Abstract

Neuraminidase (NA) is a surface glycoprotein produced by the influenza virus. Specific NA mutations that confer resistance to anti-viral drugs have been reported. The aim of this study was to demonstrate quick preparation of the mutated NAs using the yeast surface display and its applicability for screening inhibitors. Plasmids encoding the head domain of wild-type and drug-resistant NAs were constructed and introduced into yeast, and these were successfully displayed on the yeast surface, with biochemical properties similar to the native virus NAs. This system using mutated NAs-displaying yeast provides an efficient and convenient tool for screening novel inhibitors against the drug-resistant influenza virus.

Keywords: Yeast surface display, Influenza A virus neuraminidase, Avian influenza virus H5N1

Abbreviations: NA, neuraminidase; HNA, head domain of neuraminidase

Highlights

-

•

Neuraminidase (NA) is a surface glycoprotein produced by the influenza virus.

-

•

Yeasts displaying wild-type and mutated NAs were constructed.

-

•

Biochemical properties of the displayed NAs were similar to those on the native virus.

-

•

Direct and rapid assays of NA enzyme activity were carried out.

-

•

This system can be developed for screening chemical libraries for novel inhibitors.

1. Introduction

Human seasonal influenza is responsible for an estimated 250,000–500,000 deaths and 3–5 million cases of severe illness annually worldwide [1]. Recently, the novel swine-origin virus (Influenza A H1N1 2009), which emerged potentially through the reassortment of triple North American H3N2 and H1N2 swine viruses with Eurasian avian-like swine viruses [2], entered the human population and spread rapidly around the globe, prompting the WHO to declare a pandemic in 2009 [3]. In addition, the highly pathogenic avian influenza A virus H5N1 has been sporadically epidemic since 1997 with a high mortality rate of 60% in humans and poses a serious pandemic threat [4].

Neuraminidase (NA) is a viral surface glycoprotein that plays a crucial role in the release of the newly formed virus from the infected cells, and has been the main target of current influenza antiviral treatment. Oseltamivir, one of the first-developed NA inhibitors has been most widely used for the treatment of patients with influenza virus infection. However, an oseltamivir-resistant H1N1 virus that harbors a specific mutation (H274Y) in the NA protein has been recently reported [5] as has been, to a lesser extent, the emergence of the avian influenza H5N1 virus with the same mutation [6]. These facts raise public health concerns and therefore there is a need to develop a novel, efficient, and a rapid screening system for the identification of novel inhibitors.

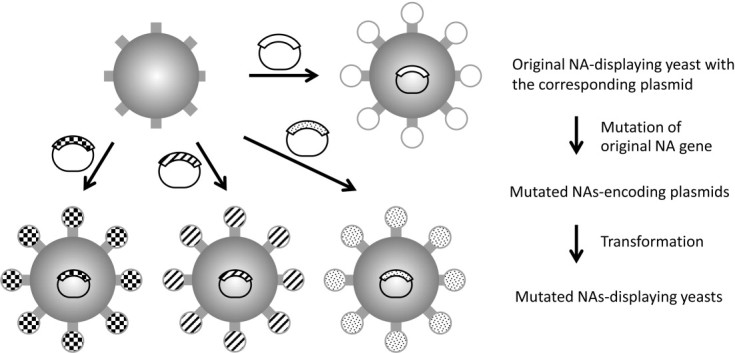

One of the first steps in drug discovery is the preparation of the target protein, which requires laborious processes including not only protein production and confirmation of activity but also purification, a most time-consuming process. As to influenza virus NAs, although their biotechnological production was achieved by the secretory system using insect, yeast, and mammalian cells for the head domain of NA, all the researchers will need several steps to purify it [7–9]. In this regard, the yeast cell surface display technology is promising; it has been used for screening binding proteins with specific affinity to a target molecule and endowing yeasts with heterogenous abilities like glucoamylase activity [10,11]. In this system, a heterologous protein of interest can be displayed on the yeast cell surface as a fusion protein with agglutinins, a cell wall protein that is involved in mating. In fact, the yeast cell surface display system has been used in various fields such as bioconversion, antibody engineering, and the development of bio-adsorbents [12–17]. Besides versatile applications as described above, the cumbersome steps involved in the purification of the recombinant proteins are avoided by using the yeast cell surface display system. Further, owing to the ease of gene manipulation, the fast growth in a low-cost medium, and the existence of the quality control system of endogenous protein production in the endoplasmic reticulum, though it is not special to yeast, we can easily prepare yeasts displaying mutated proteins of interest through construction of plasmids with mutations in the target protein-coding DNA (Fig. 1).

