Abstract

Biological materials are effectively synthesized, controlled, and used for a variety of purposes—in spite of limitations in energy, quality, and quantity of their building blocks. Whereas the chemical composition of materials in the living world plays a some role in achieving functional properties, the way components are connected at different length scales defines what material properties can be achieved, how they can be altered to meet functional requirements, and how they fail in disease states and other extreme conditions. Recent work has demonstrated this by using large-scale computer simulations to predict materials properties from fundamental molecular principles, combined with experimental work and new mathematical techniques to categorize complex structure-property relationships into a systematic framework. Enabled by such categorization, we discuss opportunities based on the exploitation of concepts from distinct hierarchical systems that share common principles in how function is created, linking music to materials science.

Keywords: Nanotechnology, biology, music, simulation, theory, experiment, design, manufacturing, nanomechanics, protein, bio-inspired, materiomics

INTRODUCTION

The junction of biology, materials and modeling has a long history. Ancient humans have used ‘models’ to understand and explain the physical world tens of thousands of years ago, exemplified in early artwork in caves [1], and expressed later in increasingly complex music or literature [2]. Model building was a radical concept that allowed humans to recreate, relive and understand their environment in a different space, and to perform virtual experiments for instance by introducing imaginary creatures. This is because the construction of a model in the form of a drawing, a story or musical piece enables us to deal with complex situations without the need to recreate its actual physical realization. Now, the emergence of models of complex hierarchical biological materials at the interface of living and non-living systems emphasizes this ancient origin of modeling, and could play an important role in the fabrication of new bio-inspired materials, such as silk-inspired fibers [3–5].

