Abstract

Instantaneous controlled pressure drop (DIC) was applied to obtain a suitable cell disruption extent as a technology in green tea processing. Microstructural observations showed that DIC increased cell disruption in an even manner as reflected from loosened palisade, distorted cells, widened space between cells, disrupted and rearranged cellular membrane in tea leaves. Color difference determination supported that DIC could facilitate the release and transport of cell contents. DIC sample showed a rise in redness, over 2.5 times greater than the control after spreading naturally for 24 h. Chemical determination revealed a better infusion behavior of tea polyphenols and amino acids in green tea manufactured by DIC method both at high and low temperature. The increase in tea polyphenols content in liquor for the first brew from twisted and needle tea was about 35% and that from flat tea was about 15% in DIC method over the traditional processing. These results suggest that DIC process can be applied in green tea processing for both a traditional product and a new kind of tea capable of making with cold water.

Keywords: Instantaneous controlled pressure drop, Infusion behavior, Tea polyphenols, Amino acids, Microstructural properties, Green tea processing

Introduction

Cell disruption is one of the key factors in tea processing by which chemical reactions within the material leaves are controlled in aspects of extent, progress, and space, leading to the development of typical quality for the six tea categories, namely green tea, black tea, Oolong tea, white tea, yellow tea and dark compressed tea. Cell disruption is achieved through an intensive rolling process in orthodox black tea and even by mechanical disintegration for LTP (Lawrie Tea Processor) and CTC (Crush, Tear, Curl) black tea (Hampton 1992). In Oolong tea, cell disruption is controlled exquisitely through scraping leaves edge against each other by stirring the material leaves interrupted with spreading in stationary state for different rounds and time in the shaking stage (Ye 1997). Cell disruption in white tea progresses following the loss of cell turgid with the gradual water loss in a natural withering way for about 52–60 h (Yuan 2006). Yellow tea undergoes similar processing stages with green tea except for a stuffy treatment and thus has a resembled cell disruption, while dark compressed tea is manufactured with green tea as its materials and the characteristic quality is thought to be further obtained in its post-fermentation stage.

In green tea, the fixation process is recognized as a key technique by which endogenous enzymes are inactivated in a short time by heating either from thermal steam or hot air (Hu 1997; Liu et al 2003). Cell disruption is achieved through the rolling stage that is mainly for its shape and brewing quality following the fixation process (Yang and Yin 2003). However, it is difficult to escape further changes unfavorable for green tea color quality through unexpected chemical reactions like autoxidation or chemical condensation, which happen easily in the inactivated leaves still with high humidity content. A rise in temperature by mechanic thermal produced with the rolling process itself would also accelerate these reactions (Liu et al 2003). Rolling in a relatively high temperature condition decreased the polyphenols content in green tea (Chen et al 1996). Bruised leaves segments and dust result from the rolling stage are either not accepted for green tea quality. To prevent these, rolling would often be applied to a reduced degree and even be totally neglected for a desirable visual appearance when tender material leaves are used as a trend for quality tea and famous tea. If not properly applied, this strategy would lead to decreased tea components in the liquor, neither favorable for the taste quality nor for the health function from its active chemicals.

The Instantaneous Controlled Pressure Drop process (DIC) was patented in Europe (Allaf et al 2000). It has been applied in food industry and chemical engineering as drying and texturing technology (Kamal et al 2008), treatment for inactivating inhibitors in soybean products, extraction process for volatile compounds and essential oils (Rezzoug et al 2005; Haddad and Allaf 2007) and for specific chemicals with higher yields (Emmel et al 2003).

DIC process was first introduced in the processing of a cold-making tea in our laboratory (Yang and Feng 2006). Water extract and chlorophyll contents were found to be increased significantly in the liquor of DIC processed tea than in the traditional one in a previous study (Wang et al 2005). The present work determined the textural difference by analyzing color changes, demonstrated textural changes by observing the microstructural properties, investigated the infusion quality of DIC processed tea.

