditionally it has been accepted that the implants should be immune-inert, it is proving to be more beneficial to design materials that allow for enhanced cell-specific responses that encourage accelerated wound healing and bone tissue regeneration (i.e., increased boneforming cell activity, and decreased NK cell activity and T and B cell-mediated immunity). One of these strategies is to design biomateri-als of ECM similar composition and structure. For instance, Smith et al. demonstrated blends of polydioxanon and collagen or elastin to have immunomodulating effects by decreasing the activity of natural killer cells, as well as T- and B-cell proliferation.85 In addition, in immuno-modulating biomaterials, the biomaterial surfaces may be modified to become more immuno-compatible. The biomaterial surface is the first most critical factor for host acute immune response upon implantation, since the surface chemistry is responsible for the type, intensity, and conformation of serum proteins that are absorbed. The biomaterial surface should limit macrophage adhesion and activation as well as their fusion into foreign body giant cells (FBGCs). For instance, hydrophilic surfaces are associated with low-integrin binding sites and, therefore, decreased dendritic cell maturation and macrophage spreading, and increased macrophage apoptosis.86,87 Biomaterial surface topography, and micro/nano-scale architecture play a significant role in modulating and activating the immune system. Cao et al. demonstrated decreased capsule formation and increased tissue regeneration in scaffolds with aligned fiber topography compared to scaffolds with randomly aligned fibers.88 Biomaterial surface treatments may also be employed to shield the biomaterial from protein absorption (i.e., coating with mic-roparticle hydrogels, surfactant polymers, etc.), or to deliver bioactive molecules (i.e., growth factors, anti-inflammatory drugs).88

Specific immunobioengineering studies have investigated the effects of pharmacologic modulation of the inflammatory response on bone regeneration in vivo; they involve cytokine-specific agents, corticosteroids, prostaglandins, non-ste-roidal anti-inflammatory drugs, and selective prostaglandin agonists.89 For instance, pro-inflam-matory synthetic thrombin peptide TP508, which activates the same signaling pathways stimulated by TNF-α, IL-1, and other pro-inflammatory cy-tokines during fracture healing, has been shown to have anabolic effects and to enhance in vivo bone regeneration.90 In a rat model, a single injection of TP508 into a femoral fracture resulted in increased strength of the healed bone, vascularization of fracture site, and accelerated fracture repair and regeneration.91 Furthermore, studies have reported similar effects on bone healing in rabbits, with the controlled release of TP508 from various biodegradable scaffolds (i.e., PLGA microspheres and poly(propylene fumarate) scaffolds).92,93

Selective prostaglandin agonists represent another interesting immunomodulating target for enhanced bone regeneration. Previously, prostaglandins have been avoided as a therapeutic agent for bone repair, due to the risk of well-recognized side effects, including severe systemic inflammation. However, the main effects of prostaglandins on bone have been recently identified to occur selectively via two prosta-glandin receptors (i.e., Prostaglandin E2 type 2 (EP2) and EP4 receptors); thus, the systemic side effects may be avoided. Several studies have demonstrated the positive effects of selective EP2 or EP4 receptor agonists on bone fracture healing in various animal models.94,95 In dogs, healing of critical-size long-bone segmental defects in the radius and tibia was accelerated and significantly enhanced with EP2 agonists encapsulated in a PLGA carrier.95

Although these results are extremely promising thus far, further studies are needed to investigate more immunomodulating targets. Most importantly, strategies to integrate inflammatory modulation into tissue engineering strategies to enhance bone regeneration are needed.

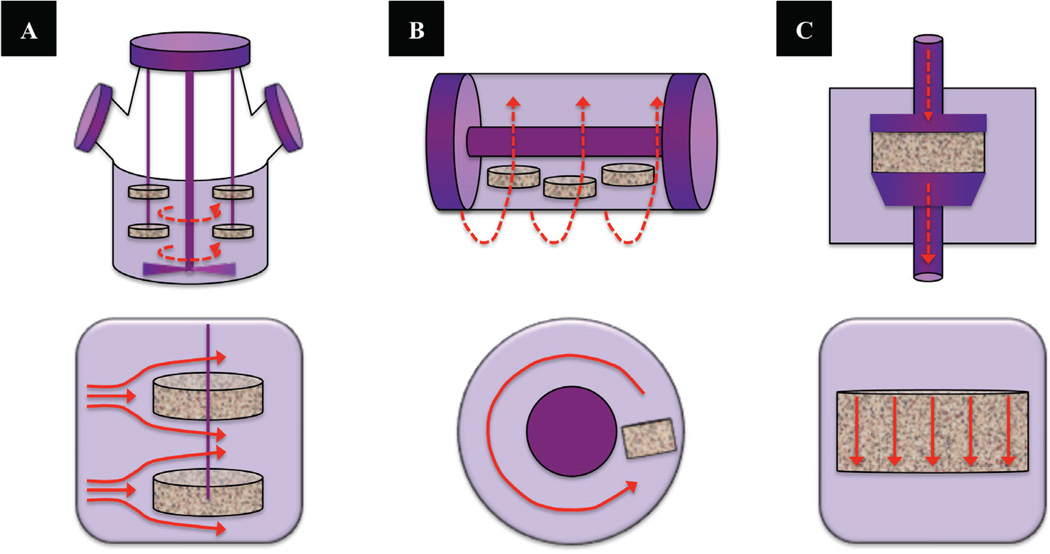

B. Biodegradable Scaffolds

1. Scaffold Mechanical Integrity, Structure, and Mechanotransduction

A key feature of BTE scaffolds is to provide temporary mechanical integrity at the defect site until the bone tissue is repaired or regenerated, and normal biomechanical function is restored. For the bone tissue engineering scaffold to be “functional” immediately upon implantation, its biomechanical properties must match the physical demand of the healthy surrounding bone.96 In addition, the mechanical strength of the scaffold affects the mechanotransduction of the adherent bone cells on the scaffold, which plays a critical role in the bone repair and remodeling processes. It has been proposed that, generally, the structural biomechanics of the BTE scaffold is related to the osteoconductive properties of the scaffold, while mechanotrans-duction is related to its potential osteoinduc-tive properties.97 Biomechanical stimuli of cells due to the scaffold deformation largely influences osteoinduction (i.e., bone ingrowth from the host). Therefore, as suggested by Sikavitsas et al., a mechanotransduction strategy may be used to control the function of bone cells in vivo by designing a scaffold with mechanical properties that allow ‘osteoinductive fluid flow’ in the scaffold. By combining three-dimensional imaging, flow modeling, and numerical simulation of scaffold physical properties, threshold permeability (k = 1/32φr2 where r is the hydraulic radius and φ is equivalent to the required cut-off radius) may be determined. Specifically, it was verified that a threshold permeability of ∼3 × 10−11 m2 of a porous bone graft implant was necessary for inducing vascularization and mineralization in an implant.98,99