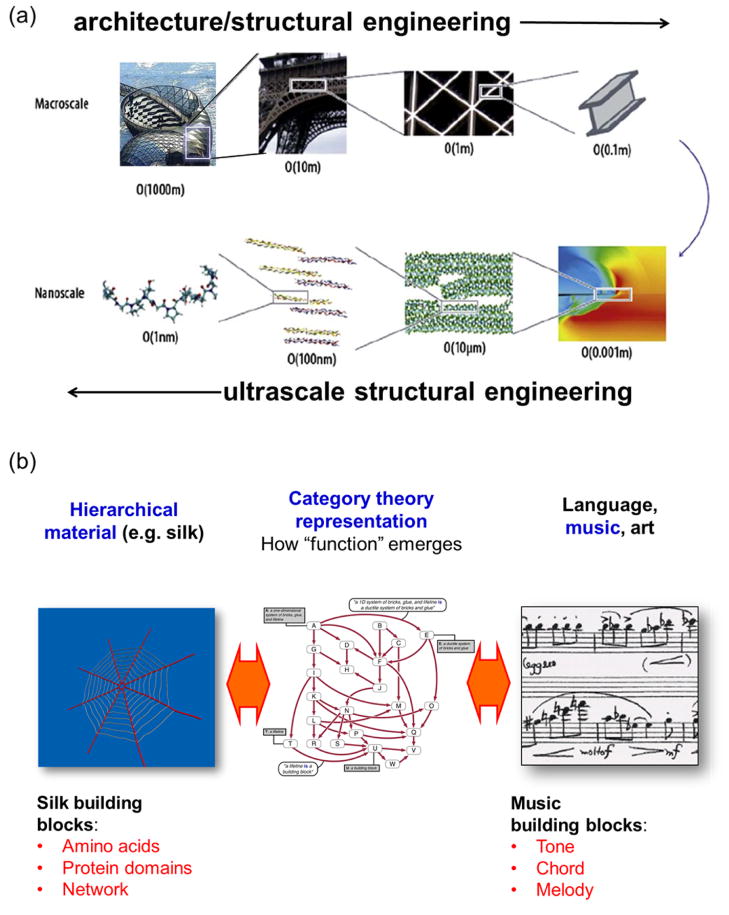

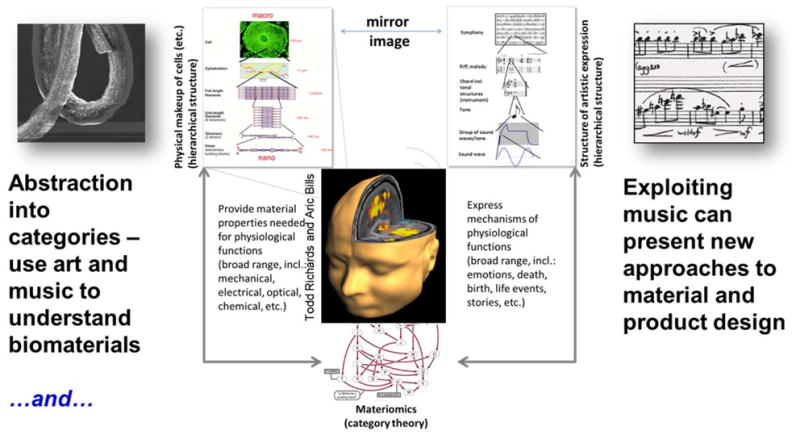

Indeed, biological materials are a fascinating area of materials science with very broad applications ranging from health care, energy, to nanotechnology [6–11]. The combination of experiment and simulation has emerged as a powerful tool to unlock the fundamental principles of materials design. An important impact is that it helped to identify common principles shared by a broad range of biological materials. For examples, a comparative approach that studied the structure and function of silk with that of bone or nacre shows the universal role of hierarchical mechanisms in creating material function – consistently, the system as a whole is more than the sum of its parts. The merger of traditional notions of “material” and “structure” enables this expanded design space in which new material properties can be achieved by simple rearranging elements rather than introducing new ones (Figure 1a) [12, 13]. Such progress has been promoted by mathematical approaches that map the functional relationships identified from both simulation and experiment for different materials into an abstract representation, where structural analogies between different systems can be easily pointed out (Figure 1b) [14–18]. This systems perspective of materials science has resulted in high-impact applications as it opened new paths towards understanding, designing and predicting complex materials behavior for the development of “ultimate materials” that combine the best of all basic elements, and that amplify the properties of the building blocks in a synergistic manner (Table 1).

Figure 1.

Common principles of biological and bioinspired material design. (a), Merger of ‘structure’ and ‘material’ across different length scales in hierarchical materials. (b), Different hierarchical systems feature common principles by which function emerges, which can be demonstrated by the application of category theory. Musical scores on the right based on a translation from designer silk sequence reported in [5].

Table 1.

Summary of critical challenges in materials science where the study of biological materials could make important contributions.

| Property | Key concept | Example |

|---|---|---|

| Amplify the best properties of all building blocks | Synergestistic interactions between different material mechanisms/structures | Stiffness of mineral crystal and ductility of protein |

| Reach high performance at large length-scales/time-scales with design that starts at the bottom | Upscaling (through length-/time-scales) | Achieve strength of single carbon nanotube in a macroscopic fiber; mechanical integrity at long time-scale (durability) |

| Achieve diversity of material properties with same building blocks | Expand design space through hierarchical structures | Use of simple peptides/proteins to manufacture various biomaterials with distinct properties (e.g.: silk, elastin, tendon, hair) |

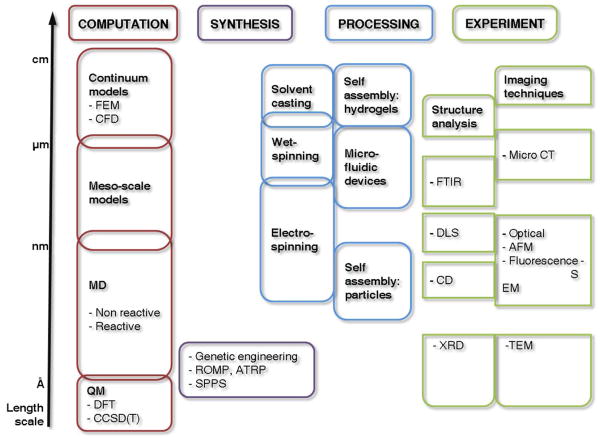

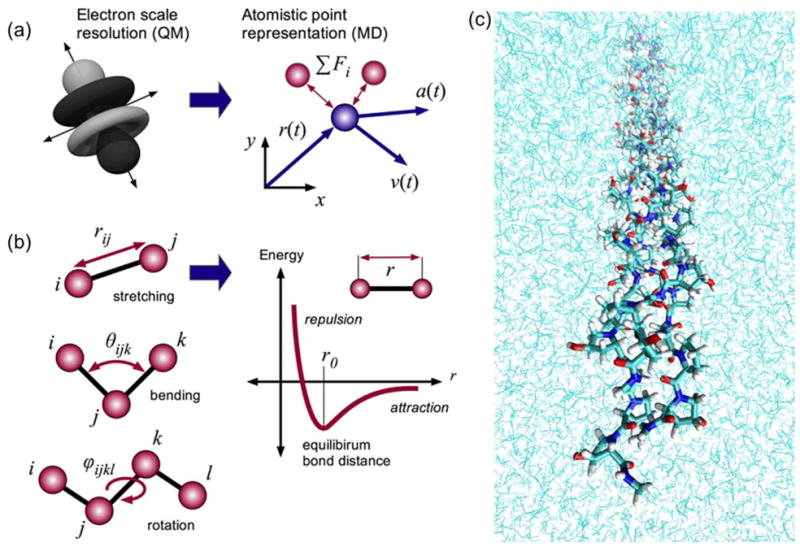

Atomistic modeling is a powerful tool that breaks down the material behavior to the level of atoms and molecules (Figure 2). The statistical distributions of positions, motions and interatomic forces can be used to compute larger-scale quantities such as stress, strain or other material properties like thermal conductivity. Enabled by the significant development of computational resources and new algorithms to enhance sampling, atomistic modeling can now be applied to treat very large systems at increasingly large time-scales (Figure 3). As reflected in the figure, the combined application of atomistic-based multiscale modeling and multiscale experiment has emerged as a particularly important area with very broad reach. This is because the use of bottom-up material models provides fundamental insights into the mechanisms by which natural and synthetic materials function and fail, enables one to explain experimental observations, and to use this insight to design new materials. The simulation of increasingly complex process conditions is an important frontier in computational materials science.

