Abstract

The change in surface roughness after different surface finishing techniques has attracted the attention of several prosthodontists regarding wear of opposing teeth or restorative material and the strength; plaque retention and appearance of the restoration. However, there is considerable controversy concerning the best methods to achieve the smoothest and strongest porcelain restorations after chair side clinical adjustments. The purpose of this in vitro study was to compare the average surface roughness of a self-glazed surface, a chair side polished surface and a reglazed surface of ceramic. Two feldspathic porcelain, namely VITA VMK94 (Vita Zahnfabrik, Bad Sachingen, Germany) and IVOCLAR CLASSIC (Vivadent AG, FL-9494 Schaan, Liechtenstein) were selected to fabricate 20 specimens of each in the shape of shade guide tabs. A medium-grit diamond rotary cutting instrument was used to remove the glaze layer, and then the surface of half the specimens were re-glazed and the other half were polished using a well-defined sequence of polishing comprising of: Shofu porcelain polishing system, White gloss disc/polishing wheel, Silicone cone with diamond polishing paste and finally with small buff wheel with pumice slurry. The surface roughness (Ra) (μm) of the specimens was evaluated using a profilometer and scanning electron microscope. The data were statistically analyzed by using Student’s t test. The results had shown that there is no statistically significant difference both quantitatively and qualitatively, between the surface roughness of reglazed and chair-side polished surface. In addition, both reglazed and chair-side polished surfaces are better than the autoglazed surface. Within all the groups, there is no significant difference between companies. Polishing an adjusted porcelain surface with the suggested sequence of polishing will lead to a finish similar to a re-glazed surface. Therefore chair-side polishing can be a good alternative to reglazing for finishing adjusted porcelain surface.

Keywords: Auto-glazed, Re-glazed, Chair-side polished, Surface profilometer, Scanning electron microscope

Introduction

Dental porcelain has been used extensively as a restorative material in a variety of dental restorations, including all-ceramic restorations like inlays, onlays, veneers, metal-ceramic crowns, all ceramic crowns and fixed partial dentures, because of its esthetic properties, durability, and biocompatibility.

Surface modifications are essential for correcting occlusal interferences and faulty contours, finishing the margins of ceramic restorations, and improving the esthetic appearance and surface smoothness of porcelain restorations. It is a common clinical practice to adjust the glazed surface of porcelain restorations before cementation by grinding [1]. These Adjustment procedures break the glaze layer which creates a rougher surface[2] which promotes plaque formation and maturation, thus producing gingival inflammation and adverse soft tissue reactions [3, 4]. It may also increase the wear of the opposing dentition or restorative material [5–7]. Therefore, glazing or polishing after the adjustment procedures is necessary to improve the flexural strength [8] and appearance of the restoration [9]. Literature reports of various techniques for finishing and polishing a porcelain restoration to achieve optimum smoothness of the glazed porcelain. Reglazing has been documented to adversely change the porcelain structure (for example devitrification) and is time consuming [10]. Polished ceramic restorations, when compared to the glazed restorations, may also have the advantage of reducing the wear of the opposing dentition. Several studies reported different polishing techniques of ceramic restorations and supported the use of polishing as an alternative to glazing. However, data evaluating different ceramic materials and surface finishing techniques, e.g. self-glazing, overglazing and polishing to achieve the smoothest and strongest porcelain restorations after chair side clinical adjustments is limited.

The purpose of this study was to compare the average surface roughness both quantitatively and qualitatively of a self-glazed surface, a chair side polished surface and a reglazed surface of ceramic of two manufacturers, i.e. Vita and Ivoclar.

Materials and Methods

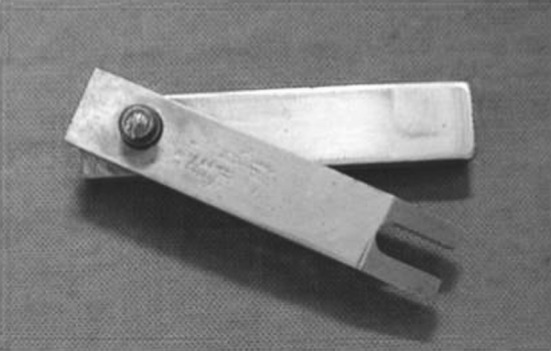

Two feldspathic porcelains, namely VITA VMK94 (Germany, Bad Sackingen) and IVOCLAR CLASSIC (Vivadent AG, FL-9494 Schaan, Liechtenstein) were selected. Enamel powder of A2 shade of both the manufacturers was used to fabricate 20 specimens of each. A mold of brass metal was fabricated in the shape of shade guide tabs. This mold is a duplicate of the mold provided by the VITA Company to prepare ceramic shade tabs. It consists of two metal plates in rectangular shape. (Fig. 1) Upper metal plate has the mold in the shape of shade tab at one end with the following dimensions:

Length—10 mm

Width—4 mm

Height—decreasing gradually from 4 to 2 mm at the open end

Fig. 1.