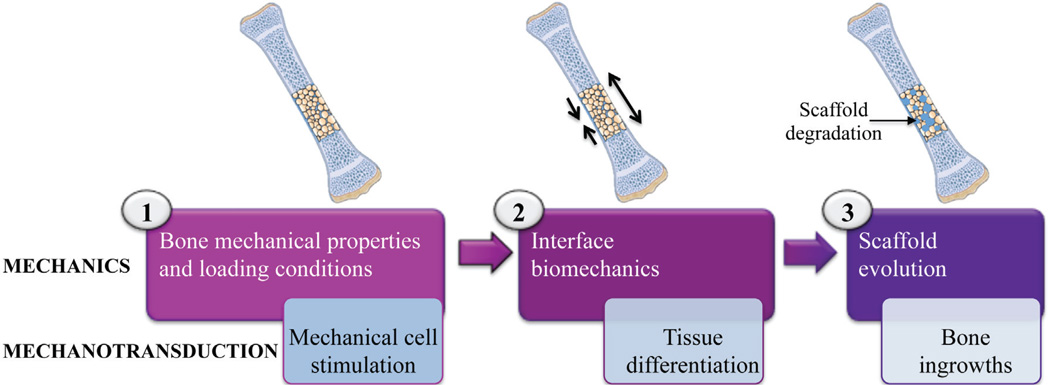

The BTE biomechanical paradigm has been well described in a step-wise fashion, where each step holds the mechanical aspects of the scaffold central to insure the safety of the surgical procedure using a BTE scaffold (Fig. 3).97 The first step, which involves the bone mechanical properties and loading conditions, is analogous to the primary fixation of the scaffold. At this point, the BTE scaffold should not induce a stress-shielding effect, which will result in peri-scaffold bone resorption as seen in metallic joint implants. Also, the elastic property of the BTE scaffold should not exceed that of bone, to maintain a proper mechanical stimulation on the peri-scaffold bone, which depends on the loading conditions. The second step involves interface biomechanics and may be identified as the secondary fixa-tion. Here, the mechanical properties of the BTE scaffold may be adapted to generate interface scaffold-bone mechanotransduction, which has been shown to influence tissue differentiation and osteointegration of the scaffold.100 The third step, which may be termed ‘final fixation,’ involves scaffold evolution, in which the ingrowing bone offers support to the mechanical load as the BTE scaffold degrades. Thus, each step revolves around mechanical aspects, which induces a biological reaction in and around the BTE scaffold via mechanotransduction. It has been suggested that the separation between these steps may be represent an engineering approach in the mechanical design of bone scaffolds. Ideally, if mechanical considerations can be used to confer osteoinductivity to a BTE scaffold, the dependency on osteogenic factors and bioreactors may be reduced. This might eventually lead to the development of an off-the-shelf product.101

FIGURE 3.

Illustration of a three-step biomechanical paradigm in BTE. In the first step, upon implantation, it is critical that the mechanical properties of the BTE scaffold should closely match that of the surrounding host bone tissue and loading conditions to reduce the stress-shielding effect. The second step involves interface biomechanics, and should allow for interface scaffold-bone mechanotransduction for enhanced osteointegration of the scaffold. Lastly, as the scaffold degrades, ingrowing bone tissue will begin to support the mechanical load of BTE scaffold. Adapted from Pioletti (97).

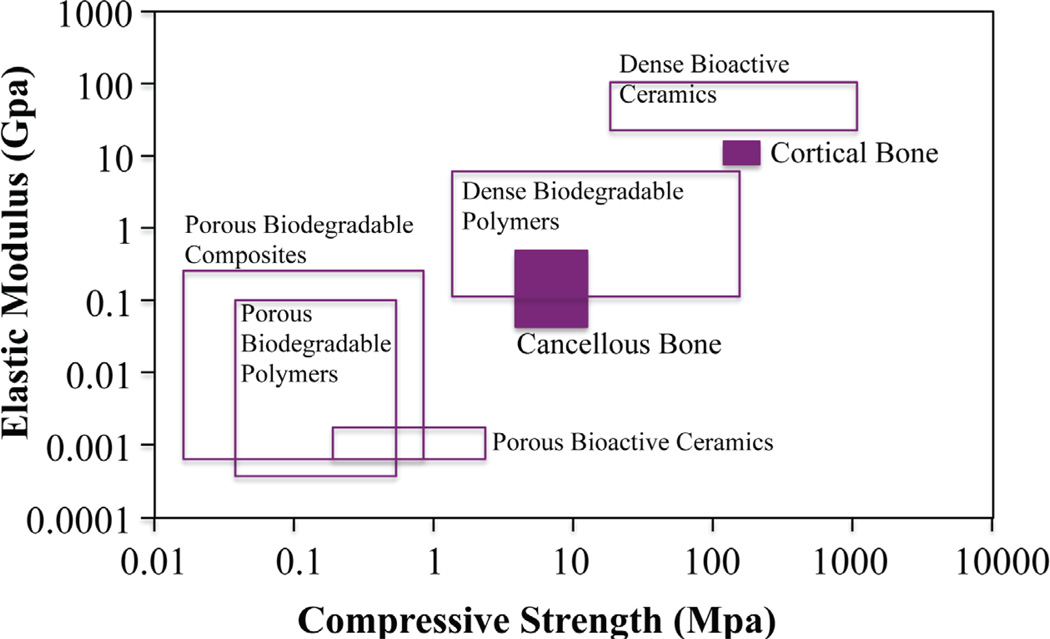

Mechanical properties of human bone vary tremendously according to location and function (i.e., load or non-load bearing). Again, the restorative scaffold’s mechanical properties should be modulated or tailored to match the demands of the defect site, to decrease or avoid complications such as stress shielding, implant-related osteopenia, and subsequent re-fracture.102 The scaffold’s material composition largely influences its mechanical properties. Dense ceramics (HA, calcium triphosphate) possess elastic moduli and compressive strength similar to human cortical bone; however, they are brittle and display slow degradation rates (Fig. 4).103 On the other hand, biodegradable polymer scaffolds display human cancellous bone compatible mechanics with tunable degradation. For this reason, the development of polymer-ceramic composite BTE scaffolds is becoming increasingly attractive: scaffold properties can be tailored to the particular mechanical and physiologic demands of the host tissue by effectively controlling volume fraction, morphology, and arrangement of the inorganic particulate phase in the polymer matrix. For example, widely investigated composites for BTE involve the incorporation of bioceramic and bioglass particles, carbon nanotubes (CNTs), or magnesium metallic or alloy particles.104–107 These inorganic inclusions positively affect the mechanical properties leading to reinforcement of the scaffold structure104 compared with non-composite polymer scaffolds. The enhancement of mechanical properties depends strongly on the inclusion shape and size distribution, as well as on the quality of the inclusion distribution in the matrix and on the strength of the inclusion–matrix interface. Although the composite strategy is promising, the scaffold mechanical properties are nowhere close to demonstrating the human cortical bone mechanical properties. On the other hand, composite scaffolds display enhanced functionality. In a study conducted in our lab on composite CNT/PLGA microsphere scaffolds, we observed increased biomimetic biomineralization of the composite scaffolds after a 14-day incubation in simulated body fluid (SBF) in vitro, in comparison to PLGA polymer scaffolds (Fig. 5). The increased bio-mineralization may be attributed to the CNTs present in the composite scaffold. The increased mechanical strength of the composite scaffolds can be attributed to the increased CNTs at the joining microsphere–microsphere areas. Thus, by forming composites with CNTs, the overall mechanical and biomimetic properties of a polymer scaffold may be effectively enhanced.104

FIGURE 4.

Elastic modulus versus compressive strength values of various BTE biomaterial classes compared to human bone. Adapted from Rezwan et al. (103).

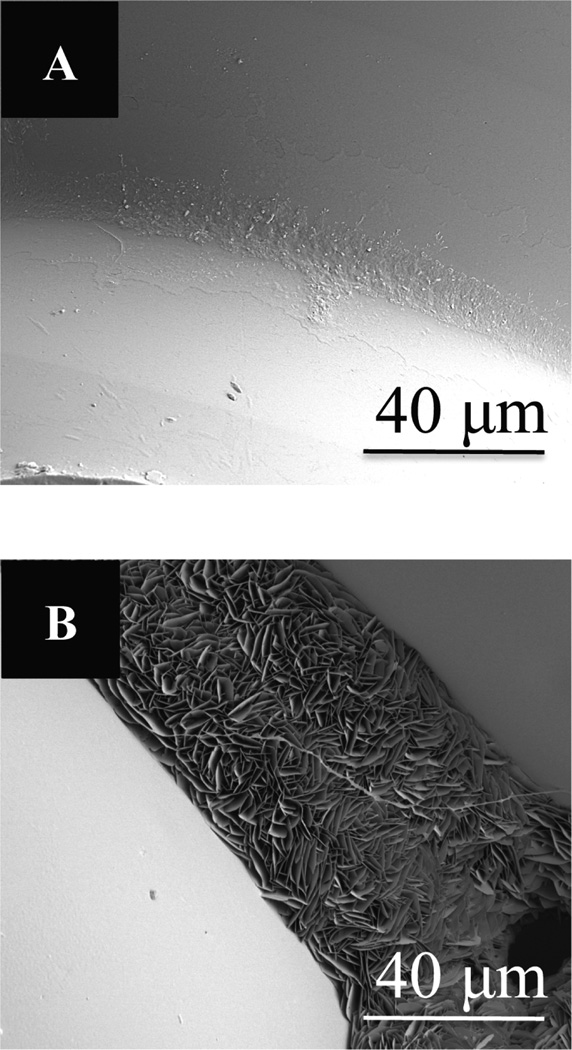

FIGURE 5.

