Abstract

Firmness and toughness of fruit, peel and pulp of seven different mango cultivars were studied over a ripening period of ten days to investigate the effects of harvesting stages (early, mid and late) on fruit quality. Parameters were measured at equatorial region of fruits using TA-Hdi Texture Analyzer. The textural characteristics showed a rapid decline in their behaviour until mangoes got ripened and thereafter, the decline became almost constant indicating the completion of ripening. However, the rate of decline in textural properties was found to be cultivar specific. In general, the changes in textural attributes were found to be significantly influenced by ripening period and stage of harvesting, but firmness attributes (peel, fruit and pulp) of early harvested mangoes did not differ significantly from mid harvested mangoes, while peel, fruit and pulp firmness of late harvested mangoes were found to be significantly lower than early and mid harvested mangoes.

Keywords: Harvesting stage, Quality, Ripening period, Cultivar, Textural characteristics, Shelf life

Introduction

Mango (Mangifera indica) is an important tropical fruit and India is the largest producer contributing about 37% of global production. Annually, India exports 50,000 ton mangoes to different parts of the world including Japan, Middle East, Europe and United States and is becoming a hub of mango supply (Pandit et al. 2009). Quality control is an important aspect of food processing for acceptable nutritional value and providing food safety to consumers. The consumer preference to any fruit is driven primarily by its physical parameters like size, shape, color, external defects/blemishes and firmness. One of the most significant quality aspects of mango for consumers is its firmness because it reflects the ripening stages of the fruit (Jha et al. 2010a). Firmness relates to maturity of many agricultural products (Sirisomboon et al. 2008) and is an important attribute to have an idea of eating quality and remaining shelf life of mango fruit (Jha et al. 2006). It is consumed fresh and can be utilised by the processing industry during different stages of growth, maturity and ripening. The products prepared from both ripe and green mangoes are highly popular in India and abroad (Jha et al. 2010a) and are therefore, harvested little earlier than the fully matured stage (Jha et al. 2007) before the onset of climacteric respiration (Lakshminarayana et al. 1970) to send them to distant market. During fruit ripening, softening occurs due to enzymatic degradation of cell walls (Johnston et al. 2002). Fruit firmness, in general, decreases as fruits become more mature and decreases rapidly as they ripen. To ensure the supply of high quality fruit, it is important to select the fruit with proper degree of maturation (Schmilovitch et al. 2000), as physical appearance, taste and postharvest shelf life depends upon maturity level at harvest. When fruits are harvested before maturity, they do not ripen uniformly and may show excessive shrinkage and low levels of sweetness. On the other hand, fruits harvested at late maturity stage, results in reduced shelf life with greater susceptibility to disease (Jha et al. 2007, Jha et al. 2010b). Overripe or injured fruit is relatively soft (Chen 1996) and excessive softening leads to physical damages during handling, transportation and storage (Goulao and Oliveira 2008). Successful delivery of fruits therefore, requires care to have minimal textural changes during storage and transport (Varela et al. 2008), for which knowledge and trend of textural properties are necessary. Mature hard green mango fruit attain a superior eating quality when ripe while immature ones do not (Medlicott et al. 1988).

In majority fleshy fruits like mango, textural characteristics are more important than other aromatic properties (Johnson and Ridout 2000) and fruit firmness is one of them. Texture perception is an important factor for quality evaluation of fruit and vegetable products (Konopacka and Plocharski 2004) and critical in determining the acceptability of fresh fruits (Sousa et al. 2007). It however, depends heavily upon environment of ripening chamber (Jha et al. 2006). Further, firmness and sensory attributes of mango had been reported to show variation with specific cultivars (Jarimopas and Kitthawee 2007). Therefore, the objective of this investigation was to study variations in firmness and toughness of fruit, peel and pulp in different mango cultivars during ripening.

Materials and methods

Sample collection

Orchards of different mango cultivars (Alphonso, Banganapalli, Chausa, Dashehri, Kesar, Maldah and Neelam) from different Indian states (Maharashtra, Andhra Pradesh, Punjab, Uttar Pradesh, Bihar and Tamilnadu) were selected and each one was divided into four blocks. One tree from each block in north, south, east and west direction and one from the centre of the orchard was selected using randomized block design. One fruit randomly from each side and one from centre of tree canopy with stalk (8–10 mm) were plucked manually in the forenoon on three different dates (Table 1). Harvesting date was selected presumably that mangoes were relatively immature, mature and over mature, based on previous experience and as suggested by the orchard owners (Jha et al. 2006). The fruits were transported to laboratory within 48 h in well ventilated corrugated fiber board boxes having partially frozen gel packs in bottom and top of mangoes’ layer to minimize the quality losses.

Table 1.

Sampling schedule for mango cultivars harvested from different locations in 2010

| Cultivar | Place of procurement | Abbreviation | Stage of harvesting | ||

|---|---|---|---|---|---|

| Early | Mid | Late | |||

| Alphonso | Maharashtra | AM | 10 April | 03 May | 19 May |

| Banganapalli | AndhraPradesh | BA | 29 March | 22 April | 26 May |

| Chausa | Punjab | CP | 08 June | 23 June | 07 July |

| Dashehri | Uttar Pradesh | DU | 27 May | 10June | 26 June |

| Kesar | Maharashtra | KM | 08 May | 19 May | 10 June |

| Maldah | Bihar | MB | 03 June | 24 June | 01 July |

| Neelam | Tamilnadu | NT | 05 May | 27 May | 23 June |

Sample preparation and ripening

Thirty mangoes free from any external injury/blemish and of visually similar size and color were sorted, destalked and desapped for each cultivar. The sorted mangoes were stored at ambient room conditions (26–38 °C, RH 60–70%) for natural ripening. The higher range of variation in temperature is due to climatic fluctuation during whole experimental season of about four months. Three mangoes of each cultivar at each ripening interval of 0, 2, 4, 6, 8 and 10 days were used in experiments.