Mold of brass metal

This upper plate is attached at one end of lower plate which allows it to slide on either side.

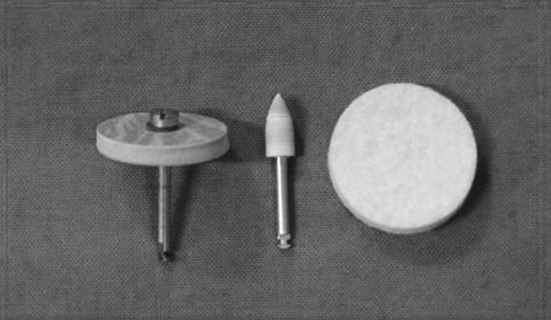

Materials and Armamentarium for Sample Fabrication (Figs. 2, 3)

Fig. 2.

Porcelain Adjustment kit

Fig. 3.

Polishing disc, cone and buff

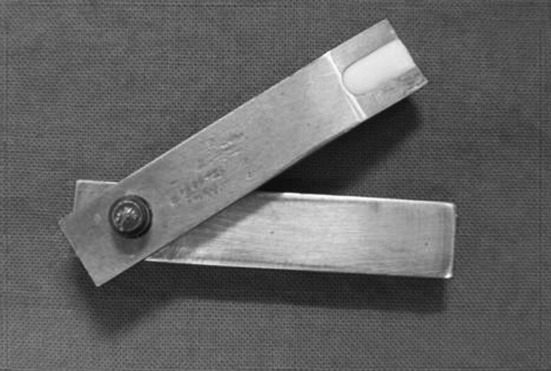

Each specimen was fabricated by weighing the porcelain powder (205.1 mg) and mixing with adequate amount of distilled water over the glass slab with metal blade instrument. Tissue paper was utilized to remove excess water by placing it at one end of the mass. The mixed mass was not allowed to dry completely while absorption of excess water. It was then loaded into the mould in increments. To condense the powder, the mold was given gentle vibrations with the serrated handle of the instrument. Tissue paper was again used to absorb excess water before adding the next increment. After complete condensation of the powder in the mold, the upper plate was slid over from the lower plate (Fig. 4) and the condensed mass was gently tapped to be released from the mould to fall over a sagger tray.

Fig. 4.

Upper plate was slid over from the lower plate

For each type of ceramic, 20 specimens were fabricated for each type of ceramic and placed over the tray. The tray was then placed in the porcelain furnace and fired according to the manufacturer’s recommendations. The specimens were allowed to cool and then finished with a medium-grit diamond points all over to remove any irregularities. The specimens were then soaked in distilled water for 5 min. Then they were placed in the furnace to obtain an autoglazed surface. All these specimens were tested at this stage for the surface roughness to act as control group.

The 20 specimens from each type of ceramic (Fig. 5) were randomly divided into two groups. One group was for reglazing and the other was for chair side polishing system. On one side of each specimen (that is the flat side), a medium-grit sintered diamond point of Shofu company attached to a straight hand piece of micromotor, was used to remove the glaze. This grinding was done at a constant speed and with constant amount of strokes given by the same operator. 20 such specimens, 10 from each type of ceramic were then subjected to reglazing with add on glaze following manufacturer’s recommended procedure and temperature.

Fig. 5.

Specimens from each type of ceramic

The remaining 20 specimens were subjected to chairside polishing with well defined sequence of a polishing system. The same investigator performed the polishing uniformly with micromotor handpiece by giving constant amount of strokes at a constant speed. The other side of the specimens, which were autoglazed, was used as a control group and 20 specimens were randomly selected for this.

For chair-side polishing of the specimens a well-defined sequence of the polishing system was utilized as follows:

Shofu Porcelain polishing system (Shofu Dental Corp., Menlo Park, California) consisting of Dura-white stones for contouring, standard Ceramiste points for smoothing surfaces and preparing them for polishing, Ultra Ceramiste points for polishing, and final polishing using the Ultra II Ceramiste points.

White gloss disc/polishing wheel.

Silicone cone was used with diamond polishing paste

Small buff wheel was used with pumice slurry.

The specimens were then cleaned with the steam, dried with a blast of air, and stored in a dust-free container at room temperature.

The surface roughness was evaluated using a surface profilometer (Perthometer- Mahr GmbH, Germany–Mahr Federal Inc. USA.). A diamond stylus (25 μm tip radius) was used under a constant measuring force of 25 mN. (Fig. 6) The instrument was calibrated using a standard reference specimen and then set to travel at a speed of 0.8 mm/s with a traversing length of 1.75 mm during testing. The surface analyzer was used to determine a roughness profile of each specimen. The roughness profile of the autoglazed, reglazed and chairside polished surface was obtained for each of the 3 passes per specimen. A mean surface roughness profile (Ra) was determined for each side of each specimen to describe the overall roughness of the surface. These values were tabulated to compare autoglazed, reglazed and chair side polished surfaces. The larger the value more is the surface roughness.