SEM images of (A) PLGA (50/50) microsphere scaffolds, and (B) composite carbon nanotube/PLGA (50:50) microsphere scaffolds after 14 days in simulated body fluid. Crystalization is seen the joining areas of mi-crospheres in only composite CNT/PLGA scaffolds. Scale bar = 40 µm.

Recently, biodegradable metals gained attention as the new generation biomaterials. They offer good mechanical properties, and therefore may be potent biomaterial options to make scaffolds with cortical bone–like mechanical properties. Particularly, magnesium metal has attracted attention because it has density and mechanical strength similar to cortical bone.108–110 Moreover, magnesium is present in small quantities in our bones. One particular disadvantage of magnesium is its rapid and uncontrolled degradation. Although this problem can be partially addressed by alloying magnesium with other metals such as zinc and aluminum, further investigations to develop and characterize magnesium-based scaffold systems for BTE are needed.111

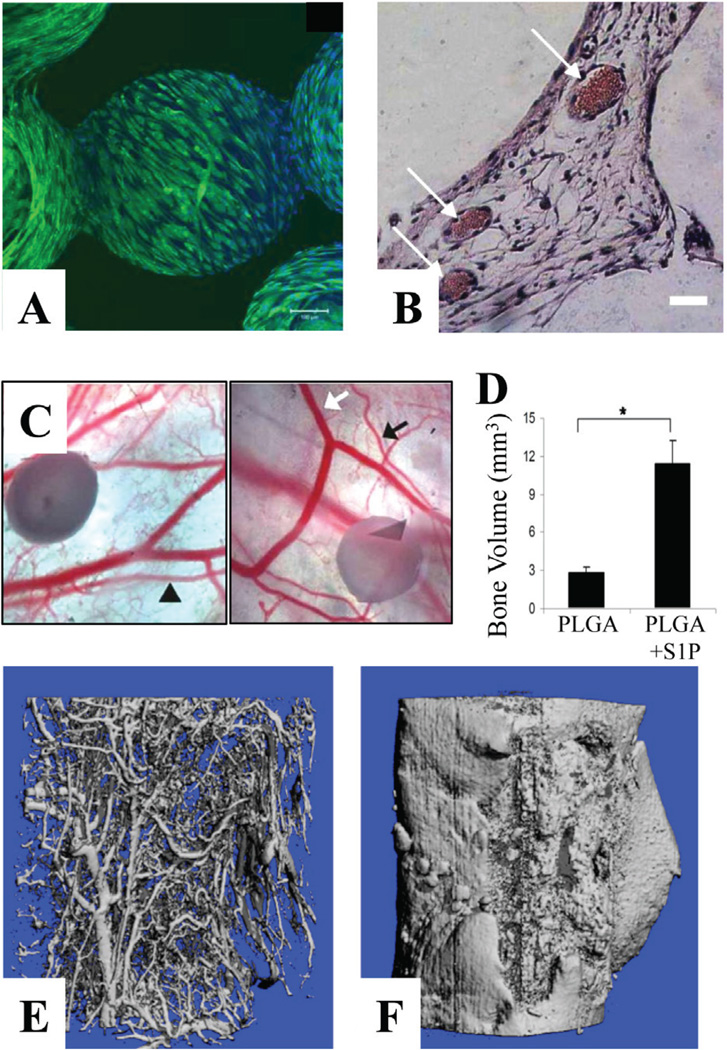

2. Scaffold Porosity

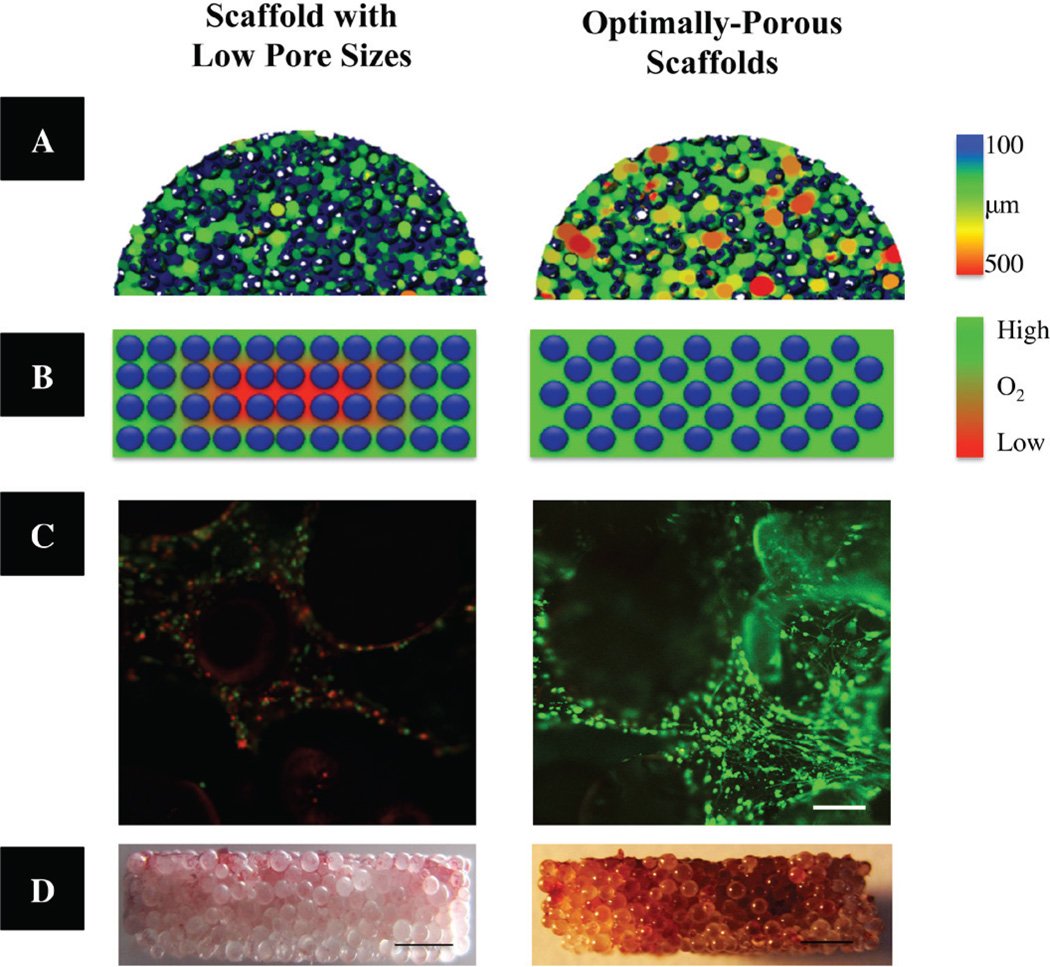

Microporosity is a critical element of the osteoconductive properties of scaffold material and the resultant bone tissue ingrowth and vascularization. Scaffold pore structure (i.e., pore size, volume, and interconnectedness) is an essential consideration for proper cell growth, cell migration, nutrient flow, vascularization, and better spatial organization for cell growth and ECM production.112,113 Although some ambiguity remains surrounding the optimal porosity and pore size for a three-dimensional bone scaffold, studies suggest that scaffolds currently designed with small pore sizes (i.e., < 200 µm) display in vitro and in vivo osteoblast survival and bone formation limited to the periphery, due to decreased oxygen and nutrient diffusion throughout the scaffolds.27 On the other hand, scaffolds with a mean pore size of 300 µm display increased osteoblast proliferation and differentiation throughout the entire scaffold, due to enhanced neo-vascularization and mass transport of oxygen and nutrients.114–117 Porogen leaching was used in combination with several traditional scaffold fabrication techniques, such as gas foaming,118,119 freeze drying,120 and phase separation121 to fabricate highly porous scaffolds. Recently, the authors have combined a microsphere sintering technique with porogen leaching to develop optimally porous and mechanically compatible scaffolds for BTE.122 As seen in Fig. 6, porogen (i.e., NaCl cystrals) leaching combined with thermal sinter of PLGA microspheres allows for the fabrication of consistent and reproducible optimally porous scaffolds with increased porosity and interconnectivity, which consequently allowed for improved oxygen availability (Fig. 6B), pre-osteoblastic cell survival (Fig. 6C) and mineralization (Fig. 6D) in the interior of the constructs. However, as porosity and mean pore sizes increase, mechanical strength is scarified; determination of a balance between mechanical strength and porosity is crucial. This study by the authors demonstrated that, by fabricating scaffolds with optimal pore size, it is possible to maintain oxygen tension and pH levels inside a scaffold that are almost similar to the values measured on the scaffold exterior. Such scaffolds, called oxygen tension controlled matrices, have been proven to support cell proliferation and mineralization throughout the scaffold structure (i.e., fully osteoconductive) in vitro and in static culture, and they may have the potential to repair large-scale or critical-size bone defects in vivo.123,124

FIGURE 6.