Measurement of textural parameters

Changes in textural parameters during ripening were measured puncturing each sample thrice at equal distance of about 4 mm on equatorial region using texture analyzer (TA-Hdi, Stable Micro systems, UK) equipped with 50 kg load cell and stainless steel probe of 2 mm diameter. The operating parameters of texture analyser were: pre-test speed, 2 mms−1, test speed, 1 mms−1 and post-test speed, 2 mms−1. The equatorial region of mango for the measurement of textural parameters was selected as it gave more consistent results than any other region on the fruit surface (Gunness et al. 2009). The maximum force applied to break up the peel was taken as peel firmness (N) (Jha et al. 2010b). Fruit firmness (N/s) has been ascertained from the slope of the force-time curve, as described by Breene (1975). The pulp firmness (N) was computed as mean of the force applied on the pulp after breaking peel (Bugaud et al. 2006) and work required to cause breakage of peel was assumed to be peel toughness (Ns), while work required to cause rupture in pulp was taken as pulp toughness (Ns) (Mohsenin 1986). Average of nine readings of each parameter for each ripening period was noted.

Statistical Analysis All the observations were made in triplicates (n = 3) and values were subjected to Analysis of Variance (ANOVA) and Post Hoc Tests (Scheffe Test) using Statistica 6.0 (StatSoft India Pvt. Ltd., New Delhi, India) to evaluate the influence of harvesting stage, cultivar and ripening period on textural properties.

Results and discussion

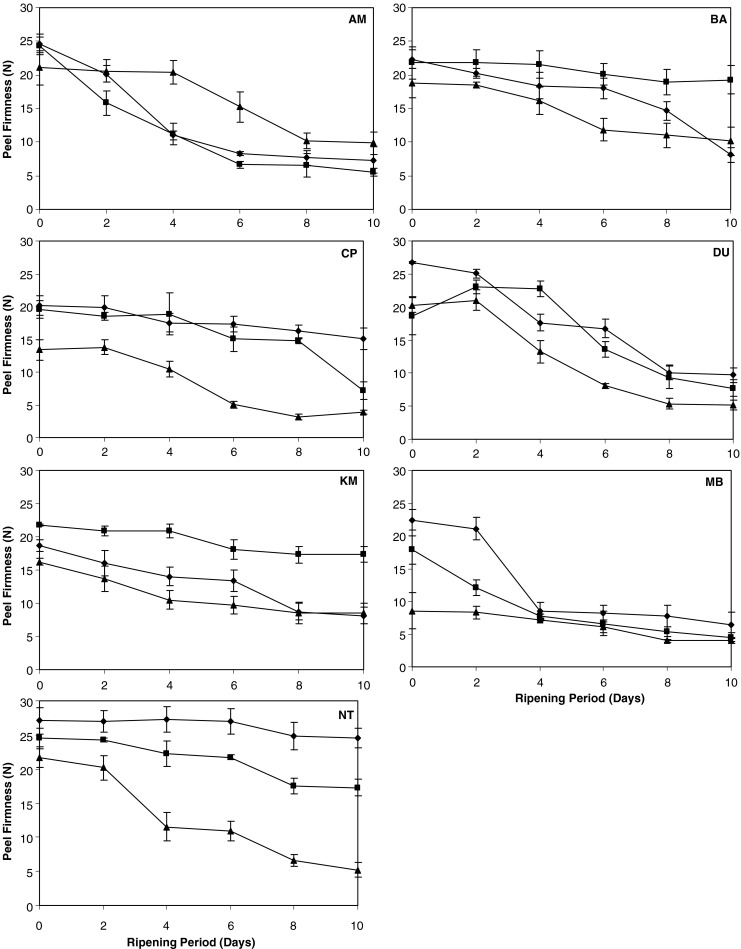

Peel firmness

The peel firmness of mango cultivars varied from initial level of 13.4–27.1 N to 3.9–24.5 N during ripening period of 10 days (Fig. 1). Early harvested mangoes of cv. CP and NT and mid harvested mangoes of cv. BA and KM didn’t show much variation in peel firmness with ripening period, where percent decline in peel firmness from 1st to 10th day of storage was found to be only 10–25% as compared to other cultivars where it was in range of 53–78%. The peel firmness of early harvested mangoes of all cultivars were found to be higher than mid and late ones on first day of examination except KM, where peel firmness of mid harvested mangoes were higher than early and late ones. Late harvested mangoes invariably showed lower peel firmness throughout the ripening period in all mango cultivars. In cv. AM and DU, peel firmness gradually declined with ripening, whereas early harvested mangoes of cv. MB showed a sharp decline in peel firmness till 4th day of storage, thereafter, it became almost constant. Decrease in firmness of various fruits has also been reported by earlier workers. Judith and Tianxia (2002) observed decrease in firmness of tomatoes from 15 to 2 N at different maturity stages. Nnadozie et al. (2007) reported the apple fruit softening during cold air storage and Qin et al. (2006) found decrease in flesh firmness dramatically in 6 days after harvest. Hosakote et al. (2006) reported ripening of mango being accompanied by a series of biochemical changes resulting in gradual textural softening.