Fig. 6.

Diamond stylus running over the specimen

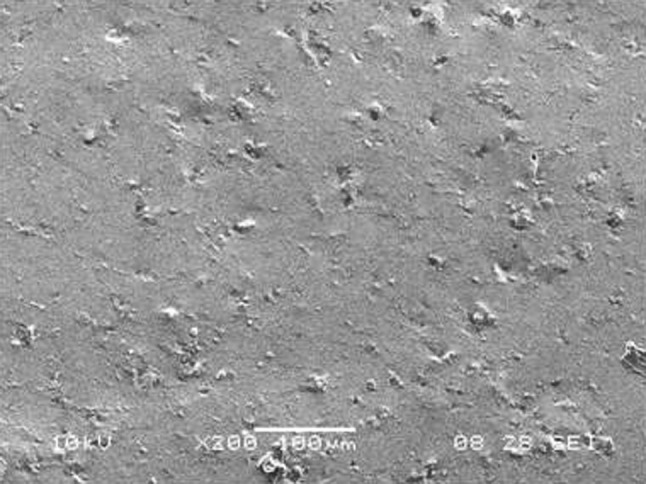

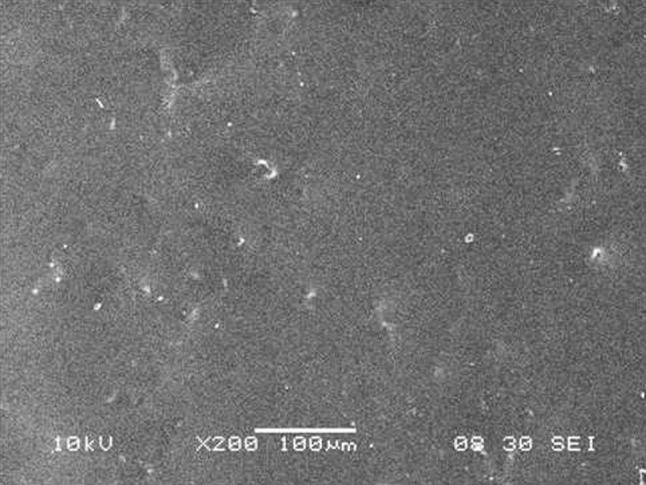

On completion of profilometric evaluation, the specimens from each group were prepared for SEM. Specimens were palladium sputtered with a fine coater machine and a scanning electron microscope (SEM) (Joel Ltd 1-2 Musashino 3-chome, Akishima, Tokyo 196-8558, Japan) was utilized to qualitatively evaluate the surface of all the specimens with different treatment. Only four specimens can be mounted on the mounting plate at a time. (Fig. 7) Both sides of each specimen were visualized at original magnification 200×. (Figs. 8, 9, 10, 11, 12, 13) Two investigators performed all procedures; the first prepared the specimens and the second was blind to the treatment and performed the data analysis.

Fig. 7.

Four specimens mounted on the mounting plate

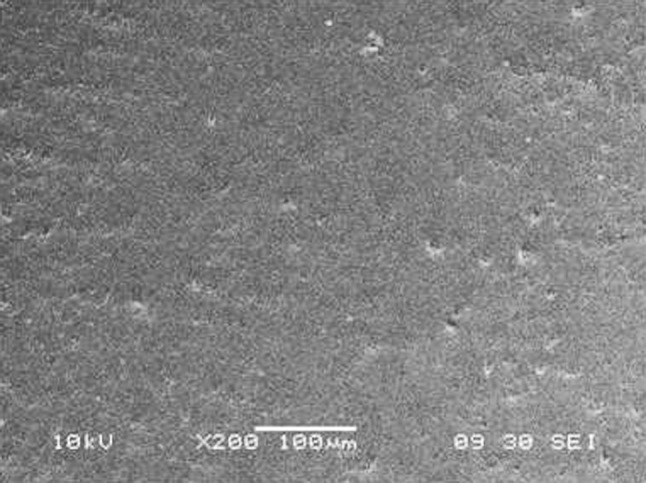

Fig. 8.

