Abstract

Background:

Frequent moves at the joint, plus external factors such as trauma, aging, and etc., are all reasons for joint damages. In order to protect and care of joints, the orthopedic textiles are used. To protect the joints, these textiles keep muscles warm to prevent shock. To produce orthopedic textiles, Neoprene foams have been traditionally used. These foams are flexible and resist impact, but are not comfortable enough and might cause problems for the consumer. This study introduces a new structure consisting of perforated Neoprene foam attached to the spacer fabric and also compares the properties of thermal and moisture comfort and impact properties of this structure in comparison with Neoprene foam.

Methods:

In order to measure the factors related to the samples lateral pressure behavior, a tensile tester was used. A uniform pressure is applied to the samples and a force – displacement curve is obtained. The test continues until the maximum compression force is reached to 50 N. The area under the curve is much greater; more energy is absorbed during the impact. In order to investigate the dynamic heat and moisture transfer of fabrics, an experimental apparatus was developed. This device made the simulation of sweating of human body possible and consisted of a controlled environmental chamber, sweating guarded hot plate, and data acquisition system.

Results:

The findings show that the Neoprene-spacer fabric structure represents higher toughness values compared to other samples (P ≤ 0.001). Neoprene-spacer fabric structure (A3) has higher rate of moisture transport than conventional Neoprene foam; because of undesirable comfort characteristics in Neoprene.

Conclusions:

Results of the tests indicate full advantage of the new structure compared with the Neoprene foam for use in orthopedic textiles (P ≤ 0.001).

Keywords: Joint damages, Neoprene foam, orthopedic textiles, spacer fabric, thermal and moisture comfort

INTRODUCTION

External forces, aging, and other factors may cause joint damages and degeneration.[1,2] In general, it's necessary to protect the sensitive joints such as knees and elbows, which are more subjected to injuries. For this aim, elastic materials due to their appropriate characteristics related to the comfort and toughness are available.[3] One of these materials is called “Orthopedic Textiles” which are widely used for old people and those who suffer from joints disease or have surgeries and so on. In addition to being comfortable, orthopedic textiles are specifically evaluated based on the rate of moisture and transpiration transport on the skin surface.

The other role of orthopedic textiles is to keep muscles warm. Lack of either the oxygen or the food could cause muscle cramps.[4] If thermal transport is prevented between body and the environment, muscles will be kept warm.[5] So, in addition to being comfortable and tough, the orthopedic textiles result in the low rate of thermal transport and so the joints and muscles will be kept warm.

To produce orthopedic textiles, neoprene foams have been traditionally used. These foams are flexible and impact resistant, but are not comfortable enough and might cause problems for the consumer. In some researches,[6,7,8] stretch spacer fabric produced from polyester and elastane, has been proposed as alternative to Neoprene. However Neoprene foams possess acceptable impact properties than spacer fabrics. In order to take the positive features of both materials, a new structure comprised of perforated neoprene foam and spacer fabric is introduced. The thermal and moisture comfort of these novel structures as well as its toughness will be studied.

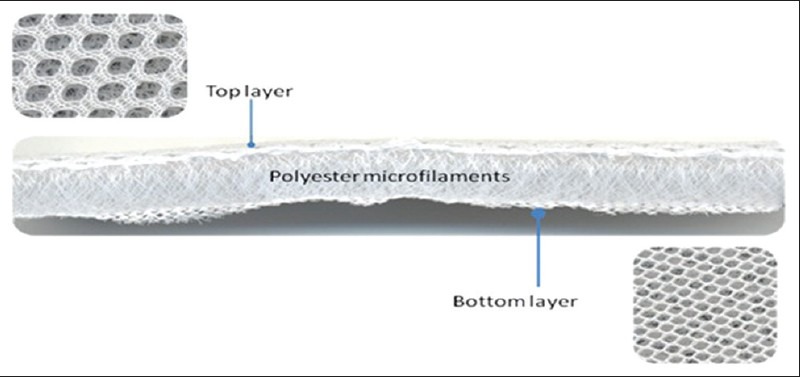

Spacer fabric is a kind of three dimensional structures consists of two fabric layers placed on its both top and bottom sides and connected to each other through the middle layer.[9] Since the middle layer comprised of monofilaments, the fabrics possess special characteristics.[10] Figure 1 illustrates a kind of spacer fabric in which its third dimension (thickness) is significant.