Fig. 1.

Variations in peel firmness with ripening period and three sampling dates [early (♦), mid (■) and late (▲)] for different mango cultivars (n = 3)

Interestingly, the peel firmness increased initially in mid and late harvested mangoes of cv. CP and DU, and decreased later during ripening period. This increase in initial days of ripening might be attributed to difference in extent of maturity and ripeness (Jha and Matsuoka 2005).

ANOVA indicated that there was significant effect of harvesting stage and ripening period on firmness of mango peel (Table 2). Further, interactions between the three (Harvesting Stage × Cultivar × Ripening Period) were also found to be highly significant. Further analysis (Scheffe test) indicated that peel firmness of late harvested mangoes were significantly different from early and mid harvested mangoes but, the variation between early and mid harvested mangoes were not significant (Data not shown).

Table 2.

Univariate tests of significance for textural parameters in different mango cultivars at three different harvesting stages (early, mid and late) during ripening period (10 days)

| Parameter | Source | SS | DF | MS | FCalculated |

|---|---|---|---|---|---|

| Peel Firmness | Harvesting Stage (H) | 2011.89 | 2 | 1005.94 | 217.61* |

| Cultivar (C) | 3644.14 | 6 | 607.36 | 131.39* | |

| Ripening Period (S) | 6033.25 | 5 | 1206.65 | 261.03* | |

| HC | 2390.52 | 12 | 199.21 | 43.09* | |

| HS | 131.87 | 10 | 13.19 | 2.85* | |

| CS | 888.31 | 30 | 29.61 | 6.41* | |

| HCS | 1189.42 | 60 | 19.82 | 4.29* | |

| Peel Toughness | Harvesting Stage (H) | 14289.00 | 2 | 7144.50 | 189.82* |

| Cultivar (C) | 369994.70 | 6 | 6165.80 | 163.82* | |

| Ripening Period (S) | 12669.70 | 5 | 2533.90 | 67.32* | |

| HC | 25224.70 | 12 | 2102.10 | 55.85* | |

| HS | 651.10 | 10 | 65.10 | 1.73 | |

| CS | 7708.60 | 30 | 257.00 | 6.83* | |

| HCS | 4423.40 | 60 | 73.70 | 1.96* | |

| Fruit Firmness | Harvesting Stage (H) | 66.98 | 2 | 33.49 | 62.11* |

| Cultivar (C) | 195.28 | 6 | 32.55 | 60.36* | |

| Ripening Period (S) | 1705.22 | 5 | 341.04 | 632.52* | |

| HC | 74.23 | 12 | 6.19 | 11.47* | |

| HS | 70.58 | 10 | 7.06 | 13.09* | |

| CS | 77.49 | 30 | 2.58 | 4.79* | |

| HCS | 116.00 | 60 | 1.93 | 3.59* | |

| Pulp Firmness | Harvesting Stage (H) | 84.61 | 2 | 42.30 | 41.15* |

| Cultivar (C) | 504.43 | 6 | 84.07 | 81.78* | |

| Ripening Period (S) | 1663.97 | 5 | 332.79 | 323.73* | |

| HC | 257.57 | 12 | 21.46 | 20.88* | |

| HS | 24.70 | 10 | 2.47 | 2.40 | |

| CS | 285.15 | 30 | 9.50 | 9.25* | |

| HCS | 252.49 | 60 | 4.21 | 4.09* | |

| Pulp Toughness | Harvesting Stage (H) | 2112.30 | 2 | 1056.20 | 30.44* |

| Cultivar (C) | 12969.10 | 6 | 2161.50 | 62.30* | |

| Ripening Period (S) | 105428.00 | 5 | 21085.60 | 607.72* | |

| HC | 12079.00 | 12 | 1006.60 | 29.01* | |

| HS | 1480.20 | 10 | 148.00 | 4.27* | |

| CS | 11546.90 | 30 | 384.90 | 11.09* | |

| HCS | 13684.40 | 60 | 228.10 | 6.57* |

SS Sum of squares, DF Degrees of freedom, MS Mean sum of squares, F Calculated Calculated F value, * Significant at p ≥ 0.05

