Abstract

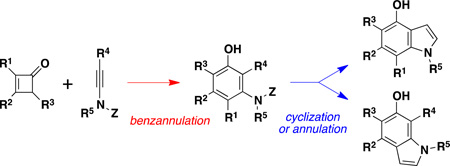

A two-stage “tandem strategy” for the synthesis of indoles with a high level of substitution on the six-membered ring is described. Benzannulation based on the reaction of cyclobutenones with ynamides proceeds via a cascade of four pericyclic reactions to produce multiply substituted aniline derivatives in which the position ortho to the nitrogen can bear a wide range of functionalized substituents. In the second stage of the tandem strategy, highly substituted indoles are generated via acid-, base-, and palladium-catalyzed cyclization and annulation processes.

INTRODUCTION

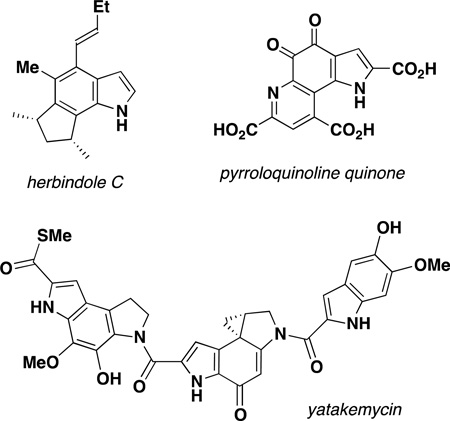

The indole ring system is a key feature in the structure of numerous natural products, pharmaceutical agents, and commercially significant synthetic compounds.1 Despite a century and a half of research, the efficient construction of indoles with certain substitution patterns remains a challenging problem.2,3 While a number of effective strategies are available for the synthesis of indoles substituted on the five-membered ring, few methods provide regiocontrolled access to indoles bearing multiple substituents on the benzenoid ring.4 Metallation and electrophilic substitution provide reliable vehicles for the introduction of substituents on the five-membered ring, but attempts to install substituents on the six-membered ring of indoles are often frustrated by problems of reactivity and regiochemical ambiguity. The efficient synthesis of multiply substituted indoles such as the natural products shown below thus continues to pose a formidable challenge for organic synthesis.

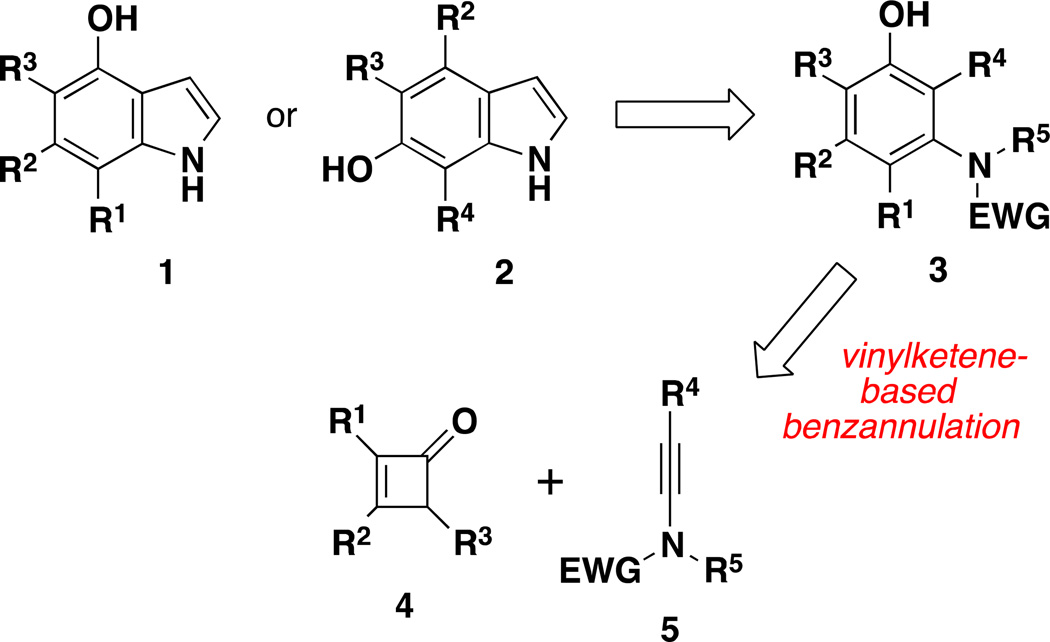

The majority of methods for the synthesis of indoles involve the elaboration of the five-membered ring from anilines, o-halo anilines, or other 2-substituted aniline derivatives. Recently we reported a versatile approach to the synthesis of highly substituted anilines based on a tandem ynamide benzannulation-ring closing metathesis strategy.5 This two-step sequence provides efficient access to highly substituted dihydroquinolines, benzazepines, and benzazocines, including a key intermediate in a formal total synthesis of (+)-FR900482. In this paper we now report the extension of this general strategy to the preparation of highly substituted indoles. As outlined in Scheme 1, benzannulation of suitably substituted ynamides with cyclobutenones furnishes multiply substituted anilines that are functionally equipped for cyclization and annulation reactions to form indoles in the second stage of this “tandem strategy”. Herein we describe a number of complementary tandem benzannulation/cyclization protocols that can be employed in this context for the synthesis of highly substituted indoles.

Scheme 1.

Tandem Strategy for the Synthesis of Highly Substituted Indoles

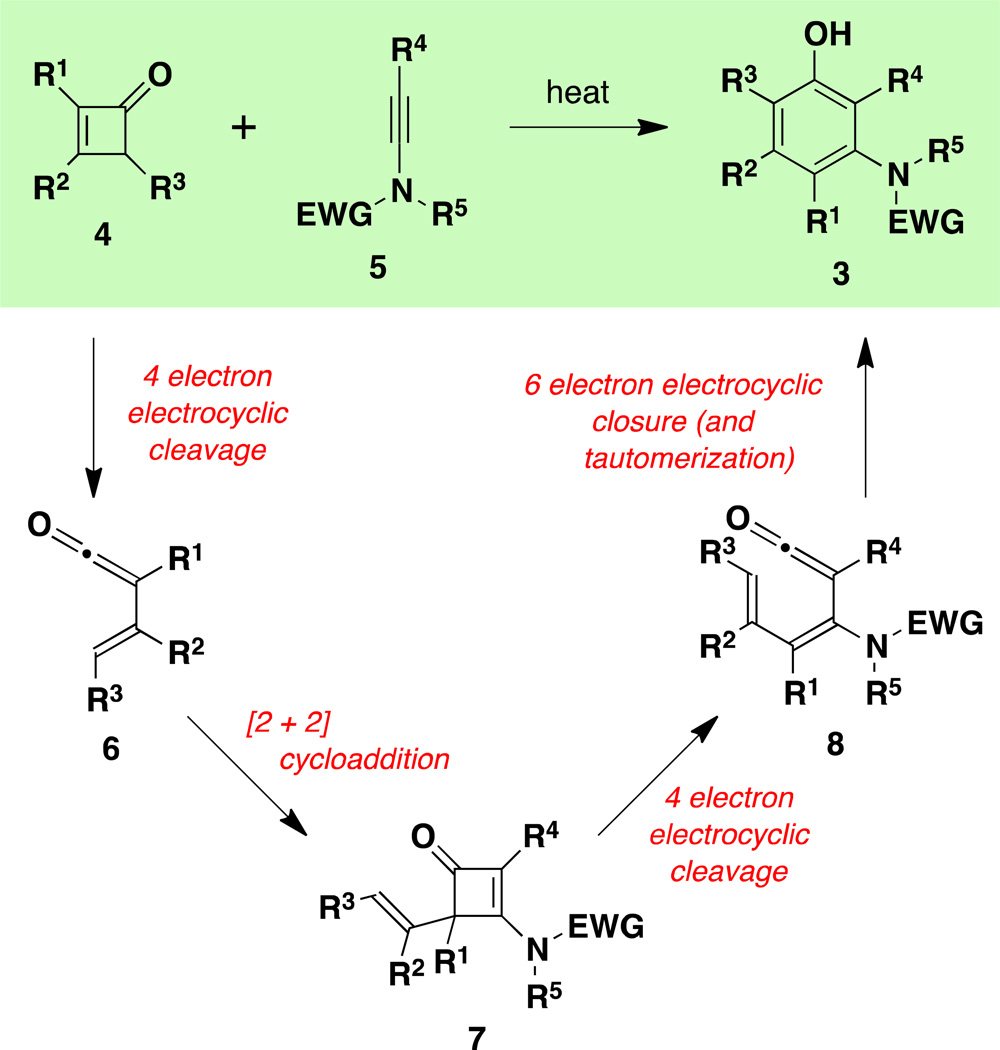

The vinylketene-based benzannulation strategy developed in our laboratory provides an efficient route to highly substituted benzenoid aromatic compounds6,7,8 as demonstrated in its application to the total synthesis of a number of naturally occurring compounds.9,10 Operationally the benzannulation involves a single synthetic step, but mechanistically it proceeds via a “cascade” of four consecutive pericyclic reactions. As outlined in Scheme 2, electrocyclic ring opening of the cyclobutenone annulation partner 4 triggers the cascade, generating a vinylketene 6 that is intercepted by the alkyne 5 in a [2 + 2] cycloaddition to afford the key 4-vinylcyclobutenone intermediate 7. Under the reaction conditions, this intermediate then undergoes reversible 4-electron electrocyclic cleavage to generate dienylketene 8, which rapidly cyclizes via 6-π electrocyclic closure to furnish the final aromatic product 3 following tautomerization. Note that while the two electrocyclic ring opening events require activation by heat or light, the [2 + 2] cycloaddition and 6-π electrocyclic closure steps proceed at room temperature or below.

Scheme 2.

Pericyclic Cascade Mechanism of the Vinylketene-Based Benzannulation

RESULTS AND DISCUSSION

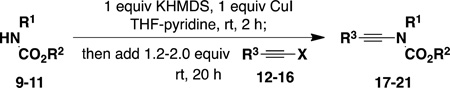

Synthesis of Benzannulation Partners

Synthesis of the requisite benzannulation partners for these studies was conveniently accomplished using methods previously developed in our laboratory. Cyclobutenones are available in 1–2 steps via ketene-alkyne cycloadditions,11 and the synthesis of ynamides12 is achieved in good yield via alkynyl bromides13 by using the copper-promoted N-alkynylation reaction pioneered in our laboratory14 and that of Hsung.15,16 Table 1 summarizes the application of our N-alkynylation protocol to the synthesis of the new carboalkoxy ynamide derivatives employed in the present study.

Table 1.

Synthesis of Ynamides from Carbamates

| ||||

|---|---|---|---|---|

| entry | carbamate | haloalkyne | ynamide | yield (%)a |

| 1b |

9 R1 = allyl R2 = Me |

12 R3 = Me X = I |

17 | 55 |

| 2 | 9 |

13 R3 = CH2OSit-BuMe2 X = Br |

18 | 55 |

| 3 | 9 |

14 R3 = (CH2)2OSit-BuMe2 X = Br |

19 | 66 |

| 4 |

10 R1 = Me R2 = t-Bu |

15 R3 = allyl X = Br |

20 | 43 |

| 5 |

11 R1 = Bn R2 = (CH2)2SiMe3 |

16 R3 = CH2CH(OMe)2 X = Br |

21 | 57–69 |

Isolated yield of products purified by column chromatography.

Reaction performed in pyridine-benzene-THF.

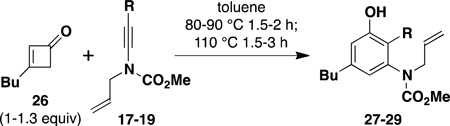

Synthesis of Indoles via N-Allyl Ynamides

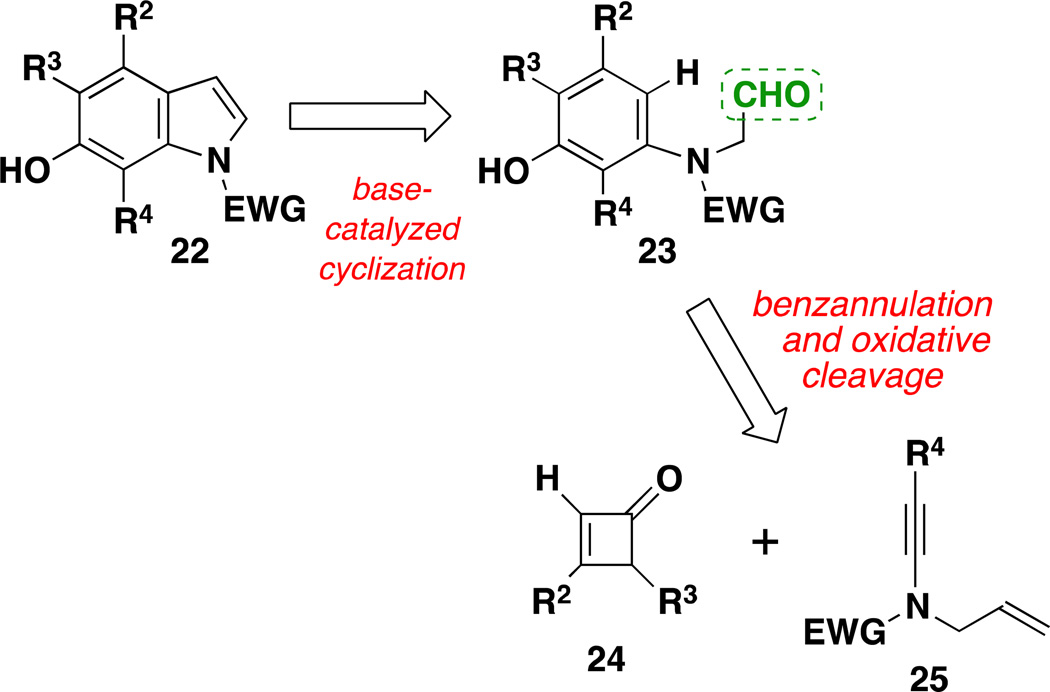

Anilines substituted on nitrogen with a 2-oxo carbon chain (or its functional equivalent) can be converted to indoles by the action of Brønsted and Lewis acids.17,18 This transformation proceeds via aromatic substitution followed by elimination and serves as a key step in the classic Bischler indole synthesis and its variants. Our first plan for the application of our tandem strategy to the synthesis of indoles called for a variant of this venerable process in which ring closure would be achieved via the base-catalyzed cyclization of an α-anilino aldehyde derivative of type 23 (Scheme 3). Benzannulation employing N-allyl ynamides of type 25 followed by oxidative cleavage would provide access to the key cyclization substrates. Of particular interest to us was the possibility of exploiting the presence of the hydroxyl group in 23, which we hoped would allow us to effect the key cyclization step under mild basic conditions in contrast to the strongly acidic conditions typically employed in the Bischler synthesis. The products of these cyclizations would be 6-(hydroxy)indoles, with the hydroxyl group serving as a potential handle for further synthetic elaboration via transition-metal-catalyzed coupling reactions of sulfonate derivatives.

Scheme 3.

Strategy for the Synthesis of Indoles via N-Allyl Ynamides

The feasibility of this approach was investigated using readily available 3-butylcyclobutenone11 as the vinylketene precursor. As expected, the optimal conditions for benzannulation with N-allyl ynamides involve a staged heating protocol as outlined in Table 2. This procedure minimizes [3,3]-sigmatropic rearrangement of the 1,6-enyne moiety present in these ynamides which occurs at temperatures above 125 °C.19 In our optimized benzannulation protocol, initial thermolysis is performed at 80–90 °C until all of the ynamide is consumed. This generally leads to a mixture of the desired benzannulation product and intermediate 4-vinylcyclobutenone (i.e., 7 in Scheme 2). Further heating at 110 °C converts the vinylcyclobutenone to the desired phenol product. As predicted, ketene [2 + 2] cycloaddition to these N-allyl ynamides occurs chemoselectively at the electron-rich ynamide π bond, and no products resulting from competitive reaction at the alkene double bond were detected in these benzannulations.

Table 2.

Benzannulation with N-Allyl Ynamides

| ||||

|---|---|---|---|---|

| entry | R | ynamide | aniline | yield (%)a |

| 1 | Me | 17 | 27 | 78 |

| 2 | CH2OSit-BuMe2 | 18 | 28 | 85 |

| 3 | (CH2)2OSit-BuMe2 | 19 | 29 | 94 |

Isolated yield of products purified by column chromatography.