Figure 1.

Structure of a spacer fabric

In general, fabrics can also breathe and stretch as well as insulate, flex and resist impact. Capillary action trough the fabric structures, wicks away perspiration from the skin for external evaporation, keeping the wound dry and preventing fungus and infection. They are also faster drying, less susceptible to odor development, have good heat retention and insulation values. The prominent characteristics of these textiles are responsible for their various applications including medical industry, military, technical and industrial textiles, geotextiles, and sport suits.[11,12,13,14]

METHODS

Characteristics of samples

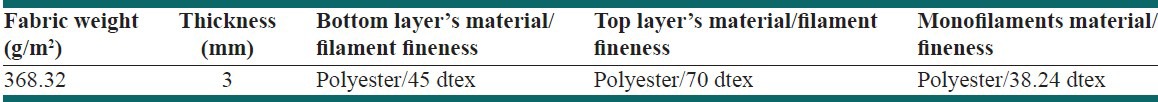

Sample A1 is a Neoprene piece with a thickness of 3 mm. In the sample A2, a 3 mm thickness perforated Neoprene is used which has 1 hole/cm2. The sample A3 is a piece of perforated Neoprene with similar characteristics to the sample A1, which is laminated to the spacer fabric. The specification of sample A3 is given in Table 1. The schematic image of this sample is shown in Figure 2.

Table 1.

Specification of spacer fabric used in sample A3

Figure 2.

Proposed Neoprene-spacer fabric structure

The sample A4 is also a piece of spacer fabric, which its characteristics are illustrated [Figure 1].

Measuring the factor regarding the samples toughness

In order to measure the factors related to the samples lateral compression behavior a tensile tester (Zwick, Series 124174) was used, which is shown in the Figure 3.

Figure 3.

Apparatus for measuring the sample toughness

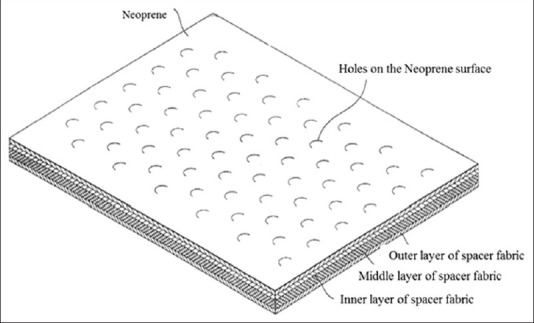

The 10 cm × 10 cm samples were prepared and then placed between the fixed and movable flat jaws. The speed of movable flat jaw was adjusted at 5 mm/min. A uniform compression force was applied to the samples and a force – displacement curve was obtained. The test continues until the maximum compression force is reached to 50 N. The area under the curve is defined as work of compression force as well as toughness. According to the materials science, toughness is defined as the amount of absorbed energy per unit volume of materials. The greater area under the curve results in the more energy absorption during the impact. Figure 4 shows a sample of force-displacement curve. This experimental trend was repeated 10 times for each sample. The area under the curve was calculated as compression work and the average of the results is reported for further analysis.

Figure 4.