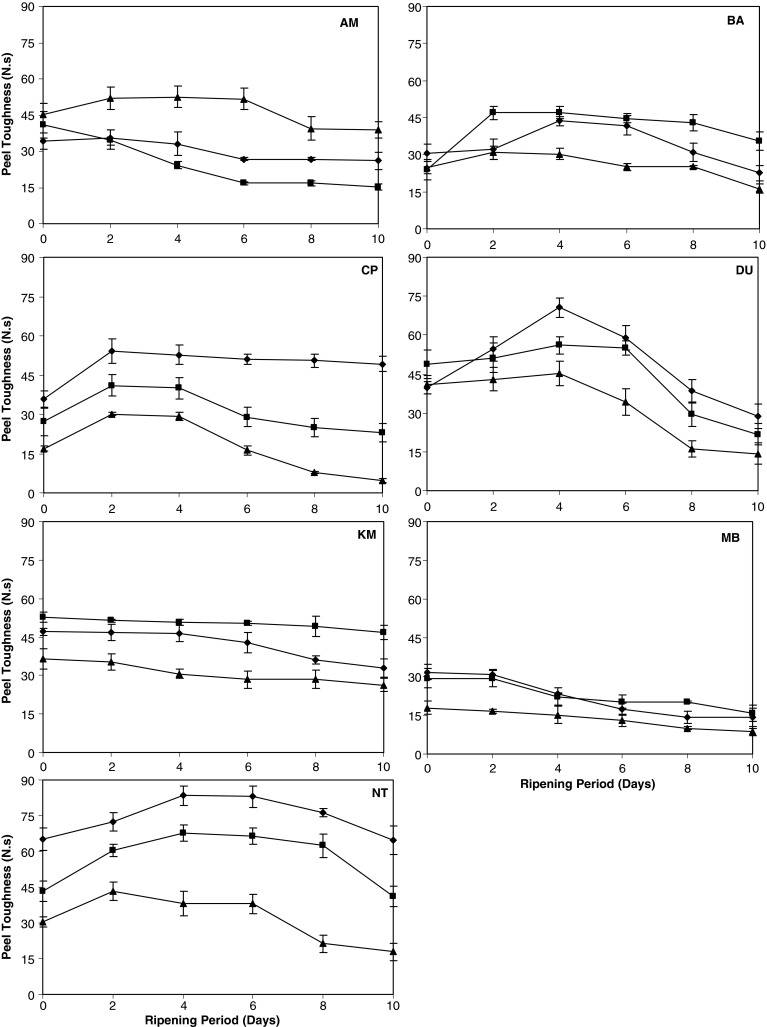

Peel toughness

The peel toughness of mango cultivars varied from 16.9–52.8 Ns to 4.6–64.8 Ns with ripening period among all cultivars reflecting significant varietal differences (Fig. 2). In general, the peel toughness of early harvested mangoes were found to be higher throughout the ripening period in all the cultivars followed by mid and late harvested mangoes. Peel toughness was observed to increase initially (2–4 days) and thereafter, it declined gradually with ripening period except in case of cv. KM and MB, where a continuous decline in peel toughness were recorded throughout the ripening period. In cv. DU, a sharp increase in peel toughness was recorded till 4th day of storage thereafter, a gradual decline was noticed. This increase in initial days of ripening might be attributed to difference in degree of maturity and ripeness (Jha and Matsuoka 2005). Further, the high summer temperatures might had caused the loss of superficial water making the peel hard. The slow decline in peel toughness of cv. KM (36.7 to 26.4 Ns) and MB (17.9 to 8.5 Ns) indicated that mangoes of the above mentioned cultivars attained physiological maturity at the time of harvesting.

Fig. 2.

Variations in peel toughness with ripening period and three sampling dates [early (♦), mid (■) and late (▲)] for different mango cultivars (n = 3)

ANOVA indicated that individually harvesting stage, cultivar and ripening period had significant effect on peel toughness of mango fruit. Further, interactions between Harvesting Stage × Cultivar and Cultivar × Ripening Period were also found to be significant. However, interaction between Harvesting Stage × Ripening Period did not show significant effect in determining peel toughness of mango fruit (Table 2).