Materials and methods

Instantaneous controlled pressure drop and traditional green tea processing

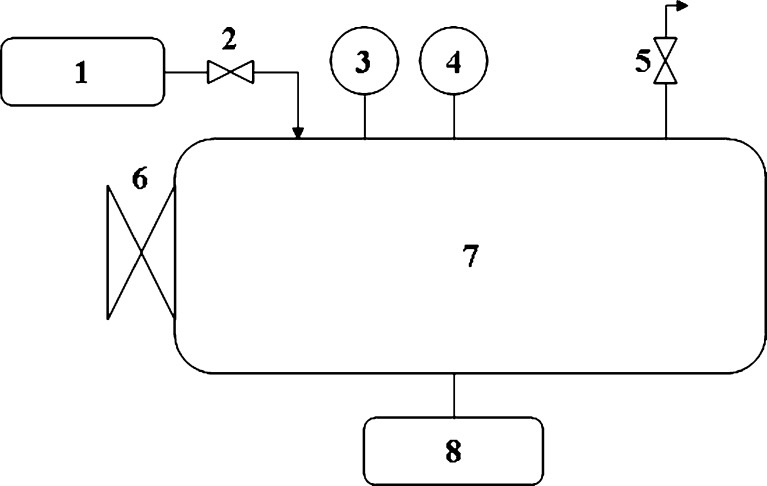

Fresh tea shoots with one bud and two leaves were plucked from tea plant (Camellia sinensis cv. Jiukeng) in the tea garden of Zhejiang University (Panban, Hangzhou, China). The control tea samples were made with the traditional green tea processing. Briefly, fresh tea shoots were subjected to a withering process around 20–30 °C for 6–7 h for a desirable water loss, then the withered material leaves underwent a fixation process (inactivation of endogenous enzymes by heating) with drum around 90 °C for 3 min. The fixed materials were made into flat, twisted, or needle shape on rolling machine of responding types at room temperature for 25 min. Then the material leaves were initially dried around 120 °C for 8 min and finally dried around 100 °C for 8 min. Instead, the withered material leaves were transferred into the instantaneous controlled pressure drop (DIC) apparatus designed according to our patent (Yang and Feng 2006) with its sketch shown in Fig. 1 and preheated for 3 min (250 °C) as a similar process to fixation. The system was then applied from outside a high pressure (0.3 MPa) by an air compressor equipped to the apparatus and the pressure in the system rose to 0.4 MPa in end with an additional pressure from the saturated thermal steam by heating the material leaves themselves besides the pressure from the air compressor. Then the outlet of the apparatus was opened suddenly, resulting in a transient drop of the pressure inside the system from 0.4 MPa to almost vacuum in less then 0.1 s. This transient pressure drop induced a mechanical effect as an outward pulling force from within the material leaves tissue, leading to the cell disruption to a desirable degree. Following the DIC process, the material leaves were drawn outside the apparatus and spread on bamboo sheet for cooling for a period. After a rolling process for by far a shorter time, and the shaping and drying operation in the same way as the traditional green tea, DIC processed teas were manufactured. Tender material leaves were processed into three shape types, i.e. flat, needle and twisted, as quality and famous green tea, and the other raw materials were manufactured as regular green tea, in both the DIC and traditional methods.

Fig. 1.

Sketch of apparatus for green tea treatment by instantaneous controlled pressure drop. (1) air compressor; (2) air compressor connector; (3) thermoelectric thermometer; (4) pressure gauge; (5) transient pressure relief valve; (6) material leaves load/discharge gate with auto lock; (7) processing vessel with electrothermal tubers; (8) electronic control panel

Color parameters and analysis

Changes in color for fixed material leaves of both the control and DIC method were determined after spread on bamboo sheet for 24 h in room by a colorimeter (model Color Quest XE, Hunter Associates Laboratory Inc., Reston, Virginia, USA) equipped with the light source D65 (Oszmianski et al 2008). The color of a sample is denoted by the three dimensions L, a and b, corresponding to the XYZ CIE lab system. The L value gives a measure of the lightness of the product color from 100 for perfect white to 0 for absolute black. The ‘redness/greenness’ and ‘yellowness/blueness’ are denoted by a and b values respectively. All the assays were performed in triplicate for each sample.