Optimally-porous, mechanically strong biodegradable scaffolds for enhanced bone regeneration. (A) Reconstructed MicroCT 3D porosity images demonstrating significantly increased interconnected pore sizes in optimally-porous scaffolds. (B) Schematic illustration of available oxygen levels throughout the scaffolds in vitro. (Scale from red to green demonstrating increasing oxygen levels.) (C) Pre-osteoblast cell viability in the center of the constructs after 14 days in vitro. Scaffolds with increasing porosity resulted significant cell survival in the interior of the macro-porous construct (right) compared to control scaffolds (left) (live cells = green; dead cells = red). Scale bar = 200 µm. (D) After 28 days in osteogenic medium, Alizarin Red staining was performed. Optimally-porous scaffolds displayed mineralization throughout the thickness of the scaffold, where as scaffolds with low pore sizes displayed mineralization to limited to the surface of the scaffolds. Scale bar = 1000 µm. Adapted and modified from Amini et al. (122).” (D) After 28 days in osteogenic medium, Alizarin Red staining was performed. Optimally-porous scaffolds displayed mineralization throughout the thickness of the scaffold, where as scaffolds with low pore sizes displayed mineralization to limited to the surface of the scaffolds. Scale bar = 1000 µm. Adapted and modified from Amini et al. (122).”

3. Nano-Featured Scaffolds

Scaffolds are meant to serve as a synthetic and temporary ECM replica that supports cell attachment and guides three-dimensional bone tissue formation. It has been well established that native bone cells interact with nano-scale proteins and minerals. Specifically, the main constituents of bone ECM (i.e., Type I collagen fibrils and hydroxyapatite (HA) crystals) are nanometers in diameter; all living molecular building blocks (i.e., proteins, lipids, carbohydrates, and nucleic acids) are governed by their nanoscale sizes, patterns, and folding. Thus, bone cells are predisposed to adhere, grow, proliferate, differentiate, and produce ECMs based on these nanoscale interactions, making nano-structural topographical properties of scaffold critical for osteoinductivity.125 Specifically, by decreasing material size to the nanoscale, scientists are able to dramatically increase the scaffold’s surface area, surface roughness, and surface area-to-volume ratios, resulting in superior physiochemical properties.

Nano-topography significantly influences osteoinductivity and osseointegration of the BTE scaffold.126–129 Specifically, studies suggest that osteoblasts demonstrate increased cell adhesion and proliferation, ALP activity, and enhanced expression of osteoblast differentiation markers RunX2, osteocalcin, and bone sialoprotein (BSP) on nano-featured biomaterials.130–134 Results from these studies suggest that nanotopography of bone scaffolds will stimulate bone formation and enhance bone-implant integration, leading to better tissue repair and regeneration at the bone implant–biomaterial interface.

Scaffold fabrication techniques that allow for development of nano-featured scaffolds include electrospinning,135–138 molecular self assembly,139–142 and phase separation.143 Nano-featured scaffolds can also be made from self-assembled into nanotubes/nanofibers that can even more accurately simulate the dimensions of natural entities, such as collagen fibers. For instance, osteogenic helical rosette nanotubes formed through the self-assembly of DNA base pairs (i.e., guanine and cytosine) in aqueous solutions have been reported for use in BTE applications. These osteogenic nanotubes have tailorable amino acid and peptide side chains that enhance osteoblast adhesion and inhibit fi-broblast adhesion (i.e., lysine and RGD); they have served as excellent mineralization templates to assemble a biomimetic nanotube/HA structure.144

4. Scaffold-induced cell homing

Stem-cell homing is a term that describes stem cell recruitment to injured tissues or their ability to navigate to other target niches/locations following mobilization.145,146 For example, a natural healing process in our bodies involves the inherent ability of mesenchymal stem cells (MSCs) to mobilize into circulation and migrate to an injury site, allowing for their participation in the regenerative process.147

For better tissue regeneration, various methods are being investigated to achieve enhanced cell homing to defect sites. These methods involve either cell-based approaches (i.e., stem cells engineered to be more responsive to the cues), or scaffold-based approaches (i.e., defect site, implanted scaffold and/or navigation cues more attractive or obvious to the cells).148 In the cell-based approach, cells are modified or engineered to express markers that are useful in guiding them to the regeneration site. For instance, MSCs modified with a nanometer-scale polymer containing sialyl Lewisx roll toward the inflamed tissue. Sialyl Lewisx is found on the surface of leukocytes and is responsible for cell rolling via the interaction with certain types of selectins present in the inflamed tissue. Sarkar et al. demonstrated surface engineered MSC rolling and homing in an inflamed ear model of the mouse.149

The latter approach or “scaffold-based homing” is based on releasing the chemokines responsible for MSC homing through biodegradable scaffolds placed in the defect site. Although the mechanisms of the mobilization of key cellular players have not yet fully elucidated, several key molecules have been identified as important factors. For instance, specific chemokine receptors (e.g., CCR1, CCR7, CCR9, CXCR4, CXCR5 and CXCR6) are important mediators. CXCR4 is the receptor of CXCR12 [also referred to as stromally derived factor-1 (SDF-1)], which has been identified to have a critical role in the recruitment and cell guidance of MSCs to bone healing sites.150 Furthermore, studies conducted by the authors have shown SDF-1 to be up-regulated in high-density MSC-seeded scaffolds in vitro.151 Also, in a mouse tibia fracture model, Granero-Molto et al. demonstrated that MSCs migrate to the injury site in a CXCR4-dependent manner.152 Another important cell type for bone regeneration and neovascular-ization of the defect site includes endothelial progenitor cells (EPCs). Various cytokines responsible for their mobilization include VEGF, stem cells factor (SCF), monocyte chemoat-tractant protein (MCP)-1/-3, and SDF-1.153 For example, Schantz et al. demonstrated enhanced cell migration and proliferation within polycap-rolactone scaffolds that delivered VEGF, SDF-1, and BMP-6 in a subcutaneous rat model.154 The incorporation of various mimetic peptide sequences (i.e., arginine-glycine-aspartic acid (RGD), glycine-phenlalanine-hydroxyproline-glycine-glutamate-arganine (GFOGER), Tyr-Ile-Gly-Ser-Arg (YIGSR), Arg-Glu-Asp-Val (REDV), and Ile-Lys-Val-Ala-Val (IKVAV)) may be used to mediate cell attachment and spreading of the cells attracted to the defect site, and such scaffolds have ultimately demonstrated enhanced osteoblast functionality and osseointegration in vivo.155 Engineered cell homing, either cell based or scaffold based, is gaining interest and may play an important role for effective bone regeneration in vivo.

5. Engineering Scaffolds for Orthopaedic Tissue Interfaces

Engineering orthopaedic tissue interfaces remains a significant and challenging endeavor in the field of BTE. Tissue–tissue interfaces are ubiquitous in our musculoskeletal system, as is their function in synchronizing joint motion and function. Failure to regenerate these interfaces results in the compromise of graft stability and long-term clinical outcome.156–158

The complexity of regenerating hard tissue– soft tissue orthopaedic interfaces (i.e., bone to soft tissues, such as ligament, tendon or cartilage) is a result of a number of factors. Orthopaedic tissue interfaces are structurally heterogeneous and intricate. The involved tissues are composed of very distinct cell populations that must operate in unison to maintain physiologic function and homeostasis. Furthermore, within these tissue interfaces is a distinct gradient of mechanical properties that allows for load transfer between the tissue types. Engineering the mechanical properties progressing from soft tissue to bone should also account for the native controlled distribution of non-mineralized and mineralized interface regions, as well as collagen fiber organization. Furthermore, the spatial distribution and interactions between interface-relevant cells are critical for the formation, maintenance, and repair of orthopaedic interfacial tissue. Thus, interface tissue engineering should strategically incorporate these biomimetic parameters into stratified scaffolds that enable both distinct and continuous multi-tissue regeneration and seamless graft integration.

