Summary

Overproduction of microbial metabolites is related to developmental phases of microorganisms. Inducers, effectors, inhibitors and various signal molecules play a role in different types of overproduction. Biosynthesis of enzymes catalysing metabolic reactions in microbial cells is controlled by well‐known positive and negative mechanisms, e.g. induction, nutritional regulation (carbon or nitrogen source regulation), feedback regulation, etc. The microbial production of primary metabolites contributes significantly to the quality of life. Fermentative production of these compounds is still an important goal of modern biotechnology. Through fermentation, microorganisms growing on inexpensive carbon and nitrogen sources produce valuable products such as amino acids, nucleotides, organic acids and vitamins which can be added to food to enhance its flavour, or increase its nutritive values. The contribution of microorganisms goes well beyond the food and health industries with the renewed interest in solvent fermentations. Microorganisms have the potential to provide many petroleum‐derived products as well as the ethanol necessary for liquid fuel. Additional applications of primary metabolites lie in their impact as precursors of many pharmaceutical compounds. The roles of primary metabolites and the microbes which produce them will certainly increase in importance as time goes on. In the early years of fermentation processes, development of producing strains initially depended on classical strain breeding involving repeated random mutations, each followed by screening or selection. More recently, methods of molecular genetics have been used for the overproduction of primary metabolic products. The development of modern tools of molecular biology enabled more rational approaches for strain improvement. Techniques of transcriptome, proteome and metabolome analysis, as well as metabolic flux analysis. have recently been introduced in order to identify new and important target genes and to quantify metabolic activities necessary for further strain improvement.

1. Introduction

Primary metabolites are microbial products made during the exponential phase of growth whose synthesis is an integral part of the normal growth process. They include intermediates and end‐products of anabolic metabolism, which are used by the cell as building blocks for essential macromolecules (e.g. amino acids, nucleotides) or are converted to coenzymes (e.g. vitamins). Other primary metabolites (e.g. citric acid, acetic acid and ethanol) result from catabolic metabolism; they are not used for building cellular constituents but their production, which is related to energy production and substrate utilization, is essential for growth. Industrially, the most important primary metabolites are amino acids, nucleotides, vitamins, solvents and organic acids. These are made by a diverse range of bacteria and fungi and have numerous uses in the food, chemical and nutriceutical industries. Many of these metabolites are manufactured by microbial fermentation rather than chemical synthesis because the fermentations are economically competitive and produce biologically useful isomeric forms. Several other industrially important chemicals could be manufactured via microbial fermentations (e.g. glycerol and other polyhydroxy alcohols) but are presently synthesized cheaply as petroleum by‐products. However, as the cost of petroleum has skyrocketed recently, there is now renewed interest in the microbial production of ethanol, organic acids and solvents.

Living cells derive energy through metabolism employing reduction and oxidation (redox) reactions (Garcia‐Vallve, 2004). The oxidation of carbon sources, e.g. glucose, and the transfer of electrons involve two paths: biosynthesis and energy metabolism. Only a small part of the electrons are used in reduction reactions to supply new cellular material (i.e. biosynthesis). Most are passed to terminal electron acceptors either directly or via a pathway of redox reactions. Terminal electron acceptors are necessary to maintain a redox balance in the cell. In aerobes, oxygen is the ultimate electron acceptor yielding water as product. For the anaerobes, a large number of acceptors are used producing many products (alcohols, fatty acids, H2). Anaerobes cannot synthesize an O2‐linked energy conversion system and thus cannot use O2 as the terminal electron acceptor. They also show a wide range of sensitivity to oxygen, some being killed by exposure to even traces of O2.

Bacteria such as streptococci and clostridia have no respiratory chain but possess complexes of integral membrane proteins and freely diffusible molecules that shuttle electrons from one complex to the next. Thus, the reducing equivalents that are produced by carbon source catabolism cannot be reoxidized by oxygen or nitrate, i.e. external electron acceptors. Instead, organic intermediates of catabolism (like fumarate or succinate) are used and the reduced products are excreted. These are the primary metabolites of such cultures.

2. Regulation of primary metabolism

Microbial metabolism is a conservative process that usually does not expend energy or nutrients to make compounds already available in the environment, and does not overproduce components of intermediary metabolism. Coordination of metabolic functions ensures that, at any given moment, only the necessary enzymes, and the correct amount of each, are made. Once a sufficient quantity of a material is made, the enzymes concerned with its formation are no longer synthesized and the activities of preformed enzymes are curbed by a number of specific regulatory mechanisms such as feedback inhibition.

Transcription is the principal site for control of bacterial and eukaryotic expression and is dependent on transcription factors, i.e. proteins which bind near or at promoters, thus activating or repressing transcription initiation in response to extracellular signals. To initiate transcription in bacteria, RNA polymerase must associate with a particular sigma factor (σ). Sigma factors are small proteins that direct RNA polymerase to specific classes of promoter sequences (Woesten, 1998). In most bacteria, sigma A or sigma D, also known as sigma 70 (the major ‘housekeeping’ sigma factor) controls the major housekeeping functions and most RNA synthesis in the growth phase. However, there are additional sigma factors, which recognize different consensus sequences. These sigma factors not only allow the cell to carry out basal gene expression and exponential growth but also to respond to developmental or environmental signals. The number of sigma factors depends on the bacteria; thus Escherichia coli makes seven sigma factors whereas Bacillus subtilis makes seventeen. There are also anti‐sigma factors which bind to and inhibit sigma factor function, thus preventing the interaction of the latter with RNA polymerases. There are even anti‐anti‐sigma factors, which are antagonists of anti‐sigma factors (Mittenhuber, 2002). A wide range of cellular processes are regulated by anti‐sigma factors, including bacteriophage growth, sporulation, stress response, flagellar biosynthesis, pigment production, ion transport and virulence expression.

The primary control of gene expression in eukaryotes is also at the level of transcription and is exerted by transcription factors. While prokaryotic transcription factors bind close to the gene to be transcribed, eukaryotic transcription factors often bind hundreds or thousands of base pairs upstream of the gene. Upstream of about 80% of eukaryotic genes is the TATA box (i.e. TATA is part of the sequence), which binds one type of transcription factor. Transcription factors include (i) helix–turn–helix structures, (ii) zinc fingers, (iii) leucine zippers, (iv) helix–loop–helix structures and (v) high‐mobility groups as their binding mechanism. After binding to DNA, the factors interact with other factors or with RNA polymerase itself to modulate transcription either in the positive direction [transcription activation (the usual case)] or in the negative direction (transcription repression). The interaction is a function of other domains in the transcription factor, which have a high concentration of acidic amino acids, glutamine residues or proline residues. Transcription repression usually occurs when a repressive transcription factor binds to DNA and blocks the attachment or action of activating transcription factors. Control of the transcription factor itself occurs by regulating its activity by protein–protein interaction, phosphorylation or glycosylation.

RNA polymerase catalyses the sequential addition of ribonucleotides using the bases of one strand of DNA as template at a rate of 43 bases s−1 (Richardson, 1993). The elongation process is very stable requiring termination signals at the end of a gene or operon to prevent transcription of neighbouring genes. Sometimes, proteins such as rho factor are required for termination of certain elongation processes. Termination is also important in attenuation control and antitermination. In attenuation, a terminator sequence is present in the leader region forming a termination structure in the mRNA and preventing transcription of the gene or operon (e.g. tryptophan in the case of the intrinsic terminator trpA). As a result, the terminator structure in the mRNA is not formed and the gene or operon is transcribed. This is often the case in amino acid biosynthetic operons. In anti‐termination, a terminator is present but under certain conditions, it can be bypassed, thus allowing transcription. These terminators are upstream of the first gene of an operon and/or between genes of an operon. Often, the first gene of an operon encodes a regulatory RNA‐binding protein, which binds to the terminator structure in mRNA and interferes with termination. Control of the operon is carried out by a metabolic signal such as an inducer.

2.1 Regulatory mechanisms involved in the biosynthesis of primary metabolites

2.1.1 Induction. This is a control mechanism by which a substrate (or a compound structurally similar to the substrate, or a metabolically related compound) ‘turns on’ the synthesis of enzymes, which are usually involved in the degradation of the substrate. Enzymes that are synthesized as a result of genes being turned on are called inducible enzymes and the chemical that activates gene transcription is called the inducer. Inducible enzymes are produced only in response to the presence of their substrate and, in a sense, are produced only when needed. In this way, the cell does not waste energy synthesizing unneeded enzymes. The inducer molecule combines with a repressor at the DNA level and thereby prevents the blocking of an operator by the repressor, leading to the transcription of the gene and translation of the messenger RNA encoding the enzyme. Although most inducers are substrates of catabolic enzymes, products can sometimes function as inducers. As examples, malto‐dextrins can induce amylase, fatty acids induce lipase, urocanic acid induces histidase, and galacturonic acid induces polygalacturonase. Some coenzymes induce enzymes, as in thiamine induction of pyruvate decarboxylase. Substrate analogues that are not attacked by the enzyme (‘gratuitous inducers’) are often excellent inducers of enzyme synthesis.