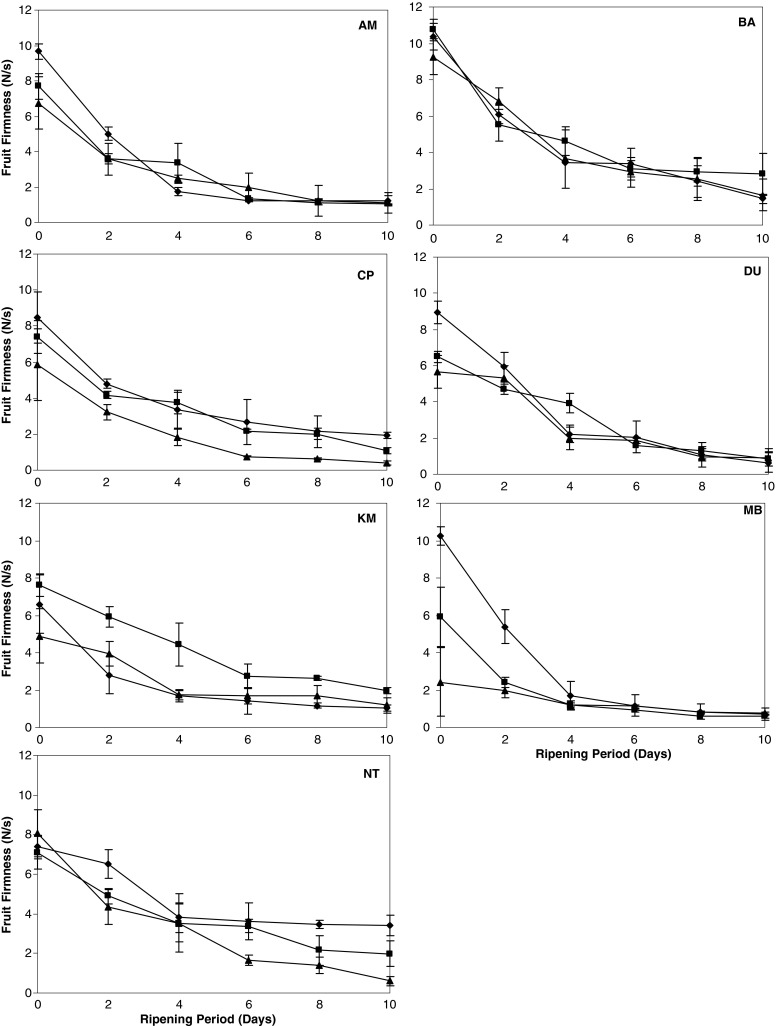

Fruit firmness

The firmness of mango fruits decreased significantly during ripening period (Fig. 3). It varied from 2.4–10.8 N/s on the initial day of experimentation to 0.4–3.4 N/s at the end of ripening period. The decrease in fruit firmness were more up to 4th day of storage in almost all mango cultivars (AM, BA, CP, DU, MB and NT), except KM, where a linear decline in fruit firmness was observed till 6th day of storage in early harvested mangoes while in mid and late harvested mangoes, a very little change in fruit firmness was recorded after 4th day of storage. The rapid decline in fruit firmness during ripening had been reported to be due to changes in structure of the pectin polymers of cell wall (Kalra et al. 1995), which later stablised indicating completion of ripening process. Hosakote et al. (2006) reported ripening of mango accompanied by a series of biochemical changes resulting in gradual textural softening. Jha et al. (2006) reported that the firmness of the mango fruits remained almost constant over the period of growth and it decreased after attaining the maturity. In late harvested mangoes of cv. MB, a very little change in fruit firmness (2.4 to 0.7 N/s) was observed during ripening period indicating that mangoes of the above mentioned variety had attained physiological maturity at the time of harvesting. Visual examination of fruit after 8th day of storage revealed the decay in mangoes of almost all cultivars except early harvested mangoes of cv. CP, NT and mid harvested mangoes of cv. BA, CP and NT, as evident from low firmness of fruits in foresaid ripening periods. Ripening imparts desirable flavor and color, but the changes in fruit firmness increase its susceptibility to attack from pathogens during latter stages of ripening or after long ripening periods (Goulao and Oliveira 2008).

Fig. 3.

Variations in fruit firmness with ripening period and three sampling dates [early (♦), mid (■) and late (▲)] for different mango cultivars (n = 3)

ANOVA indicated that firmness of mango fruit was significantly affected by harvesting stages, cultivar and ripening period (Table 2). Post Hoc Tests (Scheffe Test) indicated that differences in fruit firmness of early and mid harvested mangoes were not significant, whereas those between early:late and mid:late were found to be significant.