A variety of multi-phased scaffolds have been designed to structurally and functionally mimic native soft tissue-to-bone to support the formation of integrated multi-tissue systems. For example, Lu et al. developed a biomimetic stratified scaffold for ligament-to-bone interface tissue engineering. Briefly, a tri-phasic stratified scaffold was designed to mimic the three interface regions (ligament, fibrocartilage, and bone).159 Phase 1 is designed with PLGA (10:90) mesh intended for soft tissue (i.e., ligament) formation, phase 2 consists of PLGA (85:15) microspheres and is the interface fibrocartilage region, and phase 3 is composed of sintered PLGA (85:15) and 45S5 bioactive glass composite microspheres for bone formation. This innovative scaffold design allowed for three distinct yet continuous phases to support the formation of the multi-tissue regions observed across a ligament-bone junction after 2 months in vivo.160

For a more comprehensive review of the interfacial tissue engineering strategies, the reader is encouraged to refer to recent reviews by Lu et al. and Yang et al.157,161 Although much progress has been achieved in regenerating orthopaedic tissue interfaces, significant challenges remain. More insight into the basic developmental biology of these interfaces is required to better understand the mechanisms by which these unique transition tissues are created. Also, more information on the spatial distribution of matrix molecules and the relation of tissue structure and mechanical properties is needed. With this, biomaterials that are able to temporally and spatially control the application of cells and soluble factors, as well as bioreactors that better mimic the native stresses at these interfaces may be created and improved upon.

6. New Scaffold Fabrication Techniques

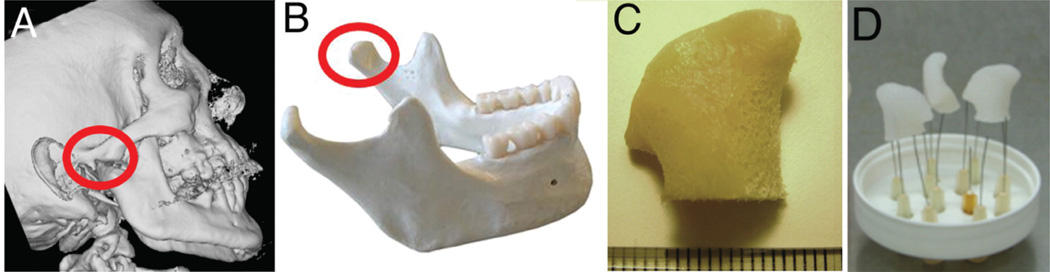

The development of personalized and anatomically shaped bone grafts has opened new doors for clinically relevant BTE. By combining computer assisted design (CAD) with computer assisted manufacturing (CAM), tissue engineers are able to produce custom-made and individualized complex scaffold architectures for the repair of complex bone defects that are often encountered in craniomaxillofacial surgeries. Grayson et al. successfully utilized the CAD/CAM systems to engineer personalized, clinically sized anatomically shaped bone grafts for the repair of human temporomandibular joint (TMJ) (Fig. 7).162

FIGURE 7.

Tissue engineering of anatomically shaped bone grafts. (A–C) Scaffold preparation. (A, B) Clinical CT images were used to obtain high-resolution digital data for the reconstruction of exact geometry of human TMJ condyles. (C) These data were incorporated into MasterCAM software to machine TMJ-shaped scaffolds from fully decellularized trabecular bone. (D) A photograph illustrating the complex geometry of the final scaffolds that appear markedly different in each projection. Adapted from Grayson et al.162

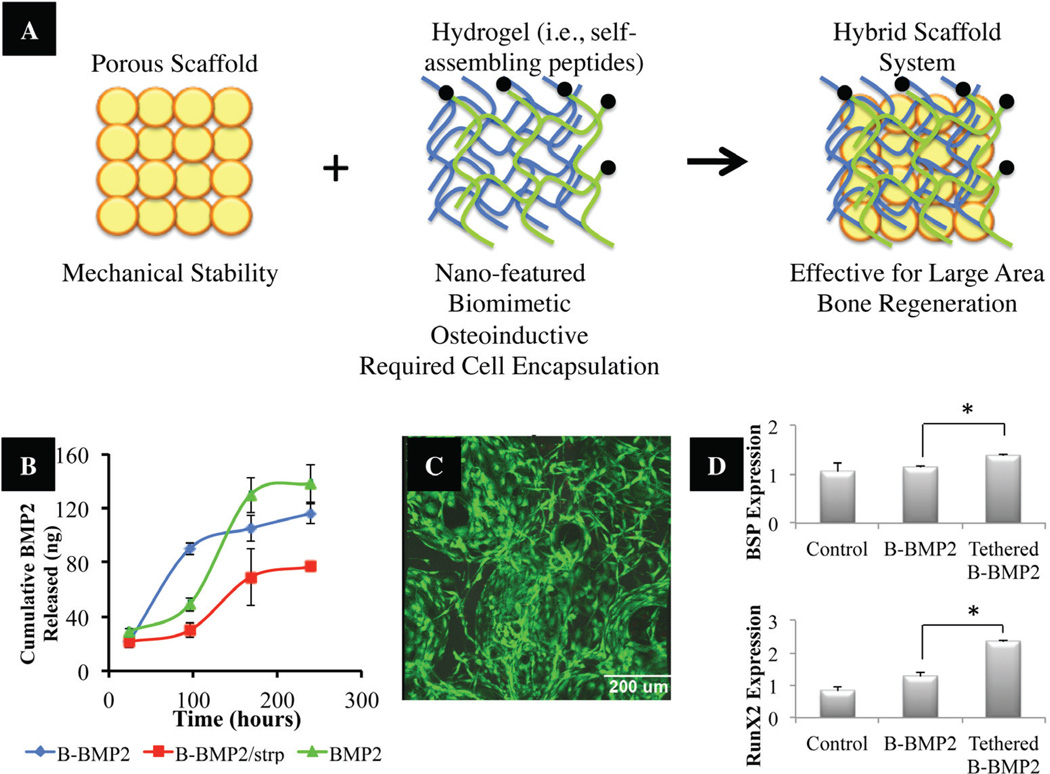

In addition, as previously described, micro-and nano-scale architectures play a critical role in native bone physiology, so scientists are investigating new fabrication techniques that would allow for multi-scale hierarchical manipulation. Several techniques, including electrospinning combined with fiber bonding,137,163,164 templating,165–167 and modified rapid prototyping,168,169 have demonstrated the ability to construct multi-scale synthetic scaffolds. Moreover, a novel hybrid approach involving the combination of mechanically strong, porous scaffolds and nano-featured self-assembling peptide hydrogels as an osteoinductive scaffold system is being investigated.79,80,170 In this approach, the mechanically strong scaffold component would allow for mechanical stability of the load-bearing defect site; whereas, the hydrogel phase will allow for efficient cell delivery into the defect implantation site, cell niche establishment and promotion of mineralization (Fig. 8). Growth factors for the promotion of accelerated bone and vascularization (i.e., BMP, VEGF) may also be covalently tethered to the hydrogel phase to allow for enhanced effects upon implantation. In a recent study, the authors have incorporated the features described above and developed a hybrid system comprised of a mechanically load-bearing scaffold infused with a self-assembling peptide hy-drogel with tethered BMP-2 (Fig. 8). The newly developed “polymer-hydrogel” hybrid system is robust: it not only satisfies mechanical needs but also has the ability to load the cells and factors required for osteogenesis and vasculogenesis. The hybrid system supported the encapsulation of rat bone-marrow–derived stromal cells and pre-os-teoblastic MC3T3-E1 cells, and it llowed for the later cell expression of key bone markers (i.e., BSP and RunX2) in vitro. Although BTE methods are currently not the gold standard in clinical practice, due to related high costs and insufficient universal manufacturing methods, recent studies have revealed methods for accelerated bone regeneration that are proving effective and are paving exciting roads for the use of BTE methods in the clinic.

