Abstract

Despite the progress in developing new therapeutic modalities, cancer remains one of the leading diseases causing human mortality. This is mainly attributed to the inability to diagnose tumors in their early stage. By the time the tumor is confirmed, the cancer may have already metastasized, thereby making therapies challenging or even impossible. It is therefore crucial to develop new or to improve existing diagnostic tools to enable diagnosis of cancer in its early or even pre-syndrome stage. The emergence of nanotechnology has provided such a possibility. Unique physical and physiochemical properties allow nanoparticles to be utilized as tags with excellent sensitivity. When coupled with the appropriate targeting molecules, nanoparticle-based probes can interact with a biological system and sense biological changes on the molecular level with unprecedented accuracy. In the past several years, much progress has been made in applying nanotechnology to clinical imaging and diagnostics, and interdisciplinary efforts have made an impact on clinical cancer management. This article aims to review the progress in this exciting area with emphases on the preparation and engineering techniques that have been developed to assemble “smart” nanoprobes.

Keywords: cancer diagnosis, biomarkers, nanotechnology, nanomedicine, bioconjugation, surface modification, imaging

1. Introduction

Cancer accounts for approximately one fourth of all deaths in the United States [1]. Prognosis of cancer patients depends largely on the time and accuracy of finding the primary and any dormant metastasis sites. Identification of these abnormal sites in an early enough stage can significantly reduce the mortality rate. For example, for breast cancer patients, the 5-year survival rate is 98% if the tumor can be diagnosed in stages 0 and I and drops to 85% for stage II and merely 20% for stage IV tumors [2]. Pancreatic cancer, on the other hand, is usually associated with a high mortality rate; about 75% of pancreatic cancer patients die within 1 year after diagnosis [3]. This high death rate stems from the recessive traits exhibited by pancreatic cancer and a lack of an effective early detection means. Needless to say, there is an urgent need for new tools that can detect cancer in the early or even pre-syndrome stage. Significant progress has been made recently thanks to advances in proteomics and genomics. These burgeoning techniques have identified various biomarkers whose abnormal regulations are closely associated with tumorigenesis and progression [4-6]. In addition, new screening technologies have been established allowing the identification of antibodies, peptide sequences, and nucleic acid aptamers with high affinity towards a specific biomarker [7, 8].

Nanotechnology, which is a multidisciplinary science involving chemistry, biochemistry, physics, and materials science, has found uses in a wide spectrum of medicine-related applications. These include nanoparticle-based imaging, drug delivery, biosensoring, and hyperthermia, and in the past decade, a number of these nanoparticle-based techniques have been translated into clinics [9]. Materials exhibit unique physical and biochemical properties when their dimensions are reduced to between several to hundreds of nanometers. By taking advantage of these unique characteristics, one can develop nanodevices that can sense and monitor biological events with unprecedented efficiency and sensitivity. When coupled to the aforementioned targeting ligands, one can produce “smart” nanoprobes that can interact with a biological system and sense changes on the molecular level. This can take place in vivo, where nanoprobes are systematically administrated, accumulated in tumors through ligand-biomarker interaction, and send out signals for sensitive diagnostic imaging. The nanoprobes are also useful to in vitro diagnosis and analysis of biological samples such as saliva, blood, and urine. Both applications are invaluable and hold great promise in revolutionizing cancer management [9]. The objective of this article is to review the recent progress in this exciting area. We will begin by discussing common tumor biomarkers and their corresponding targeting molecules, followed by a systematic description of the design and fabrication of magnetic nanoparticle-, quantum dot-, upconversion nanoparticle-, and gold nanoparticle-based diagnostic techniques, as well as their potential applications to cancer detection.

2. Tumor biomarkers

Tumor biomarkers are substances found in blood, urine, stool, or tissues of patients with cancer. They are most commonly proteins that are elevated in either cancer cells or other cells in the body in response to cancerous conditions. Measuring biomarker levels is one of the most common methods to detect, diagnose, and manage cancer.

Based on their location, protein biomarkers can be divided into three categories: intracellular, extracellular, and those that are on the cell membrane. For nanoparticle-enabled diagnosis, different biomarkers are targeted for different applications. For imaging, it is more common to target cell membrane protein biomarkers. For in vitro diagnosis, it is more convenient to target proteins that are soluble and shed into the circulation. Intracellular proteins, on the other hand, are less targeted given the relatively large size of nanoparticles and hence, their inability to pass through the cell membrane. Due to a long and ever growing list of biomarkers, it is not possible to cover all of them in this article. Instead, we will focus on introducing several biomarkers that have been well studied and are commonly targeted in validating nanoparticle-based imaging and diagnosis techniques.

2.1. EGFR and HER2

The epidermal growth factor receptor (EGFR) is a 170-kDa protein expressed on the membrane of many types of epithelial cancers [10, 11]. EGFR has long been regarded as a tumor biomarker because its mutation is often associated with autonomous cell growth, inhibition of apoptosis, and metastases [12, 13]. The epidermal growth factor (EGF)-EGFR interaction is among the first growth factor ligand-receptors studied [14]. EGFR has been found to be a member of a receptor tyrosine kinase (TK) family, the human epidermal growth factor receptor (HER) family. The other three members are HER2 (ErbB2), HER3 (ErbB3), and HER4 (ErbB4) [15]. Hence, EGFR is also referred to as HER1 (ErbB1). Upon ligand binding, the EGFR pairs with either itself or another HER member such as HER2 form an active dimer. Dimerization stimulates protein-tyrosine kinase and activates the intracellular protein kinase cascade. Monoclonal antibody-based inhibitors that target EGFR have been developed that take advantage of EGFR’s important role in cancer development. The first example in this category is cetuximab, a chimeric monoclonal antibody now used clinically to treat patients with head and neck cancer as well as metastatic colorectal cancer. With high avidity, cetuximab binds with EGFR and sterically blocks its interaction with growth factors [16]. Other EGFR targeting antibody inhibitors including panitumumab, zalutumumab, nimotuzumab, and matuzumab, are currently in clinical trials. When coupled with nanoparticle-based probes, these antibodies can guide the probes to tumors to realize targeted imaging [17, 18].

HER2 has also been intensively studied as a tumor biomarker; in particular, its implications for breast cancer. Deregulation of HER2 is found in 20-25% of breast cancer patients, making it an important indicator of breast tumor malignancy [19, 20]. HER2 usually dimerizes with EGFR or HER3 [14], although it can also dimerize with itself at high expression levels [21]. Trastuzumab, an anti-HER2 monoclonal antibody, has been used clinically to treat breast cancers with HER2 overexpression [14]. It has been coupled with various kinds of nanoparticles and studied as a tumor imaging probe in a pre-clinical setting [22, 23]. Pertuzumab, another HER2 targeting monoclonal antibody, has recently received FDA approval for the treatment of HER2-positive metastatic breast cancer.

2.2. VEGFR

The vascular endothelial growth factor (VEGF) is another family of growth factors that play a key role in angiogenesis, the process of forming new blood vessels. Angiogenesis is critical to physiological development and also is frequently implicated in pathological processes, including tumor progression [24]. The VEGF family is composed of 7 members, VEGF-A, VEGF-B, VEGF-C, VEGF-D, VEGF-E, VEGF-F, and placenta growth factor [25]. The most important one is VEGF-A, which is a homodimeric, disulfide-bound glycoprotein existing in several isoforms with different numbers of amino acid residues [26]. The most studied isoforms are VEGF165, VEGF121, and VEGF110. VEGF165 is implicated mostly in angiogenesis and vascular permeability whereas VEGF121 and VEGF110 are permeability factors [27]. VEGF-A acts on the vascular endothelium to stimulate endothelial cell mitogenesis and cell migration [27]. The receptors to VEGF-A are mainly Flt-1 (VEGFR-1) and Flk-1/KDR (VEGFR-2). VEGFR-1 is involved in physiological and developmental angiogenesis [25]. VEGFR-2 is a more important player in tumor progression and is critical to mitogenic, angiogenic, and permeability enhancement [28].

Overexpression of VEGF/VEGFR is observed from many tumor types and is indicated as a poor prognostic marker. To inhibit the interaction, one strategy is to sequester VEGF with an antibody in order to prevent VEGF from accessing VEGFR. Bevacizumab is a human monoclonal antibody against all isoforms of VEGF-A and the first antigenic agent receiving FDA approval for cancer management. Similarly, ranibizumab, a monoclonal antibody fragment (Fab) of bevacizumab, is used clinically for mascular degeneration treatment. A second approach is to employ an antibody that targets VEGFR. Upon binding, VEGFR is sterically blocked from interacting with VEGF. Several anti-VEGFR-2 antibodies, including IMC-1C11, IMC-1121B, and CDP791, have entered clinical development [29]. VEGF, anti-VEGF antibodies, and anti-VEGFR antibodies are all possible targeting ligands for tumor imaging in vivo.

2.3. Integrins

Integrins constitute a family of cell adhesion molecules [30]. They are always present as heterodimers comprising of one α and one β subunit. In mammals, 18 α-subunits and 8 β-subunits have been characterized. These subunits assemble into at least 24 integrin receptors that mediate the interactions between the cell and surrounding tissues [27]. Integrins are found upregulated on most tumor vasculature and for certain cancer types, also on tumor cell membranes. They are important players in tumor angiogenesis and metastasis [31]. In particular, integrin αvβ3 has been widely studied as a tumor biomarker [27] for ovarian [32], breast [33], lung [34], and prostate [35] cancer detection. Integrin αvβ3 binds to arginine-glycine-aspartic acid (RGD), which is a three-amino-acid sequence [36]. RGD dimers, tetramers, and octamers have also been studied for integrin αvβ3 targeting [37, 38]. RGD and its derivatives have been coupled to the surface of many types of nanoparticles for tumor imaging and site-specific drug delivery [27]. It is worth mentioning that in many animal models, integrin αvβ3 is upregulated on both tumor vasculature and tumor cells, and targeting occurs at both places when a small-molecule-based imaging probe is used. With regard to nanoparticle-based probes, especially those with a relatively large size, extravasation is a limiting factor and targeting typically occurs on the surface of endothelial cells. In addition to αvβ3, other members in the integrin family have been studied as tumor biomarkers. Examples include αvβ6 in the detection and staging of ovarian carcinomas [32] and integrin α5β1 in early stage lung cancer diagnosis [34].

2.4. Folate receptor

Folic acid belongs to the vitamin B family. It is a required nutrient for all living cells and participates in the biosynthesis of nucleotide bases. Folic acid shows high affinity (KD < 1 nM) to folate receptors (FR) including FR-a and FR-b, both of which are 38 kDa membrane-bound proteins [39]. FRs are expressed at low levels in normal tissues and mostly restricted to epithelial cells [40]. On the other hand, FRs are found overexpressed in several tumor types, particularly in ovarian and endometrial cancers [40]. Studies have shown that folic acid binds to tumor cells 20 times more than normal epithelial cells or fibroblasts [41], and this tumor-associated disregulation makes FR an attractive tumor biomarker.

Folic acid can be easily coupled to a peptide or a macromolecule with insignificant effects to the affinity to FR [42]. Various kinds of nanoparticles have been coupled to folic acid and studied for tumor imaging [40]. FR is expressed at a relatively high level in the kidneys [40]. Imaging and therapy with folic acid-small molecule conjugates can be impeded by this feature due to high kidney uptake. However, this issue is of minor concern with nanoparticle-based probes due to their inaccessibility to these regions.

