Abstract

Recovery of whey proteins with improved water holding capacity, reduction of losses of curd fines as well as improvement of ability of curd to retain moisture appear some crucial approaches to result in a product with comparatively higher yield. In the present study, endeavours were made to improve the yield of direct acidified cottage cheese through the addition of κ-carrageenan in milk before heat treatment and tetrasodium pyrophosphate (TSPP) immediately before renneting. κ-carrageenan was added at the levels of 0.005, 0.015 and 0.025% and their effect on the total protein and whey proteins contents, moisture retention and the resultant curd yield as well as the quality of cottage cheese was studied. The study showed that addition of κ-carrageenan at 0.015% level followed by heat treatment at 90 °C for 5 min significantly (P < 0.01) increased the curd yield to 13.8% against 12.2% for the control. It was also observed that addition of κ-carrageenan at the level of 0.015% significantly (P < 0.01) increased the whey proteins and total protein contents to 14.8 and 88.5% against 73.4% and 1.2%, respectively with improved (P < 0.01) moisture retention of 75.4% as compared to 74.4% for the control. However, the study showed that addition of tetrasodium pyrophosphate (TSPP) at the levels of 0.02 to 0.08% neither had any effect on the recovery of whey proteins and moisture retention as well as the consequent curd yield nor the sensory quality of cottage cheese.

Keywords: Cottage cheese, Direct acidification, Cheese yield, Whey protein recovery, κ-carrageenan, Tetrasodium pyrophosphate

Introduction

Typical yield of cottage cheese made from skim milk subjected to standard HTST pasteurization is 15–17% depending upon the protein content of the milk (Guinee et al. 1993). Retention of whey proteins in cheese can be increased by the development of procedures for binding whey proteins directly into the casein coagulum. Application of this approach to cottage cheese manufacture requires agents that coagulate whey proteins during casein coagulation thereby creating an integrated coagulum with both caseins and whey proteins or alternatively, developing procedures to aggregate or coagulate whey proteins independently and then entrap the whey protein particles in a subsequently produced casein coagula can enhance the recovery of whey proteins in cheese (Dybing and Smith 1998).

In the present study, approach was, therefore, postulated to improve the yield of direct acidified cottage cheese, which included the use of additives like κ-carrageenan before high heat treatment (90 °C/5 min) and tetrasodium pyrophosphate (TSPP) (without high heat treatment) immediately before renneting individually as well as in combination because of their possible role of binding with proteins and improving moisture holding capacity of the curd by improving gel strength. The study involved the selection of levels of addition of κ-carrageenan without hampering the quality of the final product that was achieved by the initial laboratory trials. Attempts were also made to manufacture cottage cheese with improved whey proteins content and accordingly with improved yield by using a food grade TSPP. The approach was hypothesized based on the possible interactions between proteins and anionic polyelectrolytes and thereby incorporating them into casein coagula (de Vries 2004). Dybing et al. (1982) studied the effect of addition of 0.05 and 0.20% sodium hexametaphosphate in milk in increasing the yields of cottage cheese. Based on the earlier attempts (Dybing et al. 1982), in the present study food grade TSPP was used at the levels of 0.02, 0.05 and 0.08%.