Fig. 1.

An illustration of the steps involved in use of yeast cell surface display system to produce the enzymes of interest. Once the original NA-displaying yeast cells are successfully constructed, it will take only within 3–4 days, including transformation and incubation, to obtain yeast cells displaying mutated NAs.

Here, we constructed yeasts displaying the head domain of wild-type or oseltamivir-resistant NAs. Then, we evaluated the biochemical properties such as NA enzymatic activities at different cultivation times, sensitivity to NA inhibitors, and thermal stability of the cell surface-displayed NAs.

2. Materials and methods

2.1. Strains and media

Escherichia coli DH5α (F−, ΔlacU169 (φ80dlacZΔM15), hsdR17 (rK−, mK+), recA1, endA1, deoR, thi-1, supE44, gyrA96, relA1, λ−) (TOYOBO, Osaka, Japan) was used as a host for DNA manipulation. Saccharomyces cerevisiae BY4742 (MATα, his3–1, leu2, lys2, ura3; EUROSCARF, Frankfurt, Germany) was used to construct yeasts displaying NAs. E. coli transformants were grown at 37 °C in Luria–Bertani media (1% (w/v) tryptone, 0.5% (w/v) yeast extract, and 1% (w/v) sodium chloride) containing 100 μg/mL ampicillin. Yeast transformants were selected on a synthetic dextrose (SDC) solid medium (0.67% (w/v) yeast nitrogen base without amino acids, 2% (w/v) glucose, 1% (w/v) casamino acids, 0.002% (w/v) adenine, 0.002% (w/v) l-tryptophan, and 2% (w/v) agar), and then, the resultant colonies were aerobically cultivated at 30 °C in a liquid SDC medium (pH 6.5) supplemented with 100 mM 2-morpholinoethanesulfonic acid (MES).

2.2. Vectors for expression

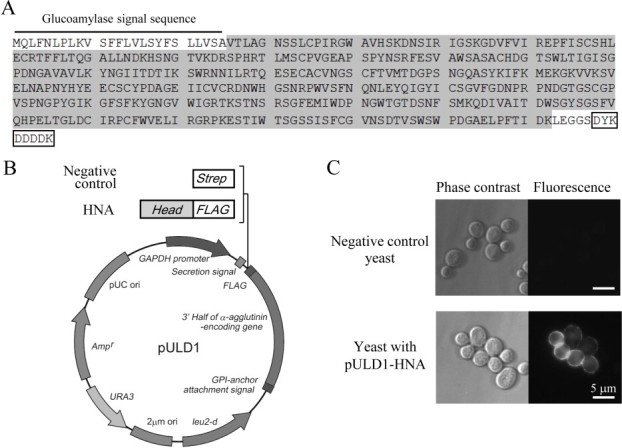

The DNA fragment encoding head domain of neuraminidase (HNA, 387 amino acids in length) was PCR-amplified from the pTZ-NA plasmid that harbors the neuraminidase gene from the Fujian H5N1 virus, using sense [5′- CTTACTTTTCTTTGCTCGTTTCTGCCGTAACATTAGCGGGCAATTCATCTC-3′], antisense [5′-CATCCTTGTAATCAGATCCACCCTCGAGCTTGTCAAT GGTGAATGGCAAC-3′] primers, and the KOD-Plus-Neo DNA polymerase (TOYOBO) (Fig. 2A). The DNA fragment was inserted into BglII/XhoI-digested pULD1, which codes for the C-terminal half of α-agglutinin downstream of the multiple cloning sites, using In-Fusion HD Cloning kit (Clontech, Mountain view, CA, USA). The resultant plasmid is referred to as pULD1-HNA/WT. The plasmid encoding the head domain of oseltamivir-resistant NA (H274Y) was constructed by mutating pULD1-HNA/WT using the primers 5′-GAATGCTCCTAATTATTACTATGAGGAATGCTCC-3′ and 5′-GGAGCATTCCTCATAGTAATAATTAGGAGCATTC-3′ (the underlines indicates mutation points) and the QuikChange Site-Directed Mutagenesis kit (Agilent Technologies, Santa Clara, CA, USA), and the plasmid was termed pULD1-HNA/H274Y. pULD1-Strep, which encodes a Strep-tag instead of a FLAG-tag, was constructed as the negative control plasmid for immunofluorescence staining.