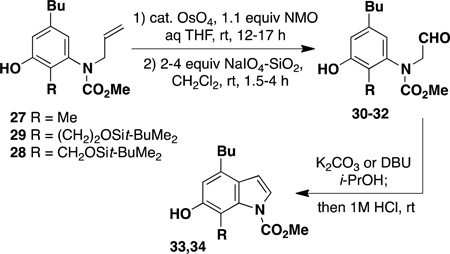

With benzannulation products 27–29 in hand, we next investigated conditions for the oxidative cleavage of the pendant alkene. Both ozonolysis and one-pot Lemieux-Johnson oxidation20 afforded the desired aldehydes in modest yield accompanied by side products that were difficult to separate by chromatography. As shown in Table 3, however, dihydroxylation followed by treatment of the resultant crude diol with NaIO4 on silica gel21 furnished the desired aldehydes in excellent yield.

Table 3.

Synthesis of Indoles 33 and 34

| ||||||

|---|---|---|---|---|---|---|

| entry | alkene | aldehyde | yield (%)a | methodb | indole | yield (%)a |

| 1 | 27 | 30 | 82–84 | A | 33 | 71 |

| 2 | B | 74–82 | ||||

| 3 | 29 | 31 | 91–98 | A | 34c | 74 |

| 4 | B | 65 | ||||

Isolated yield of products purified by column chromatography.

Method A: K2CO3 (1.0 equiv), i-PrOH, 50–70 °C, 2–4 h. Method B: DBU (0.5 equiv), i-PrOH, 65–70 °C, 1.5–2 h.

R = (CH2)2OH (cleavage of silyl group occurs during the reaction).

A systematic investigation of conditions for cyclization of aldehyde 30 revealed that best results are obtained under the basic conditions described in Table 3. Initial exploratory experiments employing Lewis acids were not promising. Importantly, we observed that cyclizations are best conducted under relatively dilute conditions (0.1–0.2 M) to minimize side reactions involving condensation of the aldehydes with the electron-rich indole products. Isopropanol proved superior to methanol as solvent as some cleavage of the carbamate protecting group was observed in the latter solvent. Reaction with DBU and K2CO3 gave similar results; under these conditions a mixture of the desired indole and its secondary alcohol precursor are typically obtained. Complete dehydration to the indole is then achieved by addition of HCl to the reaction mixture after cooling to room temperature.

Although conversion of benzannulation product 29 to indole 34 took place smoothly under these conditions, cyclization of the aldehyde (32) derived from 28 to the desired indole proceeded in low and variable yield (0–30%). In this case we believe that the intermediate phenoxide undergoes facile elimination of silanolate to afford a highly reactive ortho-quinone methide species.

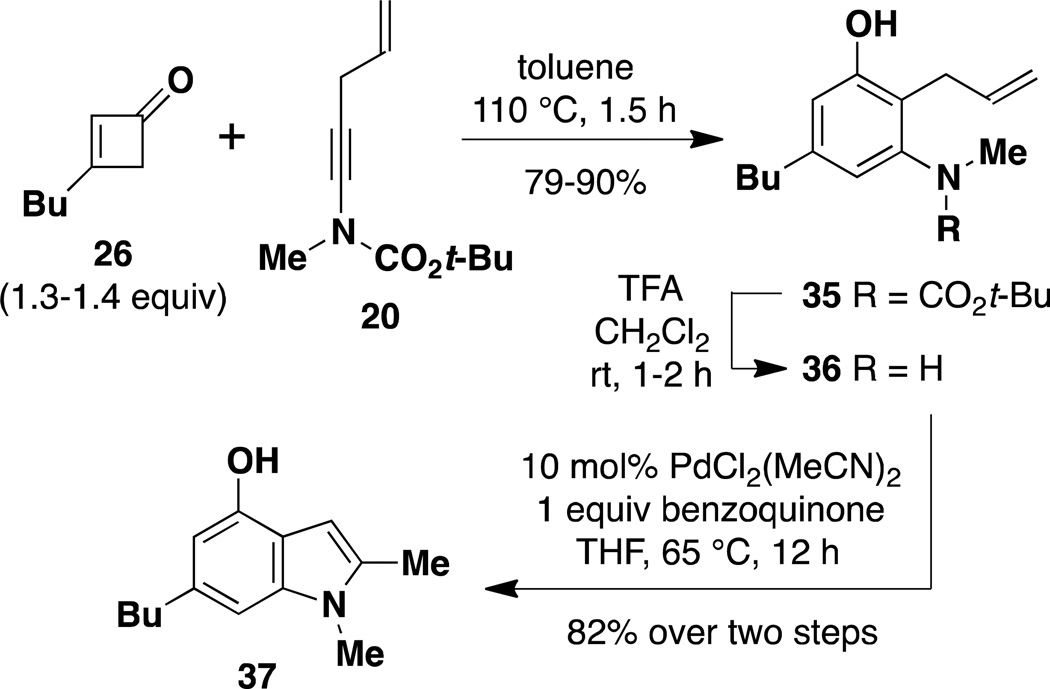

Synthesis of Indoles via C-Allyl Ynamides

Hegedus has shown that ortho-allyl anilines undergo cyclization to form indoles upon exposure to Pd(II) catalysts in the presence of benzoquinone.3,22 Scheme 4 illustrates the application of the Hegedus cyclization as the second stage of our tandem benzannulation-cyclization strategy for the synthesis of indoles. Cleavage of the BOC group on nitrogen reveals the nucleophilic amino group and exposure to the conditions developed by Hegedus results in cyclization via reaction of the Pd(II) coordinated alkene with the amino rather than hydroxyl group. Note that the products of these cyclizations are 4-(hydroxy)indoles, in contrast to the 6-hydroxy derivatives generated by the N-allyl ynamide approach.

Scheme 4.

Synthesis of Indole 37 via Benzannulation and Hegedus Cyclization

More conveniently, conversion of the BOC derivative 35 to indole 37 can be achieved in a one-pot operation as outlined in Scheme 5. In this case, Hegedus-type cyclization of 35 furnishes benzofuran 38 by cyclization via the phenolic hydroxyl group. Addition of concentrated HCl then leads directly to the desired indole, presumably via BOC cleavage, cleavage of the furan ring, and cyclization as previously described by Guiotto and coworkers.23

Scheme 5.

Indole Synthesis via Hegedus Cyclization: An Alternative Route

Synthesis of Indoles via Ynamide 21

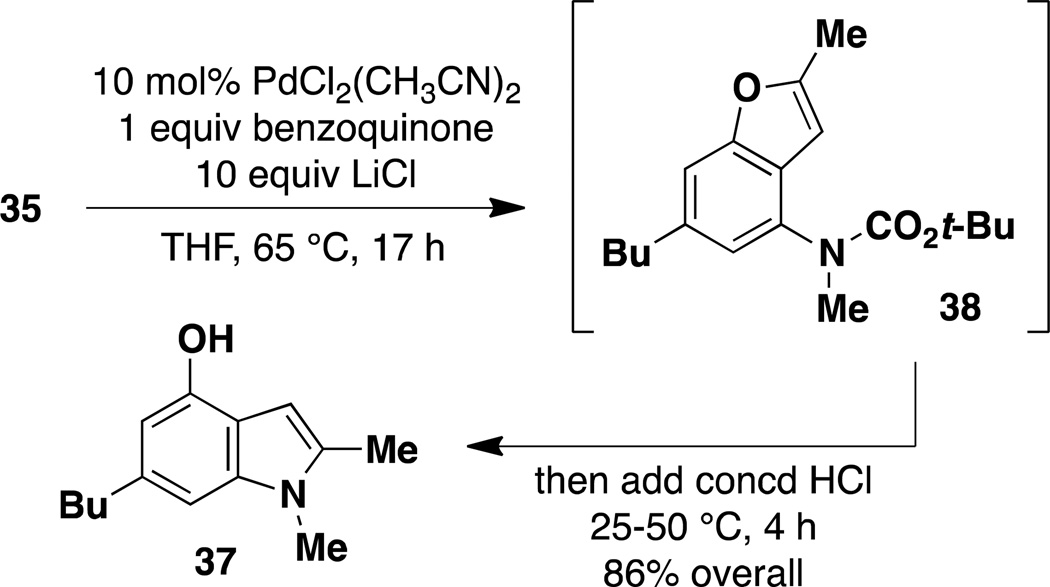

The cyclization of amino aldehydes of type 40 (Scheme 6) constitutes a well-established route to indoles. Cyclizations of this type, for example, comprise a key step in the well-known Plieninger indole synthesis.24 We anticipated that multiply substituted indoles of general structure 39 would be available via benzannulations based on alkynes of type 42 bearing a latent –CH2CHO substituent attached at C-2 of the ynamide.

Scheme 6.

Strategy for the Synthesis of Indoles via Aminobutynal Derivatives

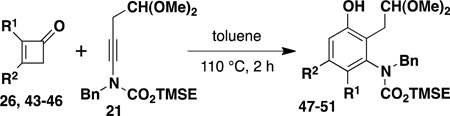

We recognized that the realization of this strategy would require carefully planned choreography in the unveiling of the various reactive functional groups to ensure that cyclization via the amino group rather than the hydroxyl group would occur. With this consideration in mind, we focused our attention on benzannulations of ynamide 21 in which the aldehyde is masked as an acetal derivative. As shown in Table 4, we found that benzannulation with this ynamide and most cyclobutenones proceed in good yield upon heating in toluene at reflux. As expected, benzannulation with the more highly substituted cyclobutenone 46 requires higher temperature, a consequence of the slower [2 + 2] cycloaddition of the “ketoketene” intermediate involved in this case.25

Table 4.

Benzannulation with Ynamide 21

| |||||

|---|---|---|---|---|---|

| entry | R1 | R2 | cyclobutenone (equiv) | aniline | yield (%)a |

| 1 | H | Bu | 26 (1.0–1.1) | 47 | 84 |

| 2 | H | Ph | 43 (1.0) | 48 | 79 |

| 3 | H | OEt | 44 (1.5) | 49 | 53–61 |

| 4 | H | SnBu3 | 45 (1.2) | 50 | 87 |

| 5b | Me | Me | 46 (1.8) | 51 | 63 |

Isolated yield of products purified by column chromatography.

Reaction conditions: 145 °C, 49 h; then 5M KOH, MeOH, 65 °C, 2.5 h (to hydrolyze some phenol ester).

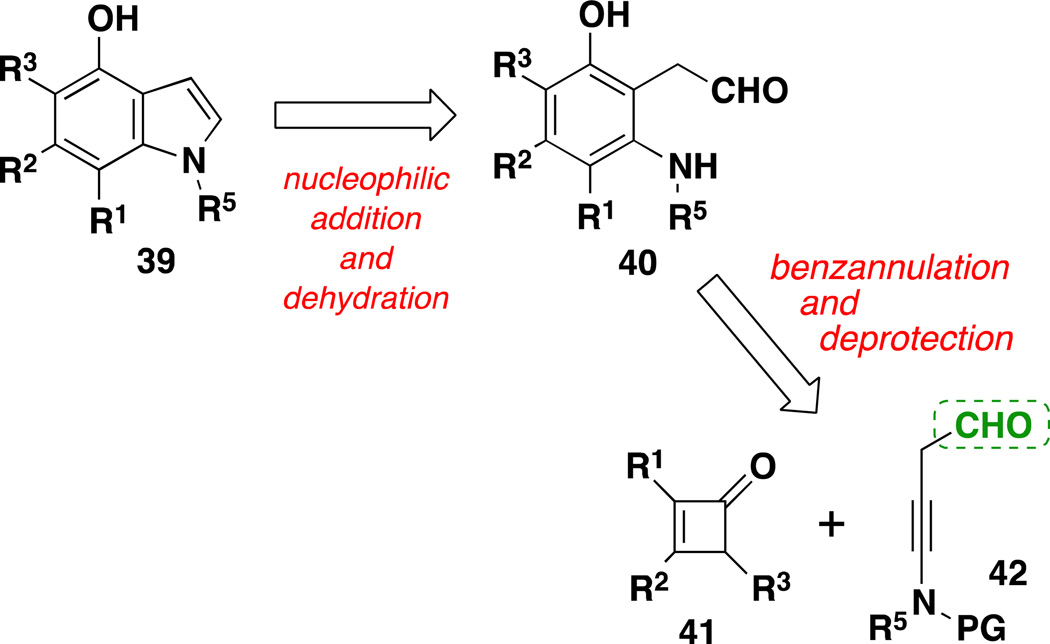

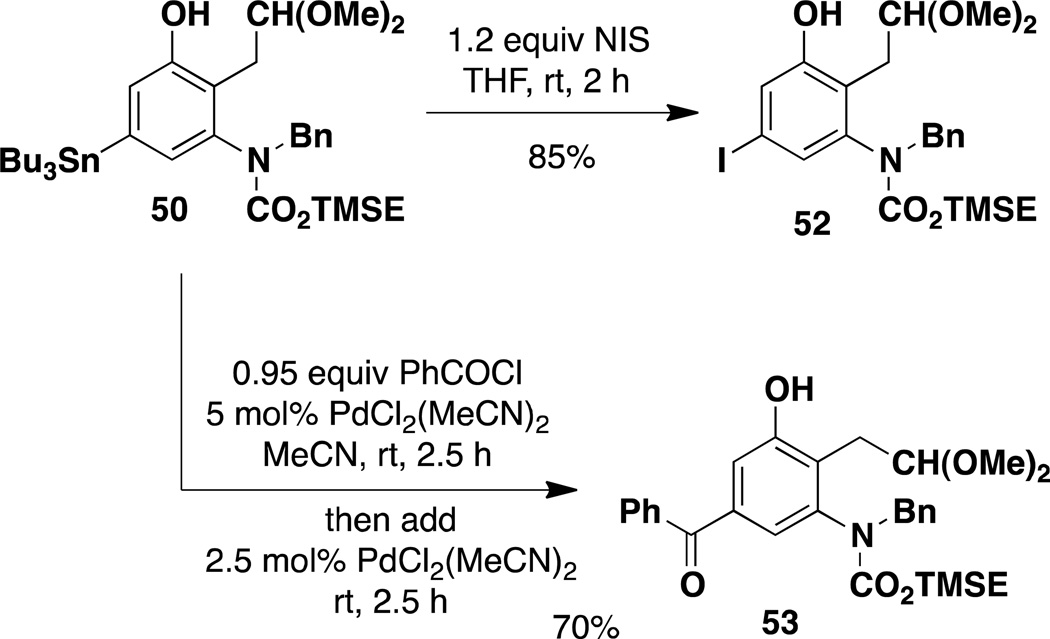

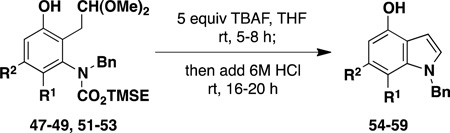

A systematic investigation of conditions for conversion of benzannulation products 47–51 to the desired indoles led to the optimized one-pot protocol shown in Table 5. First, cleavage of the trimethylsilylethyl carbamate group proceeds smoothly on exposure to excess TBAF at room temperature. HCl is added, and the reaction mixture is then stirred overnight to afford the desired indoles in good yield. Although the arylstannane benzannulation product 50 is not itself stable to these acidic cyclization conditions, it does serve as a versatile precursor to derivatives such as the iodide 52 and ketone 53 (Scheme 7) that undergo smooth cyclization to indoles 57 and 58, respectively, under the standard conditions.

Table 5.

Indole Synthesis via Nucleophilic Cyclization

| |||||

|---|---|---|---|---|---|

| entry | aniline | R1 | R2 | indole | yield (%)a |

| 1 | 47 | H | Bu | 54 | 79–84 |

| 2 | 48 | H | Ph | 55 | 78 |

| 3 | 49 | H | OEt | 56 | 85 |

| 4 | 52 | H | I | 57 | 53 |

| 5 | 53 | H | COPh | 58 | 87 |

| 6 | 51 | Me | Me | 59 | 74–80 |

Isolated yield of products purified by column chromatography.

Scheme 7.