Materials and methods

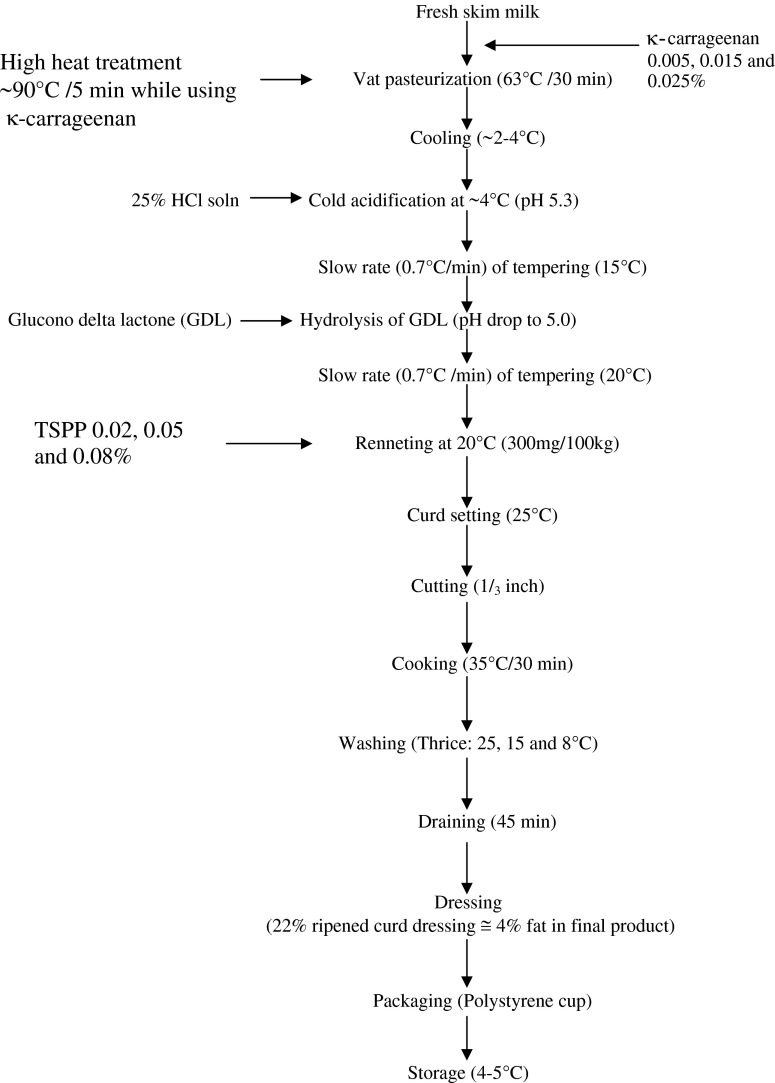

The fresh skim milk (~0.02% fat) from the Experimental Dairy, NDRI, Karnal was transferred to a pasteurizing vat. Cottage cheese was manufactured employing dual acidification technique following the procedure as outlined in Fig. 1.

Fig. 1.

Flow diagram for manufacturing direct acidified cottage cheese employing dual acidification technique

Direct acidified cottage cheese made from milk without added κ-carrageenan and TSPP and subjected to normal vat pasteurization (63 °C/30 min) served as control. While κ-carrageenan was used, the cheese milk was subjected to high heat treatment at 90 °C for 5 min because of the phenomenon that heat induced denaturation of β-lactoglobulin exposes more positively changed groups available for electrostatic interaction with the sulfate groups of κ-carrageenan (Stanley 1990) leading to complex formation, which virtually integrates into the casein coagula.

Mixed strain multiple starter culture used for ripening of curd dressing were collected from the National Collection of Dairy Cultures (NCDC), NDRI, Karnal, India. Meito rennet (M/s Meito Sangyo and Co. Ltd., Tokyo, Japan) commercially produced from Mucor pusillus var. lindt was used in the experiment. The non fat dry milk (NFDM) used to adjust the total solids (TS) content of skim milk to desired levels was procured from Doaba Milk Plant, VERKA, Punjab, India. The TSPP (GR grade) and κ-carrageenan (commercial grade) were procured from Sigma-Aldrich Inc., USA. A paste of κ-carrageenan was prepared in a 100 ml beaker with the addition of a small quantity of milk (45 °C), which was added to milk before heat treatment by washing the beaker with warm milk. Calculated quantity of TSPP was properly dissolved in small portion of milk and thereafter transferred to the cheese milk followed by renneting and mixing thoroughly.