SEM Photo of Autoglazed (Ivoclar)

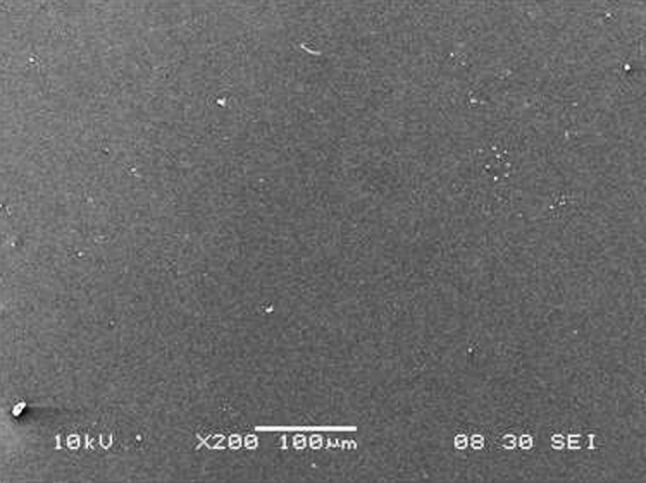

Fig. 9.

SEM Photo of Re-glazed (Ivoclar)

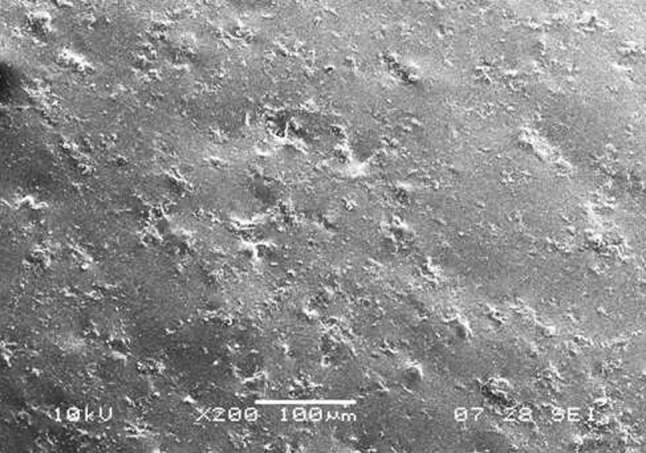

Fig. 10.

SEM Photo of Chair-side polished (Ivoclar)

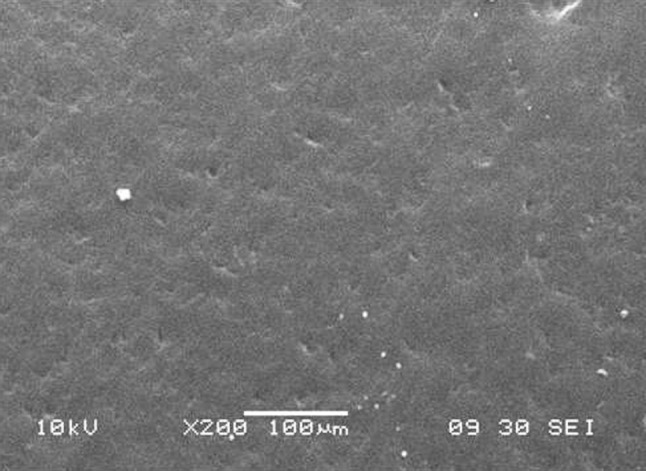

Fig. 11.

SEM Photo of Autoglazed (Vita)

Fig. 12.

SEM Photo of Re-glazed (Vita)

Fig. 13.

SEM Photo of Chair-side polished (Vita)

The observations were subjected to statistical analysis. Mean and standard deviation were calculated and Student’s ‘t’ test was used to quantitatively analyze surface roughness data for significant differences between autoglazed, reglazed and chair-side polished porcelain surfaces of two different manufacturers. It is a standard practice to make pair-wise comparisons of the groups using an appropriate adjustment for multiple comparisons.

These findings were further confirmed by qualitative analysis of the data given by SEM photographs.

Results

First the average surface roughness values were collected from the individual tracings for each of the three different groups of specimens of two different manufacturers. Then the means of surface roughness values of three different groups with their respective SD were calculated and compared (Tables 1, 2).

Table 1.

Shows the average surface roughness values collected from the individual tracings for each of the three different groups of specimens of two different manufacturers

| Surface profilometry (Quantitative test showing Ra values for surface roughness) | ||||||

|---|---|---|---|---|---|---|

| Vita (Ra values in μm) | Ivoclar (Ra values in μm) | |||||

| S. no. | Auto glazed (Control group) | Study groups | Auto glazed (Control group) | Study groups | ||

| Re-glazed | Chair side polished | Re-glazed | Chair side polished | |||

| 1 | 0.15 | 0.12 | 0.12 | 0.15 | 0.12 | 0.12 |

| 2 | 0.14 | 0.1 | 0.12 | 0.15 | 0.13 | 0.13 |

| 3 | 0.15 | 0.11 | 0.11 | 0.15 | 0.12 | 0.12 |

| 4 | 0.14 | 0.12 | 0.12 | 0.14 | 0.11 | 0.12 |

| 5 | 0.14 | 0.11 | 0.11 | 0.15 | 0.12 | 0.12 |

| 6 | 0.15 | 0.12 | 0.12 | 0.15 | 0.13 | 0.13 |

| 7 | 0.14 | 0.12 | 0.12 | 0.14 | 0.1 | 0.12 |

| 8 | 0.14 | 0.11 | 0.11 | 0.14 | 0.12 | 0.12 |

| 9 | 0.14 | 0.13 | 0.13 | 0.15 | 0.12 | 0.12 |

| 10 | 0.15 | 0.1 | 0.12 | 0.15 | 0.12 | 0.12 |

Note More is the Ra value, more is the surface roughness or more is the Ra value less is surface smoothness or finish

Table 2.