FIGURE 8.

(A) Illustration of hybrid scaffolds composed of a mechanically strong component, and a hydrogel phase for enhanced bone regeneration abilities.170 (B) In vitro release kinetics of biotinylated BMP2. Amount of BMP2 released over time was measured by ELISA. Results show cumulative release of rhBMP2 for untethered groups (BMP2-biotin, BMP2) versus tethered group. (C) Survival of pre-osteoblastic MC3T3-E1 cells in hybrid scaffold. Images show live and dead cells cultured on hybrid scaffolds; green represents live cells. (D) Bone Sialoprotein (BSP) and RunX2 gene expression profile of pre-osteoblastic MC3T3-E1 grown in BMP2 untethered versus tethered SAP gel PLGA/nHA hybrid scaffolds (p < 0.05). Adapted and modified from Igwe et al.170

C. Cellular Approaches

An unresolved debate on the most effective cell type for clinical bone regeneration continues, but it has been established that cellular-based bone regeneration approach is indeed effective. Cellular-based approaches in BTE primarily target the early stages of bone repair when the recruitment of skeletal progenitors may be impaired. Proposed mechanisms by which implanted cells enhance bone regeneration in BTE involve (1) early release of key osteogenic and vasculogenic molecules and growth factors, (2) formation of a template to recruit host osteogenic and vascu-logenic cells, and (3) actively laying down bone matrix and vascularizing the bone construct.

The major challenge in making these cellular therapies more efficient is the identification of the cell sources that can be implanted to the bone defect site and will differentiate into os-teoblasts and form neo-vasculature.171,172 Thus far, studies have investigated several cell types for their abilities to promote bone repair and regeneration: mesenchymal stem cells (MSCs), embryonic stem cells (ESCs), induced pluripotent stem cells (iPSCs), adipose derived stem cells (ADSCs) and stem cells from human exfoliated deciduous teeth (SHED). This variety of possible candidates for cell transplantation can be explained by the finding that cells involved in the reconstruction of osseous tissue undergo a progression from undifferentiated progenitors to biosynthetically mature cells; therefore, therapeutic strategies can approach supporting the healing process at different stages of bone tissue development.173 For successful clinical application in the regeneration of bone, the properties of choice include isolation and expansion efficiency, expression and stability of osteogenic markers, “bona fide” bone tissue formation, and long-term safety (i.e., immunorejection, graft-versus-host disease, tumorigenicity). Table 2 summarizes the cell types that have been utilized for clinical bone defect repair thus far.

TABLE 2.

Cell Choices for Bone Tissue Engineering

| Cell type | Source | Clinical use |

|---|---|---|

| Embryonic stem cells (ESCs) |

Embryonic bodies (EBs) | N/D |

| Induced Pluoripotent stem cells (iPSCs) |

Any cell type that could be induced to become osteoblasts |

N/D |

| Adult stem cells | Bone marrow | Segmental defects of long bones312 Large bone diaphysis defects313 Maxillary sinus augmentation314 Posterior spinal fusion251 Bone tumor resection315 |

| Adipose tissue | Large calvarial defect316 Osteonecrotic femoral heads317 Hip osteonecrosis318 |

|

| Peripheral blood | N/D | |

| Teeth (pulp, exfoliated teeth) | N/D | |

| Cord blood | N/D | |

| Amniotic fluid | N/D | |

| Stem cells derived from ESCs and iPSCs | N/D | |

| Genetically modified cells | Any cell type that could be genetically modified |

N/D |

| Autologous cells and growth factor cocktail |

Platelet-rich plasma bone marrow aspirate |

Necrosis of femur head, avascular necroses, Non-unions319 Sinus graft320 |

1. Embryonic stem cells (ESCs)

Embryonic stem cells (ESCs) are, by definition, obtained from ‘embryos,’ which are formed following the fertilization up until the ninth week of gestation. ESCs are frequently obtained from extra embryos developed by in vitro fertilization techniques, to bypass ethical debates regarding their usage. Because ESCs are pluripotent, with high proliferative activity, they can potentially be used as a single source for the derivation of multiple lineages present in adult bone, including osteogenic cells, vascular cells, osteoclasts, nerve cells for bone regeneration.174

Since their first isolation more than 30 years ago, ESCs have been intensely investigated. Specifically, it has been established that undif-ferentiated ESCs express the following surface antigens: stage-specific embryonic antigen-4 (SSEA-4), tumor rejection antigens TRA-1–60 and TRA-1–81. However, they lack the expression of SSEA-1.78 ESCs are not highly im-munogenic; they express very few major histo-compatibility complex (MHC) class I molecules. ESCs possess high alkaline phosphatase and telomerase activities, and expression of transcription factors Oct4, Sox2, and Nanog, which are crucial for the maintenance of pluripotency. Self-renewal of ESCs is regulated by cytokines of the IL-6 family. Human ESCs are confirmed in vitro by their ability to induce differentiation in embryoid bodies, which are defined as aggregates of cells cultured in suspension. Also, ESC confirmation tests involve observing their differentiation potential in vivo and the formation of tissues from all three germ layers.

ESCs require complex proliferative culture conditions, including various growth factors, feeder cell layers, specific media and/or coated culture plates.175 For instance, murine ESCs require presence of leukaemia inhibitory factor (LIF) or a feeder layer of murine embryonic fibro-blasts (MEF) to remain in the undifferentiated and proliferative state. On the other hand, human ESCs should be cultured on Matrigel or laminin in the presence of MEF-conditioned medium.176 In the absence of these conditions, ESCs differentiate spontaneously into embryoid bodies. ESCs have the potential to differentiate into numerous cell types including cardiomyo-cytes, haematopoietic cells, endothelial cells, neurons, chondrocytes, adypocytes, hepatocytes pancreatic islets, and importantly, osteoblasts.177

The potential use of ESCs for BTE has gained considerable attention among tissue engineers.178,179 Osteogenic differentiation of ESCs may be achieved by either first forming or not forming embryoid bodies. For the first method, embryoid body formation is followed by its dissociation, re-plating of dissociated single cells, and then administration of osteogenic supplements (i.e., β-glycerophosphate, ascorbic acid, dexamethasone, retinoic acid, and 1,25-hydroxy vitamin D3).180,181 However, due to the limited control of lineage-specific differentiation of ESCs within EBs, this method may result in a limited number of the cell type of interest. Thus, scientists have searched for more efficient, simple, and convenient culture strategies by directly differentiating ESCs into the osteogenic lineage, bypassing EB formation. In this method, ESCs are directly plated as a single-cell suspension and cultured in the presence of β-glycerophosphate, ascorbic acid and dexamethasone.182,183 These findings suggest that this may be a good culture strategy for applying functional ESC-derived osteogenic cells effectively to BTE.

Many studies have demonstrated the effectiveness and potential use of ESCs for BTE purposes when combined with various three-dimensional scaffolds. For instance, the expression of alkaline phosphatase and osteocalcin were significantly enhanced in human ESC culture on three-dimensional PLGA scaffolds in comparison with the same cells cultured on a two-dimensional culture plate.184 Another approach for ESC-based three-dimensional bone tissue generation involved the development of BMP-inoculated three-dimensional scaffolds, composed of PLGA and hydroxyapatite, as an ESC-derived osteoblast delivery vehicle for generating bone-like tissue in vivo. Studies have demonstrated successful bone tissue formation using ESC-derived osteoblasts subcutaneously implanted into immunodeficient mice.185

Despite their enormous potential, concerns about ESCs must be addressed prior to their potential use for tissue engineering applications. It is critical to confirm the stability of the donor ESCs and that they are not tumorogenic; prolonged culture of undifferentiated ESCs may result in spontaneous development of abnormal karyotypes, and their implantation resulting in the formation of teratomas in vivo. Also, the immunological incompatibility between donor ESCs and host cells must be addressed.