Figure 2.

Concept and application of atomistic modeling, where a material is simulated based on the motion of atoms and molecules. Panels (a) and (b) show the transition from the quantum mechanical treatment of an atom or molecule to a point of mass, and the use of interatomic and intermolecular force fields to describe their interactions in classical molecular dynamics. The image in panel (c) shows a large-scale model of a tropocollagen molecule in explicit solvent, representing a three-dimensional model of the most abundant structural protein (courtesy A. Gautieri).

Figure 3.

Overview of various computational and experimental tools, including synthesis, processing and imaging/manipulation techniques. The emergence of tools operating at different length-scales now enable the analysis of materials across all relevant scales. In this article we review applications of the multiscale modeling approach to describe molecular and coarse-grained models of silk, to integrate the chemical and macroscopic length-scales. Figure reprinted from [3].

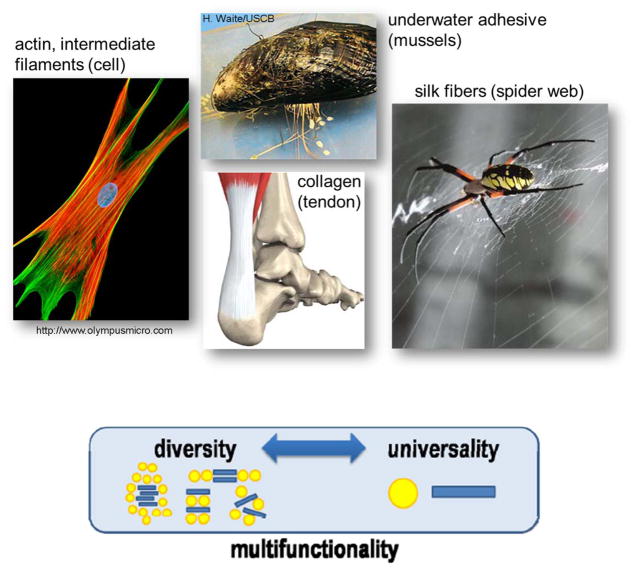

The combined application of modeling and experiment has been particularly impactful in comparative studies aimed at investigating the origin of the diversity of protein material properties in spite of their similar building blocks (all made from DNA, proteins, etc.). Indeed, this concept has been applied to materials such as collagen, bone, nacre, spider silk and intermediate filaments, with the objective to recognize and categorize their unifying and distinguishing principles (Figure 4) [19]. Recent work has exploited the use of models in the design of novel synthetic materials, for example in the development of designer silk. Other work has elucidated the role of “defects” in the understanding of disease mechanisms in biomaterials such as bone, which involve molecular-level changes to the structure that affect larger-scale mechanical properties (e.g. in the context of brittle bone disease). Applications of the insight derived from such studies include the development of novel carbon nanotube based fibers that incorporate polymers to mimic the structure seen in silk fibers. In this context, the use of simple model systems to explain a very broad range of experimental and computational observations, with a focus on integrating multiple scales, have led to the development of simple but powerful material concepts (e.g. scaling laws, models of size effects, performance envelopes, etc.) [10].

Figure 4.

Overview of the diversity protein materials found in nature, all made from the same building blocks (a library of about 20 amino acids) and forming functionally very different materials. The underlying concept is the universality-diversity-paradigm (UDP), which explains how different material properties can be achieved in spite of severe limitations in available energy, quality and quantity of a material’s basic elements (see, e.g. [19, 34] for further discussion).

As visualized in Figure 1b, an abstract “systems approach” to materials science – referred to as “materiomics” – is not limited to the study of materials. As depicted, we can also use this paradigm to map concepts from materials into seemingly different space – music – and learn about the mechanisms by which materials work from listening to music (and conversely, improve materials by composing music) [5, 13, 18]. Such an interdisciplinary discourse to materials research that introduces creative concepts into the design process pushes the limits of what we can design today. The heightened level of functional properties that can be achieved using this paradigm may one day play a critical role in advanced manufacturing, where properties specific to products, processes or technologies can be realized “on demand”. Merging materials design with product design, extending the concept shown in Figure 1a towards materials processing, could play a leading role in innovating the advanced manufacturing sector. In the following sections we review the key concepts of biological materials design – both natural systems and the synthesis of de novo materials – in the context of silk and silk-inspired materials and discuss the impact of relevant computational modeling associated with this field. Indeed, our ability to build models of our physical world has come a long way since the ancient drawings in caves and now involves petaflop and exaflop computing, storage and analysis of large amounts of data in situ (Figure 3), and our ability to use mathematics to demonstrate clear analogies between seemingly different fields provides us with tools to address the challenges with large amounts of data.