Shows the means of surface roughness values of three different groups with their respective standard deviations

| Company | Group | Mean | N | Standard Deviation |

|---|---|---|---|---|

| Ivoclar | Autoglazed | .1470 | 10 | .00483 |

| Reglazed | .1190 | 10 | .00876 | |

| Chair-side polished | .1220 | 10 | .00422 | |

| Total | .1293 | 30 | .01413 | |

| Vita | Autoglazed | .1440 | 10 | .00516 |

| Reglazed | .1140 | 10 | .00966 | |

| Chair-side polished | .1180 | 10 | .00632 | |

| Total | .1253 | 30 | .01525 | |

| Total | Autoglazed | .1455 | 20 | .00510 |

| Reglazed | .1165 | 20 | .00933 | |

| Chair-side polished | .1200 | 20 | .00562 | |

| Total | .1273 | 60 | .01471 |

For both the porcelain materials, there was no statistically significant difference between the surface roughness of reglazed and chair-side polished surface. Both reglazed and chair-side polished surfaces are better than the autoglazed surface.

The SEM photomicrogaphs of three different groups of specimens of two different manufacturers were evaluated according to the aforementioned criteria based on a scale 1–3 (Table 3):

1 rating means—Good finish

2 rating means—Very good finish

3 rating means—Excellent finish

Table 3.

Shows the observations about the SEM photomicrogaphs of the three different groups of specimens of two different manufacturers

| SEM (Qualitative test for surface roughness) | ||||||

|---|---|---|---|---|---|---|

| Vita | Ivoclar | |||||

| S. no. | Auto glazed (Control group) | Study groups | Auto glazed (Control group) | Study groups | ||

| Re-glazed | Chair side polished | Re-glazed | Chair side polished | |||

| 1 | 1 | 2 | 2 | 1 | 2 | 2 |

| 2 | 1 | 3 | 2 | 1 | 2 | 2 |

| 3 | 1 | 2 | 2 | 1 | 2 | 2 |

| 4 | 1 | 2 | 2 | 1 | 3 | 2 |

| 5 | 1 | 2 | 2 | 1 | 2 | 2 |

| 6 | 1 | 2 | 2 | 1 | 2 | 2 |

| 7 | 1 | 2 | 2 | 1 | 3 | 2 |

| 8 | 1 | 2 | 2 | 1 | 2 | 2 |

| 9 | 1 | 2 | 2 | 1 | 2 | 2 |

| 10 | 1 | 3 | 2 | 1 | 2 | 2 |

A qualitative analysis was done by using Mann Whitney test and p values were again obtained and they also showed the similar results.

Discussion

Ceramic materials intrinsically have multiple flaws because of the inhomogeneous distribution of crystals in a glassy matrix. Additional defects induced during ceramic processing reduce the strength and increase the wear of enamel of opposing tooth. Sealing these with glazing or polishing may improve the strength and reduce the abrasiveness of dental ceramics [11].

Earlier researchers have advocated that adjusted porcelain should be reglazed only. It has been a common practice to reglaze the adjusted porcelain surface prior to cementation. However various disadvantages have been reported with reglazing like Devitrification, marginal distortion, reduced fracture toughness which is affected with the thickness of glaze, wearing of reglazed layer in short period of time and lastly an extra appointment to the patient.

The documentation of comparative evaluation of various methods to obtain a smoothest porcelain surface is limited. Some authors found the initial smoothness of a glazed surface to be superior to the polished surface [12–14], some found no significant difference between the glazed and polished surfaces [9, 15] and others concluded that surface polishing could equal or surpass the smoothness accomplished with surface glazing. [6, 16, 17] Studies that are more recent suggest that a polished surface is smoother and foster less plaque accumulation than a glazed surface [3, 18]. Esthetics results also may be improved by polishing rather than by glazing [10]. Therefore no comprehensive conclusion could be drawn from various studies, regarding which is a better method for finishing, reglazing or chair-side polishing.

In spite of advances in ceramic materials, the traditional feldspathic ceramics are still widely used [19] because of the fact that they give good esthetic results, which is achieved with the natural stratification and the artisan work of the dental ceramist. Therefore, in this study feldspathic porcelain was used for making the specimens, to check the efficacy of chairside polishing in reducing surface roughness.