Fig. 2.

(A) Sequence of head domain of neuraminidase (HNA). The gray color shows the sequence of the HNA. The box indicates FLAG tag. (B) Plasmid constructed for yeast surface display of the HNA. Head, head domain. (B) A microscopic observation of surface display after immunofluorescence staining. Forty-eight hours after cultivation of the yeast, the display of NAs on yeast was examined by immunofluorescence staining using an anti-FLAG M2 mouse IgG antibody followed by an Alexa Flour 488-conjugated anti-mouse IgG antibody. The yeast suspension was transferred onto a glass slide and observed under a fluorescence microscope. Scale bars indicate 5 μm.

2.3. Transformation of yeast

Yeasts were transformed using the Frozen-EZ Yeast Transformation-II kit (Zymo Research, Irvine, CA, USA). After the introduction of plasmids, the yeast transformants were selected on a uracil-deficient SDC solid medium.

2.4. Neuraminidase activity assay

Yeast transformants were pre-cultivated in a buffered SDC medium for 36 h, and then the main cultivation was initiated at an initial optical density (OD) of 0.1 at 600 nm in 10 mL of buffered SDC medium. At the indicated times of cultivation, the yeast cells were collected and suspended in the NA assay buffer containing 5 mM CaCl2 and 50 mM MES pH 6.5. The yeast suspension (50 μL) containing 107 cells was transferred onto a 96-well microplate (353072; BD Biosciences, CA, USA) and mixed with 50 μL of the NA assay buffer containing 100 μM 4-methylumbelliferyl-N-acetyl-α-d-neuraminic acid (MUNANA) (Sigma―Aldrich, St.Louis, MO, USA) as a fluorogenic substrate. After incubation for 15 min at 37 °C, 250 mM glycine pH 10.4 was added to stop the reaction and then the fluorescence was measured with a Fluoroskan Ascent Fluorometer (Labsystems, Helsinki, Finland) with an excitation at 355 nm and an emission at 460 nm. For the inhibition assay, 2 types of NA inhibitors, oseltamivir carboxylate (Shanghai Haoyuan Chemexpress, Shanghai, China) and zanamivir (LKT Laboratories, St. Paul, MN, USA), were used.

2.5. Microscopic observation and determination of the HNA display efficiency

Yeasts were collected at 107 cells per tube in a 1.5 mL microtube and washed once with 1 mL of phosphate-buffered saline (PBS) pH 7.4. The pellets after centrifugation were suspended in PBS containing 0.5% (w/v) bovine serum albumin and 2.5 μg/mL anti-FLAG M2 mouse IgG antibody (Sigma–Aldrich) and incubated for 1 h with rotation. After washing with PBS, the pellets were suspended in PBS containing 0.5% (w/v) bovine serum albumin and 5 μg/mL Alexa Flour 488-conjugated anti-mouse IgG antibody (Invitrogen, Carlsbad, CA, USA) and incubated for 1 h with rotation. After washing twice with PBS, the pellets were suspended in 300 μL of PBS and transferred onto a glass slide for fluorescence microscopic observation. To determine the display efficiency, 250 μL of the cell suspension was transferred into a 96-well microplate, and the fluorescence was measured with a Fluoroskan Ascent Fluorometer, with an excitation at 485 nm and an emission at 537 nm [17].

2.6. Evaluation of thermal stability

Yeast displaying HNA/WT was suspended in NA assay buffer at the concentration of 2 × 108 cells/mL and incubated at 37 °C for 72 h, and the enzyme activity was assayed by the same method described above. The activity was indicated as a percentage, with the activity of control sample incubated at 4 °C for 72 h considered to be 100%.

3. Results

3.1. Confirmation of HNA display on yeast surface

To display the head domain of Fujian H5N1 virus-derived NA (HNA), we constructed expression plasmid, pULD1-HNA/WT (Fig. 2B) and introduced it into S. cerevisiae BY4742. After the cultivation, we detected the displayed NAs on the yeast cell surface by fluorescence immunostaining (Fig. 2C). These results indicated that HNA was successfully displayed on the yeast surface.