Microstructure observation

Microstructural properties of fixed material leaves in both DIC and traditional methods were investigated by light microscopy, scanning electron microscopy (SEM) and transmission electron microscopy (TEM). In brief, samples were fixed in FAA, dehydrated in an alcohol series and embedded in paraffin. The 8 μm thick sections were cut with a rotary microtome, stained with hematoxylin-eosin solution (pH 4.7), and observed by a light microscope (×200) (Olympus, Japan). Meanwhile, samples were kept in 4.0% gluteraldehyde (v/v) in 0.1 M PBS (sodium phosphate buffer, pH 7.4) overnight for fixation. For SEM observation, the samples were passed through an alcohol series (30%, 50%, 70%, 90% and 100%) for dehydration and then dried in HCP-2 critical point drier (Hitachi, Japan) by using liquid CO2 as carrier gas. The mounted specimens were coated with a 1.5 nm thin gold-palladium by IB5 Ion Coater (Eiko, Japan) for 4–5 min and investigated with scanning electron microscope (Philips XL-30, The Czech Republic). In TEM study, after washed with 0.1 M PBS (pH 7.4) three times, the gluteraldehyde fixed samples were post fixed in 1% OsO4 (osmium (VIII) oxide) for 1 h and washed three times with 10 min intervals in 0.1 M PBS (pH 7.4). Then, the samples were dehydrated in a graded ethanol series (50, 60, 70, 80, 90, 95, and 100%) with 15–20 min intervals and finally in absolute acetone for 20 min. Undergoing infiltration, the samples were embedded in Spurr’s resin (SPI-CHEM, USA) overnight. After heated at 70 °C for 9 h, ultra-thin sections (80 nm) were prepared from the specimens and mounted on copper grids for viewing in the transmission electron microscope (JEOL TEM-1230EX, Japan) at an accelerating voltage of 60.0 kV.

Tea liquor preparation

Two experiments were carried out for the infusion behavior investigation. In the first experiment, liquor was prepared according to the standard organoleptic examination procedures for green tea. The first brew was made by pouring boiling water on the made tea and standing for 3 min without any stirring, and the second brew was obtained by pouring boiling water on the residual leaves from the first brewing and also standing quietly for 3 min. To probe the possibilities of potential cold brewing tea, in the second experiment the infusion behavior was investigated in liquor made with water of 4, 25, and 60 °C for 10, 30, 60 min respectively from the regular green tea in a broken appearance in both the two tea processing methods.

Phytochemical analysis

Total tea polyphenols contents were determined spectrophotometrically according to the modified Folin–Ciocalteu method with gallic acid as the standard (GB/T 8313–2008, GAQSIQ, P. R. China, 2008; Chen et al 2008) and contents of amino acids in tea liquor were determined by a spectra-photometric method with ninhydrin dying method (GB/T 8314–2002, GAQSIQ, P. R. China, 2002) except for the prepared tea liquor in the experiments was used instead of solution from solvent extraction for contents analysis in dry tea samples.

Statistical analysis

All the experiments were carried out in triplicate. One-way ANOVA was performed using SAS (version 9.0) package for statistical analysis. The results were expressed as means ± SD and Least Significant Difference (LSD) test was employed to separate the means at 5% level of significance.

Results and discussion

Changes in color of the DIC fixed material tea leaves

The colors of the six formulations based on the CIELAB system for the fixed material tea leaves from both the traditional green tea processing and the DIC technology were assayed after spread on bamboo sheet for a period of 24 h in a natural room condition and the results were shown in Table 1. A significant difference (p < 0.05) was observed for all the L, a and b parameters between the control sample and the DIC process, with an increase in all the three values for the DIC sample over the control. Among the parameters, the DIC sample showed the greatest rise in redness, over 2.5 times greater than the control, followed by an increased intensity in yellowness, with a value about 1.5 times that of the traditional processing.

Table 1.

Changes in color parameters of the treated and control tea leaves

| L | a | b | |

|---|---|---|---|

| Control | 30.60 ± 0.71 a* | 2.26 ± 0.95 a | 7.57 ± 0.21 a |

| Treatment | 36.45 ± 0.41 b | 5.54 ± 0.51 b | 11.37 ± 0.04 b |

*Different letters in the same column mean a difference at significant level (p < 0.05) between the control and the treatment. Tea leaves were placed in room for 24 h

Chemical changes would probably occur to great extents, even though endogenous enzymes like PPO, CAT and POD had been almost inactivated by heating both in the traditional fixation stage and the DIC process if the fixed material leaves were not left for the following process to get a dried state. These changes through non-enzymatic conversion like autoxidation and chemical condensation would be influenced by a set of factors, mainly the possibilities of a contact between the substrates dislocated from their original cell compartments, the accessibility of air in the tissue, and the environment condition such as humidity content, temperature, and light (Liu et al 2003). In this experiment, non-enzymatic changes in the DIC sample happened to a greater degree since the changes in color parameters showed a rise in redness and yellowness more prominently than the control. Considering the fact that the fixed material leaves from the two methods were spread in the same room condition, the difference between the two samples can be concluded to lie in their textures, with a greater cell disruption in DIC sample, which is easier for close substrate contact and air accessibilities, leading to chemical conversion. These results implied that microstructural modification (Fig. 2) had a great influence on the chemical conversion inside material leaves and that the DIC processed tea shoots should be dealt with more carefully in the following green tea processing stages.