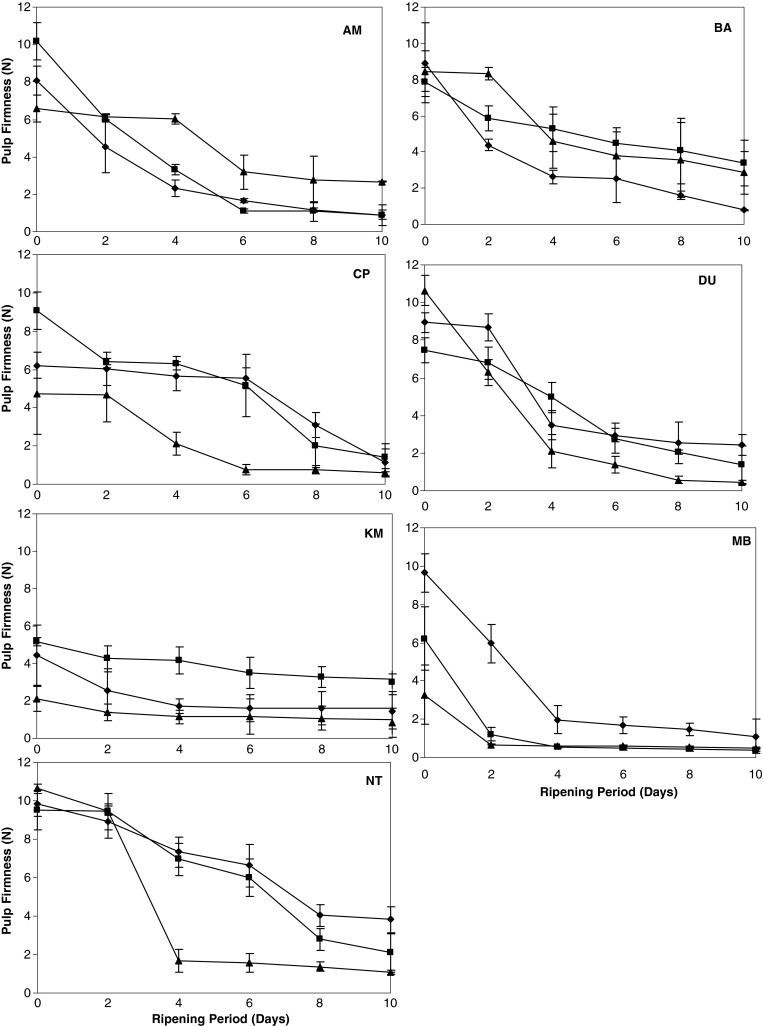

Pulp firmness

The variation in pulp firmness profile of mango cultivars is presented in Fig. 4. It varied from 2.1–10.6 N on the first day of experimentation to 0.4–3.8 N on the 10th day of ripening indicating significant variations between mango cultivars. This might be attributed to many physiological and biochemical modifications that include conversion of starch to sugars, biosynthesis of flavor and aromatic volatiles and changes in the cell wall ultra-structure and metabolism which are thought to result in loss of firmness of the pulp (Goulao and Oliveira 2008). Jha et al. (2010a) also observed decrease in pulp firmness of mango hybrids from 5.0–0.3 N during 12 days of storage. Hosakote et al. (2006) too observed softening in fruit texture from unripe to ripe stage of mango as a result of decrease in the starch content from 18.0% to 0.1%; pectin from 1.9% to 0.5%; cellulose from 2.0% to 0.9% and hemicelluloses from 0.8% to 0.2% but increase in the total soluble solids from 7% to 20% and total soluble sugars from 1% to 15%. In cv. AM, BA and CP, decline in pulp firmness with ripening period was gradual in all three harvesting stages (early, mid and late). Early and mid harvested mangoes of cv. DU and NT also showed gradual decline in pulp firmness with ripening period. Pulp firmness of late harvested mangoes of cv. DU, NT and early harvested mangoes of cv. MB showed a sharp decline till 4th day of storage, thereafter, it became slow in DU and almost constant in MB and NT. Mid and late harvested mangoes of cv. MB also followed a similar trend but a sharp decline was noticed only up to 2nd day of storage, thereafter, it became almost constant. The variations in pulp firmness between mangoes of the three harvesting stages (early, mid and late) on the first day of experimentation were observed to be low in cv. BA (8.9–7.9 N) and NT (10.6–9.5 N) and maximum in cv. MB (9.6–3.3 N). Mangoes of all the three harvesting stages of cv. KM showed very little change in pulp firmness with ripening period indicating that mangoes of the above mentioned variety had attained physiological maturity at the time of harvesting.

Fig. 4.

Variations in pulp firmness with ripening period and three sampling dates [early (♦), mid (■) and late (▲)] for different mango cultivars (n = 3)

ANOVA indicated that firmness of mango pulp was significantly affected by harvesting stage, cultivar and ripening period (Table 2). Post Hoc Tests (Scheffe Test) indicated that differences in pulp firmness of early and mid harvested mangoes were not significant, whereas those between early:late and mid:late were significant.

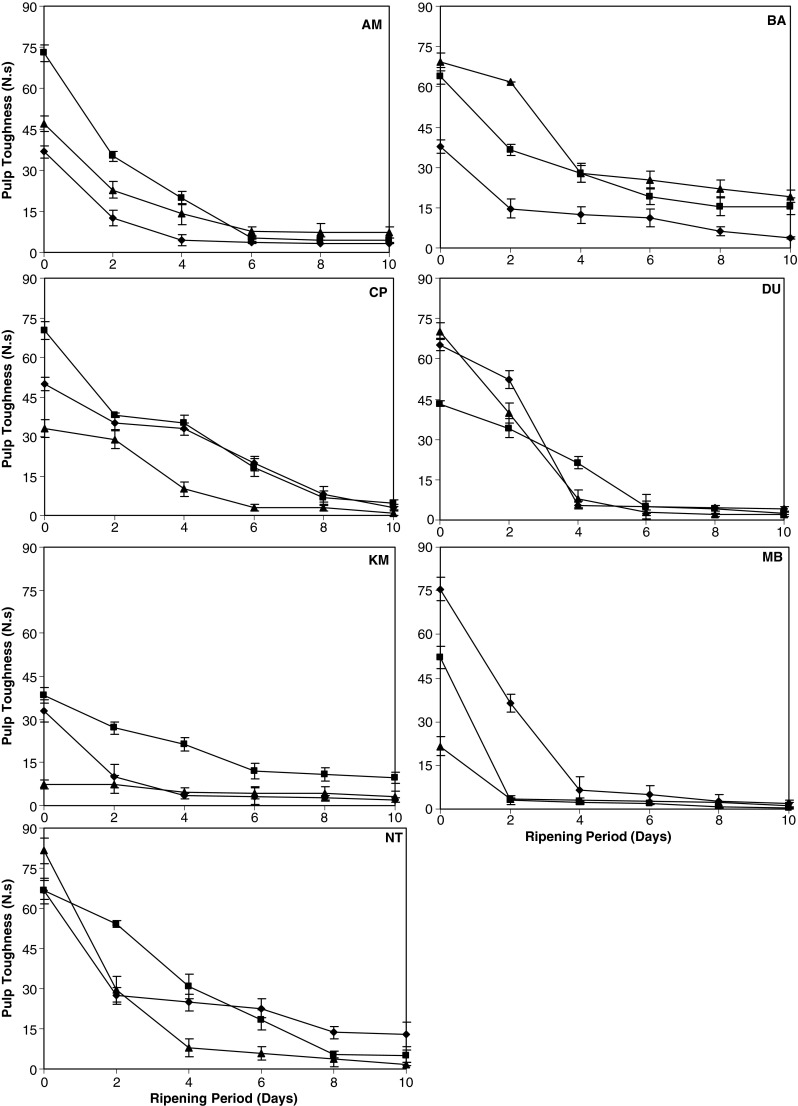

Pulp toughness

The initial pulp toughness of mango cultivars were found to be in the range of 7.4–81.5 Ns, which decreased to 1.0–19.1 Ns on the 10th day of ripening period (Fig. 5). Majority of mango cultivars in all the three harvesting stages showed a rapid decline in pulp toughness till 4th day, thereafter, the declining rate was slow. Mid and late harvested mangoes of cv. MB and early harvested mangoes of cv. KM showed rapid decline till 2nd day of storage while mid harvested mangoes of cv. DU and KM, showed a linear decline till 6th day of storage and thereafter, it became stablised. The sudden decline during initial days may be attributed to the metabolic events responsible for textural changes in fruits are believed to involve loss in turgor pressure, degradation and other physiological changes in composition of membranes, degradation of starch and modifications in cell wall structure and dynamics (Goulao and Oliveira 2008). The pulp toughness of late harvested mangoes of cv. KM did not show any significant change with ripening period indicating that mangoes of the above mentioned cultivar attained physiological maturity at the time of harvesting.