CASE STUDY: SPIDER SILK

Silk is truly an amazing material – genetically programmable, processable and flexible in its natural and potential engineering applications, in particular when combined with other proteins (natural and synthetic ones) [20–24]. In its natural role it serves as a multipurpose protein fiber with hierarchical organization to provide structural support, prey procurement or protection of eggs (Figure 5). In a series of recent studies [25–30] we demonstrated how the different hierarchical levels in silk – from the protein molecules to an entire spider web – play together to create a mechanically strong, robust and resilient structure. It is a demonstration of how the paradigm of merging ‘structure’ and ‘material’ is critical to overcome the limitations of the inferior natural building blocks of this material to achieve a system whose overall performance can’t yet be rivaled by any engineered substitute.

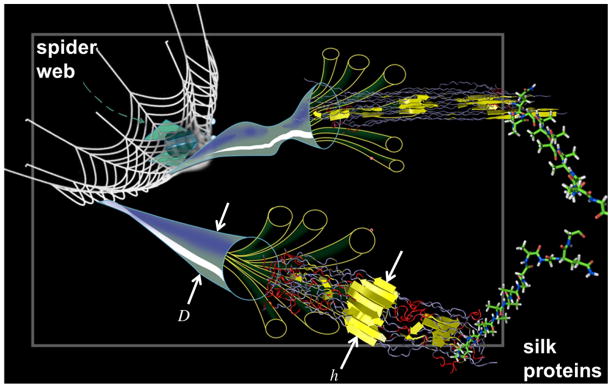

Figure 5.

Overview of the different scales in hierarchical biological materials, here for spider silk, from the level of silk proteins (right) to a spider web (left). Our work has demonstrated that the synergistic interaction of mechanisms at different length-scales is key to explain the remarkable properties of the entire system, the spider web. The image marks two important length-scales – the fiber diameter D and the size of beta-sheet nanocrystals h, whose effect on material properties will be explored in Figures 8 and 9, respectively. Image courtesy of the National Science Foundation/M. Buehler and based on a recent article [26].

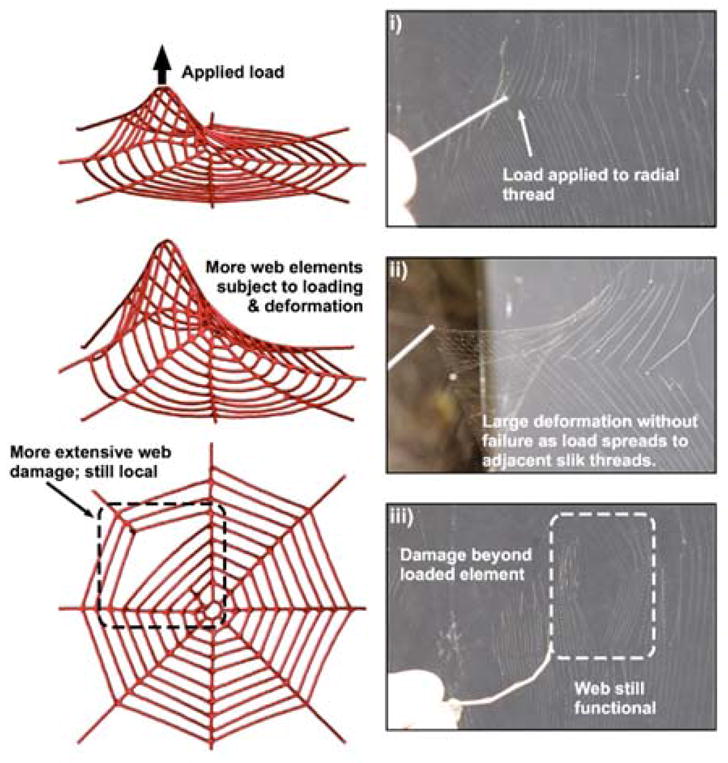

First, it was demonstrated that the great strength, toughness and flexibility of spider silk, exceeding that of steel and many other engineered materials, can be explained by the material’s unique structural makeup that involves multiple hierarchical levels that span amino acid sequence, proteins, nanocomposite, fibrils, fibers and a web structure (Figure 5). These hierarchical levels are a manifestation of how the biochemical information that defines the protein sequence directly affects the behavior of the system at the structural scale of an entire spider web, which is exposed to a range of mechanical loading (wind, prey capture, falling debris, etc.). Second, this work has shown that each level in the material contributes to the overall properties, and that the remarkable properties of the entire system emerge because of a series of synergistic interactions across the scales (where the sum is more than its parts) [31]. A particularly interesting aspect is how the nonlinear material behavior of silk fibers affects the web behavior [26]. Silk fibers typically soften at the yield point to dramatically stiffen during large deformations until point of failure, whose origin has been traced to the particular structure of silk proteins and the nanocomposite they form. Their particular stress-strain behavior is what allows for localization of deformation upon loading, and is what makes spider webs robust and extremely resistant to defects, as compared to a hypothetical linear-elastic or elastic-plastic silk fiber. Through in situ experiments on spider webs, we confirmed the computational prediction that locally applied loading results in minimal damage, as depicted in Figure 6. It was also found that under global loads such as wind, the material behavior of silk under small-deformation – typically showing a small but very stiff regime – is crucial to maintaining the structural integrity of the web. This study presented an example of a combined computational-experimental study paired with a theoretical mechanics analysis of the findings, where a fracture mechanics based scaling law was identified to generalize the insights. What’s unique about this work is it began at the molecular level and assessed the impact of the material composition from the chemical scale all the way to the macroscopic structure of a web.

