Abstract

During freehand performance of vitreoretinal microsurgery the surgeon must perform precise and stable maneuvers that achieve surgical objectives and avoid surgical risk. Here, we present an improved smart handheld microsurgical tool which is based on a ball lens fiber optic sensor that utilizes common path swept source optical coherence tomography. Improvements include incorporation of a ball lens single mode fiber optic probe that increases the working angle of the tool to greater than 45 degrees; and increases the magnitude of the distance sensing signal through water. Also presented is a cutting function with an improved ergonomic design.

Keywords: SMART, ball lens, CP-OCT, vitreoretinal microsurgery, handheld surgical instrument

1. INTRODUCTION

Vitroretinal surgery is eye surgery that is performed in the intraocular space and requires stable micron scale maneuvers. These rely on excellent motor control to perform critical tasks and must overcome hand tremor on the order of 50–100 microns. Surgeons and patients’ unexpected movements have difficulties in completing important surgical tasks or may bring about disastrous ocular damages. At the present time, even the highly experienced surgeon cannot reach some micron scale maneuvers superior to the precise motor control. Most of surgeons attempt to reduce physiological tremor to finish microsurgical steps effectively and precisely. Various optomechatronic systems have been developed to maximize a micro-surgeon’s surgical performance during microsurgery [1–2].

Compared to other range-finding techniques such as ultrasound imaging (200–300 um resolution, 150mm imaging depth) or MRI (less than 100 um resolution, unlimited imaging depth) in biological sample application, optical coherence tomography (OCT) based distance sensing has a high accuracy of about 1–20 um range even though OCT has a few millimeter measurement range [3]. However, the millimeter range is sufficient for its role as a microsurgical tool in vitreoretinal surgery. Additional advantage is that the acquisition and processing time of OCT is very fast. At the present time OCT has been broadly used as an ocular imaging modality for diagnostic purposes in ophthalmology. If surgical tools equipped with OCT imaging function were available, the surgeon could locate the surgical tool without any additional complex imaging apparatus. In addition, common path optical coherence tomography (CP-OCT) is an optical fiber single-arm low-coherence interferometer interrogated by a broadband swept source that’s capable of high-resolution axial distance sensing. Swept source OCT as an imaging modality is usually based on the Michelson interferometer, while here we used the CP-OCT scheme which is based on a single-arm interferometer. The distal end of the single mode fiber plays a role as the reference arm in CP-OCT. A CP-OCT scheme has merits technically and economically such as a compact configuration and a disposable surgical tool usage, cost-effective composition, and circumvention of polarization and dispersion mismatch troubles between two arms, particularly in this kind of surgical system implementation. Common-path phase-sensitive optical coherence tomography system has been applied to implement a surgical force sensor with the distal end of the fiber introducing a Fabry–Pérot (FP) cavity [4]. Also CP-OCT has been presented as a preclinical distance sensor to achieve surface topology and motion tracking system, and a micro-incision instrument [5–6]. Recently, we developed a novel microsurgical tool platform, Smart Micromanipulation Aided Robotic-surgical Tool (SMART) for effectively cancelling a surgeon’s physiological tremor during microsurgery [7]. The practical surgical tool, SMART consists of a common path, swept source optical coherence tomography (CP SS-OCT) and a piezoelectric motor. This demonstrated successful reduction of unwanted surgeon’s hand tremor and tool tip movement on a viable chicken embryo model. Also, this SMART was applied to a motion-compensated hand-held probe for image-guided intervention [8].

In the present work we demonstrates that a ball lens fiber optic SMART combined with a single mode fiber increases the working angle of the tool to over 45 degree as compared to the limited working angle of the bare fiber sensor. This SMART also increases the magnitude of the distance sensing signal in water, which is optically analogous to the vitreous body prior to vitrectomy and the liquid vitreous of the vitrectomized eye. The SMART achieves real-time depth tracking using a PZT motor based closed-loop control scheme to “sense” and suppress unintended hand tremor on the order of 0–15 Hz. The SMART allows more exact and versatile function during microsurgery. This improved SMART tool may serve as a platform used to combine dynamic fiber optic distance sensing and a motion cancellation scheme into one handheld instrument. Its clinical relevance includes increased stability and more precise instrument actions; micro-manipulation based cutting skills, minimization of clinical risk, and improved surgeon capabilities. The upgraded SMART platform which combines high-speed OCT distance measurement and piezoelectric motor based active tremor reduction was demonstrated as a functional handheld microsurgical instrument.