Compression force-displacement curve obtained from tensile tester apparatus

Designing the dynamic transport of moisture and thermal in the sample

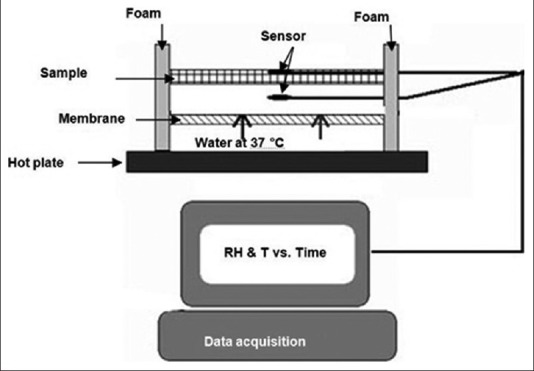

In order to investigate the dynamic heat and moisture transfer of fabric samples, an experimental apparatus based on the Borhani et al. researches,[15] was developed. This device comprising has the ability to simulate the possible body condition comprising a controlled environmental chamber, sweating guarded hot plate, and data acquisition system. The instrument used for the experiments is shown schematically in Figure 5. The sweating guarded hot plate was placed in a chamber with ambient conditions of 25°C, and 65% relative humidity (RH). This guarded hot plate comprised of different components including a 37°C hot plate as a heat source, a water container, a piece of animal skin for simulating human skin and the sensors for humidity and temperature determination. One side of the sample faces the sweating skin but not in contact, whereas the other side is exposed to the controlled environment. Five humidity and temperature sensors were located above and below the sample. The driving forces for the movement of moisture vapor are the temperature and vapor gradients maintained between the points where the moisture vapor emerges from the simulated skin (37°C, 90% RH) and the ambient environment controlled at 25°C and 65% RH.

Figure 5.

Schematic design of the instrument for measurement of moisture transfer

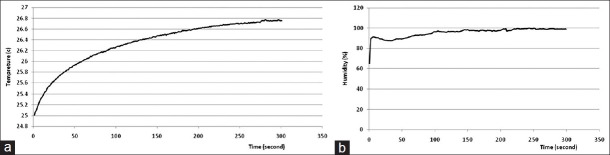

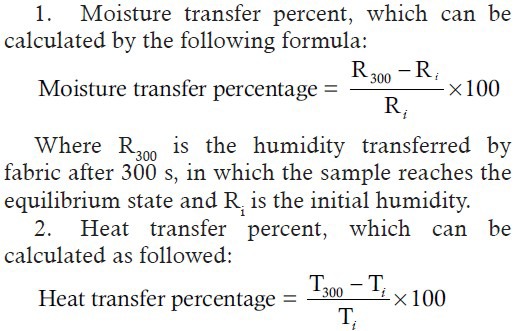

Two different curves, humidity-time and temperature-time, were obtained from the data acquisition unit. Two typical curves are shown in Figure 6. During the initial balance, the temperature and humidity in the inner and outer surfaces of the fabric are the same with respect to the environment. After inserting the fabric into the apparatus, the temperature and humidity in the microclimate increase rapidly since the sweat evaporation from the simulated skin occurred. At the same time, the temperature and humidity in the fabric's inner surface and the gradient between the two sides of the fabric also increase rapidly. After a while, the ascending velocity of the temperature and humidity tends to level out. When the rate of evaporation from the simulated skin is equivalent to the rate of diffusion from the fabric to the environment, a new balance is achieved and the temperature and humidity retain a static state. From the dynamic relative humidity and heat transfer curves in [Figure 6a and b], we can get such dynamic characteristic values as follows:

Figure 6 (a-b):

Typical curves obtained from the heat and moisture transfer

Where T300 is the heat transferred by fabric after 300 s and Ti is initial temperature.

Before testing, the samples were kept in the standard condition for at least 24 h with 25 ± 1°C temperature and a 65 ± 2 RH%. The experiment was carried out 5 times for each sample and average of the results was reported.

RESULTS

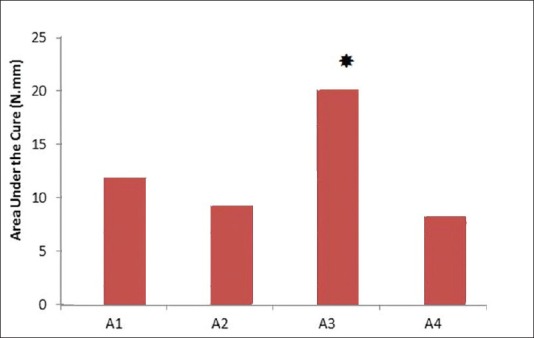

Toughness results

The average amounts diagram of area under the force-displacement curve as well as toughness of samples A1, A2, A3, and A4 is shown in Figure 7. The findings show that the Neoprene-spacer fabric structure represents higher toughness values compared to other samples (P ≤ 0.001).

Figure 7.