Figure 6.

Computational and experimental predictions of web failure mechanisms (images i) to iii) correspond to increasing applied load). Figure adapted from [26]. The characteristic stiff-soft-stiff behavior of silk threads, also shown in Figure 8, is critical to achieve a mechanically resilient web structure that can deal with both global wind and local point loading.

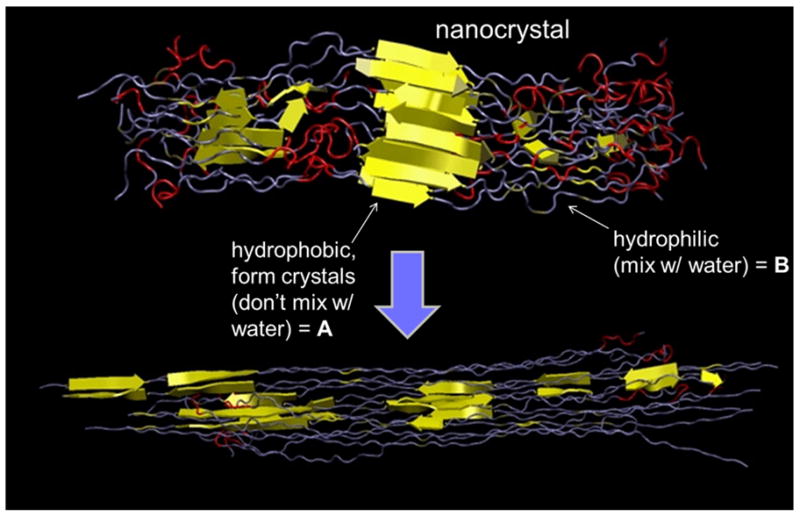

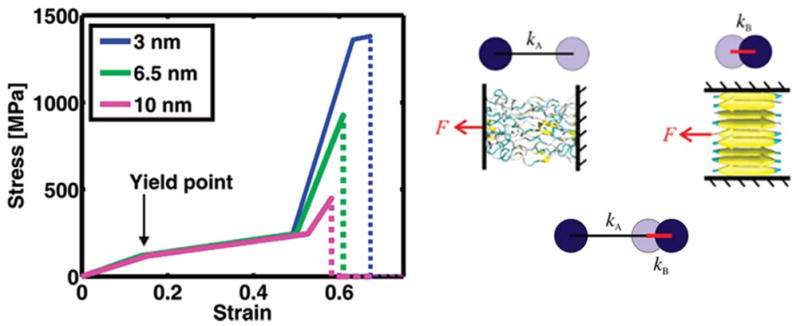

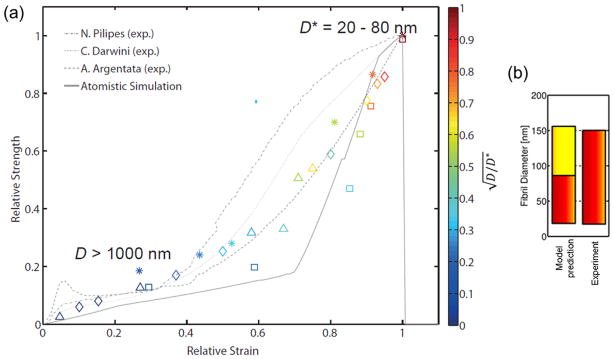

From a more fundamental point of view one could ask if there are unifying fundamental principles that govern the behavior of silk and other biological materials? While silk’s characteristic stiffening behavior is similar to that found in many other natural polymers such as rubber, it is highly controlled based on the silk protein’s sequence and processing conditions during spinning. The combination of extensive computational and experimental work has revealed simple physical mechanisms by which the material behavior of silk fibers can be controlled. As eluded to above, it’s all in the protein sequence, which is used to generate distinct microstructures (so-called secondary structures) – which are realized by sequence patterns rich in the amino acid Alanine that generate very stiff and strong crystals (they don’t like to mix with water, called “A”), and those rich in Alanine amino acids that lead to more disorganized, labile and very soft regions (they like to mix with water, called “B”) [24, 28, 30, 32]. The two phases are depicted in Figure 7. The relative amount and combination of these building blocks is the paradigm by which silk threads can achieve very diverse mechanical signatures, as depicted in Figure 8 (spiders can produce many different types of silks for different purposes, which show dramatically changed mechanical behaviors). The importance of the hierarchical structure and the relevance of length-scales has been emphasized in several follow-up works. Figure 9a shows a comparison of silk fiber stress-strain curves, various experimental results and computational prediction with varied fiber diameter D. In that study, the computer model allowed us to test the performance of silk fibers that don’t naturally exist in a series of virtual experiments. The analysis revealed that the geometric confinement of the silk fiber diameter to < 100 nm ≈ D* is critical to exploit the full potential of the material behavior endowed from the molecular scale [27]. This is a remarkable result in light of the fact that silk fibers are indeed found to be constructed with such geometrical features (Figure 9b).

Figure 7.

Structure and mechanics of silk molecules, and a visualization of two universal structural domains – a hydrophobic domain “A” and a hydrophilic domain “B”. Their combination results in a nanocomposite that gives rise to the particular properties of silk fibers.

Figure 8.

Simple coarse-grained model (at the “mesoscale”) based on the interplay of the two structural domains “A” and “B” (visualizations of these see Figure 5), used here to explain the stress-strain response of silk fibers depending on the size of beta-sheet nanocrystals, denoted by h [30].1

Figure 9.

Effect of fiber diameter confinement on silk mechanics. (a), Comparison of silk fiber stress-strain curves, various experimental results and computational prediction with varied fiber diameter D. The analysis shows that the geometric confinement of the silk fiber diameter to less than 100 nm ≈ D* is critical to exploit the full potential of the material behavior endowed from the molecular scale. The overall agreement of the stress-strain response of silk with respect to the theoretical model is remarkable, and also reflects the study depicted in Figure 8 that emphasized on the role of nanocrystal confinement to achieve the maximum strength and toughness of beta-sheet cross-links. (b), Comparison of predicted fiber diameters with experimentally determined dimensions, showing excellent agreement. Figure adapted from [27].