Analysis

TS content, total protein as well as the casein of skim milk was determined according to AOAC (2000) method. Estimation of whey proteins in skim milk was carried out by subtracting non-protein nitrogen (NPN) from non-casein nitrogen (NCN). The AOAC (2000) Kjeldahl procedure was used to determine the NCN and NPN in milk. Moisture content in cottage cheese curd was determined by oven drying to constant weight as per AOAC (2000) method. Total protein content of the curd was estimated using Kjeldahl method as described in AOAC (2000). For this, 3 g sample was accurately weighed and placed in a porcelain mortar. The sample was ground with the addition of 2.5% glacial acetic acid in a mortar. After a smooth paste was formed, more acetic acid solution was added. The cheese suspension was transferred to a 100 ml volumetric flask and the mortar was rinsed with added acetic acid solution. The rinsing was transferred to the flask until 100 ml mark was attained. Thereafter, AOAC (2000) Kjeldahl method was followed to determine the total nitrogen content in the cheese suspension and calculation was made accordingly. Determination of whey proteins in cottage cheese curd was performed by subtraction method from the results obtained for NCN and NPN. For estimation of NCN and NPN in cottage cheese curd, around 1.25 g sample placed in a porcelain mortar. The sample was ground with the addition of 10 ml warm water (45 °C) and 0.5 ml acetic acid and smooth suspension was prepared, which was transferred to a 100 ml beaker. The mortar was rinsed thrice with total of 40 ml warm (45 °C) water. The rinsing was transferred to the 100 ml beaker. Thereafter the AOAC (2000) Kjeldahl procedure described for milk was followed to determine the NCN and NPN in cottage cheese curd. Yield of cottage cheese curd was expressed as per cent of the cheese milk.

Sensory evaluation

Sensory evaluation of cottage cheese was carried out using the standard cottage cheese scorecard recommended by the ADSA (2004). Descriptive sensory analysis method was performed using 10 trained panellists of the Institution, constituted based on their interest, performance, motivation, compliance and availability (ISO 8586–1: 1993E). Attributes evaluated were flavour, body and texture as well as colour and appearance. The panellists received preliminary training according to the methods recommended by the ISO (ISO 8586: 1993E). The analysis was performed in Sensory Laboratory designed according to the recommendations in ISO standards (ISO 8589: 1985). Before profiling, two sessions were used to train the assessors in the definition of attributes of a standard identity cottage cheese. The panellists were allowed to use water and bland crackers for palate cleansing between the samples. All the samples (100 g), randomly coded using three digit numbers, were evaluated in each session and each panellist was given the samples (25 °C) in white 100 ml plastic cup always 2 h before and after meals. Each sample was served in duplicate. The panellists expressed their judgments about the samples using the structured numeric scale as per the guidelines of ADSA (2004).

Statistical analysis

All experiments were in triplicate. The data were statistically analyzed as per the methods described by Evanston (1990) with the application of SYSTAT software, VERSION 6.01 COPYRIGHT (C) 1996, SPSS INC employing Least Squares Analysis of Variance of a one factor design experiment and Two Sample t-test in the case while only one type of experimental sample was subjected to comparison with the control. When significant (1 and 5% levels) differences were observed, individual means were compared by using Fisher’s Least Significant Difference model. Graphical representation of the results has been made using GraphPad Prism® Software, Version 3.02, GraphPad Software Inc, 5755 Oberlin Dr #110, San Diego, CA 92121.

Results and discussion

Gross composition of skim milk

The TS content of initial skim milk largely affects the yield of cottage cheese curd and thereby yields of the final product. Skim milk intended for use in the present study was adjusted to a TS level of 10.5% using good quality NFDM. The gross composition (%) of standardized skim milk was TS 10.5 ± 0.21, total protein 2.8 ± 0.12, Casein 2.2 ± 0.10 and Whey proteins 0.53 ± 0.022.

For manufacturing good quality cottage cheese, a desired level of TS content should be achieved by using either concentrated skim milk or reconstituted dried skim milk. Several workers (Tuckey 1952; Makleby and Zakariasen 1954) also reported that there appears to be critical solids not fat (SNF) level of 8.5 to 8.8% below which weak curd and excessive shrinkage becomes prominent. It was too observed that good quality cottage cheese could be made by fortifying the skim milk to 11% TS by adding low heat non-fat dry milk (Durrant et al. 1961; Stone 1975). Whitaker (1956) reported several advantages including firmer curd, shorter cooking, increased vat capacity and easy curd handling in favour of fortification of skim milk for cottage cheese.

