I. Introduction and Scope

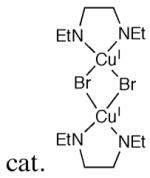

The chemistry of copper is extremely rich because it can easily access Cu0, CuI, CuII, and CuIII oxidation states allowing it to act through one-electron or two-electron processes. As a result, both radical pathways and powerful two-electron bond forming pathways via organmetallic intermediates, similar to those of palladium, can occur. In addition, the different oxidation states of copper associate well with a large number of different functional groups via Lewis acid interactions or π-coordination. In total, these feature confer a remarkably broad range of activities allowing copper to catalyze the oxidation and oxidative union of many substrates.

Oxygen is a highly atom economical, environmentally benign, and abundant oxidant, which makes it ideal in many ways.1 The high activation energies in the reactions of oxygen require that catalysts be employed.2 In combination with molecular oxygen, the chemistry of copper catalysis increases exponentially since oxygen can act as either a sink for electrons (oxidase activity) and/or as a source of oxygen atoms that are incorporated into the product (oxygenase activity). The oxidation of copper with oxygen is a facile process allowing catalytic turnover in net oxidative processes and ready access to the higher CuIII oxidation state, which enables a range of powerful transformations including two-electron reductive elimination to CuI. Molecular oxygen is also not hampered by toxic byproducts, being either reduced to water, occasionally via H2O2 (oxidase activity) or incorporated into the target structure with high atom economy (oxygenase activity). Such oxidations using oxygen or air (21% oxygen) have been employed safely in numerous commodity chemical continuous and batch processes.3

However, batch reactors employing volatile hydrocarbon solvents require that oxygen concentrations be kept low in the head space (typically <5–11%) to avoid flammable mixtures, which can limit the oxygen concentration in the reaction mixture.4,5,6 A number of alternate approaches have been developed allowing oxidation chemistry to be used safely across a broader array of conditions. For example, use of carbon dioxide instead of nitrogen as a diluent leads to reduced flammability.5 Alternately, water can be added to moderate the flammability allowing even pure oxygen to be employed.6 New reactor designs also allow pure oxygen to be used instead of diluted oxygen by maintaining gas bubbles in the solvent, which greatly improves reaction rates and prevents the build up of higher concentrations of oxygen in the head space.4a,7 Supercritical carbon dioxide has been found to be advantageous as a solvent due its chemical inertness towards oxidizing agents and its complete miscibility with oxygen or air over a wide range of temperatures.8 An number of flow technologies9 including flow reactors,10 capillary flow reactors,11 microchannel/microstructure structure reactors,12 and membrane reactors13 limit the amount of or afford separation of hydrocarbon/oxygen vapor phase thereby reducing the potential for explosions.

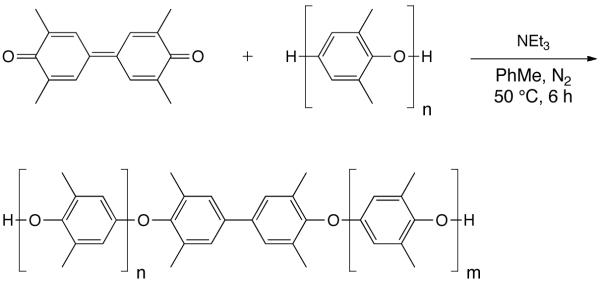

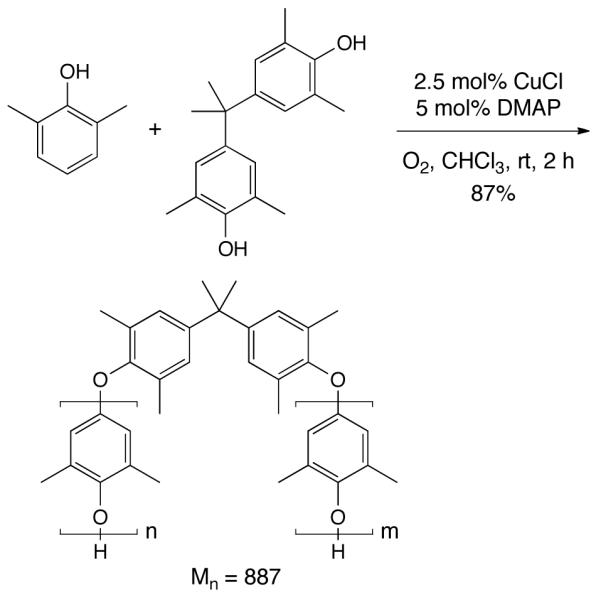

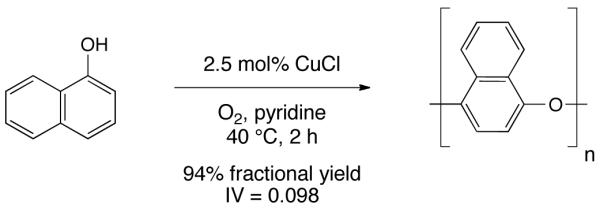

Enzymatic oxidizing systems based upon copper that exploit the many advantages and unique aspects of copper as a catalyst and oxygen as an oxidant as described in the preceding paragraphs are well known. They represent a powerful set of catalysts able to direct beautiful redox chemistry in a highly site-selective and stereoselective manner on simple as well as highly functionalized molecules. This ability has inspired organic chemists to discover small molecule catalysts that can emulate such processes. In addition, copper has been recognized as a powerful catalyst in several industrial processes (e.g. phenol polymerization, Glaser-Hay alkyne coupling) stimulating the study of the fundamental reaction steps and the organometallic copper intermediates. These studies have inspiried the development of nonenzymatic copper catalysts. For these reasons, the study of copper catalysis using molecular oxygen has undergone explosive growth, from 30 citations per year in the 1980s to over 300 citations per year in the 2000s.

A number of elegant reviews on the subject of catalytic copper oxidation chemistry have appeared. Most recently, reviews provide selected coverage of copper catalysts14 or a discussion of their use in the aerobic functionalization of C–H bonds.15 Other recent reviews cover copper and other metal catalysts with a range of oxidants, including oxygen, but several reaction types are not covered.16 Several other works provide a valuable overview of earlier efforts in the field.17 This review comprehensively covers copper catalyzed oxidation chemistry using oxygen as the oxidant up through 2011. Stoichiometric reactions with copper are discussed, as necessary, to put the development of the catalytic processes in context. Mixed metal systems utilizing copper, such as palladium catalyzed Wacker processes, are not included here. Decomposition reactions involving copper/oxygen and model systems of copper enzymes are not discussed exhaustively. To facilitate analysis of the reactions under discussion, the current mechanistic hypothesis is provided for each reaction. As our understanding of the basic chemical steps involving copper improve, it is expected that many of these mechanisms will evolve accordingly.

II. Reactions of Hydrocarbons

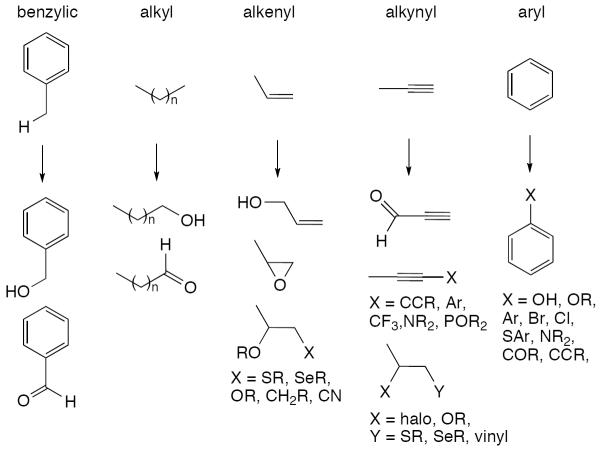

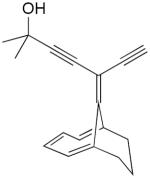

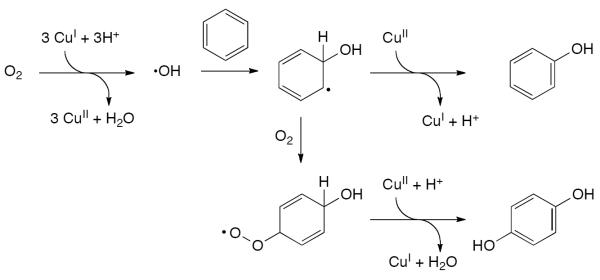

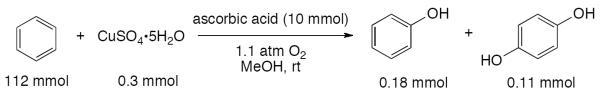

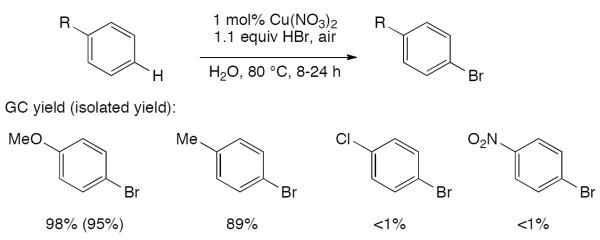

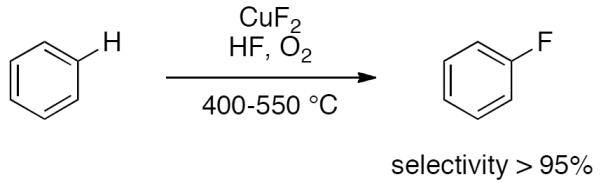

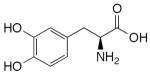

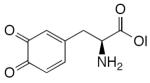

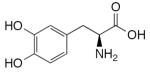

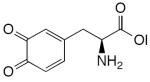

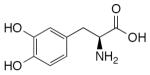

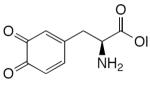

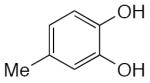

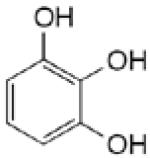

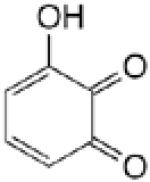

Enzymatic copper-dioxygen derived species are highly effective in aliphatic and arene C-H bond hydroxylations with examples including dopamine β-monooxygenase, peptidylglycine α-amidating monooxygenase, and particulate methane monooxygenase. Much effort has focused on biomimetic versions, attempting to achieve the high selectivity and reactivity of these enzymatic systems with small molecule copper catalysts and oxygen, typically via radical intermediates. While considerable progress has been made, general, selective functionalization of C-H groups is not yet efficient as a standard synthetic procedure for a range of structures. Both selectivity and reactivity remain as significant challenges. In the section below, the progress to date for oxygenation of different classes of hydrocarbons, including benzylic, alkyl, alkenyl, alkynyl, and aryl (Scheme 1), is outlined.

Scheme 1.

Copper-catalyzed oxidations of hydrocarbons.

II.A. Benzylic Oxidation

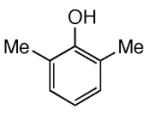

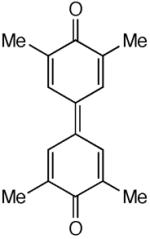

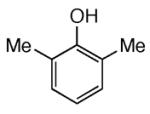

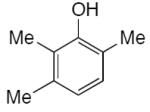

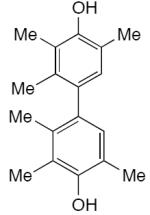

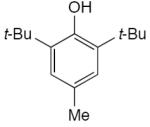

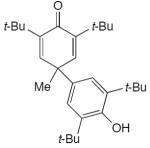

Benzylic oxidation is aided by the much weaker benzylic C–H bond, aiding in processes involving radical abstraction. Consequently, conditions are generally milder than those seen for alkane or arene oxidation. Oxidation occurs through two primary mechanisms. In acidic or activated substrates, deprotonation can occur, followed by single electron oxidation to form the key radical species that then reacts with molecular oxygen. As demonstrated below, these processes can be highly efficient, but are inherently limited in scope. In unactivated substrates, the benzylic radical species is formed directly via hydrogen abstraction. These operations typically require more forcing conditions, and efficiency and selectivity remain significant obstacles. For both modes of oxidation, controlling the degree of oxygenation is critical since the acid, aldehyde, or alcohol can be produced. As of yet there is no general catalyst available for a broad range of substrates. However, a variety of different copper catalysts have been devised that operate on electron-poor or electron-rich substrates.

II.A.1 Oxygenation of Acidic Benzylic Positions

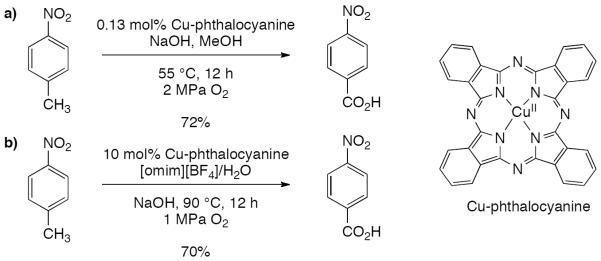

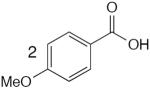

Highly acidic benzylic substrates undergo oxidation more readily by virtue of the greater acidity allowing facile oxidation via benzyl anion. Although the scope of these transformations is fairly narrow, several useful cases with copper catalysts have been reported. For example, efficient conversion of nitrotoluene to nitrobenzoic acid (Scheme 2a) has been demonstrated in the presence of sodium hydroxide and a copper phthalocyanine catalyst under 2 MPa of oxygen.18 High selectivity was observed, with only trace amounts of the alcohol and the aldehyde formed. The process was later demonstrated to proceed in an ionic solvent (Scheme 2b).19 Although slightly higher temperature was necessary, simple acidification of the aqueous layer conveniently provided the pure product and allowed recycling of the ionic liquid solvent, lending the process amenable to large scale industrial applications. Notably, other metal catalysts gave superior results in this transformation and only one substrate was demonstrated with the copper catalyst.

Scheme 2.

Selected oxidations of nitrotoluene.

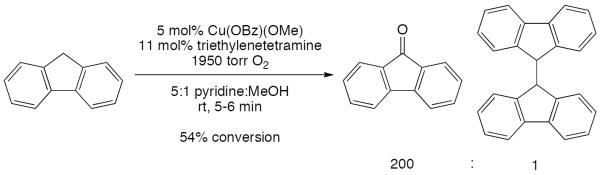

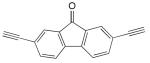

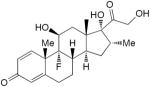

In an early report by Allara20, fluorene was readily oxidized to fluorenone at room temperature using Cu(OBz)(OMe) with triethylenetetraamine (trine) as a ligand and pyridine/MeOH as solvent. Despite only moderate conversion, excellent selectivity (200:1) of corresponding ketone to homocoupled 9,9'-bifluorene was observed (Scheme 3). The proposed mechanism proceeds through oxidation of the fluorenyl anion by copper, coupling of the radical with molecular oxygen, and decomposition of the resulting peroxide by base deprotonation to give the ketone product. Kinetic studies using 9,9'-didueterofluorene indicated that the rate-limiting step was deprotonation of the substrate. Although the oxidation proceeded in the presence of base (NaOMe) and oxygen, the addition of copper catalyzed increased the rate by ~500 fold.

Scheme 3.

Copper(II)-catalyzed oxygenation of fluorene.

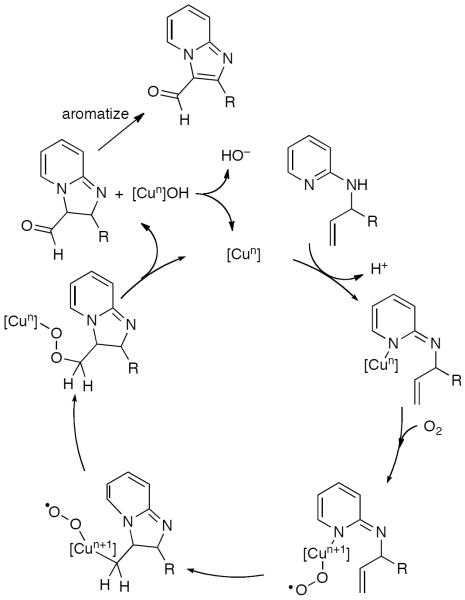

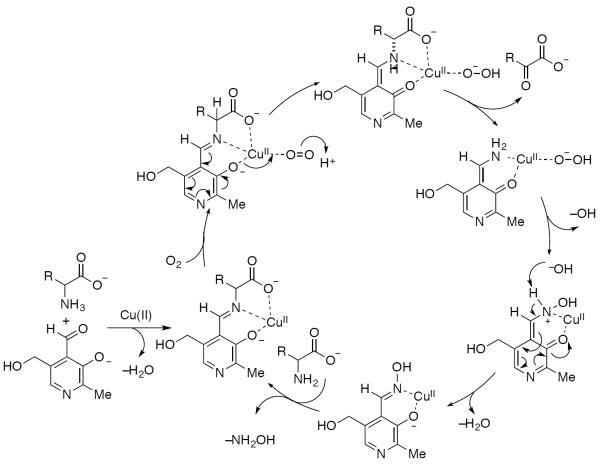

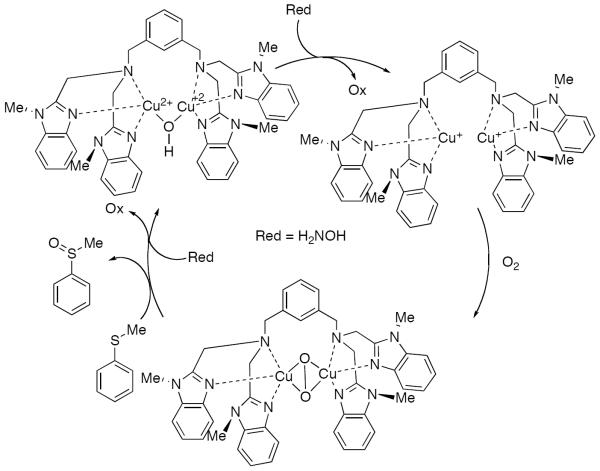

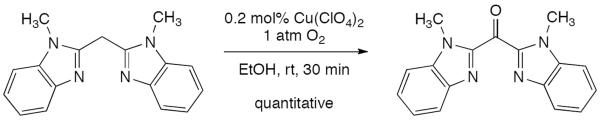

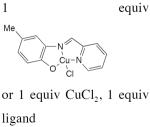

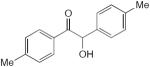

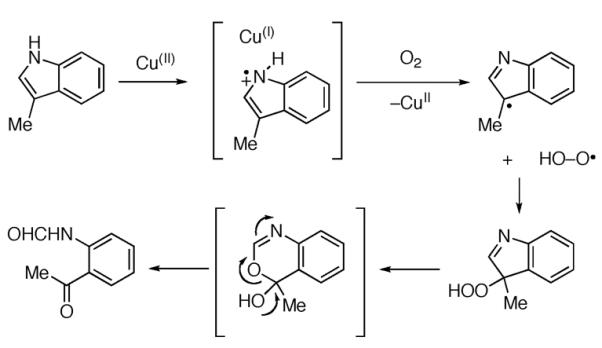

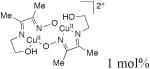

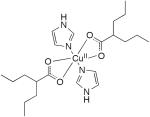

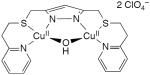

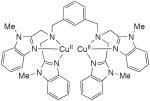

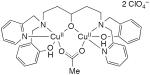

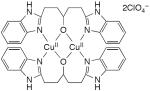

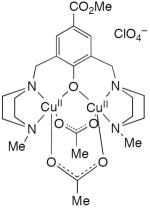

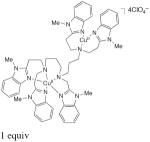

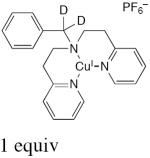

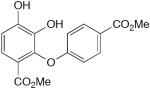

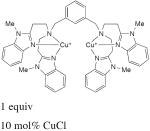

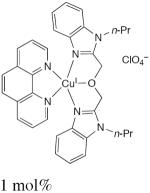

Activated substrates can also be oxidized without strongly basic conditions via a similar system as for unactivated systems (see next Section II.A.2). A striking example by Züberbuhler and coworkers centers the facile copper-mediated oxidation of bis(1-methyl-benzimiazol-2-yl)methane (Scheme 4).21 Full conversion to the respective ketone is effected using just 0.2 mol% Cu(ClO4)2 at room temperature under 1 atm O2.

Scheme 4.

Oxidation of bis(1-methyl-benzimiazol-2-yl)methane.

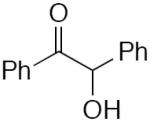

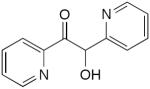

Little incorporation of 18O at the carbonyl carbon was observed when performing the reaction in a vast excess of D218O, indicating that dioxygen is supplying the ketone oxygen. While Co+2 displayed comparable catalytic activity, Fe+2, Fe+3, Zn+2, Ni+2, and Mg+2 did not significantly increase the rate over background. Significantly, addition of either base or acid strongly inhibited the reaction. No product was detected when subjecting 1,2-dimethylbenzimidazole or any higher bis(1-methyl-benzimidazolyl)alkanes to the reaction conditions, illustrating the necessity of the doubly pseudobenzyilic position. Despite these limitations to the generality of the oxidation, the method was also effectively adapted to bis(2-pyridyl)methanes.22 One mechanism that is consistent with the data for this reaction is formation a benzylic radical intermediate that undergoes reaction with dioxygen. On the other hand, deprotonation and subsequent anion oxidation is also viable and is most likely occurring for those systems that incorporate strong bases (Scheme 2, Scheme 3). For those cases without base (Scheme 4, Scheme 5), metal-assisted deprotonation has been raised as a possibility.22

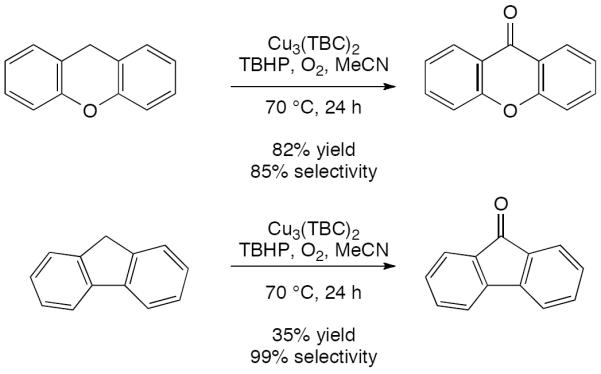

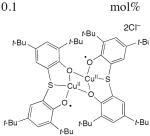

Scheme 5.

Cu3(TBC)2 catalyzed oxidation of xanthene and fluorene.