The most thoroughly studied inducible enzyme system is that for lactose hydrolysis in E. coli, which provided the basis of a model system for negative control of protein synthesis (Jacob and Monod, 1961). Negative control means that a regulatory protein encoded by a regulator locus interferes with transcription. In the case of the lac operon in E. coli, about 10 molecules of repressor are made per regulator locus. The operator locus of the lac operon is 27 base pairs long. The lac repressor is a tetramer protein with a molecular mass of 150 000 containing 347 amino acid residues. In Pseudomonas putida, tryptophan synthetase is induced by indoleglycerophosphate and the entire tryptophan branch is induced by chorismate in B. subtilis.

Positive regulation of transcription by the regulator locus is another type of control mechanism. Here, the regulatory protein encoded by the regulator gene is necessary for transcription to occur. Binding of the inducer activates this regulatory protein. The complex binds at the operator region and turns on gene expression. Positive control occurs in E. coli for utilization of l‐rhamnose, maltose and arabinose. Another induction system involving positive control is galactose utilization in Saccharomyces cerevisiae. The system consists of seven genes and no operons. Five of the pathway genes are regulated by galactose but not gal5 (encoding phosphoglucomutase), which is constitutive. The system involves four different chromosomes. The GAL4 protein transcriptionally activates the other five genes. The GAL80 protein binds directly to GAL4 preventing its activating function. The inducer, formed from galactose by the seventh gene, gal3, inactivates GAL80 thus allowing GAL4 to activate transcription of the five pathway genes. Induction in filamentous fungi such as Aspergillus nidulans is mainly of the positive control type.

2.1.2 Carbon source regulation. Like enzyme induction, carbon source regulation [more commonly known as carbon catabolite repression (CCR)] is one of the conservative mechanisms which safeguards against wasting a cell's protein‐synthesizing machinery, and operates when more than one utilizable substrate is present in the environment. The cell produces enzymes to catabolize the most rapidly assimilated carbon source while synthesis of enzymes utilizing other substrates is repressed until the primary substrate is exhausted. The repressed enzymes are usually inducible. Carbon catabolite repression is a phenomenon usually caused by glucose, but in different organisms, other rapidly metabolized carbon sources can cause repression and, indeed, sometimes repress catabolism of glucose. An example of this occurs in Pseudomonas aeruginosa, where citrate is the preferred carbon source over glucose (Ng and Dawes, 1973). In Pseudomonas, there are up to five overlapping CCR systems coordinating carbon utilization (Rojo and Dinamarca, 2004) and even different CCR systems modulate catabolite repression simultaneously (Del Castillo and Ramos, 2007).

Several mechanisms for CCR have been reported in microorganisms. One involves the phosphoenolpyruvate:phosphotransferase system (PTS) which utilizes a protein phosphoryl transfer chain to transport and phosphorylate its sugar substrates.

In E. coli, PTS consist of four high‐energy phosphoprotein intermediates and five protein domains. One of these proteins, EIIAglc, is phosphorylated by a heat‐stable phosphoprotein (HPr). In this form, EIIAglc∼P transfers its phosphate to high‐affinity protein EIIB/C. For this purpose, EIIAglc contains two histidines (His75 and His90). His90 is the acceptor for the phosphate group from HPr and His75 is important for its transfer to a high‐affinity enzyme IIB/C. Enzyme IIB/C occurs in the membrane as a homodimer. The amino acid chain of domain IIC crosses the membrane eight times harbouring the sugar binding site. The hydrophilic domain IIB transfers the phosphate group from EIIAglc∼P to the glucose, producing glucose 6‐phosphate.

Besides transferring the phosphate group, EIIAglc∼P activates adenylate cyclase. Activated adenylate cyclase synthesizes cyclic 3′,5′‐adenosine monophosphate (cAMP), which has been defined as a second messenger. This nucleotide is necessary for synthesis of inducible enzymes and its intracellular levels mediate carbon catabolite repression. To activate transcription, cAMP binds to the DNA promoter region via a specific binding protein (cAMP receptor protein or CRP), a dimer of identical subunits and two separate domains. Each CRP subunit finds one cAMP molecule and after binding, undergoes an allosteric transition to an active state in which it binds to specific portions of promoter DNA. The N‐terminal attaches to cAMP and the C‐terminal to DNA thus increasing the affinity of RNA polymerase to that particular promoter and thus the frequency of transcription (Botsford and Harman, 1992). The consensus sequence to which CRP binds in the presence of cAMP [aa‐TGTGA(N7)CACa‐t] occurs at a variety of locations in the promoter relative to the start site for transcription (Gottesman, 1984). As promoters of different operons have different affinities for the complex (Piovant et al., 1975), not all promoters are binding the complex and undergoing transcription initiation at the same time. In the presence of glucose, the sugar is transported into the cell and concomitantly phosphorylated. This event causes dephosphorylation of EIIAglc∼P, mediates inducer exclusion and deactivates adenylate cyclase (Stewart, 1993). Inactivation of adenylate cyclase causes the cytoplasmic cAMP concentration to diminish and promotes dissociation of the cAMP–CRP complex from the DNA and deactivation of transcriptional initiation. In its phosphorylated form (no glucose present), EIIAglc has no activity to exclude inducers and activates adenylate cyclase (De Reuse and Danchin, 1991). The gene for EIIAglc is called crr, because mutants of E. coli lacking this gene are not subject to CCR.

During glucose assimilation, the intracellular concentration of cAMP is depressed 1000‐fold, whereas metabolism of a non‐repressive carbon source has little effect on cAMP levels. cAMP reverses CCR of many enzymes in E. coli. Mutants that cannot make CRP or adenylate cyclase fail to grow, or grow poorly, on lactose, glycerol and other carbon sources, whereas mutants lacking cAMP phosphodiesterase (which degrades cAMP to AMP) are insensitive to CCR (Monard et al., 1969). Transport systems known to inhibit adenylate cyclase include those of the PTS (glucose, mannitol), proton symport (lactose) and facilitated diffusion (glycerol). Protein kinase in E. coli is independent of cAMP (Dadssi and Cozzone, 1985).

Carbon catabolite repression occurs in other organisms such as Bacillus species, P. aeruginosa, Arthrobacter crystallopoietes, Rhizobium meliloti and anaerobic bacteria, e.g. Bacteroides fragilis. However, in some of these microorganisms, cAMP has not been detected, nor has it been shown to play a role in CCR. cAMP was found in B. subtilis but only when grown with oxygen limitation (Mach et al., 1984). Adenylate cyclase and phosphodiesterase were also found under these conditions. cAMP was found in Bacillus circulans but only in media rich in glucose. Furthermore, its addition repressed the formation of xylanase (inducible) and 1,3,β‐d‐glucanases as did glucose (Esteban et al., 1984). It appears that cAMP is a negative effector in this strain. Other strains of B. circulans and other Bacillus species (megaterium and cereus) do not contain cAMP.

In Gram‐positive bacteria, carbon source utilization is regulated by carbon catabolite repression. Most of the knowledge on this regulatory mechanism has been obtained with B. subtilis. Here, CCR is due to a complex of two proteins acting at a cis‐acting locus, upstream of catabolite repressible genes (Hueck and Hillen, 1995). The two proteins are a PTS‐carrier protein (Hpr) and a catabolite control protein A (CcpA). It is known that uptake of a rapidly utilized sugar is effected by the PTS. Uptake leads to a build‐up of glycolytic intermediates, which results in phosphorylation of protein HPr at Ser‐46. The catalyst is an ATP‐dependent protein kinase activated by fructose‐1,6‐diphosphate and other glycolytic intermediates. The phosphorylated HPr interacts with CcpA before binding, as a specific ternary complex, to the cis‐active operator DNA sequence called cre, present in the promoter or the 5′ region of at least 29 genes, thus interfering with their expression. The complex consists of two molecules of HPr(Ser‐P), a CcpA dimer and the cre sequence (Reizer and Reizer, 1996; Jones et al., 1997). CcpA is composed of a helix–turn–helix DNA‐binding domain and a C‐terminal domain which binds to HPr(Ser‐P) but not to unphosphorylated HPr. It causes repression of a number of enzymes such as α‐amylase, gluconate kinase, β‐glucanase, glucitol dehydrogenase, lichenase, mannitol‐1‐phosphate dehydrogenase and mannitol‐specific PTS permease. In addition, it affects several operons like the xylose operon, the gluconate operon and the histidine‐utilization operon. When glucose is low, a phosphatase inactivates Hpr(Ser‐P) by dephosphorylation and carbon catabolite repression is relieved. Transcriptional profiling of B. subtilis in response to glucose revealed that: (i) the transcriptional regulator CcpA represses genes involving utilization of secondary carbon sources, (ii) glucose induces glycolytic enzymes, the genes involved in conversion of pyruvate to acetate with concomitant phosphorylation, and (iii) excess glucose represses genes required for complete oxidation of glucose [i.e. those of the tricarboxylic acid (TCA) cycle, and terminal respiration] (Blencke et al., 2003). Pentose phosphate cycle genes are unaffected by glucose.