Elaboration of Arylstannane 50

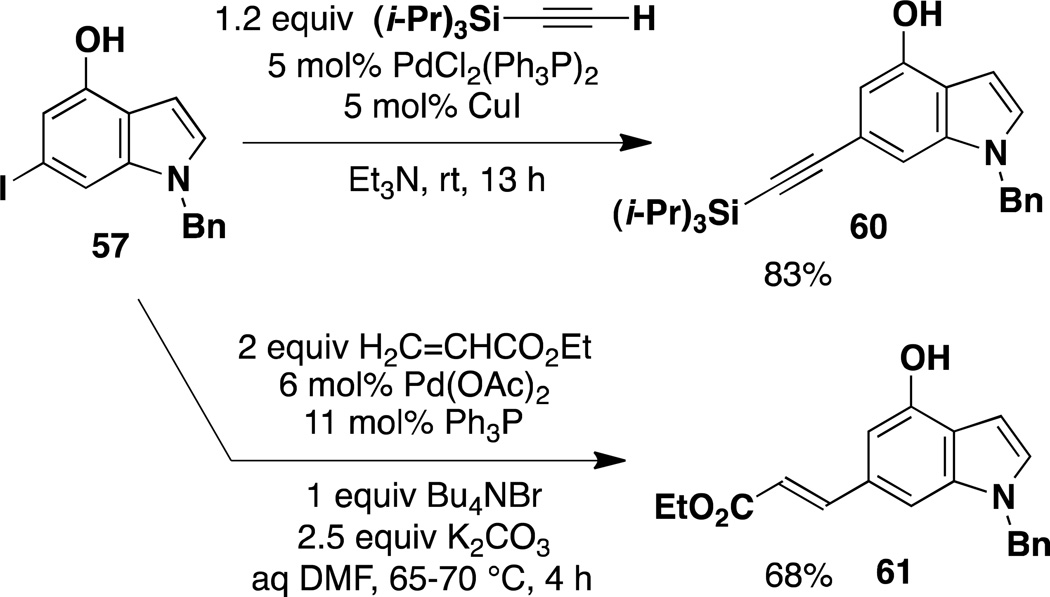

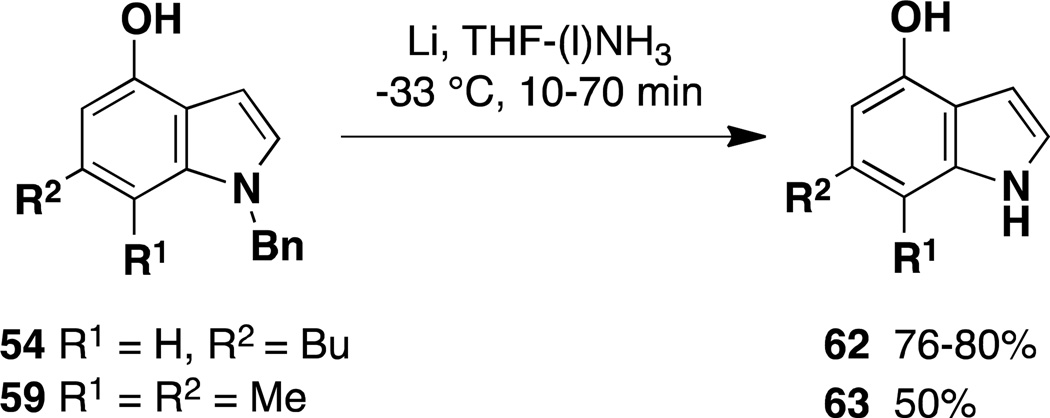

The 6-iodoindole 57 is itself a particularly versatile intermediate, serving as a precursor to indoles with a variety of substituents at the C-6 position as illustrated in Scheme 8. Finally, if desired, debenzylation of the indole products can be conveniently effected under dissolving metal conditions as shown in Scheme 9.

Scheme 8.

Cross-coupling Reactions of 6-Iodoindole 57

Scheme 9.

Debenzylation of Indoles 54 and 59

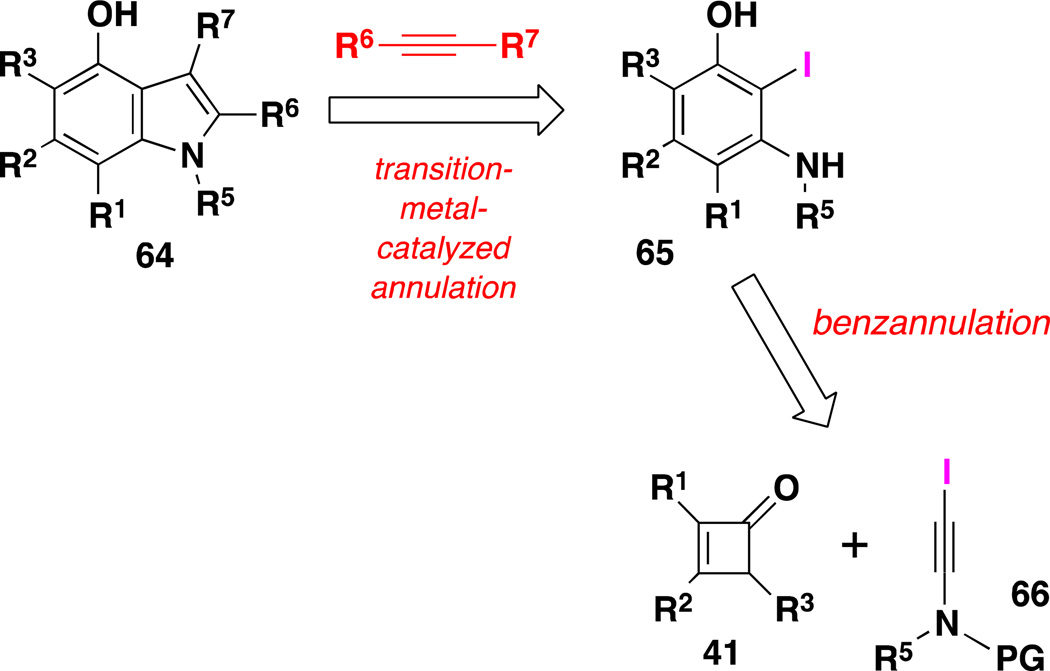

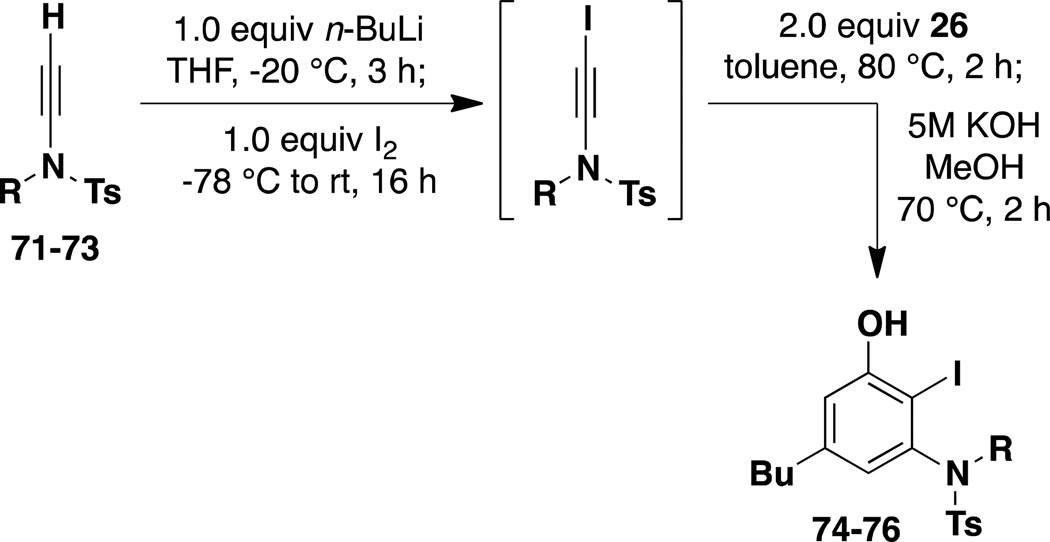

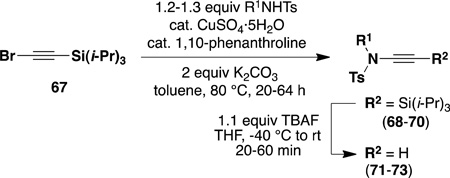

Synthesis of Indoles via Iodoynamides

Recently we reported the first synthesis of 2-iodoynamides and demonstrated that these compounds participate in [2 + 2] cycloadditions with ketene to furnish 2-iodocyclobutenones in good yield.26 We recognized that benzannulation with this new class of ynamides could furnish access to 2-iodoanilines whose utility as substrates in a variety of indole-forming annulation processes is well established. We therefore turned our attention to the investigation of tandem strategies based on the application of iodoynamides in our vinylketene-based benzannulation in conjunction with various transition-metal-catalyzed annulation processes (Scheme 10).

Scheme 10.

Strategy for the Synthesis of Indoles via Iodoynamides

The N-sulfonyl ynamides employed in this variant of our tandem strategy were best prepared by using the N-alkynylation protocol of Hsung (Table 6). Conversion of terminal ynamides 71–73 to the corresponding iodo derivatives then proceeded smoothly under our previously reported conditions26 (Table 7). Attempts to purify the iodoynamides using column chromatography resulted in significant losses and these ynamides were therefore employed in benzannulations without purification. Optimization studies indicated that reaction of the iodoynamides with cyclobutenone 26 were best conducted by heating in toluene at 80 °C for 2 h at which point TLC analysis indicated that all of the ynamide had been consumed. We believe that the ynamide is reacting primarily by [2 + 2] cycloaddition since we had previously observed in control experiments that pure N-sulfonyl iodoynamides have half lives on the order of 40 h at 80 °C in toluene and that iodoynamides are recovered unchanged after heating for several hours at 80 °C in the presence of phenols such as the benzannulation products 74–76. Improved yields in these benzannulations were obtained by using an excess of the cyclobutenone and by treating the crude product with KOH in methanol. Base treatment serves to hydrolyze any esters formed by trapping of the phenolic hydroxyl group with ketene intermediates during the reaction.27

Table 6.

Synthesis of Alkynyl Sulfonamides

| ||||

|---|---|---|---|---|

| R1 | silyl ynamide |

yield (%)a | terminal ynamide |

yield (%)a |

| PMB | 68 | 88 | 71 | 94–96 |

| allyl | 69b | 90–91 | 72c | 87–91 |

| 2-furfuryl | 70 | 61–64d | 73 | 94–98 |

Isolated yield of products purified by column chromatography.

Zhang, Y.; DeKorver, K. A.; Lohse, A. G.; Zhang, Y.-S.; Huang, J.; Hsung, R. P. Org. Lett. 2009, 11, 899–902.

Ref. 54.

Reaction performed in toluene-DMF.

Table 7.

Iodination and Benzannulation of Terminal Ynamides 71–73

Overall two-step isolated yield of products purified by column chromatography.

KHMDS is used in place of n-BuLi in the first step.

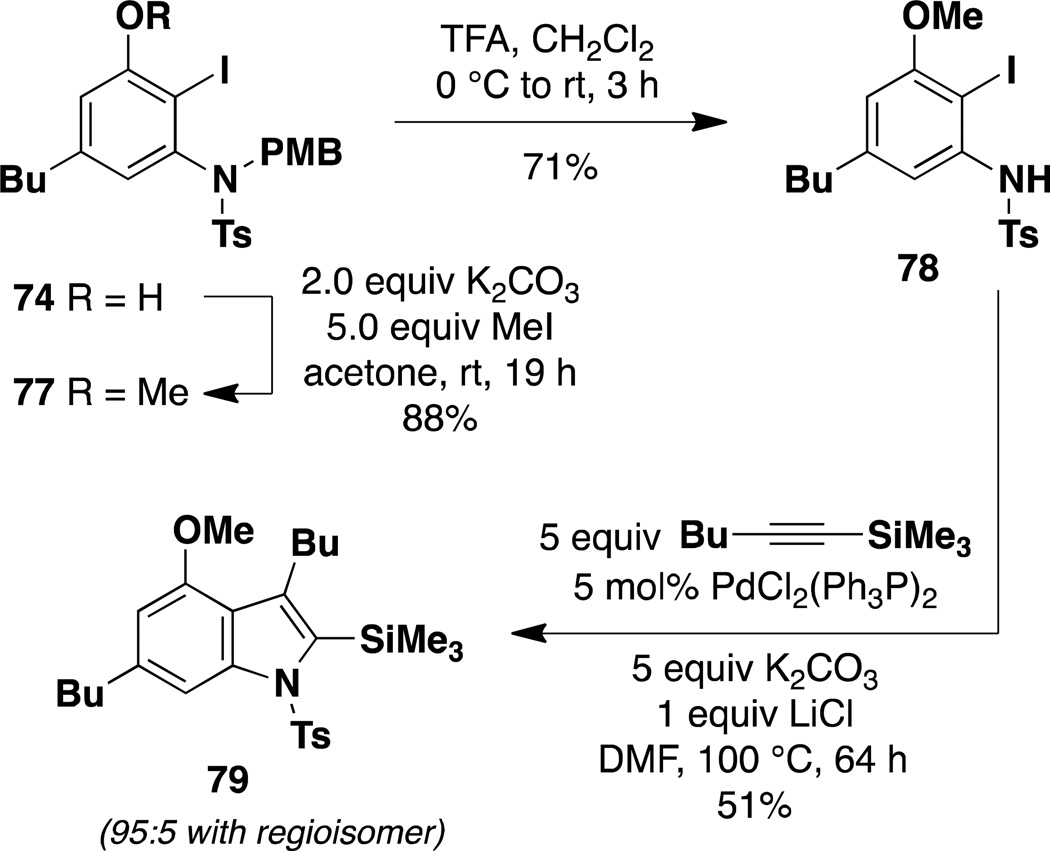

In recent years, the “Larock indole synthesis” has emerged as one of the most powerful methods for the construction of 2,3-disubstituted indoles.3, 28 This heteroannulation process involves the palladium-catalyzed reaction of 2-iodoanilines with internal alkynes and its chief limitation in scope is the difficulty associated with the regioselective synthesis of substituted iodoaniline substrates. We recognized that our vinylketene-based benzannulation provides an attractive means of accessing substituted substrates for the Larock heteroannulation and Scheme 11 illustrates an application of this strategy. To avoid potential complications resulting from competitive reaction of the nucleophilic phenolic oxygen,29 the hydroxyl group was first protected as a methyl ether. After removal of the PMB group,30 reaction with 1-trimethylsilyl-1-hexyne under standard Larock conditions gave indole 79 in 51% yield after chromatographic purification.

Scheme 11.

Synthesis of Indole 79 via Larock Heteroannulation

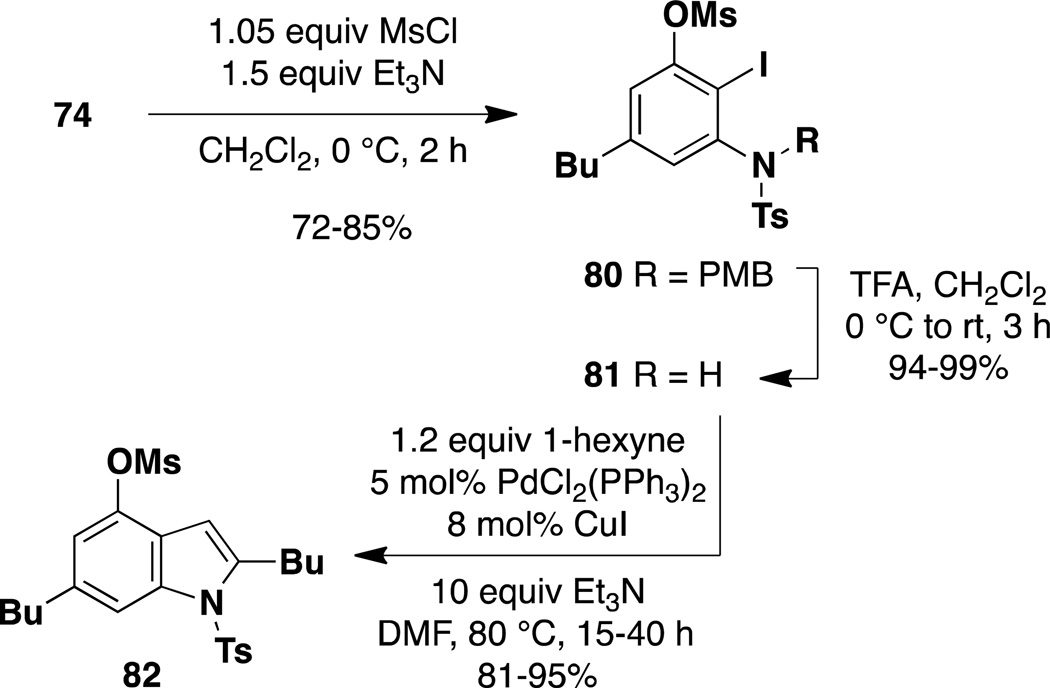

The Castro-Stephens reaction and its variants provide a useful vehicle for elaborating indoles from 2-iodoanilines by reaction with terminal alkynes.3,31 This heteroannulation process involves initial Sonogashira reaction of the aryl iodide with the alkyne to produce a 2-(alkynyl)aniline that cyclizes either in situ or in a separate step to furnish a 2-substituted indole.32 Scheme 12 illustrates the application of a one-pot variant of the Castro-Stephens reaction to a 2-iodoaniline generated via our ynamide-based benzannulation. In this case the phenolic hydroxyl group was first converted to the corresponding mesylate, providing a potential handle for further elaboration via cross-coupling chemistry. Heteroannulation with 1-hexyne proceeded efficiently under the indicated conditions to afford indole 82 in high yield.