In all the specimens one side is autoglazed which is kept as a control group to keep a check on surface roughness due to intrinsic flaws caused by variation in the condensed mass. The dimensions for the specimen were similar to previous studies and it was kept small to be compatible with the mounting plate of SEM.

Flat surfaces of all the specimens were ground with a medium grit diamond point at constant speed and for limited strokes. Since it was difficult to control the variation of force, same operator did all the grinding. And later, half of the specimens were subjected to reglazing and other half was subjected to chair-side polishing. It was very important to note here that the diamond point should be of medium or low grit as high grit points widens the pores opened during grinding. These large pores are difficult to close with both reglazing and chair side polishing [11].

After the use of shofu kit for initial polishing, the specimens were further polished with diamond paste with the help of silicone cone. Various studies have highlighted the importance of using a diamond paste during final stages to achieve the best possible finish [20, 21]. The smoothness produced by diamond paste can be explained by the particle size of the diamond polishing paste, which is 2 μm [22]. It is probable that, in the absence of a lubricant, porcelain particles removed from the surface become part of the abrasive system and contribute to an increase in roughness rather than smoothing of the surface. A lubricant and water spray can be expected to remove free and potentially abrasive particles. Grieve et al. [23] showed favorable results in terms of smoothness of porcelain using diamond paste, with no significant differences between this and glazed porcelain. Finally, the specimens were polished with pumice slurry and buff wheel [15].

Earlier studies have tested different properties affected or influenced by the finishing technique. However, the basic property that influences other properties is surface roughness. More is the surface roughness more is the wear caused, more is plaque accumulation, lesser is the fracture strength and poorer is the final esthetic appearance. Therefore, surface roughness was evaluated both quantitatively and qualitatively by surface profilometer and SEM respectively. This is in consensus with various studies that had used the same machines [1, 12, 24–27].

The results of this study has shown that both reglazing and chairside polishing is better than autoglazed. Reason for this could be that the pores (due to internal flaws while condensation) which are exposed while grinding of the ceramic surface are of variable size and are inhomogeneous in nature. Therefore, these could not be completely filled by autoglazing. These pores can be reduced or eliminated only with reglazing and chair-side polishing. Various earlier studies [7, 9, 12, 15, 22, 25, 27–29], had proved that chair-side polishing is equal to autoglazing. Some studies [1, 6, 26, 30, 31], had also proved that chair-side polishing is better than autoglazing. Only few studies had shown the opposite results, that is autoglazing or glazing is better than chair-side polishing [13, 14, 26, 32, 33]. And only one study reported in the literature, has compared autoglazing, reglazing and chair-side polishing [34].

In that study both autoglazing and reglazing were proved to be better than chairside polishing in terms of surface roughness and flexural strength.

Reasons for variation of results in different studies could be explained by:

Size and number of surface pores or flaws that are opened due to grinding of porcelain depends upon the extent of condensation of ceramic particles. But in all the studies one specimen was used for reglazing or self glazing and the other was used for chairside polishing. So one cannot be sure about the uniformity of condensation in both the specimens. There can be false negative results due to variation of internal flaws that can be a cause of increase in surface roughness. In this study constant mass of ceramic powder was condensed for each specimen to control this factor to some extent.

The coarseness of the diamond point used for grinding to simulate clinical adjustments. Although low grit diamond bur on air rotar handpiece with copious amount of water flow should be used but in this study medium grit diamond bur was used to grind the surface. It was not possible to do otherwise as it is difficult to control speed in air rotor handpiece.

Polishing instruments were used with the presence or absence of a lubricating paste for final finishing. In this study diamond paste and pumice slurry was used for final finishing.

Operator’s variable which limits the standardization for grinding and polishing. Manual grinding and polishing is always difficult to standardize. However, in this study same operator has done the grinding and polishing, to reduce the variations to some extent.

Different methods of evaluation were used.

Most of the studies have compared autoglazed with chair side polished. Only one study-compared autoglazed, reglazed and chairside polished surfaces.

Within the limited scope of the study, the study indicated that the chair-side polishing can be an effective alternative to reglazing in order to get similar surface finish after clinical adjustments.

This study has assessed only surface roughness, so further studies are required to assess other properties simultaneously, to confirm the efficacy of chair-side polishing.

Conclusion

The degree of success of any polishing technique for porcelain is dependent upon having well-condensed porcelain, because porosities in the porcelain cannot be eliminated. With well-condensed porcelain, the surface achieved by polishing can be as smooth as that of a glazed surface. Therefore, within the limits of this study, the following conclusions were drawn:

Polishing an adjusted porcelain surface with Shofu polishing system along with the diamond paste and pumice slurry, reduced the surface roughness significantly such that the difference in roughness between the resulting polished surface and reglazed surface was not significant.