Addition of κ-carrageenan

The approach of addition of κ-carrageenan was based on the phenomena that κ-carrageenan possesses strong gel forming ability and shows interaction with whey proteins thereby including them with the casein during coagulation. Our preliminary experiments demonstrated that addition of κ-carrageenan in milk at the levels greater than 0.025% followed by heating of 90 °C for 5 min showed prominent gel forming sign upon cooling, which was undesirable for manufacturing cottage cheese that requires an acid gel formation. Therefore, it was decided to add κ-carrageenan in milk at the levels 0.005, 0.015 and maximum of 0.025% to study their effect on the curd yield as well as the quality of cottage cheese.

Effect on the yield

It was observed that with the addition of 0.005% κ-carrageenan, recovery of whey proteins and thereby total protein contents in curd significantly (P < 0.01) increased to 14.5 and 88.3% as compared to 1.2 and 73.4% respectively for the control sample (Table 1.). Further increase in of κ-carrageenan level to 0.015 and 0.025% slightly increased the recovery of whey proteins and accordingly total protein content. Use of 0.005% κ-carrageenan significantly (P < 0.05) enhanced the moisture retention in curd as compared to the control sample; however, further increase in κ-carrageenan level to 0.015% improved (P < 0.01) the moisture retention to 75.4%. It was also observed that while the level of addition of κ-carrageenan was again elevated to 0.025%, no significant improvement was noticed.

Table 1.

Effect of addition of different levels of κ-carrageenan in milk following high heat treatment (90 °C/5 min) on the yield of direct acidified cottage cheese curd

| Level of κ-carrageenan,% | |||||

|---|---|---|---|---|---|

| Control | 0.005 | 0.015 | 0.025 | CD0.01/0.05 | |

| Protein,% | 73.4 ± 0.10a | 88.3 ± 0.04b | 88.5 ± 0.03b | 88.5 ± 0.04b | 0.498/0.292 |

| Whey proteins,% | 1.2 ± 0.04a | 14.5 ± 0.06b | 14.8 ± 0.07b | 14.8 ± 0.07b | 0.515/0.302 |

| Moisture,% | 74.4 ± 0.07a/p | 74.9 ± 0.08a,b/q | 75.4 ± 0.09b/r | 75.5 ± 0.10b/r | 0.741/0.434 |

| Yield,% | 12.2 ± 0.06a/p | 13.3 ± 0.10b/q | 13.8 ± 0.08b/r | 13.9 ± 0.06 b/r | 0.638/0.374 |

Means with different superscripts columns in (a, b) and in row (p, q, r) differ significantly (P < 0.01)

Yield of the control curd was 12.2% which upon the addition of κ-carrageenan 0.005 to 0.025%, significantly (P < 0.01) improved the yield to 13.3–13.9% as compared to the control sample. Increasing the level of κ-carrageenan from 0.005 to 0.015% again increased (P < 0.05) the curd yield from 13.3 to 13.8%, which upon further increase to 0.025% exhibited no marked improvement in curd yield.

Some of the major concerns of cottage cheese manufacture are low yields and high whey disposal cost. Attempts have been made to increase the yield of cottage cheese using high heat treatments (Stone 1975; White and Ray 1977) addition of sodium hexametaphosphate, capable of precipitating whey proteins (Dybing et al. 1982), addition of κ-carrageenan and combination with sodium hexametaphosphate (Manning et al. 1985) and thermization at 74 °C for 10 s followed by storage at 3 °C for 7 days and thereafter HTST (Dzurec and Zall 1982).

The increase in recovery whey proteins and thereby the total protein in cottage cheese curd was attributed to the possible interaction between whey proteins and κ-carrageenan, which led incorporation of whey proteins into coagulum. The mode of action of κ-carrageenan has been attributed to its ability to bind water as well as its interaction with the casein micelles (Puvanenthiran et al. 2001). Long before, Snoeren et al. also (1975) suggested that a segment of κ-casein is capable of an electrostatic reaction with the negatively charged sulfate groups of κ-carrageenan.