Scheme 12.

Synthesis of Indole 82

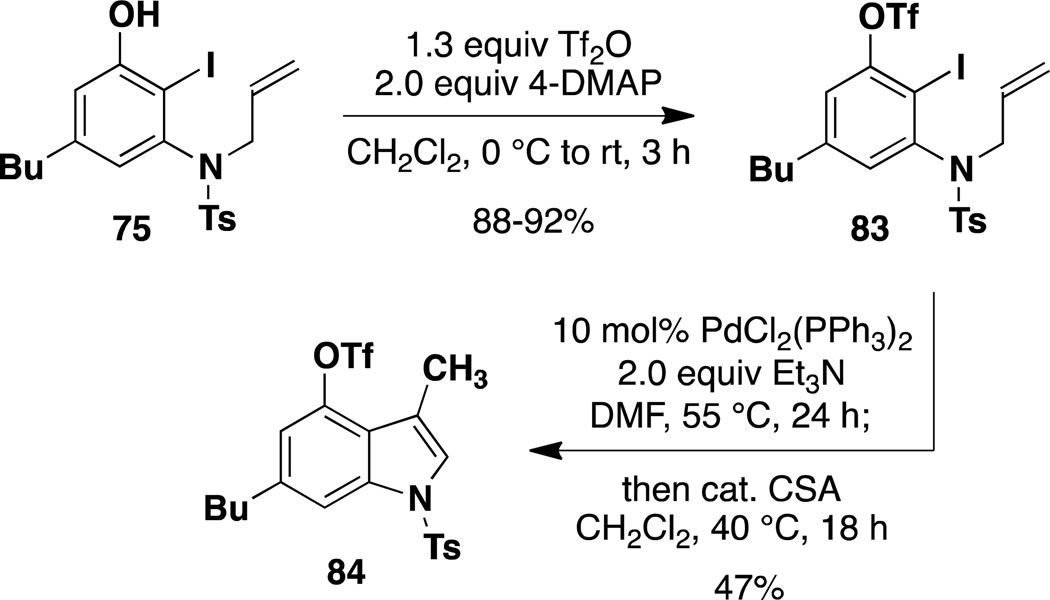

Iodoanilines of type 65 bearing an N-allyl moiety are potential substrates for intramolecular Heck reactions leading to indolines and indoles. This approach to the synthesis of indoles was pioneered by Mori and Ban3,33 and its application to an iodoaniline prepared by our ynamide-based benzannulation is illustrated in Scheme 13. Since the Mori-Ban cyclization can be performed at low temperatures, in this case we found it possible to employ the triflate derivative of 75 in the cyclization leading to formation of the 3-(methyl)indole 84 that is equipped with a handle for further elaboration at the C-4 carbon.

Scheme 13.

Synthesis of Indole 84 via Mori-Ban Cyclization

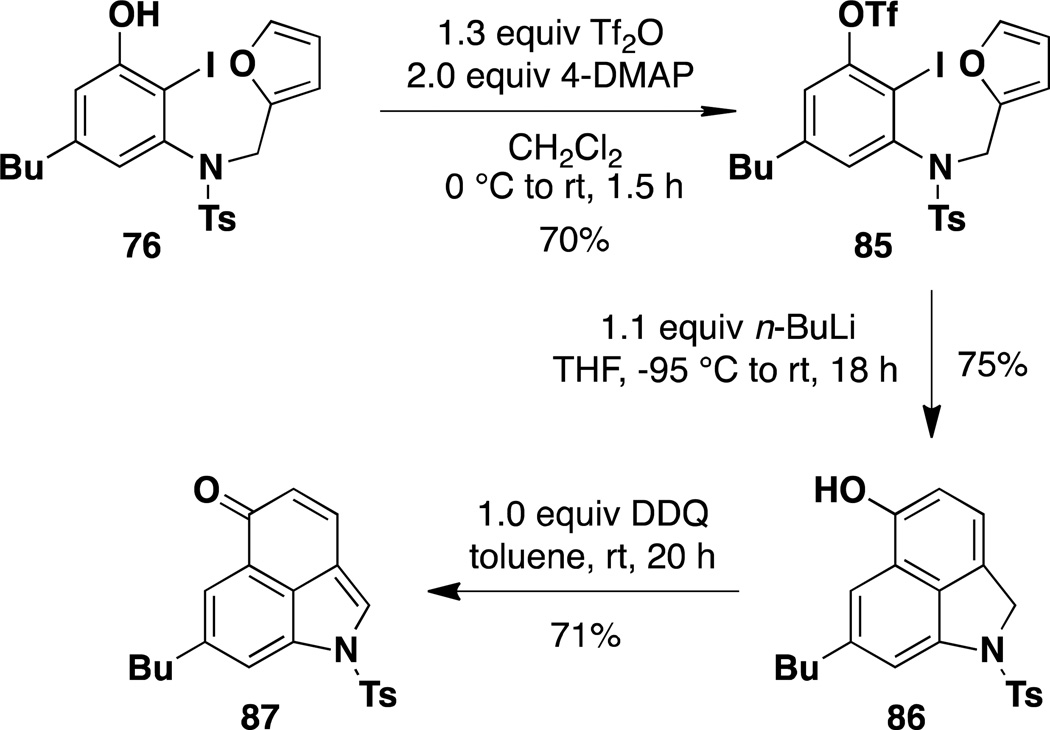

Scheme 14 presents a final example of the application of iodoynamide-derived benzannulation products as intermediates for the synthesis of highly substituted indoles. This approach exploits the ortho relationship of the hydroxyl and iodo substituents on the benzannulation products, which enables these compounds to serve as precursors to arynes via vicinal elimination of their triflate derivatives.34 Treatment of benzannulation product 76 with Tf2O furnishes triflate 85, setting the stage for an intramolecular aryne cycloaddition involving the tethered furan ring. On exposure to n-BuLi, tricyclic phenol 86 forms presumably via initial [4 + 2] cycloaddition of an aryne followed by ring opening-isomerization of the resulting highly-strained bridged ring species. Finally, oxidation of 86 with DDQ35 furnishes the benz[cd]indolone 87 in good yield.36

Scheme 14.

Intramolecular Aryne Cyclization and Oxidation from Aniline 76

CONCLUSION

The combination of the ynamide-based benzannulation with various heterocyclization and annulation processes provides access to indoles bearing multiple substituents on the benzenoid ring. In the present study, cyclobutenones were employed as the vinylketene precursors, and this version of the benzannulation serves as the basis for a versatile synthesis of indoles of type 1 (Scheme 1) with substituents R2 and R3, and of indoles of type 2 with substituents R2 and R4. Our previous studies have established that substituted cyclobutenones are readily available in one or two steps from alkyne-ketene cycloadditions, and that a variety of cyclobutenone vinylketene precursors participate in the benzannulation in good yield. For the synthesis of indoles bearing substituents R3, or in which the benzenoid ring is fused to another ring system, we anticipate that the “second generation” version of our benzannulation strategy will be the preferred method, and the application of this photo-Wolff variant of our strategy6b to the synthesis of indoles is under active investigation in our laboratory.

EXPERIMENTAL SECTION

General Procedures

All reactions were performed in flame-dried glassware under a positive pressure of argon and stirred magnetically unless otherwise indicated. Air- and moisture-sensitive liquids and solutions were transferred via gas-tight syringe or cannula and introduced into reaction vessels through rubber septa. Reaction product solutions and chromatography fractions were concentrated at 20 mmHg and then at 20 °C and 0.05 mmHg overnight unless otherwise indicated. Filtration was conducted through sintered-glass Buchner funnels with vacuum suction (20 mmHg) unless otherwise indicated. Thin layer chromatography was performed on precoated glass-backed silica gel 60 F-254 250 µm plates. Column chromatography was performed using 230–400 mesh silica gel.

Materials

Commercial grade reagents and solvents were used without further purification except as indicated below. Dichloromethane, diethyl ether, and tetrahydrofuran were purified by pressure filtration through activated alumina. Toluene was purified by pressure filtration through activated alumina and Cu(II) oxide. Pyridine and triethylamine were distilled under argon from calcium hydride. Dimethylformamide and 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU) were distilled under vacuum from calcium hydride. Triflic anhydride was distilled under argon from P2O5. Lithium chloride and potassium carbonate were dried at 110–130 °C, 0.1 mmHg for 24 h. N-Bromosuccinimide was recrystallized from boiling water.37 Copper(I) iodide was extracted with THF for 24 h in a Soxhlet extractor and then dried under vacuum (0.05 mmHg) in a vacuum desiccator over P2O5 for 24 h. Iodomethane was passed through neutral alumina immediately prior to use. Bis(triphenylphosphine)palladium(II) chloride was prepared according to the method of Heck38 and recrystallized from chloroform. Sodium periodate supported on silica gel was prepared according to the procedure of Zhong and Shing.21 n-Butyllithium was titrated according to the Watson-Eastham method using menthol in THF with 1,10-phenanthroline as an indicator.39

Instrumentation

Melting points were determined with a Fisher-Johns melting point apparatus and are uncorrected. 1H NMR chemical shifts are expressed in parts per million (δ) downfield relative to tetramethylsilane (with the CHCl3 peak at 7.27 ppm used as a standard). 13C NMR chemical shifts are expressed in parts per million (δ) downfield relative to tetramethylsilane (with the central peak of CDCl3 at 77.23 ppm used as a standard). High resolution mass spectra (HRMS) were measured with a Fourier transform ion cyclotron resonance mass spectrometer.

2-(Trimethylsilyl)ethyl N-Benzylcarbamate (11)

A 250-mL, three-necked, round-bottomed flask equipped with a rubber septum fitted with a thermocouple temperature probe, glass stopper, and reflux condenser fitted with an argon inlet adapter was charged with phenylacetic acid (7.085 g, 52.0 mmol, 1.0 equiv), 70 mL of toluene, and Et3N (8.0 mL, 5.8 g, 58 mmol, 1.1 equiv). Diphenylphosphoryl azide (11.7 mL, 15.0 g, 54 mmol, 1.0 equiv) was added via syringe over 20 min (exothermic) at a rate to maintain the internal temperature below 36 °C. The rubber septum was replaced by a glass stopper, and the reaction mixture was heated at 85 °C for 2 h, during which time the evolution of N2 was observed. The reaction mixture was allowed to cool to room temperature, and 2-trimethylsilylethanol (9.0 mL, 7.4 g, 63 mmol, 1.2 equiv) was rapidly added via syringe over ca. 2 min. The reaction mixture was then heated at 85–90 °C for 16 h. After cooling to room temperature, the reaction mixture was transferred to a 300-mL, one-necked, round-bottomed flask and concentrated to a volume of ca. 10 mL. This residue was dissolved in 150 mL of Et2O, washed with two 100-mL portions of 10% NaOH solution and 100 mL of H2O, dried over MgSO4, filtered, and concentrated to a volume of ca. 20 mL at which point a white ppt appeared. This residue was filtered, washing with ca. 50 mL of Et2O, and the filtrate was concentrated to afford 12.8 g of a pale yellow gel. This material was triturated with 80 mL of hexanes and cooled at −18 °C for 1 h. The white crystalline solid formed was filtered, washing with ca. 30 mL of hexanes, and then the filtrate was concentrated to provide ca. 12 g of a yellow oil containing a small amount of white solid. Column chromatography on 150 g of silica gel (elution with 10% EtOAc-hexanes) provided 9.474 g (72%) of carbamate 11 as a pale yellow oil: IR (film) 3334, 3065, 3032, 2953, 1697, 1530, 1454, 1250, 1179, 1135, 1060, and 1043 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.25–7.39 (m, 5H), 4.95 (br s, 1H), 4.38 (d, J = 5.9 Hz, 2H), 4.20 (t, J = 8.5 Hz, 2H), 1.00 (t, J = 8.5 Hz, 2 H), 0.05 (s, 9H); 13C NMR (100 MHz, CDCl3) δ 156.9, 138.8, 128.6, 127.5, 127.4, 63.2, 44.9, 17.8, and −1.3; HRMS (ESI) m/z: [M+Na]+ Calcd for C13H21NO2Si 274.1234; Found 274.1242.

4,4-Dimethoxybut-1-yne.40

A 250-mL, three-necked, round-bottomed flask equipped with a rubber septum fitted with a thermocouple temperature probe, cold-finger reflux condenser, and addition funnel fitted with an argon inlet adapter was charged with aluminum powder (2.7 g, 100 mmol, 1.5 equiv) and 20 mL of Et2O. To this stirred suspension was added HgCl2 (0.100 g, 0.37 mmol, 1.0 equiv), and the reaction mixture was heated at 33 °C (bath temperature 50 °C) for 30 min. The oil bath was removed, and propargyl bromide solution (90 wt % in toluene, ca. 0.2 mL) was rapidly added dropwise over ca. 1 min via syringe. As soon as the reaction of aluminum and propargyl bromide began (indicated by an increase in internal temperature), a solution of propargyl bromide (90 wt % in toluene, 13.3 g, 101 mmol, 1.5 equiv) diluted with 40 mL of Et2O was added dropwise via the addition funnel over 30 min. During this addition the internal temperature increased to 38 °C. The black suspension was kept at reflux for 1 h and then allowed to cool to room temperature. After the solid settled, the supernatant solution was transferred via cannula (rinse with 250 mL of Et2O) to a 1-L, three-necked, round-bottomed flask equipped with a rubber septum fitted with a thermocouple temperature probe, glass stopper, and argon inlet adapter. The solution was cooled at −78 °C while a solution of trimethyl orthoformate (7.1 mL, 6.9 g, 65 mmol, 1.0 equiv) in 15 mL of Et2O was added via syringe over 20 min. The milky-white mixture was stirred at −78 °C for 15 min, and then cooled at −90 °C while 90 mL of H2O was added in 10 portions over 45 min, while keeping the internal temperature below −65 °C. The cold bath was removed and the reaction mixture was allowed to warm to room temperature over 2 h. The organic layer was separated and the aqueous layer was extracted with three 40-mL portions of Et2O. The combined organic layers were washed with 80 mL of ice-cold aq 5M NaOH solution, two 80-mL portions of H2O, dried over MgSO4, and filtered into a 1-L, one-necked, round-bottomed flask. Most of the Et2O was removed via shortpath distillation at 35 °C (760 mmHg). The residue was next distilled through a 75-mm, vacuum-jacketed Vigreux column topped with a Perkin triangle. Initially additional Et2O distilled at 35 °C (760 mmHg) after which the residue was transferred to a 50-mL, one-necked, round-bottomed flask. Distillation was then continued to afford a forerun of 2.830 g of a colorless oil (bp 30–66 °C, 75 mmHg) which was a mixture of the desired product, toluene, and Et2O. The desired acetal distilled at 66–68 °C (75 mmHg) yielding 4.656 g (63%) of a colorless oil: IR (film) 3291, 2940, 2834, 2124, 1448, 1423, 1364, 1241, 1194, 1123, and 1068 cm−1; 1H NMR (400 MHz, CDCl3) δ 4.56 (t, J = 5.6 Hz, 1H), 3.39 (s, 6H), 2.54 (dd, J = 5.6, 2.6 Hz, 2H), and 2.05 (t, J = 2.6 Hz, 1H); 13C NMR (125 MHz, CDCl3) δ 102.4, 79.5, 70.3, 53.7, and 23.9; HRMS (ESI) [M+Na]+ calcd for C6H10O2: 137.0573, found 137.0576.