In S. cerevisiae, cAMP is not thought to be a mediator of carbon catabolite repression (Eraso and Gancedo, 1984). In this yeast, glucose repression is mediated by both hexokinases (P1 and P2) but not by glucokinase. Hexokinase PII appears to be the repressor protein of glucose repression in Saccharomyces carlsbergensis, an organism which has three hexokinases (hexokinase PI and PII and glucokinase). Mutants in hexokinase PII are resistant to CCR of α‐glucosidase and invertase. High glucose leads to increased hexokinase PII whereas glucose limitation leads to decreased hexokinase PII. Addition of xylose to high glucose led to 98% inactivation of hexokinase PII and derepression of invertase (Fernandez et al., 1985).

It is doubtful that cAMP plays any role in carbon catabolite repression in molds such as A. nidulans (Arst and Bailey, 1977). The gene for carbon catabolic repression in A. nidulans and Aspergillus niger is creA (Drysdale et al., 1993). It encodes a DNA‐binding protein with two zinc‐finger domains of the C2H2 class. The sequence 5′‐SYGGRG‐3′ has been proposed as the DNA consensus for Cre‐A binding (Cubero and Scazzochio, 1994). A similar protein, Cre1, mediates glucose repression in Trichoderma reesei (Strauss et al., 1995). Similarity in amino acid sequence is 55% between Cre1 and CreA. The DNA sequence to which CreA binds is 5′‐GCGGAG‐3′ which matches well with the sequence of the above CreA binding site. These genes act by positive control. Genes creB and creC, possibly encoding membrane proteins, are also involved in carbon source regulation in A. nidulans in that their mutation leads to carbon source derepression of carbon controlled enzymes (Hynes and Kelly, 1977).

2.1.3 Nitrogen source regulation. Nitrogen can be assimilated from inorganic or organic sources. Its assimilation from inorganic sources requires reduction to ammonia, followed by incorporation into intracellular metabolites. The appropriate distribution of nitrogen among various pathways usually involves specific or local regulatory mechanisms, such as end‐product inhibition or end‐product‐mediated transcriptional control. In addition, some global regulators control the expression of genes from several pathways and thereby coordinate metabolism. The ability to assimilate particular inorganic or organic nitrogen sources depends on the particular organism. Organic nitrogen sources are usually monomeric units of macromolecules (e.g. amino acids or nucleobases) or compounds derived from them (e.g. agmatine or putrescine). Ammonia usually supports the fastest growth rate and is therefore considered the preferred nitrogen source for E. coli. The biochemical basis of this ‘ammonium preference’ is explained by the repression of enzymes acting on the alternative nitrogenous substrates present in the culture medium. Nitrogen source regulation (NSR) is known by many other names such as nitrogen metabolite repression, nitrogen catabolite repression and ammonia repression. Enzymes typically under such control are proteases, amidases, ureases and those that degrade amino acids.

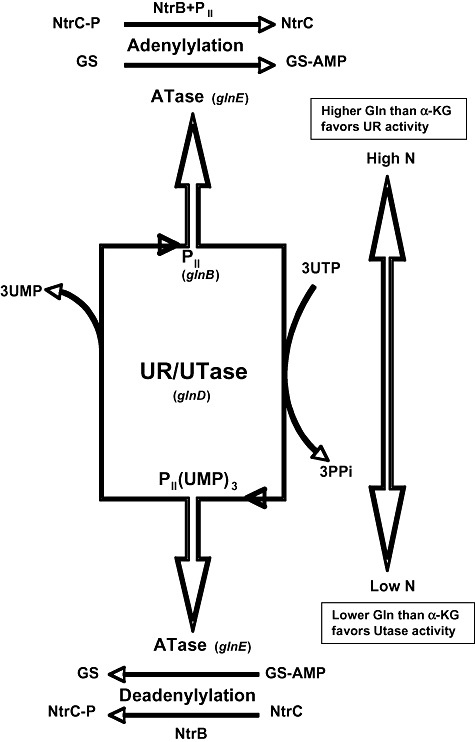

Key enzymes that are involved in the mechanism of NSR are those of ammonium assimilation such as NADP‐glutamate dehydrogenase (GDH), glutamine synthetase (GS or GSI), glutamate synthase (GOGAT) and alanine dehydrogenase (ADH). It appears that they are not involved as regulatory proteins but simply as catalytic proteins; in the latter case, the pool sizes of one or more substrates and/or products of these enzymes, e.g. glutamine, glutamate or alanine, are critical in bringing about repression. In enteric organisms, the two enzymes which mainly account for NH3 incorporation are: (i) GSI and (ii) GOGAT. They constitute a single system whereby GSI converts glutamate and NH3 to glutamine and GOGAT converts one mole of glutamine and one mole of α‐ketoglutarate to two moles of glutamate. The overall reaction produces glutamate from α‐ketoglutarate and NH3. GSI contains 12 identical subunits. GSI from enteric organisms and streptomycetes are post‐translationally modified by adenylylation but those from Bacillus and Clostridium are not. The most active form of GSI is the unmodified form. The least active contains an adenylate molecule on each subunit. Nitrogen sufficiency leads to adenylylation whereas nitrogen deficiency leads to deadenylylation. Adenylylation is catalysed by adenylyl transferase (ATase). Adenylylation by ATase is promoted by deuridylated PII which is produced by UR action on PII(UMP)3 under nitrogen sufficiency (high glutamine/α‐ketoglutarate ratio). Deadenylylation by ATase is promoted by PII(UMP)3 formed by UTase action on PII under nitrogen limitation (low glutamine/α‐ketoglutarate ratio).

A regulatory gene (glnG) in E. coli and other enteric bacteria encodes nitrogen regulator I (NRI), a dimer protein with a subunit weight of 54 000. NRI is produced at a high level (90 molecules per cell) under nitrogen limitation and at a low level (5 molecules per cell) under nitrogen excess. It activates transcription of glnA, encoding glutamine synthetase, under nitrogen limitation and represses it under conditions of excess nitrogen. NRI binds to DNA at or near the promoter of glnA and is thought to regulate production of all nitrogen‐regulated systems (Shiau et al., 1992). Furthermore in enteric organisms, glutamine synthetase and the other enzymes are regulated in positive and negative directions by three genes (ntrA, ntrB, ntrC). Two of these, ntrB and ntrC, are located next to the glutamine synthetase structural gene; ntrA is at a distance. NtrA is a sigma factor also known as RpoN or σ54 (Elderkin et al., 2005). The nitrogen regulation (ntr) system in enteric bacteria is responsible for activation of the glutamine synthetase operon (glnAntrBC), the uptake systems for glutamine (glnHPQ), arginine (argT) and histidine (hisJQMP), nitrate and nitrite assimilation (nasFEDCBA), and nitrogen fixation (nifLA). The system is complex (Merrick and Edwards, 1995) and responds to the sufficiency or limitation of the intracellular nitrogen pool. It is composed of four proteins: (i) response regulator NtrC, (ii) sensor histidine protein kinase NtrB, (iii) PII, a small protein encoded by glnB, and (iv) uridyltransferase/uridyl‐removing enzyme (Utase/UR) encoded by glnD (Fig. 1). For nitrogen‐controlled genes to be turned on, they need phosphorylated NtrC. NtrC is the response regulator of the signal transduction system; NtrB is its partner sensor kinase. In its phosphorylated state (NtrC‐P), it activates transcription of the nitrogen‐regulated genes. It binds to DNA having a helix–turn–helix motif in its C‐terminal domain. NtrB, the sensor protein kinase, catalyses its own phosphorylation and then NtrC phosphorylation under conditions of nitrogen deficiency. On the contrary, NtrC dephosphorylation occurs under nitrogen sufficiency. NtrB is cytoplasmic and dephosphorylates NtrC‐P only when it interacts with protein PII and can only phosphorylate NtrC when it interacts with PII(UMP)3. Protein PII can either be in its native state (PII) or its uridylated state [PII(UMP)3]. The uridylation reaction is carried out by Utase under conditions of nitrogen deficiency. The deuridylation reaction is catalysed by UR under conditions of nitrogen sufficiency. This uridylation/deuridylation system responds to the glutamine/α‐ketoglutarate ratio. Low ratios indicate nitrogen limitation leading to PII‐uridylation and hence NtrC‐P, whereas high ratios indicate nitrogen sufficiency leading to PII deuridylation and NtrC.

Figure 1.

Schematic model for the regulation of the GS activities and NtrC protein in response to nitrogen status. UTase (glnD product) catalyses the uridylylation of PII (glnB product). UR activity of UTase catalyses PII deuridylylation. Adenyltransferase (Atase: glnE product) catalyses the adenylylation and deadenylylation of GS. NtrB protein kinase catalyses the phosphorylation and dephosphorylation of NtrC, a DNA‐binding response regulator.