Area under the curve as well as toughness of samples (*Statistically significant)

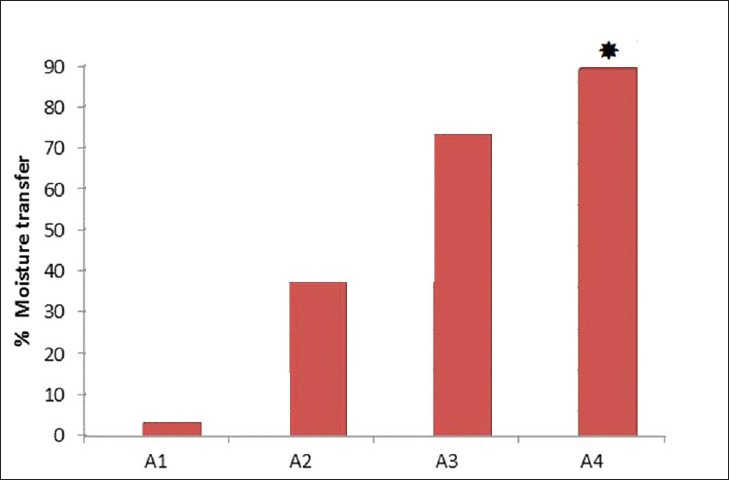

Moisture transport results

In Figure 8, the diagram of moisture transfer percent of the samples is shown. As it can be seen through the results, the sample A4 (which is a piece of spacer fabric) has the highest percent of moisture transport (P ≤ 0.001). Neoprene-spacer fabric structure (sample A3) has the second highest rate of moisture transport. Furthermore, the results show a very low rate of moisture transport for Neoprene foam A1 because of undesirable comfort characteristics in Neoprene.

Figure 8.

Moisture transfer percent of samples (*Statistically significant)

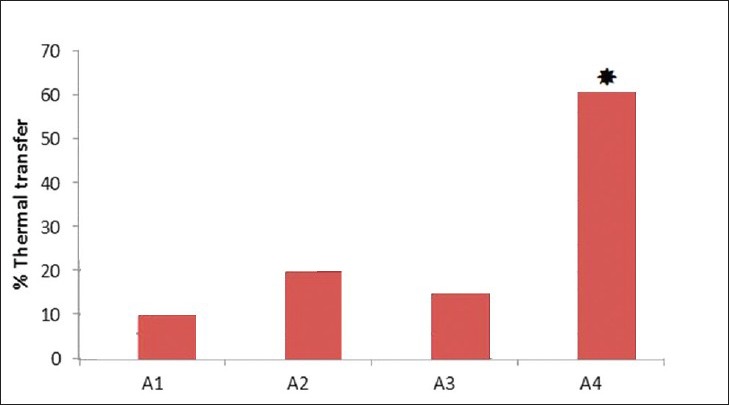

Heat transfer results

Heat transfer experiment was carried out 5 times for each sample and the average amount is reported as shown in Figure 9. The results show that spacer fabric A4 has higher rate of heat transfer between all other samples (P ≤ 0.001). Furthermore, it can be understood that Neoprene foam (sample A1) represents the lowest heat transfer percent. Structure A3 including Neoprene foam and spacer fabric has higher heat transfer percent than Neoprene foam (sample A1).

Figure 9.

Heat transfer percent of samples (*Statistically significant)

DISCUSSION

For orthopedic textiles three characteristics are required simultaneously: High toughness, low rate of heat transfer and proper moisture comfort.[7] Although the Neoprene foams is used commonly in orthopedic textiles, but the lack of humidity comfort is its disadvantage. In order to improve this defect, a new structure consists of spacer fabric and perforated Neoprene foam was used in this study. Also, investigating the characteristics of this structure including thermal and moisture comfort, impact resistant and toughness, were being under consideration trough this research.

The findings indicated that the Neoprene-spacer fabrics represent higher toughness values compared with other samples. This means that this structure absorbs more energy during impact. In a spacer fabric, the monofilaments of middle layer are oriented in the direction of fabric thickness. This feature increases compressibility, resiliency, and toughness of such fabrics. When a compression force is applied on the spacer fabric, the compression force distributes uniformly on the fabrics structure and the energy of this force is absorbed by folding the monofilaments of middle layer, which results in changing the fabric thickness.[8]

The results showed that the sample A4 (a piece of spacer fabric) has the highest percent of moisture transferring. Presence of monofilaments in the middle layer of spacer fabrics causes capillary action and helps the transpiration transport from the skin. Besides, high rate of permeability in these fabrics provide the comfort for the consumer due to the moisture transferring.