2. SYSTEM: SMART

The objective of this work is to make an already enhanced surgical tool into an even “smarter” tool by incorporating fiber-optic sensors and motion control to allow surgeons to maneuver the tool tip precisely and safely. A fiber-optic common-path optical coherence tomography for distance sensing and an active surgical tool tip capable of high-speed and high-resolution axial motion are the main components of the SMART. The fiber OCT sensor, SMART senses the hand tremor and the target motion and uses the piezoelectric motor control to keep the needle tip position stable.

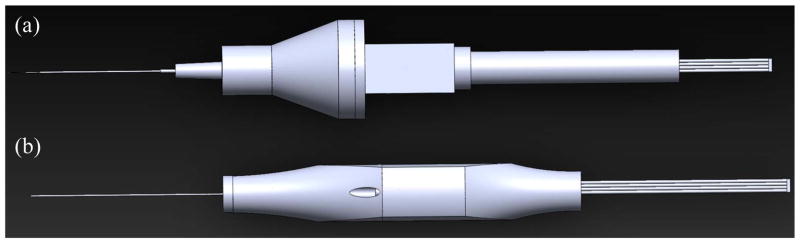

Implementation of a ball lens fiber optic sensor based SMART is proposed. The ergonomics of the SMART are further improved by reducing its cross-sectional area compared with previous SMART. The SMART cover is simplified into three parts (front holder, back holder, joint) while the previous design is composed of four separate parts (front holder, back holder, tail, and joint). This design simplifies the manufacturing and assembly process. Moreover, a small connection part was inserted to align and fix the optical fiber in the end of the motor drive rod. The inner needle was robustly combined with the motor drive rod by using a luer-lock hypodermic needle, while the hole of the front holder also acts as a drive supporter of the inner needle replacing the previous outer needle. A single-mode fiber for real-time distance sensing between the needle tip and the sample is located in the inner needle. The fiber optic cable inside the inner needle is an indispensable component required to measure the distance information of the tool tip. The joint part works as not only the channel of the single-mode fiber for OCT signals but is also combined with the piezo-motor drive rod and the inner surgical needle. The SMART uses a piezoelectric motor with a maximum speed of 20 mm/s and maximum stroke of 55 mm. The motor dimensions (22 mm x 10.8 mm x 18.7 mm) determine the minimum cross-sectional area of the SMART. The length of SMART is 108 mm without the surgical needle. The front holder has a room to travel up to 10 mm. Fig. 1 shows CAD-based top view image of previous and current SMART. The piezoelectric motor is connected to the tool tip and moves the tool tip in accordance with the CPOCT sensor input.

Fig 1.

Fig. 1 shows the top view of SMART configuration including CP SS-OCT (a) previous SMART (b) current SMART

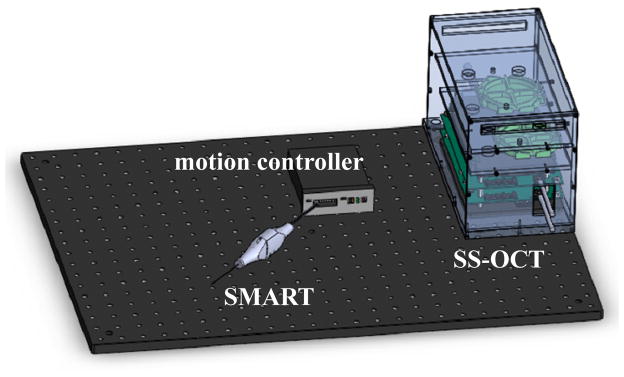

Fig. 2 shows the SMART configuration including the SSOCT system and a motor controller without a workstation (Dell, T7500). The fiber optic distance sensor, SSOCT system has a swept source engine, a 2x2 coupler, a photodiode, and electronics for signal processing. The laser is sent down the center of the needle because the single mode fiber is located inside the inner needle. The SMART introduces the AXSUN 1060 nm OCT swept source OEM engine which has a high speed sweep rate of 100 kHz, high output power of 15mW average, and a wide tuning bandwidth from 980–1100nm that can give an axial resolution of about 10 μm. The OCT engine introduces Camera Link Data Acquisition Board to acquire OCT Data at a sampling rate of up to 500 MSPS with 12 bit resolution. The output of a Camera Link DAQ Board in Axsun swept source engine is integrated with the Camera Link input of a NI frame grabber. The DAQ board can be compactly combined within the Axsun SSOCT Engine without enlarging the assembly footprint. A quad-core workstation processes high-speed OCT data to find the sample surface. The piezo-motor controller has a LabVIEW based feedback control scheme. The feedback controller operates the closed-loop with an update speed of 500 Hz to hold the surgical needle at the target height. The scheme of the PID feedback control is the same as the previous SMART and includes: 1. Initialization of inner needle; 2. An edge detection method finding the sample surface; 3. Predetermined threshold based triggering the motion compensation; 4. A feedback control loop based automated surgical tool actions. The distance that is measurable by OCT is limited to approximately 3 mm from the target surface. The distance sensor measures and compensates the motion at 500 Hz which is much higher than the typical tremor frequency of 0–15 Hz.

