This issue of Microbial Biotechnology includes a review by L.P. Wackett on microbial‐based fuels that brings into focus an emerging field of research in biotechnology that is becoming increasingly important (Wackett, 2008). Biofuels are on fashion, and there are good reasons for it. Our current dependence on fossil fuels for energy generation is clearly not sustainable. Fossil fuels such as crude oil, natural gas or coal are non‐renewable. The demand is continuously increasing and will continue to do so as economic growth goes on. However, the supplies are limited and the discovery of new reserves does not match the increasing needs. Furthermore, burning fossil fuels leads to a net increase in the atmospheric carbon dioxide, which is very likely contributing to the global warming process that is generating a growing concern. Current demands require energy sources that are sustainable, cheap and non‐contaminant. It seems unlikely that a single energy source will solve all these problems in the years to come, which leaves us with diversification as the best solution. Among other alternatives, new technologies applied to the generation of biofuels are emerging as an attractive possibility that, in some cases, have already reached the markets.

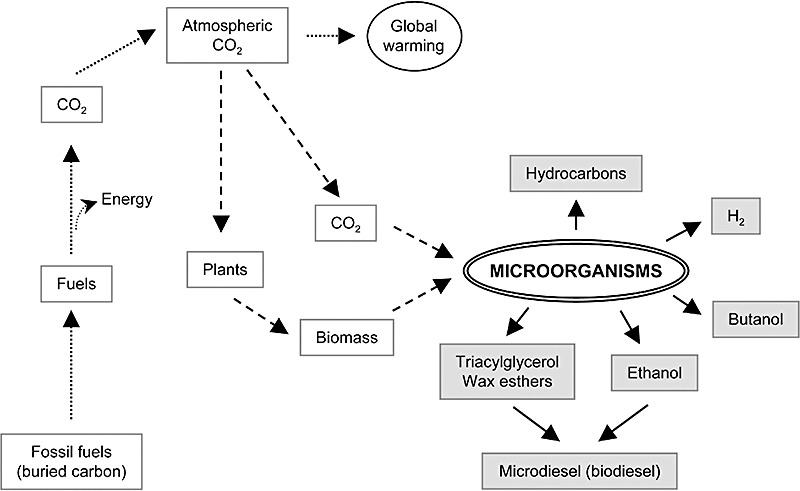

Biofuels are not really new, because for example wood has been and it is still being used as an energy source. Modern technologies, however, and biotechnology in particular, are making big efforts to transform biomass from diverse sources into compounds that can serve as efficient fuels at a cost that can compete with current crude oil prices. Burning these biomass‐derived compounds will release to the atmosphere CO2 that had been previously fixed by photosynthesis, which makes them neutral from the point of view of global warming (Fig. 1). In addition, biomass would be a renewable and sustainable source of fuels. However, when considering all costs from generation of the biomass to the production of the final product, it becomes clear that yields and costs are a problem to solve. The success of biofuels will rely in finding cost‐effective processes to generate biomass‐derived compounds with physicochemical properties that allow them to serve as substitutes for oil‐derived fuels. This is not trivial. The review by L.P. Wackett puts together aspects of the problem that are normally discussed separately: a comprehensive description of known biological processes generating compounds potentially useful as biofuels, and the economical aspects regarding their practical implementation as a solution to current needs.

Figure 1.

Biofuels generated by microorganisms. Burning of fossil fuels releases CO2 to the atmosphere, generating a net increase in the concentration of this gas and contributing to global warming (dotted lines). Part of this CO2 can be fixed by plants or by photosynthetic microorganisms (dashed lines). Some microorganisms, using either CO2 (photosynthetic) or biomass as carbon source, can generate a number of carbon compounds that are useful as fuels (shaded in grey). Burning of these biofuels is neutral for global warming, as the CO2 generated ultimately derives from CO2 previously fixed from the atmosphere by photosynthesis. A challenge of biotechnology is to allow producing these compounds in a sustainable and economically feasible way.