2. Induced Pluripotent Stem Cells

Induced pluripotent stem cells (iPSCs) are pluripotent stem cells that are artificially derived from a non-pluripotent cell via the induction of a “forced” expression of specific genes. iPSCs were first produced from mouse fibroblasts by retroviral delivery of four transcription factors (i.e., Oct4, Sox2, Klf4, and Myc) in 2006.186 In the following year, terminally differentiated human somatic cells were also converted into iP-SCs using a similar method.187,188 Studies have shown human iPSCs to possess properties similar to those of human ESCs, not only in respect to their morphology, gene expression, surface antigens but also their in vitro differentiation potential and pluripotency. However, the inherent epigenetic memory of the starting non-pluripo-tent cell may influence the differentiation potential and in vivo functionality of tissues derived from such iPSCs.189 Additional research in this area is needed to determine the best starting somatic cell for iPSC generation for human clinical applications. Furthermore, possible resultant tumor formation due to integrated oncogenes requires special attention and investigation. In addition, it is paramount to develop non-viral induction methods to produce clinically safe iPS cells for BTE.

3. Adult Stem Cells

A. Mesenchymal Stem Cells (MSCs)

Mesenchymal stem cells (MSCs) have long been recognized for their potential in engineering bone grafts because they differentiate and form bone during the natural bone development process. Their great potential in BTE has led to their characterization and the identification of a plethora of sources for their isolation. MSCs have been defined through the expression of various CD markers (i.e., negative for CD34, CD45, CD14, CD11a, CD19, and HLA-DR and positive for STRO-1, CD29, CD73, CD90, CD105, CD106, CD166, CD146, and CD44).190 Also, MSCs have been isolated from a number of adult sources including bone marrow,191 peripheral blood,192 umbilical cord blood,193 sy-novial membrane,194 deciduous teeth,195 dental pulp,196 amniotic fluid,197 adipose tissue,198 brain, skin, heart, kidneys and liver199 through a relatively simple protocol that primarily relies on their ability to adhere to plastic in tissue culture. 200 In addition, their high proliferative potential combined with their ability to withstand freezing conditions allows for their in vitro expansion to obtain clinically relevant cell numbers.191

In addition to adult sources, MSCs have recently been derived from embryonic stem cells, as well as iPS cells.201 These embryonic- and iPSC-derived MSCs have the same in vitro and in vivo multi-potent characteristics as MSCs derived from other adult sources (i.e., bone marrow). However, unlike MSCs derived from adult sources, iPSC-derived MSCs can be expanded with a lower rate of senescence. Their enhanced survival potential, both in vitro and in vivo, may be attributed to higher telomerase activity.201 In any case, MSCs of embryonic and iPSC origin must be further tested to rule out the possibility of teratoma formation before they are considered for clinical application.

The incorporation of MSCs into BTE bio-materials is a widely studied strategy for accelerated bone formation and osteointegration during bone defect repair and regeneration. Mechanisms by which enhanced bone regeneration occurs involves directly providing MSCs for osteogenic differentiation and bone formation, as well as enhanced osteoinductivity of the biomaterial via the release of osteogenic growth factors and stimulation of the migration and differentiation of host osteoprogeni-tors. In addition, pre-differentiating MSCs into the osteogenic lineage before implantation has been shown to further accelerate defect repair and osteointegration of the construct in vivo by delivering a more mature osteogenic population capable of immediate bone formation. Pre-clinical trials with MSC-seeded constructs have proven effective in accelerating bone repair in various scenarios, including critical-size femoral defects, cranio-maxillofacial deformities, and spinal fusions.202

Although MSCs may seem to represent a great cellular option for enhanced BTE, several issues with their use have been identified. First, several studies have shown that a maximum of 24–40 population doublings are reached before MSCs reach senescence-associated growth arrest. Also, osteogenic differentiation potential in vitro and bone forming efficiency in vivo signifi-cantly decreases with increasing donor age and systemic disease. Additionally, the lack of knowledge about common markers for MSCs isolated from different sources makes it difficult to define MSCs.190,203 These factors significantly limit the actual amount and the quality of MSCs obtainable for clinical application. Approximately 4–6 weeks is required for cell expansion before possible patient treatment. Furthermore, long-term culture may lead to forced selection under artificial culture conditions, which increases the possibility of abnormal karyotype development and malignant cell transformation. Lastly, the use of fetal bovine serum (FBS) during in vitro expansion poses a risk of transmitting zoonotic or prion-related diseases, which may induce an immune response triggered by xenogenic proteins. The option of using synthetic serum with range of recombinant growth factors or serum-free media are being explored as alternatives.173

At present, a number of strategies have been reported that are capable of augmenting the loss of both proliferative capacity and osteogenic differentiation potential of MSCs after extensive population doublings ex vivo. These methods include cultivation of MSCs in the presence of basic fibroblastic growth factor (FGF-2) and maintenance of MSCs on several extracellular matrices (i.e., basement membrane-like extracellular matrix produced by bovine corneal endo-thelial cells, denatured collagen type I matrix) instead of conventional tissue-culture plastic during progressive passages.202 The mechanism controlling how various ECMs may influence the retention of MSC osteogenic differentiation potential after ex vivo expansion remains to be elucidated; however, it has been suggested that the physical interactions between MSCs and certain ECM motifs (i.e., integrins and their li-gands) may play a significant role.

The variability of colony formation and culture conditions necessary to sustain prolifera-tive capacity have led to an interesting proposal regarding the creation of a universal allogenic human MSC cell line providing “off the shelf” or “ready to use” cells.112 Though it may not seem possible without requiring the use of im-munosuppressive drugs to reduce associated risks of rejection, it has recently been shown that cultured MSCs exhibit a poorly immuno-genic phenotype (i.e., evidenced by MHC class I+, MHC Class II-, and low levels of expression of co-stimulatory molecules, CD40, CD80, and CD86). Also, MSCs have been shown to be immune suppressive (i.e., immune privileged). Specifically, MSCs do not induce the proliferation of lymphocytes, and they suppress the proliferation of T cells and cytokine production in response to alloantigens or insignificant mito-gens, as well as inhibiting the function of B cells, dendritic cells, and the natural killer cells. These data greatly enhance the therapeutical appeal of MSCs in BTE.

B. Adipose-Derived Stem Cells

Adipose-derived stem cells (ADSCs) represent an easily accessible, widely available, and abundant source of autologous osteogenic cells. ADSCs have multi-lineage differentiation potential (i.e., osteogenic, chondrogenic, adipo-genic, neural, cardiomyocyte, and endothelial lineages).203–206 Isolation protocols of ADSCs include density gradient centrifugation of the col-lagenase-digested lipoaspirates (ranging from 100 ml to several liters), and culture expansion of the adherent cell population. Lipoaspirates house a relatively high frequency of ADSCs (1 to 5% of isolated cells), in comparison to MSCs in bone marrow (0.001% to 0.1% of isolated cells). Similar to MSC isolation, the successful numbers of cell isolated are influenced by the tissue harvesting procedure, as well as the site of tissue harvesting (e.g., arm, thigh, abdomen, breast). ADSCs also share a common surface-antigen expression pattern, including CD44, CD90, CD13, CD29, CD73, CD166 and CD105.205,207 However, the expression of STRO-1 and CD34 antigens remains controversial. Some researchers have reported that ADSCs do not express STRO-1,208 and others have reported the absence or extremely low levels of expression of STRO-1 or CD34 antigens on the surface of ADSCs.198 Expression of surface markers on ADSCs may vary according to passage number and isolation techniques;209 hence, the characterization of ADSCs requires further clarification.

The osteogenic differentiation potential of ADSCs has been demonstrated not only in vitro but also in vivo. Osteogenic differentiation in vitro may be achieved through the addition of supplements, including β-glycerophosphate, ascorbic acid, and dexamethasone, which are similar to those used for osteogenic differentiation of bone-marrow-derived MSCs.205,210,211 It has also been shown that other exogenic factors may be applied to direct osteogenic differentiation of ADSCs, such as brief treatment of BMP-2.212 Furthermore, pre-differentiated ADSCs have demonstrated good adhesion, proliferation activity, and homogenous bonelike tissue formation on various biocompatible three-dimensional scaffolds in vitro and on ec-topic bone formation in vivo.213–215 In addition, osteogenic performance of ADSCs has been assessed in orthotopic in vivo environments, which provide a more inductive, and physiological/ clinically relevant environment. Although enhanced bone regeneration has been demonstrated with implanted ADSCs,216,217 the mechanisms by which ADSCs promote bone healing in these orthotopic models has not been investigated.