General Procedure for the Bromination of Terminal Acetylenes. 1-Bromo-3-(tert-butyldimethylsiloxy) prop-1-yne (13)

A 250-mL, one-necked, round-bottomed flask equipped with a rubber septum and argon inlet needle was charged with tert-butyldimethyl(2-propynyloxy)silane (1.954 g, 11.5 mmol, 1.0 equiv) and 60 mL of acetone. NBS (2.250 g, 12.6 mmol, 1.1 equiv) and silver(I) nitrate (0.098 g, 0.58 mmol, 0.05 equiv) were added. The flask was wrapped in aluminum foil, and the resulting mixture was stirred at room temperature for 1 h. The resulting cloudy mixture was diluted with 200 mL of 1:1 Et2O-pentane, extracted with 50 and 30-mL portions of 10% Na2S2O3 solution, 50 mL of H2O, and 50 mL of saturated NaCl solution, dried over MgSO4, filtered, and concentrated at 30 mmHg to yield 2.741 g (96%) of alkyne 13 as a colorless oil: IR (film) 2930, 2886, 2858, 2220, 1472, 1463, 1364, 1255, and 1100 cm−1; 1H NMR (400 MHz, CDCl3) δ 4.35 (s, 2H), 0.92 (s, 9H), and 0.13 (s, 6H); 13C NMR (125 MHz, CDCl3) δ 78.7, 52.6, 44.8, 25.9, 18.4, and −5.0; HRMS (ESI) m/z: [M+H]+ Calcd for C9H17BrOSi 249.0305; Found 249.0316.

1-Bromo-4,4-dimethoxybut-1-yne (16)

Reaction of 4,4-dimethoxybut-1-yne (4.699 g, 41.2 mmol, 1.0 equiv), NBS (8.092 g, 45.5 mmol, 1.1 equiv), and silver(I) nitrate (0.077 g, 0.45 mmol, 0.01 equiv) in 200 mL of acetone for 1 h according to the general procedure gave 7.652 g (96%) of alkyne 16 as a colorless oil: IR (film) 2993, 2939, 2833, 2224, 1446, 1421, 1362, 1238, 1193, 1121, 1071, 1037, and 1009 cm−1; 1H NMR (400 MHz, CDCl3) δ 4.54 (t, J = 5.4 Hz, 1H), 3.38 (s, 6H), 2.55 (d, J = 5.6 Hz, 2H); 13C NMR (125 MHz, CDCl3) δ 102.2, 75.3, 53.7, 40.2, and 25.0; HRMS (ESI) m/z: [M+Na]+ Calcd for C6H9BrO2 214.9678; Found 214.9686.

N-Methoxycarbonyl-N-prop-2-enylprop-1-ynylamine (17)

A 250-mL, three-necked, round-bottomed flask equipped with a rubber septum, glass stopper, and addition funnel fitted with a rubber septum and argon inlet needle was charged with carbamate 941 (0.860 g, 7.47 mmol, 1.0 equiv) and 30 mL of pyridine. The solution was cooled at 0 °C while 8.2 mL of KHMDS solution (0.91 M in THF, 7.5 mmol, 1.0 equiv) was added via syringe over 5 min. The resulting yellow slurry was stirred at 0 °C for 10 min, and then a solution of CuI (1.42 g, 7.47 mmol, 1.0 equiv) in 15 mL of pyridine was added via cannula in one portion (5-mL pyridine rinse). The ice bath was removed, and the dark green reaction mixture was stirred at room temperature for 2 h. A solution of iodo alkyne 1242 (25 mL, 0.60 M in benzene, 15 mmol, 2.0 equiv) was then added via the addition funnel over 1 h, and the resulting dark brown mixture was stirred at room temperature for 22 h. The reaction mixture was diluted with 500 mL of Et2O and washed with three 200-mL portions of a 2:1 mixture of saturated NaCl solution and concentrated NH4OH solution. The combined aqueous layers were extracted with three 75-mL portions of Et2O, and the combined organic layers were washed with 150 mL of saturated NaCl solution, dried over MgSO4, filtered, and concentrated to provide 2.81 g of a dark brown oil. Column chromatography on 90 g of silica gel (elution with 10% EtOAc-hexanes) afforded 0.689 g of a yellow oil, which was purified on 35 g of silica gel (elution with 10% EtOAc-hexanes) to give 0.629 g (55%) of ynamide 17 as a pale yellow oil: IR (film) 3085, 2956, 2920, 2858, 2271, 1726, 1646, 1446, 1396, 1370, 1343, 1299, 1281, 1236, 1192, and 1152 cm−1; 1H NMR (500 MHz, CDCl3) δ 5.86 (ddt, J = 17.0, 10.5, 5.5 Hz, 1H), 5.27 (dd, J = 17.0, 1.0 Hz, 1H), 5.23 (dd, J = 10.5, 1.0 Hz, 1H), 4.04 (d, J = 5.5 Hz, 2H), 3.81 (s, 3H), and 1.93 (s, 3H); 13C NMR (125 MHz, CDCl3) δ 156.0, 131.9, 118.1, 72.4, 65.4, 53.9, 52.5, and 3.2; HRMS (ESI) m/z: [M+Na]+ Calcd for C8H11NO2 176.0682; Found 176.0683.

General Procedure for the Synthesis of Ynamides via N-Alkynylation of Carbamates. N-Methoxycarbonyl-N-prop-2-enyl-3-(tert-butyldimethylsiloxy)prop-1-ynylamine (18)

A 100-mL, three-necked, round-bottomed flask equipped with a rubber septum, glass stopper, and addition funnel fitted with a rubber septum and argon inlet needle was charged with carbamate 941 (0.584 g, 5.07 mmol, 1.0 equiv) and 20 mL of THF. The pale yellow solution was cooled at 0 °C while KHMDS solution (5.6 mL, 0.91 M in THF, 5.1 mmol, 1.0 equiv) was added via syringe over 3 min. The resulting yellow solution was stirred at 0 °C for 10 min, and then pyridine (10 mL, 9.8 g, 123 mmol, 24 equiv) and CuI (0.966 g, 5.07 mmol, 1.0 equiv) were added. The ice bath was removed, and the dull green reaction mixture was stirred at room temperature for 2 h, during which time the reaction mixture turned brown. A solution of bromo alkyne 13 (2.53 g, 10.2 mmol, 2.0 equiv) in 10 mL of THF was added via the addition funnel over 1 h, and the resulting dark brown mixture was stirred at room temperature for 22 h. The reaction mixture was diluted with 120 mL of Et2O and washed with three 60-mL portions of a 2:1 mixture of saturated NaCl solution and concentrated NH4OH solution. The combined aqueous layers were extracted with two 40-mL portions of Et2O, and the combined organic layers were washed with two 40-mL portions of ice-cold 1M HCl solution and 80 mL of saturated NaCl solution, dried over MgSO4, filtered, and concentrated to provide 2.905 g of a brown oil. This material was dissolved in ca. 20 mL of CH2Cl2 and concentrated onto 12 g of silica gel. The free flowing powder was added to the top of a column of 120 g of silica gel and eluted with 0–5% EtOAc-hexanes to provide 1.4 g of a mixture of ynamide 18 and the diyne byproduct as a brown oil. This material was purified by column chromatography on 70 g of silica gel (elution with 0–2.5% EtOAc-hexanes) to afford 0.334 g of ynamide 18 as a yellow oil and 0.755 g of a mixture of ynamide 18 and the diyne byproduct as a yellow oil. The mixed sample was purified by column chromatography on 30 g of silica gel (elution with 0–2.5% EtOAc-hexanes) to give 0.199 g of ynamide 18 as a yellow oil and 0.361 g of a mixture of ynamide 18 and the diyne byproduct as a yellow oil. This mixture was purified on 10 g of silica gel (elution with 1–2.5% EtOAc-hexanes) to provide 0.253 g of ynamide 18 as a yellow oil. The total yield was 0.786 g (55%) of ynamide 18 as a yellow oil: IR (film) 3086, 2956, 2930, 2858, 2255, 1736, 1646, 1444, 1392, 1361, 1297, 1280, 1253, 1237, and 1079 cm−1; 1H NMR (400 MHz, CDCl3) δ 5.86 (ddt, J = 17.1, 10.2, 6.0 Hz, 1H), 5.28 (dd, J = 17.7, 1.3 Hz, 1H), 5.24 (dd, J = 10.3, 1.2 Hz, 1H), 4.46 (s, 2H), 4.07 (d, J = 6.0 Hz, 2H), 3.81 (s, 3H), 0.92 (s, 9H), and 0.13 (s, 6H); 13C NMR (125 MHz, CDCl3) δ 155.8, 131.6, 118.6, 78.6, 69.5, 54.1, 52.6, 51.9, 25.9, 18.4, and −4.9; HRMS (ESI) m/z: [M+Na]+ Calcd for C14H25NO3Si 306.1496; Found 306.1496.

N-Methoxycarbonyl-N-prop-2-enyl-4-(tert-butyldimethylsiloxy)but-1-ynylamine (19)

Reaction of a solution of carbamate 941 (0.519 g, 4.50 mmol, 1.0 equiv) in 18 mL of THF with KHMDS (5.0 mL, 0.91 M in THF, 4.55 mmol, 1.0 equiv), pyridine (9.0 mL, 8.8 g, 111 mmol, 25 equiv), CuI (0.857 g, 4.50 mmol, 1.0 equiv), and bromo alkyne 1443 (2.373 g, 9.01 mmol, 2.0 equiv) in 9.0 mL of THF for 21 h according to the general procedure gave 2.578 g of a brown oil. This material was dissolved in ca. 20 mL of CH2Cl2 and concentrated onto 13.5 g of silica gel. The free flowing powder was added to the top of a column of 135 g of silica gel and eluted with 0–5% EtOAc-hexanes to provide 0.886 g (66%) of ynamide 19 as a yellow oil: IR (film) 3085, 2955, 2930, 2857, 2262, 1732, 1646, 1445, 1391, 1330, 1298, 1233, and 1105 cm−1; 1H NMR (400 MHz, CDCl3) δ 5.86 (ddt, J = 17.0, 10.3, 6.0 Hz, 1H), 5.25 (d, J = 18.4 Hz, 1H), 5.23 (d, J = 10.4 Hz, 1H), 4.04 (d, J = 5.9 Hz, 2H), 3.80 (s, 3H), 3.71 (t, J = 7.1 Hz, 2H), 2.51 (t, J = 7.1 Hz, 2H), 0.90 (s, 9H), and 0.08 (s, 6H); 13C NMR (100 MHz, CDCl3) δ 156.0, 131.8, 118.3, 74.4, 67.0, 62.3, 53.9, 52.7, 25.9, 22.9, 18.4, and −5.1; HRMS (ESI) m/z: [M+Na]+ Calcd for C15H27NO3Si 320.1652; Found 320.1650.

N-tert-Butoxycarbonyl-N-methylpent-4-en-1-ynylamine (20)

Reaction of a solution of carbamate 1044 (0.683 g, 5.21 mmol, 1.0 equiv) in 21 mL of THF with KHMDS (5.8 mL, 0.91 M in THF, 5.3 mmol, 1.0 equiv), pyridine (10.0 mL, 9.78 g, 124 mmol, 23.8 equiv), CuI (0.992 g, 5.21 mmol, 1.0 equiv), and bromo alkyne 155 (13 mL, 0.60 M in benzene, 7.8 mmol, 1.5 equiv) according to the general procedure afforded 2.235 g of a brown oil. Column chromatography on 110 g of silica gel (gradient elution 0–5% EtOAc-hexanes) gave 0.517 g of a yellow oil. This material was further purified by column chromatography on 50 g of silica gel (elution with 3% EtOAc-hexanes) to afford 0.436 g (43%) of ynamide 20 as a pale yellow oil: IR (film) 2980, 2934, 2267, 1720, 1642, 1478, 1457, 1421, 1369, 1318, 1254, and 1155 cm−1; 1H NMR (400 MHz, CDCl3) δ 5.83 (ddt, J = 16.8, 10.0, 4.8 Hz, 1H), 5.35 (br d, J = 16.8 Hz, 1H), 5.09 (dd, J = 10.0, 1.6 Hz, 1H), 3.07 (s, 3H), 3.04–3.06 (m, 2H), and 1.48 (s, 9H); 13C NMR (125 MHz, CDCl3) δ 155.0, 133.2, 115.8, 82.1, 78.3, 64.8, 37.3, 28.2, and 22.9; HRMS (ESI) m/z: [M+Na]+ Calcd for C11H17NO2 218.1151; Found 218.1156.

N-Benzyl-N-2-(trimethylsilyl)ethoxycarbonyl-4,4-dimethoxybut-1-ynylamine (21)

Reaction of a solution of carbamate 11 (1.355 g, 5.39 mmol, 1.0 equiv) in 22 mL of THF with KHMDS (5.9 mL, 0.91 M in THF, 5.4 mmol, 1.0 equiv), pyridine (11.0 mL, 10.8 g, 136 mmol, 25 equiv), CuI (1.03 g, 5.41 mmol, 1.0 equiv), and bromo alkyne 16 (2.14 g, 11.1 mmol, 2.1 equiv) in 10 mL of THF for 18 h according to the general procedure45 gave 2.905 g of a brown oil. This material was dissolved in ca. 50 mL of CH2Cl2 and concentrated onto 12 g of silica gel. The free flowing powder was added to the top of a column of 150 g of silica gel and eluted with 10% EtOAc-hexanes to afford 1.623 g of a mixture of ynamide 21 and unreacted carbamate 11 as a yellow oil. This material was dissolved in ca. 25 mL CH2Cl2 and concentrated onto 8 g of activated basic aluminum oxide. The free flowing powder was added on the top of a column of 90 g of activated basic aluminum oxide and eluted with 10% EtOAc-hexanes to give 1.123 g (57%) of ynamide 21 as a pale yellow oil (another run of the reaction on a larger scale provided the product in 69% yield): IR (film) 2953, 2831, 2267, 1721, 1455, 1400, 1275, 1250, 1218, 1121, and 1067 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.28–7.41 (m, 5H), 4.60 (s, 2H), 4.46 (t, J = 5.7 Hz, 1H), 4.28 (t, J = 8.5 Hz, 2H), 3.33 (s, 6H), 2.59 (d, J = 5.7 Hz, 2H), 1.06 (t, J = 8.4 Hz, 2H), and 0.05 (s, 9H); 13C NMR (100 MHz, CDCl3) δ 155.8, 136.5, 128.5, 128.5, 127.9, 102.8, 75.5, 65.6, 53.7, 53.4, 53.4, 23.9, 17.6, and −1.3; HRMS (ESI) m/z: [M+Na]+ Calcd for C19H29NO4Si 386.1758; Found 386.1765.

General Procedure for the Synthesis of Highly-Substituted Aniline Derivatives: Method A, via the Benzannulation of Cyclobutenones and Ynamides with Two Stages of Heating. N-Methoxycarbonyl-N-prop-2-enyl-(5-butyl-3-hydroxy-2-methylphenyl)amine (27)

A 10-mL, one-necked, round-bottomed flask equipped with a reflux condenser fitted with an argon inlet adapter was charged with ynamide 17 (0.262 g, 1.71 mmol, 1.0 equiv), cyclobutenone 2611 (0.219 g, 1.76 mmol, 1.0 equiv) and 2.1 mL of toluene. The yellow solution was heated at 75–90 °C for 2 h, at reflux for 3 h, and then allowed to cool to room temperature. Concentration provided 0.475 g of an orange solid, which was dissolved in 10 mL of CH2Cl2 and concentrated onto 2 g of silica gel. The free flowing powder was added to the top of a column of 48 g of silica gel and eluted with 30% EtOAc-hexanes to afford 0.370 g (78%) of 27 as a pale yellow solid: mp 94–95 °C; IR (film) 3344, 2956, 2929, 2858, 1675, 1619, 1586, 1515, 1456, 1391, 1318, and 1272 cm−1; 1H NMR (500 MHz, toluene-d8, 90 °C) δ 6.51 (s, 1H), 6.32 (s, 1H), 5.84–5.92 (m, 1H), 5.12 (br s, 1H), 4.97 (dd, J = 17.3, 1.0 Hz, 1H), 4.93 (dd, J = 10.5, 1.0 Hz, 1H), 4.27 (br s, 1H), 3.91 (br s, 1H), 3.45 (s, 3H), 2.40 (t, J = 7.8 Hz, 2H), 2.05 (s, 3H), 1.50 (app quintet, J = 7.5 Hz, 2H), 1.28 (app sextet, J = 7.3 Hz, 2H), and 0.87 (t, J = 7.3 Hz, 3H); 13C NMR (125 MHz, CDCl3, 20 °C, mixture of two rotamers) for major rotamer: δ 156.5, 154.6, 141.6, 141.0, 133.3, 120.4, 119.7, 118.3, 114.5, 53.6, 53.2, 35.2, 33.4, 22.4, 14.1, and 10.6; additional resonances appeared for the minor rotamer at: δ 155.0, 133.6, 120.3, 117.8, and 114.9; HRMS m/z: [M+Na]+ Calcd for C16H23NO3 300.1570; Found 300.1567; Anal. Calcd for C16H23NO3: C, 69.29; H, 8.36; N, 5.05. Found: C, 69.21; H, 8.36; N, 4.98.