3.2. Enzyme activity and display efficiency of HNAs on the yeast cell surface

We next examined the enzymatic activity of the displayed HNAs (both the wild-type and the mutant) by using a fluorogenic substrate under the condition without an interfering effect of yeasts on the fluorescence intensity (Supplementary Fig. 1). The HNA mutant with H274Y substitution (HNA/H274Y) was chosen because this mutant is resistant to oseltamivir, one of the most widely used drugs for the treatment of influenza infection in humans. The mechanism by which the HNA/H274Y has resistance to oseltamivir is the interference of its access to the active site owing to a pentoxyl group at position 3 in oseltamivir, whose functional group does not exist in zanamivir [18].

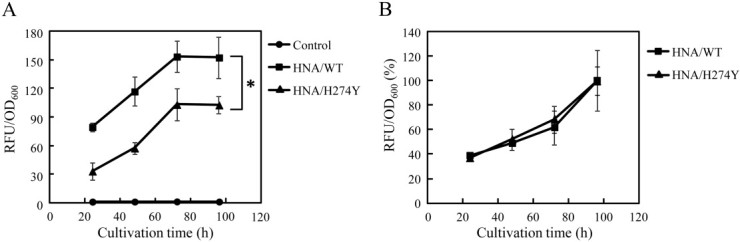

We evaluated the NA enzymatic activity of the yeast transformants displaying HNA/WT and HNA/H274Y at different cultivation times. When HNA/WT was displayed on the yeast surface, the NA activity was significant at 24 h (79.7 ± 4.5 RFU/OD600), with the peak being observed at 72 h (153.5 ± 16.5 RFU/OD600). A similar trend was also observed in yeasts displaying HNA/H274Y, although the enzyme activity level was 1.5- to 2.4-fold lower than that observed in the HNA/WT-displaying yeasts at the all time points examined (Fig. 3A), and this difference in enzyme activity was statistically significant (p < 0.05). The control yeast without HNAs on the surface showed no enzyme activity at all the cultivation times tested.

Fig. 3.

Time course of the enzyme activity (A) and display efficiency (B) for HNA/WT and HNA/H274Y. The enzyme activity is represented in relative fluorescence units (RFU) divided by OD600. The display efficiency was determined by immunofluorescence staining and measurement of the fluorescence intensity by Fluoroskan Ascent Fluorometer with an excitation at 485 nm and an emission at 537 nm. The data were expressed as percent of RFU in which the value of HNA/WT-displaying yeast at 96 h was 100%. The data represent the average of 3 independent experiments, and the error bars depict the SEM. *p < 0.05, determined by two-way ANOVA.

In order to confirm that the difference in the enzyme activity observed is due to the H274Y substitution in the HNA, we determined the display efficiencies of both HNAs on yeast surface by immunofluorescence staining. As seen in Fig. 3B, the display efficiencies of HNA/WT and HNA/H274Y on the yeast surface were not different. These results demonstrated that the H274Y mutation does not alter the display efficiency, but lowers the enzyme activity (Fig. 3A). In support of this conclusion, the previous study by Collins et al. [18] reported that the Michaelis constant for the enzyme carrying the H274Y mutation increased when compared to that of the wild-type enzyme.

For the influence of the C-terminal FLAG tag on enzyme activity, the yeast with the FLAG tag-free NA showed 1.4-fold higher activity than that with the NA possessing FLAG tag at the C-terminus (Supplementary Fig. 2).