The study of biological materials is not limited to the fundamental science of understanding how nature works. Rather, the fundamental insight derived from the interplay of sequence, structure and performance of a structure as large as a spider web opens the door to play with nature’s building blocks, take the pieces and reassemble them in new ways – such as creating varied silk sequences made from the building blocks “A” and “B” – e.g., AB3 and A3B. We have recently designed and applied this concept an integrated experimental-computational methodology to design new silk-based materials by engineering the sequence of protein building blocks [4, 5, 33].

ENABLING A CREATIVE APPROACH

While at first glance, there do not appear to be many similarities between music and biopolymers, each of these seemingly disparate fields involves actually very similar processes with emergent behaviors based on specific relationships between the different length- and time-scales involved. These may one day form revolutionary paths to understand, design and model materials and have already invoked a systems perspective through the use of category theory models of hierarchical materials. Through an abstraction of knowledge from the physical system, silk, to a mathematical model using category theory, collaborative work with modelers, experimentalists, composers and a performer has illustrated how the mechanism of spinning fibers from proteins can be translated into music through a process that assigns a set of rules that governs the construction of the system [5]. This technique, following the idea presented earlier in Figure 1b, allowed us to express the structure, mechanisms and properties of the ‘material’ in a different domain, ‘music’. The integration of science and art through categorization of structure-property relationships presents a novel paradigm to create new bioinspired materials, through the translation of structures and mechanisms from distinct hierarchical systems and in the context of the limited number of building blocks that universally governs these systems.

As reported in [5] we considered different designer silk sequences based on the building blocks described above -- AB3 and A3B. AB3 is a successful protein that forms fibers, and includes many more repetitions of the “B-block”. The other protein A3B contains a much larger amount of beta-sheet nanocrystal forming domains, but don’t form fibers. This is because in this case relatively few of the A3B proteins assemble into large globular clusters without forming a well-connected network. The differences between the two systems was audible in the music, where the more aggressive music resembled the protein A3B which formed many but unconnected globular structures. These results suggested that a certain musical character may be considered more conducive to forming fiber than the other. Understanding these relationships may eventually help us in using musical pieces to improve the design of materials. Indeed, exciting opportunities may emerge through the translation from music to materials. For example, can we use Beethoven’s symphonies to inform the development of new nanomaterials by translating musical patterns into protein sequences, mechanisms and processing conditions?

As shown in Figure 10, the structure of biological materials and the structure of art, language and virtually any other forms of human expression (physical or aesthetic) show striking similarities (from the composition of a symphony, a painting, a sculpture, or a sonnet). We use such forms of expression to describe a range of functions, emotions, life events and stories. Is there a fundamental reason for these similarities, rooted in the common patterns of structure-property relationships, where the expression of arts is a direct reflection of the physical structure of our body, organs and the brain? If considered an inherent part of us, music and other forms of art could be a direct expression of the structure and function of our brain, tissues, organs etc., and thereby serve as a new type of analysis to understand the way biological materials function and fail [10]. It remains an open question whether or not the study of language and music will teach us new insight about the biological mechanisms that govern the physiology and disease of organs or cells, but it deserves attention.