The surface roughness of anautoglazed porcelain was always found to be more than a reglazed and a chair-side polished surface.

There is no statistically significant difference between the surface finish of Vita and Ivoclar as obtained by glazing, reglazing and chair-side polishing.

Chair-side polishing can be a good alternative to reglazing for finishing adjusted porcelain surface.

Acknowledgments

The authors thank all the staff members in the Department for rendering their help in any form.

References

- 1.Wright MD, et al. Comparison of three systems for the polishing of an ultra-low fusing dental porcelain. J Prosthet Dent. 2004;92:486–490. doi: 10.1016/j.prosdent.2004.07.021. [DOI] [PubMed] [Google Scholar]

- 2.Al-Wahadni A, Martin DM. Glazing and finishing dental porcelain: a literature review. J Can Dent Assoc. 1998;64:580–583. [PubMed] [Google Scholar]

- 3.Kawai K, Urano M, Ebisu S. Effect of surface roughness of porcelain on adhesion of bacteria and their synthesizing glucans. J Prosthet Dent. 2000;83:664–667. [PubMed] [Google Scholar]

- 4.Clayton JA, Green E. Roughness of pontic materials and dental plaque. J Prosthet Dent. 1970;23:407–411. doi: 10.1016/0022-3913(70)90007-7. [DOI] [PubMed] [Google Scholar]

- 5.Schlissel ER, Newitter DA, Renner RR, Gwinnett AJ. An evaluation of postadjustment polishing techniques for porcelain denture teeth. J Prosthet Dent. 1980;43:258–265. doi: 10.1016/0022-3913(80)90399-6. [DOI] [PubMed] [Google Scholar]

- 6.Jagger DC, Harrison A. An in vitro investigation into the wear effects of unglazed, glazed, and polished porcelain on human enamel. J Prosthet Dent. 1994;72:320–323. doi: 10.1016/0022-3913(94)90347-6. [DOI] [PubMed] [Google Scholar]

- 7.Al-Hiyasat AS, Saunders WP, Sharkey SW, Smith G, Gilmour WH. The abrasive effect of glazed, unglazed and polished porcelain on the wear of human enamel, and the influence of carbonated drinks on the rate of wear. Int J Prosthodont. 1997;10:269–282. [PubMed] [Google Scholar]

- 8.Giordano RA, Campbell S, Pober R. Flexural strength of feldpathic porcelain treated by ion exchange, overglaze and polishing. J Prosthet Dent. 1994;71:468–472. doi: 10.1016/0022-3913(94)90184-8. [DOI] [PubMed] [Google Scholar]

- 9.Brewer JD, Garlapo DA, Chipps EA, Tedesco LA. Clinical discrimination between autoglazed and polished porcelain surfaces. J Prosthet Dent. 1990;64:631–635. doi: 10.1016/0022-3913(90)90284-J. [DOI] [PubMed] [Google Scholar]

- 10.McLean JW. The science and art of dental ceramics. Vol 2. Chicago: Quintessence Publishing Co; 1979. pp. 45–79. [Google Scholar]

- 11.Oh W, DeLong R, Anusavice KJ. Factors affecting enamel and ceramic wear: A literatura review. J Prosthet Dent. 2002;87:451–459. doi: 10.1067/mpr.2002.123851. [DOI] [PubMed] [Google Scholar]

- 12.Klausner LH, Cartwright CB, Charbeneau GT. Polished versus autoglazed porcelain surfaces. J Prosthet Dent. 1982;47:157–162. doi: 10.1016/0022-3913(82)90180-9. [DOI] [PubMed] [Google Scholar]

- 13.Campbell SD. Evaluation of surface roughness and polishing techniqes for new ceramic materials. J Prosthet Dent. 1989;61:563–568. doi: 10.1016/0022-3913(89)90276-X. [DOI] [PubMed] [Google Scholar]

- 14.Patterson CJW, Mclundie AC, Stirrups DR, Taylor WG. Efficacy of a porcelain refinishing system in restoring finish after grinding with fine and extra-fine diamond. J Prosthet Dent. 1992;68:402–406. doi: 10.1016/0022-3913(92)90400-5. [DOI] [PubMed] [Google Scholar]

- 15.Sulik WD, Plekavich EJ. Surface finishing of dental porcelain. J Prosthet Dent. 1981;46:217–221. doi: 10.1016/0022-3913(81)90312-7. [DOI] [PubMed] [Google Scholar]

- 16.Haywood VB, Heymann HO, Kusy RP, Whitley JQ, Andreaus SB. Polishing porcelain veneers: an SEM and specular reflectance analysis. Dent Mater. 1988;4:116–121. doi: 10.1016/S0109-5641(88)80003-4. [DOI] [PubMed] [Google Scholar]