In P. aeruginosa, glutamine appears to be the effector of nitrogen source repression. In a GS‐negative mutant, urease and histidase are derepressed when growth was limited for glutamine; addition of ammonia or glutamate has no effect. Addition of glutamine does cause repression of these two enzymes as well as NADP‐GDH (Janssen et al., 1981). In B. subtilis, there are two transcriptional regulators of nitrogen metabolism, GlnR and TnrA (Fisher, 1999). They are very similar proteins, binding to the same DNA consensus sequence but are active under different nutritional growth conditions. The activities of both proteins are regulated by GS. In the case of TnrA, the regulation involves a protein–protein interaction. TnrA is active only under conditions of nitrogen limitation. In nitrogen excess, TnrA becomes bound to the feedback inhibited form of GS and is unable to bind to DNA. When nitrogen becomes limiting, TnrA is released and can then bind to DNA. Gene glnA is part of a glnRA operon. Expression of glnRA is repressed by GlnR in media with high nitrogen (Fisher and Sonenshein, 1991). GlnR is small (125 residues) and dimeric, and binds to two operators upstream of glnRA to inhibit transcription (Gutowski and Schrier, 1992). Enzymes under N control are glutamine synthetase I, aspartase, asparaginase, urease, GABA permease but only GSI is regulated by GlnR; an unknown system(s) must regulate the others.

Nitrogen regulation in the yeast S. cerevisiae involves three main elements: (i) the enzymes catalysing the synthesis and interconversion of nitrogenous compounds, (ii) the permeases for uptake of nitrogenous compounds, and (iii) the transcription factors and membrane trafficking proteins which control the activity of the enzymes and permeases (Magasanik and Kaiser, 2002). Preferred nitrogen sources are glutamine, asparagine; those non‐preferred are proline, α‐aminobutyrate, ornithine, allantoin and urea. The expression of nitrogen‐regulated genes is activated by transcription factors Gln3p and Ni11p with intracellular glutamine and glutamate acting as signals preventing such activation.

The gene controlling NSR in Aspergillus is areA (Marzluff, 1981) named Nre (for nitrogen regulator) in other fungi. The gene encodes a regulatory protein (AREA) exerting positive control on transcription. The regulatory protein is active under conditions of derepression (e.g. low ammonium supply). The intracellular effector appears to be glutamine rather than ammonia but more work is needed on this point. Mutations can be of the type areAr in which a large variety of nitrogen sources can no longer be utilized for growth and the enzymes catalysing their usage cannot be derepressed, or another type, areAd in which they cannot be repressed by ammonia; all still require inducer. Some areAd type mutants produce more enzyme than their parents. There has been considerable controversy as to whether protein elements such as NADP‐GDH or GS also play a direct role but, at present, the data favour glutamine itself as being the master effector in fungi. Glutamine produced in the presence of high ammonium, in some unknown fashion, causes nitrogen metabolite repression. Glutamine does not appear to bind directly to the AREA protein. In Aspergillus, factor NMR‐A (similar to NMR found previously in Neurospora) acts negatively. Upon ammonium limitation, glutamine concentration would drop, the regulatory protein would assume an active conformation, and bind at the recognition sites of the structural genes. Nitrogen sources that are more repressive than ammonia are probably more easily converted to glutamine; that is, they may not have to be converted to ammonia before exerting repression. The stability of the AREA mRNA is controlled. It turns over rapidly during conditions of nitrogen repression but is more stable when nitrogen sources are limiting.

In Neurospora crassa, NSR is exerted by ammonium, glutamine and glutamate. Ammonium and glutamate may act via glutamine formation. These compounds repress the formation of the nit‐2 gene product which acts as a positive control agent for use of poorer nitrogen sources, i.e. the nit‐2 gene product is a positive effector for expression of structural genes encoding enzymes involved in the utilization of secondary nitrogen sources. One such repressible enzyme is an extracellular l‐amino acid deaminase. Its expression requires inducer (one of many amino acids), lifting of nitrogen metabolite repression and the presence of the nit‐2 gene product. Glutamine does not appear to act directly to repress nit‐2. Instead, another gene, nmr‐1, binds to two regions of NIT2 and inhibits its function. NMR is not believed to be activated directly by glutamine, but another, still unknown, factor must bind glutamine and lead to nitrogen repression. Thus, mutations of nmr‐1 allow production of these enzymes in the presence of glutamine, NH4 or glutamate (DeBusk and Ogilvie, 1984). In addition to the positively acting nit‐2 nitrogen control gene of N. crassa, a negatively acting nmr control gene exists. Unlike the situation in Aspergillus, the NIT2 mRNA is relatively stable under both nitrogen limitation and nitrogen repression conditions. An interaction between the NIT2 protein and the pathway‐specific NIT4 protein is required for optimal expression of nitrate‐inducible genes, e.g. nit‐3 which encodes nitrate reductase. It is also interesting that Neurospora possesses several additional GATA factors with DNA binding activities identical to or very similar to that of NIT2. It now appears that specific control is exerted in each case by interactions with proteins restricted to the distinct area of metabolism (Feng and Marzluff, 1998; Feng et al., 2000).

2.1.4 Phosphorus source regulation. In natural environments, inorganic phosphorus is commonly the major growth‐limiting nutrient. Thus, biological systems have evolved a variety of responses to modulate their phosphorus requirement or to optimize its utilization. In E. coli, over 30 genes are part of the phosphate regulon (Pho regulon) and are transcriptionally activated by phosphorylated PhoB when the cell finds itself in low phosphate (Shinagawa et al., 1994). These genes encode proteins involved in uptake and utilization of phosphorus compounds. PhoR promotes the phosphorylation of PhoB under limiting phosphate conditions and dephosphorylation of PhoB in excess phosphate. PhoR and PhoB are thus a two‐component signal transduction system. PhoR autophosphorylates and transfers the phosphate to PhoB. The environmental concentration of phosphate is monitored by the periplasmic phosphate‐binding protein PstS, which transmits the signal for excess phosphate across the cytoplasmic membrane via PstC, PstA, PstB, PhoU to PhoR. Phosphorylated PhoB binds to the promoters of 31 genes containing pho boxes and interacts with RNA polymerase allowing initiation of mRNA synthesis.

Nucleases and phosphatases are usually repressed by phosphate in fungi. In addition, phosphate represses proteases, isocitrate lyase, fructose diphosphate aldolase, NADP isocitrate dehydrogenase and malate dehydrogenase in Neurospora. Phosphate also suppresses the production of riboflavin by Eremothecium ashbyii (Mehta and Modi, 1981). Phosphate‐derepressed mutants can be selected by growth with a phosphate ester (e.g. β‐glycerol phosphate) as the sole source of carbon in the presence of high phosphate (Torriani and Rothman, 1961).

Of great interest is inorganic polyphosphate (poly P) which is a linear polymer of many tens or hundreds of orthophosphate (Pi) residues linked by high‐energy phosphoanhydride bonds. Poly P is found in cells of all bacteria, archaea, fungi, protozoa, plants and animals and is prominent in many organisms, especially so in the vacuoles of yeast, where it may represent 10–20% of the cellular dry weight. It is produced by polyphosphate kinase (PPK), which catalyses the reversible transfer of the terminal phosphate of ATP to form a long‐chain poly P (Ahn and Kornberg, 1990). Paradoxically, despite the huge amounts of poly P in yeast, PPK‐like activity has not been found in whole‐cell lysates, although a feeble activity has been extracted and partially purified from a vacuolar preparation. The E. coli gene (ppk) encoding PPK has been cloned, sequenced and overexpressed (about 100‐fold). The gene possesses an open reading frame for 687 amino acids (mass of 80 278 Da). Polyphosphate kinase has been purified from overproducing cells after release from attachment to the cell outer membrane; the purified soluble PPK reassociates with cell membrane fractions. About 850 molecules of PPK are found in a wild‐type cell. The poly P roles can be summarized as follows: substitute for ATP and energy source, reservoir for inorganic phosphate, chelator of metal ions, channel for DNA entry, regulator for stress and survival, and regulator of development. However, the most widely used and most significant roles of polyphosphate are probably regulatory control in nutritional stringencies, environmental stresses, stationary‐phase adaptations and development (Kornberg et al., 1999).

2.1.5 Sulfur source regulation. Sulfatases are regulated by sulfate and sulfur amino acids. In addition to a variety of nutrients used to maintain continuous growth, bacteria require a source of sulfur. As for other nutrients, the use of sulfur is controlled by one or a few pleiotropic transcriptional regulatory proteins. Thus, in E. coli and the closely related Salmonella typhimurium, sulfur metabolism is controlled by the CysB transcriptional activator (Kredich, 1992). The cysteine regulon includes most of the genes required for synthesis of cysteine and genes for uptake of sulfur sources such as l‐cystine, sulfate, thiosulfate and taurine. Transcriptional activation of these genes requires CysB, the inducer N‐acetyl‐l‐serine and conditions of sulfur limitation. CysB is a tetrameric LysR‐type regulator with an N‐terminal DNA‐binding domain, a central inducer‐binding domain and a C‐terminal oligomerization domain that is essential for stability (Lochowska et al., 2001). Its activity is regulated by an efflux pump specific for cysteine metabolites. CysB is also an autorepressor, preventing expression of its own structural gene, cysB. In E. coli and S. typhimurium, cysB mutations influence carbon oxidation and carbohydrate fermentation, and possibly carbon utilization. Both effects are at the transcriptional level and are partially reversed by exogenous cAMP or a sulfur source such as cysteine or djenkolate. The effect seems to be via the regulation of the cAMP biosynthetic enzyme, adenylate cyclase, which is activated by the IIAGlc protein of the PTS. Cysteine inhibits inducer synthesis, resulting in maximal repression of the sulfur regulon. Growth with poor sulfur sources such as glutathione results in maximal derepression of the sulfur regulon.