Figure 10.

Why music is part of us (figure adapted from [10] and [5]). Music (and other forms of the arts) is an expression of our body’s materials in a different manifestation. Exploiting this concept may enable us to identify new avenues to better understand biomaterials, through the study of music or literature. They may also provide revolutionary insights into the design of novel materials. Musical scores on the right based on a translation from a designer silk sequence as reported in [5].

CONCLUSION

The development and application of molecular modeling as a tool to better understand materials has received significant attention. Flexibility, integration and changeable properties play a critical role in the establishment of a new era of materials manufacturing. Not limited to nanotechnology, this field aims at designing and producing the best-performing material at minimal cost. Hierarchical materials, with their expanded design space and potential for synergetic interactions of mechanisms across scales (Figure 1), promise to play a very important role in enabling our ability to design structures for very different purposes, to reconfigure, reassemble and redefine properties on demand. An emerging concept is the exploitation of the “multiscope”, which reflects a systems perspective on the use of multiple length-scales in generating designer materials.

Acknowledgments

Support from NSF (CAREER 0642545), ONR (PECASE N00014-10-1-0562), AFOSR (FA9550-11-1-0199), as well as NIH (U01 EB014976) is acknowledged.

Biography

Markus J. Buehler is an Associate Professor in the Department of Civil and Environmental Engineering at the Massachusetts Institute of Technology, where he directs the Laboratory for Atomistic and Molecular Mechanics (LAMM). His work has been recognized with numerous awards, including the Presidential Early Career Award for Scientists and Engineers (PECASE), the Harold E. Edgerton Faculty Achievement Award for exceptional distinction in teaching and research, the Leonardo da Vinci Award, and the Materials Research Society Outstanding Young Investigator Award.

Footnotes

An associated online applet can be downloaded at: http://web.mit.edu/mbuehler/www/SIMS/Deformation%20of%20Spider%20Silk.html

References

- 1.Clottes J. In: Chauvet Cave: The Art of Earliest Times. PGB, translator. Salt Lake City, UT: University of Utah Press; 2003. [Google Scholar]

- 2.Patel AD. Language, music, syntax and the brain. Nature Neuroscience. 2003;6(7):674–681. doi: 10.1038/nn1082. [DOI] [PubMed] [Google Scholar]

- 3.Gronau G, Krishnaji ST, Kinahan ME, Giesa T, Wong JY, Kaplan DL, Buehler MJ. A review of combined experimental and computational procedures for assessing biopolymer structure-process-property relationships. Biomaterials. 2012 doi: 10.1016/j.biomaterials.2012.06.054. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Krishnaj ST, Bratzel G, Kinahan ME, Kluge JA, Staii C, Wong JY, Buehler MJ, Kaplan DL. Advanced Functional Materials. 2012. Sequence–structure–property relationships of recombinant spider silk proteins: Integration of biopolymer design, processing, and modeling. accepted for publication. [Google Scholar]

- 5.Wong JY, McDonald J, Taylor-Pinney M, Spivak DI, Kaplan DL, Buehler MJ. Nano Today. 2012. Materials by Design: Merging Proteins and Music. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Espinosa HD, Rim JE, Barthelat F, Buehler MJ. Merger of structure and material in nacre and bone - Perspectives on de novo biomimetic materials. Progress in Materials Science. 2009;54(8):1059–1100. [Google Scholar]

- 7.Fratzl P, Weinkamer R. Nature’s hierarchical materials. Progress in Materials Science. 2007;52(8):1263–1334. [Google Scholar]

- 8.Meyers MA, Chen PY, Lin AYM, Seki Y. Biological materials: Structure and mechanical properties. Progress in Materials Science. 2008;53(1):1–206. [Google Scholar]

- 9.Huebsch N, Mooney DJ. Inspiration and application in the evolution of biomaterials. Nature. 2009;462(7272):426–32. doi: 10.1038/nature08601. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Cranford SW, Buehler MJ. Biomateriomics. 1. New York: Springer; 2012. [Google Scholar]

- 11.Omenetto FG, Kaplan DL. New Opportunities for an Ancient Material. Science. 2010;329(5991):528–531. doi: 10.1126/science.1188936. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Buehler MJ, Ackbarow T. Fracture mechanics of protein materials. Materials Today. 2007;10(9):46–58. [Google Scholar]

- 13.Buehler MJ. Tu(r)ning weakness to strength. Nano Today. 2010;5(5):379–383. [Google Scholar]

- 14.Spivak DI, Kent RE. Ologs: a categorical framework for knowledge representation. PLoS One. 2012;7(1):e24274. doi: 10.1371/journal.pone.0024274. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Giesa T, Spivak D, Buehler M. Category Theory Based Solution for the Building Block Replacement Problem in Materials Design. Advanced Engineering Materials. 2012 doi: 10.1002/adem.201200109. [DOI] [Google Scholar]