2.5. MMPs

Matrix metalloproteinases (MMPs) are a family of zinc-dependent endopeptidases. There are at least 20 members in this protease family and they are capable of degrading multiple components of the extracellular matrix (ECM) [43]. Based on their substrate specificity, MMPs can be classified as collagenases, gelatinases, stromelysins, and so on. Another subset is MMPs 14 to 17 which contain a transmembrane domain and are known as membrane-associated MMPs (MT-MMPs). In normal tissues, MMPs are expressed at a very low level [43], but when active tissue remolding occurs, MMPs are rapidly transcribed, secreted, and activated [44]. Such activation is usually associated with a pathological process such as cancer. Indeed, high MMP expression levels are found in many types of tumors and are expressed by the host stromal cells and sometimes by tumor cells [45]. For instance, MMP2 is highly expressed in breast cancers and an increased ratio of active MMP2 is usually indicative of a higher malignancy [46, 47]. MMPs 1, 3, 9, 14 are also key players in tumor cell growth, metastasis, and angiogenesis [43].

These implications make MMPs an important class of tumor biomarkers. In the previous decade, efforts were made to prepare MMP-targeted tumor imaging probes. Targeting can be achieved using a high affinity peptide. For instance, Zhu et al. found that a peptide sequence, HWKHLHNTKTFL, had high MT1-MMP binding affinity and when coupled with a dye molecule, could efficiently target tumors [48]. Koivunen et al. reported a short target peptide, CTTHWGFTLC, which could specifically bind MMP-2 and MMP-9 thus inhibiting the migration of human endothelium and cancer cells [49]. An alternative approach is to take advantage of the enzymatic function of MMPs and develop an MMP-activatable imaging probe that displays amplified signals in the tumor region. Gold nanoparticle-based MMP activatable imaging probes, for instance, have recently been reported by Lee and Xie et al. [50, 51].

2.6. PSMA

The prostate-specific membrane antigen (PSMA) is a 100-kDa type II transmembrane glycoprotein composed of a short and amino-terminal cytoplasmic tail (19 amino acids), hydrophobic transmembrane domain (24 amino acids), and large extracellular domain (707 amino acids) at the carboxy-terminus [52, 53]. PSMA is expressed at a low or moderate level in most hyperplastic and benign prostates, but is highly up-regulated in malignant tissues [54]. The increased PSMA expression is related to tumor aggressiveness, and the highest PSMA levels are usually found from high-grade tumors, metastatic lesions, and androgen-independent disease [55]. PSMA is also found abundantly expressed on neovasculature of non-prostatic solid tumors, including lung, colon, breast, renal, liver, and pancreatic carcinomas as well as sarcomas and melanoma [55]. Antibodies against PSMA such as 7E1, J591 and MDX-070 are now used clinically for either imaging or therapeutic purposes [55]. In addition to antibodies, other motifs have been discovered for PSMA targeting. Langer’s group, for instance, has been working on aptamer- [56, 57] and small molecule-based [54,55] ligands with high avidity towards PSMA. One of the technologies developed by the group, BIND-014, recently entered clinical trial for solid tumor therapy. BIND-014, a polylactide (PLA)-based nanoparticle bearing a cytotoxic drug docetaxel, uses S-2-[3-[5-amino-1-carboxypentyl]-ureido]-pentanedioic acid, a small molecule with high selectivity to PSMA for tumor targeting [54,55].

2.7. Phosphatidylserine

Cancer cells are essentially cells that grow out of control and lose the physiological balance of renewal and senescence. Most therapeutic approaches work by inducing apoptosis to cancerous cells. A widely acknowledged apoptosis biomarker is phosphatidylserine (PS), which in normal cells is fastened on the cytosolic side of the cell membrane, but is flipped to the exterior side when the cell undergoes apoptosis [58]. Measuring the PS level is a proven means to monitor the cell apoptotic level and evaluate the response of cancerous cells to a treatment [59]. High level of PS has also been found on tumor vascular endothelium [60]. Positive PS staining was observed on 4% to 40% tumor vasculature but not on normal tissues. Boasting high selectivity toward PS, Annexin-V is the most commonly used apoptosis probe. Flow cytometry assays with effusions from ovarian carcinoma patients showed good correlation between Annexin-V level and stage, overall survival (p = 0.005), as well as progression-free survival (p = 0.013) [61]. Annexin-V can be labeled with radio- or optical-tags for tumor detection or monitoring of therapeutic response [62].

In this section, we summarized some common biomarkers targeted for cancer detection. However, it is still debatable whether some of these proteins can be called early-detection biomarkers. Nonetheless, they are the most commonly targeted from the perspective of nanoparticle-based imaging/delivery technology. Active research is being conducted to identify other protein or even non-protein-based signatures that better represent early stage cancer [63, 64]. Therefore, it will not be surprising to see in the near future an increased number of reports pertaining to the development of nanoparticle-based probes/carriers that target these novel biomarkers.

3. Engineering of nanoparticles for tumor detection

Nanoparticles can be used as probes in in vivo imaging, biosensing, and immunostaining because nanoparticle-based probes offer many advantages. First of all, they deliver high sensitivity. Many nanoscale materials show unique magnetic, optical, or acoustic properties and they can be further imparted with other types of imaging functionalities to result in probes with multimodal abilities. Secondly, their size is appropriate. Most nanoparticles have a size that is above the threshold of renal clearance (<7 nm) allowing them to remain in circulation for a relatively long time before reaching the desired targets [65, 66]. On the other hand, nanoparticles are also small enough to penetrate many biological barriers such as endothelial barriers, cell membranes, or even nuclear envelopes to efficiently interact with biological systems on the molecular level [67]. Thirdly, they are multivalent. Multiple targeting ligands can be tethered onto one nanoparticle surface. This leads to a larger rate of receptor binding and smaller rate of dissociation, both contributing to higher tumor uptake and longer retention time [68, 69], the so-called multivalency effect. Moreover, it is possible to impart more than one type of targeting ligand [70, 71]. Recent studies have confirmed improved tumor cell selectivity from such a dually-targeting targeted approach [72-74]. Fourthly, they offer combined therapy and diagnosis. In addition to imaging functionalities, therapeutics can be loaded onto nanoplatforms. The resulting nanoparticles, so-called nano-theranostics, have both imaging and therapeutic capabilities [75]. Nano-theranostics are appealing for potentially allowing therapy response to be monitored in real-time by imaging methods, an emerging concept in modern personalized medicine [76].

In the following section, recent progress on nanoparticle-based probes/sensors for cancer diagnosis is reviewed. Owing to limited space, we will only describe magnetic nanoparticles, quantum dots, gold nanoparticles, and upconversion nanoparticles. Readers who are interested in other materials such as carbon nanotubes and graphene are referred to other excellent reviews [77-81].

3.1. Magnetic nanoparticles

Magnetic nanoparticles have been investigated extensively in the field of biomedicine and one of their important applications is contrast probes used in magnetic resonance imaging (MRI). Magnetic nanoparticles create microscopic field gradients in a strong magnetic field; causing shortening and diphase of longitudinal (T1) or transverse relaxation times (T2 and T2*) of nearby nuclei, most commonly protons. This induces hyper- (for T1) or hypo-intensities (for T2 and T2*) on MRI maps and by doing so, highlighting the areas that are concentrated with the particles. Magnetic nanoparticles, particularly iron oxide nanoparticles (IONPs), are used in liver imaging, lymph node imaging, and cell tracking. Recently, devices with extremely high sensitivity using magnetic nanoparticles as probes have been developed. In this section, we will describe the synthesis, surface modification, and biological applications of magnetic nanoparticles with a focus on IONPs which are by far the most common magnetic nanoparticles.

3.1.1. Synthesis of magnetic nanoparticles

3.1.1.1. Iron oxide nanoparticles made by co-precipitation

Bulk iron oxide, either magnetite or hematite, is a ferromagnetic material with a strong magnetic moment. In the ambient environment, magnetite and hematite have magnetic moments of 90 and 76 emu g-1, respectively. However, both Fe3O4 and Fe2O3 nanoparticles show zero remnant magnetism in the ambient environment. This is because on such a small scales, thermal energy is sufficient to overcome the anisotropy energy of each small magnet thereby causing random fluctuations in the magnetization and an overall zero magnetic moment [82]. When an external magnetic field is applied, the nanoparticle magnets are easily magnetized and re-aligned to reach a saturation magnetic moment. However, when the magnetic field is turned off, the magnets are again randomized and the magnetism drops to zero. This phenomenon, termed superparamagnetism, is also observed from other types magnetic nanoparticles [82]. One of the most important reasons IONPs are so commonly used is the biocompatibility of iron oxide. Iron oxide has low toxicity and can be degraded by a biological system to become part of the body’s iron stores. Another reason is well-established surface chemistry. In the past decade, many surface engineering techniques have been developed that can modify IONPs, making them stable in physiological environments and easy to be conjugated with various bio-molecule species.

Traditionally, IONPs are synthesized by co-precipitation (Table 1) [83]. In brief, Fe(II) and Fe(III) precursors are dissolved in an aqueous solution into which an alkaline medium is added to induce particle formation. The size, shape, and composition of the magnetic nanoparticles depends on the type of the salts used (e.g. chlorides, sulfates, nitrates), Fe2+/Fe3+ ratio, reaction temperature, pH value, and ionic strength [83-85]. This synthetic approach is straightforward and has a high throughput, but the resulting particles exhibit low magnetism, typically in the range of 30 to 50 emu g-1 [86]. Bare IONPs are not stable and tend to aggregate. To improve their stability, it is common to include stabilizing agents in the reaction. They are usually polymers such as polyvinylpyrrolidone (PVP), dendrimers, polyaniline, and dextrans [87-93] which lower the surface energy and increase electrostatic repulsion, resulting in improved colloidal stability. Most IONPs used clinically, including Feridex, Combidex, Resovist, and Ferumoxytol, are made by the co-precipitation method using dextran and its derivatives as the coating materials [94, 95].

Table 1.

Summary of magnetic nanoparticles of various types

| Particle | Synthesis | Surface coating | r1 (mM-1 s-1) | r2 (mM-1 s-1) |

|---|---|---|---|---|

| Fe3O4 | co-precipitation | cross-linked aminated dextran [100] | 22.4 [100] | 76.7 [100] |

| Zn0.4Mn0.6Fe2O4 | thermal decomposition of metal chloride (MCl2, M= Zn2+, Mn2+, and Fe2+) and Fe(acac)3 | DMSA | N/A | 860 [114] |

| Fe | thermal decomposition of Fe(CO)5 | PEGylated dopamine | N/A | 220 [119] |

| MnO | Thermal decomposition of Mn-oleate complex | silica | 0.99 [148] | N/A |

| Mn NMOFs [154] | reverse-phase microemulsion using MnCl2 and [NMeH3]2(BDC) | PVP/silica | 4.6 [154] | 141.2 [154] |

| Gd-apoferritin | loading GdHPDO3A into apoferritins | apoferritin | 80±5 [157] | N/A |

| Metallofullerene | arc-burning of Gd2O3 and graphite | carbon | 207 [161] | N/A |

A sugar coating does not favor direct bio-molecule coupling, and to make the particles conjugation-friendly, a post-synthesis surface engineering step is usually required. A common approach is to treat the dextran-coated particles with epichlorohydrin and ammonia. This treatment produces a more rigid, cross-linked coating [96] and more importantly, introduces multiple amine groups on the particle surface that can be used for bio-conjugation [97-99]. The treated nanoparticles, termed cross-linked iron oxide, can be coupled to antibodies, peptides, aptamers, as well as drug molecules for the purpose of tumor imaging and therapy [100].