Little is known about the genes and enzymes involved in sulfur assimilation in B. subtilis, or about the regulation of their expression or activity. Study of a wild‐type strain grown with either sulfate or glutathione as sole sulfur source revealed that the synthesis of 15 proteins is modified under these two conditions (Coppee et al., 2001). In the presence of sulfate, an increased amount of proteins involved in the metabolism of C1 units (SerA, GlyA, FolD) and in the biosynthesis of purines (PurQ, Xpt) and pyrimidines (Upp, PyrA, PyrF) was observed. In the presence of glutathione, the syntheses of two uptake systems (DppE, SsuA), an oxygenase (SsuD), cysteine synthase (CysK) and two proteins of unknown function (YtmI, YurL) were increased. The ytmI gene is part of a locus of 12 genes which are co‐regulated in response to sulfur availability. This putative operon is activated by a LysR‐like regulator, YtlI. This is the first regulator involved in the control of expression in response to sulfur availability to be identified in B. subtilis.

In N. crassa, sulfate uptake is an important point of regulation of sulfur metabolism (Tao and Marzluf, 1998). Sulfate uptake is subject to sulfur (metabolite) repression in which excess sulfate turns off the expression of sulfate permease‐encoding genes. Also, structural genes coding for aryl sulfatase, choline sulfatase, sulfate permeases I and II, a high‐affinity methionine permease and an extracellular protease are turned on when sulfur becomes limiting. These unlinked genes are regulated by the cys‐3 gene, a positively acting master sulfur regulatory gene whose product activates their expression. This gene product is a 236‐amino‐acid residue protein containing a leucine zipper element in its basic region. The leucine zipper is characteristic of DNA‐binding proteins (a leucine zipper is a protein sequence in which a leucine or methionine occurs at exactly every seventh position). The CYS‐3 protein binds to DNA at the 5′‐upstream portion of cys‐14 (encoding sulfate permease). It also binds to an upstream sequence of the cys‐3 gene itself suggesting the possibility of autoregulation. Mutation in the basic region eliminates DNA binding (Fu and Marzluf, 1990). Another regulatory gene, scon, controls the expression of cys‐3 in a negative fashion, i.e. scon mutants are insensitive to sulfur source repression and produce the enzymes constitutively.

2.1.6 Feedback regulation. The most important mechanism responsible for regulation of the enzymes involved in biosynthesis of amino acids, nucleotides and vitamins is not induction or nutrient repression, but feedback regulation. This category of regulation functions at two levels: enzyme action (feedback inhibition) and enzyme synthesis (feedback repression and attenuation).

In feedback inhibition, the final metabolite of a pathway, when present in sufficient quantities, inhibits the action of the first enzyme of the pathway to prevent further synthesis of intermediates and products of that pathway. Feedback repression involves the turning off of enzyme synthesis when sufficient amounts of the product have been made and it starts to accumulate. The end‐product of the pathway acts as a co‐repressor. The aporepressor specified by the regulator locus is inactive in the absence of its co‐repressor and is unable to bind to the operator. However, in the presence of co‐repressor, an active repressor is formed which binds to the operator to prevent transcription by RNA polymerase and hence prevents enzyme synthesis.

Many of the amino acid biosynthetic pathways are regulated not by the amino acids themselves but by their charged tRNA molecules. Thus, whereas feedback repression is effected by the amino acid end‐products acting as co‐repressors interfering with transcription initiation, another type of control called attenuation (transcription termination control) involves charged tRNA and transcription termination. Unless a significant number of the intracellular tRNA molecules for a particular amino acid are in the uncharged state, the genes coding for that amino acid's biosynthetic enzymes cannot be efficiently transcribed. In the presence of an excess of charged tRNA, transcription is initiated but terminated between the operator and the first structural gene (Kolter and Yanofsky, 1982). Attenuation is known to control certain bacterial amino acid biosynthetic operons, e.g. threonine, isoleucine, valine, leucine, phenylalanine, histidine. Unlike these operons, the tryptophan operon is regulated by both repression and attenuation, whose combined action permits a level of expression over a 600‐fold range. Repression is responsible for an 80‐fold range and attenuation for a sevenfold range. Repression responds to the level of tryptophan in the cell and attenuation to the level of charged tRNAtrp. The two mechanisms act at different degrees of tryptophan deprivation. Repression acts first, i.e. when the tryptophan level drops to that of moderate starvation, whereas attenuation acts in the moderate to severe tryptophan starvation range (Yanofsky et al., 1984).

In S. cerevisiae, the leu3 gene of the leucine biosynthetic pathway appears to be the master regulatory gene of specific control of branched amino acid biosynthesis. It encodes an 886‐amino‐acid polypeptide that is produced upon leucine starvation. This positively acting DNA binding protein (LEU‐3) binds to a decapeptide palindromic sequence (CCGG pur pur CCGG) in the promoters of at least four genes of leucine biosynthesis and one gene of isoleucine‐valine biosynthesis (Friden and Schimmel, 1988) and activates their transcription. This control probably acts on more than these five genes, i.e. on many genes of the branched amino acid pathway, all of which would have this decanucleotide sequence in their promoter. The site of this decanucleotide is within 130–376 nucleotides upstream of the transcriptional start site and defines a leucine‐sensitive upstream activation sequence.

Feedback repression of purine nucleotide biosynthesis in E. coli is exerted by binding of the co‐repressor, hypoxanthine or guanine, to the product of the purR gene (Rolfes and Zalkin, 1990). Hypoxanthine and guanine act cooperatively to change the conformation of PurR, thus enhancing its binding to DNA.

2.1.7 Additional types of regulation. Other types of regulation include metabolic interlock (Jensen, 1969), stringent control (Cashel et al., 1996) and regulatory inactivation (Switzer, 1977). The effector of stringent control is the alarmone guanosine 5′‐diphosphate 3′‐diphosphate (ppGpp) (Laurie et al., 2003). It binds to the core of RNA polymerase resulting in activation or repression of gene expression. It is produced by ribosomes via ppGpp synthetase (‘stringent factor’) encoded by relA. Synthesis occurs via binding of uncharged tRNA to the ribosome A site. Control by ppGpp involves the effect of amino acid deficiency on a large number of physiological activities in bacteria (Gallant, 1979). Deficiency of any amino acid leads to production of ppGpp from GTP. This intracellular effector redirects the cells activities to correction of the amino acid deficiency. In stringent control, ppGpp shuts off stable RNA synthesis, i.e. rRNA and tRNA as well as mRNA for ribosomal proteins. The rate of total mRNA synthesis drops only modestly however. This shut‐off acts at the level of transcription. It appears that ppGpp interferes with the binding of RNA polymerase to promoters of stringently controlled operons. The operons controlling threonine and isoleucine biosynthesis are positively regulated by ppGpp

Regulatory inactivation refers to the selective inactivation of enzymes (Switzer, 1977) by two different mechanisms. In modification inactivation, the enzyme remains intact but its physical state is changed or it is covalently modified. Covalent modifications include phosphorylation of a specific serine or threonine residue, nucleotidylation of a specific tyrosine residue, ADP ribosylation of an arginine residue, methylation of a glutamate or aspartate carboxyl group, acetylation of an ε‐amino group of a lysine residue or tyrosinolation of a protein terminal carboxyl group (Chock et al., 1980). In degradative inactivation, at least one peptide bond is broken; it may represent the first step in protein turnover. It is carried out by proteases which are restricted from non‐selective action by confinement in vacuoles or by protease inhibitors. Regulatory inactivation usually occurs after the exponential phase of growth, especially after exhaustion of a source of carbon or nitrogen. This inactivation serves to prevent futile cycles of metabolism, to destroy enzymes no longer needed and to divert branch point metabolism from one branch to another.

3. Approaches to strain construction

3.1 Mutation and screening or selection

Organisms used today for industrial production of primary metabolites have been developed by programmes of mutation followed by selection or screening. Such efforts often start with organisms having some capacity to make the desired product but which require multiple mutations leading to deregulation in a particular biosynthetic pathway before high productivity can be obtained. The sequential mutations ensure that nutrients are channelled efficiently to the appropriate products without significant deviation to other pathways. These mutations presumably involve not only release of feedback controls but also enhancement of the formation of pathway precursors and intermediates. This approach to strain improvement has been remarkably successful in producing organisms that make industrially significant concentrations of primary metabolites. However, some of the problems with this ‘brute force’ approach include (i) the necessity of screening large numbers of mutants for the rare combination of traits sequentially obtained that lead to overproduction, and (ii) the weakened vigour of the producing strain following several rounds of mutagenesis.