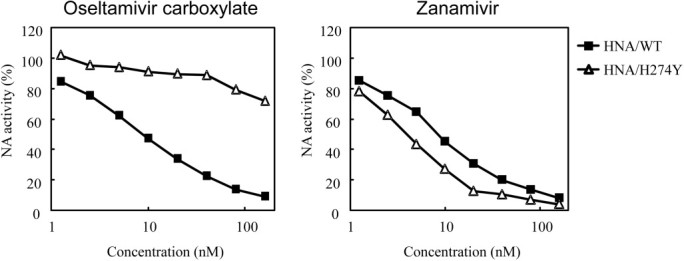

3.3. Inhibition of the displayed HNAs on yeast by NA inhibitors

Both HNA/WT and HNA/H274Y showed significant enzymatic activity and we examined the effect of 2 types of selective NA inhibitors on this activity. Oseltamivir carboxylate (the active ingredient of Tamiflu) and zanamivir (the active ingredient of Relenza) were used as inhibitors. When we conducted a test for concentration-response curve on the HNA/WT on yeast, the IC50 was 9.1 and 8.8 nM for oseltamivir carboxylate and zanamivir, respectively (Fig. 4). On the other hand, while zanamivir showed the near or higher inhibition activity on the HNA/H274Y whose IC50 was 4.1 nM, oseltamivir carboxylate was only able to inhibit the activity by 28% even at 160 nM, the highest concentration in this test. This inhibition properties and IC50 values of oseltamivir carboxylate and zanamivir on the HNA/WT and the HNA/H274Y were consistent with the previous reports in which NA derived from influenza virus grown in hen eggs or MDCK cells was used for carrying out inhibition study [18,19]. Thus, we conclude that the HNAs displayed on the yeast surface have the same property as the native and mutated NAs present on the virus surface.

Fig. 4.

Concentration–response curve on HNAs displayed on yeast with increasing dose of inhibitors, oseltamivir carboxylate (left) and zanamivir (right). HNA/WT or HNA/H274Y displayed on the yeast cell surface was subjected to an inhibition assay by the addition of the indicated concentrations of the inhibitors. The enzyme activity without any inhibitors was represented as 100%, and IC50 values were calculated based on the inhibition curves.

3.4. Thermal stability

When enzymes (including NAs) are used to screen for inhibitors, the thermal stability of the displayed proteins during the enzyme reaction is important in evaluating the inhibitors. For example, certain newly acquired mutations in enzymes of interest have been reported to give rise to drug-resistance and lowered stability simultaneously, which impairs an effective screening. Specifically, McKimm-Breschkin et al. [20] reported such mutant NAs that simultaneously displayed drug-resistance and reduced thermal stability. Therefore, we examined the effect of heat treatment on the enzyme activity of the HNAs displayed on the yeast surface. The HNA displayed on the yeast surface retained their activity even after prolonged heating (Fig. 5). In contrast, recombinant NA produced in insect cells is less stable and is inactivated upon heat treatment [19]. These findings suggest that the thermal stability of the NA displayed on the yeast cell surface is superior to that of the soluble NA produced in insect cells.

Fig. 5.

Thermal stability of displayed HNA/WT. Yeast displaying HNA/WT was suspended in NA assay buffer at the concentration of 2 × 108 cells/mL and incubated at 37 °C for 72 h, and the enzyme activity was assayed. The data represent the average of 3 independent experiments, and the error bars depict the SEM. n.s. indicates not significant.

4. Discussion

In the present study, we successfully produced the head domain of the NA from influenza H5N1 virus on the yeast cell surface. The recombinant enzyme showed sufficient enzyme activity and high thermal stability. Importantly, the available small inhibitors were able to reasonably inhibit the activity of these enzymes displayed on the yeast surface. The successful heterologous production of the head domain of NA from avian influenza virus H5N1 was first reported using the methylotropic yeast Pichia pastris [9]. However, the recombinant NA was produced as a secreted, soluble protein which requires several steps for purification. On the other hand, it should be noted that in the present study, the yeast displaying the HNA on the cell surface only requires to be centrifuged and does not require any further purification prior to examination of the enzyme activity. This makes the yeast surface display system very effective, especially in studying the application of enzymes (mutated and non-mutated) and screening for novel enzyme inhibitors.

NA is a mushroom-shaped tetramer of identical subunits, with the head of the mushroom suspended from the virus membrane. Each of the subunits that form the head of the mushroom is made up of a six-bladed propeller-like structure [21]. Although it is unclear whether the HNAs displayed on the yeast surface have a proper folding or tetramer structure, the proper folding of HNAs on the yeast surface will be partly supported by the fact that the HNA/WT or HNA/H274Y showed reasonable enzyme activities and inhibition properties by NA inhibitors. The same is true on a proper tetramerization of NA, but we think that it is not critical for application to drug screening because NA inhibitors attack the active site of NA monomer not tetramer.