3.1.1.2. Magnetic nanoparticles made by thermal decomposition

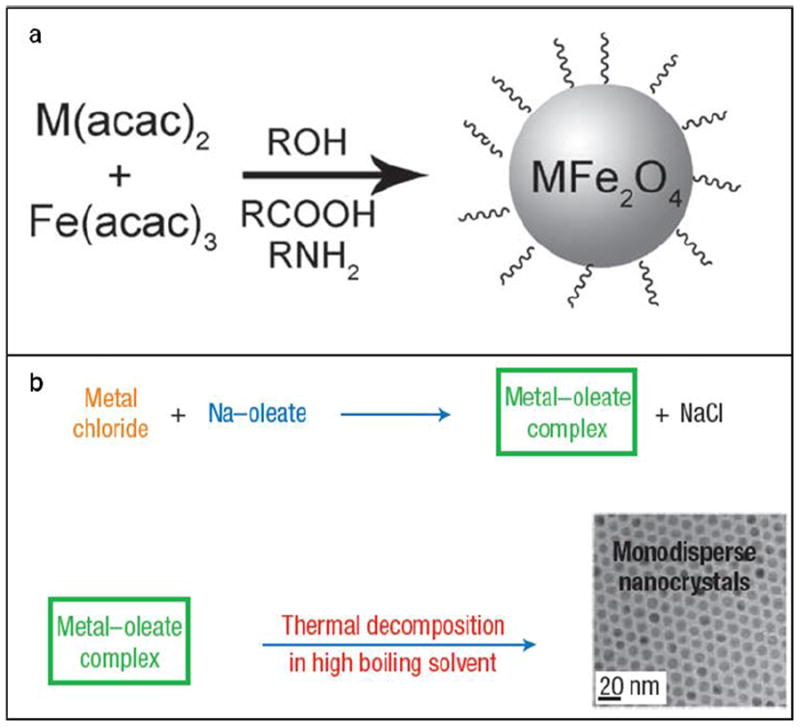

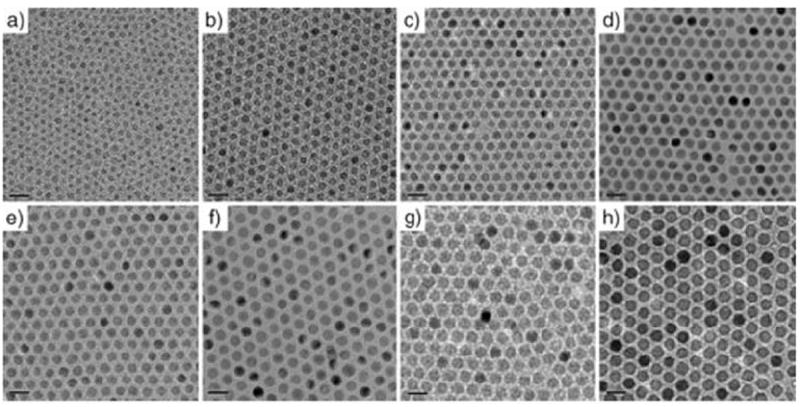

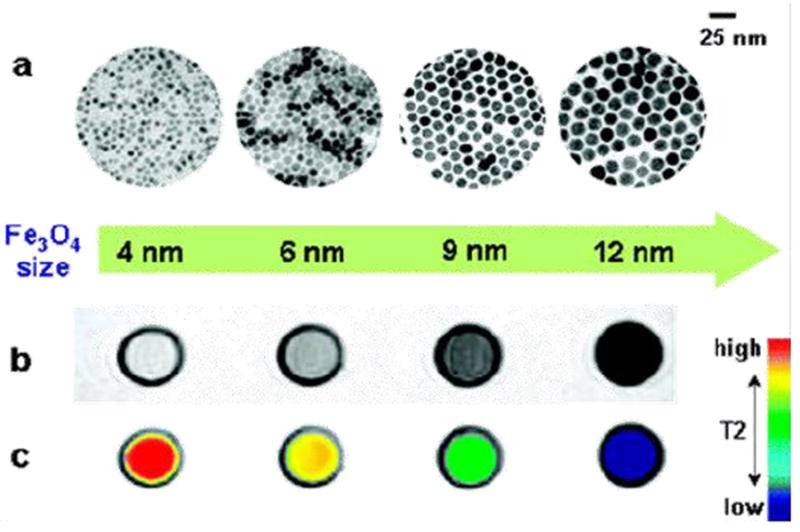

Thermal decomposition has become a popular synthetic approach in IONP preparation (Table 1) [101, 102]. Instead of using an aqueous solution as the reaction medium, thermal decomposition takes place in an organic solvent with a high boiling point. In a typical synthesis, organometallic compounds such as Fe(CO)5, Fe(acac)3, and Fe-oleate are heated to a high temperature to induce nucleation and particle growth, as illustrated in Fig. 1 [103-105]. Surfactants, such as oleic acid (OA) and oleylamine (OAm), are also essential to the process because they dynamically interact with the growing particle surface and determine the monodispersity and morphology of the products. In general, thermal decomposition provides better product quality control over co-precipitation methods. By changing/adjusting the surfactant, precursor, precursor concentration, surfactant/precursor ratio, heating rate, and reaction temperature [106-109], IONPs with single crystallinity, narrow size distribution, and controllable size can be produced. For instance, Woo et al. prepared monodispersed IONPs by thermal decomposition of Fe(CO)5 in a solution of octyl ether and oleic acid [110]. Sun et al. heated Fe(acac)3 with 1,2-hexadecanediol in the presence of OA and OAm to make monodispersed IONPs with size of 4 to 20 nm (Fig. 1a) [111]. An increase in size can be achieved using a seed-mediated process using small particles as the seeds. Park et al. reported that monodispersed magnetic IONPs with a continuous size between 6 and 13 nm could be synthesized by a procedure similar to seed-mediated growth (Fig. 2) [106]. In this process, the metal-surfactant complexes generated in situ are thermally decomposed to form nanoparticles. A prominent size effect is observed from these pyrolysis-yielded nanoparticles. Generally, particles with a larger diameter possess larger magnetic moments due to spin disorder and canting on the particle surface [112]. For instance, 4, 6, 9, and 12 nm IONPs have magnetic moments of 25, 43, 80, and 102 emu g-1, respectively (Fig. 3) [113]. The difference in magnetism dramatically affects their ability as T2 contrast agents in MRI.

Fig. 1.

Schematic illustration of the synthesis of monodisperse magnetic nanoparticles using different precursors: (a) metal acetylacetonates, (b) metal–oleate. Reprinted with permission from refs. [111] and [149].

Fig. 2.

TEM images of IONPs synthesized by a thermal decomposition route with precise control of their diameters. (a) 6 nm, (b) 7 nm, (c) 8 nm, (d) 9 nm, (e) 10 nm, (f) 11 nm, (g) 12 nm, (h) 13 nm. Reproduced with permission from [106].

Fig. 3.

Nanoscale size effect of IONPs on MR signals. (a) TEM images of nanoparticles of 4, 6, 9, and 12 nm. (b) Size-dependent T2-weighted MR images of IONPs at 1.5 T. (c) Size-dependent changes in color-coded MR images based on T2 values. Reprinted with permission from [113].

The thermal decomposition method can be extended to prepare other magnetic nanoparticles with even larger magnetic moments. For example, MFe2O4 (M = Co, Mn, Ni) nanoparticles can be prepared by simply replacing one third of the Fe(acac)3 precursor with Co(acac)2/Mn(acac)2/Ni(acac)2 (Fig. 1). The nanoparticles produced possess different magnetic properties. MnFe2O4 nanoparticles with a size of 15 nm possess a magnetic moment of 74 emu g-1 which is higher than that of IONPs with the same size [111]. Other transition metals can be incorporated into the matrix as well. Cheon’s group reported the preparation of ZnxMn1-xFe2O4 nanoparticles. Zn2+ was introduced into the tetrahedral sites, and because Zn2+ resides mainly in the Td sites rather than Oh sites, magnetism is significantly increased in comparison with normal spinel metal ferrite nanoparticles [114]. In particular, Zn0.4Mn0.6Fe2O4 nanoparticles with a size of 15 nm have an extremely high magnetic moment of 175 emu g-1 and r2 value of 860 mM-1 s-1.

Synthesis of metallic nanoparticles such as Fe and Co have been reported [115]. Bulk Fe and Co have magnetic moments of 218 and 162 emu g-1, respectively, both of which are significantly larger than iron oxide’s. Metallic Fe nanoparticles have been synthesized by thermal decomposition of Fe(CO)5 in the presence of stabilizing surfactants such as polyisobutene and decalin [116, 117]. By adjusting the ratio of Fe(CO)5 to surfactants, Fe nanoparticles with a size of 2 to 10 nm and narrow size distribution (polydispersity of approximately 10%) have been fabricated. However, these Fe particles are not stable in the ambient environment. They are easily oxidized, leading to reduced magnetic susceptibility. Sun’s group reported a simple one-pot synthetic approach to make air-stable Fe nanoparticles [118, 119]. Briefly, Fe(CO)5 was decomposed in the presence of hexadecylammonium chloride, an oxidizing agent. This treatment led to the formation of a crystalline Fe3O4 shell that protected the Fe core from continued oxidation [120].

Synthesis of Co nanoparticles has been reported by a number of groups. Alivisatos and co-workers reported the synthesis of cobalt nanodisks by thermal decomposition of Co2(CO)8 [121, 122]. Co nanoparticles also suffer from the air-sensitivity problem. Bonnemann et al. described the synthesis of air stable monodisperse colloidal Co nanoparticles by thermolysis of Co2(CO)8 in the presence of aluminum alkyl compounds [123]. By varying the alkyl chain length of the organoaluminum compounds, the size of the Co particles can be tuned in the range of 3–11 nm.

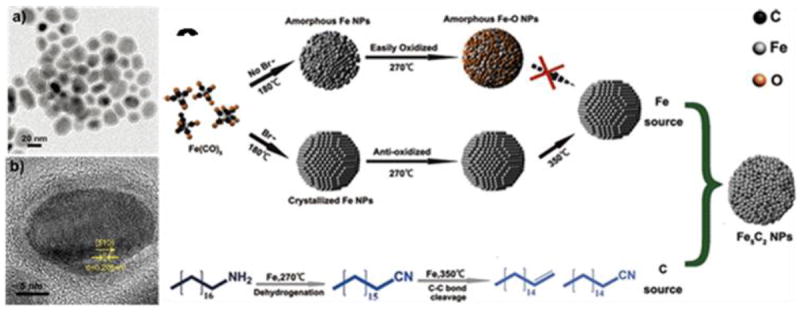

Nanoscale particles of many other magnetic materials have been made. Hou’s group employed a facile wet-chemical route to synthesize Hägg iron carbide (Fe5C2) nanoparticles, in which bromide was found to be the key to inducing the conversion of Fe(CO)5 to Fe5C2 (Fig. 4) [124]. The Fe5C2 nanoparticles were ~20 nm in diameter (Fig. 4a) and had a core-shell structure (Fig. 4b). Dai’s group adopted a chemical vapor deposition method to synthesize FeCo/single-graphitic-shell nanocrystals [125] and Sun et al. reported the synthesis of FePt nanoparticles via thermal decomposition of Pt(acac)2 and Fe(CO)5 in benzyl ether [126].

Fig. 4.

Fe5C2 nanopaticles synthesized by thermal decomposition. (a) TEM and (b) HRTEM images of 20 nm Fe5C2 nanopaticles. (c) schematic illustration of the formation mechanism of Fe5C2 nanopaticles. Reprinted with permission from [124].

In summary, nanoparticles of iron oxide and other types of magnetic materials have been produced mainly by co-precipitation and thermal decomposition. Co-precipitation is straightforward, repeatable, and has a high throughput. However, the particles produced have a relatively broad size distribution and suboptimal magnetism. Thermal decomposition allows better control of the particle size, shape, and composition, but requires stricter reaction conditions (high temperature, oxygen and water free, etc.). Another disadvantage of thermal decomposition is that the synthesized nanoparticles are coated with a thick alkyl coating and not water soluble. Subsequent surface modification needs to be performed before the particles can be used in biological applications.