3.2 Genetic engineering

More recent approaches utilize the techniques of modern genetic engineering to develop strains overproducing primary metabolites. This rationale for strain construction relies largely on the same principles of regulation discussed in the previous sections, but aims at assembling the appropriate characteristics by means of in vitro recombinant DNA techniques. This is particularly valuable in organisms with complex regulatory systems, where deregulation would involve many genetic alterations.

Production of a particular primary metabolite by deregulated organisms may inevitably be limited by the inherent capacity of the particular organism to make the appropriate biosynthetic enzymes, i.e. even in the absence of repressive mechanisms, there may not be enough of the enzyme made to obtain high productivity. One way to overcome this is to increase the number of copies of structural genes coding for these enzymes by genetic engineering. Another way often used in combination with this strategy is to increase the frequency of transcription, which is related to the frequency of binding of RNA polymerase to the promoter region (Rosenberg and Court, 1979). The former can be achieved by incorporating the biosynthetic genes in vitro into a plasmid which, when placed in a cell by genetic transformation, will replicate into multiple copies; some ‘amplifiable’ plasmids, such as pBR322, can exist at a level of 50 copies per cell. Increasing the frequency of transcription involves constructing a hybrid plasmid in vitro, which contains the structural genes of the biosynthetic enzymes but lacks the regulatory sequences (promoter and operator) normally associated with them. Instead, the structural genes are placed next to an efficiently and frequently read promoter and operator, and are now subject to regulation by these sequences. The ideal plasmid for metabolite synthesis would contain a regulatory region with a constitutive phenotype, preferably not subject to nutritional repression.

One of the major problems in using strains in which the desired characteristics are encoded by a plasmid is the difficulty in maintaining the plasmids during fermentation. Plasmid instability in the absence of selective pressure leads to a dilution of the plasmid in the population and loss of the desired phenotype. One solution is to use antibiotic pressure during fermentation so that only organisms resistant to the antibiotic (due to the presence of a plasmid‐borne resistance gene) can survive. Plasmid stabilization was also accomplished by cloning the valyl‐tRNA synthetase gene in a plasmid which was transformed into E. coli carrying a temperature‐sensitive mutation in the chromosomal valyl‐tRNA synthetase gene. At the non‐permissive temperature, growth was dependent on the plasmid. The plasmid was stabilized for at least 150 generations (Nilsson and Skogman, 1986). Effective recombinant DNA plasmid construction in E. coli can lead to 20% of the total cell protein being that of a single protein.

Combinations of deregulation and plasmid amplification can yield a synergistic effect. For example, a chromosomal regulatory gene mutation in E. coli yielded fivefold overproduction of phosphatidylserine synthetase. Recombinant DNA technology using a plasmid containing the structural gene resulted in 10‐fold overproduction. Putting both in the same strain led to 50‐fold overproduction (Sparrow and Raetz, 1983).

3.3 Novel genetic technologies

‘Genome‐based strain reconstruction’ achieves the construction of a superior strain which only contains mutations crucial to hyperproduction, but not other unknown mutations which accumulate by brute‐force mutagenesis and screening (Ohnishi et al., 2002). This approach was used to improve lysine production (see Section 4.1.2).

The directed improvement of product formation or cellular properties via modification of specific biochemical reactions or introduction of new ones with the use of recombinant DNA technology is known as ‘metabolic engineering’ (Stephanopoulos, 1999; Nielsen, 2001). Analytical methods are combined to quantify fluxes and to control them with molecular biological techniques in order to implement suggested genetic modifications. Different means of analysing flux are (i) kinetic based models, (ii) control theories, (iii) tracer experiments, (iv) NMR magnetization transfer, (v) metabolite balancing, (vi) enzyme analysis and (vii) genetic analysis (Eggeling et al., 1996). The overall flux through a metabolic pathway depends on several steps, not just a single rate‐limiting reaction (Kacser and Acerenza, 1993). Amino acid production is one of the fields with many examples of this approach (Sahm et al., 2000). Other processes improved by this technique include vitamins, carotenoids, organic acids, ethanol and 1,3‐propanediol (see Sections 4.3, 4.4, 4.5.1 and 4.5.3).

A genome‐wide transcript expression analysis called ‘massive parallel signature sequencing’ (Brenner et al., 2000) was successfully used to discover new targets for further improvement of riboflavin production by the fungus Ashbya gossypii (see Section 4.3.2). These recent technologies and mathematical approaches will all contribute to the generation and characterization of microorganisms able to synthesize large quantities of commercially important metabolites. Ongoing sequencing projects involving hundreds of genomes, the availability of sequences corresponding to model organisms, new DNA microarray and proteomics tools, as well as the new techniques for mutagenesis and recombination described above, will accelerate strain improvement programmes. The development and combined application of these technologies will help to develop what was already succinctly described several years ago as ‘inverse metabolic engineering’ (Bailey et al., 1996), i.e. a method to identify, construct or calculate a desired phenotype, identify the molecular basis of that desirable property, and incorporate that phenotype into another strain or other species by genetic and environmental manipulations.

Molecular breeding techniques such as ‘DNA shuffling’ come closer to mimicking natural recombination by allowing in vitro homologous recombination (Ness et al., 2000). These techniques not only recombine DNA fragments but also introduce point mutations at a very low controlled rate (Stemmer, 1994; Zhao and Arnold, 1997). Unlike site directed mutagenesis, this method of pooling and recombining parts of similar genes from different species or strains has yielded remarkable improvements in enzymes in a very short amount of time (Patten et al., 1997). ‘Whole genome shuffling’ is a novel technique for strain improvement combining the advantage of multiparental crossing allowed by DNA shuffling with the recombination of entire genomes. Such recursive genomic recombination has been used to improve acid tolerance of a commercial lactic acid‐producing Lactobacillus sp. (Patnaik et al., 2002).

4. Microbial processes

4.1 Amino acid production processes

Among the amino acids, l‐glutamate and l‐lysine, mostly used as feed and food additives, respectively, represent the largest products in this category. Produced by fermentation are 1.5 million tons of l‐glutamate and 850 000 tons of l‐lysine‐HCl. Table 1 shows the annual production of amino acids. The total amino acid market was about 4.5 billion dollars in 2004 (Leuchtenberger et al., 2005).

Table 1.

Worldwide production of selected amino acids.

| Example | Production (tons) | Method |

|---|---|---|

| l‐Alanine | 500 | E |

| l‐Aspartic acid | 10 000 | E |

| l‐Arginine | 1 200 | F |

| l‐Cysteine | 4 000 | C, E |

| l‐Glutamate | 1 500 000 | F |

| l‐Glutamine | 2 200 | F |

| Glycine | 22 000 | C |

| l‐Histidine | 400 | F |

| l‐Isoleucine | 400 | F, Ex |

| l‐Leucine | 500 | F, Ex |

| l‐Lysine | 850 000 | F |

| dl‐Methionine | 500 000 | C |

| l‐Phenylalanine | 13 000 | F, C |

| l‐Proline | 350 | F |

| l‐Serine | 300 | F |

| l‐Threonine | 70 000 | F |

| l‐Tryptophan | 3 000 | F, E |

| l‐Tyrosine | 170 | F |

| l‐Valine | 500 | F |

C, chemical synthesis; E, enzymatic; Ex, extraction; F, fermentation. Ikeda (2003); Pfefferle et al. (2003); Kraemer (2004); Kroemer et al. (2004); Business Communications Company (2005); Wendisch (2005); Leuchtenberger et al. (2005); Wada and Takagi (2006); Li et al. (2007).

Top fermentation titres reported in the literature are shown in Table 2. Genetic engineering has made an impact by use of the following strategies: (i) amplification of a rate‐limiting enzyme of pathway, (ii) amplification of the first enzyme after a branch point, (iii) cloning of a gene encoding an enzyme with more or less feedback regulation, (iv) introduction of a gene encoding an enzyme with a functional or energetic advantage as replacement for the normal enzyme, and (v) amplification of the first enzyme leading from central metabolism to increase carbon flow into the pathway followed by sequential removal of bottlenecks caused by accumulation of intermediates. Transport mutations have also become useful, i.e. a mutation decreasing amino acid uptake allows for improved excretion and lower intracellular feedback control. This has been especially useful in production of tryptophan and threonine. In cases where excretion is carrier‐mediated, increase in activity of these carrier enzymes increases production of the amino acid. Exporter genes in Corynebacterium glutamicum are known for lysine, isoleucine and threonine.

Table 2.