The review starts with the important question as to what constitutes a good motor fuel: it should be preferably a liquid or an easy to handle gas, stable, easy to store and to transport, highly combustible but not explosive, having a high energy to mass ratio, and inexpensive (Wackett, 2008). Low‐ and medium‐molecular‐weight hydrocarbons meet most of these criteria, but those currently used as fuels derive from crude oil. However, many bacteria, plants and animals produce hydrocarbons for different means (Oro et al., 1967; Post‐Beittenmiller, 1996; Greene and Gordon, 2003; Park, 2005). This is why it is so frequent to find hydrocarbon‐degrading microorganisms; they do not normally live on the hydrocarbons derived from man‐made crude oil spills, but on those produced naturally by plants and algae. The bad news is that these hydrocarbons are produced in low amounts. A challenge of biotechnology is to increase the yields using cheap compounds as carbon source. Again, this is not trivial, but is an interesting emerging issue that is covered in detail in Wackett's review.

Other low‐molecular‐weight carbon compounds such as ethanol or butanol, or fatty acid alcohol esters (biodiesel), are good candidates as well, and are in fact currently finding their way into the markets. Still, there are many practical issues to solve. Ethanol production by biological means is not new, and even today it is still produced by fermentation and distillation, which has a limited efficiency. Obtaining yields allowing it to compete in price terms with crude oil as an energy source requires technological improvements leading to more efficient conversion methods. In this regard, several research efforts are underway to obtain sugars by enzymatic degradation of raw plant materials such as cellulose; these sugars would then be converted to ethanol (Doi, 2003, and references therein). The biodiesel that is starting to be used in some countries for car engines is produced from renewable biomass by alkali‐catalysed transesterification of triacylglycerols from plant oils with alcohols such as methanol or ethanol, yielding monoalkyl esters of long‐chain fatty acids. Biodiesel has many advantages such as reduced emissions of sulfur, aromatic compounds or particles during combustion in diesel engines, and the fact that most of the carbon atoms derive from renewable biomass (Kalscheuer et al., 2006). However, some problems are that the methanol used at present for transesterification is produced from fossil fuels, and that a substantial increase in biodiesel production would require the use of bulk plant materials such as cellulose, rather than plant oils. Biotechnology has again something to say here. Some microalgae have oil productivities that greatly exceeds that of the best‐producing oil crops (Chisti, 2007), and may well constitute a renewable source of oils for the subsequent synthesis of biodiesel. There are also some reports of non‐photosynthetic bacteria that can accumulate substantial amounts of triacylglycerols and wax esters as storage material (Alvarez and Steinbuchel, 2002; Kalscheuer et al., 2007). Finally, a recent very interesting paper reports on the development of an engineered Escherichia coli strain that, when fed with glucose and fatty acids, produces ethanol from glucose and catalyses the esterification of the fatty acids with the ethanol generated, rendering a biodiesel that has been named ‘microdiesel’ (Kalscheuer et al., 2006). This is a very promising approach, although it still needs a further improvement so that the bacteria can generate sufficient amounts of fatty acids from glucose, rather than being provided with them.

Hydrogen is also a promising fuel (reviewed in Vadar‐Schara et al., 2008). It has a higher energy content than oil and its oxidation product, water, does not create an environmental problem. The drawback is that its high volatility creates serious storage problems. Current methods to produce hydrogen require plenty of energy. However, microbes can produce hydrogen at ambient temperature and pressure either by photosynthesis or by fermentation, using hydrogenases. Yields are low, however, although several research efforts are underway to improve hydrogen production by microbes through metabolic engineering (Maeda et al., 2007; Maeda et al., 2008). A promising way to use the hydrogen produced by biological means is through microbial fuel cells, in which a suitable electrode (anode) captures electrons from the hydrogen produced by bacterial metabolism, releasing H+, thus generating an electrical current (Rabaey and Verstraete, 2005). Efficient electricity generation depends not only on the optimization of hydrogen production by microorganisms, but on the development of efficient electrodes to capture this hydrogen. The design of electrodes made of highly porous biocompatible scaffolds in which bacteria can proliferate in close contact with the electrode surface may help in the hydrogen uptake (Gutiérrez et al., 2007).