3.1.2. Surface modification of magnetic nanoparticles

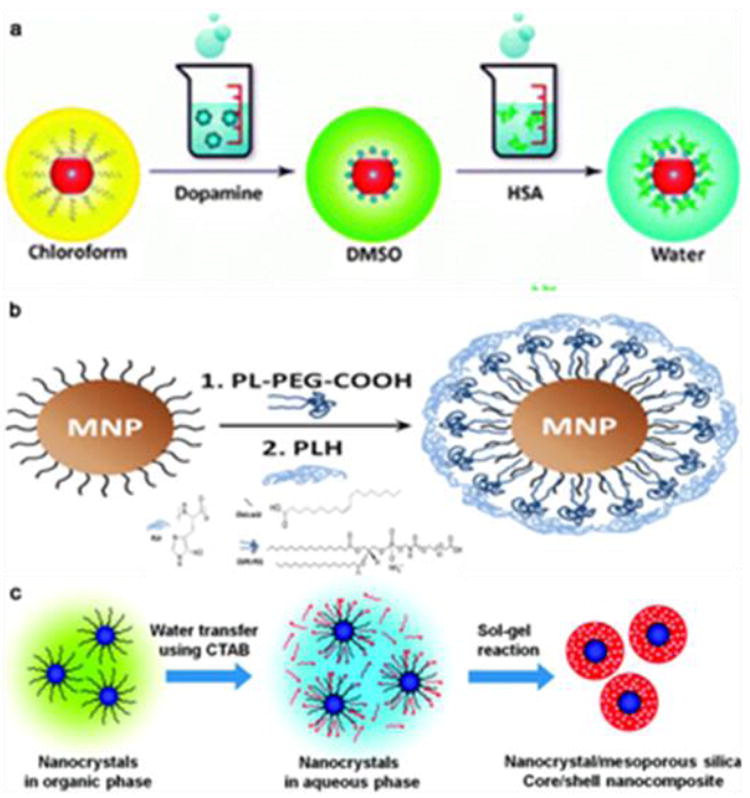

The two most commonly used surface modification approaches are ligand exchange and ligand addition. The former refers to the strategy of introducing a ligand with higher affinity to the particle surface. The latter involves the use of an amphiphilic substance that interacts with the existing hydrophobic alkyl layer via hydrophobic-hydrophobic interactions while leaving the hydrophilic section outward to suspend the particles, as shown in Fig. 5.

Fig. 5.

Representative IONPs surface modification methods. (a) Ligand exchange; (b) ligand addition; (c) silica coating. Reproduced by permission from ref. [134], [140], and [145].

3.1.2.1. Ligand exchange

Polymers such as poly(pyrrole), poly(aniline), poly(alkylcyanoacrylates), poly(methylidene malonate), poly(lactic acid), poly (glycolic acid), and poly(e-caprolactone) [127-131] have been studied as ligands to replace the original alkyl coating layer on the surface of magnetic nanoparticles. These polymers contain amine, carboxylate, phosphate, or hydroxyl end groups, and due to their multi-dentate nature, they can chemically adsorb onto the nanoparticle surface to form a protective coating. Alternatively, small molecule-based anchors that chelate with surface metals can be used as a replacing ligand. For IONPs, one good example is dopamine and its derivatives. This bidentate enediol compound can chelate with the under-coordinated surface Fe and convert it to a bulk-like lattice structure with an octahedral geometry [132]. This results in strong binding between the dopamine moiety and surface of the IONPs. This method was first reported by Xu et al. who successfully anchored nickel nitrilotriacetic acid (Ni-NTA) on the iron oxide shell of Co or SmCo5.2 nanoparticles using dopamine as the anchor [132]. Afterwards, Sun’s group reported surface-modifications of IONPs with PEGylated dopamine and evaluated the stability and potential applications of these PEGylated nanoconjugates [133]. Xie et al. reported a two-step surface modification approach for IONPs. In this process, the particles were first ligand-exchanged with dopamine and subsequently adsorbed with a layer of human serum albumin (HSA) as shown in Fig. 5a [134]. Another commonly used anchor compound is dimercaptosuccinic acid (DMSA), which is able to chelate with surface iron via the two carboxylic groups. These particles can be further stabilized by disulfide cross-linkages formed among the ligands [135]. Bio-molecules can be coupled onto the particle surface by utilizing the surface thiol groups. Herceptin, for instance, has been coupled onto DMSA modified particles [135].

It is common to observe particle aggregation during ligand exchange and phase transition. This is attributed to the dramatic polarity change on the particle surface which makes the particles more susceptible to clustering. Moreover, the interaction between the new ligand and particle surface is usually pH sensitive and can be labile in a harsh environment, such as that in endosomes/lysosomes. Nonetheless, ligand exchange remains a popular surface modification strategy in the field.

3.1.2.2. Ligand addition

Unlike ligand exchange, the native hydrophobic coatings are retained in ligand addition. The new ligands are usually amphiphilic materials such as poloxamine, poly(lactic-co-glycolic acid), poly(maleic anhydride alt-1-tetradecene) [136, 137], and phospholipids [138]. The hydrophobic segments, mostly hydrocarbons, intercalate/interact with the alkyl tails of the native ligands. The hydrophilic segments, usually containing PEG and/or multiple charged chemical groups, are pointed outward to improve water solubility. Ligand addition and phase transition are usually achieved by film hydration as shown in Fig. 5b [139, 140]. Using phospholipids as an example, the phospholipids and nanocrystals are first mixed in chloroform to form a homogeneous solution. The solvent is evaporated with a rotary evaporator to produce a film with uniformly distributed components. Afterwards, the film is hydrated and the components self-assemble into water-dispersible nanoparticles. This dispersing step usually requires energy input from heating and sonication [138].

The coating thickness impacts the relaxation times of the magnetic nanoparticles. LaConte et al. used PEGylated phospholipids of PEG chains with various lengths to modify IONPs. As the coating thickness increased, R2 decreased and R1 increased [141] due to physical exclusion of protons from the magnetic field and residence time of protons in the coating zone. It is worth mentioning that PEGylation is a common method used in nanoparticle surface modification [133, 138-141]. In the blood, nanoparticles can be easily adsorbed with a layer of opsonin proteins and as a result, recognized by the immune system and removed from circulation. PEGylation has proven to be able to stabilize nanoparticles, inhibit serum protein absorption, and extend particle circulation half-lives [138].

Small molecules, such as drug molecules, can be introduced along with IONPs into polymer/liposome matrices. For instance, Hu et al. fabricated core/shell particles containing an IONP core and a thermally responsive polymer shell into which hydrophobic drugs were encapsulated [142].

3.1.2.3. Silica coating

In addition to ligand addition and exchange with organic compounds, surface modification can also be performed using thick and dense inorganic materials. Compared to organic coatings, the rigid structure of an inorganic coating can better prevent the particle cores from contacting each other and the environment. The most commonly used inorganic coating is silica. For IONPs made by thermal decomposition, the coating usually occurs in a reverse microemulsion containing hydrophobic IONPs and tetraethylorthosilicate (TEOS) [143, 144]. TEOS hydrolyzes and condenses onto the particles to form a silica shell. Other silanes, such as N-(6-aminohexyl)-aminopropyltrimethoxysilane (AHAPS) and 3-(triethoxysilyl)propylsuccinic anhydride) (SSA), can be mixed with TEOS as the precursors. The resulting nanoparticles have surface amine or thiol groups suitable for further bio-conjugation. Alternatively, functional molecules can be pre-conjugated with silanes and encapsulated into the silica matrix. Dye molecules such as rhodamine B isothiocyanate (RITC), for instance, can first be coupled with 3-aminopropyltriethoxysilane (APTES) and co-condensed to form a fluorescent silica coating, as shown in Fig. 5c [145]. To further improve the physiological stability, PEGylation is usually added to the silica coating [146].

Functionality loading can also be achieved by using a mesoporous silica coating. This is formed by including cetrimonium bromide (CTAB) as a coating precursor [147]. CTAB works as a surfactant to transfer IONPs to the aqueous phase where TEOS condenses to form a silica coating on the IONPs. CTAB is then removed by refluxing gently in a hydrochloric acid/ethanol solution at 60 °C for 3 h. This produces 2-6 nm pores on the silica coating surface, into which small molecules can be easily encapsulated via physical interactions [148].

3.1.3. Magnetic nanoparticles-based T1 contrast probes

The aforementioned magnetic nanoparticles are made of ferromagnetic materials. These materials can significantly reduce the transverse relaxation time of protons and are primarily used as T2/T2* contrast agents. On the contrary, nanoparticles made of paramagnetic materials are used in T1 contrast probes. One example is MnO nanoparticles. MnO nanoparticles can be made by pyrolyzing Mn-oleate in a high boiling point solvent [22, 149]. By adjusting the heating time and temperature, monodispersed MnO nanoparticles with size variations of < 5% can be synthesized.

Like IONPs, the synthesized MnO nanoparticles are coated with a layer of OA/OAm which isolates the particle surface from the surroundings [150]. To become water soluble, both the ligand addition and ligand exchange routes have been investigated. A significant difference in MRI contrast ability has been found from particles surface-modified by different approaches. For example, an r1 relaxivity of 0.37 mM-1s-1 is observed from 20 nm MnO nanoparticles coated with PEGylated 1,2-distearoyl-sn-glycero-3-phosphoethanolamine (DSPE) (DSPE-PEG) [151]. On the other hand, the same size MnO nanoparticles modified by a dopamine-plus-human serum albumin (HSA) approach showed a r1 of 1.97 mM-1s-1 [152]. The difference is due to the dependence of T1 reduction on the probe-water interaction. When a DSPE-PEG coating is used, a hydrophobic inner layer remains on MnO surface that isolates the cores from the surroundings. The dopamine-HSA coating, on the other hand, is more hydrophilic and compact, leading to more efficient water interactions on the MnO surface.

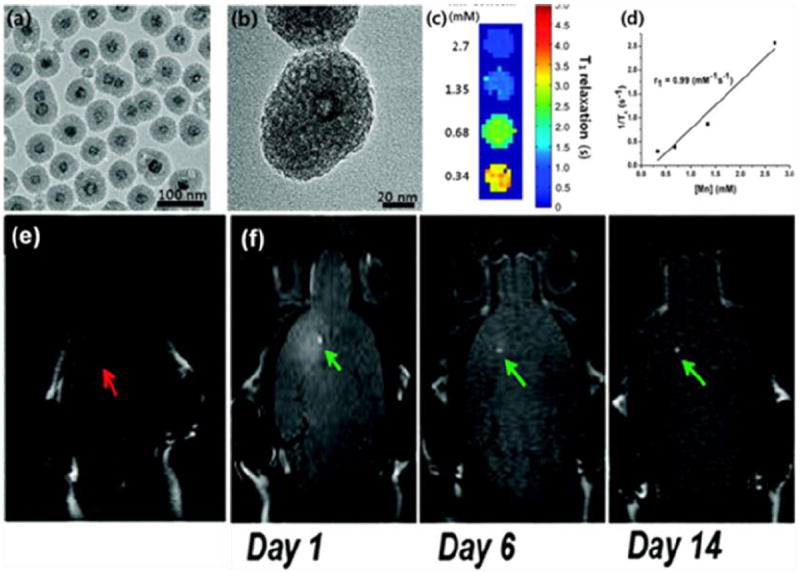

Mesoporous silica-coated hollow manganese oxide (HMnO@mSiO2) nanoparticles have also been studied as a T1 MRI contrast agent. The mesoporous shell enables optimal access of water molecules to the magnetic core and an r1 of 0.99 mM-1s-1 is observed at 11.7 T. These nanoparticles have been used to label adipose-derived mesenchymal stem cells (MSCs) with electroporation. Intracranial grafting of these HMnO@mSiO2-labeled MSCs enables serial MR monitoring of the cell transplants over a period of 14 days (Fig. 6) [148].

Fig. 6.