Some examples of amino acids levels produced by fermentation.

| Amino acid | Titre (g l−1) | Microorganism | Reference |

|---|---|---|---|

| l‐Alanine | 75 | Arthrobacter oxydans | Hashimoto and Katsumata (1998) |

| l‐Arginine | 96 | Serratia marcescens | Ikeda (2003) |

| l‐Glutamate | 88 | Brevibacterium lactofermentum | Das (1995) |

| l‐Glutamine | 49 | Corynebacterium glutamicum | Li et al. (2007) |

| l‐Histidine | 42 | Serratia marcescens | Sugiura et al. (1987) |

| l‐Isoleucine | 30 | C. glutamicum | Eggeling et al. (1997) |

| l‐Leucine | 34 | B. lactofermentum | Tsuchida and Momose (1986) |

| l‐Lysine‐HCl | 170 | C. glutamicum | Kraemer (2004) |

| l‐Methionine | 25 | Brevibacterium heali | Mondal and Chatterjee (1994) |

| l‐Phenylalanine | 51 | Escherichia coli | Ikeda, 2003 |

| l‐Proline | 108 | Clostridium acetoacidophilum | Nakanishi et al. (1987) |

| l‐Serine | 65 | Methylobacterium sp. | Ikeda (2003) |

| l‐Threonine | 100 | E. coli | Debabov (2003) |

| l‐Tryptophan | 58 | C. glutamicum | Ikeda and Katsumata (1999) |

| l‐Tyrosine | 26 | C. glutamicum | Ikeda and Katsumata (1999) |

| l‐Valine | 99 | C. glutamicum | Ikeda (2003) |

Amino acids produced by microbial process are the l‐forms. Such stereospecificity makes the process advantageous as compared with synthetic process. Microbial strains employed in microbial process for amino acid production are divided into four classes, i.e. wild‐type strains, auxotrophic mutants, regulatory mutants and auxotrophic regulatory mutants. Using bacterial mutants, all the essential amino acids can be produced by ‘direct fermentation’ from cheap carbon sources such as carbohydrate materials or acetic acid.

Plasmid vector systems for cloning in C. glutamicum were established and amino acid production by C. glutamicum and related strains has been improved by gene cloning (Jetten and Sinskey, 1995; Kirchner and Tauch, 2003). Extensive research has been performed on sequencing the genome of C. glutamicum and to investigate its genetic repertoire (Moeckel et al., 1999). The genome was sequenced by Kyowa Hakko scientists (Ikeda and Nakagawa, 2003) and also by a collaboration of German workers (Kalinowski et al., 2003). The latter group reported a single circular chromosome with 3 282 708 base pairs, 3002 protein‐coding genes of which 2489 could be assigned functions. The whole‐genome sequence of C. glutamicum has been deposited in the DDBJ/GenBank/EMBL database under the Accession No. BA000036. The genome of the closely related glutamate‐overproducing species, Corynebacterium efficiens, has also been sequenced (Nishio et al., 2003).

One of the key tasks in targeted strain optimization is the identification of genetic modifications that lead to improved strain characteristics. The experience of the past clearly shows that a detailed quantitative knowledge of metabolic physiology is required for the rational design of superior production strains. Metabolic reconstruction via functional gene annotation revealed fascinating insights into C. glutamicum, including functional predictions for over 60% of the identified genes (Ikeda and Nakagawa, 2003). Gene expression (transcriptome) analysis has been performed by the development of specific DNA microarrays which are being used to investigate gene expression during the growth of C. glutamicum (Wendisch, 2003). Expression profiles of selected genes of central metabolism (Loos et al., 2001) and amino acid production (Glanemann et al., 2003) have been determined. For proteome analysis, two‐dimensional gel electrophoresis was used to identify different proteins and to study the influence of nitrogen starvation on the proteome (Schmid et al., 2000). An excellent review of proteomics in this organism has been published (Schaffer and Burkovski, 2005). For the quantification of metabolic fluxes (the ‘fluxome’), comprehensive approaches combining 13C tracer experiments, metabolite balancing and isotopomer modelling have been developed and applied to C. glutamicum. They involve comparative fluxome analysis during growth on different carbon sources, and glutamate and lysine production in batch cultures by different mutants (Kiefer et al., 2004). Reviews on metabolic engineering of amino acid producers include those of Sonntag and colleagues (1995), Eggeling and colleagues (1996) and Ikeda (2003). A useful review of the amino acid fermentation field is Kraemer (2004).

4.1.1 l‐Glutamic acid. Monosodium glutamate (MSG) is a potent flavour enhancer made by fermentation. The glutamic acid fermentation was discovered in Japan by Kinoshita, Udaka and Shimono in 1957 (Kinoshita et al., 1957). Although many genera and species are included in the group of glutamate overproducers, e.g. species of Micrococcus, Corynebacterium, Brevibacterium and Microbacterium, all are taxonomically similar and Brevibacterium lactofermentum and Brevibacterium flavum are now classified as C. glutamicum ssp. lactofermentum and ssp. flavum respectively. These organisms were shown to possess the Embden‐Meyerhof glycolytic pathway (EMP), the pentose monophosphate pathway, the TCA cycle and the glyoxylate bypass (Kinoshita, 1985). The TCA cycle requires a continuous replenishment of oxaloacetate in order to replace the intermediates withdrawn for the synthesis of biomass and amino acids. This anaplerotic function is fulfilled by phosphoenolpyruvate carboxylase (Ozaki and Shiio, 1969) and a pyruvate‐carboxylating enzyme (Tosaka et al., 1979). An excellent review of the metabolism of C. glutamicum has appeared (Wendisch, 2006).

Glucose is the preferred C source for C. glutamicum (Georgi et al., 2005). Fructose and sucrose are as good as glucose for glutamate production but not as good for lysine production (Kiefer et al., 2002). Glucose does not exert catabolite repression on use of other C sources except for l‐glutamate (Wendisch, 2006).

Normally, glutamic acid overproduction would not be expected to occur due to feedback regulation. Glutamate feedback controls include repression of PEP carboxylase, citrate synthase and NADP‐GDH; the last‐named enzyme is also inhibited by glutamate. However, by decreasing the effectiveness of the cell barrier to outward passage, glutamate can be pumped out of the cell thus allowing its biosynthesis to proceed unabated. The excretion of glutamate frees the glutamate pathway from feedback control until excessive levels are accumulated.

Glutamate excretion is intentionally effected by various manipulations. Limitation of biotin was the first means discovered to bring about glutamate overproduction in C. glutamicum. All glutamate overproducers are natural biotin auxotrophs. Biotin is a cofactor of acetyl‐CoA carboxylase which is essential for biosynthesis of fatty acids. The surprising report (Somerson and Phillips, 1961) that the addition of penicillin to cells grown in high biotin resulted in excretion of glutamic acid led Shiio and colleagues (1962) to postulate: (i) that growth of the glutamate‐overproducing bacterium in the presence of non‐limiting levels of biotin results in a cell envelope permeability barrier restricting the outward passage of intracellular amino acids out of the cell, and (ii) that inhibition of cell wall biosynthesis by penicillin alters the permeability properties of the cell envelope and allows glutamate to pass out of the cell. The commonality in the various manipulations that had been found to bring about high‐level production of l‐glutamic acid, i.e. limitation of biotin, addition of penicillin or fatty acid surfactants (e.g. tween 60) to exponentially growing cells, was recognized and the permeability mechanism was strongly supported (Demain and Birnbaum, 1968; Demain, 1971). Apparently all of these manipulations result in an altered lipid composition of the cell envelope, which favours active exit of glutamate from the cell. This view was further supported by the discoveries that oleate limitation of an oleate auxotroph (Kitano et al., 1972) and glycerol limitation of a glycerol auxotroph (Nakao et al., 1972) also brought about glutamate excretion. Both oleate and glycerol are precursors of phospholipids. Glutamate‐excreting cells were later found to have a major decrease in cell lipids especially phospholipids (Laneelle and Clement, 1986). It thus became clear that high‐level glutamate excretion required (i) growth inhibition in the presence of unlimited carbon and energy sources, and (ii) a change in strain on the envelope caused by deficiency of biotin, oleate or glycerol or addition of certain agents.

The cell envelope of C. glutamicum is very different from most Gram‐positive bacteria and resembles those of Gram‐negative bacteria (Schluesener et al., 2005). It contains the following layers: (i) plasma membrane which is mainly phosphatidylglycerol, (ii) peptidoglycan covalently attached to arabinogalactan esterified with mycolic acids, (iii) free mycolic acids and (iv) a crystalline protein layer known as the S layer. The permeability of the cell envelope is affected by lipid composition (Puech et al., 2000) and by specific import and export systems.

Despite the above evidence, the leaky envelope hypothesis was discounted (Hoischen and Kraemer, 1989), in favour of an efflux system specific for glutamate which was regulated by the energy state of the cell. However, the criticism was not absolute as these authors acknowledged the change in the composition of the cell membrane and stated that this membrane lipid alteration was an essential (but not sufficient) requirement for effective glutamate secretion. The action of biotin was attributed to effects on intermediary metabolism, correlating with the activity of fatty acid synthetases. Lambert and colleagues (1995) claimed that a change in membrane fluidity or general leakiness was not involved in glutamate excretion.