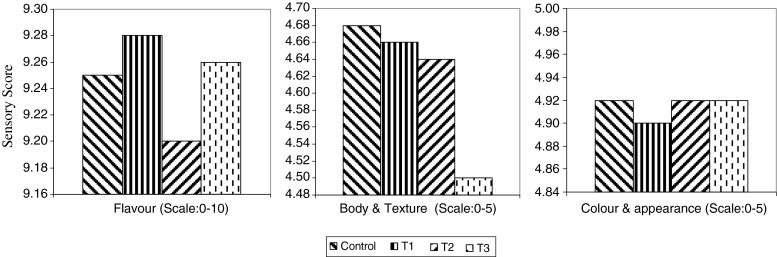

Sensory quality of cheese-effect of κ-carrageenan

κ-carrageenan was added followed by heat treatment at 90 °C for 5 min, quality of cottage cheese with regard to body and texture remained unaffected, which suggests that addition of κ-carrageenan possibly counteracted the effect of high heat treatment on the quality of product. This can be explained by the fact that κ-carrageenan aids in strengthening the milk gels because of its interaction with milk proteins. With addition of κ-carrageenan at a level of 0.025%, the final product achieved comparatively a poor score for body and texture as compared to the control sample (Fig. 2). This could be due to the presence of fairly hard and brittle curd particles resulted by the addition of higher level of κ-carrageenan.

Fig. 2.

Sensory quality of direct acidified cottage cheese as affected by the addition of different levels of κ-carrageenan in milk following high heat treatment (90 °C/5 min). T1, T2 and T3 imply direct acidified cottage cheese samples made from milk added with κ-carrageenan at the levels of 0.005, 0.015 and 0.025%, respectively following high heat treatment at 90 °C for 5 min

Addition of TSPP

Effect on the yield

Cottage cheese curd made as per the standardized procedure without the addition of TSPP exhibited whey proteins content of 1.2% with a total protein content of 73.4%, whereas the curd made from milk added with varying levels of TSPP showed a corresponding range of 1.17–1.20 and 73.4–73.5%, respectively (Table 2). Addition of TSPP also displayed no consequence on the moisture retention in curd and consequently, no improvement was found in curd yield.

Table 2.

Effect of addition of different levels of tetrasodium pyrophosphate in milk on the yield of direct acidified cottage cheese curd

| Level of TSPP (%) | |||||

|---|---|---|---|---|---|

| Control | 0.02 | 0.05 | 0.08 | CD0.01/0.05 | |

| Protein,% | 73.4 ± 0.10 | 73.5 ± 0.11 | 73.4 ± 0.09 | 73.4 ± 0.09 | 0.811/0.476 |

| Whey proteins,% | 1.20 ± 0.039 | 1.18 ± 0.038 | 1.17 ± 0.04 | 1.20 ± 0.037 | 0.320/0.187 |

| Moisture,% | 74.4 ± 0.07 | 74.4 ± 0.05 | 74.3 ± 0.06 | 74.4 ± 0.07 | 0.534/0.313 |

| Yield,% | 12.2 ± 0.06 | 12. 2 ± 0.05 | 12.2 ± 0.05 | 12.1 ± 0.05 | 0.443/0.260 |

Means within different columns do not differ significantly

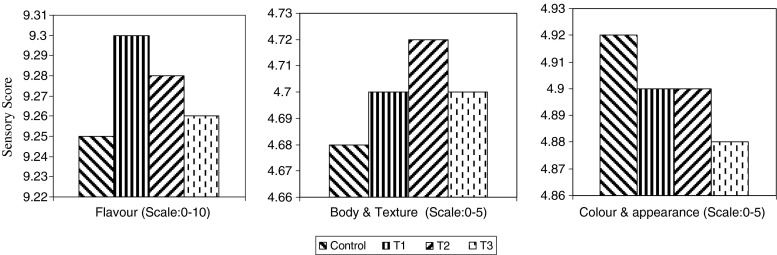

Effect on sensory quality

Sensory attributes of final cottage cheese remained unaffected by the addition of TSPP in milk (Fig. 3). Addition of TSPP in milk at levels ranging from 0.02 to 0.08% even hardly affected the body and texture of the final product.