In vivo MRI tracking of transplanted adipose-derived MSCs bearing HMnO@mSiO2. (a) TEM and (b) HRTEM images of HMnO@mSiO2 nanoparticles. (c) T1 map of HMnO@mSiO2 nanoparticles of different concentrations at 11.7 T. (d) Plot of R1 versus Mn concentration. In vivo MRI results when (e) unlabeled MSCs and (f) HMnO@mSiO2-labeled MSCs were injected into small animal models. Reprinted with permission from [148].

Paramagnetic nanoparticles made from other materials and methods have also been studied. For instance, Lin’s group has reported the preparation of paramagnetic nanoscale metal-organic frameworks (NMOFs) [153, 154], a new class of isoreticular materials built from linking metal ions with well-defined coordination geometry using organic bridging ligands. Paramagnetic transition cations are built into these NMOFs and their potential as T1 contrast probes has been evaluated [153, 154]. For instance, Mn-containing NMOFs with controllable morphologies were synthesized using reverse-phase microemulsion techniques at room temperature and a surfactant-assisted procedure at 120 °C with microwave heating [154]. The resulting nanoparticles showed a modest r1 of 5-8 mM−1 s−1 on a per Mn basis. Similarly, Gd-containing NMOFs were prepared and the nanoparticles had an r1 relaxivity of 1.5 mM-1s-1 [153]. Luminescent lanthanide ions such as Eu and Tb can also be doped into the NMOF matrices to produce MR and optical dual functional imaging probes [155]. For both Mn- and Gd-containing NMOFs, the nanoparticles can be coated with silica and coupled with functional molecules [156]. In one study, a cyclic RGD peptide and a dye molecule were both covalently coupled onto silica-coated, Mn-containing NMOFs [154].

Protein-based nanoparticles can be encapsulated with Gd and used as T1 contrast agents. In particular, Gd has been encapsulated into apoferritin nanocages and the conjugates show a T1 relaxivity of about 80 ± 5 mM-1 s-1 at 20 MHz and 298 K. This value is almost 20 times higher than those of commercial Gd agents [157, 158].

Yin et al. described a metallofullerene nanoparticle-based MRI contrast agent [159, 160]. These nanoparticles are synthesized by arc-burning of composite rods consisting of Gd2O3 and graphite in a He atmosphere. The Gd cations are encapsulated inside the fullerene of the nanostructures. Using Gd3N@C80(OH)26(CH2CH2COOM)16 (M=Na or H) nanoparticles as an example, r1 is 207 mM-1s-1 and 50 times higher than that of commonly used Gd3+ complexes, including Omniscan and Magnevist [161].

3.1.4. Magnetic nanoparticles for cancer detection

3.1.4.1. Magnetic nanoparticle-based probes for tumor imaging

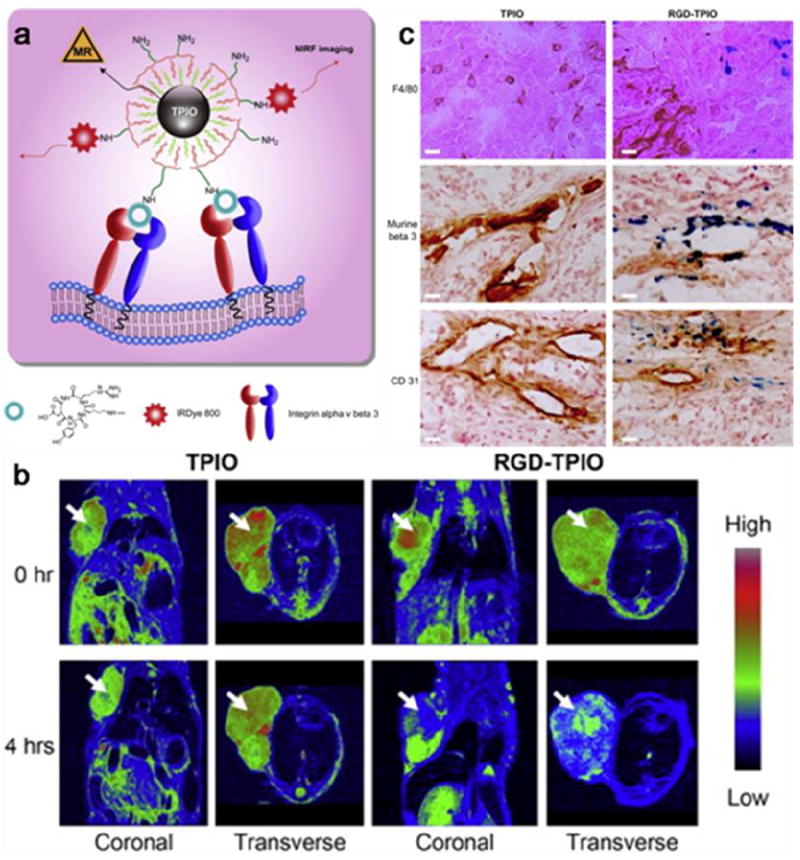

Magnetic nanoparticles made of ferromagnetic materials have been coupled with targeting motifs and studied for tumor homing and imaging. For instance, RGD has been coupled onto silica [37], triblock-copolymers [162], polyaspartic acid [163], and dextran [69, 164] coated IONPs and evaluated as MRI contrast probes. Coupling of multiple RGD on the particle surface results in a significant increase in the affinity to integrin αvβ3 due to the multivalent effect [165]. Taking polyaspartic acid (PASP)-coated IONPs as an example, the IC50 values of the RGD conjugates are 34 ± 5 nM, compared to 250 ± 60 nM of free RGD [68]. Chen et al. used a PEGylated triblock copolymer consisting of a polybutylacrylate segment, polyethylacrylate segment, polymethacrylic acid segment, and a hydrophobic hydrocarbon side chain to coat IONPs prepared by thermal decomposition (Fig. 7a). A cyclic RGD peptide, c(RGDyK), along with a NIRF dye IRDye800, were covalently coupled onto the particle surface. When the materials were tested on a U87MG subcutaneous model strong hypointensities were observed from the tumor areas and peaked at 4 hours post-injection (p.i.) (Fig. 7b). Postmortal immunohistological studies revealed nanoparticles in both the tumor endothelial cells and tumor cells (Fig. 7c) [162], both of which overexpressed integrin αvβ3 [165, 166]. Similar targeting profiles were observed from BT-20 (human breast cancer) tumor models with RGD-IONP conjugates [109,110].

Fig.7.

Triblock copolymer coated IONPs (TPIONPs) conjugated with RGD peptides and dye molecules for tumor targeting. (a) Schematic illustration of the optical/MR dual-modal imaging probes. (b) MR imaging of U87MG tumor-bearing mice injected with RGD–TPIONPs or TPIONPs. (c) Prussian blue and CD31/murine β3/F4/80 double staining withthe tumor sections. Reprinted with permission from ref. [162].

Other peptide-based targeting molecules have been studied. Chlorotoxin (CTX) was conjugated with IONPs and studied on 9L (rat gliosarcoma) xenograft models for tumor imaging [167]. The nanoparticles were found to induce a maximum R2 change of 16 s-1 in tumors after 12 h. It was subsequently shown in a transgenic mouse model that the CTX-IONPs could cross the blood-brain barrier (BBB) and specifically target brain tumors [168] without damaging the BBB. Although the exact mechanism is not clear, the BBB penetration is likely associated with CTX on the particle surface. Moreover, A54, CREKA, bombesin, F3, tumorstatin, and LHRH have been studied as targeting motifs for IONP-based imaging [169-172].

Magnetic nanoparticles have been coupled with antibodies [23]. Lee et al. coupled Herceptin with MnFe2O4 nanoparticles and evaluated the MR imaging capability on breast and ovarian tumor models [173]. Hadjipanayis et al. coupled IONPs with a purified antibody that selectively binds to the EGFR deletion mutant EGFRvIIIAb present in human glioblastoma multiforme cells [174]. In vivo MRI revealed hypointensities in or adjacent to intracranial human xenograft tumors and the IONPs continued producing contrast days later. In both studies, the antibodies had therapeutic abilities and the conjugates were therefore examples of nano-theranostics.

Magnetic nanoparticle-aptamer conjugates have also been reported. Hwang et al. conjugated the AS1411 aptamer (MF-AS1411) onto silica coated CoFe2O4 nanoparticles [175]. MF-AS1411 is a sequence that targets nucleolin, a cellular membrane protein highly expressed on the surface of many cancer types. The nanoparticle conjugates labeled with 67Ga were evaluated in vivo on a C6 glioma xenograft model. Accumulation in the tumor areas was observed by both MRI and single-photon emission computed tomography (SPECT) imaging. On the other hand, little tumor accumulation was found when the AS1411 mutant (where core nucleotides G in AS1411 aptamer were substituted with C) was coupled onto IONPs.

Paramagnetic nanoparticle-based T1 contrast probes have been studied in tumor imaging. Na et al. coupled MnO nanoparticles with Herceptin [22]. The conjugates were able to locate breast cancer metastasis in the brain, while those not conjugated with Herceptin could not. Crich et al. studied Gd-loaded apoferritin nanoparticles in tumor angiogenesis imaging using a two-step approach [157]. Firstly, a biotinylated derivative of C3d peptide was injected. With high affinity, C3d bound to the neural cell adhesion molecule (NCAM) that is overexpressed in tumor endothelial cell linings of human carcinomas. Secondly, biotinylated Gd-loaded apoferritin (Gd-Apo-Bio) and streptavidin were injected. With streptavidin as a cross-linker, Gd-Apo-Bio migrated to endothelial cells to induce hyperintensities in the T1-weighted MRI maps. However, in vivo imaging of tumors with nanoparticle-based T1 contrast agents is relatively scarce due to the relatively less prominent signal change and concerns with particle toxicity.

3.1.4.2. Magnetic nanoparticle-based biosensors

Detection and accurate measurement of biomarkers in biological samples are invaluable to healthcare. Devices employing magnetic nanostructures have shown marked progress toward this goal. The greatest advantage of magnetic nanoparticle-based biosensors over traditional diagnostic methods is the near absence of biological background interference. This enables the detection schemes to deliver high sensitivity on biological specimens.

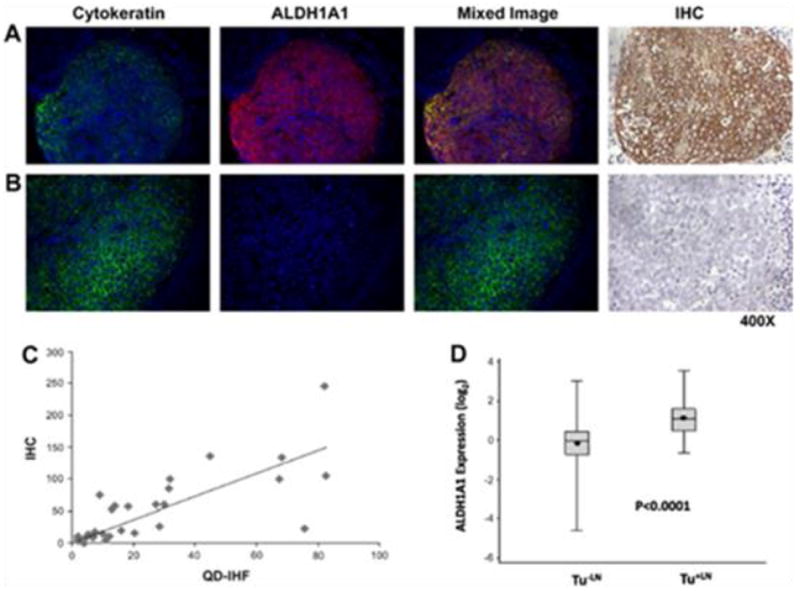

Weissleder’s group has recently developed a technology called diagnostic magnetic resonance (DMR) which exploits magnetic nanoparticles as proximity sensors to modulate the spin-spin relaxation time of water molecules surrounding the molecularly-targeted nanoparticles [176]. When a few magnetic nanoparticles bind to the intended molecular target through affinity ligands, the particles form soluble nanoscale clusters causing a decrease in T2. Instead of performing analysis on traditional and expensive NMR equipment, the group has developed miniaturized easy-to-use systems that provide accurate and rapid readouts. With antibody-conjugated IONPs, they are able to profile mammalian cells using the expressions of a number of biomarkers such as Her2/neu and EGFR [177]. They have also demonstrated the potential of using DMR for multiplexed screening and 8 biomarkers can be simultaneously analyzed on a 2×4 microcoil array. In the early studies, dextran-coated IONPs with a suboptimal r2 (62 mM-1s-1) were used. They later employed MnFe2O4 nanoparticles with a much higher r2 (420 mM-1s-1) as the probes, and this significantly improved the sensitivity. As few as 2 cancer cells in 1-μL volumes of unprocessed fine-needle aspirates of tumors can be detected and analyzed for biomarker expression [178]. This sensitivity is comparable to that of clinical methods such as flow cytometry and Western blot, but is performed in a much shorter time (< 15 min) [178].