In summary, biotechnology offers several alternatives regarding the development of biofuels, but there is still plenty of research to be made. Wackett's review provides a clear and comprehensive view on the current advances and possible new directions. It is a great challenge, but it is worth the effort.

Acknowledgments

Work in author's lab was supported by Grant BFU2006‐00767/BMC.

References

- Alvarez H.M., Steinbuchel A. Triacylglycerols in prokaryotic microorganisms. Appl Microbiol Biotechnol. 2002;60:367–376. doi: 10.1007/s00253-002-1135-0. [DOI] [PubMed] [Google Scholar]

- Chisti Y. Biodiesel from microalgae. Biotechnol Adv. 2007;25:294–306. doi: 10.1016/j.biotechadv.2007.02.001. [DOI] [PubMed] [Google Scholar]

- Doi R.H. Microbial conversion of corn stalks to riches. J Bacteriol. 2003;185:701–702. doi: 10.1128/JB.185.3.701-702.2003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Greene M.J., Gordon D.M. Social insects: cuticular hydrocarbons inform task decisions. Nature. 2003;423:32. doi: 10.1038/423032a. [DOI] [PubMed] [Google Scholar]

- Gutiérrez M.C., García‐Carvajal Z.Y., Hortigüela M.J., Yuste L., Rojo F., Ferrer M.L., Del Monte F. Biocompatibility of MWCNT scaffolds for immobilization and proliferation of E. coli. J Mater Chem. 2007;17:2992–2995. [Google Scholar]

- Kalscheuer R., Stolting T., Steinbuchel A. Microdiesel: Escherichia coli engineered for fuel production. Microbiology. 2006;152:2529–2536. doi: 10.1099/mic.0.29028-0. [DOI] [PubMed] [Google Scholar]

- Kalscheuer R., Stoveken T., Malkus U., Reichelt R., Golyshin P.N., Sabirova J.S. Analysis of storage lipid accumulation in Alcanivorax borkumensis: evidence for alternative triacylglycerol biosynthesis routes in bacteria. J Bacteriol. 2007;189:918–928. doi: 10.1128/JB.01292-06. et al. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Maeda T., Sanchez‐Torres V., Wood T.K. Enhanced hydrogen production from glucose by metabolically engineered Escherichia coli. Appl Microbiol Biotechnol. 2007;77:879–890. doi: 10.1007/s00253-007-1217-0. [DOI] [PubMed] [Google Scholar]

- Maeda T., Sanchez‐Torres V., Wood T.K. Metabolic engineering to enhance bacterial hydrogen production. Microb Biotechnol. 2008;1:30–39. doi: 10.1111/j.1751-7915.2007.00003.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Oro J., Tornabene T.G., Nooner D.W., Gelpi E. Aliphatic hydrocarbons and fatty acids of some marine and freshwater microorganisms. J Bacteriol. 1967;93:1811–1818. doi: 10.1128/jb.93.6.1811-1818.1967. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Park M.O. New pathway for long‐chain n‐alkane synthesis via 1‐alcohol in Vibrio furnissii M1. J Bacteriol. 2005;187:1426–1429. doi: 10.1128/JB.187.4.1426-1429.2005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Post‐Beittenmiller D. Biochemistry and molecular biology of wax production by plants. Annu Rev Plant Physiol Plant Mol Biol. 1996;47:405–430. doi: 10.1146/annurev.arplant.47.1.405. [DOI] [PubMed] [Google Scholar]

- Rabaey K., Verstraete W. Microbial fuel cells: novel biotechnology for energy generation. Trends Biotechnol. 2005;23:291–298. doi: 10.1016/j.tibtech.2005.04.008. [DOI] [PubMed] [Google Scholar]

- Vadar‐Schara G., Maeda T., Wood T.K. Metabolically engineered bacteria for producing hydrogen via fermentation. Microb Biotechnol. 2008;1:100–118. doi: 10.1111/j.1751-7915.2007.00009.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wackett L.P. Microbial‐based fuels: science and technology. Microb Biotechnol. 2008;1:211–225. doi: 10.1111/j.1751-7915.2007.00020.x. [DOI] [PMC free article] [PubMed] [Google Scholar]