Because Schmidt et al. [19] indicated that the NA bound to the virus surface was highly stable during incubation at 37 °C compared with the soluble NA produced in insect cells, we considered that the reduced flexibility of NA by being fixed on the virus surface might be one of the factors contributing to thermal stabilization. Yeast surface display system is also expected to have the same stabilizing effect as virus, but whether the intrinsically instable NA with E119G mutation reported by McKimm-Breschkin et al. [20] is stabilized as well should be investigated for further research.

In general, exogenous proteins produced in yeast are known to get high mannose type glycosylation, potentially deteriorating innate properties of target proteins. One of the examples is the soluble NA produced in P. pastris, which showed a larger molecular weight due to hyperglycosylation [9]. On the other hand, when HNA was intracellularly produced in S. cerevisiae, we detected the main band around 44 kDa probably showing the HNA in western blotting (Supplementary Fig. 3). In addition, the yeast without HNA on the surface showed a band at 102 kDa indicating α-agglutinin only, and the yeast displaying HNA showed a band that is 44 kDa higher than the α-agglutinin. These results suggest that the HNA produced in S. cerevisiae is likely not to have hyperglycosylation, unlike the HNA produced in P. pastris.

In addition to application in enzyme assays, the yeast displaying HNA could be utilized for yeast-based vaccines that could be administered subcutaneously as a whole yeast [22]. Although yeast which produces target antigens intracellularly has been investigated, yeast with desired antigens on the cell surface might be more effective because of accessibility to immune cells. The in vivo efficacy of soluble neuraminidase as vaccines has been demonstrated in mice challenged with recombinant N2 neuraminidase [7], and therefore, a prophylactic effect of the HNA-displaying yeast constructed here can be expected [23].

In conclusion, this system to display HNA on the yeast surface can be applied for screening chemical libraries in order to obtain inhibitors of NAs carrying various novel mutations. As it is less time consuming, this technique can also be applied for quick preparation of recombinant protein antigens from frequently mutating viruses.

Footnotes

This is an open-access article distributed under the terms of the Creative Commons Attribution-NonCommercial-No Derivative Works License, which permits non-commercial use, distribution, and reproduction in any medium, provided the original author and source are credited.

Supplementary material

Supplementary material associated with this article can be found, in the online version, at doi:10.1016/j.fob.2013.10.007.

Appendix. Supplementary materials

Supplementary Fig. 1 Standard curve of methylumbelliferone (MU), a fluorogenic substance released after the cleavage of MUNANA by neuraminidase, with or without yeasts. Yeasts suspended in NA assay buffer at the number of 107 or the buffer only were transferred into 96-well microplate, and then MU solutions at the indicated concentrations were added. The fluorescent intensity of MU was measured in Fluoroskan Ascent Fluorometer with an excitation at 355 nm and an emission at 460 nm. RFU at each blank solution without MU was subtracted from each all other value.

Supplementary Fig. 2 Enzyme activity of yeast-displayed HNA with or without FLAG-tag at the C-terminus. A plasmid encoding a FLAG tag-free HNA was constructed and introduced Saccharomyces cerevisiae BY4742, and then the NA enzyme activity was compared with the yeast displaying HNA with FLAG tag at the C-terminus. NA assay was performed as indicated in Section 2. The data represent means ± SD.

Supplementary Fig. 3 Western blotting of protein extracts from yeast with or without displayed HNA and yeast producing HNA within the cell. The yeasts without or with HNA on the cell surface (lanes 1 and 2, respectively) and the yeast producing HNA internally (lane 3) were crushed by beads-shocker in PBS solution, and then, the supernatants were separated by 5–20% SDS–PAGE. Immunoblotting was conducted using anti-FLAG M2 mouse IgG antibody conjugated with horseradish peroxidase.

References

- 1.WHO. Influenza (Seasonal) Fact sheet 211, 2009.

- 2.Dawood F.S., Jain S., Finelli L., Shaw M.W., Lindstrom S., Garten R.J., Gubareva L.V., Xu X., Brides C.B., Uyeki T.M. Emergence of a novel swine-origin influenza A (H1N1) virus in humans. N. Engl. J. Med. 2009;360:2605–2615. doi: 10.1056/NEJMoa0903810. [DOI] [PubMed] [Google Scholar]

- 3.WHO. Pandemic (H1N1) 2009 update 112, 2009.