Conjugation chemistry also impacts the sensitivity of DMR. Instead of using the traditional bioconjugation techniques, a new conjugation technology between 1,2,4,5-tetrazine (Tz) and trans-cyclooctene (TCO) has been evaluated [179, 180]. Because of the small size of the coupling reagents, a higher multiplicity of antibodies per nanoparticle is observed [181]. This leads to a higher number of particles binding to cells and in turn, improves the detection sensitivity [181]. A clinical study has recently been performed using this method [178]. The DMR system was used to analyze cells obtained by fine-needle aspirates from suspected lesions in 50 patients. With a four-protein signature, 96% accuracy in cancer diagnosis was accomplished. This is a large improvement over clinical immunohistochemistry which boasted an accuracy rate of 84%. Further tests conducted on 20 patients yielded an accuracy rate of 100%. The time required to perform the analysis is reduced from three days, for the clinical method, to less than an hour for DMR. This technology holds great clinical promise pertaining to the analysis of a wide range of targets including whole cells, proteins, DNA/mRNA, metabolites, drugs, viruses, and bacteria [176].

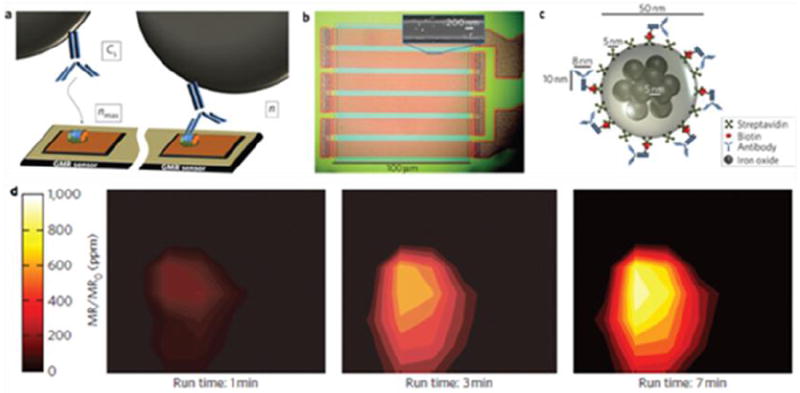

Another magnetic nanoparticle-based biosensor technology has been developed by Wang et al. based on the magnetoresistive (GMR) sensor [182]. Using protein analysis as an example, in a typical assay, a captured antibody for the desired analyte is attached to a magnetoresistive sensor. The samples are added to the sensor but only the targeted analytes remain by interaction with the captured antibody. A second, biotinylated antibody is then introduced to bind to the previously captured analytes. Finally streptavidin-coated magnetic nanoparticles are applied and immobilized on the sensor via the biotin-streptavidin interaction. The attached nanoparticles alter the voltage in the magnetoresistive sensor yielding quantitative signals. Initial studies show that multiple protein-based biomarkers can be detected at fM concentration levels with a dynamic range of more than four orders of magnitude [182]. The detection limit can be further improved by adopting an amplification step to lower the detection limit down to 50 aM, which is 1,000 times lower than that of ELISA [183]. Gaster et al. used this system to monitor the dynamic changes of CEA, VEGF, and EpCAM in a human colorectal cancer xenograft mouse model [183]. A strong correlation between the CEA concentrations and tumor growth was observed. On the other hand, ELISA failed to detect the CEA level change as the concentrations were below the detection limit. The GMR-based biosensor technology has been improved and a recent publication shows that it can be scaled to over 100,000 sensors per cm² to measure the binding kinetics of various proteins with high spatial and temporal resolution, as shown in Fig. 8 [184]. Moreover, the detection limit has been improved to as low as 20 zeptomoles of the solute.

Fig. 8.

Magnetic nanoparticle-based biosensors. (a) Schematic representation of antibody–antigen binding on the GMR sensor surface. (b) Optical micrograph showing the GMR sensor architecture. Inset: SEM image of one stripe of the GMR sensor that is bound with magnetic nanoparticle tags. (c) Schematic representation of a magnetically labeled antibody, drawn to scale. (d) Visualization of CEA protein surface concentration at different times using a high-density GMR sensor array. Reprinted with permission from ref. [184].

3.2. Quantum dots

3.2.1. Optical properties of quantum dots

Optical fluorescence imaging is used in tumor diagnosis, especially in preclinical circumstances. Fluorescence microscopy has advanced the fields of immunology and cellular biology. The recent advent of small animal whole-body fluorescence imaging systems offers a sensitive and cost-effective tool in preclinical cancer studies and has found widespread use in biomarker discovery and drug development. An intrinsic drawback of fluorescence imaging is limited tissue penetration. On account of scattering and absorption, light transmission is severely attenuated when traveling both in and out of tissues. This leads to a shallow penetration depth of typically less than 1 cm [185]. Using fluorophores with absorption and emission in the near-infrared region can alleviate the energy loss to a certain extent, but in general, in vivo fluorescence imaging has been limited to small animal models with targets close to the skin. Notably, the limited penetration does not exclude the clinical use of fluorescence imaging. Fluorescence imaging has found extensive uses in immunostaining for analyzing patient samples. Moreover, extensive research is being conducted to develop fluorescence-based imaging technologies at endoscopic and intraoperative settings, where tissue penetration is less a concern.

Organic dye molecules were overwhelmingly used in fluorescence imaging in the past, but recently, inorganic nanoparticle-based fluorophores have been found to offer advantages over traditional organic dyes. One of the most studied fluorescent nanoparticles is quantum dots (QDs), which are semiconductor nanoparticles composed of groups II and VI elements (e.g. CdSe and CdTe) or groups III and V elements (e.g. InP and InAs). Bulk semiconductors have relatively small band gaps (less than 4 eV), thus behave like insulators at ambient conditions and exhibiting electrical conductivity only under external stimulation. QDs, on the other hand, have a physical size of 2 to 10 nanometers in diameter, which is smaller than the exciton Bohr radius. This results in a 3-dimensional quantum confinement of charge carriers, limiting the number of possible energy states that an electron can occupy. In most cases, relaxation of an excited electron in QDs results in the release of the band gap energy in the form of light in the visible or near-infrared (NIR) region [186, 187]. This fluorescence mechanism gives rise to unique absorption and emission profiles. Unlike organic fluorophores which yield an emission spectrum that is usually a mirror image of the absorption one, QDs exhibit a broad absorption spectrum but a narrow and usually symmetrical emission spectrum. This allows a group of QDs with distinctly different emissions to be excited by the same light source, making them ideal tags for multiplex imaging.

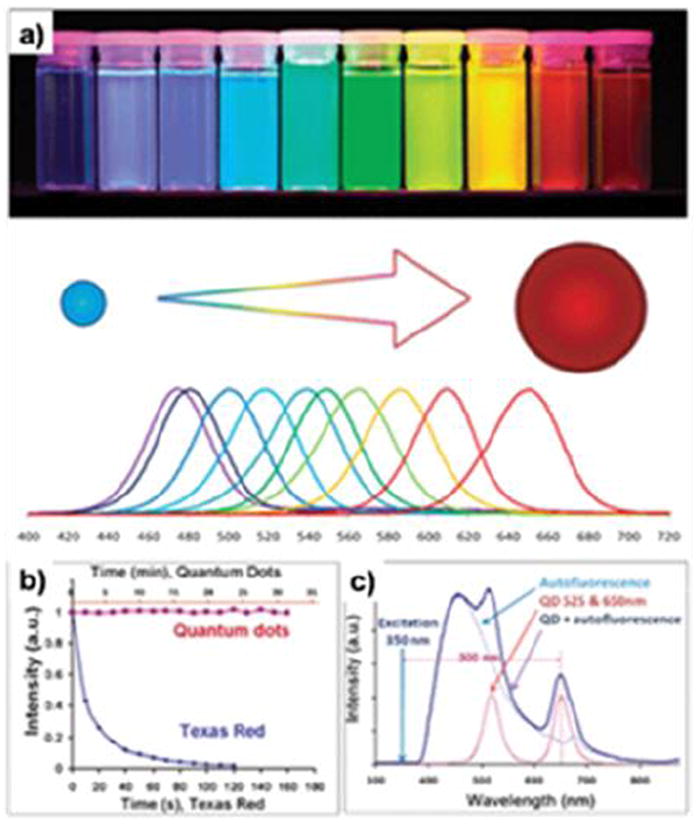

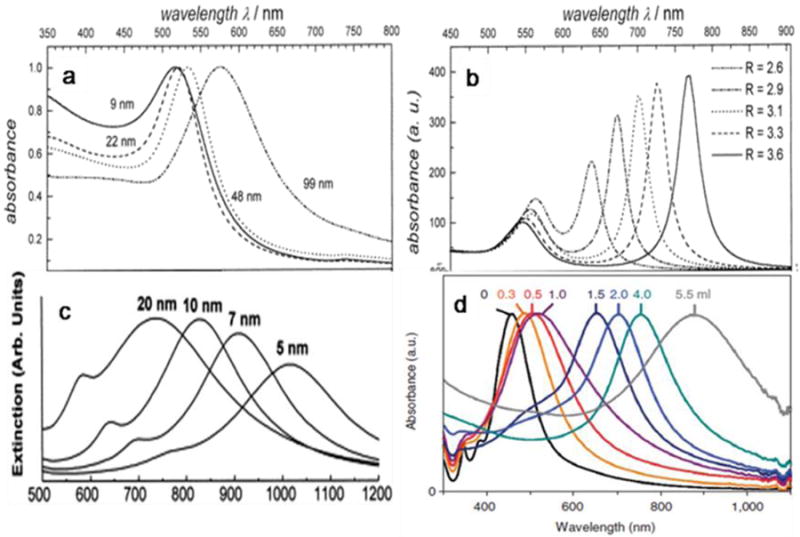

The emission from QDs is size dependent (Fig. 6a). A smaller particle size leads to an increased degree of confinement and in turn, increases the difference in energy between the discrete ground and excited states [188-191]. Taking CdSe nanoparticles as an example, a red shift is observed when the QD size increases from 1.5 to 8 nm [192, 193]. The emission also depends on the composition of the QDs. For example, in ZnxHg1–xSe QDs, the emission can be tuned by adjusting the composition to cover most of the visible and NIR region [194]. On top of the semiconductor core, a ZnS or CdS shell is usually deposited. The shell is several atomic layers thick and passivates the photoactive cores of the QDs [195, 196]. With a wider band gap, the shell efficiently confines the excitation to the core to reduce the nonradiative relaxation pathways and increase the quantum yield (QY) [197]. The shell thickness can have a significant impact on the photo-physical properties of the QDs. While thinner shells (1–2 monolayers) usually produce higher QY, thicker shells (4–6 monolayers) protect the cores more effectively from photooxidation and degradation [196, 198]. A thicker shell also reduces QD “blinking”. QD blinking is an intermittence in light emission associated with charge trapping and un-trapping at surface defects in a nanomaterial or due to charge ejection from the QD (Auger ionization) followed by recombination [199-201]. Reduced blinking is desired in diagnosis since blinking may cause signal fluctuations in ultrasensitive detection, loss of distance information when movement of a single molecule is observed, and spectral jumping (change in the emission peak position) [202].