- 16.Mac Lane S. Categories for the working mathematician. New York: Springer; 1998. [Google Scholar]

- 17.Spivak DI, Giesa T, Wood E, Buehler MJ. Category Theoretic Analysis of Hierarchical Protein Materials and Social Networks. PLoS ONE. 2011;6(9) doi: 10.1371/journal.pone.0023911. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Giesa T, Spivak D, Buehler MJ. Reoccurring Patterns in Hierarchical Protein Materials and Music: The Power of Analogies. BioNanoScience. 2011;1(4):153–161. [Google Scholar]

- 19.Buehler MJ, Yung YC. Deformation and failure of protein materials in physiologically extreme conditions and disease. Nature Materials. 2009;8(3):175–88. doi: 10.1038/nmat2387. [DOI] [PubMed] [Google Scholar]

- 20.Huang XP, Liu GQ, Wang XW. New Secrets of Spider Silk: Exceptionally High Thermal Conductivity and Its Abnormal Change under Stretching. Advanced Materials. 2012;24(11):1482–1486. doi: 10.1002/adma.201104668. [DOI] [PubMed] [Google Scholar]

- 21.Blackledge TA, Kuntner M, Agnarsson I. The Form and Function of Spider Orb Webs: Evolution from Silk to Ecosystems. Advances in Insect Physiology, Vol 41: Spider Physiology and Behaviour - Behaviour. 2011;41:175–262. [Google Scholar]

- 22.Rammensee S, Slotta U, Scheibel T, Bausch AR. Assembly mechanism of recombinant spider silk proteins. Proceedings of the National Academy of Sciences of the United States of America. 2008;105(18):6590–6595. doi: 10.1073/pnas.0709246105. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Scheibel T. Silk - a biomaterial with several facets. Applied Physics a-Materials Science & Processing. 2006;82(2):191–192. [Google Scholar]

- 24.Omenetto F, Kaplan D. From Silk Cocoon to Medical Miracle. Scientific American. 2010;303(5):76–77. [PubMed] [Google Scholar]

- 25.Bratzel G, Buehler MJ. Sequence-structure correlations in silk: Poly-Ala repeat of N. clavipes MaSp1 is naturally optimized at a critical length scale. J Mech Behav Biomed Mater. 2012;7:30–40. doi: 10.1016/j.jmbbm.2011.07.012. [DOI] [PubMed] [Google Scholar]

- 26.Cranford SW, Tarakanova A, Pugno NM, Buehler MJ. Nonlinear material behaviour of spider silk yields robust webs. Nature. 2012;482(7383):72–U91. doi: 10.1038/nature10739. [DOI] [PubMed] [Google Scholar]

- 27.Giesa T, Arslan M, Pugno NM, Buehler MJ. Nanoconfinement of Spider Silk Fibrils Begets Superior Strength, Extensibility, and Toughness. Nano Letters. 2011;11(11):5038–5046. doi: 10.1021/nl203108t. [DOI] [PubMed] [Google Scholar]

- 28.Keten S, Buehler MJ. Nanostructure and molecular mechanics of spider dragline silk protein assemblies. Journal of the Royal Society Interface. 2010;7(53):1709–1721. doi: 10.1098/rsif.2010.0149. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Keten S, Xu Z, Ihle B, Buehler MJ. Nanoconfinement controls stiffness, strength and mechanical toughness of beta-sheet crystals in silk. Nature Materials. 2010;9(4):359–67. doi: 10.1038/nmat2704. [DOI] [PubMed] [Google Scholar]

- 30.Nova A, Keten S, Pugno NM, Redaelli A, Buehler MJ. Molecular and Nanostructural Mechanisms of Deformation, Strength and Toughness of Spider Silk Fibrils. Nano Letters. 2010;10(7):2626–2634. doi: 10.1021/nl101341w. [DOI] [PubMed] [Google Scholar]

- 31.Tarakanova A, Buehler MJ. A Materiomics Approach to Spider Silk: Protein Molecules to Webs. Jom. 2012;64(2):214–225. [Google Scholar]

- 32.Kaplan D, Adams WW, Farmer B, Viney C. Silk - Biology, Structure, Properties, and Genetics. Silk Polymers. 1994;544:2–16. [Google Scholar]

- 33.Rye S, Gronau G, Kinahan ME, Krishnaji ST, Kaplan D, Wong JY, Buehler MJ. Structure and mechanical properties of silk-inspired flow-assembled fibers: Modeling and experiment. 2012 in submission. [Google Scholar]

- 34.Knowles TPJ, Buehler MJ. Nanomechanics of functional and pathological amyloid materials. Nature Nanotechnology. 2011;6(8):469–479. doi: 10.1038/nnano.2011.102. [DOI] [PubMed] [Google Scholar]