Garcia and coworkers tested the oxidation of xanthene, another doubly benzylic system, using a metal organic framework composed of 1,3,5-benzenetricarboxylate (BTC).23 Although the most selective metal was found to be Fe+2, Cu3(BTC)2 also provided the ketone product at 70 °C in good yield and usable selectivity (Scheme 5). Under the same conditions, fluorene could also be converted to fluorenone in moderate conversion but excellent selectivity. The catalysts were easily recovered and could be reused after drying with minimal loss in activity.

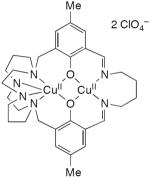

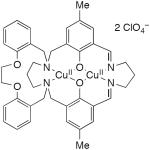

II.A.2 Oxygenation of Unactivated Benzylic Substrates

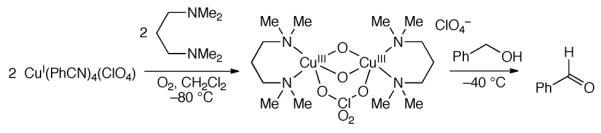

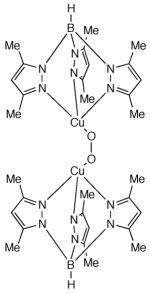

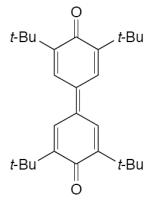

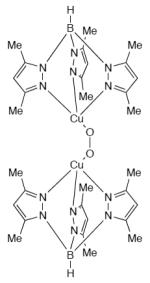

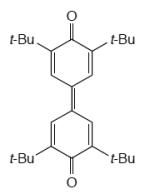

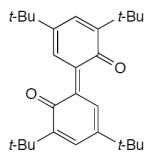

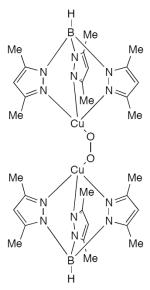

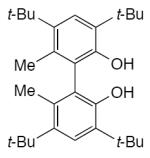

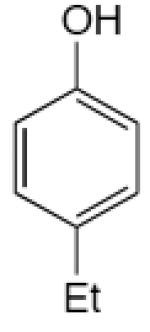

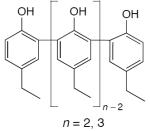

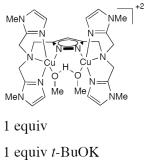

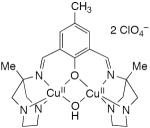

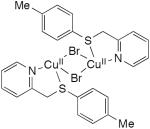

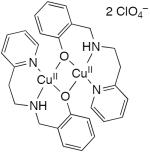

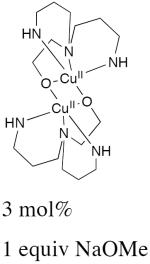

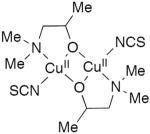

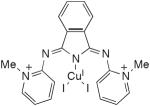

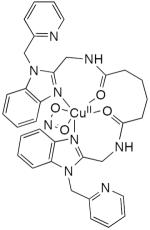

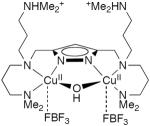

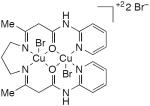

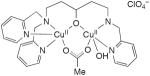

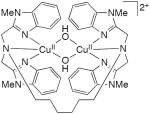

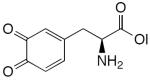

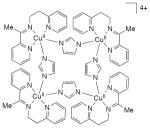

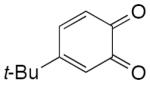

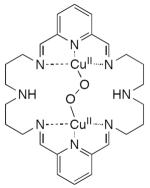

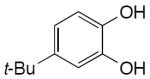

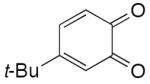

Benzylic oxygenation of simple hydrocarbons using molecular oxygen represents a highly desirable process, particularly on an industrial scale. Enzymatic systems are capable of performing such oxidations very well24, and biomimetic systems have been identified. For example, Karlin and coworkers have recently reported the synthesis of a dicopper(II)-μ-1,2-peroxo complex at low temperatures (−80 °C).25 Allowing the complex to warm to ambient temperature in the presence of a toluene or ethylbenzene caused thermal decomposition of the complex with concomitant benzylic oxidation. Experiments using complexes formed with 18O2 demonstrated that oxygen incorporation occurred from molecular oxygen. A copper peroxo complex stable at room temperature was similarly reported using tetraamine tripodal ligands.26 Reaction of the complex with toluene at room temperature yielded benzaldehyde in 20% yield. Despite the impressive activity of these biomimetic systems, turnover has yet to be achieved.

Several examples using copper catalysis to achieve oxygenation of aliphatic substrates have been reported, yet both conversion and selectivity remain significant challenges on unactivated substrates. An important aspect is that the initial oxygenation product, the hydroperoxide or peroxide anion, can readily convert to the alcohol and ketone in the presence of a metal catalyst. Consequently, a mixture of oxygenated products, including peroxide, alcohol, and carbonyl compounds are often obtained.

While several investigations have probed the oxidation of benzylic compounds that do not proceed via anionic intermediates27, the exact mechanism is currently unknown. The complete inhibition of the reaction in the presence of radical trapping agents suggests a radical chain pathway. Alternately, direct hydroxylation by metal oxo insertion into the benzylic C–H bond, mimicking the oxidation of alkanes by cytochrome P450, would also be consistent with this finding. However, the hydroperoxide intermediates have been demonstrated28,29 in many cases, pointing away from this theory. The subsequent metal-catalyzed degradation to the alcohol and ketone products are well-established.

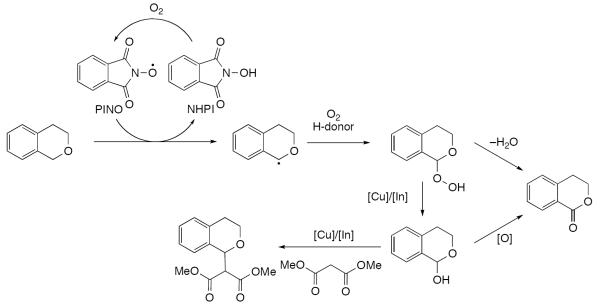

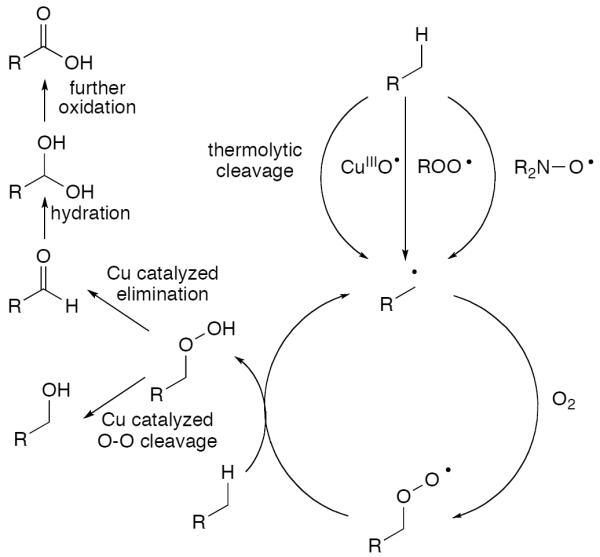

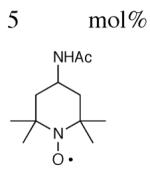

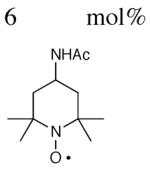

Based on these observations, the key benzyl radical intermediate reacts with molecular oxygen to form the peroxo radical, which continues propagation via benzylic hydrogen abstraction (Scheme 6). The radical initiation can occur via several modes. In some cases, reaction occurs in the absence of an obvious radical initiator. The high temperatures and long induction periods in these examples point to a thermolytic radical formation. Alternatively, several radical initiators have been employed in the presence of a copper catalyst. Commonly, a peroxide is employed, although a sacrificial aldehyde, which converts to the peroxide in situ under the reaction conditions, may also be used. In these cases, homolytic cleavage of the peroxide would provide a radical that could initiate the radical chain reaction. However, in the presence of a copper catalyst, reaction of the peroxides with the copper is likely to occur more rapidly giving rise to a [CuIII–O·] species, which, in turn, initiates the reaction via benzylic hydrogen abstraction.28 Consistent with these theories, other radical initiators/mediators such as H2O2, t-BuOOH, AIBN, and ACBN have been used in conjunction with copper catalysts. In a different paradigm, a stabilized N–O radical mediator such as N-hydroxyphthalimide (NHPI) has been used as a radical mediator, which is reoxidized by the copper catalysts.30 In some of these reactions, it is highly likely that more than one pathway operates (e.g., [CuIII–O·] and peroxyl radical).

Scheme 6.

General mechanism for benzylic oxidation of unactivated substrates.

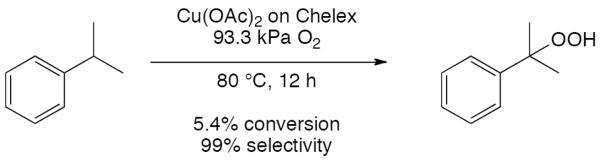

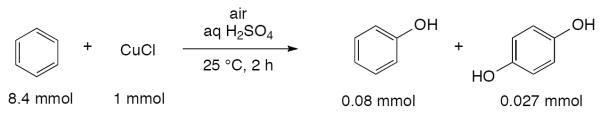

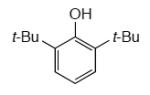

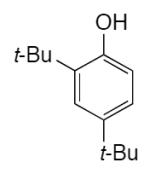

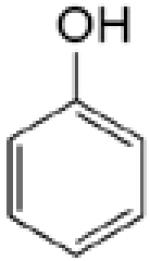

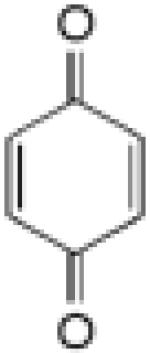

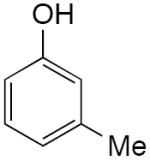

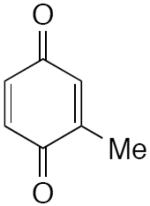

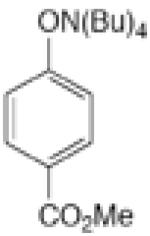

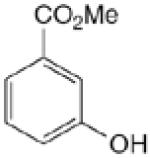

Table 1 displays the results of oxidation on a variety of unactivated benzylic substrates. As illustrated, the success of the reaction varies based on substrate and initiator. Oxidation of several substrates has been achieved with varied success without utilizing a clear initiator. For example, Gardner demonstrated the heterogeneous oxidation of p-xylene, a challenging substrate, simply using CuBr and catalytic LiBr, but very high temperature and O2 pressure were required to achieve even low conversion (Table 1, entry 2).31 While the aldehyde was obtained as the major product, overoxidation to the acid as well as diaryl products were observed. Interestingly, other substrates demonstrated very poor selectivity using these conditions, and toluene was converted almost exclusively to benzyl bromide. Oxidation of cumene to cumyl hydroperoxide represents an industrially significant process that accounts for the majority of the global production of both phenol and acetone.32 A selective oxidation of cumene was reported by Cheng and coworkers, in which Cu(OAc)2 on Chelex® was used as a heterogeneous catalyst in the absence of a radical initiator (Table 1, entry 12).33 Although only minor conversion is observed, the hydroperoxide is formed in almost perfect selectivity, with only trace (<1%) alcohol detected (Scheme 7).

Table 1.

Benzylic oxidation of unactivated hydrocarbons.

| product distribution (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| entry | substrate | radical initiator | catalysta | conditions | conv (%) | hydroperoxide | alcohol | carbonyl | ref |

| 1 | Toluene | HPPDO | CuCl2 | 4.9 atm O2, | 71 | 4:94b | 43 | ||

| 2 | p-Xylene | none | CuBr | cat LiBr, 7.8 atm O2, 150 °C, 2 h | 20 | 88c | 31 | ||

| 3 | Ethylbenzene | aldehyde | CuCl2, 18-Crown-6 | 1 equiv MeCHO, 1 atm O2, CH2Cl2, 24 h, rt | 8.5 | 24 | 76 | 34a | |

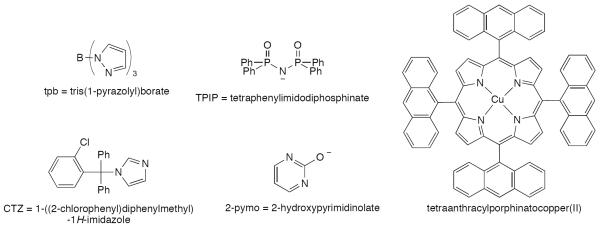

| 4 | peroxide | [CuI(pyr)(tpb)] | 1 mol% TBHP, 1 atm O2, 1:2 AcOH:pyr, rt, 24 h | 5.8 | 1 | 99 | 35 | ||

| 5 | Indane | aldehyde | Cu(OAc)2 | 1 equiv MeCHO, MeCN/CH2Cl2, rt, 36 h | 35 | 23 | 77 | 42 | |

| 6 | aldehyde | Cu(TPIP)2 | 6 equiv isobutyraldehyde, O2 DCE, rt, 4 h | 49 | 63 | 12 | 24 | 28 | |

| 7 | aldehyde | CuCl2, 18-Crown-6 | 1 equiv MeCHO, 1 atm O2, CH2Cl2, 70 °C, 24 h, rt | 36 | 31 | 69 | 34a | ||

| 8 | Tetralin | none | [Cu(CTZ)2Cl2]2 | 35 atm air, 100 °C, 9 h | 57 | 25 | 75 | 36 | |

| 9 | none | Cu(2-pymo)2 | 1 atm air, 90 °C, 48 h | 52 | 2 | 26 | 71 | 37 | |

| 10 | aldehyde | CuCl2, 18-Crown-6 | 1 equiv MeCHO, 1 atm O2, CH2Cl2, 70 °C, 24 h, rt | 37 | 25 | 75 | 34a | ||

| 11 | peroxide | Cu(OH)2 | cat H2O2, 14.6 atm O2, i-PrOH/DMA, cat FeCl3, 90 °C, 30 min |

49 | 21 | 79 | 38 | ||

| 12 | Cumene | none | Cu(OAc)2 on Chelex | 0.9 atm O2, 80 °C, 12 h | 5.4 | 99 | 33 | ||

| 13 | AIBN | Cu(acac)2, NHPI | 3 mol% AIBN, 1 atm O2, MeCN, 60 °C, 4.5 h | 72 | 19 | 63 | 15 | 30 | |

| 14 | ACBN | Cu(acac)2, NHPI | 3 mol% ACBN, 1 atm O2, benzonitrile, 90 °C, 3 h | 29 | 4 | 26 | 57 | 30 | |

| 15 | Cyclohexyl-benzene | none | α,β,γ,δ-tetraanthracyl-porphinato-copper(II) | 13.6 atm O2, 115 °C, 4.9 h | 14 | 99d | 39, 40 | ||

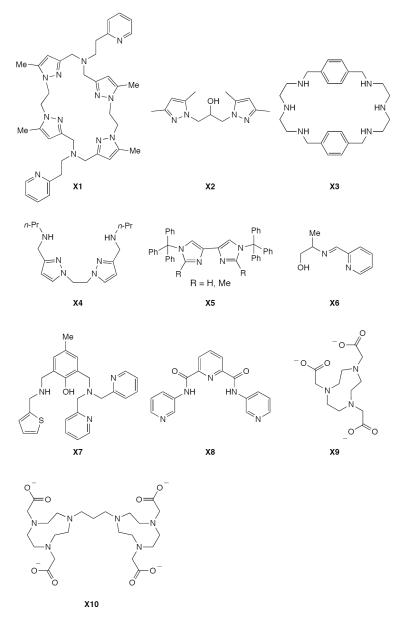

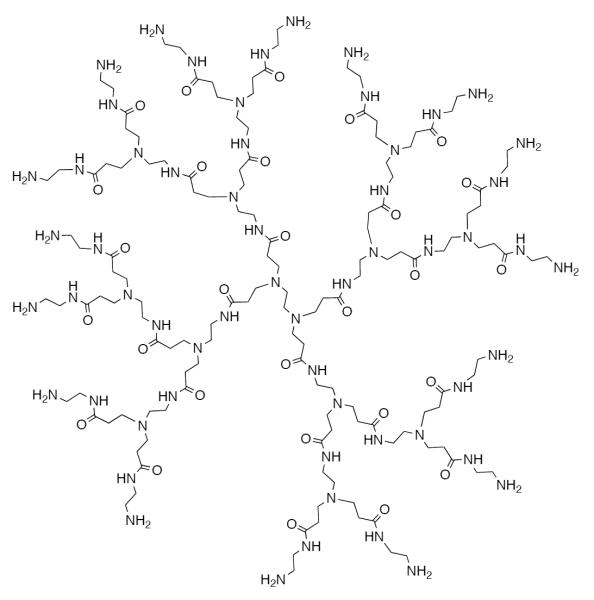

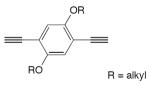

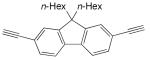

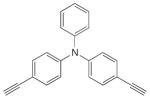

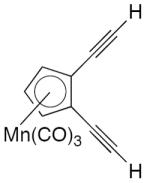

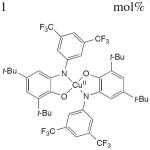

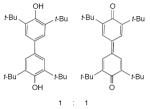

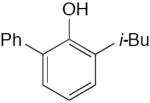

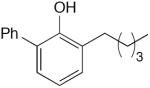

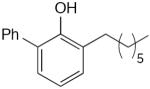

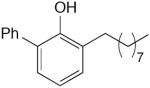

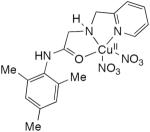

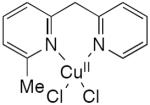

See Chart 1 for ligand structures.

4:94 benzaldehyde:benzoic acid.

Acid and diaryls were the other major products.

Includes oxidation products at other positions of the cyclohexyl ring.

Scheme 7.

Cumene oxidation with a copper catalyst and oxygen.

Orlinska and Zawadiak attempted the oxidation of more complex substrates, 4,4'-diisopropylbiphenyl and 2,6-diisopropylnaphthalene, using CuCl2 and n-Bu4NBr under oxygen.41 Monoalcohol and peroxide dimers were the major products, along with smaller amounts of ketone, monohydroperoxide, and bishydroperoxide. Trace amounts of substrate underwent oxidation at both benzylic positions.

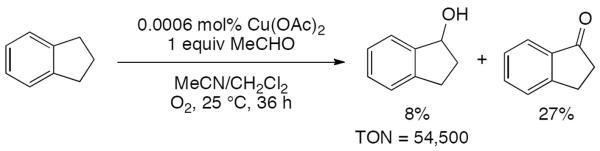

Oxidations in which a peroxide or aldehyde (which converts to peroxyacid under the reaction conditions) are present in addition to a copper catalyst are often able to avoid the induction periods and high temperatures otherwise associated with these processes. For example, extremely high turnovers (TON = 54,500) have been observed in the room temperature oxidation of indane using copper(II) acetate (0.0006 mol%) in conjunction with acetonitrile, which can function as a ligand, and 1 equivalent of acetaldehyde (Table 1, entry 5).42 Moderate conversion was observed, with indanone as the major product (Scheme 8).

Scheme 8.

Indane oxidation with an aldehyde additive.

Use of N–O radical mediators have also been reported. For example, Orlinska and coworkers studied the oxidation of cumene in the presence of a variety of metals, a radical initiator, and NHPI (Table 1, entry 13–14).30 Interestingly, NHPI in the absence of a metal cocatalyst afforded cumyl hydroperoxide in moderate conversions but excellent selectivity (>99%). Addition of metal salts changed the product distribution, presumably from catalyzing the decomposition of the initial hydroperoxide adduct. Copper was found to be the most effective, affording either the alcohol or rearranged ketone as the major product depending on solvent and temperature. Notably, much higher conversion but poorer selectivity was observed in the oxygenation of cumene when NHPI, radical initiator, and Cu(acac)2 were employed in comparison to the heterogeneous Cu(OAc)2 on Chelex system (Table 1, entry 12–13).

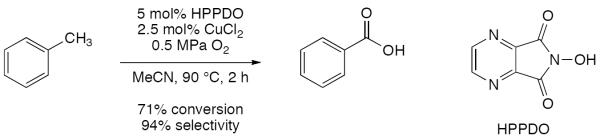

Recently, the selective oxidation of toluene to benzoic acid was reported through the use of a modified NHPI structure in conjunction with CuCl2 (Table 1, entry 1).43 Although elevated temperatures and pressures are used, good conversion to the acid is afforded along with only a minor amount of intermediate benzaldehyde (Scheme 9). The increased activity of the HPPDO catalyst in comparison to NHPI may be attributed to the electron-withdrawing nature of the pyrazine, which creates a more reactive N–O radical. Moreover, a metal additive was demonstrated to bind to the pyrazine nitrogens, further increasing destabilizing the radical and increasing the rate. Copper was found to be the most effective in terms of both conversion and selectivity.

Scheme 9.

Selective oxidation of toluene with N–O radical mediator.