Fig. 3.

Sensory quality of direct acidified cottage cheese as affected by addition of different levels of tetrasodium pyrophosphate: T1, T2 and T3 imply direct acidified cottage cheese samples made from milk added with tetrasodium pyrophosphate at the levels of 0.02, 0.05 and 0.08%, respectively

Adding TSPP alone at the levels of 0.02 to 0.08% in milk immediately before renneting neither put forth any effect on the recovery of whey proteins and moisture retention nor the sensory quality of cottage cheese. The inability of TSPP to increase whey proteins recovery in curd was thought to be due to higher pH of milk, i.e. pH 5.0 at which TSPP was added.

The addition of phosphates to muscle food homogenates, raw and cooked meats, in sausages, hams, poultry, and seafood will decrease the amount of drip loss, enhance water binding and water holding capacity resulting in enhanced sensory characteristics (Fennema 1985). Dybing et al. (1982) also reported that the inability to reduce pH of the milk to the levels used in some of the procedures for recovering whey proteins from whey with polyelectrolytes, i.e. pH 3.0 (Hidalgo et al. 1973) and 3.2 (Hill and Zadow 1974; Zadow and Hill 1975) might explain the lack of significant whey protein recovery. Whey proteins recovery using TSPP in milk requires a pH of 3.0 to 3.2, which would be undesirable, because casein becomes increasingly soluble as the pH goes below its isoelectric point, i.e. pH 4.6. Although, preceding studies showed that addition of sodium hexametaphosphate (Dybing et al. 1982) enhanced the yield of cottage cheese and addition of monobasic calcium phosphate improved the yield of Edam cheese (Vorobyev 1962). However, nearly all of the increase in yield demonstrated in these studies seemed to be associated with the recovery of the added reagent rather than an improved recovery of whey proteins (Dybing and Smith 1998).

Conclusion

The present investigation was carried out to increase the yield of direct Cottage cheese. Direct acidification technique resulted in poor retention of moisture which also adversely affected the body and texture of cheese. In order to increase the yield of cottage cheese different levels of κ-carrageenan and tetrasodium pyrophosphate were tried. The study revealed that addition of 0.015% carrageenan followed by heat treatment at 90 °C for 5 min enhanced the yield by 13.6% due to increased recovery of whey proteins and moisture retention in cheese. Addition of tetrasodium pyrophosphate had no beneficial effect on the yield of cottage cheese. Therefore, κ-carrageenan could be utilized in the manufacture of good quality cottage cheese with increased yield.

References

- ADSA (2004) Cottage cheese score card, 2003 rules. In: 83rd annual collegiate dairy products evaluation contest. Committee on dairy product evaluation, American Dairy Science Association. 1111 N. Dunlap Avenue Savoy. IL 61874. USA. p 16

- AOAC (2000) Association of official analytical chemists. Official methods of analysis, 17th edn. In: Horwitz W (ed) Vol. II. Assc Official Agric Chem, Washington DC

- de Vries R. Monte Carlo simulations of flexible polyanions complexing with whey proteins at their isoelectric point. J Chem Phys. 2004;120:3475–3481. doi: 10.1063/1.1641003. [DOI] [PubMed] [Google Scholar]

- Durrant NW, Stone WK, Large PM. Effect of increasing serum protein of cottage curd on yield and quality. J Dairy Sci. 1961;44:1171–1174. [Google Scholar]

- Dybing ST, Parsons JG, Martin JH, Spurgeon KR. Effect of sodium hexametaphosphate on cottage cheese yields. J Dairy Sci. 1982;65:544–551. doi: 10.3168/jds.S0022-0302(82)82232-7. [DOI] [Google Scholar]

- Dybing ST, Smith DE. The ability of phosphates or κ-carrageenan to coagulate whey proteins and the possible uses of such coagula in cheese manufacture. J Dairy Sci. 1998;81:309–317. doi: 10.3168/jds.S0022-0302(98)75579-1. [DOI] [Google Scholar]