The three dimensional nature of a spacer fabric leads to much air trapped in the fabric structure. If the fabric is in contact with air from one side, the trapped air will circulate between the upper and bottom layers because of the high air permeability in these fabrics. This feature cause to transfer the moisture and heat of skin surface through the circulating air.[8]

If the air within the fabric is trapped by the skin from one side and the Neoprene foam from the other side, the used structure will be greatly thermally isolated. Therefore, remarkable difference between the heat transfer rates of samples A3 and A4 will be justified. Since Neoprene foam is perforated, it is to expect that the air trapped within the fabric structure starts to circulate and that's why the heat transfer rate of sample A3 is a little more than that of sample A1.

CONCLUSION

The results show that not only spacer fabric and perforated Neoprene foam structure keep the human body temperature, but it also provides more moisture comfort and more desirable toughness in order to be used in orthopedic textiles.

Footnotes

Source of Support: Nil

Conflict of Interest: None declared.

REFERENCES

- 1.Mescher AL. Vol. 12. United States of America: McGraw Hill; 2003. Junqueira's Basic Histology, Text and Atlas; p. 8. [Google Scholar]

- 2.Postlethwait JH, Hopson JL. Lancet. Vol. 1. New York: Holt, Rinehart, Winston; 2008. Modern Biology; pp. 911–6. [Google Scholar]

- 3.Guyton CG, Hall JE. 10th ed. Philadelphia, United States of America: Saunders; 2000. Medical Physiology; pp. 66–78. [Google Scholar]

- 4.Peter H, Raven W. Vol. 6. France: CB/McGraw-Hill; 1999. Biology; pp. 992–6. [Google Scholar]

- 5.Sadava D, Hillis DM, Heller HC, Berenbaum M. Vol. 1. New York: Print and Media Resources; 2009. Life. The Science of Biology. [Google Scholar]

- 6.Heide M, Moehring U. 3D effects: Pressure relief, microclimate, support. Kettenwirk Pranis. 2003;1:20–2. [Google Scholar]

- 7.Yip J, Ng S. Study of three-dimensional spacer fabrics: Physical and mechanical properties. J Mater Process Technol. 2008;206:359–64. [Google Scholar]

- 8.Gross D. 3D spacer knit fabrics for medical applications. JTATM. 2003;4:26–8. [Google Scholar]

- 9.Liu Y, Lv L, Sun B, Hu H, Gu B. Dynamic response of 3D biaxial spacer weft-knitted composite under transverse impact. J Reinforced Plast Compos. 2006;25:1629–41. [Google Scholar]

- 10.Bruer SH, Powel N, Smith G. Three-dimensionally knit spacer fabrics: A review of production techniques and applications. JTATM. 2005;4:4. [Google Scholar]

- 11.Wollina U, Heide M, Müller-Litz W, Obenauf D, Ash J. Functional textiles in prevention of chronic wounds, wound healing and tissue engineering. Curr Probl Dermatol. 2003;31:82–97. doi: 10.1159/000072239. [DOI] [PubMed] [Google Scholar]

- 12.2013. Jul, Available from: http://www.terrot.de/aktuelles/en/berichte/04-05.asp .

- 13.Scheiber W, Fauth Ch. Mediction from 3D plasters, warp knitted spacer fabrics as textile carriers. Kettenwrik praxis, Karl mayer. Lancet. 2004;3:30. [Google Scholar]

- 14.Mayer K. When the seat starts to perspire, the climatic comfot of car seats. Kettenwrik- praxis, Karl Mayer. Lancet. 2005;2:20–1. [Google Scholar]

- 15.Borhani S, Seirafianpour S, Ravandi SA. Computational and experimental investigation of moisture transport of spacer fabrics. J Eng Fiber Fabr. 2010;5:42–8. [Google Scholar]