Fig. 5.

Variations in pulp toughness with ripening period and three sampling dates [early (♦), mid (■) and late (▲)] for different mango cultivars (n = 3)

ANOVA indicated that toughness of mango pulp was significantly affected by harvesting stage, cultivar and ripening period (Table 2). Post Hoc Tests (Scheffe Test) indicated that differences in pulp firmness between early and late harvested mangoes were not significant. However, those between early:mid and mid:late were found to be significant.

Late harvested mangoes as compared to early and mid ones, of all cultivars showed least variation in textural properties with ripening period indicating that mangoes were over matured at time of harvesting and may have shorter shelf life. This is also evident from lower textural properties and higher total soluble solids (TSS) content (Jha et al. 2006) of mangoes. Peel toughness of late harvested mangoes of cv. AM, however was found to be higher than early and mid ones, reflecting differences in degree of maturity and ripeness of individual mango (Jha and Matsuoka 2005) probably. Textural properties of peel of all cultivars changed gradually with ripening period except in cv. MB, where no significant change was noticed after 4th day of storage. It might be due to its thinner peel as compared to rest of the varieties leading to an early structural change in cell wall, resulting into decline in peel firmness/toughness. A comparison of pulp quality of all mango cultivars showed faster deterioration in pulp firmness and toughness in cv. MB, followed by cv. KM and DU. These mango cultivars were harvested in peak summer season which might have caused superficial water loss, leading to decline in textural properties of fruits (Jha and Matsuoka 2005). Interestingly, in cv. KM, the textural properties of peel (21.77–8.14 N, 52.80–26.36 Ns) were comparable with other mango cultivars but, the pulp firmness and/or toughness (5.18–0.98 N, 38.39–2.06 Ns) were observed to be lower than rest of cultivars. Also, no significant change in pulp firmness and toughness was noticed with ripening period indicating that pulp of cv. KM attained full maturity at the time of harvesting itself. This is also evident from high TSS value (data not shown) of this cultivar as compared to others. Rest of mango cultivars showed a gradual decline in pulp qualities with ripening period and least deterioration was observed in cv. BA. This might be attributed to thicker peel together with comparatively low temperature at the time of harvesting and ripening of this variety.

Conclusion

Fruit, peel and pulp firmness; and toughness of peel and pulp of seven cultivars of mango harvested thrice (early, mid and late) during ripening period of ten days were found to be cultivar specific and influenced by the stage of harvesting and ripening period. Peel firmness, fruit firmness and pulp firmness of early and mid harvested mangoes did not show any significant variation, while in late harvested mangoes, the firmness of peel, fruit and pulp were significantly lower. In general, the textural properties of mangoes declined with ripening period and rate of decline was highest for MB and lowest for BA. Peel toughness of all cultivars increased initially, before following a decline with ripening period. Fruit firmness, pulp firmness and pulp toughness decreased rapidly before getting stabilised at the end of ripening period.

Acknowledgement

This research was supported by the National Agricultural Innovation Project (NAIP), Indian Council of Agricultural Research (ICAR) through its subproject entitled “Development of non-destructive systems for evaluation of microbial and physico-chemical quality parameters of mango” (Code number-C1030).

Contributor Information

Shyam Narayan Jha, Email: snjha_ciphet@yahoo.co.in.

Pranita Jaiswal, Email: pranitajaiswal@gmail.com.

Kairam Narsaiah, Email: knarsan@yahoo.com.

Poonam Preet Kaur, Email: poonam.pkaur@gmail.com.

Ashish Kumar Singh, Email: ashish.singh0510@gmail.com.

Ramesh Kumar, Email: rk_jangra@rediffmail.com.

References

- Breene WM. Application of texture profile analysis to instrumental food texture evaluation. J Texture Studies. 1975;6:53–82. doi: 10.1111/j.1745-4603.1975.tb01118.x. [DOI] [Google Scholar]

- Bugaud C, Chillet M, Beaute MP, Dubois C. Physicochemical analysis of mountain bananas from the French West Indies. Sci Hort. 2006;108:167–172. doi: 10.1016/j.scienta.2006.01.024. [DOI] [Google Scholar]

- Chen P (1996) In: Quality Evaluation Technology for Agricultural Products, Proceedings of the International Conference on Agricultural Machinery Engineering, Seoul, Korea, 12–15 November 1996.

- Goulao LF, Oliveira CM. Cell wall modifications during fruit ripening: when a fruit is not the fruit – A Review. Trends Food Sci Technol. 2008;19:4–25. doi: 10.1016/j.tifs.2007.07.002. [DOI] [Google Scholar]

- Gunness P, Kravchuk O, Nottingham ST, D’arcy BR, Gidley MJ. Sensory analysis of individual strawberry fruit and comparison with instrumental analysis. Postharvest Biol Technol. 2009;52:164–172. doi: 10.1016/j.postharvbio.2008.11.006. [DOI] [Google Scholar]

- Hosakote MY, Tyakal NP, Rudrapatnam NT. Mango ripening: changes in cell wall constituents in relation to textural softening. J Sci Food Agric. 2006;86:713–721. doi: 10.1002/jsfa.2404. [DOI] [Google Scholar]