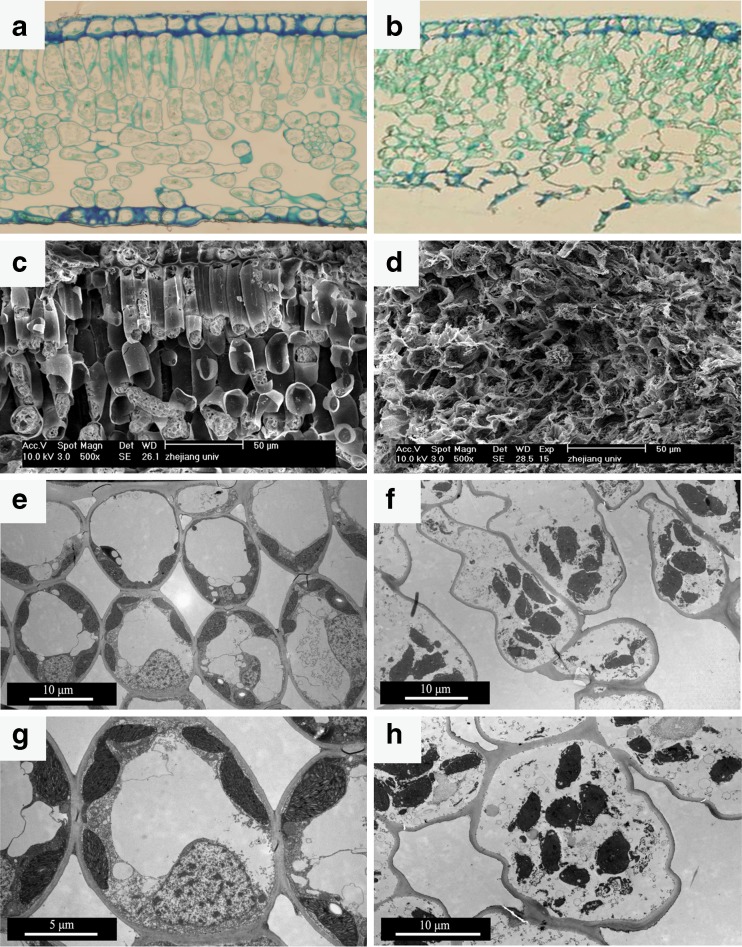

Fig. 2.

Micrographs of the instantaneous controlled pressure drop treated tea leaves and the control samples. Light microscopy of the control (a) and the DIC sample (b). Scanning electron microscopy of the control (c) and the DIC sample (d). Transmission electron microscopy of the control (e, g) and the DIC sample (f, h)

Microstructural properties of the DIC fixed material tea leaves

Microstructural properties have influence on tea quality both chemically by facilitating the contact of substrates and the accessibilities of air required for chemical conversion and physically by changing the capabilities of tea components entering liquor diffusively. Changes in microstructure of the fixed material leaves from both the traditional green processing and the DIC technology were investigated microscopically as seen in Fig. 2. Cross-sections in light microscopic observations revealed that cells were in an orderly contact state in the control sample while tissues were distorted in the DIC sample with loosened palisade cells and disrupted spongy tissue. However, the material leaves from DIC process were still kept in an intact state as a whole like in the traditional processing method, which is expected for a good quality of visual appearance in green tea, especially for quality and famous tea. Similar observations were demonstrated in the control sample by scanning electron microscopy, with closely arranged contact palisade cells, and in contrast, cells were found disrupted dramatically with distorted cell shape in the DIC sample. Transmission electron microscopy showed that cells in the control leaves stand relatively closely in an orderly manner with evident contact organelle inside the cells while in the DIC sample the gap between cells was widened, cell organelle were broken into peaces, cellular membrane was disrupted, broken organelle was mixed and redistributed in the cells.