- 4.Abdel-Ghafar A.N., Chotpitayasunondh T., Gao Z., Hayden F.G., Nguyen D.H., de Jong M.D., Naghdaliyev A., Peiris J.S., Shindo N., Soeroso S., Uyeki T.M. Update on avian influenza A (H5N1) virus infection in humans. N. Engl. J. Med. 2008;358:261–273. doi: 10.1056/NEJMra0707279. [DOI] [PubMed] [Google Scholar]

- 5.Sheu T.G., Deyde V.M., Okomo-Adhiambo M., Garten R.J., Xu X., Bright R.A., Butler E.N., Wallis T.R., Klimov A.I., Gubareva L.V. Surveillance for neuraminidase inhibitor resistance among human influenza A and B viruses circulating worldwide from 2004 to 2008. Antimicrob. Agents Chemother. 2008;52:3284–3292. doi: 10.1128/AAC.00555-08. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.de Jong M.D., Tran T.T., Truong H.K., Vo M.H., Smith G.J., Nguyen V.C., Bach V.C., Phan T.Q., Do Q.H., Guan Y., Peiris J.S., Tran T.H., Farrar J. Oseltamivir resistance during treatment of influenza A (H5N1) infection. N. Engl. J. Med. 2005;353:2667–2672. doi: 10.1056/NEJMoa054512. [DOI] [PubMed] [Google Scholar]

- 7.Deroo T., Jou W.M., Fiers W. Recombinant neuraminidase vaccine protects against lethal influenza. Vaccine. 1996;14:561–569. doi: 10.1016/0264-410x(95)00157-v. [DOI] [PubMed] [Google Scholar]

- 8.Nivitchanyong T., Yongkiettrakul S., Kramyu J., Pammemgpetch S., Wanasen N. Enhanced expression of secretable influenza virus neuraminidase in suspension mammalian cells by influenza virus nonstructural protein 1. J. Virol. Methods. 2011;178:44–51. doi: 10.1016/j.jviromet.2011.08.010. [DOI] [PubMed] [Google Scholar]

- 9.Yongkiettrakul S., Boonyapakron K., Jongkaewwattana A., Wanitchang A., Leartsakulpanich U., Chitnumsub P., Eurwilaichitr L., Yuthavong Y. Avian influenza A/H5N1 neuraminidase expressed in yeast with a functional head domain. J. Virol. Methods. 2009;156:44–51. doi: 10.1016/j.jviromet.2008.10.025. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Kuroda K., Ueda M. Cell surface engineering of yeast for applications in white biotechnology. Biotechnol. Lett. 2011;33:1–9. doi: 10.1007/s10529-010-0403-9. [DOI] [PubMed] [Google Scholar]

- 11.Ueda M., Tanaka. A. Cell surface engineering of yeast: construction of arming yeast with biocatalyst. J. Biosci. Bioeng. 2000;90:125–136. [PubMed] [Google Scholar]

- 12.Aoki W., Yoshino Y., Morisaka H., Tsunetomo K., Koyo H., Kamiya S., Kawata N., Kuroda K., Ueda M. High-throughput screening of improved protease inhibitors using a yeast cell surface display system and a yeast cell chip. J. Biosci. Bioeng. 2011;111:16–18. doi: 10.1016/j.jbiosc.2010.08.006. [DOI] [PubMed] [Google Scholar]

- 13.Chao G., Lau W.L., Hackel B.J., Sazinsky S.L., Lippow S.M., Wittrup K.D. Isolating and engineering human antibodies using yeast surface display. Nat. Protoc. 2006;1:755–768. doi: 10.1038/nprot.2006.94. [DOI] [PubMed] [Google Scholar]

- 14.Inaba C., Maekawa K., Morisaka H., Kuroda K., Ueda M. Efficient synthesis of enantiomeric ethyl lactate by Candida antarctica lipase B (CALB)-displaying yeasts. Appl. Microbiol. Biotechnol. 2009;83:859–864. doi: 10.1007/s00253-009-1931-x. [DOI] [PubMed] [Google Scholar]