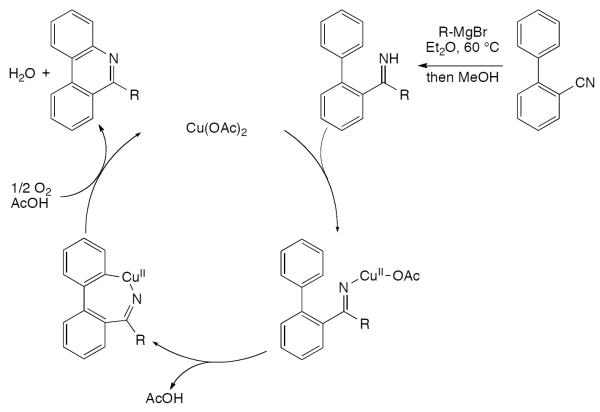

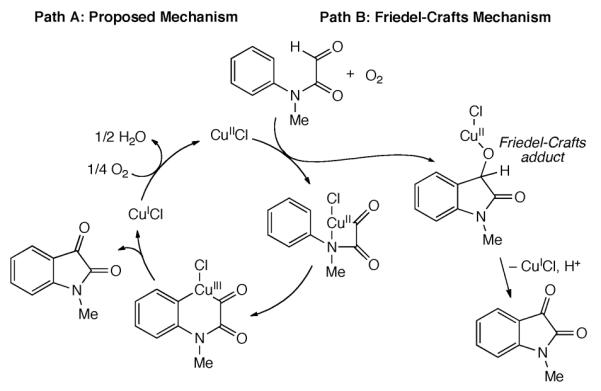

II.A.3 Directed Benzylic Oxidation

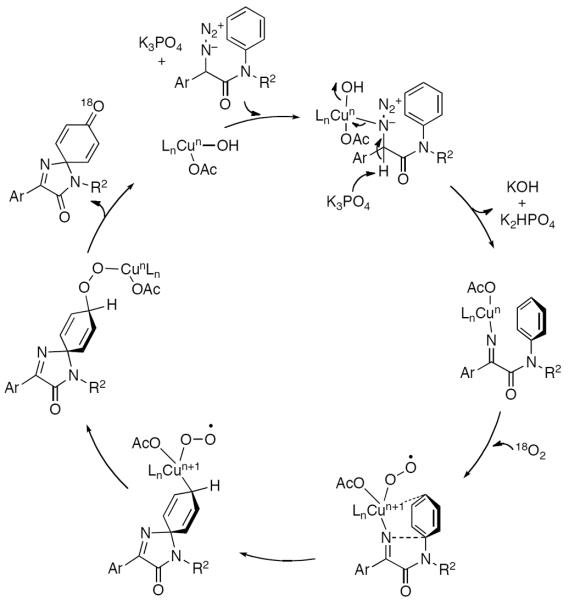

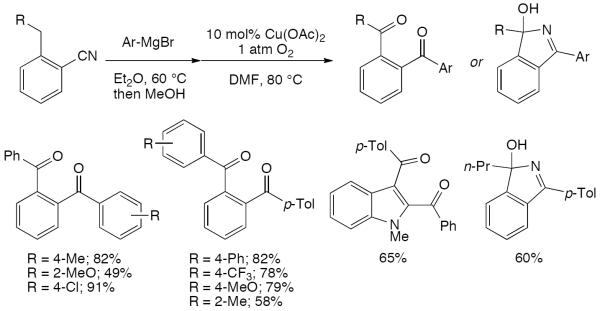

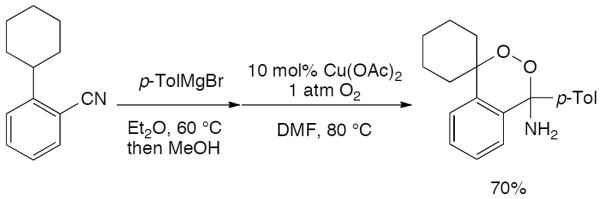

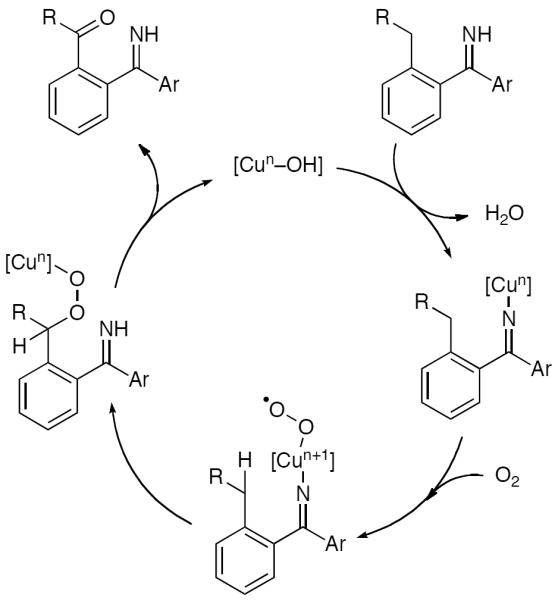

A recent report by Chiba and coworker details an effective aerobic benzylic oxidation that operates by employing an ortho-imine as a directing group (Scheme 10).44 The imine is generated in situ via Grignard addition to nitrile-containing substrates followed by protonation with MeOH. Treatment of the imine intermediate with Cu(OAc)2 and 1 atm O2 affords the diketone products upon acidic workup. In certain cases, quenching the reaction with pH 9 buffer afforded the N,O-ketal. The authors further demonstrated the synthetic utility of the method through direct transformation of the products to phthalazines (one-pot) or isoindolines (two-pot). Interestingly, subjecting 2-cyclohexylbenzonitrile to the reaction conditions afforded an aminoperoxide product in good yield, and the structure was secured by X-ray crystallographic analysis (Scheme 11). Performing the reaction under 18O2 provided the diacylbenzene product with labeled oxygens in both carbonyls, suggesting that H218O is produced during the reaction to hydrolyze the imine. The proposed reaction mechanism proceeds through a key iminyl copper species, which reacts with molecular oxygen to form a peroxycopper intermediate (Scheme 12). An intramolecular 1,5-H-shift can give rise to a benzylic peroxycopper species, which releases the active copper species and affords the ketoimine precursor to either diketone or N,O-ketal products.

Scheme 10.

Directed benzylic oxidation.

Scheme 11.

Directed oxygenation to form an aminoperoxide.

Scheme 12.

Mechanism for imine-directed benzylic oxidation.

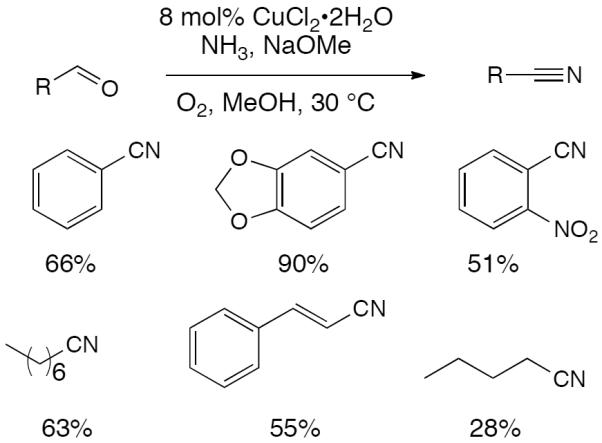

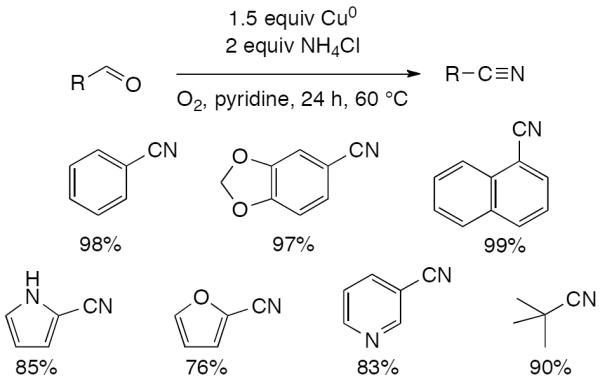

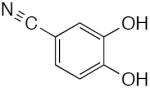

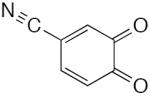

II.A.4 Generation of Nitriles from Benzylic Substrates (Ammoxidation)

The oxidation of hydrocarbons in the presence of both molecular oxygen and ammonia to form nitriles is known as ammoxidation.45 This reaction is a critical industrial process for the production of allylic and benzylic nitriles, such as benzonitrile, acetonitrile, and acrylonitrile.46 As ammoxidation is typically performed using flow reactors, it is not amenable to small, laboratory-scale purposes, and the forcing conditions required generally preclude all but the simplest of substrates. Additionally, the combination of oxygen (an oxidant) with ammonia (a reductant) means that controlling the relative reactivity is crucial.

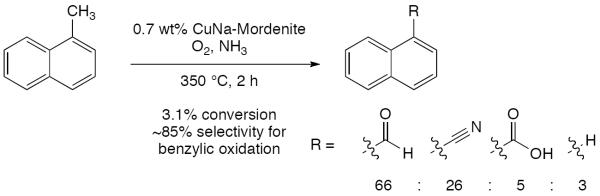

While several investigations of ammoxidation using copper catalysts have been reported, selectivity, conversion, and scope remain problematic. For example, Solinas and coworkers studied the ammoxidation of 1-methylnaphthalene in the presence of copper impregnated Na-Mordenite as a solid support catalyst (Scheme 13).47 The copper additive was found to increase conversion while only slightly modifying selectivity. However, even at 350 °C only slight conversion was observed with an 85% selectivity of oxidation at the benzylic position. The process afforded a mixture of products, with significant amounts of both the aldehyde and nitrile forming. In accord with the proposed mechanism involving an aldehyde intermediate (see below), formation of nitrile products was only observed when aldehydes were also detected.

Scheme 13.

Ammoxidation using Cu-impregnated mordenite.

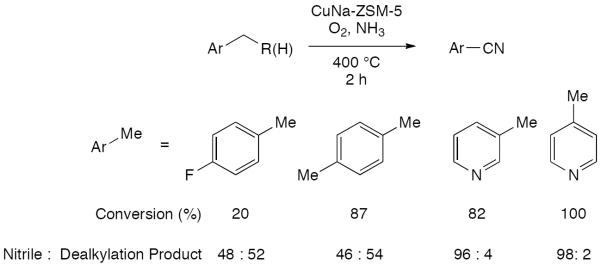

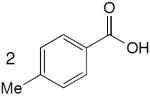

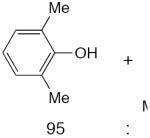

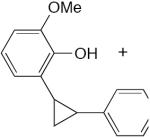

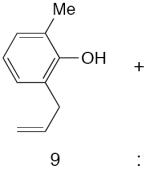

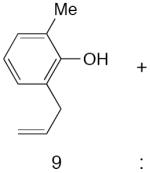

Using Cu impregnated zeolites (Cu-H-ZSM-5) under NH3/O2 at 400 °C and 450 °C, para-xylene has been shown to react more quickly than meta-xylene (~90% selectivity) giving rise to para-tolylnitrile.48 A broader investigation by Chon and Kim surveyed a series of metal impregnated ZSM5 zeolite catalysts in the ammoxidation of benzylic hydrocarbons.49 Compared to the other metals tested (Mn2+, Co2+, Ni2+, Zn2+, Ag+1), Cu2+ was found to be the most active and selective. At 400 °C, good conversions were obtained, particularly for more electron-rich substrates, as is consistent with a process involving formation of benzylic radicals (Scheme 14). However, this high temperature led to significant demethylation, presumably via decarboxylation of an overoxidized carboxylic acid intermediate. While substituted toluenes generally formed considerable amounts of dealkylation products, picolines yielded the corresponding nitriles in excellent conversion and selectivity.

Scheme 14.

Ammoxidation using CuNa-ZSM-5.

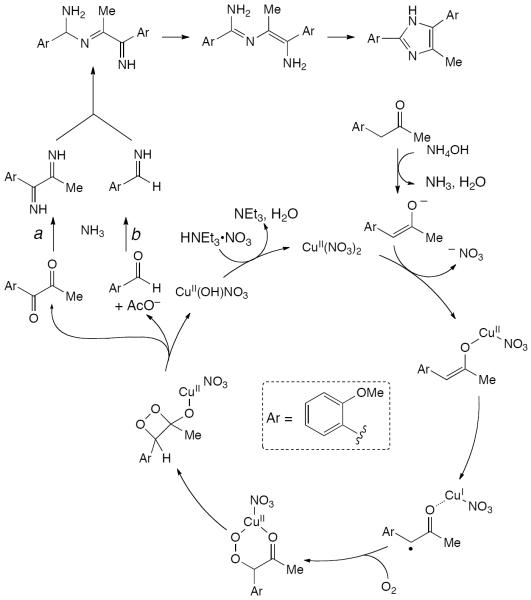

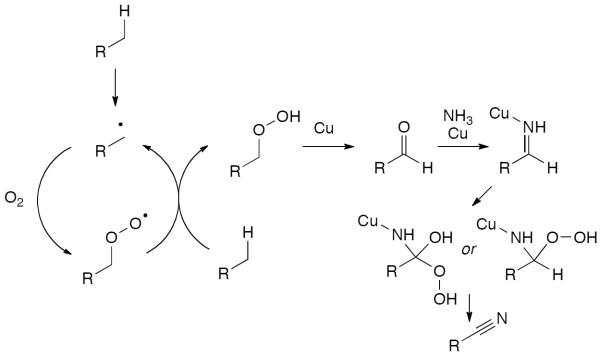

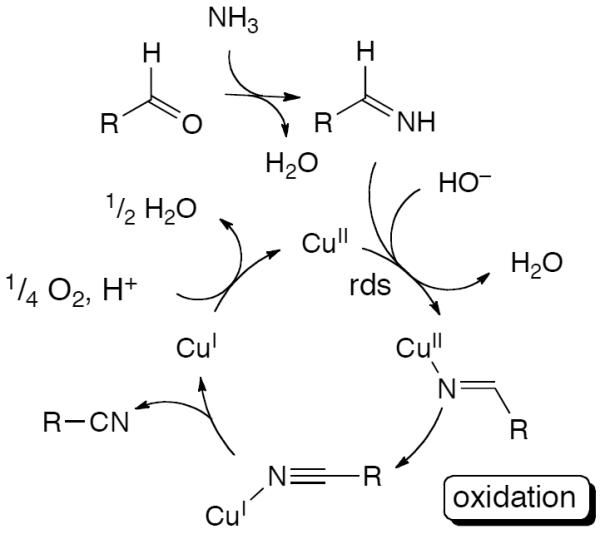

When the reaction was performed using benzyl alcohol, benzylamine, or benzaldehyde as the substrate, benzonitrile was formed in >90% selectivity with full conversion. Additionally, no conversion of toluene in the absence of oxygen flow was detected up to 500 °C. These results support a general mechanism similar to that described in Section II.A.2, in which the key benzyl radical combines with molecular oxygen. Condensation of the intermediate aldehyde with ammonia affords an N–H imine (Scheme 15), which upon further oxidation would provide the nitrile product (see Section V.B and Section IX.A.4). The exact mechanism for the final oxidation remains unclear, but oxidation via an N,O-acetal is plausible.

Scheme 15.

General mechanism of ammoxidation.

II.B. Alkane Oxidation

Aerobic oxidation of alkanes employing copper catalysts shares many of the characteristics of benzylic analogs. Owing to the higher C–H bond strength in alkanes, more forcing conditions are required. As a result, control of regioselectivity is challenging and formation of overoxidized and elimination products is common. Current efforts are primarily focused on the conversion of base hydrocarbon building blocks into their more oxygenated analogs, vital industrial processes. An important, and highly studied case, is the conversion of cyclohexane to cyclohexanone, a key precursor to caprolactam. Commercially, this process is achieved via aerial oxidation using pressurized air at ~160 °C in the presence of a homogeneous cobalt catalyst, providing a mixture of cyclohexanone, cyclohexanol, and cyclohexyl hydroperoxide as approximately 70–90% of the product at <6% conversion.50 Table 2 provides an overview of the reported oxidations of alkanes using copper catalysts, organized by substrate.

Table 2.

Alkane oxidation with copper catalysts.

| product distribution (%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| entry | substrate | radical initator | catalysta | conditions | conv (%) | ketone | alcohol | ref |

| 1 | Cyclohexane | none | CuSO4·5H2O on functionalized silica | Zn0, AcOH, 1 atm O2, 24 h, rt | 0.6 | 90 | 10 | 60 |

| 2 | none | Cu0 on functionalized silica | Zn0, AcOH, 1 atm O2, 24 h, rt | 1.3 | 85 | 15 | 60 | |

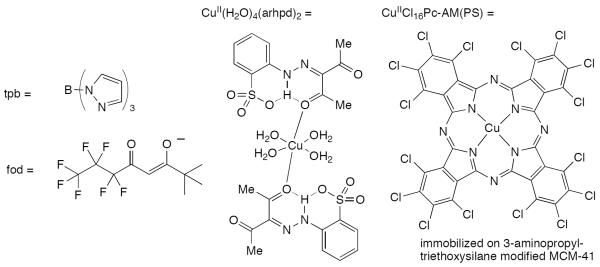

| 3 | none | Cu nanoparticles on TiO2 | 20 atm O2, 120 °C, 24 h | 11.5 | 92 | 8 | 55 | |

| 4 | none | Cu nanoparticles on γ-Al2O3 | 20 atm O2, 120 °C, 24 h | 13.7 | 58 | 42 | 55 | |

| 5 | none | Cu nanoparticles on Fe2O3 | 20 atm O2, 120 °C, 24 h | 14.2 | 34 | 66 | 55 | |

| 6 | none | 1:2 CuCl2:1,10-phenanthroline | 2 equiv K2CO3, MeCN, air, rt, 72 h | 24.4 | 100 | 0 | 58 | |

| 7 | aldehyde | CuCl2, 18-crown-6 | 1 equiv MeCHO, 1 atm O2, CH2Cl2, 70 °C, 24 h | 4.1 | 76 | 24 | 34a | |

| 8 | aldehyde | Cu(OH)2 | 3 equiv MeCHO, 1 atm O2, CH2Cl2, rt, 17 h | 4.5 | 58 | 38 | 53 | |

| 9 | aldehyde | CuIICl16Pc-AM(PS) | 3 equiv PhCHO, MeCN, 1 atm O2, 50 °C | 9.4 | 68 | 32 | 61 | |

| 10 | peroxide | CuI(pyr)(tpb) | 1 mol% TBHP, 1 atm O2, 1:2 AcOH:pyr, rt, 24 h | ~1 | 87 | 13 | 35 | |

| 11 | peroxide | Cu(en)2(NO3)2 | 11 mol% TBHP, 25 bar O2, 70 °C, 24 h | 4.9 | 26 | 43b | 52 | |

| 12 | peroxide | Cu(OPiv)2 | 11 mol% TBHP, 25 bar O2, 70 °C, 24 h | 5.0 | 28 | 38c | 52 | |

| 13 | peroxide | CuII(H2O)4(arhpd)2 | 10 equiv H2O2, HNO3, MeCN/H2O, air, rt 6 h | 19.8 | 10.9 | 8.9d | 62 | |

| 14 | halogen lamp irradiation | CuCl2·2H2O | 1 atm O2, 13 °C, MeCN, 18 h | 58 | 22 | 24 | 57c | |

| 15 | Cycloheptane | peroxide | Cu@SiCN | 2 mol% TBHP, 20 bar air, 80 °C, 75 h | 6.0 | 68 | 25 | 54 |

| 16 | Cyclooctane | aldehyde | CuCl2, 18-crown-6 | 1 atm O2, MeCHO, CH2Cl2, 70 °C, 24 h | 4.6 | 80 | 20 | 34a |

| 17 | aldehyde | Cu(OH)2 | 3 equiv MeCHO, 1 atm O2, CH2Cl2, rt, 17 h, | 9.9 | 88 | 9 | 53 | |

| 18 | peroxide | Cu(fod)2 | 18 mol% TBHP, 60 °C, 24 h, air | 6.0 | 38 | 14e | 51 | |

| 19 | peroxide | Cu(fod)2 | 18 mol% TBHP, 60 °C, 24 h, Ar | 11.3 | <2 | <1e | 51 | |

| 20 | peroxide | Cu(fod)2 | 18 mol% TBHP, 60 °C, 24 h, O2 | 13.4 | 77 | 19e | 51 | |

| 21 | peroxide | Cu@SiCN | 2 mol% TBHP, 20 bar air, 80 °C, 75 h | 13.9 | 73 | 16 | 54 | |

| 22 | Cyclodecane | peroxide | Cu@SiCN | 2 mol% TBHP, 20 bar air, 80 °C, 75 h | 16.0 | 74 | 19 | 54 |

| 23 | Adamantane | aldehyde | Cu(OH)2 | 3 equiv MeCHO, 1 atm O2, CH2Cl2, rt, 17 h | 29 | 3 | 92f | 53 |

| 24 | peroxide | [CuI(pyr)(tpb)] | 10 mol% TBHP, 1 atm O2, 1:2 AcOH:pyr, rt, 24 h | ~2.5 | 26 | 74g | 35 | |

| 25 | n-Hexane | aldehyde | CuCl2, 18-crown-6 | 1 atm O2, MeCHO, CH2Cl2, 70 °C, 24 h | 2.4 | 91h | 9 | 34a |

| 26 | n-Decane | aldehyde | CuIICl16Pc-AM(PS) | 3 equiv PhCHO, MeCN, 1 atm O2, 50 °C | 15.4 | 100i | 61 | |

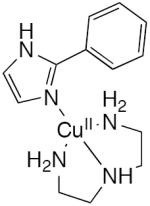

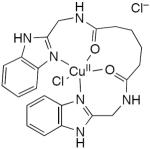

See Chart 2 for ligand structures.

Also 28% cyclohexene.

Also 26% cyclohexene.

Mixture of alcohol and hydroperoxide.

Remainder of product is cyclohexene.

Approximately 93:7 of 1-adamantol:2-adamantol.

Approximately 98:2 of 1-adamantol:2-adamantol.

Afforded oxidation products in an approximately 1:1 ratio at the 2- and 3-positions.

Mixture of decanones.

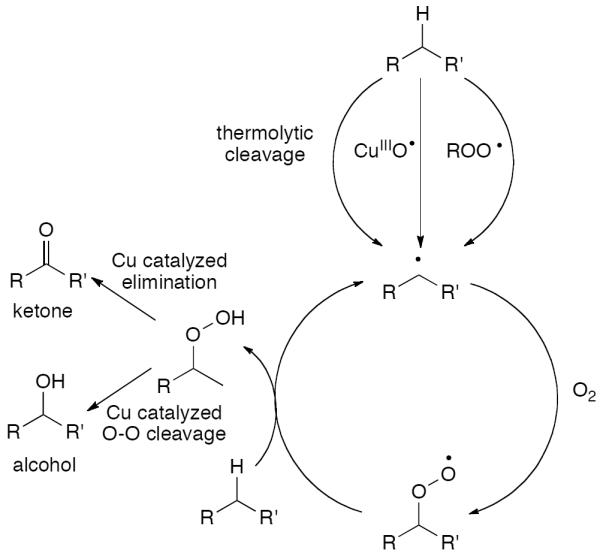

The mechanism for copper-catalyzed oxidation of alkanes (Scheme 16) is similar to that proposed for benzylic substrates (see Section II.A.2). Initial hydrogen abstraction can occur by a thermolytic process, although a peroxide initiator (often in the form of an aldehyde precursor) is more common. The resulting alkyl radical can react with molecular oxygen to form a peroxy radical and enter the propagation cycle. The hydroperoxide can undergo copper-catalyzed elimination or O–O bond scission to form the ketone or alcohol products, respectively.

Scheme 16.

General mechanism for alkane oxidation.

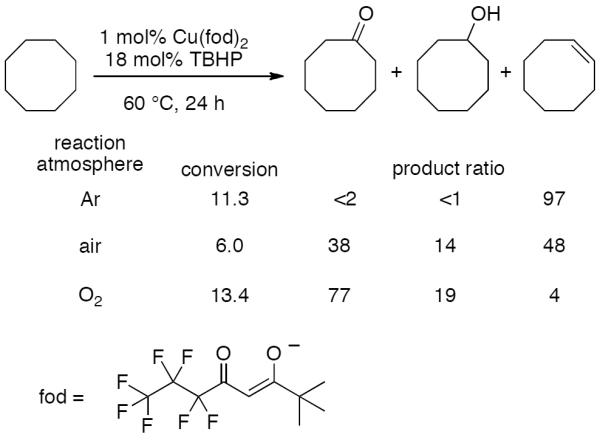

A series of investigations in hydrocarbon functionalization led by Sir Derek Barton involved the use of copper catalyst in the oxidation of alkanes.51 The oxidation of cycloctane with TBHP and homogeneous Cu(fod)2 (fod = 2,2-dimethyl-6,6,7,7,8,8,8-heptafluoro-3,5-octanedionate) under an oxygen atmosphere afforded the ketone in moderate selectivity along with the alcohol and elimination product in low conversions at 60 °C (Scheme 17). Performing the reaction under air or argon drastically changed the product distribution, with the latter nearly exclusively affording the alkene.