In general, QDs have high absorption coefficients and QYs [203]. They can be 10-20 times brighter on an individual basis than organic dyes [204]. QDs are also much more photostable, as shown in Fig. 9b. Wu et al. compared the photostability of QD 608–streptavidin and Alexa 488–streptavidin with specimens mounted with glycerol or the antifade mounting medium Vectashield [205]. Without an antifade medium, the fluorescence intensity of Alexa 488 diminished to 50% of the initial intensity at 10 s, and to 10% at 60 s. With protection by the antifade reagents, Alexa 488 retained 80% of the initial intensity at 60 s and 55% at the end of 3 minutes of illumination. For QD 608–streptavidin, the intensity was 104% of the initial intensity from the glycerol-mounted specimens and 97% from the antifade medium–mounted specimens at the end of the illumination. Gao et al. showed that QDs were several thousand times more stable against photobleaching than organic dyes (e.g. Texas red) under the same excitation conditions (Fig. 9b) [206]. These observations suggest the advantages of QDs over organic dyes, especially for quantitative analysis and longitudinal tracking (Fig. 9c) [206].

Fig. 9.

Photo-physical properties of QDs. (a) Size-dependent light emission. (b) Comparison of photostability between QDs and dye molecules. (c) Capability of absorbing high-energy (Uv-blue) light and emitting fluorescence with a large Stokes shift enables efficient separation of the QD signal over the fluorescent background. Reprinted with permission from ref. [202, 206].

3.2.2. Synthesis of quantum dots

Initially, QD synthesis was performed in aqueous solutions which yielded particles with relatively poor fluorescence efficiencies and large size variation [207, 208]. Advancements in synthetic procedures and surface chemistry have enabled production of water-soluble QDs with higher QYs (up to 40–50%) and narrower size distributions. For instance, the spectral emission widths are 50 nm from CdTe/CdSe particles and 19 nm from ZnSe QDs made by water-based approaches [207, 209, 210]. However, in general, aqueous synthesis is suboptimal in controlling the photo-physical and physiochemical properties of QDs.

In 1993, Bawendi and coworkers developed a high-temperature decomposition procedure to produce QDs, and the procedures are now widely used [211]. In this process, organometallic precursors are pyrolyzed at high temperature to induce nucleation and nanocrystal growth. The protecting ligands such as trioctyl phosphine/trioctyl phosphine oxide (TOP/TOPO) are involved in the reaction by interacting with the unsaturated surface metal atoms and preventing the formation of the bulk semiconductor. In a typical CdSe nanoparticle synthesis, the liquid precursors, e.g. a solution of Se and Cd(CH3)2, and capping ligands, e.g. tributylphosphine, are injected into an organic solvent comprised of TOPO and hexadecylamine at high temperature (~300 °C). To maximize the photo-physical properties, a layer of ZnS is usually grown on top of the CdSe cores. It is noted that Cd(CH3)2 is highly toxic and unstable, and special equipment and safety measures must be adopted. Alternatively, other Cd precursors (e.g. CdO) have been developed to allow QD preparation under milder conditions [212-214].

Various reaction parameters such as the precursor, precursor concentrations, solvent, temperature, and reaction time can be tuned to achieve controlled QD synthesis [215-219]. A selective precipitation step is commonly employed to produce nanoparticles with the desired size. Dabbousi et al. used selective precipitation to prepare CdSe/ZnS QDs with the size of cores ranging from 2.3 to 5.5 nm [195]. The emission from these QDs spans most of the visible spectrum from blue to red with QYs of 30-50%. Alternatively, size control can be achieved by gradually increasing the reaction temperature. Zlateva et al. reported large-scale synthesis of six colors of CdSe QDs in a single reaction by using a slow-increasing temperature gradient [220]. The QD fractions have a narrow size distribution and produce sharp photoluminescence spectra with good QY (45–70% in organic solvent) and an overall high productive yield (~95%) since every gradient is useful.

The photo-physical properties of QDs depend on the ratio of the metals. Zhong et al. prepared a series of alloyed ZnxCd1-xS (x = 0.10, 0.25, 0.36, 0.53) nanocrystals by pyrolyzing a mixture of CdO- and ZnO-oleic acid complexes with sulfur in octadecene [221]. As the Zn content was increased, the photoluminescence spectra blue-shifted systematically across the visible spectrum from 474 to 391 nm. Qu et al. found that for CdSe QDs, the initial Cd:Se ratio of the precursors was critical to the emission wavelength, QY, types of the bright points (sharp or flat), and sharpness of the luminescent peak [203]. In particular, a large excess of the selenium precursor was found necessary to achieve a high QY and narrow emission profile. Weiss et al. found that the ratio of Cd to Se (Cd/Se) in colloidal CdSe QDs is a function of the particle radius [133]. A Cd/Se ratio of 1.2:1 was observed from QDs with a radius larger than 3.3 nm. This number increased to 6.5 when the radius was reduced to 1.9 nm, associated with the blue-shifting of emission wavelength.

Much effort has been directed to the preparation of QDs with NIR emission. This is because tissue pigments, most importantly water and hemoglobin, exhibit minimum absorption in the NIR region. This makes the NIR region (650 nm to 900 nm) a relatively transparent spectrum window and ideal for in vivo fluorescence imaging [222]. Peng et al. reported a one-pot synthesis of InAs/CdSe QDs with bright, stable, and narrow NIR photoluminescence [194]. Kelley’s group prepared NIR PbS QDs with a QY of ~26% [223]. Alloyed QDs emitting in the NIR region such as CuIn5Se8 [224], CdxHg1-xTe [225, 226], and Cu-doped InP [227] have been synthesized [228-230]. However, Cd-free QDs in general have poorer stability and inferior photo-physical properties than Cd-containing ones [202]. Recently, Nie’s group found that lattice strain could be used to adjust the emission wavelength of QDs [231]. They prepared QDs by epitaxial deposition of a compressive shell (ZnSe or CdS) on a soft and small nanocrystalline core (CdTe). The lattice mismatch between the core and shell led to dramatic changes in both the conduction and valence band energies and in turn, a large spectral shift. These strain-tunable QDs exhibit narrow light emission with high QY (60%) across a broad range of visible and NIR wavelengths (500 nm to 1050 nm).

3.2.3. Surface modification of quantum dots

QDs made by thermal decomposition are highly hydrophobic. One common surface modification approach is to substitute the native TOPO/TOP coating with a bifunctional ligand comprised a surface-anchoring group (mostly thiols) and a hydrophilic functional group. Examples include negatively-charged carboxyl-terminated thiols such as mercaptoacetic (MAA) [232], mercaptopropionic (MPA) acids [233] and thiol-containing zwitterionic molecules such as cysteine [66, 234]. In addition to providing hydrophilicity, these terminal chemical groups can be utilized in conjugation with other biological species such as proteins, peptides, or nucleic acids. Despite the simplicity of the procedure, ligand exchange with monodentate surface ligands is often associated with compromised fluorescence efficiency, photochemical stability, and shelf life. Because of limited binding affinity, monodentate ligands tend to detach from the QD surface, leaving behind surface trap sites and causing nanoparticle aggregation [235, 236]. The stability can be dramatically improved by using multidentate ligands. Liu et al. used a di-thiol ligand, PEGylated dihydrolipoic acid (DHLA), to modify QDs. The surface modification process led to aqueous stable nanoparticles with a moderate drop in QY (from 65% to 43%) [237]. Sukhanova et al. reported the use of cysteine to modify QDs and further stabilization of the particles with poly(allylamine). They observed an increase in QY from 40% to 65% [238]. Jiang et al. improved the stability of a mercaptoundecanoic acid (MUA) shell by covalently cross-linking neighboring molecules with lysine [239]. However, crosslinking also resulted in a dramatic increase in the nanoparticle size (from 8.7 to 20.3 nm). Recently, Smith and Nie developed a new class of multidentate polymer coatings only 1.5–2 nm thick [240]. Consisting of a poly(acrylic acid) backbone grafted with multiple anchors (thiol and amine groups), this coating renders CdTe QDs biocompatible and colloidally stable, while keeping the final particle size between 5.6 and 9.7 nm.

Silane-based coatings have also been proposed [241, 242]. 3-(mercaptopropyl)trimethoxysilane (MPS) has been used as a ligand to displace the native TOPO molecules. Upon addition of base, the silanol groups are hydrolyzed and condense to form a stable and compact (1–5 nm thick) silica/siloxane shell rendering the particles hydrophilic. The QDs can also be encapsulated by silica using a reverse microemulsion coating method [243]. However, the resulting coating is usually thicker, typically larger than 25 nm. Co-polymers have also been used in QDs coatings. By using the ligand addition approach, the amphiphilic materials are coated onto the hydrophobic QD surface via hydrophobic-hydrophobic interactions, leaving the hydrophilic section free to interact with surrounding water molecules to suspend the particles. Gao et al. used an amphiphilic triblock copolymer to coat QDs [244]. The resulting QDs were very stable in water and able to be coupled with targeting agents such as antibodies in tumor imaging. This ligand addition approach usually produces QDs with a large hydrodynamic size.

3.2.4. Toxicity of quantum dots

In biomedical applications, the toxicity of the materials and their interaction with biological systems must be addressed. Extensive toxicity studies have been performed on QDs both in vitro and in vivo but there is no common consensus, partially due to the diversity of QDs. It is important that each type of QD is characterized individually as not only the constituent metals, but also the QD size, charge, and functional group should be considered as contributing factors to QD toxicity [245].

Protection layers and surface coatings can reduce the toxicity of QDs. This is because QDs deteriorate in the physiological environment and release toxic heavy metals into the surroundings. The organic coating or inorganic shell can inhibit or retard this process and consequently, reduce the toxicity. Derfus et al. studied the cytotoxicity of CdSe QDs and found that without a coating, the cytotoxicity of CdSe cores could be correlated with the liberation of free Cd2+ ions [246]. With the appropriate coating, CdSe QDs could be rendered nontoxic and used to track cell migration and reorganization. Lovric et al. found that CdTe QDs coated with MPA and cysteamine were much less toxic to rat pheochromocytoma cells (PC12) than uncoated ones [247]. However, the coating itself can be the source of toxicity. For instance, Hoshino et al. observed severe cytotoxicity from EL-4 (mouse lymphoma) cells when they were treated with a QD capping ligand, MUA at 100 μg/mL [248]. They believed that it was MUA, not the QD cores, that was the major cause of the cytotoxicity but their postulate is debatable [249]. A multidentate coating may help reduce the toxicity. Voura et al. treated B16F10 melanoma cells with DHLA-capped CdSe/ZnS QDs (5 μL/mL) and found no detectable reduction in cell growth [250]. Jaiswal et al. treated HeLa and Dictyostelium discoideum cells with DHLA-capped CdSe/ZnS QDs (400–600 nM) for one week and observed no adverse effects on the cell morphology and physiology [251]. This can be attributed to a more stable coating and reduced risk of the capping falling off.