Studies of Kawahara and colleagues (1997), Kimura and colleagues (1999), Nakamatsu (2001) and Shimizu and colleagues (2003) led to another possibility, i.e. attributing glutamate overproduction to a decrease in the activity of α‐ketoglutarate dehydrogenase (ODHC). In addition to metabolic flux studies, a C. glutamicum mutant with a deletion of the odhA gene, encoding the E1 subunit of ODHC, was found to excrete high levels of glutamate without any of the above‐mentioned triggers (biotin limitation or addition of penicillin), supporting that a change in the metabolic flux alone is sufficient to cause glutamate secretion (Asakura et al., 2007). This complex was shown to be regulated by a mechanism that involves a 15 kDa protein named OdhI and a serine/threonine protein kinase G (PknG). In its unphosphorylated state, OdhI binds to the E1 subunit (OdhA) of ODHC and, thereby, inhibits its activity. Inhibition is relieved by phosphorylation of OdhI at threonine residue 14 by PknG under conditions requiring high ODHC activity (Schultz et al., 2007).

In 2001, however, the permeability modification hypothesis was further supported. The various manipulations leading to glutamate overproduction were shown to cause increased permeability of the mycolic acid layer of the cell wall (Eggeling and Sahm, 2001). The glutamate‐overproducing bacteria are characterized by a special cell envelope containing mycolic acids which surrounds the entire cell as a structured layer and is thought to be involved in permeation of solutes. The mycolic acids esterified with arabinogalactan and the non‐covalently bound mycolic acid derivatives form a second lipid layer, the cytoplasmic membrane being the first. As stated by these authors, ‘The concepts of “permeability of the cell wall” as originally used in the very first work on l‐glutamate production more than forty years ago now takes on a new meaning’. Nampoothiri and colleagues (2002) provided evidence that overexpression or inactivity of genes involved in lipid synthesis changes glutamate efflux dramatically, alters the chemical and physical properties of the cytoplasmic membrane, and that this was necessary to achieve efflux of l‐glutamate. Indeed, the authors state ‘that altering the phospholipid content alone is sufficient to enable l‐glutamate efflux’. Burkovski and Kraemer (2002) further stated that ‘There is no doubt that stimulation of glutamate excretion in C. glutamicum is directly or indirectly related to membrane and/or cell wall integrity’. Further support to this view came from Radmacher and colleagues (2005) who showed that ethambutol (EMB), an anti‐Mycobacterium tuberculosis agent, caused l‐glutamate efflux by targeting the arabinosyltransferase of C. glutamicum. The consequence of EMB addition was a marked disorder of the cell envelope, due to less arabinan deposition in the cell wall arabinogalactan, and a reduced content of the cell wall‐bound mycolic acids. Also, a mechanosensitive channel homologue has been found to induce glutamate production (Nakamura et al., 2007). It thus appears that either an increase in cell envelope permeability or a decrease in α‐ketoglutarate dehydrogenase can elicit overproduction and excretion of glutamate.

l‐Glutamate titres over 80 g l−1 have been described in the literature (Das et al., 1995; Delaunay et al., 1999). Metabolic engineering approaches have been used to analyse the fermentation (Sonntag et al., 1995; Eggeling et al., 1996; Takac et al., 1998; Kimura, 2003).

4.1.2 l‐Lysine. The bulk of the cereals consumed in the world are deficient in the amino acid, l‐lysine. This is an essential ingredient for the growth of animals, and is an important part of a billion‐dollar animal feed industry. Lysine supplementation converts such cereals into balanced food or feed for animals for poultry, swine and other livestock. In addition to animal feed, lysine is used in pharmaceuticals, dietary supplements and cosmetics. It has also been shown to be useful in the prevention of atherosclerosis and for treatment of herpes simplex virus infections.

Lysine is a member of the aspartate family of amino acids. It is made in bacteria by a branched pathway that also produces methionine, threonine and isoleucine. This pathway is controlled very tightly in an organism like E. coli, which contains three aspartate kinases, each of which is regulated by a different end‐product. In addition, after each branch point, the initial enzymes are inhibited by their respective end‐products and no overproduction usually occurs. However, in lysine fermentation organisms (C. glutamicum and its relatives), there is a single aspartate kinase which is regulated via concerted feedback inhibition by threonine plus lysine. Molar fluxes through various pathways leading to glutamate or lysine have been measured (Sonntag et al., 1995). Whereas the pentose phosphate pathway only contributes 20% of the total carbon flux for glutamate formation, it contributes 60–70% for lysine overproduction (Ishino et al., 1991). This is evidently due to the high level of NADPH required for lysine formation. Use of rDNA technology has shown that the major limiting factors in lysine overproduction are: (i) feedback inhibition of aspartokinase by lysine plus threonine, (ii) the low level of dihydrodipicolinate synthase, (iii) the low level of PEP carboxylase and (iv) the low level of aspartase. Much work has been done on auxotrophic and regulatory mutants of the glutamate‐overproducing strains for the production of lysine. By genetic removal of homoserine dehydrogenase, a glutamate‐producing wild‐type Corynebacterium strain is converted into a lysine‐overproducing mutant that cannot grow unless methionine and threonine are added to the medium. As long as the threonine supplement is kept low, the intracellular concentration of threonine is limiting and feedback inhibition of aspartate kinase is bypassed, leading to excretion of over 70 g l−1 lysine in culture fluids. In some strains, addition of methionine and isoleucine to the medium increases lysine overproduction. Selection for S‐2‐aminoethylcysteine (AEC; thialysine) resistance blocks feedback inhibition (up to 1 mM l‐lysine plus 5 mM l‐threonine) of aspartate kinase (Sahm, 1996). Other antimetabolites useful for deregulation of aspartate kinase include a mixture of α‐ketobutyrate and aspartate hydroxamate. Leucine auxotrophy can also increase lysine production. A production strain (B‐6) of C. glutamicum of Kyowa Hakko produces about 100 g l−1l‐lysine (Hayashi et al., 2006). Transcriptome analysis revealed that B‐6, as compared with the wild type, is upregulated in the pentose–phosphate path and amino acid biosynthetic genes and downregulated in TCA cycle genes. l‐Lysine titres are known to be as high as 170 g l−1 (Kraemer, 2004).

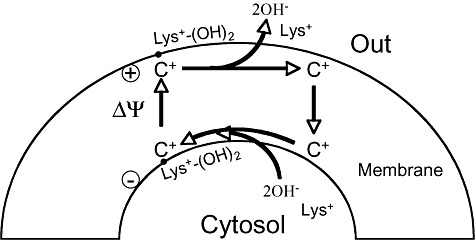

Excretion of lysine by C. glutamicum is by active transport reaching a concentration of several hundred millimolar in the external medium. Lysine, a cation, must be excreted against the membrane potential (outside is positive) and excretion is carrier‐mediated (Fig. 2). It uses a 2 OH‐/lysine symporter (Broer et al., 1993) and is catalysed specifically by a dipeptide uptake system (Erdmann et al., 1993). The system is dependent on electron motive force, not ATP.

Figure 2.

Mechanism of l‐lysine excretion. The carrier is loaded at the cytosolic side, translocates the substrate from the inner side and releases it outside the cell, and then the carrier is reconstituted. ΔΨ, electron motive force.

Genome‐based strain reconstruction was used to improve the lysine production rate of C. glutamicum by comparing high‐producing strain B‐6 (production rate slightly less than 2 g l−1 h−1) with a wild‐type strain (Ohnishi et al., 2002). Comparison of 16 genes from strain B‐6, encoding enzymes of the pathway from glucose to lysine, revealed mutations in five of the genes. Introduction of three of these mutations (hom, lysC and pyc encoding homoserine dehydrogenase, aspartokinase and pyruvate carboxylase respectively) into the wild type created a new strain which produced 80 g l−1 in 27 hours, at a rate of 3 g l−1 h−1, the highest rate ever reported for a lysine fermentation. An additional increase (15%) in l‐lysine production was observed by introduction of a mutation in the 6‐phosphogluconate dehydrogenase gene (gnd). Enzymatic analysis revealed that the mutant enzyme was less sensitive than the wild‐type enzyme to allosteric inhibition by intracellular metabolites. Isotope‐based metabolic flux analysis demonstrated that the gnd mutation resulted in 8% increased carbon flux through the pentose phosphate pathway during l‐lysine production (Ohnishi et al., 2005).

Metabolic engineering has been used in C. glutamicum to improve l‐lysine production (Sahm et al., 2000). Metabolic flux studies of wild‐type C. glutamicum and four improved lysine‐producing mutants available from the ATCC showed that yield increased from 1.2% to 24.9% relative to the glucose flux.

4.1.3 l‐Threonine. This amino acid is the second major amino acid used for feeding of pigs and poultry. The pathway of threonine biosynthesis is similar in all microorganisms. Starting from l‐aspartate, the pathway involves five steps catalysed by five enzyme activities: aspartokinase (AK), aspartate‐semialdehyde dehydrogenase (ASA‐DH), homoserine dehydrogenase (HDI), homoserine kinase (HK) and threonine synthetase (TS).