Scheme 17.

Oxidation of cyclooctane under various atmospheres.

A later report by Schuchardt and coworkers details the oxidation of cyclohexane with the use of Fe(III) or Cu(II) catalysts and peroxide initiator under pressurized O2 and heat.52 The iron catalysts were found to generate significant quantities of overoxidized adipic acid product, which deactivated the catalyst. Copper provided less overoxidized product, but produced an unselective mixture of ketone, alcohol, alkene, in addition to minor amounts of adipic acid, glutaric acid, cyclohexenol, and cyclohexenone, illustrating the difficulty in controlling these reaction systems (Table 2, entries 11–12). In 1993, Murahashi and coworkers reported the simple oxidation of hydrocarbons using Cu(OH)2 and several equivalents of acetaldehyde as a peroxide precursor.53 At room temperature and 1 atm O2, low conversion to mixtures of ketone and alcohol was observed for cyclohexane, cyclooctane, and adamantane (Table 2, entries 8,17,23). Interestingly, the addition of 18-crown-6 to this copper(II) system was later found to provide much higher activity, allowing extremely high TONs, albeit with still low conversion (Scheme 18).34 The crown ether ostensibly functions via coordination to the copper catalyst, stabilizing an oxo-copper species responsible for initial hydrogen abstraction from the alkane. These assertions are strengthened by the isolation and X-Ray analysis of the crown ether-CuCl2 complex.

Scheme 18.

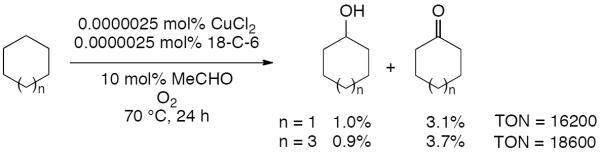

Copper-crown ether catalyzed oxygenation of alkanes.

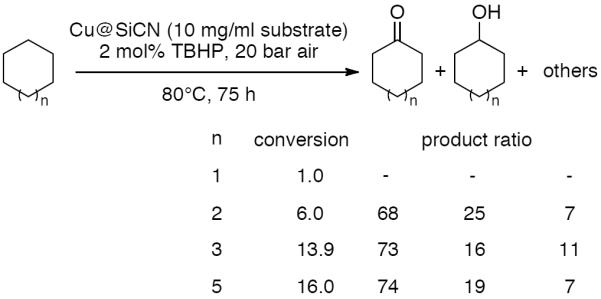

Several studies incorporating copper-modified solid supports for heterogeneous oxidation of alkanes have also been reported. For example, Kempe and coworkers recently reported the reaction of cycloalkanes under air with copper-modified SiCN ceramics (Cu@SiCN).54 Oxidation afforded the ketone as the major product, and larger cycloalkanes afforded greater conversions, with cyclohexane affording almost no conversion at all (Scheme 19). The catalysts were formed through the cross-linking of cupper-coordinated poly(oraganosilazanes), and were able to be recycled with only a small loss of activity.

Scheme 19.

Oxidation of cycloalkanes with copper-modified ceramic.

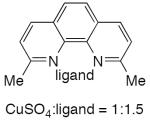

While the use of a peroxide or peroxide precursor is most common, thermolytic initiation can also occur under more forcing conditions. Copper nanoparticle-doped solid supports were tested for the catalytic oxidation of cyclohexane in the absence of a radical initiator.55 At 20 atm O2 and 120 °C, low conversions (~11–14%) were observed and titanium dioxide was the most selective support, though alumina demonstrated opposite selectivity toward the alcohol (Table 2, entries 3–5). Immobilized copper(II) catalysts on a fiberglass solid support have been studied in cyclohexane oxidation using hydrogen peroxide and molecular oxygen, although selectivities and yields were not reported.56 Interestingly, a series of studies have demonstrated that irradiation with visible light aids initiation in the oxidation of a variety of simple hydrocarbons using copper and oxygen.57 In one report employing CuCl2 as the catalyst, moderate conversion was achieved at comparatively mild conditions (1 atm O2 and 13 °C), yet poor selectivity between the alcohol and ketone products remains an issue, as well as formation of other side products, including alkyl chloride (Table 2, entry 14). In an isolated case, the system of CuCl2, 1-10-phenanthroline, and 2 equivalents of potassium carbonate was reported to oxidize cylohexane to cyclohexanone with 100% selectivity at rt under air (Table 2, entry 6).58 The ratio of phenanthroline ligand to copper was found to be critical to both conversion and selectivity. Though the role of the base is not clear, it is speculated to aid in the initial hydrogen abstraction to allow such facile oxidation. The importance of base in alcohol oxidation, and particularly potassium carbonate, has been reported.59

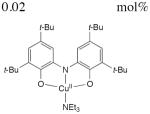

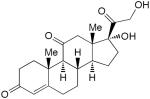

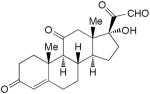

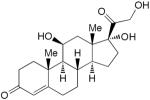

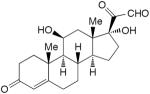

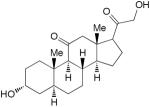

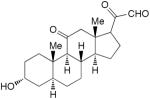

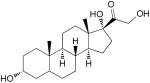

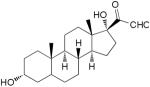

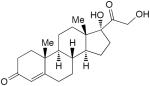

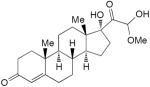

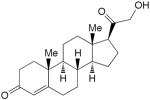

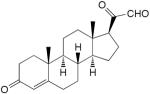

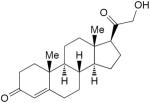

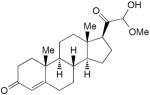

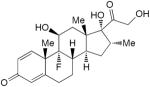

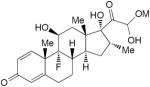

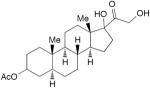

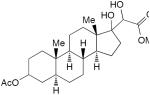

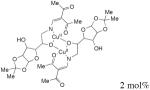

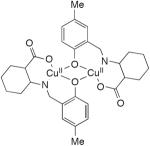

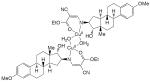

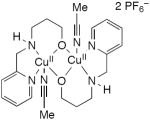

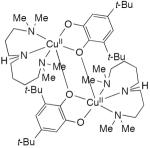

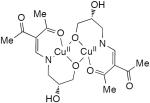

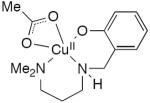

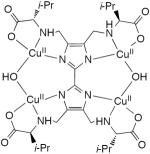

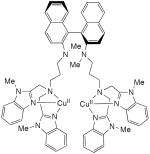

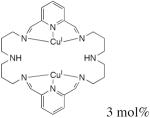

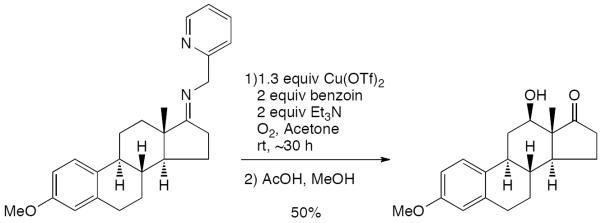

As demonstrated above, studies on alkane oxygenation are largely restricted to simple and symmetric hydrocarbons due to the lack of selectivity afforded by present systems. Schönecker and coworkers have, in contrast, demonstrated a highly selective hydroxylation of steroidal motifs using a copper and molecular oxygen.63 In this system, an 2-iminopyridyl moiety is effectively used as a directing group, forming a bidentate copper(II) complex. After reduction to copper(I) by benzoin and triethylamine, the complex reacts with molecular oxygen to ultimately afford the β-hydroxylated product after decomplexation and hydrolysis of the directing group.

Working with very simple substrates, a biomimetic oxidation employing a highly active bis(μ-oxo) dicopper species on a zeolite support was found to be effective by Groothaert and coworkers.64 While the process was not catalytic, methane was selectively oxidized to methanol at 398 K and ethane was oxidized to a 4:1 mixture of ethanol:acetaldehyde in just 2 minutes at ambient temperature. The above two examples, while requiring stoichiometric copper species, demonstrate the potential power of mild, selective alkane C–H oxygenation. Development of catalytic variants possessing similar control and reactivity would represent a significant advance in the field.

II.C. Alkene Oxidation

II.C.1. Allylic Oxidation

As was the case for propargylic systems (see preceding section), aerobic oxygenation of allylic systems is complicated by the potential for the unsaturated portion (i.e., the alkene) to also react. Many catalysts and oxidants have been examined to achieve this transformation,65 which has broad utility both in the production of commodity chemicals and in the synthesis of pharmaceuticals and natural products. The use of oxygen as the oxidant in this transformation is still difficult although some examples have been documented.

Typical allylic oxidations using copper and oxygen occur through either thermolytic or peroxide initiated hydrogen abstraction at the allylic position, generally under milder conditions than those for the corresponding alkyl or benzylic substrates (see Sections II.A and II.B). As for the oxidations in the preceding sections, selective formation of the potential oxygenation products (alcohol, carbonyl, peroxide) remains challenging although copper catalysts have been identified that give good conversion and high levels of selectivity.

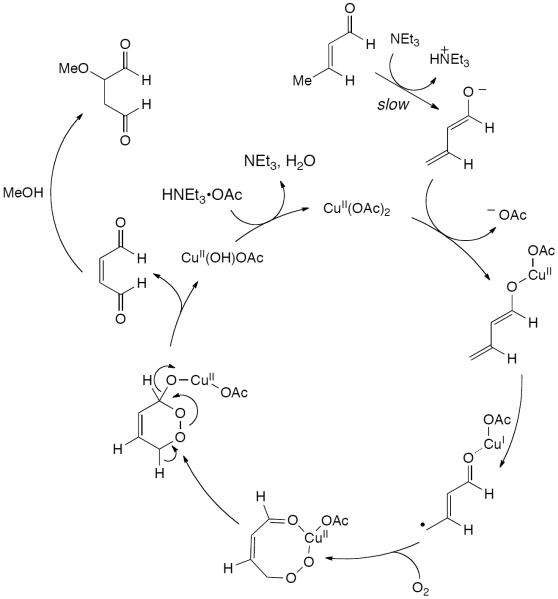

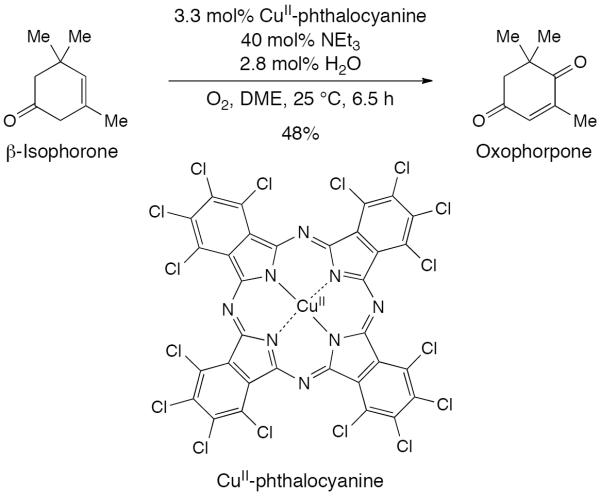

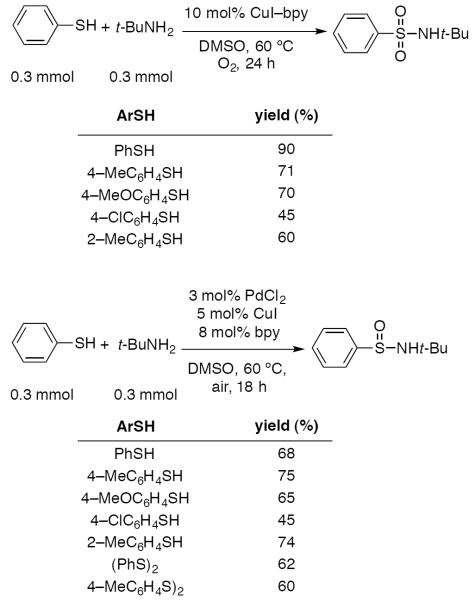

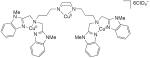

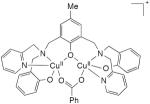

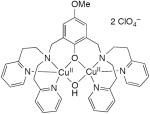

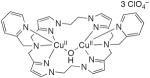

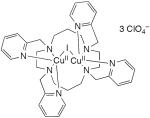

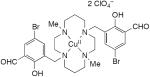

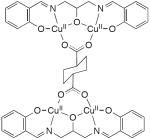

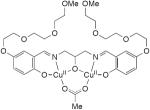

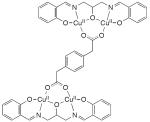

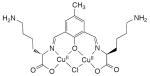

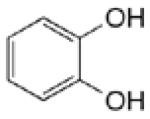

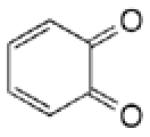

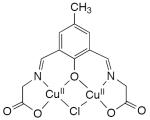

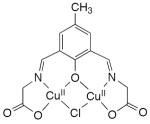

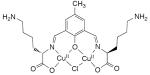

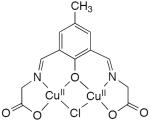

A key substrate for allylic oxidation is propylene, which is employed in the current process for acrolein production using various multicomponent mixed metal catalysts.66 Studies of copper oxides in a flow reactor for this transformation indicate competing combustion, particularly when the catalyst was oxidized before use.67,68 Even without pre-oxidation, a ratio of ~52:44 acrolein:CO2 was observed, with small amounts of acetaldehyde and propionaldehyde also detected.68 A copper phthalocyanine catalyst on a silica matrix at low loading (<0.1 wt %) has been reported to catalyze the conversion of propene and oxygen to acrolein at 475–500 °C with approximately 50% selectivity and 10% yield.69 A more highly studied substrate is cyclohexene, the oxidation products of which are precursors to many commodity chemicals. Table 3 contains a summary of this transformation with copper catalysts using oxygen.

Table 3.

Allylic oxidation of cyclohexene.

| product distribution (%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| entry | radical initator | Catalysta | conditions | conv (%) | ketone | alcohol | epoxide | ref |

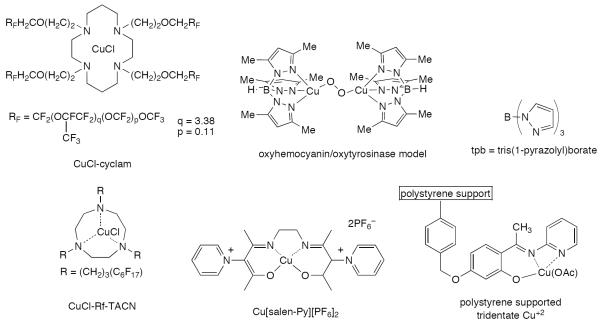

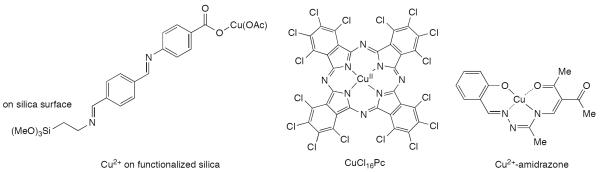

| 1 | peroxide | CuCl-cyclam | 1 mol% TBHP, 1 atm O2, rt, 8 h perfluorohexane | 6 | 75 | 25 | 0 | 70 |

| 2 | peroxide | CuCl-Rf-TACN | 1 mol% TBHP, 1 atm O2, rt, 24 h, perfluoroheptane | 5 | 78 | 22 | 0 | 71 |

| 3 | peroxide | Cu+2 on SBA 15 | 1 equiv H2O2, 1 atm O2, 60 °C, 27 h, MeCN | 84 | 48 | 46 | 1b | 72 |

| 4 | peroxide | CuI(pyr)(tpb) | 1 mol% TBHP, 1 atm O2, 1:2 AcOH:pyr, rt, 24 h | 26 | 91 | 19 | 0 | 35 |

| 5 | peroxide | Cu-polyphthalocyanine | 1 mol% cumyl peroxide, pyridine | – c | 73 | |||

| 6 | none | oxyhemocyanin/oxytyrosinase model | 1 atm O2, CHCl3, rt, 2 h | 6 | 48 | 50 | 2 | 74 |

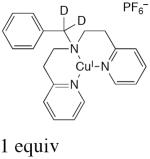

| 7 | none | Cu[salen-Py][PF6] | 1 atm O2, 78 °C, 22 h, MeCN | 100 | 63 | 31 | 5d | 75 |

| 8 | none | polystyrene supported tridentate Cu+2 | 1 atm O2, 70 °C, 10 h | 52 | 41 | 33 | 2e | 76 |

| 9 | none | CuMOF [Cu(bpy)(H2O)2(BF4)2(bpy)] | 1 atm O2, neat, 45 °C, 15 h | 8 | 7 | 4 | 2f | 77 |

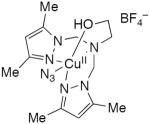

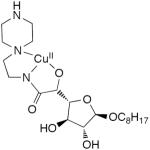

See Chart 3 for ligand structures.

5% diol observed.

Exact conversion and distribution not reported. At lower temperatures, hydroperoxide is the major product, with alcohol and ketone principally forming as the temperature is increased. The alcohol entry typically represents the sum of peroxide and alcohol products generation in the reaction.

~95% allylic selectivity.

24% peroxide observed.

87% peroxide observed.

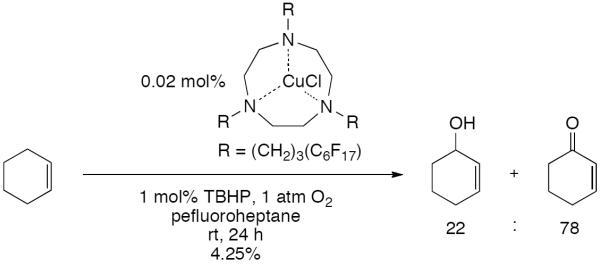

A report by Quici and coworkers explored the fluorous biphasic oxidation of hydrocarbons using a copper catalyst prepared by N-perfluoroalkylation of the commercially available 1,4,8,11-tetraazacyclotetradecane (Table 3, entry 1).70 In this reaction, the metal catalyst is soluble in perfluorohexane solvent, while the cyclohexene substrate and oxygenated products are immiscible, allowing convenient recycling of the catalytic system. Use of 1 mol % TBHP as an initiator provided a 3:1 mixture of cyclohexenone to cyclohexenol in 6% conversion at ambient temperature (Scheme 21). Notably, no competitive reactivity of the alkene was observed. Under the same conditions, cyclooctane provided less than 1% conversion, demonstrating the higher reactivity of allylic C–H bonds. Further work by Fish and coworkers identified a fluorous-phase copper catalyst able to be recovered and recycled in the oxidation of cyclohexenone (Table 3, entry 2).71

Scheme 21.

Allylic alkene oxidation with a tetraazacyclotetradecane copper catalyst.

Copper-salen complexes attached to various mesoporous or amorphous silica supports have been tested in the oxidation of cyclohexene (Table 3, entry 3).72 These catalysts provided high conversions at 60 °C with a peroxide initiator and oxygen atmosphere. However, the alcohol and ketone products were produced in a nearly 1:1 ratio for all copper catalysts tested. Interestingly, high allylic selectivity was achieved even using stoichiometric H2O2 initiator.

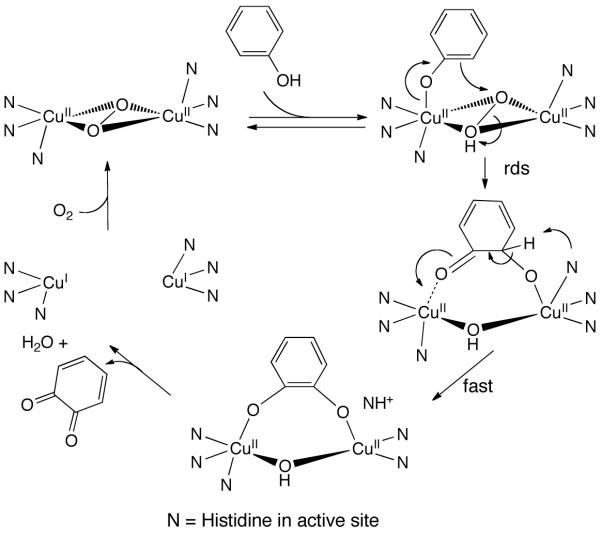

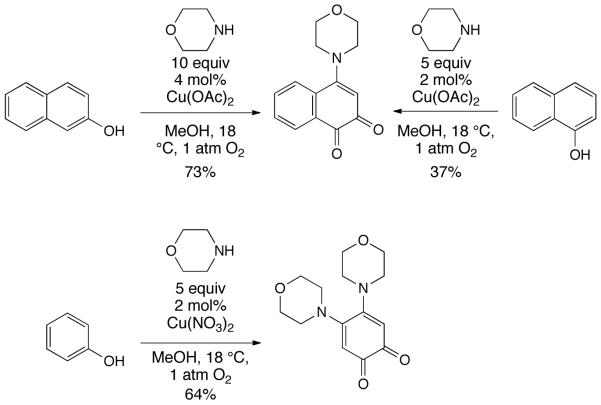

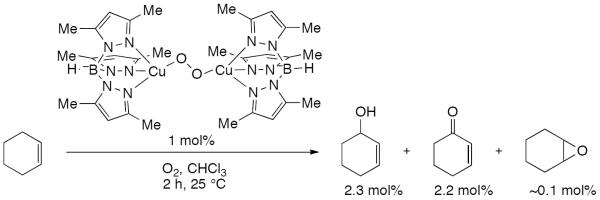

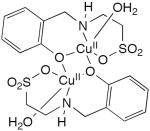

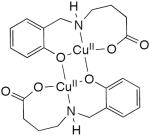

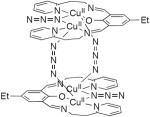

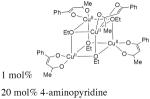

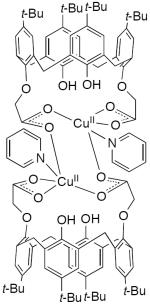

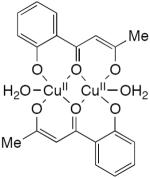

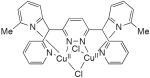

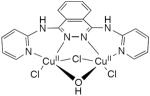

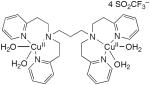

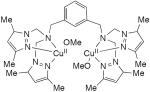

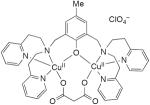

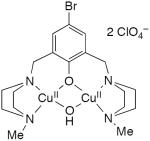

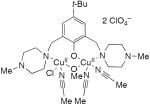

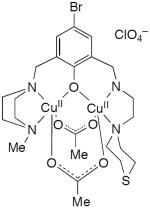

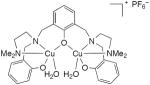

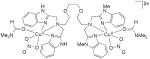

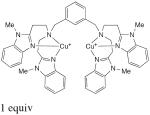

An example of an oxyhemocyanin/oxytyrosinase model compound capable of selective allylic oxidation of cyclohexene is outlined in Scheme 22 (Table 3, entry 6).74 The significance of the ligand sphere is particularly evident here in comparison to other copper systems that result in epoxidation of alkenes (see Section II.C.2). Labeling experiments confirmed exogenous oxygen as the source of oxygen atoms in the product rather than from the catalyst peroxo ligand.