Fig 2.

Fig. 2 shows the SMART system on optical table including SS-OCT and a motion controller without a computer.

In the present work swept source optical coherence tomography is introduced as a high-speed high-precision fiber-optic distance sensor to place the surgical tip at the desired position by measuring the exact height between the surgical needle tip and the sample surface. Swept source OCT for imaging is usually based on the Michelson interferometer, but the common path OCT (CP-OCT) scheme is used as a fiber optic distance sensor to acquire the precise height information at high-speed, rather than as an imaging modality, which does not require the separated reference arm. The merits of common-path OCT include but are not limited to a compact cost-effective configuration for disposable surgical tool usage and prevention of polarization and dispersion mismatch problems that would occur between two arms as the distal end of the single mode fiber functions as a partial reflector of the reference arm.

To generate an interference OCT signal a strong sample arm signal is necessary. The required signal is small as compared to the reference arm signal. Strong back reflection from the fiber end is required to make a good reference arm signal and get good SNR. Most of the OCT signal should be acquired under the detection saturation limit of the photodiode and the proposed OCT system is designed to achieve this.

Ball micro lenses have been commonly used as an important optical element to achieve signal coupling between optical fibers, lasers, and detectors. For example, it can be useful for fiber communication, endoscopes, bar code readers, optical pick-up devices, and other sensor applications. Here, we introduce a Sapphire (Al2O3) ball lens with a diameter of 0.4 mm and index of refraction of 1.77 into the surgical tip of the single mode fiber. In this scheme the SMART’s compensation system offers improved performance when evaluating the task of keeping a constant holding-still position.

3. EXPERIMENTAL RESULTS

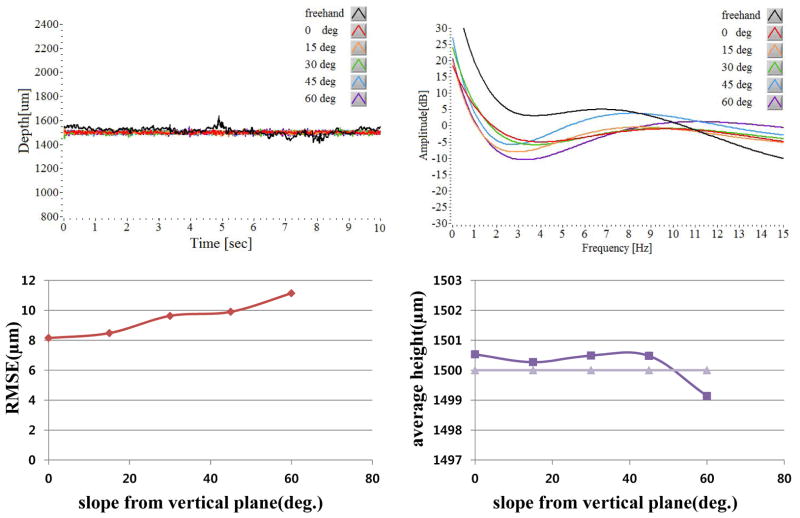

The effective height of the present SMART for imaging tissue is in the range between 1 mm and 3 mm from the sample surface. We previously reported on the tremor reduction performance in a dry phantom and in a chicken embryo model with all the testing occurring free hand in an air medium. In this work, we attempt to cancel surgeon hand tremor with holding still for 10 seconds in a water medium which is analogous to human vitreous. Fig. 3 shows the freehand and compensated positions and the graphs of their Fourier analyses of up to 15 Hz for 10 second period in accordance with the angle of inclination of the SMART. Lower inclination shows better reduction in the low frequency band less than 10 Hz. Fig. 3 also shows their root mean square error (RMSE) of the target positions. The RMSE was from 8 μm to 11 μm as a function of the angles. The average distance of the tool tip from the target surface during acquisition of the motion compensation data in water was from 1499 μm to 1501 μm.

Fig. 3.

Compensation position, Fourier analysis, RMSE, and average height of the ball lens based SMART on the dry sample in water, as a function of the slope with reference to the vertical plane in motion compensation mode.