N-Methoxycarbonyl-N-prop-2-enyl-[5-butyl-2-(tert-butyldimethylsiloxy)methyl-3-hydroxyphenyl]amine (28)

Reaction of a solution of ynamide 18 (0.354 g, 1.25 mmol, 1.0 equiv) and cyclobutenone 26 (0.160 g, 1.29 mmol, 1.0 equiv) in 1.6 mL of toluene at 80 °C for 90 min and then at reflux for 2 h according to general procedure A gave 0.508 g of an orange oil. Column chromatography on 20 g of silica gel (elution with 10% EtOAc-hexanes) afforded 0.433 g (85%) of 28 as a pale yellow solid: mp 60–62 °C; IR (film) 3339, 3081, 2955, 2858, 1711, 1680, 1628, 1579, 1461, 1388, 1313, 1254, 1194, 1148, and 1054 cm−1; 1H NMR (400 MHz, CDCl3) δ 8.66 (s, 1H), 6.67 (d, J = 1.6 Hz, 1H), 6.46 (s, 1H), 5.86–5.94 (m, 1H), 5.14 (d, J = 10.1 Hz, 1H), 5.13 (d, J = 17.1 Hz, 1H), 4.76–4.83 (m, 2H), 4.22 (dd, J = 14.5, 6.2 Hz, 1H), 4.00 (dd, J = 14.7, 6.7 Hz, 1H), 3.64 (s, 3H), 2.53 (t, J = 7.7 Hz, 2H), 1.57 (app quintet, J = 7.6 Hz, 2H), 1.34 (app sextet, J = 7.4 Hz, 2H), 0.93 (s, 9H), 0.92 (t, J = 7.6 Hz, 3H), 0.14 (s, 3H), and 0.13 (s, 3H); 13C NMR (125 MHz, CDCl3) δ 157.6, 156.0, 144.1, 138.4, 133.0, 119.5, 118.8, 118.7, 116.3, 61.8, 53.8, 53.1, 35.2, 33.2, 25.8, 22.4, 18.2, 14.0, −5.4, and −5.5; Anal. Calcd for C22H37NO4Si: C, 64.82; H, 9.15; N, 3.44. Found: C, 64.78; H, 9.18; N, 3.48.

N-Methoxycarbonyl-N-prop-2-enyl-[5-butyl-2(tert-butyldimethylsiloxy)ethyl-3-hydroxyphenyl]amine (29)

Reaction of a solution of ynamide 19 (0.379 g, 1.27 mmol, 1.0 equiv) and cyclobutenone 26 (0.212 g, 1.71 mmol, 1.3 equiv) in 1.6 mL of toluene at 90 °C for 2 h and then at reflux for 90 min according to general procedure A gave 0.607 g of a light brown solid. This material was dissolved in ca. 10 mL of CH2Cl2 and concentrated onto 3 g of silica gel. The free flowing powder was added to the top of a column of 50 g of silica gel and eluted with 20% EtOAc-hexanes to provide 0.501 g (94%) of 29 as a light yellow solid: mp 95.5–95.7 °C; IR (KBr pellet) 3320, 2956, 2930, 2858, 1710, 1680, 1619, 1584, 1460, 1387, 1256, and 1083 cm−1; 1H NMR (400 MHz, CDCl3) δ 8.57 (s, 1H), 6.75 (s, 1H), 6.50 (s, 1H), 5.84–5.94 (m, 1H), 5.12 (d, J = 9.6 Hz, 1H), 5.10 (d, J = 17.4 Hz, 1H), 4.28 (dd, J = 14.4, 5.8 Hz, 1H), 3.92 (dd, J = 14.7, 6.8 Hz, 1H), 3.75–3.91 (m, 2H), 3.62 (s, 3H), 2.70–2.86 (m, 2H), 2.53 (t, J = 7.7 Hz, 2H), 1.57 (app quintet, J = 7.6 Hz, 2H), 1.33 (app sextet, J = 7.4 Hz, 2H), 0.92 (s, 9H), 0.89–0.92 (m, 3H), 0.10 (s, 3H), and 0.09 (s, 3H); 13C NMR (100 MHz, CDCl3) δ 156.8, 156.4, 143.1, 140.5, 133.2, 122.4, 120.3, 118.5, 116.9, 65.0, 54.1, 52.9, 35.2, 33.2, 29.2, 25.9, 22.4, 18.4, 14.1, and −5.5; Anal. Calcd for C23H39NO4Si: C, 65.52; H, 9.32; N, 3.32. Found: C, 65.49; H, 9.29; N, 3.35.

General Procedure for the Synthesis of Amino Aldehyde Precursors to Indoles via the Oxidative Cleavage of N-Allylaniline Derivatives. N-Methoxycarbonyl-N-2-oxoethyl-(5-butyl-3-hydroxy-2-methylphenyl)amine (30)

A 25-mL, one-necked, round-bottomed flask equipped with a rubber septum and argon inlet needle was charged with carbamate 27 (0.335 g, 1.21 mmol, 1.0 equiv), 9 mL of THF, 3 mL of H2O, OsO4 (4 wt% in H2O, 0.160 mL, 0.154 g, 0.024 mmol, 0.02 equiv), and NMO (0.156 g, 1.33 mmol, 1.1 equiv). The rubber septum and argon inlet needle were replaced by an argon inlet adapter and the light brown solution was stirred at room temperature for 12 h (TLC with 60% EtOAc:hexanes, Rf of carbamate 27: 0.65; Rf of diol: 0.2). A solution of NaHSO3 (1.3 g, 13 mmol, 11 equiv) in 12 mL of water was added, and the resulting mixture was stirred at room temperature for 10 min. The mixture was diluted with 20 mL of saturated NaCl solution and extracted with three 30-mL portions of EtOAc. The combined organic layers were dried over MgSO4, filtered, and concentrated to give 0.382 g of the diol as a white foam used in the next step without purification: IR (film) 3354, 2956, 2930, 2872, 1679, 1619, 1585, 1459, 1393, 1337, 1280, 1196, 1142, 1126, and 1035 cm−1.

A 25-mL, one-necked, round-bottomed flask equipped with a rubber septum and argon inlet needle was charged with NaIO4 supported on silica gel (2.0 g, 2.4 mmol, 2.0 equiv) and 6 mL of CH2Cl2. To this stirred suspension was added a solution of the diol (0.382 g, 1.0 equiv) prepared in the previous reaction in 6 mL of CH2Cl2. The yellow suspension was stirred at room temperature for 40 min. The reaction mixture was filtered through a sintered glass funnel, and the residue was washed with three 10-mL portions of CH2Cl2. The filtrate was concentrated to provide 0.347 g of a yellow oil, which was purified by column chromatography on 25 g of silica gel (elution with 30% EtOAc-hexanes) to give 0.277 g (82%) of aldehyde 30 as a white solid: mp 88–90 °C; IR (film) 3373, 2957, 2929, 2859, 1731, 1680, 1619, 1585, 1458, 1376, 1279, 1198, 1144, 1126, 1053, and 1024 cm−1; 1H NMR (400 MHz, CDCl3, ca. 76:24 mixture of rotamers) for major rotamer: δ 9.74 (s, 1H), 6.66 (s, 1H), 6.61 (s, 1H), 4.78 (s, 1H), 4.53 (d, J = 18.4 Hz, 1H), 4.03 (d, J = 18.4 Hz, 1H), 3.71 (s, 3H), 2.52 (t, J = 7.8Hz, 2H), 2.10 (s, 3H), 1.55 (app quintet, J = 7.6 Hz, 2H), 1.34 (app sextet, J = 7.4 Hz, 2H), and 0.92 (t, J = 7.4 Hz, 3H); additional resonances appeared for the minor rotamer at: δ 6.58 (s, 1H), 4.88 (s, 1H), 4.44 (d, J = 18.4 Hz, 1H), 3.79 (s, 3H), and 2.11 (s, 3H); 13C NMR (100 MHz, CDCl3, mixture of rotamers) for major rotamer: δ 197.8, 156.9, 154.7, 142.4, 141.2, 120.0, 119.5, 114.9, 60.3, 53.8, 35.2, 33.4, 22.5, 14.1, and 10.5; additional resonances appeared for the minor rotamer at: δ 119.7, 115.3, 60.4, 53.7, and 22.6; Anal. Calcd for C15H21NO4: C, 64.50; H, 7.58; N, 5.01. Found: C, 64.55; H, 7.53; N, 4.97.

N-Methoxycarbonyl-N-2-oxoethyl-[5-butyl-2-(tert-butyldimethylsiloxyethyl)-3-hydroxyphenyl]amine (31)

Reaction of alkene 29 (0.498 g, 1.18 mmol, 1.0 equiv) with OsO4 (4 wt% in H2O, 0.375 mL, 0.390 g, 0.036 mmol, 0.05 equiv) and NMO (0.166 g, 1.42 mmol, 1.2 equiv) in 8 mL of THF and 4 mL of H2O for 14 h according to the general procedure gave 0.550 g of a pale yellow oil. This material was transferred to a 50-mL, one-necked, recovery flask equipped with an argon inlet adapter, and 12 mL of CH2Cl2 and NaIO4 supported on silica gel (2.95 g, 3.54 mmol, 3.0 equiv) were added. The yellow suspension was stirred at room temperature for 2 h. The reaction mixture was filtered through a sintered glass funnel, and the residue was washed with three 15-mL portions of CH2Cl2. The filtrate was concentrated to provide 0.473 g (95%) of aldehyde 31 as a pale yellow solid: mp 92–93.5 °C; IR (KBr pellet) 3291, 2957, 2930, 2858, 2711, 1753, 1734, 1678, 1615, 1582, 1509, 1461, 1432, 1402, 1379, 1342, 1292, 1254, 1194, 1131, and 1077 cm−1; 1H NMR (400 MHz, CDCl3, ca. 78:22 mixture of rotamers) for major rotamer: δ 9.70 (s, 1H), 8.62 (s, 1H), 6.77 (s, 1H), 6.60 (s, 1H), 4.44 (d, J = 18.3 Hz, 1H), 4.08 (d, J = 18.3 Hz, 1H), 3.87 (t, J = 4.8 Hz, 2H), 3.67 (s, 3H), 2.88 (t, J = 5.0Hz, 2H), 2.52 (t, J = 7.8Hz, 2H), 1.56 (app quintet, J = 7.6 Hz, 2H), 1.34 (app sextet, J = 7.4 Hz, 2H), 0.92 (s, 9H), 0.88–0.95 (m, 3H), 0.10 (s, 3H), and 0.09 (s, 3H); additional resonances appeared for the minor rotamer at: δ 8.72 (s, 1H), 4.36 (d, J = 18.8 Hz, 1H), 4.14 (d, J = 18.8 Hz, 1H), and 3.75 (s, 3H); 13C NMR (100 MHz, CDCl3) δ 197.1, 157.0, 156.8, 143.9, 140.8, 122.3, 119.6, 117.4, 65.0, 61.0, 53.5, 35.2, 33.2, 29.2, 25.9, 22.5, 18.4, 14.1, and −5.4; Anal. Calcd for C22H37NO5Si: C, 62.38; H, 8.80; N, 3.31. Found: C, 62.38; H, 8.67; N, 3.36.

4-Butyl-6-hydroxy-1-methoxycarbonyl-7-methylindole (33)

A 100-mL, one-necked, recovery flask equipped with a rubber septum and argon inlet needle was charged with aldehyde 30 (0.186 g, 0.67 mmol, 1.0 equiv), 44 mL of isopropanol, and DBU (0.050 mL, 0.051 g, 0.34 mmol, 0.5 equiv). The colorless solution was heated at 65 °C for 100 min, during which time the color changed to pale yellow. The reaction mixture was allowed to cool to room temperature and then treated with 5 mL of aq 1M HCl solution to adjust the pH to 7. The resulting mixture was concentrated to a volume of ca. 5 mL and then diluted with 50 mL of Et2O, washed with 15 mL of H2O and 15 mL of saturated NaCl solution, dried over MgSO4, filtered, and concentrated to afford 0.175 g of a pale orange solid. This material was dissolved in 5 mL of CH2Cl2 and concentrated onto 1 g of silica gel. The free flowing powder was added to the top of a column of 11 g of silica gel and eluted with 20% EtOAc-hexanes to give 0.129 g (74%) of indole 33 as a white solid: mp 75–77 °C; IR (film) 3411, 2956, 2923, 2857, 1708, 1602, 1451, 1382, 1343, 1278, 1075, 1028, and 1018 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.46 (d, J = 4.0 Hz, 1H), 6.67 (s, 1H), 6.56 (d, J = 4.0 Hz, 1H), 4.94 (s, 1H), 3.99 (s, 3H), 2.75 (t, J = 7.6 Hz, 2H), 2.42 (s, 3H), 1.64 (app quintet, J = 7.7 Hz, 2H), 1.39 (app sextet, J = 7.4 Hz, 2H), and 0.94 (t, J = 7.4 Hz, 3H); 13C NMR (100 MHz, CDCl3) δ 152.2, 152.1, 136.3, 133.6, 126.5, 125.2, 112.5, 109.0, 106.7, 54.1, 33.1, 32.5, 22.7, 14.2, and 13.6; Anal. Calcd for C15H19NO3: C, 68.94; H, 7.33; N, 5.36. Found: C, 68.78; H, 7.32; N, 5.31.

4-Butyl-6-hydroxy-7-(2-hydroxyethyl)-1-methoxycarbonylindole (34)

A 100-mL, one-necked, round-bottomed flask equipped with a rubber septum and argon inlet needle was charged with aldehyde 31 (0.250 g, 0.59 mmol, 1.0 equiv), 30 mL of isopropanol, and K2CO3 (0.082 g, 0.59 mmol, 1.0 equiv). The septum was replaced by a cold-finger condenser fitted with an argon inlet, and the colorless mixture was heated at 75–80 °C for 2 h, during which time the color changed to yellow. The reaction mixture was allowed to cool to room temperature, and then diluted with 15 mL of H2O and treated with 5 mL of 1M HCl solution to adjust the pH to 1. The resulting mixture was concentrated to a volume of ca. 10 mL and diluted with 70 mL of Et2O, washed with two 30-mL portions of H2O and 30 mL of saturated NaCl solution, dried over MgSO4, filtered, and concentrated to afford 0.177 g of a brown oil. This material was dissolved in 5 mL of CH2Cl2 and concentrated onto 1 g of silica gel. The free flowing powder was added to the top of a column of 14 g of silica gel and eluted with 10% EtOAc-benzene to give 0.128 g (74%) of indole 34 as a white solid: mp 129–130.5 °C; IR (KBr pellet) 3409, 3184, 2953, 2840, 1754, 1723, 1597, 1440, 1392, 1342, 1271, 1208, and 1032 cm−1; 1H NMR (400 MHz, CDCl3) δ 8.60 (s, 1H), 7.45 (d, J = 4.0 Hz, 1H), 6.82 (s, 1H), 6.56 (d, J = 4.0 Hz, 1H), 4.34–4.37 (m, 2H), 3.94 (s, 3H), 3.12 (t, J = 4.8 Hz, 2H), 2.77 (t, J = 7.7 Hz, 2H), 2.36 (t, J = 3.5 Hz, 1H), 1.66 (app quintet, J = 7.6 Hz, 2H), 1.40 (app sextet, J = 7.4 Hz, 2H), and 0.94 (t, J = 7.3 Hz, 3H); 13C NMR (100 MHz, CDCl3) δ 154.7, 152.3, 136.0, 135.0, 125.9, 125.0, 114.3, 112.1, 107.0, 66.1, 54.1, 33.0, 32.5, 30.8, 22.7, and 14.2; Anal. Calcd for C16H21NO4: C, 65.96; H, 7.27; N, 4.81. Found: C, 65.94; H, 7.41; N, 4.85.