Scheme 22.

Allylic alkene oxidation with an oxyhemocyanin/oxytyrosinase model compound.

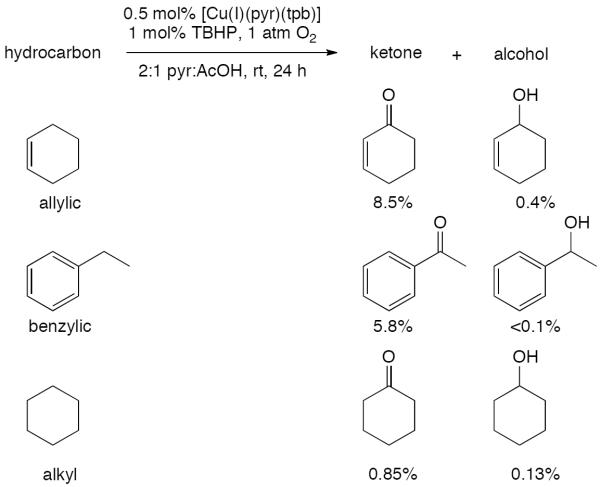

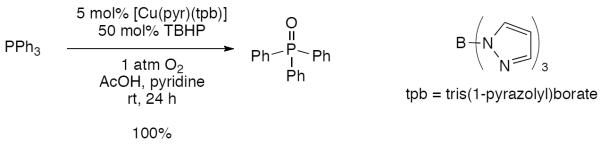

The oxidation of a series of hydrocarbon has been tested using a tris(pyrazolyl)borate-copper complex employing catalytic TBHP and an oxygen atmosphere.35 The results of these studies provide a useful comparison of the reactivity and selectivity of representative secondary alkyl, benzylic and allylic substrates under identical conditions (Scheme 23). In each case, ketone is the predominant product, with smaller amounts of alcohol also forming. Notably, no competitive alkene reactivity (epoxide formation) was reported for cyclohexene, and very high ketone selectivity was observed for ethylbenzene. The conversions are expectedly dissimilar, with a general reactivity trend of allylic>benzylic>>alkyl observed. The particular reticence of the unactivated alkyl C–H bond toward oxidation is clearly observed.

Scheme 23.

Comparative oxidation of secondary hydrocarbons.

While the above studies are pertinent with regard to industrial processes, poor selectivity found in current methods precludes allylic oxidation in the routine functionalization of complex alkenes. Nonetheless, allylic oxidation is a powerful synthetic transformation, and a copper catalytic system using oxygen under milder conditions would possess many advantages over reported reagents and catalysts, which rely on toxic metals or costly oxidants.78

II.C.2. Epoxidation of Alkenes

Catalytic oxidations of alkenes with molecular oxygen under mild conditions is a significant goal. Though copper containing oxygenase enzymes can effect successful epoxidation,24a,79 small molecule copper catalysts have been much less explored in the context of epoxidation (Table 4) due to the potential to undergo competing allylic oxidation (Section II.C.1).

Table 4.

Copper-catalyzed epoxidation of alkenes.

| entry | substrate | catalysta | conditions | conv (%) | epoxide selectivity (%) | ref |

|---|---|---|---|---|---|---|

| 1 | Propylene | Cu nanoparticles on SiO2 | 1 atm O2, 225 °C | 0.25 | 53 | 80 |

| 2 | Propylene | CuNO3 on KOAc modified SBA-15 | 1 atm O2, 225 °C | 0.4 | 59 | 81 |

| 3 | Propylene | K+-CuOx-SiO2 | 1 atm O2, 250 °C | 2.3 | <33 | 82 |

| 4 | Cyclohexene | Cu(OH)2 | 3 equiv CyCHO, 1 atm O2, CH2Cl2, rt, 17 h | 100 | 79a | 34b |

| 5 | Cyclohexene | Cu2+ on functionalized silica | 3.4 equiv i-PrCHO, 1 atm O2, rt, 6 h | 80 | 99 | 83 |

| 6 | Cyclohexene | CuCl16Pc on modified MCM-41 | 3 equiv i-PrCHO, 1 atm O2, MeCN, 40 °C, 8 h | 80 | 96 | 84 |

| 7 | 1-Decene | Cu(OH)2 | 3 equiv CyCHO, 1 atm O2, CH2Cl2, rt, 17 h | 32 | 84b | 34b |

| 8 | 1-Decene | CuCl16Pc on modified MCM-41 | 3 equiv i-PrCHO, 1 atm O2, MeCN, 40 °C, 8 h | 44 | 92 | 84 |

| 9 | trans-5-Decene | Cu(OH)2 | 3 equiv CyCHO, 1 atm O2, CH2Cl2, rt, 17 h | 83 | 96b | 34b |

| 10 | cis-5-Decene | Cu(OH)2 | 3 equiv CyCHO, 1 atm O2, CH2Cl2, rt, 17 h | 96 | 85b | 34b |

| 11 | Styrene | CuCl16Pc on modified MCM-41 | 3 equiv i-PrCHO, 1 atm O2, MeCN, 40 °C, 8 h | 100 | 74 | 84 |

| 12 | trans-Stilbene | Cu(OH)2 | 3 equiv CyCHO, 1 atm O2, CH2Cl2, rt, 17 h | 93 | 82b | 34b |

| 13 | cis-Stilbene | Cu(OH)2 | 3 equiv CyCHO, 1 atm O2, CH2Cl2, rt, 17 h | 81 | 79b | 34b |

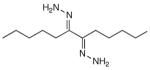

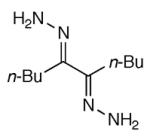

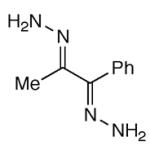

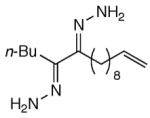

| 14 | Norbornene | Cu-amidrazone | 1 atm O2, THF, 70 °C, 24 h | 83 | 100 (exo) | 85 |

| 15 | α-Pinene | Cu(OH)2 | 3 equiv CyCHO, 1 atm O2, CH2Cl2, rt, 17 h | 100 | 83b | 34b |

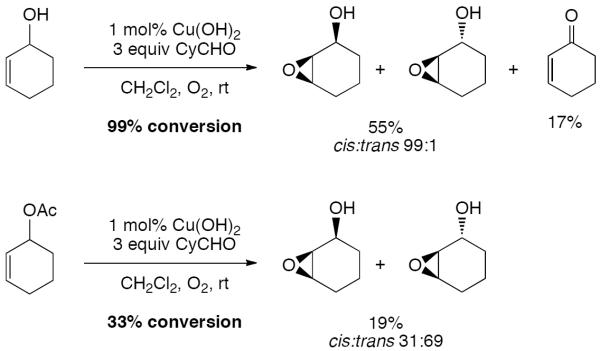

| 16 | Cyclohex-2-enol | Cu(OH)2 | 3 equiv CyCHO, 1 atm O2, CH2Cl2, rt | 99 | 55b | 34b |

| 17 | Cyclohex-2-en-1-yl acetate | Cu(OH)2 | 3 equiv CyCHO, 1 atm O2, CH2Cl2, rt | 33 | 58b | 34b |

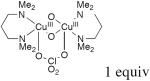

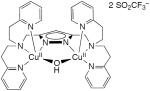

See Chart 4 for ligand structures.

Based on GLC yield of epoxide.

Propylene oxide is an important synthetic intermediate in the chemical industry. Currently, methods for production of propylene oxide face environmental issues due to the nature of the catalyst and oxidants or due to poor selectivity, which requires separations that generate many byproducts. The catalytic epoxidation of propylene by a “green” oxidant such as molecular oxygen would be highly desirable. Some success has been seen with copper catalysts on solid supports80–82 that display stable behavior when using O2 as the oxidant; however, a large proportion of the substrate is still converted to other byproducts (Table 4, entries 1–3). Unlike most conditions for alkene epoxidation (see below), the absence of cooxidant additives implicates copper oxygen intermediates as the reactive species. An incomplete understanding of these species has limited development of improved catalysts.

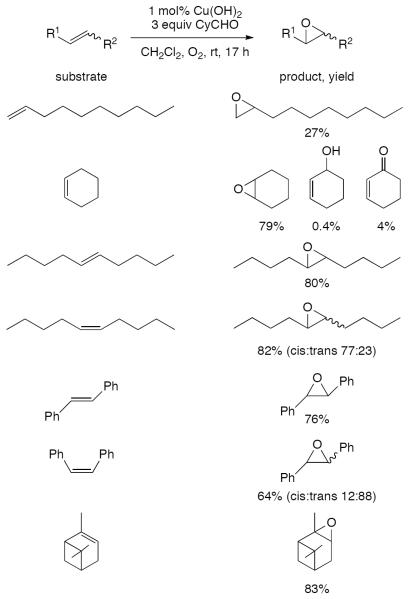

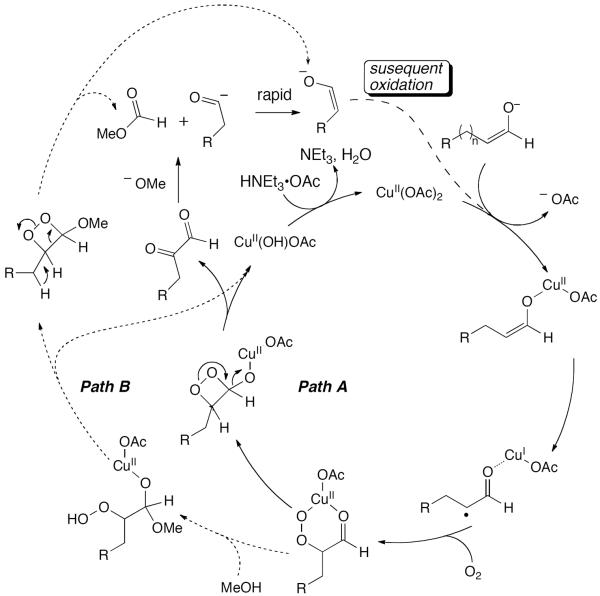

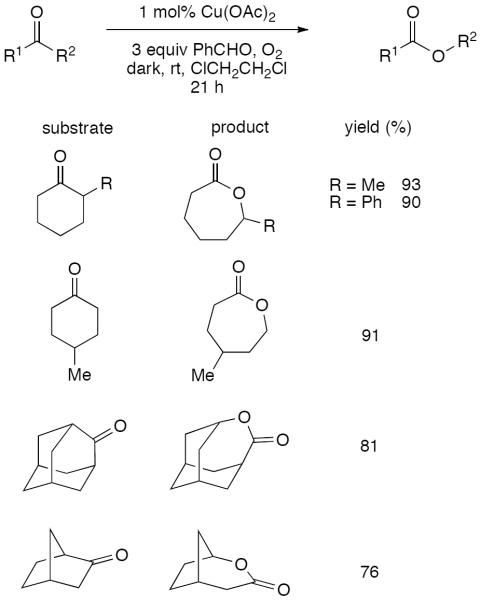

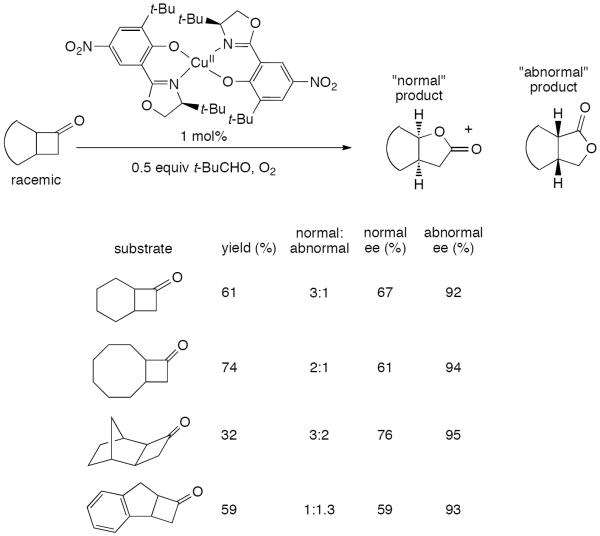

An example demonstrating the potential of copper with higher alkene homologues is outlined in Scheme 24. 34b,53 Using an aldehyde cooxidant, the process works well for di- and trisubstituted alkenes producing very little of the allylic C-H insertion products.

Scheme 24.

Epoxidation of alkenes with a copper catalyst.

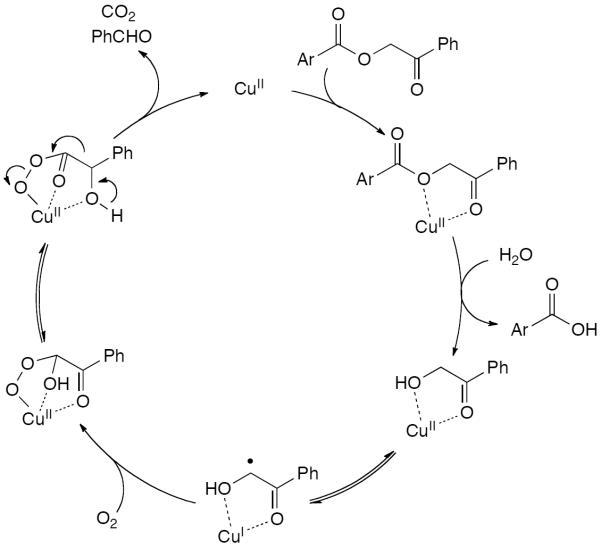

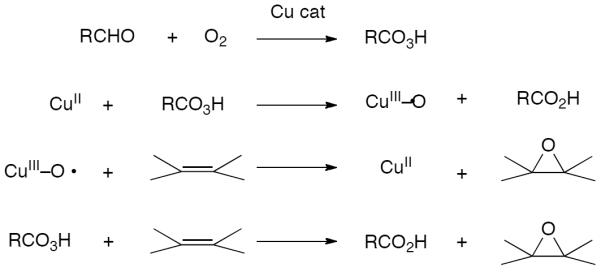

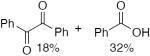

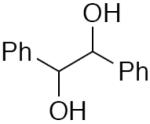

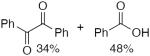

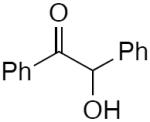

With copper and oxygen, the aldehyde cooxidant is believed to form peroxy acids. The epoxidation mechanism appears to involve both peroxy acids and radical species (Scheme 25). The latter is consistent with the formation of mixtures of epoxide diastereomers when utilizing cis alkenes as subststrates (Scheme 24). The high ratio of hydroxyl directed cis-epoxidation seen with the copper catalyst, however, is very similar to that observed with MCPBA (meta-chloroperoxybenzoic acid) supporting the intervention of a peroxy acid (Scheme 26). The acetate protected version give predominantly the trans-epoxide, again similar to MCPBA (Scheme 26). Both peroxy acids and radical species appear to form under the reaction conditions, with the former accounting for product formation except when the substrates can stabilize radical intermediates (i.e. the stilbenes, Scheme 24).

Scheme 25.

Mechanism of epoxidation of alkenes with a copper catalyst.

Scheme 26.

Substrate directed copper catalyzed epoxidation.

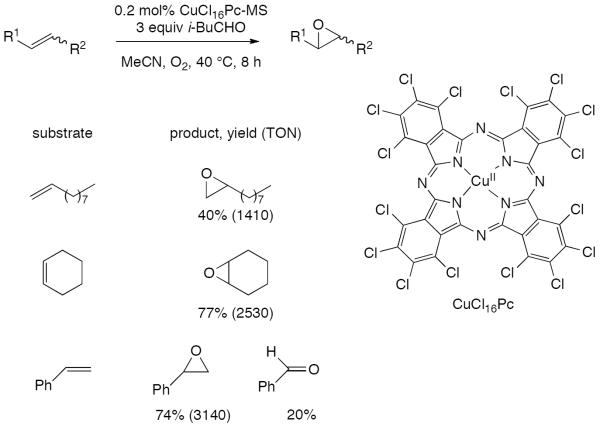

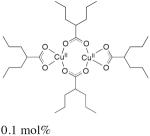

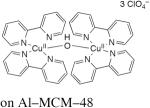

Other sources of copper have been investigated in similar epoxidations of styrene, cylcohexene, and decene utilizing air/O2 and an aldehyde with limited success.86 The most promising system at this time is comprised of a copper perchlorophthalocyanine (CuCl16Pc) complex, the activity of which is greatly improved by placement in the channels of HSi-MCM-41 molecular sieves (Scheme 27).84 Notably, this system gave superior results with molecular oxygen vs TBHP (tert-butylhydroperoxide) as the oxidant. The electron-withdrawing effect of the chloro substituents on the phthalocyanine stabilizes the reduction of the copper species thereby facilitating oxidation of the substrates. The hydrophobic nature of the cavities containing the copper catalyst in the HSi-MCM-41 molecular sieves further facilitates the oxidation reaction.

Scheme 27.

Copper perchlorophthalocyanine catalyzed epoxidation.

A key drawback to the above reaction formulation is the presence of radical generating species similar to those employed in allylic C-H functionalization (see Section II.C.1 above). These species are responsible for the allylic alcohol and allylic ketone byproducts. In an elegant series of studies, Lambert and coworkers demonstrated that a copper surface preoxidized with molecular oxygen provided the epoxides in high selectivity with several substrates including butadiene, styrene, and even β-methyl styrene.87 These studies show that the high selectivities in copper catalyzed alkene epoxidation with oxygen are possible if alternate radical reaction pathways can be suppressed.

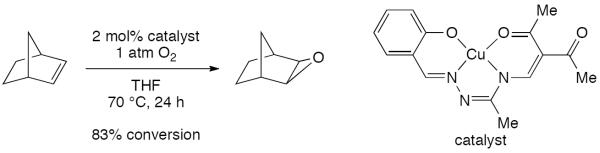

Apart from flow reactor experiments with propylene, copper catalyzed epoxidations typically utilize stoichiometric aldehyde as a peracid precursor. In an interesting departure from this pattern, the epoxidation of norbornene with a copper amidrazone catalyst and oxygen has been reported in the absence of aldehyde or peroxide (Scheme 28).85 Complete selectivity to the exo product is reported in high conversion as detected by GC. Due to the bicyclic structure, the corresponding allylic radical cannot undergo resonance stabilization; as a consequence, allylic oxidation is not competitive. Hypothetically, the higher temperatures in this reaction might allow formation of a copper-oxo species, which acts as the oxygenating source in the absence of typical peracid.

Scheme 28.

Epoxidation of norbornene in the absence of aldehyde or peroxide.

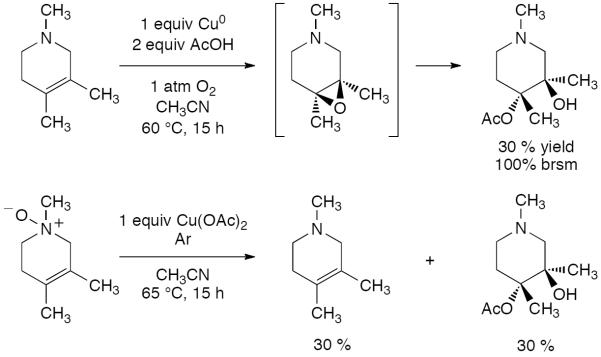

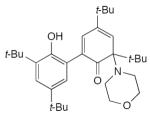

The investigation of epoxidation employing copper and oxygen has overwhelmingly focused on simple hydrocarbon substrates. However, a unique report by Capdevielle and coworkers describes the selective epoxidation of tetrahydropyridines with Cu0, oxygen, and acetic acid (Scheme 29).88 Under the reaction conditions, the epoxide is opened with acetic acid to form the α-hydroxyacetate products. The authors propose a copper(II) oxo as the active species. When the N-oxide of the substrate was prepared, the same product was obtained with stoichiometric Cu(II) under nitrogen. These conditions putatively gives rise the same active copper(II) oxo species. Although stoichiometric copper is required and conversions are low, the reaction is notable due to the high selectivity in the presence of another oxidizable functional group.

Scheme 29.

Selective epoxidation of tetrahydropyridines.