- Dzurec DJ, Zall RR. Effect on farm heating and storage of milk on cottage cheese yield. J Dairy Sci. 1982;65:2296–2300. doi: 10.3168/jds.S0022-0302(82)82500-9. [DOI] [Google Scholar]

- Evanston IL (1990) System of Statistics (SYSTAT). Evanston IL (ed), Wilkinson

- Fennema O. Food chemistry. 2. New York: Marcel Dekker; 1985. [Google Scholar]

- Guinee TP, Pudja PD, Farkye NY (1993) Fresh acid curd cheese varieties. In: Fox PF (ed), Cheese: chemistry, physics and microbiology, 2nd edn. Chapman and Hall, 2: 363–420

- Hidalgo J, Kruseman J, Bohren HU. Recovery of whey proteins with sodium hexametaphosphate. J Dairy Sci. 1973;56:988–993. doi: 10.3168/jds.S0022-0302(73)85294-4. [DOI] [Google Scholar]

- Hill RD, Zadow JG. The precipitation of whey proteins by carboxymethyl cellulose of differing degrees of substitution. J Dairy Sci. 1974;41:373–380. doi: 10.1017/s0022029900019828. [DOI] [PubMed] [Google Scholar]

- ISO 8586:1993E. Sensory analysis-methodology-general guidance. International Organization for Standardization, Geneva, Switzerland

- ISO 8586–1:1993E. Sensory analysis-general guidance for the selection, training and monitoring of assessors. International Organization for Standardization, Geneva, Switzerland

- ISO 8589:1985. Sensory analysis-general guidance for the design of test rooms. International Organization for Standardization, Geneva, Switzerland

- Makleby RW, Zakariasen BM. The effect of fortification of fluid skim milk with non-fat dry milk solids on the yield of cottage cheese curd. J Dairy Sci. 1954;37:637–639. [Google Scholar]

- Manning DW, Jr, Wilt H, Ames J. In: Gums and stabilizers for the food industry. Phillips GO, Wedlock DJ, Williams PA, editors. London: Elsevier Applied Science; 1985. pp. 379–385. [Google Scholar]

- Puvanenthiran A, Goddard SJ, Augustin MA. Gelation of mixed gels containing κ-carrageenan and skim milk components. J Food Sci. 2001;67:573–577. doi: 10.1111/j.1365-2621.2002.tb10640.x. [DOI] [Google Scholar]

- Snoeren ThHM, Payens TAJ, Jeunink J, Both P. Electrostatic interaction between κ-carrageenan and κ-casein. Milchwissenschaft. 1975;30:393–396. [Google Scholar]

- Stanley NF. In: Food gels. Harris P, editor. England: Elsevier Applied Science; 1990. p. 79. [Google Scholar]

- Stone WK. Manufacture of cottage cheese curd from ultrahigh temperature processed milk. J Dairy Sci. 1975;58:799–803. [Google Scholar]

- Tuckey SL. Problems in production of cottage cheese. Milk Dealer. 1952;40:46–48. [Google Scholar]

- Vorobyev AI (1962) Coagulation of milk and ripening of cheese (using calcium phosphates and calcium chlorides). In: Proc Int Dairy Congress, Copenhagen, Part B, p 576–580

- Whitaker R. The selection and use of non-fat dry milk solids in the manufacture of cottage cheese. J Dairy Sci. 1956;39:231–233. doi: 10.3168/jds.S0022-0302(56)94736-1. [DOI] [Google Scholar]

- White CH, Ray B. Influence of heat treatment on methods of acidification of milk on manufacture and properties of cottage cheese. J Dairy Sci. 1977;60:1236–1244. doi: 10.3168/jds.S0022-0302(77)84016-2. [DOI] [Google Scholar]

- Zadow JG, Hill RD. The precipitation of whey proteins by carboxymethyl cellulose. J Dairy Sci. 1975;42:267–275. doi: 10.1017/s0022029900015302. [DOI] [PubMed] [Google Scholar]