General Procedure for the Synthesis of Highly-Substituted Aniline Derivatives: Method B, via Benzannulation of Cyclobutenones and Ynamides in Toluene at Reflux. N-tert-Butoxycarbonyl-N-methyl-(5-butyl-3-hydroxy-2-prop-2-enylphenyl)amine (35)

A 25-mL, one-necked, round-bottomed flask equipped with a reflux condenser fitted with an argon inlet adapter was charged with ynamide 20 (0.430 g, 2.20 mmol, 1.0 equiv), cyclobutenone 26 (0.362 g, 2.90 mmol, 1.3 equiv), and 2.8 mL of toluene. The light brown solution was heated at reflux for 80 min, allowed to cool to room temperature, and then concentrated to give 0.830 g of a brown oil. Column chromatography on 90 g of silica gel (elution with 10% EtOAc-hexanes) provided 0.635 g (90%) of 35 as a light yellow solid: mp 82–85 °C; IR (film) 3323, 3077, 2958, 2931, 2859, 1668, 1616, 1584, 1435, 1385, 1367, 1340, 1253, and 1156 cm−1; 1H NMR (500 MHz, CDCl3, mixture of two rotamers) for major rotamer: δ 6.62 (s, 1H), 6.54 (s, 1H), 5.92–6.00 (m, 1H), 5.11–5.18 (m, 2H), 5.07 (s, 1H), 3.24–3.36 (m, 2H), 3.10 (s, 3H), 2.53 (t, J = 7.5 Hz, 2H), 1.49–1.60 (m, 4H), 1.33 (s, 9H), and 0.91 (t, J = 7.3 Hz, 3H); for the minor rotamer the resonance of the tert-butyl group appears at δ 1.52 (s, 9H); 13C NMR (125 MHz, CDCl3, mixture of two rotamers) for major rotamer: δ 155.7, 155.2, 143.1, 142.7, 136.1, 120.3, 120.1, 116.1, 115.0, 80.4, 37.7, 35.1, 33.4, 29.9, 28.4, 22.2, and 14.1; for minor rotamer: δ 155.7, 155.2, 143.1, 142.7, 137.0, 121.4, 119.5, 115.5, 115.2, 79.9, 38.6, 35.3, 33.2, 30.2, 28.6, 22.6, and 14.1; HRMS m/z: [M+Na]+ Calcd for C19H29NO3 342.2040; Found 342.2039; Anal. Calcd for C19H29NO3: C, 71.44; H, 9.15; N, 4.38. Found: C, 71.49; H, 9.15; N, 4.38.

5-Butyl-3-methylamino-2-prop-2-enylphenol (36)

A 25-mL, one-necked, round-bottomed flask equipped with a rubber septum and argon inlet needle was charged with carbamate 35 (0.217 g, 0.679 mmol, 1.0 equiv), 7 mL of CH2Cl2, and trifluoroacetic acid (0.78 mL, 1.2 g, 10 mmol, 15 equiv). The brown solution was stirred at room temperature for 1 h, and then diluted with 5 mL of CH2Cl2 and washed with 5 mL of saturated NaHCO3 solution. The aqueous layer was neutralized to pH 7 by dropwise addition of aq 1M HCl solution and then extracted with three 5-mL portions of CH2Cl2. The combined organic layers were washed with 20 mL of saturated NaCl solution, dried over MgSO4, filtered, and concentrated to give 0.149 g (100%) of phenol 36 as a brown oil which darkened upon storage: IR (film) 3433, 3361, 3076, 2956, 2929, 2857, 2815, 1633, 1618, 1589, 1529, 1454, 1419, 1313, 1204, and 1123 cm−1; 1H NMR (400 MHz, CDCl3) δ 6.12 (s, 1H), 6.10 (s, 1H), 5.92 (ddt, J = 16.8, 10.4, 5.6 Hz, 1H), 5.05–5.11 (m, 2H), 4.54 (s, 1H), 3.74 (br s, 1H), 3.33 (dt, J = 5.6, 2.0 Hz, 2H), 2.84 (s, 3H), 2.52 (t, J = 7.8 Hz, 2H), 1.55–1.63 (m, 2H), 1.37 (app sextet, J = 7.4 Hz, 2H), and 0.93 (t, J = 7.4 Hz, 3H); 13C NMR (100 MHz, CDCl3) δ 153.8, 148.8, 143.2, 136.0, 115.3, 107.0, 105.5, 103.9, 36.0, 33.6, 31.3, 28.1, 22.7, and 14.1; HRMS (ESI) m/z: [M+H]+ Calcd for C14H21NO 220.1696; Found 220.1700.

6-Butyl-4-hydroxy-1,2-dimethylindole (37)

A 25-mL, one-necked, round-bottomed flask equipped with a cold-finger condenser with argon inlet side arm was charged with PdCl2(CH3CN)2 (0.018 g, 0.069 mmol, 0.1 equiv), benzoquinone (0.072 g, 0.67 mmol, 1.0 equiv), and 6.5 mL of THF. The orange solution was stirred for 5 min and a solution of aniline 36 (0.146 g, 0.67 mmol, 1.0 equiv) in 7 mL of THF was added via syringe. The resulting dark orange solution was heated at reflux for 12 h and then allowed to cool to room temperature. The reaction mixture was filtered through a 1.5-cm pad of silica gel in a 30-mL sintered glass funnel with the aid of three 20-mL portions of Et2O. The orange filtrate was concentrated to give 0.264 g of a dark brown oil, which was dissolved in 5 mL of CH2Cl2 and concentrated onto 1.5 g of silica gel. The free flowing powder was added to the top of a column of 23 g of silica gel and eluted with 5–10% EtOAc-hexanes to give 0.120 g (82%) of indole 37 as a pale yellow solid: mp 95–96 °C; IR (KBr pellet) 3461, 3404, 2954, 2924, 2854, 1624, 1583, 1552, 1473, 1445, 1425, 1350, 1222, and 1019 cm−1; 1H NMR (500 MHz, CDCl3) δ 6.69 (s, 1H), 6.37 (s, 1H), 6.21 (s, 1H), 4.77 (s, 1H), 3.62 (s, 3H), 2.68 (t, J = 7.5 Hz, 2H), 2.41 (s, 3H), 1.65 (app quintet, J = 7.6 Hz, 2H), 1.39 (app sextet, J = 7.4 Hz, 2H), and 0.94 (t, J = 7.3 Hz, 3H); 13C NMR (100 MHz, CDCl3) δ 147.8, 139.6, 137.1, 135.3, 115.2, 105.3, 101.8, 95.3, 36.3, 34.5, 29.9, 22.6, 14.3, and 13.0; Anal. Calcd for C14H19NO: C, 77.38; H, 8.81; N, 6.45. Found: C, 77.41; H, 8.82; N, 6.53.

N-Benzyl-N-2-(trimethylsilyl)ethoxycarbonyl-[5-butyl-3-hydroxy-2-(2,2-dimethoxyethyl)phenyl]amine (47)

Reaction of a solution of ynamide 21 (0.657 g, 1.81 mmol, 1.0 equiv) and cyclobutenone 26 (0.256 g, 2.06 mmol, 1.1 equiv) in 2.0 mL of toluene at reflux for 100 min according to general procedure B provided 0.864 g of a yellow oil, which was dissolved in ca. 10 mL of CH2Cl2 and concentrated onto 5 g of silica gel. The free flowing powder was added to the top of a column of 85 g of silica gel and eluted with 15% EtOAc-hexanes to afford 0.748 g (85%) of acetal 47 as a viscous yellow oil: IR (film) 3321, 2954, 2932, 1700, 1670, 1624, 1572, 1437, 1408, 1361, 1315, 1296, 1251, and 1115 cm−1; 1H NMR (500 MHz, CDCl3, ca. 72:28 mixture of rotamers) for major rotamer: δ 8.03 (s, 1H), 7.15–7.30 (m, 5H), 6.70 (d, J = 1.5 Hz, 1H), 6.30 (s, 1H), 4.81 (d, J = 14.0 Hz, 1H), 4.61 (d, J = 14.0 Hz, 1H), 4.10–4.50 (m, 3H), 3.39 (br s, 3H), 3.32 (br s, 3H), 2.62 (d, J = 5.3 Hz, 2H), 2.48 (t, J = 7.6 Hz, 2H), 1.51 (app quintet, J = 7.6 Hz, 2H), 1.30 (app sextet, J = 7.4 Hz, 2H), 0.92 (t, J = 7.4 Hz, 3H), 0.89 (br s, 2H), and −0.05 (s, 9H); additional resonances appeared for the minor rotamer at: δ 6.40 (s, 1H), 1.17 (br s, 2H), and 0.11 (s, 9H); 13C NMR (125 MHz, CDCl3) δ 156.6, 156.5, 143.4, 141.0, 137.6, 129.6, 128.5, 127.8, 121.2, 118.9, 117.1, 105.6, 64.2, 54.8, 53.6, 35.2, 33.2, 30.5, 22.3, 17.9, 14.1, and −1.5 (one additional resonance at 129.1 for the minor rotamer); HRMS (ESI) m/z: [M+Na]+ Calcd for C27H41NO5Si 510.2646; Found 510.2635.

N-Benzyl-N-2-(trimethylsilyl)ethoxycarbonyl-[3-hydroxy-2-(2,2-dimethoxyethyl)-5-phenylphenyl]amine (48)

Reaction of a solution of ynamide 21 (0.350 g, 0.96 mmol, 1.0 equiv) and cyclobutenone 4311 (0.138 g, 0.96 mmol, 1.0 equiv) in 1.2 mL of toluene at reflux for 90 min according to general procedure B gave 0.501 g of a viscous yellow oil. This material was dissolved in ca. 10 mL of CH2Cl2 and concentrated onto 2.5 g of silica gel. The free flowing powder was added to the top of a column of 45 g of silica gel and eluted with 0–20% EtOAc-hexanes to provide 0.383 g (79%) of acetal 48 as a viscous yellow oil: IR (film) 3305, 3032, 2952, 2833, 1699, 1668, 1621, 1563, 1454, 1409, 1322, 1250, 1115, and 1069 cm−1; 1H NMR (400 MHz, CDCl3, ca. 73:27 mixture of rotamers) for major rotamer: δ 8.21 (s, 1H), 7.17–7.49 (m, 10H), 7.14 (d, J = 1.8 Hz, 1H), 6.75 (s, 1H), 4.86 (d, J = 14.1 Hz, 1H), 4.72 (d, J = 14.3 Hz, 1H), 4.07–4.50 (m, 3H), 3.40 (s, 3H), 3.32 (s, 3H), 2.65 (d, J = 4.4 Hz, 2H), 0.81–0.94 (m, 2H), and −0.08 (s, 9H); additional resonances appeared for the minor rotamer at: δ 8.26 (s, 1H), 6.86 (s, 1H), 1.08–1.21 (m, 2H), and 0.10 (s, 9H); 13C NMR (100 MHz, CDCl3) δ 157.1, 156.4, 141.7, 141.4, 140.0, 137.5, 129.7, 128.8, 128.6, 127.9, 127.6, 126.9, 120.9, 119.8, 115.6, 105.5, 64.4, 54.9, 53.7, 30.6, 17.9, and −1.4; HRMS (ESI) m/z: [M+Na]+ Calcd for C29H37NO5Si 530.2333; Found 530.2316.

N-Benzyl-N-2-(trimethylsilyl)ethoxycarbonyl-[5-ethoxy-3-hydroxy-2-(2,2-dimethoxyethyl)phenyl]amine (49)

Reaction of a solution of ynamide 21 (0.360 g, 0.99 mmol, 1.0 equiv) and cyclobutenone 4446 (0.168 g, 1.50 mmol, 1.5 equiv) in 1.2 mL of toluene at reflux for 90 min according to general procedure B gave 0.539 g of a dark brown oil. This material was dissolved in ca. 10 mL of CH2Cl2 and concentrated onto 3 g of silica gel. The free flowing powder was added to the top of a column of 51 g of silica gel and eluted with 20% EtOAc-hexanes to provide 0.289 g (61%) of 49 as a yellow solid: mp 103–105 °C; IR (KBr pellet) 3333, 2985, 2961, 1659, 1617, 1589, 1512, 1438, 1375, 1324, 1283, 1173, 1125, and 1042 cm−1; 1H NMR (400 MHz, CDCl3, ca. 75:25 mixture of rotamers) for major rotamer: δ 8.17 (s, 1H), 7.13–7.34 (m, 5H), 6.44 (d, J = 2.6 Hz, 1H), 6.12 (s, 1H), 4.73 (s, 2H), 3.96–4.43 (m, 3H), 3.79–3.95 (m, 2H), 3.35 (s, 3H), 3.27 (s, 3H), 2.51 (d, J = 5.1 Hz, 2H), 1.34 (t, J = 6.9 Hz, 3H), 0.82–0.96 (m, 2H), and −0.06 (s, 9H); additional resonances appeared for the minor rotamer at: δ 6.20 (s, 1H), 1.04–1.22 (m, 2H), and 0.08 (s, 9H); 13C NMR (100 MHz, CDCl3) δ 158.9, 157.6, 156.2, 141.9, 137.4, 129.5, 128.5, 127.7, 114.1, 107.5, 105.6, 103.3, 64.3, 63.4, 54.7, 53.6, 30.2, 17.9, 14.8, and −1.5; Anal. Calcd for C25H37NO6Si: C, 63.13; H, 7.84; N, 2.94. Found: C, 63.09; H, 7.85; N, 2.89.

N-Benzyl-N-2-(trimethylsilyl)ethoxycarbonyl-[3-hydroxy-2-(2,2-dimethoxyethyl)-5-tributylstannylphenyl]amine (50)

Reaction of a solution of ynamide 21 (0.587 g, 1.61 mmol, 1.0 equiv) and cyclobutenone 4547 (0.688 g, 1.93 mmol, 1.2 equiv) in 2.0 mL of toluene at reflux for 2 h according to general procedure B gave 1.301 g of a brown oil. Column chromatography on 60 g of silica gel (elution with 15% EtOAc-hexanes) afforded 1.011 g (87%) of 50 as a golden brown oil: IR (film) 3324, 2955, 2927, 2852, 1700, 1669, 1550, 1456, 1410, 1359, 1289, 1249, 1116, and 1040 cm−1; 1H NMR (400 MHz, CDCl3, ca. 74:26 mixture of rotamers) for major rotamer: δ 8.02 (s, 1H), 7.13–7.32 (m, 5H), 6.97 (s, 1H), 6.51 (s, 1H), 4.87 (d, J = 14.1 Hz, 1H), 4.57 (d, J = 14.1 Hz, 1H), 4.08–4.53 (m, 3H), 3.38 (br s, 3H), 3.31 (br s, 3H), 2.64 (d, J = 4.7 Hz, 2H), 1.37–1.58 (m, 6H), 1.30 (app sextet, J = 7.3 Hz, 6H), 0.99–1.20 (m, 2H), 0.96 (t, J = 8.1 Hz, 6H), 0.88 (t, J = 7.3 Hz, 9H), and −0.09 (s, 9H); additional resonances appeared for the minor rotamer at: δ 8.08 (s, 1H) and 0.09 (s, 9H); 13C NMR (125 MHz, CDCl3) δ 156.5, 156.0, 142.3, 140.6, 137.5, 129.5, 128.8, 128.5, 127.7, 124.6, 121.3, 105.5, 64.2, 54.9, 53.5, 30.7, 29.1, 27.4, 17.8, 13.8, 9.6, and −1.4 (one additional resonance at 54.8 for the minor rotamer); HRMS (ESI) m/z: [M+Na]+ Calcd for C35H59NO5SiSn 744.3094; Found 744.3063.