- Jarimopas B, Kitthawee U. Firmness properties of mangoes. Int J Food Properties. 2007;10:899–909. doi: 10.1080/10942910701221731. [DOI] [Google Scholar]

- Jha SN, Matsuoka T. Determination of post-harvest storage life of tomato fruits. J Food Sci Technol. 2005;42(6):526–529. [Google Scholar]

- Jha SN, Kingsly ARP, Chopra S. Physical and mechanical properties of mango during growth and storage for determination of maturity. J Food Eng. 2006;72:73–76. doi: 10.1016/j.jfoodeng.2004.11.020. [DOI] [Google Scholar]

- Jha SN, Chopra S, Kingsly ARP. Modelling of color values for nondestructive evaluation of maturity of mango. J Food Eng. 2007;78:22–26. doi: 10.1016/j.jfoodeng.2005.08.048. [DOI] [Google Scholar]

- Jha SK, Sethi S, Srivastav M, Dubey AK, Sharma RR, Samuel DVK, Singh AK. Firmness characteristics of mango hybrids under ambient storage. J Food Eng. 2010;97:208–212. doi: 10.1016/j.jfoodeng.2009.10.011. [DOI] [Google Scholar]

- Jha SN, Narsaiah K, Sharma AD, Singh M, Bansal S, Kumar R. Quality parameters of mango and potential of non-destructive techniques for their measurement – a review. J Food Sci Technol. 2010;47(1):1–14. doi: 10.1007/s13197-010-0004-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Johnson DS, Ridout MS. Effects on the quality of stored apple fruit. In: Shewfelt RL, Bruckner B, editors. Fruit and vegetable quality - An integrated view. Lancaster: Technomic; 2000. pp. 67–84. [Google Scholar]

- Johnston JW, Hewett EW, Hertog MLATM. Postharvest softening of apple (Malus domestica) fruit - A review. NZ J Crop Hort Sci. 2002;30:145–160. doi: 10.1080/01140671.2002.9514210. [DOI] [Google Scholar]

- Judith AA, Tianxia Wu. Firmness and force relaxation characteristics of tomatoes stored intact or as slices. Postharvest Biol Technol. 2002;24(1):59–68. doi: 10.1016/S0925-5214(01)00133-8. [DOI] [Google Scholar]

- Kalra SK, Tondon DK, Singh BP. In: Handbook of fruit science and technology: Production, Composition, Storage and Processing. Salunkhe DK, Kadam SS, editors. New York: Marcel Dekker Inc; 1995. pp. 123–170. [Google Scholar]

- Konopacka D, Plocharski WJ. Effect of storage conditions on relationship between apple firmness and texture acceptability. Postharvest Biol Technol. 2004;32:205–211. doi: 10.1016/j.postharvbio.2003.11.012. [DOI] [Google Scholar]

- Lakshminarayana S, Subhadra NV, Subramanyam H. Some aspects of developmental physiology of mango fruit. J Hort Sci. 1970;45:133–142. [Google Scholar]

- Medlicott AP, New SW, Thompson AK. Harvest maturity effects on mago fruit ripening. Trop Agric (Trinidad) 1988;65:153–157. [Google Scholar]

- Mohsenin NN. Physical properties of plant and animal materials. New York: Gordan and Breach Science Publishers; 1986. [Google Scholar]

- Nnadozie CO, Richard KV, Claire JW, Heather CMB, Alistair JH, Susan EG. Influence of Md-ACS1 alletype and harvest season within an apple germplasm collection on fruit softening during cold air storage. Postharvest Biol Technol. 2007;44(3):212–219. doi: 10.1016/j.postharvbio.2006.12.013. [DOI] [Google Scholar]

- Pandit SS, Chidley HG, Kulkarni RS, Pujari KH, Giri AP, Gupta VS. Cultivar relationships in mango based on fruit volatile profiles. Food Chem. 2009;114:363–372. doi: 10.1016/j.foodchem.2008.09.107. [DOI] [Google Scholar]

- Qin W, Rongchao M, Qiao D, Yao X. Studies on postharvest physiology and the storage technology of mango (Mangifera indica L.) J Food Process Preserv. 2006;30(6):670–683. doi: 10.1111/j.1745-4549.2006.00097.x. [DOI] [Google Scholar]

- Schmilovitch Z, Mizrach A, Hoffman A, Egozi H, Fuchs Y. Determination of mango physiological indices by near-infrared spectrometry. Postharvest Biol Technol. 2000;19:245–252. doi: 10.1016/S0925-5214(00)00102-2. [DOI] [Google Scholar]

- Sirisomboon P, Boonmung S, Pornchaloempong P, Pithuncharurnlap M. A preliminary study on classification of mango maturity by compression test. Int J Food Prop. 2008;11:206–212. doi: 10.1080/10942910701435430. [DOI] [Google Scholar]

- Sousa MB, Canet W, Alvarez MD, Fernandez C. Effect of processing on the texture and sensory attributes of raspberry (cv. Heritage) and blackberry (cv. Thornfree) J Food Eng. 2007;78:9–21. doi: 10.1016/j.jfoodeng.2005.08.047. [DOI] [Google Scholar]

- Varela P, Salvador A, Fiszman S. Shelf life estimation of ‘Fuji’ apples II. The behaviour of recently harvested fruit during storage at ambient conditions. Postharvest Biology Technol. 2008;50:64–69. doi: 10.1016/j.postharvbio.2008.03.016. [DOI] [Google Scholar]