The particle size also has an impact. Lovric et al. observed that smaller cationic QDs (2.2 ± 0.1 nm) induced more pronounced cytotoxicity than larger cationic QDs (5.2 ± 0.1 nm) [247]. Later studies revealed that the variation was associated with the different subcellular distribution pattern of the two particles. While larger QDs are mainly distributed in the cytosol, smaller QDs are localized to the nuclei which are more susceptible to damage. Toxicity can be caused by several factors including free Cd ions, free radicals, or QD interaction with intracellular components. To elucidate the mechanism, QDs were co-incubated with N-acetylcysteine (NAC; a known inhibitor of Cd toxicity) and Trolox (a water-soluble vitamin E). While NAC improves the viability, Trolox fails to do so, suggesting that the toxicity stems from Cd in lieu of the free radicals. Since it is generally believed that the released heavy metals are the main source of QD toxicity, researchers have developed non-Cd formulations such as InAs/ZnSe [252], InAs/InP/ZnSe [253], and Cu-In-Se/ZnS QDs [254]. Although there are still toxic elements such as indium and arsenic, the toxicity is significantly mitigated compared to those containing Cd, Hg, and Pb [255].

The size of QDs determines their distribution and circulation in a biological system and therefore affects the toxicity profiles. A reduced particle size may lead to a longer circulation half-life and lower liver uptake. However, further reducing the particle size to <10 nm will meet the threshold of renal filtration and urinary excretion. This may be desirable in imaging because the unbound probes will not stay in the body for a long time but instead be excreted via urine. An important study was conducted by Frangioni et al. who intravenously administered QDs into rodents and studied the size effect. They studied CdSe/ZnS nanoparticles coated with DHLA, cysteamine, cysteine, and PEGylated DHLA with hydrodynamic sizes ranging from 4.4 to 8.7 nm. A hydrodynamic size of 5.5 nm was found to be a critical point below which nanoparticles could be efficiently eliminated from the body through renal clearance [66]. Gao et al. prepared MPA coated InAs/InP/ZnSe QDs with a hydrodynamic size of less than 10 nm [256]. UV/Vis absorption and fluorescence emission analyses detected QDs in urine samples from the administrated animals, suggesting that QDs could be cleared through the urinary excretion.

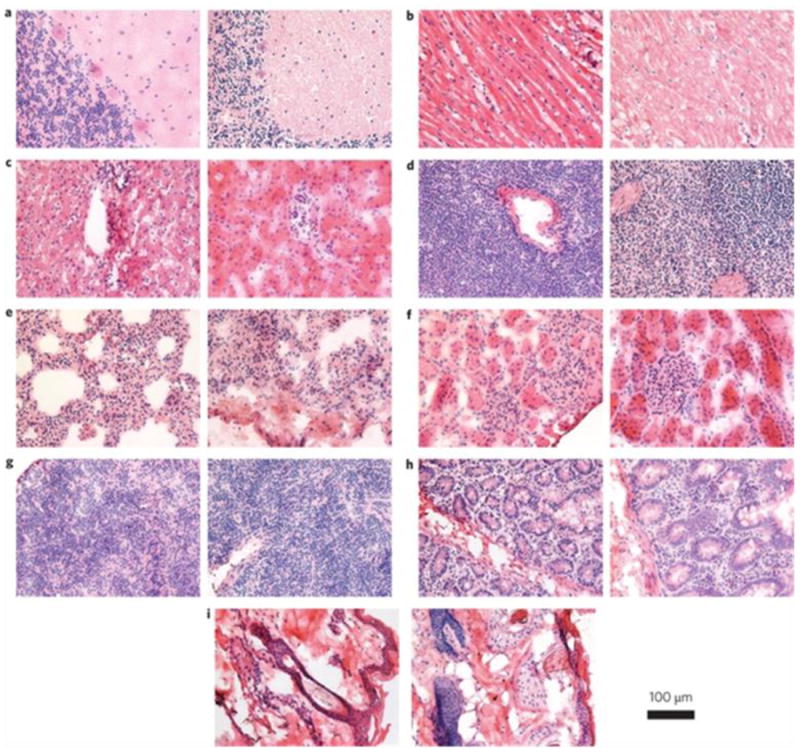

The majority of in vivo studies with QDs have hitherto shown no obvious toxicity. Larson et al. observed no noticeable ill effects in mice injected with 20 nM and 1 μM solutions of CdSe/ZnS QDs [257]. Ballou et al. injected amphiphilic polymer coated QDs at a 20 pmol QD/g dose to mice [258]. The injected mice remained viable for 133 days and histology studies found no signs of necrosis at the sites of tissue deposition. More exciting news came recently from a pilot toxicity study on non-human primates which found no adverse response to intravenous injection of QDs (Fig. 11) [259]. The researchers injected rhesus macaques with phospholipid micelle encapsulated CdSe/CdS/ZnS QDs at a dose of 25 mg/kg. The blood and biochemical markers were found to be in the normal range and histology of major organs showed no abnormalities after 90 days. Two treated monkeys underwent continued evaluation and showed no ill effects for one year. However, it was observed that most of the initial cadmium dose remained in the liver, spleen, and kidneys after 90 days. The ultimate fate of the heavy metals and their long-term impact on the body require further analysis, but nonetheless, this encouraging pilot study suggests a potential role of QDs in clinical applications.

Fig. 11.

Histological images from the major organs of the rhesus macaques three months after intravenous injection of the QD formulation. In each pair, the left image is from the control animal and the right image is from a treated animal. Tissues were collected from brain (a), heart (b), liver (c), spleen (d), lung (e), kidney (f), lymph (g), intestine (h) and skin (i). Images were taken at ×40 magnification. Reprinted with permission from ref. [259].

3.2.5 Quantum dots for in vivo imaging

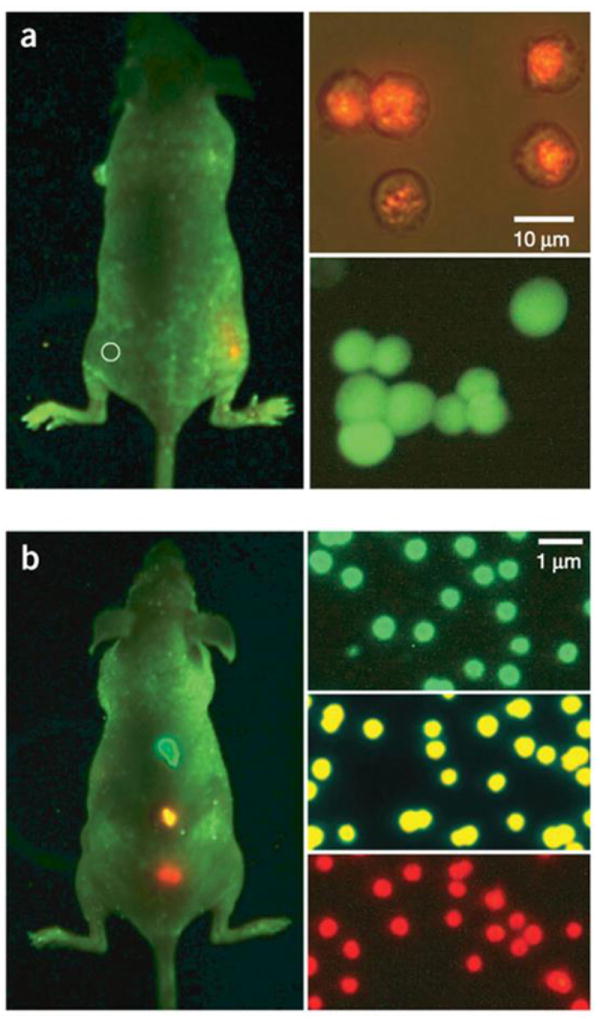

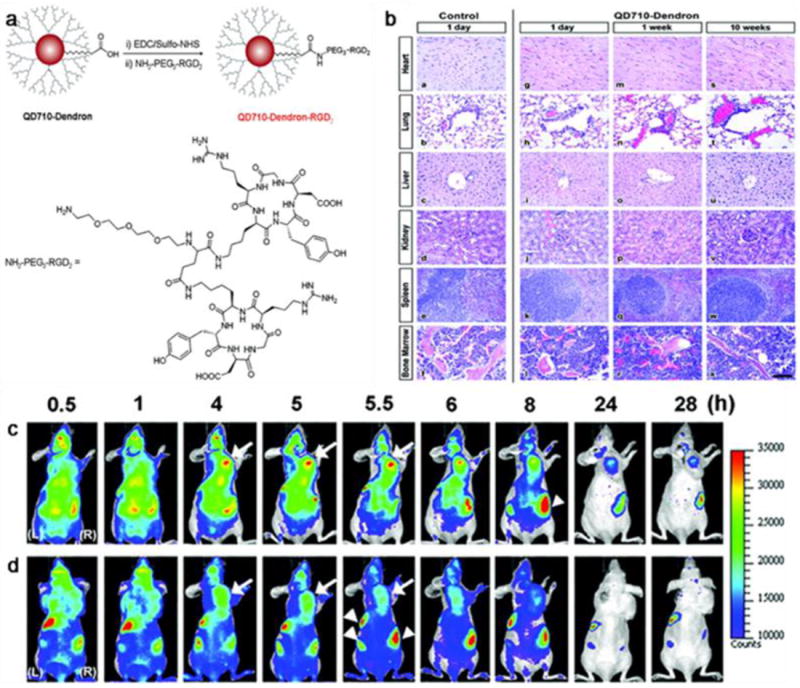

Despite controversies, tumor targeting is believed to benefit from a long circulation half-life, and for this purpose, a stable and thick coating offers many advantages [260]. A coating with high molecular weight PEG has been found to reduce rapid clearance of QDs by liver and bone marrow [258], and the use of branched PEG may further improve circulation [260, 261]. Amphiphilic triblock copolymer coated QDs show a circulation half-life of 5-8 h [260]. Nie et al. have coated CdSe/ZnS QDs with a triblock copolymer and conjugated onto the coating an anti-PSMA antibody [244]. In vivo imaging conducted on subcutaneous tumor models reveals good tumor accumulation attributable to the enhanced permeability and retention effect (EPR) as well as antibody-PSMA interaction (Fig. 12). Cai et al. conjugated c(RGDyK) onto polymer coated NIR QDs (705 nm) and studied tumor targeting on a subcutaneous U87MG human glioblastoma model [262]. The tumor fluorescence intensity reached a maximum at 6 h p.i. with good tumor-to-normal-tissue contrast, and the targeting was mainly caused by the RGD-integrin interaction. Recently, Gao et al. reported a dendron-coated InP/ZnS core/shell QD with 710 nm emission [263]. After coupling with a RGD dimer, the particles had a hydrodynamic size of ~12 nm, but unexpectedly, the fluorescent signals were found in urinary bladder and urine collected 90 min after administration. A pilot mouse toxicity study confirmed that the particles did not cause significant toxicity at their particular doses. The nanoparticles showed a long circulation half-life that allowed clear delineation of the tumor up to 28 hours p.i. (Fig. 13). Gao et al. also conjugated anti-HER2 antibody molecules onto phospholipid coated QDs [264] and the resulting conjugates were able to specifically target HER2 positive tumors with a peak tumor-to-background ratio of ~4 at the 4 h p.i. time point.

Fig. 12.

In vivo imaging of implanted QD-tagged tumor cells. (a) Bright QD tags enable visualization of tumor cells with a non-invasive whole-animal fluorescence imaging, whereas organic dye signal is indistinguishable from autofluorescence. (b) Imaging of subcutaneously implanted QD-loaded microbeads shows the potential for multiplexed in vivo cell detection and tracking. Reprinted with permission from ref. [244].

Fig. 13.

In vivo NIR fluorescence imaging results with QDs. (a) Structure and synthesis of QD710-Dendron-RGD2 conjugate. (b) Representative organ histology of PBS and QD710-Dendron treated animals. Scale bar, 100 μm. The dorsal images of SKOV3 tumor-bearing (arrows) mice (L, left side; R, right side) injected with (c) QD710-Dendorn-RGD2 (200 pmol) and (d) QD710-Dendron (200 pmol) at 0.5, 1, 4, 5, 5.5, 6, 8, 24, and 28 h p.i. Reprinted with permission from ref. [263].