II.C.3. Oxidative Difunctionalization of Alkenes

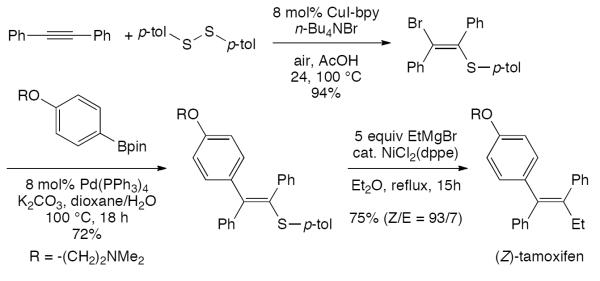

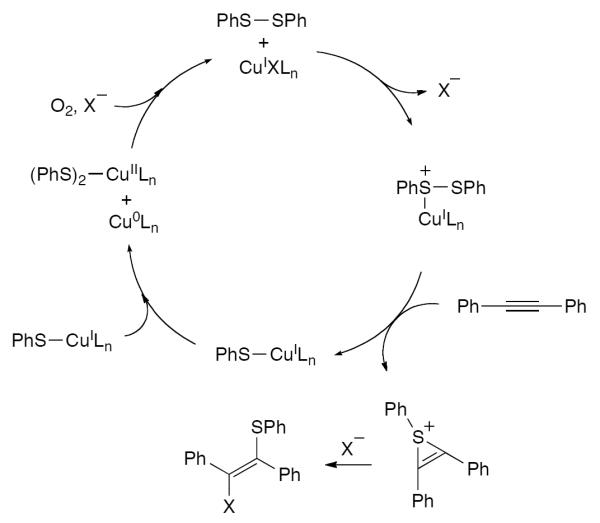

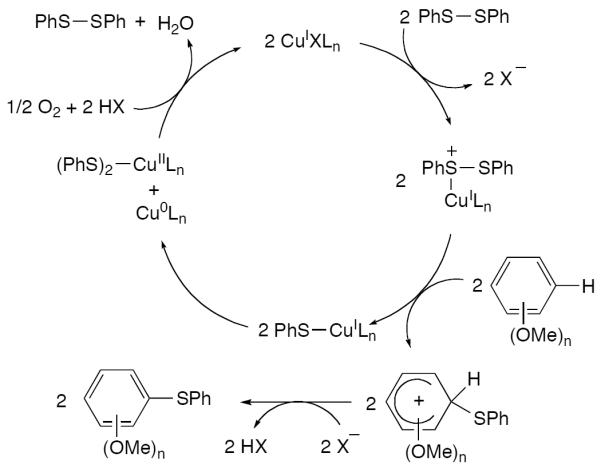

Oxidative difunctionalization has been more broadly applied to alkynes (see Section II.D.4), but several examples with can also be found with alkenes. These transformations typically commence with addition of a heteroatom-copper species across a double bond and subsequent oxidative displacement of the copper. Examples of initiating heteroatoms and pseudoheteroatoms include oxygen, nitrogen, sulfur, selenium, and cyanide. In select reactions, radical-mediated processes may also occur. Formation of polyperoxide polymers has also been shown, for example, by oxidation of styrene.89

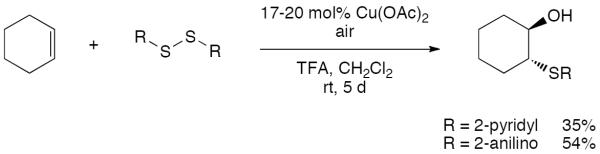

An early report by Owton and coworkers first detailed the catalytic hydroxysulfenylation of alkenes, a process that previously required stoichiometric lead(IV) salts.90 Simple alicyclic and aliphatic alkenes were found to react with disulfides in the presence of catalytic copper acetate under air to afford the corresponding 1,2-hydroxysulfides (Scheme 30). However, only arylsulfides containing a nitrogen coordinating group afforded product, and yields were poor to moderate. The proposed mechanism proceeds via copper chelation of the amine and adjacent sulfur, weakening the disulfide bond and accelerating nucleophilic attack by the alkene. The resulting cation is trapped by trifluoroacetate, which is subsequently cleaved to the free hydroxyl group under the reaction conditions (see below).

Scheme 30.

Hydroxysulfenylation of alkenes with disulfides containing proximal directing groups.

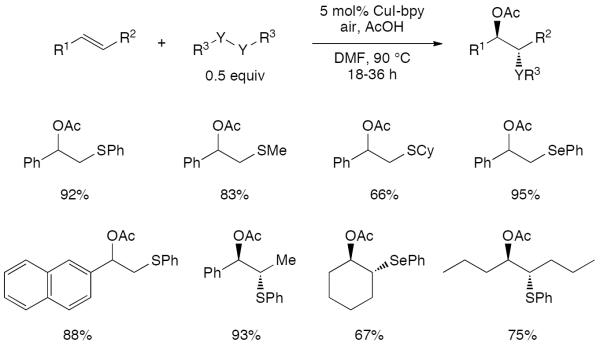

Later work by Taniguchi greatly expanded the utility of this process, discovering that a 2,2'-bipyridyl copper(I) iodide catalyst no longer required a coordinating group on the aryl disulfide (Scheme 31).91 This method afforded the anti-1,2-acetoxysulfenylated products in a good yield for a large substrate scope. In addition to disulfides, diselenides could also be used to good effect (for a similar reaction with alkynes see Section II.D.4).

Scheme 31.

Acetoxysulfenylation of alkenes.

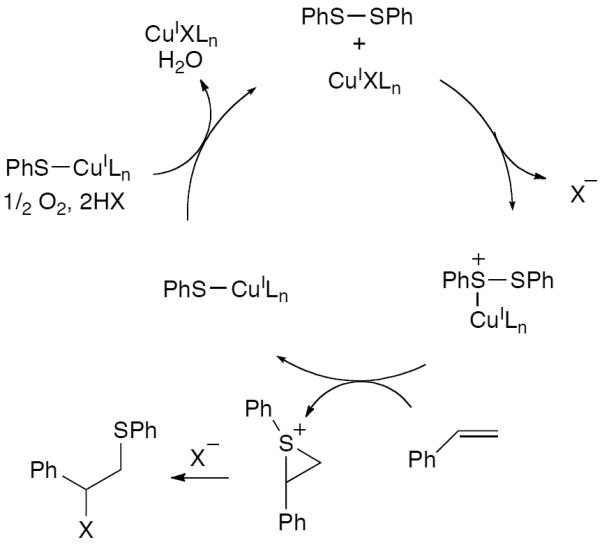

The mechanism for this reaction proceeds via initial copper coordination to the disulfide, facilitating nucleophilic attack by the alkene (Scheme 32). The resulting sulfonium ion is then trapped by acetic acid, releasing the acetoxysulfenylated product. Oxidation of the PhSCu(I) with oxygen regenerates the Cu(I)X catalyst and disulfide to close the catalytic cycle while also allowing both “halves” of the disulfide to react. Support for this mechanism is demonstrated by the finding that preformed PhSCu(I) converts to (PhS)2 in good yield under the acidic reaction conditions. When the reaction of styrene with (PhS)2 was attempted under a nitrogen atmosphere, only trace amount of product was observed.

Scheme 32.

Mechanism for the acetoxysulfenylation of alkenes.

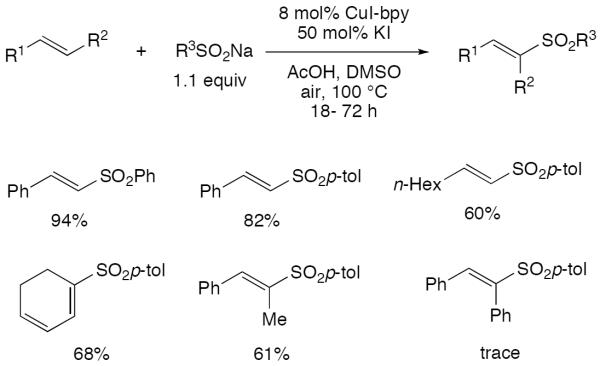

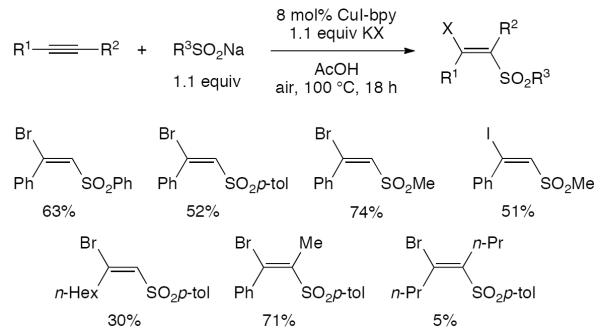

In a recent paper, Taniguchi has also reported the direct, catalytic preparation of alkenyl sulfones via oxidative coupling of alkenes and sulfinate salts (Scheme 33).92 Although high temperatures are required, a variety of alkyl and aryl alkenes reacted with bipyridyl copper(I) iodide under air with sulfinate salts to provide the alkenyl sulfones in good yield. Interestingly, when KI was omitted from the reaction, small but significant amounts of β-ketosulfone was detected. Both terminal and internal alkenes could be utilized, with only (E)-isomers forming regardless of initial alkene geometry. Although the reaction is reported to proceed via radical mechanism, alternative pathways, including halonium formation, may also be postulated. For similar reactions with alkynes, see Section II.D.4.

Scheme 33.

Oxidative sulfonylation of alkenes.

The reaction is reported to proceed via a radical mechanism in which the sulfinate salt is initially oxidized by a copper species. However, Ratnasamy93 and Stahl94 have reported the oxidation of bromide to bromine with copper and oxygen in the mechanism for oxidative oxybromination of arenes (see Section II.E.2). A similar oxidation here would lead to iodine and alternate mechanisms. Further study is needed to delineate the detailed steps of this process.

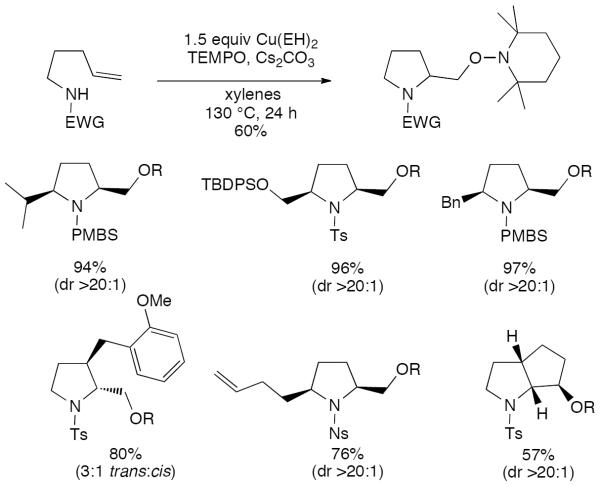

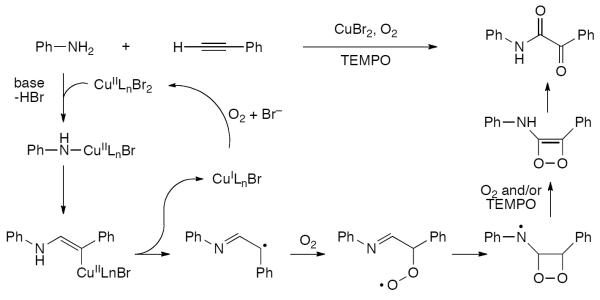

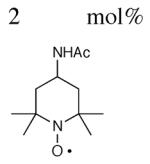

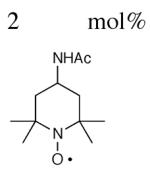

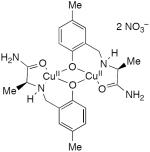

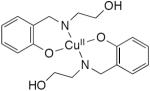

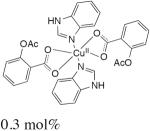

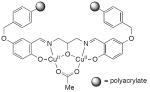

Alkenes can also react with nitrogen nucleophiles in aminofunctionalization reactions. A useful review of asymmetric aminofunctionalization of unactivated alkenes was reported in 2009.95 Chemler and coworkers described a diasteroselective synthesis of pyrrolidines via intramolecular copper-mediated aminooxygenation of alkenes.96 In this process, intramolecular aminocupration of the alkene is followed by oxidative trapping with TEMPO to afford the aminooxygenated products. Specifically, α-substituted 4-pentenyl sulfonamides with copper(II) ethylhexanonate [Cu(EH)2] yielded 2,5-cis-pyrrolidines in excellent diastereoselectivity (dr > 20:1) with excellent yields, while γ-substitution provided 2,3-trans-pyrrolidines in moderate diastereoselectivity (dr ~ 3:1) (Scheme 34). Further oxidation of the TEMPO moiety with m-CPBA can afford the pyrrolidyl aldehyde motif, as was demonstrated in a succinct formal synthesis of (+)-monomorine.

Scheme 34.

Aminoxygenation of alkenes with stoichiometric copper.

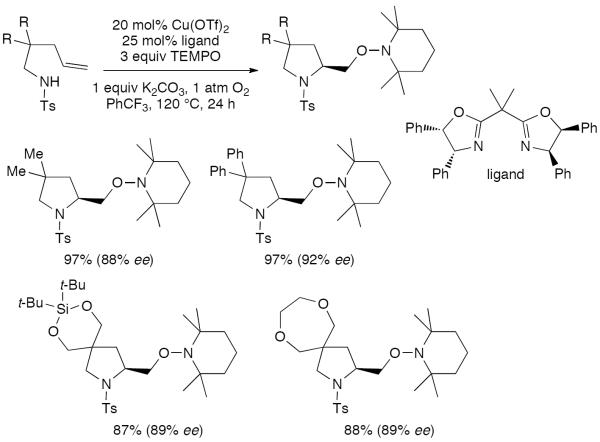

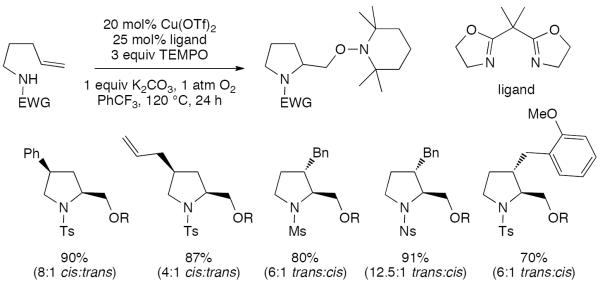

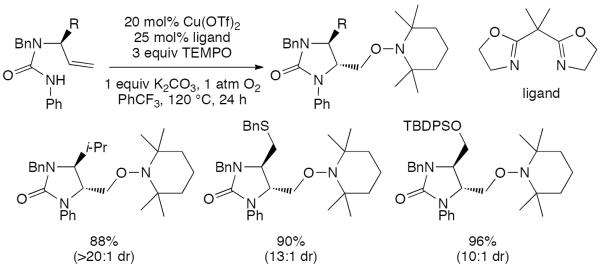

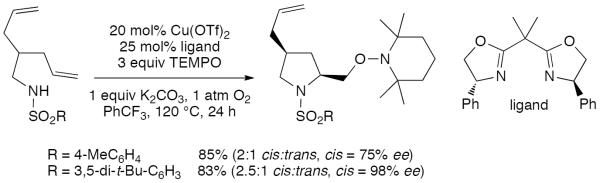

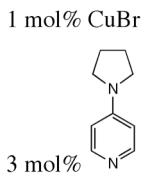

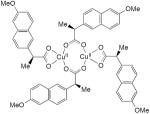

An extension of the method was later reported in which catalytic copper could be employed under oxygen to afford substituted pyrrolidine and cyclic urea products from the corresponding alkenylsulfonamides (Scheme 35) and N-allylureas (Scheme 36).97 Again, excellent (>20:1) diastereoselectivity was observed for α-substituted substrates. Generally, the use of Cu(OTf)2 with an achiral bisoxazoline ligand was found to provide higher yields and diastereoselectivities than use of Cu(EH)2 alone for β- or γ-substituted pentenylsulfonamides. In addition to studying ligand and nitrogen substituent effects on diastereoselectivity, enantioselective desymmetrization reactions were successful when a bulky sulfonamide group was employed (Scheme 37).

Scheme 35.

Aminooxygenation of alkenes with catalytic copper and oxygen.

Scheme 36.

Catalytic aminooxygenation of alkenes to form cyclic ureas.

Scheme 37.

Catalytic asymmetric desymmetrization via aminooxygenation.

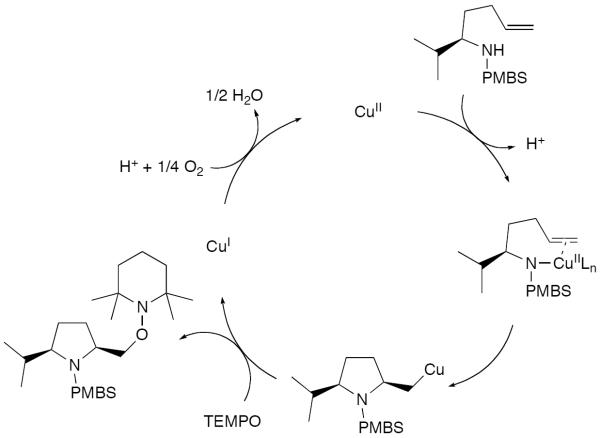

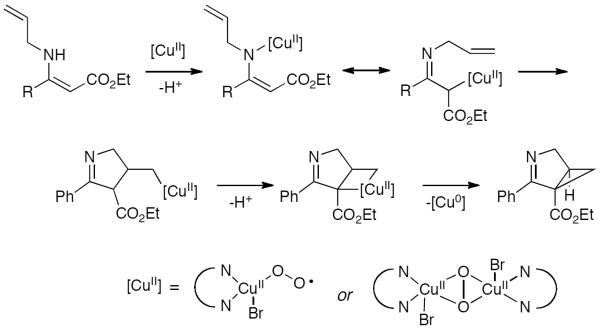

The proposed mechanism proceeds with initial coordination and deprotonation of the sulfonamide to the copper species followed by syn-aminocupration (Scheme 38). Subsequent homolytic cleavage of the Cu–C bond affords a Cu(I) species and a primary radical, which is readily trapped with TEMPO. Reoxidation of the Cu(I) to Cu(II) by oxygen regenerates the active catalyst.

Scheme 38.

Mechanism for the catalytic aminooxygenation of alkenes.

An enantioselective variant of the aminooxygenation of alkenes utilized Cu(OTf)2 with a chiral bisoxazoline ligand to afford the corresponding indoline and pyrrolidine products in excellent yield and high optical purity (Scheme 39).98 While TEMPO alone could trap the proposed alkyl-copper intermediate in addition to acting as the terminal oxidant, performing the reaction under oxygen was necessary for complete conversion to the pyrrolidine products.

Scheme 39.

Asymmetric catalytic aminooxygenation of alkenes.

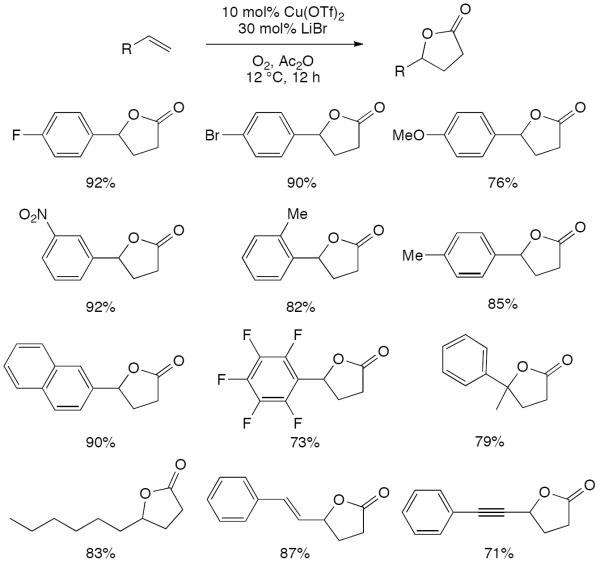

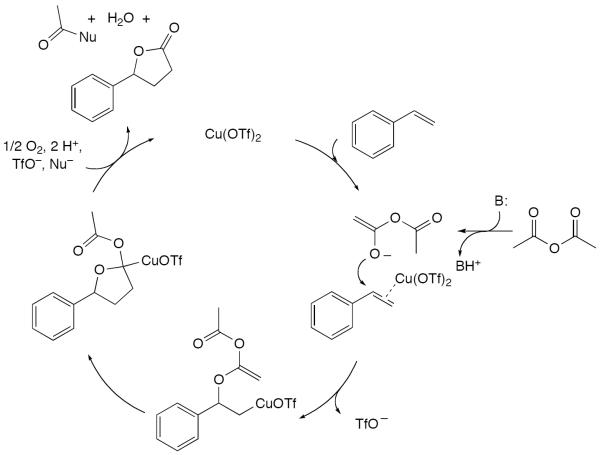

A catalytic copper and oxygen system has been described for the novel synthesis of γ-lactones through a formal oxidative [3+2] addition between alkenes and anhydrides (Scheme 40).99 This novel difunctionalization employs Cu(OTf)2 under oxygen to afford a wide array of functionalized lactones using inexpensive anhydrides, such as acetic anhydride, as carboesterification agents. High yields were observed for a large array of terminal alkenes. Internal alkenes however, were not tolerated, and use of secondary anhydrides, such as propionic anhydride, afforded the products in a 1:1 syn:anti ratio. Alternate oxidants such as DDQ and TBHP were found to provide only benzaldehyde and recovered starting material when styrene was the substrate.

Scheme 40.

Carboacetoxylation of alkenes with anhydrides.

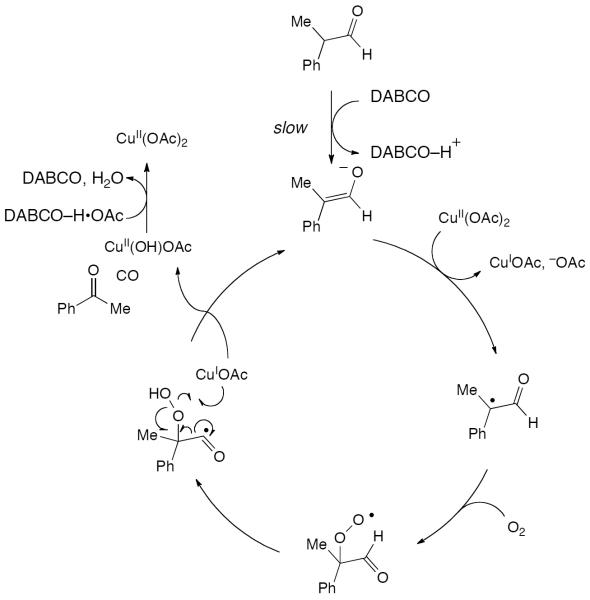

Mechanistic studies using stereospecifically deuterium-labeled styrene established a syn-oxycupration process (Scheme 41). Addition of a TEMPO or BHT did not noticeably affect the reaction, lending evidence to a non-radical pathway. A potential mechanism for the reaction involves initial oxycupration via attack of the enolate form of the anhydride with the alkene. In this instance, the carbocuprate then undergoes carbometalation of a second alkene to generate the cyclic system. Oxidative decomposition generates the product and regenerates the catalytic copper species.

Scheme 41.

Potential mechanism for the carboacetoxylation of alkenes.