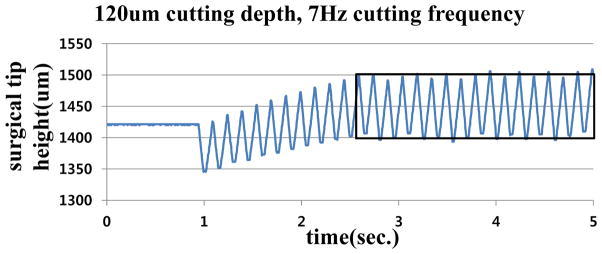

Next, we test the cutting mode of the SMART using the Piezo LEGS motor that has a hysteresis in its forward and backward movements. In order to avoid cumulative step function error, the motor position is always compensated by setting a predetermined offset distance from the top of the sample. The transition time of the position is about 1–2 second. Fig. 4 shows one of the cutting modes measured by the OCT distance sensor. The maximum position of the tool tip is always changed into 1500 μm that we already determined, with 120 μm cutting range and a 7Hz cutting frequency.

Fig 4.

Fig. 4 shows cutting performance with a current SMART blade.

4. CONCLUSION

Delicate freehand maneuvers performed with dexterity and precision are required to perform vitreoretinal microsurgery. Undesirable instrument movement contributes to unexpected damages, and prohibits the finest microsurgical manipulations. Here, we present a method to improve the performance of our first smart handheld microsurgical tool, SMART, as well as provide upgrades to its ergonomic design. This SMART is based on common path swept source optical coherence tomography (CP SS-OCT) and in this work now incorporates a ball lens fiber optic distance sensor for working in an aqueous environment layer as well as a piezoelectric motor tuned for tremor compensation. The CP SS-OCT and piezoelectric motor are used for distance sensing and tremor compensation, respectively. OCT is coupled to a feedback loop designed to hold the target position of the tool tip steady. In first application, the ball lens based SMART was used to demonstrate the reduction of hand tremor in accordance with the angle of inclination of SMART in water. Compared to prior free hand experiments in air the ball lens based SMART performed similarly with regard to dampening of involuntary physiological hand tremor of around 0–15 Hz, with best performance in the low frequency band. In second application, the cutting mode of SMART was assessed and its performance was analyzed by measuring the tool tip position using the ball lens fiber optic distance sensor. This “SMART” was also capable of fine motion control in water and its sensing function could be used to significantly enhance the surgical performance of retina surgeons. Clinical value would also contain precise tool tip targeting, improved surgeon abilities, active micron scale maneuvers, reduction of surgical risk and innovative microsurgical training methods.

Acknowledgments

The research reported in this paper was supported by the U.S. National Institutes of Health and the National Eye Institute (NIH/NEI) Grant R01EY021540-01A1 and Research to Prevent Blindness (RPB).

References

- 1.Balicki M, Uneri A, Iordachita I, Handa J, Gehlbach P, Taylor R. Micro-force Sensing in Robot Assisted Membrane Peeling for Vitreoretinal Surgery. Med Image Comput Assist Interv. 2010;13(Pt 3):303–310. doi: 10.1007/978-3-642-15711-0_38. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.MacLachlan RA, Becker BC, Cuevas Tabarés J, Podnar GW, Lobes LA, Jr, Riviere CN. Micron: an actively stabilized handheld tool for microsurgery. IEEE Trans Robot. 2012;28(1):195–212. doi: 10.1109/TRO.2011.2169634. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Tao YK, Ehlers JP, Toth CA, Izatt JA. Intraoperative spectral domain optical coherence tomography for vitreoretinal surgery. Opt Lett. 2010;35(10):3315–3317. doi: 10.1364/OL.35.003315. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Liu X, Iordachita I, He X, Taylor R, Kang J. Miniature fiber-optic force sensor based on low-coherence Fabry-Pérot interferometry for vitreoretinal microsurgery. Biomed Opt Express. 2012;3(5):1062–1076. doi: 10.1364/BOE.3.001062. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Zhang K, Kang J. Common-path low-coherence interferometry fiber-optic sensor guided microincision. J Biomed Opt. 2011;16(9):0950031–0950034. doi: 10.1117/1.3622492. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Zhang K, Kang J, et al. A Surface Topology and Motion Compensation System for Microsurgery Guidance and Intervention Based on Common-Path Optical Coherence Tomography. IEEE Trans Biomed Eng. 2009;56(9):2318–2321. doi: 10.1109/TBME.2009.2024077. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Song C, Gehlbach PL, Kang JU. Active tremor cancellation by a “Smart” handheld vitreoretinal microsurgical tool using swept source optical coherence tomography. Opt Express. 2012;20(21):23414–23421. doi: 10.1364/OE.20.023414. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Huang Y, Liu X, Song C, Kang JU. Motion-compensated hand-held common-path Fourier-domain optical coherence tomography probe for image-guided intervention. Biomed Opt Express. 2012;3(12):3105–3118. doi: 10.1364/BOE.3.003105. [DOI] [PMC free article] [PubMed] [Google Scholar]