- 15.Lin Y., Tsumuraya T., Wakabayashi T., Shiraga S., Fujii I., Kondo A., Ueda M. Display of a functional hetero-oligomeric catalytic antibody on the yeast cell surface. Appl. Microbiol. Biotechnol. 2003;62:226–232. doi: 10.1007/s00253-003-1283-x. [DOI] [PubMed] [Google Scholar]

- 16.Murai T., Ueda M., Yamamura M., Atomi H., Shibasaki Y., Kamasawa N., Osumi M., Amachi T., Tanaka A. Construction of a starch-utilizing yeast by cell surface engineering. Appl. Environ. Microbiol. 1997;63:1362–1366. doi: 10.1128/aem.63.4.1362-1366.1997. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Nishitani T., Shimada M., Kuroda K., Ueda M. Molecular design of yeast cell surface for adsorption and recovery of molybdenum, one of rare metals. Appl. Microbiol. Biotechnol. 2010;86:641–648. doi: 10.1007/s00253-009-2304-1. [DOI] [PubMed] [Google Scholar]

- 18.Collins P.J., Haire L.F., Lin Y.P., Liu J., Russell R.J., Walker P.A., Skehel J.J., Martin S.R., Hay A.J., Gamblinet S.J. Crystal structures of oseltamivir-resistant influenza virus neuraminidase mutants. Nature. 2008;453:1258–1261. doi: 10.1038/nature06956. [DOI] [PubMed] [Google Scholar]

- 19.Schmidt P.M., Attwood R.M., Mohr P.G., Barrett S.A., McKimm-Breschkin J.L. A generic system for the expression and purification of soluble and stable influenza neuraminidase. PLoS One. 2011;6:e16284. doi: 10.1371/journal.pone.0016284. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.McKimm-Breschkin J.L., McDonald M., Blick T.J., Colman P.M. Mutation in the influenza virus neuraminidase gene resulting in decreased sensitivity to the neuraminidase inhibitor 4-guanidino-Neu5Ac2en leads to instability of the enzyme. Virology. 1996;225:240–242. doi: 10.1006/viro.1996.0595. [DOI] [PubMed] [Google Scholar]

- 21.Varghese J.N., Laver W.G., Colman. P.M. Structure of the influenza virus glycoprotein antigen neuraminidase at 2.9 Å resolution. Nature. 1983;303:35–40. doi: 10.1038/303035a0. [DOI] [PubMed] [Google Scholar]

- 22.Ardiani A., Higgins J.P., Hodge. J.W. Vaccines based on whole recombinant Saccharomyces cerevisiae cells. FEMS Yeast Res. 2010;10:1060–1069. doi: 10.1111/j.1567-1364.2010.00665.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Shibasaki S., Nomura W., Miyoshi T., Tafuku A., Sewaki S., Ueda M. An oral vaccine against candidiasis generated by yeast molecular display system. FEMS Pathog. Dis. 2013 doi: 10.1111/2049-632X.12068. in press. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary Fig. 1 Standard curve of methylumbelliferone (MU), a fluorogenic substance released after the cleavage of MUNANA by neuraminidase, with or without yeasts. Yeasts suspended in NA assay buffer at the number of 107 or the buffer only were transferred into 96-well microplate, and then MU solutions at the indicated concentrations were added. The fluorescent intensity of MU was measured in Fluoroskan Ascent Fluorometer with an excitation at 355 nm and an emission at 460 nm. RFU at each blank solution without MU was subtracted from each all other value.

Supplementary Fig. 2 Enzyme activity of yeast-displayed HNA with or without FLAG-tag at the C-terminus. A plasmid encoding a FLAG tag-free HNA was constructed and introduced Saccharomyces cerevisiae BY4742, and then the NA enzyme activity was compared with the yeast displaying HNA with FLAG tag at the C-terminus. NA assay was performed as indicated in Section 2. The data represent means ± SD.

Supplementary Fig. 3 Western blotting of protein extracts from yeast with or without displayed HNA and yeast producing HNA within the cell. The yeasts without or with HNA on the cell surface (lanes 1 and 2, respectively) and the yeast producing HNA internally (lane 3) were crushed by beads-shocker in PBS solution, and then, the supernatants were separated by 5–20% SDS–PAGE. Immunoblotting was conducted using anti-FLAG M2 mouse IgG antibody conjugated with horseradish peroxidase.