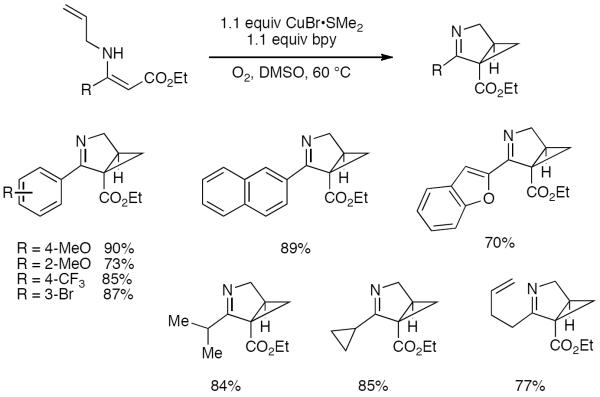

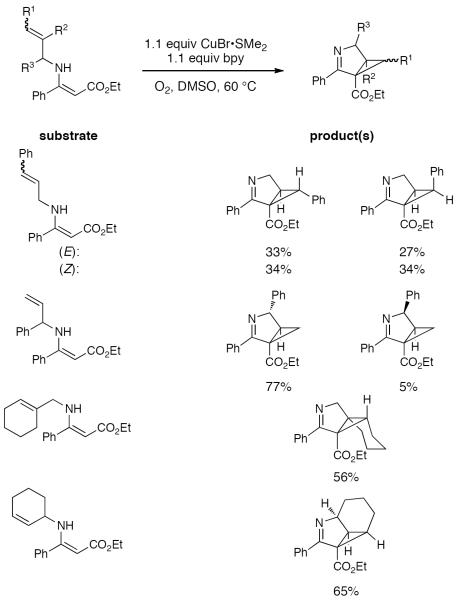

Chiba and coworkers have described a unique method for the intramolecular cyclopropanation of alkenes utilizing stoichiometric copper and oxygen.100 Specifically, treatment of N-allyl enamine carboxylates with CuBr•SMe2, 2,2-bipyridine, and oxygen under mild heating affords 3-azabicyclo[3.1.0]hex-2-enes in high yield. Overall, the transformation represents addition of two carbons across a double bond. Various aryl and alkyl substituents are tolerated on the enamine (Scheme 42) and allyl (Scheme 43) moieties. Notably, substrates containing cyclic allyl groups afforded highly strained tricyclic products in good yield. The reaction of both (Z) and (E)-N-phenylallyl substrates afforded an approximately 1:1 mixture of diastereomers, providing evidence of a stepwise process.

Scheme 42.

Cyclopropanation of N-allyl enamine carboxylates.

Scheme 43.

Cyclopropanation of substituted N-allyl enamine carboxylates.

The reaction occurs sluggishly in the absence of oxygen, providing only small amounts of cyclized product. Oxygen is therefore proposed to initially react with copper(I) to form a copper(II)peroxo species. After initial coordination to the substrate (Scheme 44), carbocupration of the allyl group affords a five-membered ring and an alkyl-copper bond. Formation of a metallocyclobutane, via deprotonation and ligand exchange, could then afford the tricyclic product via carbon-carbon bond forming reductive elimination.

Scheme 44.

Mechanism for the cyclopropanation of N-allyl enamine carboxylates.

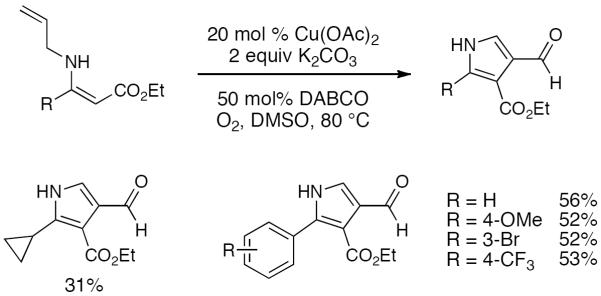

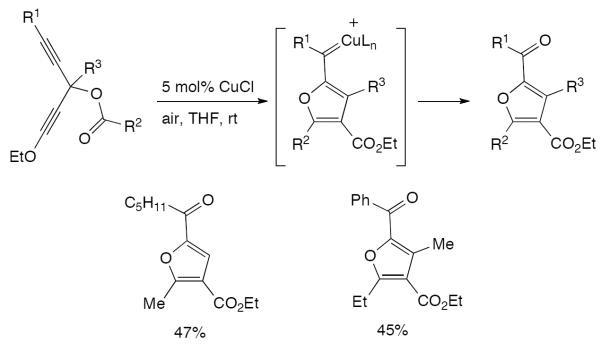

Interestingly, simple addition of potassium carbonate to the previously described method provides orthogonal reactivity, avoiding the cyclopropanation pathway and instead undergoing carbooxygenation of the allyl double bond. This complementary process utilizes catalytic Cu(OAc)2 to afford 4-formylpyrroles from N-allyl enamine carboxylate in moderate yield (Scheme 45). Formation of 4-ketopyrroles by terminal substitution of the allyl moiety was not tolerated, affording complex mixtures. However, a variety of 4-benzoylpyrroles could be formed from substituted N-propargyl enamine carboxylates via alkyne carbooxygenation (see Section II.D.4).

Scheme 45.

Carbooxygenation of N-allyl enamine carboxylates to afford 4-formylpyrroles.

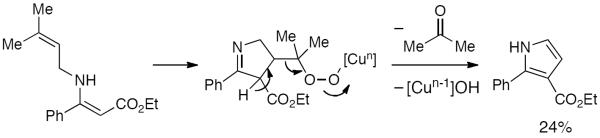

Although the role of potassium carbonate in controlling product selectivity remains inconclusive, the authors propose a mechanism beginning with formation of a peroxycopper adduct with the enamine substrate(Scheme 46). Carbocupration of the N-allyl double bond affords a cyclized intermediate with a pendant alkyl-peroxycopper species. Subsequent isomerization and elimination of a reduced copper species installs the aldehyde moiety. Oxidative aromatization then forms the 4-formylpyrrole product. Subjecting an N-3,3-dimethylallyl enamine substrate to the reaction conditions provided 2-phenylpyrrole-3-carboxylate in 24% yield (Scheme 47). Formation of this product may be explained by C–C bond cleavage to form acetone and a reduced copper species, lending support for a mechanism involving a peroxide intermediate.

Scheme 46.

Carbooxygenation mechanism for N-allyl enamine carboxylates.

Scheme 47.

Fragmentation mechanism under carbooxygenation conditions

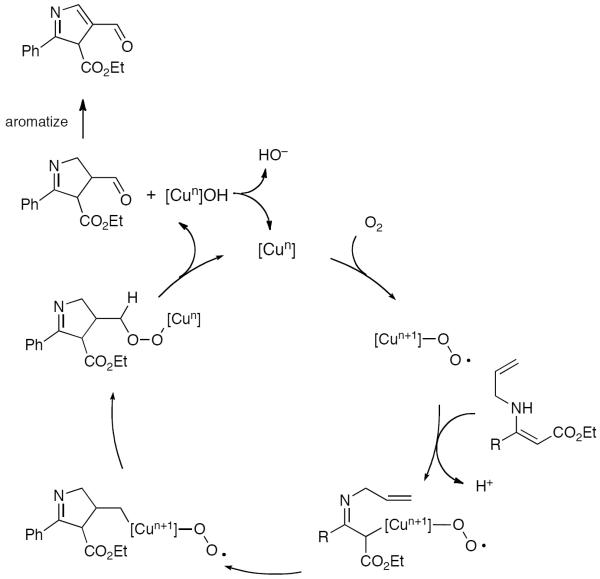

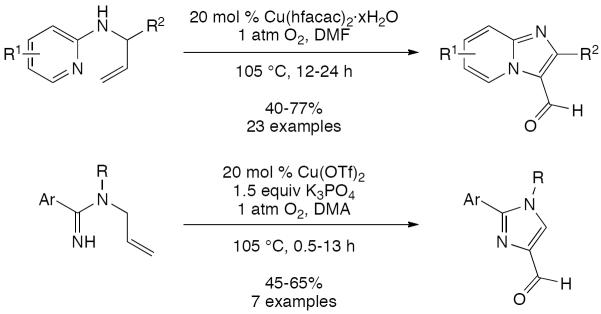

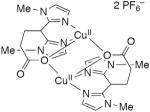

Recently, Zhu and coworkers treated N-(1-phenylallyl)-2-aminopyrazine with a copper(II) species and oxygen, anticipating a copper-promoted C–H amination of the double bond and oxidative aromatization.101 However, a heterocyclic aldehyde was formed instead via an aminooxygenation process. This reaction was found to be general for a wide range of N-allyl-2-aminopyradines, providing the aldehyde products in good to moderate yields (Scheme 48). Under slightly different conditions, N-allylamidines provided the imidizolyl aldehyde products in more modest yields.

Scheme 48.

Aminooxygenation of N-allyl-2-aminopyridines and N-allylamidines.

Mechanistic studies ruled out formal benzylic C–H or alcohol oxidation following ring closure as a potential pathway. Addition of TEMPO yielded no carbon-TEMPO adduct, and no reaction was observed when performing the reaction with superstoichiometric copper under argon. Using an 18O2 atmosphere provided the product with 95% isotopic incorporation, precluding adventitious water as the oxygen source. On the basis of the above results, a mechanism is proposed (Scheme 49) in which initial coordination of the pyridyl ring to copper is followed by deprotonation. The subsequent adduct reacts with dioxygen to form a peroxycopper intermediate. Aminocupration of the alkene generates an alkyl-copper intermediate, which, upon rearrangement and elimination of a reduced copper hydroxide species, yields the aldehyde product.

Scheme 49.

Aminooxygenation mechanism of N-allyl-2-aminopyridines.

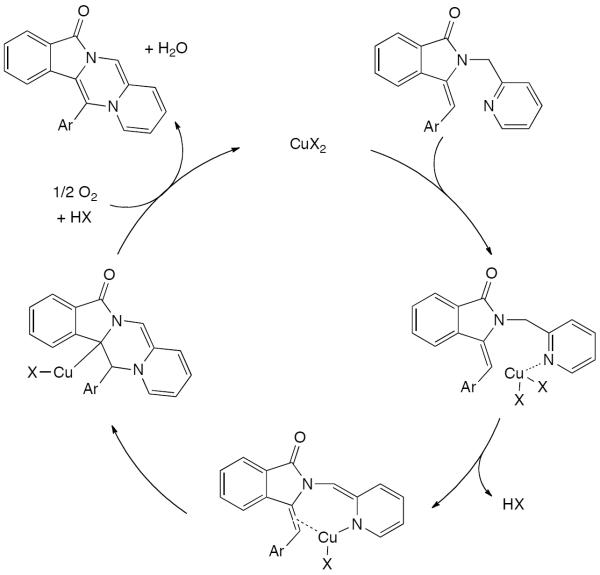

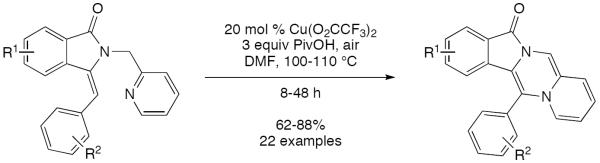

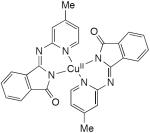

In a related system, a direct intramolecular C–H amination of pyridines with alkenes has been reported to provide complex N-heterocycles in good yields.102 Specifically, pyridyl substituted 3-methyleneisoindolin-1-ones were treated with catalytic copper(II) trifluoroacetate under air to afford the polycyclic N-heterocycles in good yield (Scheme 50). Limitations to the method include little allowance for structural changes in the substrate and the requirement of several equivalents of pivalic acid.

Scheme 50.

Oxidative alkene C–H amination to afford complex N-heterocycles.

The mechanism of the transformation proceeds through initial chelation of the pyridyl moiety with copper and subsequent deprotonation (Scheme 51). In marked contrast to the aforementioned reactions, the proposed aminocupration results in an internal, tertiary carbon–copper bond, although an oxidative radical cyclization may also be envisioned. Further oxidation then provides the conjugated alkene.

Scheme 51.

Mechanism for cyclization of pyridyl substituted 3-methyleneisoindolin-1-ones.

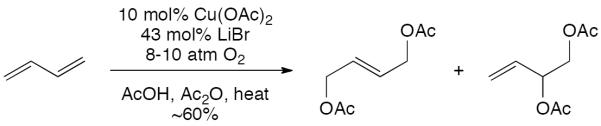

A series of studies by Teyssie and coworkers focused on the copper-catalyzed difunctionalization of vinylogous substrates, and particularly butadiene. In these systems, reaction at the termini of the substrates is presumably mediated by conjugation. A primary investigation focused on the oxidative diacetoxylation of butadiene.103 Optimized conditions consisting of Cu(OAc)2, LiBr, and acetic acid/acetic anhydride solvent provided a mixture of 3,4 and 1,4-diacetoxybutene in ~60% yield along with 5% monoacetoxybutenes (Scheme 52). In nearly all of these trials, the diacetoxybutene regioisomers were isolated in an approximate 1:1 ratio due to a slow isomerization pathway under the reaction conditions. High pressures of oxygen were necessary to diminish formation of monoacetoxylation product. The use of LiBr was found to be necessary for catalytic activity. Both epoxybutene and dihalobutenes, postulated intermediates for the reaction, were tested under the reaction conditions. Although the epoxide intermediate provided isomer ratios similar to the primary reaction, other potential pathways and intermediates, including a bromonium species, cannot be excluded.

Scheme 52.

Oxidative diacetoxylation of butadiene.

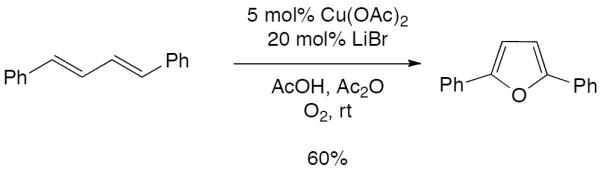

Interestingly, when the aforementioned diacetoxylation conditions were applied to 1,5-diphenylbutadiene, 2,5-diphenylfuran was isolated in good yield (Scheme 53).104 The unique nature of this substrate ostensibly favors an oxidative vinylogous cyclization pathway. A possible mechanism may proceed via attack of a peroxo-copper species on the benzylic position, forming a radical stabilized through extended conjugation. This intermediate can then close to the furan through O–O bond scission and subsequent rearomatization.

Scheme 53.

Oxidative vinylogous cyclization.

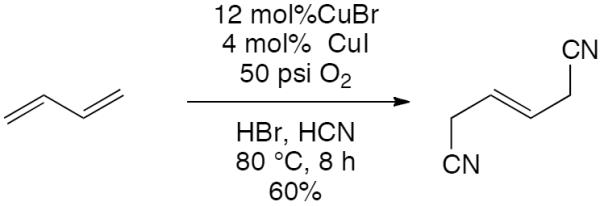

Oxidative dicyanation of butadiene, a similar reaction, was later investigated and found to be a more regioselective process.105 Using a combination of copper(I) bromide and copper(I) iodide with hydrogen cyanide could produce 1,4-dicyanobutene in 60% yield (Scheme 54). Unfortunately, the process appears restricted to butadiene: reaction of 1,3-pentadiene yielded <17% of dicyanated product. The fact that radical traps did not retard the reaction and that a halide source was critical for high conversion, suggest the intermediacy of a halonium pathway.

Scheme 54.

Oxidative vinylogous dicyanation of butadiene.

II.D. Alkyne Oxidation

II.D.1. Propargylic Oxidation

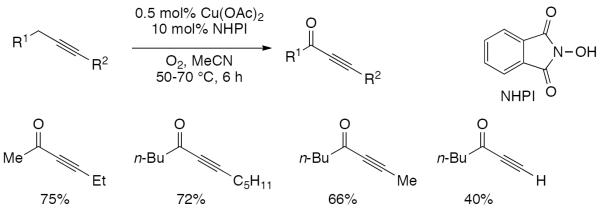

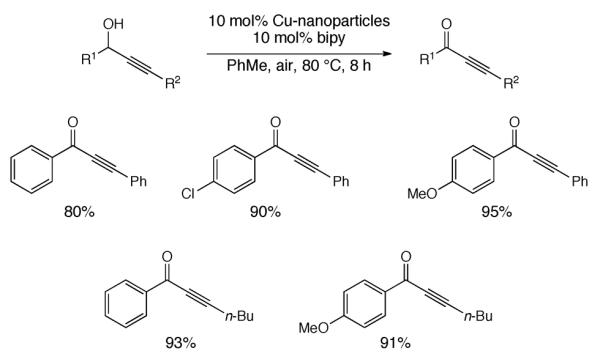

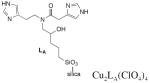

Aerobic oxidation of propargylic substrates is complicated by competitive alkyne reaction pathways as well as potential overoxidation to carboxylic acid products. One system that overcomes these challenges utilizes NHPI in conjunction with a copper(II) catalyst to selectively oxidize propargylic substrates to the corresponding conjugated carbonyl products (Scheme 55).106 While NHPI alone can catalyze the reaction of certain substrates, the addition of the copper catalyst significantly enhances reactivity, allowing for lower reaction temperatures, as well as playing a key role in the final oxidation of the initial propargylic alcohol to the ketone product. Presumably, the mechanism proceeds via formation of the NHPI radical (for example, see Scheme 6).

Scheme 55.

Oxygenation of alkynes to α,β-acetylenic ketones.