ADSCs may further serve as an attractive cell population for the implementation of a one-step, intra-operative bone grafting approach, avoiding the cost and time of cell expansion. In this approach, tissue harvest, cell isolation, cell seeding onto a scaffold, and subsequent implantation could occur within a few hours, with no ex vivo cell culture. As previously mentioned, because ADSCs frequency in human lipoaspirates is relatively high (i.e., 500-fold larger numbers of colony forming units than human bone-marrow aspirates), these cells may represent a suitable cell source for such a one-step surgical procedure.218,219 Muller et al. offered proof-of-principle for this intra-operative approach by demonstrating vascularized tissue formation with positive staining of bone sialoprotein and osteocalcin 8 weeks post-implantation of ADSCs, which were implanted ectopically in nude mice 3 hours after harvest.220 These findings have significant implications for BTE applications in which ADSCs could be used for the fabrication of tissue-engineered bone.

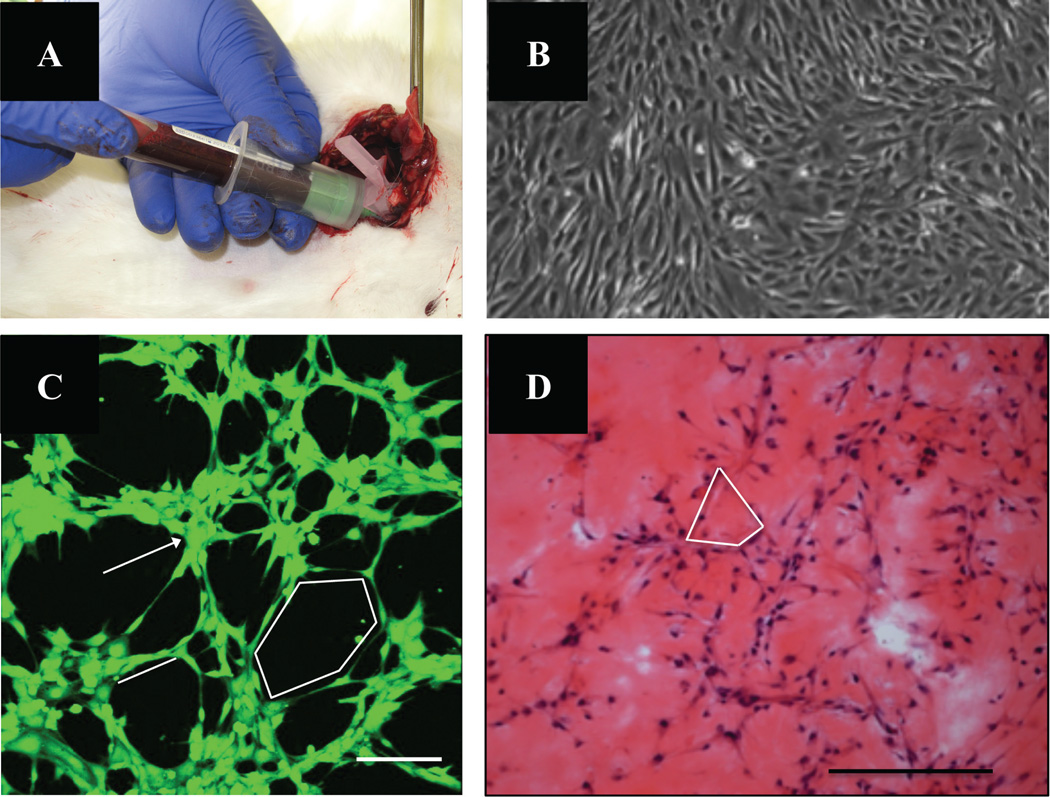

C. Peripheral Blood–Derived Stem Cells

The isolation of stem cells from the patient’s peripheral blood (PB) represents a minimally invasive (i.e., no donor site morbidity) and convenient method for obtaining two effective cell populations for bone and vascular regeneration, namely MSCs and endothelial progenitor cells (EPCs). Traditionally, MSCs have been isolated from bone marrow; however, recent studies have identified peripheral blood as a site for MSC isolation (PB-MSCs). In fact, Chong et al. suggested that from 2 mL of peripheral blood, approximately 0.5–1 million cells were obtainable after 2 weeks from cell seeding (passage 0) and approximately 5 million PB-MSCs were obtainable at the end of passage 2. PB-MSCs display the same differentiation potential profile as MSCs isolated from bone marrow (i.e., tri-lineage; chondrogenic, osteogenic, and adipogenic).221 Furthermore, EPCs, especially those isolated from peripheral blood, have demonstrated high angiogenic potential and an effective cell population for promoting neo-vascu-larization of bone defect sites.222 Although the effectiveness of these two cell types, both isolated from peripheral blood, has not been thoroughly investigated in bone regeneration, other isolation sources (i.e., bone marrow) have been sought that have demonstrated superior bone regeneration and vascularization of bone defect sites.223,224 Thus, the effectiveness of PB-EPCs and PB-MSCs in vivo should be further investigated; they represent a potent alternative to cell transplantation procedures.

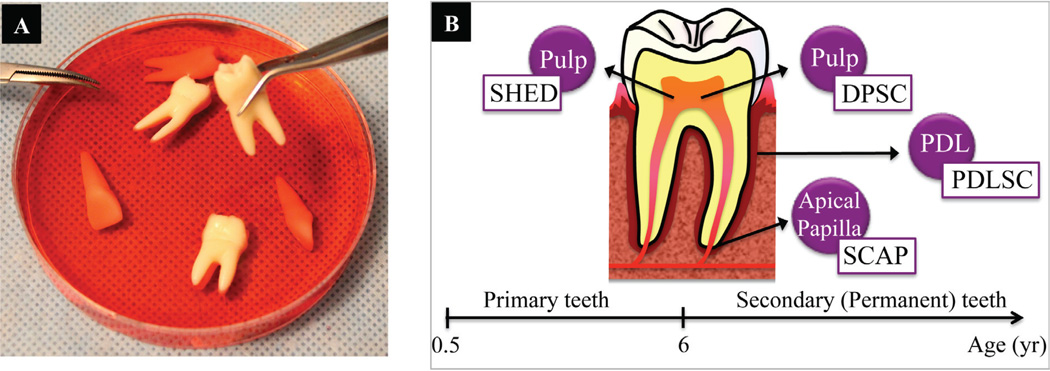

D. Tooth-Derived Stem Cells

a. Dental Pulp–Derived Stem Cells

Interesting findings within the last decade have pointed to stem cells residing in dental pulp tissue as an attractive cell source for BTE.225,226 Dental pulp derived stem cells (DPDSCs) can differentiate into a number of cell types, including odontoblasts, chon-drocytes, osteoblasts, endothelial cells, adi-pocytes and neural cells.227,228 DPSCs have been isolated from digested pulp tissue by either a single-colony selection or an immunomagnetic isolation method using anti-STRO-1 antibody and magnetically activated cell sorting (MACS). DPDSCs are highly proliferative, and they display the typical immunoreactivity profile of MSCs.230

Successful osteogenic differentiation of DPDSCs has been demonstrated and involves the administration of osteogenic medium (i.e., supplements of ascorbic acid, dexamethasone, β-glycerophosphate). Furthermore, in vivo transplantation of such DPSCs into nude rats generated living fibrous lamellar bone tissues containing osteocytes.231 Recent BTE studies have also shown the potential for use of DPSCs in combination with a three-dimensional scaffolds. For example, highly mineralized tissue formation was reported in an autologous implantation study with rabbit DPSCs and a poly(lactide-co-glycolide) (PLGA) scaffold construct implanted subcutaneously.232

b. Stem cells from Human Exfoliated Deciduous Teeth (SHEDs)

With the discovery of DPDSCs in 2000, that of stem cells in deciduous teeth came soon after, in 2003. Stem cells from human exfoliated deciduous teeth (SHED) have a similar differentiation potential as DPDSCs; however, they also have several key advantages. SHEDs have a higher proliferation rate, and they may also be readily accessible in young patients that have disposable primary teeth. Also, SHEDs have a distinctive osteoinductive ability and high plasticity. Lastly, upon transplantation, SHEDs are capable of differentiating into blood vessels that anastomose with the host vasculature.233