- 17.Haywood VB, Heymann HO, Scurrria MS. Effects of water, speed and experimental instrumentation on finishing and polishing porcelain intraorally. Dent Mater. 1989;5:185–188. doi: 10.1016/0109-5641(89)90011-0. [DOI] [PubMed] [Google Scholar]

- 18.Ward MT, Tate WH, Powers JM. Surface roughness of opalescent porcelain alter polishing. Oper Dent. 1995;20:106–110. [PubMed] [Google Scholar]

- 19.Christensen GJ. The use of porcelain fused to metal restorations in current dental practice. J Prosthet Dent. 1986;56:1–3. doi: 10.1016/0022-3913(86)90271-4. [DOI] [PubMed] [Google Scholar]

- 20.Goldstein RE. Finishing of composites and laminates. Dent Clin North Am. 1989;33:305–318. [PubMed] [Google Scholar]

- 21.Newitter DA, Schlissel ER, Wolf HJ. An evaluation of adjustment and postadjustment finishing techniques on the surface of porcelain-bonded-to-metal crowns. J Prosthet Dent. 1982;43:388–395. doi: 10.1016/0022-3913(82)90071-3. [DOI] [PubMed] [Google Scholar]

- 22.Al-Wahadni A, Martin DM. An in vitro investigation into the wear effects of glazed, unglazed and refinished dental porcelain on an opposing material. J Oral Rehábil. 1999;26:538–546. doi: 10.1046/j.1365-2842.1999.00394.x. [DOI] [PubMed] [Google Scholar]

- 23.Grieve AR, Jeffrey WM, Sharma SJ. An evaluation of three methods of polishing porcelain by comparison of surface topography with the original glaze. Restor Dent. 1991;7:34–36. [PubMed] [Google Scholar]

- 24.Zalkind M, Lauer S, Stern N. Porcelain surface texture after reduction and natural glazing. J Prosthet Dent. 1986;55:30–33. doi: 10.1016/0022-3913(86)90067-3. [DOI] [PubMed] [Google Scholar]

- 25.Goldstein GR, Barnhard BR, Penugonda B. Profilometer, SEM and visual assessment of porcelain polishing methods. J Prosthet Dent. 1991;65:627–634. doi: 10.1016/0022-3913(91)90196-4. [DOI] [PubMed] [Google Scholar]

- 26.Scurria MS, Powers JM. Surface roughness of two polished ceramic materials. J Prosthet Dent. 1994;71:174–177. doi: 10.1016/0022-3913(94)90027-2. [DOI] [PubMed] [Google Scholar]

- 27.Magne P, Won-Suck Oh, Pintado MR, Delong R. Wear of enamel and veneering ceramics after laboratory and chairside finishing procedures. J Prothet Dent. 1999;82:669–679. doi: 10.1016/S0022-3913(99)70008-9. [DOI] [PubMed] [Google Scholar]

- 28.Sarac D, Sarac YS, Yuzbasioglu E, Bal S. The effects of porcelain polishing systems on the color and surface texture of feldspathic porcelain. J Prothet Dent. 2006;96:122–128. doi: 10.1016/j.prosdent.2006.05.009. [DOI] [PubMed] [Google Scholar]

- 29.Al-Wahadni A. An in vitro investigation into the surface roughness of glazed, unglazed and refinished ceramic materials. Quintessance Int. 2006;37:311–317. [PubMed] [Google Scholar]

- 30.Raimondo RL, Jr, Richardson JT, Wiedner B. Polished versus autoglazed dental porcelain. J Prosthet Dent. 1990;64:553–557. doi: 10.1016/0022-3913(90)90126-W. [DOI] [PubMed] [Google Scholar]

- 31.Olivera AB, Marques MM. The effect of glazed and polished ceramic on human enamel wear. Int J Prosthodont. 2006;19:547–548. [PubMed] [Google Scholar]

- 32.Patterson JW, McLundie AC, Stirrups DR, Taylor WG. Refinishing of porcelain by using a refinishing kit. J Prosthet Dent. 1991;65:383–388. doi: 10.1016/0022-3913(91)90229-P. [DOI] [PubMed] [Google Scholar]

- 33.Schuh C, Kinast EJ, Mezzomo E, Kapczinski MP. Effect of glazed and polished surface finishes on the friction coefficient of two low-fusing ceramics. J Prothet Dent. 2005;93:245–252. doi: 10.1016/j.prosdent.2004.12.010. [DOI] [PubMed] [Google Scholar]

- 34.Chu FCS, Frankel N, Smales RJ. Surface roughness and flexural strength of self-glazed, Polished and reglazed In-ceram/vitadur alpha porcelain laminates. Int J Prothodont. 2000;13:66–71. [PubMed] [Google Scholar]