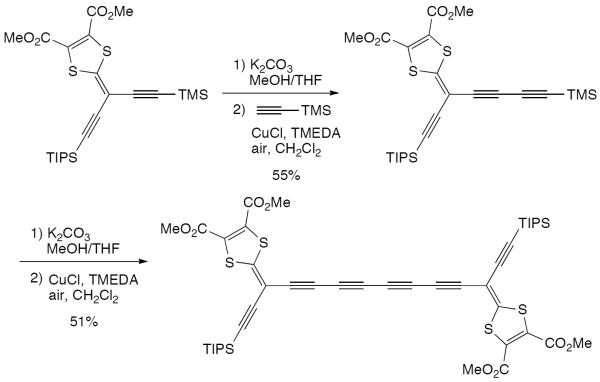

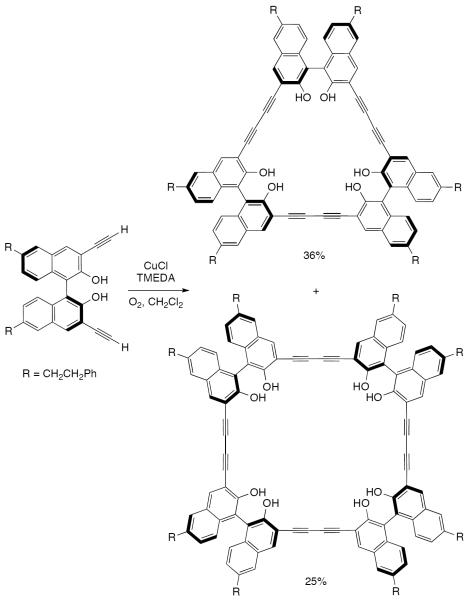

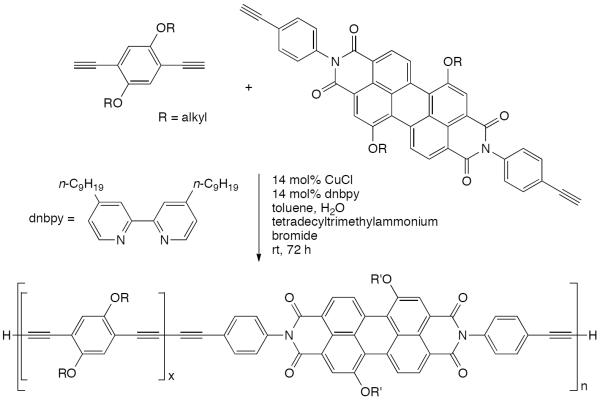

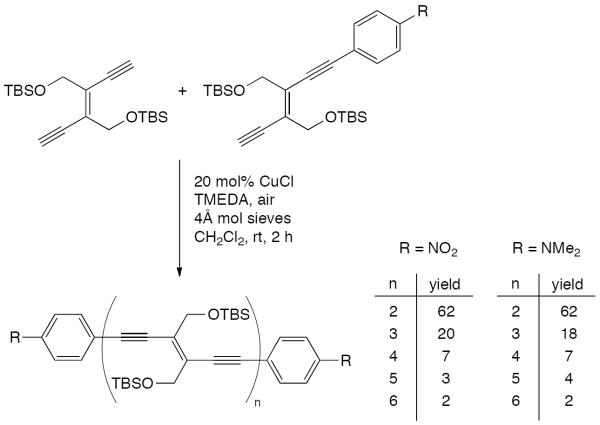

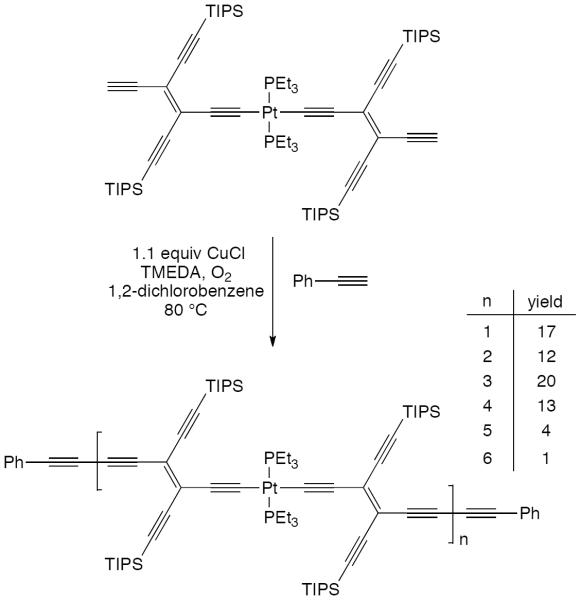

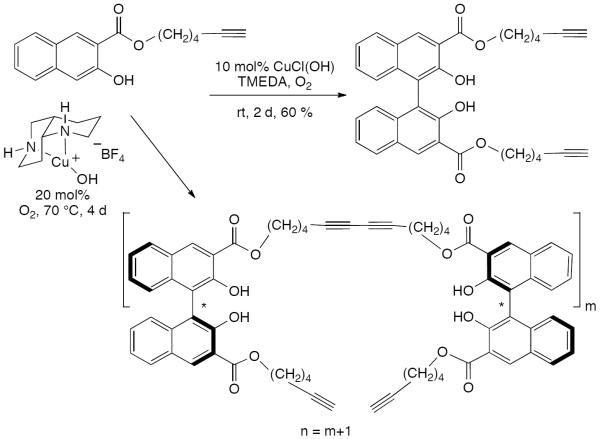

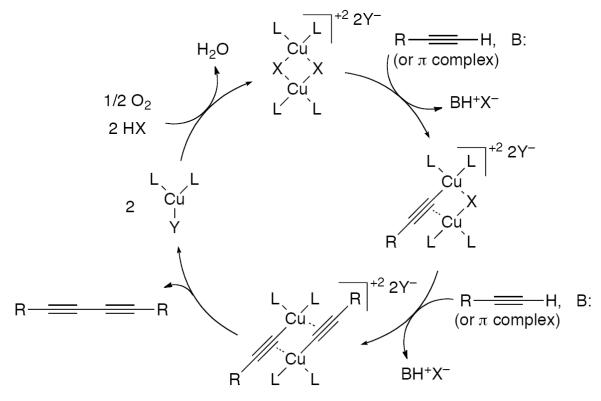

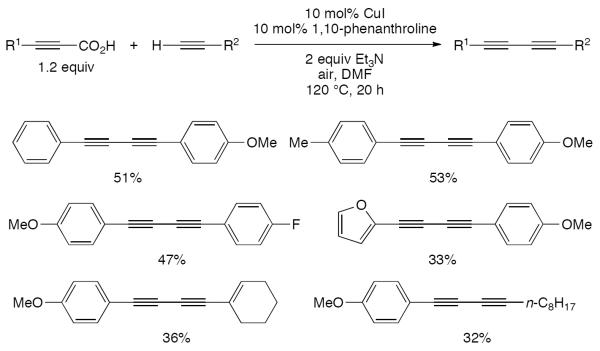

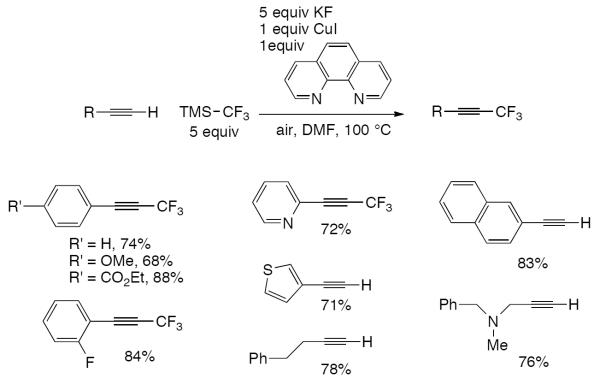

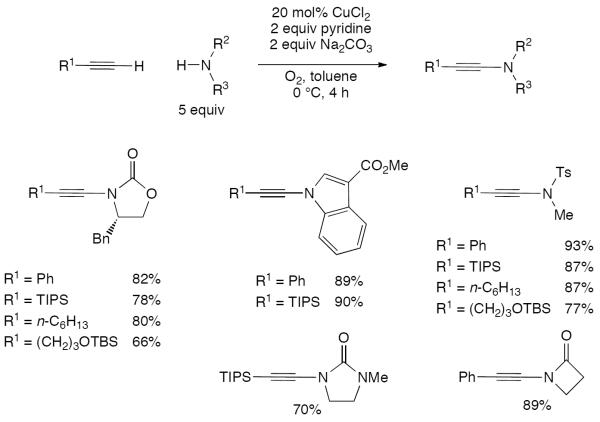

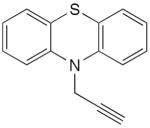

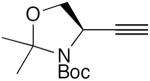

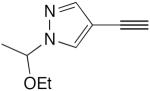

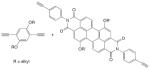

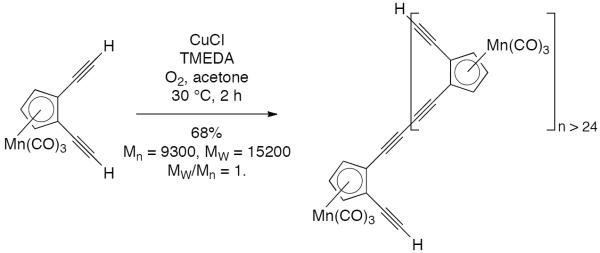

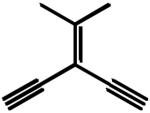

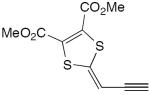

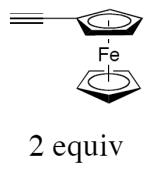

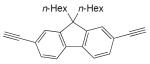

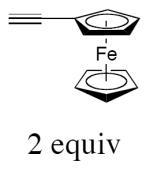

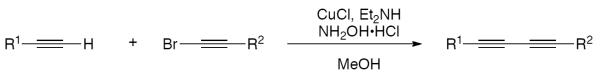

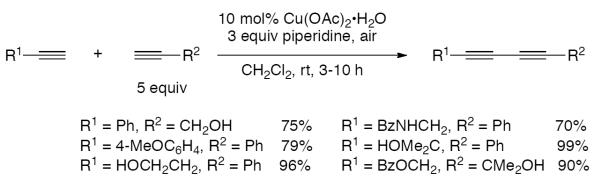

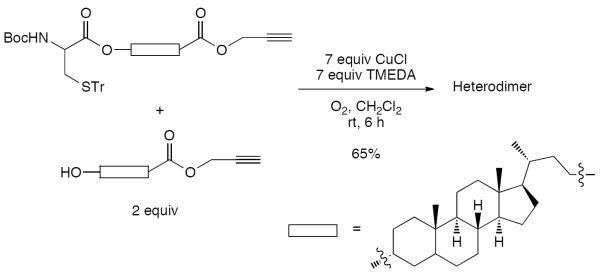

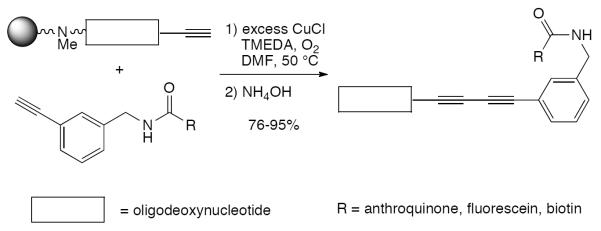

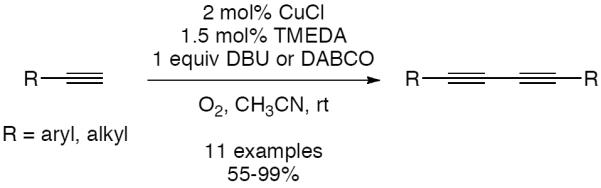

II.D.2. Glaser-Hay Reaction

The copper-catalyzed dimerization of terminal alkynes to form 1,3-diynes is a facile C–C bond forming process. It has been employed in numerous applications, including the construction of linear π-conjugated acetylenic oligomers and polymers, the synthesis of natural products, and the polymerization of diacetylenes. A comprehensive review by Cadiot and Chodkiewisz appeared in 1969,107 as well as a further review by Diederich in 2000.108 A general review of hydrocarbon couplings was published in 2010.109 In this section, the development of the Glaser-Hay coupling is presented with representative examples, and a comprehensive overview of couplings from 2000–2011 is provided.

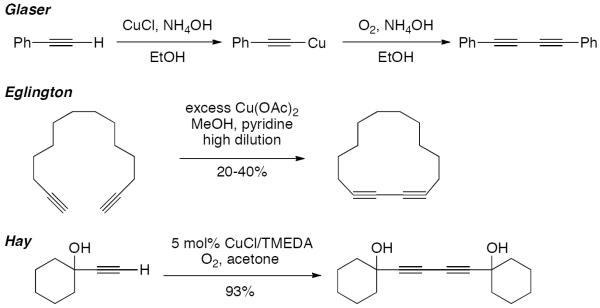

The origin of the Glaser-Hay reaction dates back to 1869, when Carl Glaser formed the copper(I) salt of phenylacetylene upon treatment with a copper(I) and ammonia (Scheme 56).110 Upon exposure to air, the homocoupled 1,3-diyne was isolated. It was not until 1956 that Eglinton and Galbraith improved the synthetic viability of the reaction by reporting the homogeneous coupling of alkynes using stoichiometric copper(II)acetate in the presence of pyridine and methanol.111 The use of catalytic copper and oxygen to effect the oxidative homocoupling of terminal alkynes was published in a landmark advance by Hay in 1962.112

Scheme 56.

Evolution of the Glaser-Hay process.

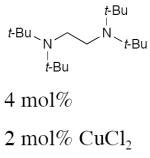

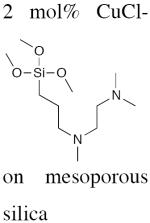

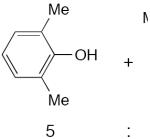

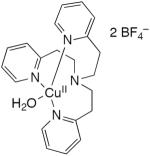

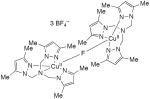

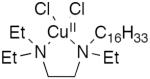

The bidentate tertiary amine ligand N,N,N',N'-tetramethylethylenediamine (TMEDA) provides enhanced solubility to the reactive copper intermediate, and the classical Hay conditions (CuCl, TMEDA, and oxygen) continue to be widely used. These mild conditions typically provide high yields. The reaction conditions permit many functional groups to be employed including unprotected hydroxyls (see Scheme 56 above). The poor ability of alkynes to transfer from copper in conjugate addition means that enones and carbonyls are also compatible. Homocoupling predominates even with mixtures of alkynes. The appearance of an Organic Syntheses description is a manifestation of the high reliability of the process (Scheme 57).113

Scheme 57.

Preparative scale Hay coupling.

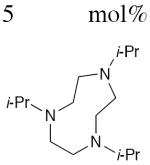

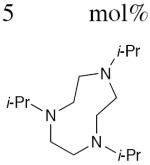

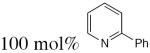

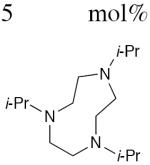

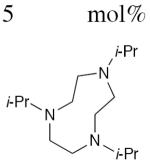

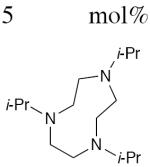

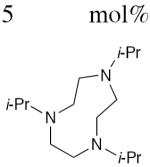

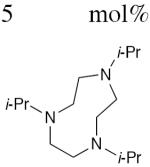

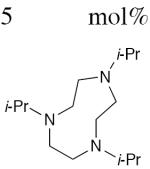

Several studies to further optimize and expand alkyne dimerization have been reported. For example, Beifuss and co-workers undertook a systematic study of ligand and base effects on the homocoupling of various acetylenes.114 While TMEDA was again demonstrated to be the ligand of choice, addition of one equivalent of hindered base further improved the reaction efficiency. Specifically, DBU was effective for aryl acetylenes and DABCO for alkyl acetylenes. The authors attribute this difference in the latter case due to the decreased acidity of the acetylenic proton.

A recent study has demonstrated that the addition of a equimolar amount of a Ni(0) catalyst to standard Hay conditions greatly increases reaction rate in homocoupling and heterocoupling of terminal alkynes.115,116 The authors demonstrate that nickel undergoes redox with oxygen as the oxidant, while Cu forms copper acetylides that transmetallate to nickel. A similar cooperative behavior has also been reported with iron117 and palladium118for alkyne coupling.

Wan and coworkers demonstrated the use of piperidine and toluene as alternative conditions for the dimerization of aryl and alkyl terminal alkynes.119 High yields were obtained for a variety of substrates, although higher temperatures were necessary in comparison to classical conditions. In an effort to identify a “greener” modification of the Hay coupling, Chen and coworkers reported solvent-free conditions, using just 3 mol% CuCl and 3 mol% pyridine in air.120 Both alkyl and aryl acetylenes were homocoupled in good yield, although higher temperatures were required in comparison to typical conditions. Similarly, polyethylene glycol can be used as an environmentally benign reaction medium.121 And, ionic liquids have been employed with the classical Hay catalyst (CuCl, TMEDA, O2, rt).122 These solvents have the advantage of being easily recyclable after extraction of the product with an organic solvent.

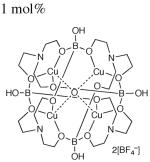

Heterogeneous catalysis has been applied to the Hay coupling. Examples of supported catalysts include supported copper hydroxide on titania123 and cuprous chloride-doped zeolites.124 Although these systems afford good yields of homocoupled products without added ligand, greatly elevated temperatures (100–110 °C) are required. A homogeneous copper-containing silicotungstate catalyst has also been reported to effect the Hay coupling.125 The catalyst could be recycled via precipitation, and no added ligand was necessary. However, similar to the heterogeneous and ligand-free catalysts, greatly increased temperatures were necessary. The use of ball milling alkyl or aryl alkynes with KF-Al2O3 and CuI catalyst has also been reported to provide the corresponding diyne products in good yield.126 This process avoids the use of both solvent and ligand.

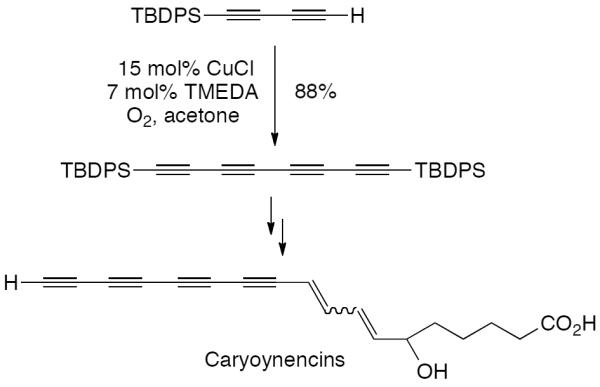

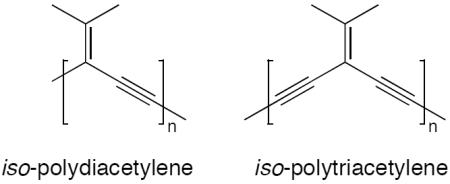

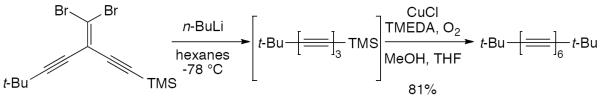

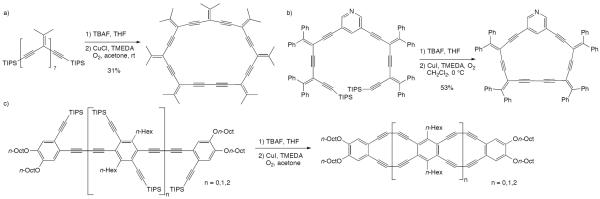

Numerous dimerizations via Glaser-Hay coupling have been implemented (see Table 5). In the context of natural product synthesis, the method proved key in approaching the caryoynencins, which contain 1,3,5,7-octatetraynes and show potent antibacterial activity. Specifically, the conjugated polyynes are highly unstable, polymerizing readily, and present a significant synthetic challenge. The mild nature of Hay alkyne dimerization afforded the requisite tetrayne in high yield en route to the caryoynencins (Scheme 59).127

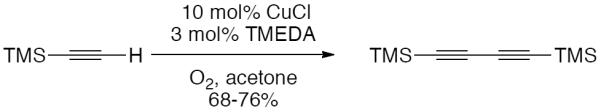

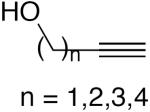

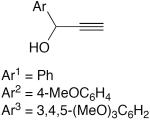

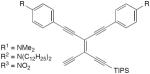

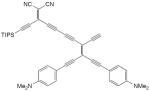

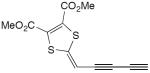

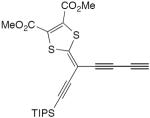

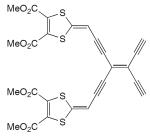

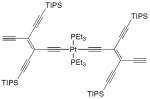

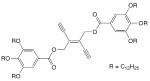

Table 5.

Glaser Hay dimerization reactions.

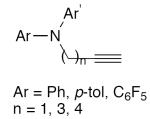

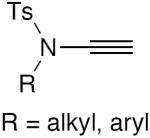

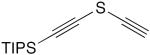

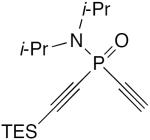

| entry | substrate | conditions | yield(%) | ref |

|---|---|---|---|---|

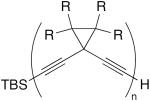

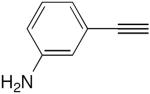

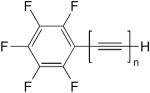

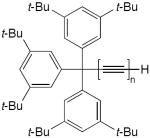

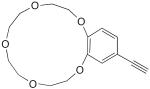

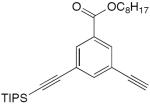

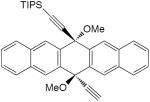

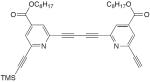

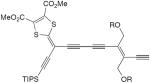

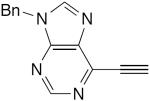

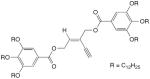

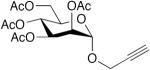

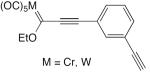

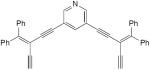

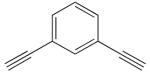

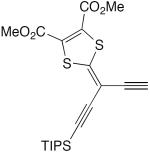

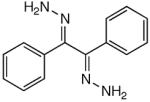

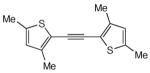

| 1 |

|

8 mol% Cu(OAc)2·H2O, TMEDA, acetone, air, rt, 2h | 91 | 145 |

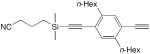

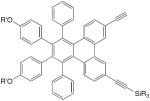

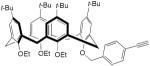

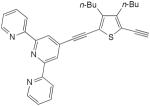

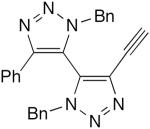

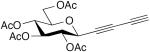

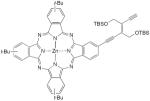

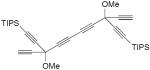

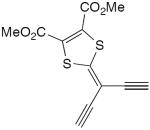

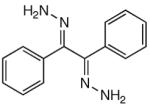

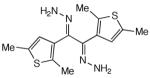

| 2 |

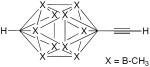

|

CuCl, TMEDA, O2, MeOH, THF | 81a | 130 |

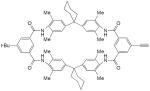

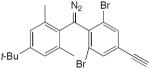

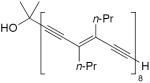

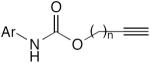

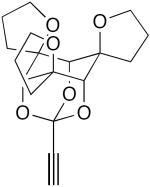

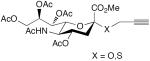

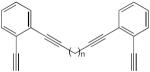

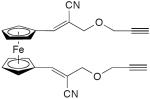

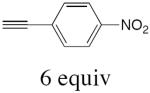

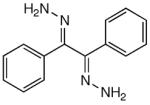

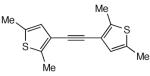

| 3 |

|

5 mol% CuI, TMEDA, DME, O2, 55 °C, overnight | ≥90 | 146 |

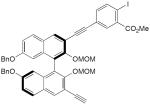

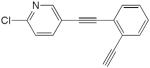

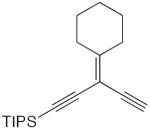

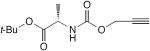

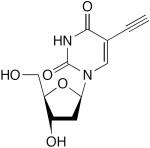

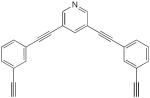

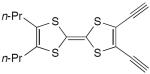

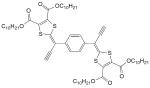

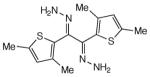

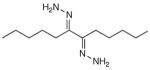

| 4 |

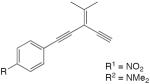

|

15 mol% CuCl, 30 mol% pyridine, MeOH, O2, rt | Ar1 = 91 | 147 |

| Ar2 = 93 | ||||

| Ar3 = 75 | ||||

| 5 |

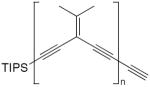

|

10 mol% CuCl, TMEDA, MeOH, air, rt, 24 h | 60–72 | 148 |

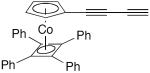

| 6 |

|

10 mol% CuI, TMEDA, O2, acetone, rt, 3 h | 84–100 | 149 |

| 7 |

|

CuCl, TMEDA, air, CHCl3 | 94 | 150 |

| 8 |

|

10 mol% CuI, 20 mol% TMEDA, acetone, air, rt | 67 | 151 |

| 9 |

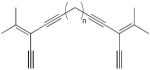

|

3 equiv CuCl, TMEDA, acetone, O2, 1 h, rt | 76 (n = 3, R = Me) | 152 |

| 86 (n = 3, R = H) | ||||

| 95 (n = 6, R = H) | ||||

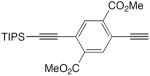

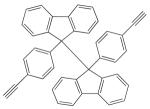

| 10 |

|

4 mol% CuCl, TMEDA, acetone, O2, rt, 6 h | 84 | 153 |

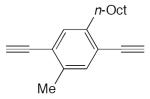

| 11 |

|

14 mol% CuCl, TMEDA, acetone, O2, rt, 4 h | 52 | 154 |

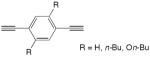

| 12 |

|

CuCl, TMEDA, CH2Cl2, O2 | 50a (n = 2) | 155 |

| 44a (n = 3) | ||||

| 19a (n = 4) | ||||

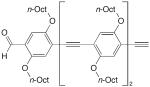

| 13 |

|

CuCl, TMEDA, CH2Cl2, O2 | 92 (n = 2) | 156 |

| 66 (n = 3) | ||||

| 97 (n = 4) | ||||

| 14 |

|

40 mol% CuCl, pyridine, air, 24 h, rt | 95 | 157 |

| 15 |

|

25 mol% CuCl, pyr, air, 40 °C, 1.5 h | 60 | 158 |

| 16 |

|

1 equiv CuCl, TMEDA, CH2Cl2, air, 30 °C, 2–4 h | 99 | 159 |

| 17 |

|

6.3 equiv CuCl, TMEDA, CH2Cl2, air, rt, 12 h | 91 | 160 |

| 18 |

|

CuCl, TMEDA, CH2Cl2, air | 68 | 161 |

| 19 |

|

CuCl, TMEDA, air, acetone, rt, overnight | 43 | 162 |

| 20 |

|

12 mol% CuCl, TMEDA, chlorobenzene, O2, rt, 3d | 50 | 163 |

| 21 |

|

4.8 equiv CuCl, TMEDA, acetone, O2, rt, 48 h | 88 | 164 |

| 22 |

|

CuCl, TMEDA, CH2Cl2, O2, rt, 24 h | 91 | 165 |

| 23 |

|

30 mol% CuCl, O2, DMF, rt, 12 h | 26 | 166 |

| 24 |

|

CuCl, TMEDA, O2, CH2Cl2, rt | 99 | 167 |

| 25 |

|

1 equiv CuCl, TMEDA, CH2Cl2, O2, rt, 4 h | 60 | 168 |

| 26 |

|

5 mol% CuCl, TMEDA, toluene, 65 °C, 1.5 h | 45 | 169 |

| 27 |

|

catalytic CuCl(OH)·TMEDA, CH2Cl2, O2, rt, overnight | 57 | 170 |

| 28 |

|

20 mol% CuCl, pyr, O2, rt, 24 h | 86 | 171 |

| 29 |

|

30 mol% CuCl, TMEDA, O2, acetone, rt, 48 h | 89 | 172 |

| 30a |

|

4 equiv CuI, TMEDA, CH2Cl2, O2, rt | 96a (n= 1) | 173 |

| 78a (n = 2) | ||||

| 68a (n = 3) | ||||

| 31 |

|

CuCl, TMEDA, CH2Cl2, rt, O2 | R1 = 87 | 174 |

| R2 = 68 | ||||

| 32 |

|

4 equiv CuCl, TMEDA, CH2Cl2, O2, rt | 32a (n =2) | 175 |

| 20a (n = 3) | ||||

| 34a (n = 4) | ||||

| 34a (n = 5) | ||||

| 22a (n = 7) | ||||

| (cyclic dimers) | ||||

| 33 |

|

CuCl, TMEDA, O2, CH2Cl2 | R1 = 70 | 176 |

| R2 = 86 | ||||