N-Benzyl-N-2-(trimethylsilyl)ethoxycarbonyl-[3-hydroxy-2-(2,2-dimethoxyethyl)-5,6-dimethylphenyl]amine (51)

A threaded Pyrex tube (O.D. 13 mm; length 10.2 cm) equipped with a rubber septum and argon inlet needle was charged with ynamide 21 (0.172 g, 0.47 mmol, 1.0 equiv), cyclobutenone 4648 (0.083 g, 0.86 mmol, 1.8 equiv), and 1.0 mL of toluene. The yellow solution was degassed (three freeze-pump-thaw cycles at −196 °C, 0.05 mmHg) and then the tube was sealed with a threaded teflon cap. The reaction mixture was heated at 145 °C for 49 h, allowed to cool to room temperature, and then concentrated to give 0.252 g of a yellow oil. Filtration through a column of silica gel (3 cm wide, 1 cm high) with the aid of 50 mL of 20% EtOAc-hexanes and concentration gave 0.237 g of an ester derivative of the desired product. This material was transferred to a 25-mL, one-necked, round-bottomed flask equipped with a cold-finger condenser with argon inlet side arm, and 2 mL of MeOH and 2 mL of 5M KOH solution were added. The reaction mixture was heated at 65–70 °C for 2.5 h and then allowed to cool to room temperature. The resulting brown mixture was diluted with 30 mL of Et2O and washed with 15 mL of 1M HCl solution. The pH of the aqueous layer was adjusted to 7 using ca. 2 mL of 10% NaOH solution and then extracted with two 15-mL portions of Et2O. The combined organic layers were washed with 30 mL of saturated NaCl solution, dried over MgSO4, filtered, and concentrated to provide 0.213 g of a yellow oil. This material was dissolved in ca. 10 mL of CH2Cl2 and concentrated onto 1 g of silica gel. The free flowing powder was added to the top of a column of 11 g of silica gel and eluted with 15% EtOAc-hexanes to afford 0.182 g of a yellow oil. This material was further purified by column chromatography on 15 g of silica gel (elution with 15% EtOAc-hexanes) to give 0.144 g of a pale yellow oil. This material was taken up in 25 mL of Et2O, washed with three 10-mL portions of saturated NaHCO3 solution and 15 mL of saturated NaCl solution, dried over MgSO4, filtered, and concentrated to provide 0.137 g (63%) of acetal 51 as a pale yellow oil: IR (film) 3328, 3031, 2951, 2834, 1698, 1619, 1575, 1495, 1456, 1408, 1361, 1312, 1251, and 1116 cm−1; 1H NMR (400 MHz, CDCl3, ca. 80:20 mixture of rotamers) for major rotamer: δ 7.81 (s, 1H), 7.06–7.28 (m, 5H), 6.72 (s, 1H), 4.91 (d, J = 14.0 Hz, 1H), 4.25 (d, J = 13.9 Hz, 1H), 3.99–4.35 (m, 3H), 3.28 (s, 3H), 3.14 (s, 3H), 2.35 (d, J = 5.3 Hz, 2H), 2.17 (s, 3H), 1.79 (s, 3H), 0.76–0.92 (m, 2H), and −0.12 (s, 9H); additional resonances appeared for the minor rotamer at: δ 7.79 (s, 1H), 4.87 (d, J = 14.0 Hz, 1H), 3.30 (s, 3H), 3.16 (s, 3H), 1.88 (s, 3H), 1.12–1.17 (m, 2H), and 0.07 (s, 9H); 13C NMR (100 MHz, CDCl3, mixture of two rotamers) for major rotamer: δ 156.6, 154.0, 139.7, 137.6, 137.1, 130.1, 128.5, 127.9, 126.3, 119.2, 118.7, 105.6, 64.2, 55.1, 54.5, 52.8, 31.1, 20.6, 18.0, 14.3, and −1.5; for minor rotamer: δ 155.7, 154.1, 140.1, 137.7, 136.9, 129.8, 128.5, 128.0, 126.2, 119.7, 118.9, 105.8, 64.3, 55.6, 54.3, 52.8, 31.1, 20.6, 18.2, 14.4, and −1.2; HRMS (ESI) m/z: [M+Na]+ Calcd for C25H37NO5Si 482.2333; Found 482.2334.

N-Benzyl-N-2-(trimethylsilyl)ethoxycarbonyl-[3-hydroxy-5-iodo-2-(2,2-dimethoxyethyl)phenyl]amine (52)

A 25-mL, one-necked, round-bottomed flask equipped with a rubber septum and argon inlet needle was charged with arylstannane 50 (0.398 g, 0.55 mmol, 1.0 equiv), 11 mL of THF, and N-iodosuccinimide (0.149 g, 0.66 mmol, 1.2 equiv). The flask was wrapped in aluminum foil, and the reaction mixture was stirred at room temperature for 2 h and then concentrated to a volume of ca. 0.5 mL. CH2Cl2 (ca. 20 mL) was added to give a pink solution, which was divided equally in two 50-mL, one-necked, round-bottomed flasks equipped with argon inlet adapters. 1M NaOH solution (10 mL) was added to each flask.49 The resulting mixtures were stirred vigorously for 2 h and then combined. The aqueous layer was separated and the organic layer was washed with 20 mL of 1M NaOH solution. The combined aqueous phases were adjusted to pH 7 with ca. 14 mL of 10% HCl solution and then extracted with two 15-mL portions of CH2Cl2. The combined organic layers were washed with 40 mL of saturated NaCl solution, dried over MgSO4, filtered, and concentrated to give 0.467 g of a yellow oil. Column chromatography on 45 g of silica gel (elution with 20% EtOAc-hexanes) afforded 0.303 g of a pale yellow oil. This was further purified by column chromatography on 30 g of silica gel (elution with 20% EtOAc-hexanes) to provide 0.260 g (85%) of aryl iodide 52 as a yellow oil: IR (film) 3266, 3031, 2952, 2833, 1700, 1667, 1593, 1574, 1495, 1454, 1408, 1360, 1285, 1249, 1178, 1115, and 1069 cm−1; 1H NMR (400 MHz, CDCl3, ca. 68:32 mixture of rotamers) for major rotamer: δ 8.26 (s, 1H), 7.27–7.33 (m, 3H), 7.23 (app d, J = 2.0 Hz, 2H), 7.20 (s, 1H), 6.90 (s, 1H), 4.77 (d, J = 14.4 Hz, 1H), 4.63 (d, J = 14.1 Hz, 1H), 3.89–4.46 (m, 3H), 3.34 (s, 3H), 3.25 (s, 3H), 2.42–2.61 (m, 2H), 0.88 (br s, 2H), and −0.06 (s, 9H); additional resonances appeared for the minor rotamer at: δ 9.23 (s, 1H), 4.79 (d, J = 14.4 Hz, 1H), 1.13 (br s, 2H), and 0.08 (s, 9H); 13C NMR (100 MHz, CDCl3, mixture of rotamers) for major rotamer: δ 157.5, 155.9, 142.2, 136.9, 129.5, 128.6, 128.0, 126.3, 122.4, 105.0, 100.4, 91.8, 64.5, 54.8, 53.6, 30.6, 17.9, and −1.4; additional resonances appeared for the minor rotamer at: δ 136.8, 129.8, 128.7, 128.1, 104.7, 64.7, and 54.7; HRMS (ESI) m/z: [M+Na]+ Calcd for C23H32INO5Si 580.0987; Found 580.0973.

N-Benzyl-N-2-(trimethylsilyl)ethoxycarbonyl-[5-benzoyl-3-hydroxy-2-(2,2-dimethoxyethyl)phenyl]amine (53)

A 25-mL, one-necked, round-bottomed flask equipped with rubber septum and argon inlet needle was charged with PdCl2(MeCN)2 (0.007 g, 0.026 mmol, 0.05 equiv) and then the flask was evacuated and filled with argon (three cycles). Arylstannane 50 (0.374 g, 0.52 mmol, 1.0 equiv), 5.2 mL of acetonitrile, and benzoyl chloride (0.069 mg, 0.057 mL, 0.49 mmol, 0.95 equiv) were then added. The resulting brown solution was stirred at room temperature for 2.5 h and then PdCl2(MeCN)2 (0.0035 g, 0.013 mmol, 0.025 equiv) was added in one portion. The reaction mixture was stirred for 2.5 h and then diluted with 50 mL of acetonitrile and washed with four 50-mL portions of hexanes to remove tin byproducts. The acetonitrile layer was concentrated to provide 0.272 g of a brown oil, which was purified by column chromatography on 15 g of silica gel (elution with 30% EtOAc-hexanes) to afford 0.222 g of a light tan oil consisting of a mixture of the desired ketone and tin byproducts. This material was dissolved in ca. 5 mL of CH2Cl2 and concentrated onto 1.2 g of silica gel. The free flowing powder was added on the top of a column of 20 g of silica gel and eluted with 25% EtOAc-hexanes to give 0.195 g (70%) of ketone 53 as a colorless paste: IR (film) 3289, 2953, 2834, 1699, 1660, 1598, 1576, 1495, 1422, 1366, 1323, 1249, 1178, 1116, and 1069 cm−1; 1H NMR (400 MHz, CDCl3, ca. 70:30 mixture of rotamers) for major rotamer: δ 8.40 (s, 1H), 7.68 (app d, J = 7.1 Hz, 2H), 7.57 (t, J = 7.3 Hz, 1H), 7.43 (app t, J = 7.7 Hz, 2H), 7.37 (s, 1H), 7.16–7.34 (m, 5H), 6.98 (s, 1H), 4.67–4.97 (m, 2H), 4.10–4.58 (m, 3H), 3.42 (s, 3H), 3.34 (s, 3H), 2.75 (br s, 2H), 0.81–0.99 (m, 2H), and −0.05 (s, 9H); additional resonances appeared for the minor rotamer at: δ 7.14 (s, 1H), 1.07–1.26 (m, 2H), and 0.10 (s, 9H); 13C NMR (100 MHz, CDCl3) δ 195.2, 156.9, 156.1, 141.2, 137.5, 137.1, 137.0, 132.4, 129.9, 129.4, 128.6, 128.3, 127.9, 127.1, 122.9, 118.4, 104.9, 64.5, 54.8, 54.6, 53.7, 31.0, 17.8, and −1.5; HRMS (ESI) m/z: [M+Na]+ Calcd for C30H37NO6Si 558.2282; Found 558.2261.

General Procedure for the Synthesis of Indoles from Benzannulation Products Derived from Ynamide 21. 1-Benzyl-6-butyl-4-hydroxyindole (54)

A 25-mL, one-necked, round-bottomed flask equipped with a rubber septum and argon inlet needle was charged with carbamate 47 (0.302 g, 0.62 mmol, 1.0 equiv) and 3.1 mL of THF and the resulting solution was cooled at 0 °C while TBAF solution (1M in THF, 3.1 mL, 3.1 mmol, 5.0 equiv) was added dropwise over 3 min. The brown reaction mixture was stirred at room temperature for 8 h, and then cooled to 0 °C and treated with 6M aq HCl (3.1 mL, 18.6 mmol, 30 equiv) dropwise over 3 min. The rubber septum was replaced by an argon inlet adapter and the pale yellow solution was stirred at room temperature for 20 h. During this time the reaction mixture turned green and then dark blue. The reaction mixture was diluted with 50 mL of Et2O and washed with two 25-mL portions of saturated NaHCO3 solution. The combined aqueous layers were extracted with two 20-mL portions of Et2O, and the combined organic phases were washed with 40 mL of saturated NaCl solution, dried over MgSO4, filtered, and concentrated to provide 0.204 g of a brown oil. This material was dissolved in ca. 5 mL of CH2Cl2 and concentrated onto 0.9 g of silica gel. The free flowing powder was added to the top of a column of 12 g of silica gel and eluted with 15% EtOAc-hexanes to give 0.146 g (84%) of indole 54 as a pale brown solid: mp 81.5–83 °C; IR (film) 3398, 2955, 2927, 2856, 1629, 1576, 1508, 1495, 1465, 1453, 1373, and 1242 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.27–7.35 (m, 3H), 7.12 (app d, J = 6.9 Hz, 2H), 6.99 (d, J = 3.2 Hz, 1H), 6.81 (s, 1H), 6.53 (d, J = 3.2 Hz, 1H), 6.40 (s, 1H), 5.28 (s, 2H), 4.85 (s, 1H), 2.63 J = 7.7 Hz, 2H), 1.60 (app quintet, J = 7.6 Hz, 2H), 1.34 (app sextet, J = 7.4 Hz, 2H), and 0.91 (t, J = 7.3 Hz, 3H); 13C NMR (100 MHz, CDCl3) δ 148.7, 138.7, 138.5, 137.8, 128.9, 127.7, 127.0, 126.8, 116.3, 105.4, 102.5, 97.8, 50.3, 36.6, 34.3, 22.6, and 14.2; Anal. Calcd for C19H21NO: C, 81.68; H, 7.58; N, 5.01. Found: C, 81.47; H, 7.59; N, 4.93.

1-Benzyl-4-hydroxy-6-phenylindole (55)

Reaction of carbamate 48 (0.294 g, 0.58 mmol, 1.0 equiv) with TBAF (1M in THF, 2.9 mL, 2.9 mmol, 5.0 equiv) in 2.9 mL of THF for 5 h and then with 6M aq HCl (2.9 mL, 17.4 mmol, 30 equiv) for 16 h according to the general procedure provided 0.222 g of a brown oil. This material was dissolved in ca. 10 mL of CH2Cl2 and concentrated onto 1.5 g of silica gel. The free flowing powder was added to the top of a column of 12 g of silica gel and eluted with 20% EtOAc-hexanes to give 0.136 g (78%) of indole 55 as a pale yellow solid: mp 117–119 °C; IR (KBr pellet) 3434, 3098, 3058, 3025, 2929, 1624, 1571, 1502, 1465, 1433, 1373, 1246, and 1182 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.58 (app dd, J = 8.3, 1.2 Hz, 2H), 7.42 (app t, J = 7.6 Hz, 2H), 7.31 (app d, J = 7.3 Hz, 1H), 7.28–7.35 (m, 3H), 7.15 (app d, J = 6.6 Hz, 2H), 7.11 (s, 1H), 7.10 (d, J = 3.2 Hz, 1H), 6.81 (d, J = 1.2 Hz, 1H), 6.61 (dd, J = 3.2, 0.8 Hz, 1H), 5.36 (s, 2H), and 5.04 (s, 1H); 13C NMR (100 MHz, CDCl3) δ 149.2, 142.2, 138.9, 137.4, 136.8, 128.9, 128.8, 127.9, 127.8, 127.5, 126.9, 126.9, 117.6, 104.3, 101.8, 98.1, and 50.4; Anal. Calcd for C21H17NO: C, 84.25; H, 5.72; N, 4.68. Found: C, 84.10; H, 5.64; N, 4.51.

1-Benzyl-6-ethoxy-4-hydroxyindole (56)

Reaction of carbamate 49 (0.205 g, 0.43 mmol, 1.0 equiv) with TBAF (1M in THF, 2.2 mL, 2.2 mmol, 5.1 equiv) in 2.2 mL of THF for 7 h and then with 6M aq HCl (2.2 mL, 13.2 mmol, 31 equiv) for 19 h according to the general procedure provided 0.138 g of a brown oil. This material was dissolved in ca. 10 mL of CH2Cl2 and concentrated onto 0.5 g of silica gel. The free flowing powder was added to the top of a column of 6 g of silica gel and eluted with 20% EtOAc-hexanes to give 0.098 g (85%) of indole 56 as a pale yellow solid: mp 122.5–124.5 °C; IR (KBr pellet) 3381, 3029, 2979, 2900, 1630, 1596, 1506, 1476, 1452, 1436, 1400, 1252, 1166, 1129, and 1050 cm−1; 1H NMR (400 MHz, CDCl3) δ 7.23–7.35 (m, 3H), 7.11 (app d, J = 6.8 Hz, 2H), 6.95 (d, J = 3.3 Hz, 1H), 6.50 (d, J = 3.2 Hz, 1H), 6.37 (d, J = 1.3 Hz, 1H), 6.25 (d, J = 1.9 Hz, 1H), 5.23 (s, 2H), 4.96 (s, 1H), 3.99 (q, J = 7.0 Hz, 2H), and 1.39 (t, J = 7.0 Hz, 3H); 13C NMR (125 MHz, CDCl3) δ 156.6, 149.5, 138.5, 137.6, 128.9, 127.7, 126.9, 126.1, 112.8, 98.0, 95.3, 87.6, 64.1, 50.3, and 15.0; Anal. Calcd for C17H17NO2: C, 76.38; H, 6.41; N, 5.24. Found: C, 76.46; H, 6.30; N, 5.09.

1-Benzyl-4-hydroxy-6-iodoindole (57)

Reaction of carbamate 52 (0.237 g, 0.43 mmol, 1.0 equiv) with TBAF (1M in THF, 2.2 mL, 2.2 mmol, 5.1 equiv) in 2.2 mL of THF for 7 h and then with 6M aq HCl (2.2 mL, 13.2 mmol, 31 equiv) for 20 h according to the general procedure provided 0.152 g of a reddish brown oil.50 This crude material was dissolved in ca. 10 mL of CH2Cl2 and concentrated onto 0.7 g of silica gel. The free flowing powder was added to the top of a column of 15 g of silica gel and eluted with 20% EtOAc-hexanes to give 0.078 g (53%) of indole 57 as a pink solid: mp 141–143 °C; IR (KBr pellet) 3328, 2921, 1617, 1567, 1496, 1462, 1435, 1351, 1297, 1239, and 1201 cm−1; 1H NMR (500 MHz, CD2Cl2) δ 7.26–7.34 (m, 3H), 7.27 (s, 1H), 7.07–7.11 (m, 2H), 7.04 (d, J = 3.2 Hz, 1H), 6.82 (d, J = 1.2 Hz, 1H), 6.55 (dd, J = 3.2, 0.8 Hz, 1H), 5.25 (s, 2H), and 5.24 (s, 1H); 13C NMR (100 MHz, CDCl3) δ 149.5, 139.3, 137.0, 129.0, 128.0, 127.5, 126.8, 118.0, 113.4, 112.4, 98.5, 85.5, and 50.4; Anal. Calcd for C15H12INO: C, 51.60; H, 3.46; N, 4.01. Found: C, 51.48; H, 3.31; N, 4.29.

6-Benzoyl-1-benzyl-4-hydroxyindole (58)