In many experiments (Rezzoug et al. 2005; Kamal et al 2008; Amor and Allaf 2009), DIC process can modify the structure of plant materials at various levels from interstitial surfaces for permeability of components to broken cell walls and disrupted cells for promoting the diffusivity of components in the cells and releasing of functional elements from cellular compartments through different operations of the process, depending on different purpose. In green tea processing, the desirable cell disruption would be achieved with a definite range of pressure applied to the DIC system depending on the tenderness of material leaves and the humidity content inside. A pressure about 0.3 MPa was found to be suitable for the microstructural modification although cell disruption would reach a greater degree if a heavier pressure were applied from the air compressor. Overpressure would lead to broken leaves or segment, which is not acceptable for the appearance quality of green tea, whether for regular tea or quality and famous tea.

Infusion quality of DIC processed green tea

The infusion behavior of tea polyphenols and amino acids for the DIC processed tea and the traditional green tea of the three shapes, namely flat tea, twisted tea and needle tea, was shown in Table 2, standing for quality and famous tea prepared twice with boiling water in a standard way for typical green tea organoleptic evaluation. As compared with the traditional tea, a significant increase (p < 0.05) in the content of tea polyphenols and amino acids was determined in liquor from the DIC processed tea in all the three shapes and in both the two brews, especially for the first. The increase in the content of tea polyphenols in liquor for the first brew from the twisted and needle tea (about 35%) was more prominent than that from flat tea (about 15%) over the traditional processing. A similar difference was also found in the content of amino acids among the three shape types. The total content of both tea polyphenols and amino acids of the two brews showed a similar trend. These results showed prominent advantages for DIC technology in quality and famous tea. Flat shape, like Dragon Well tea, twisted shape, such as Maofeng tea, and needle shape, as Yinzheng tea with material leaves of only one bud, are the three most popular types in famous green tea with tender tea shoots. To obtain the flat shape, material leaves would be applied a mechanical pressure and a scraping process for a long period, resulting in tissue disruption to some extents, although less than in the DIC method. For keeping leaves intact in appearance, rolling process would be probably conducted to a reduced degree in twisted tea and even be neglected in needle tea. From these points, DIC technology brought a more prominent increase of the two tea components in liquor from twisted tea and needle tea than from flat tea.

Table 2.

Effects of instantaneous controlled pressure drop on the infusion behavior of tea polyphenols and amino acids in liquor of green tea in different shapes

| Tea polyphenols (mg/ml) | Amino acids (mg/ml) | ||||||

|---|---|---|---|---|---|---|---|

| 1st brew | 2ed brew | Total | 1st brew | 2ed brew | Total | ||

| Flat shape | Control | 1.12 ± 0.12 b* | 0.71 ± 0.05 bc | 1.15 ± 0.06 b | 0.175 ± 0.010 b | 0.044 ± 0.007 c | 0.111 ± 0.005 d |

| Treatment | 1.31 ± 0.14 a | 0.81 ± 0.06 a | 1.29 ± 0.07 a | 0.221 ± 0.010 a | 0.055 ± 0.006 abc | 0.135 ± 0.012 d | |

| Twisted shape | Control | 1.04 ± 0.07 b | 0.65 ± 0.02 cd | 1.11 ± 0.05 b | 0.122 ± 0.007 c | 0.056 ± 0.006 abc | 0.242 ± 0.037 bc |

| Treatment | 1.32 ± 0.10 a | 0.77 ± 0.04 ab | 1.32 ± 0.08 a | 0.178 ± 0.009 b | 0.065 ± 0.007 a | 0.285 ± 0.033 b | |

| Needle shape | Control | 0.50 ± 0.07 d | 0.52 ± 0.03 e | 0.93 ± 0.06 c | 0.059 ± 0.007 e | 0.052 ± 0.006 bc | 0.229 ± 0.034 c |

| Treatment | 0.70 ± 0.07 c | 0.61 ± 0.04 d | 1.09 ± 0.03 b | 0.084 ± 0.007 d | 0.062 ± 0.009 ab | 0.376 ± 0.022 a | |

*Chemical determination was made in tea liquor compared with hot water at 100 °C after a 3 min infusion. Different letters in the same column mean a difference at significant level (p < 0.05) between the control and the treatment and also between different tea shapes

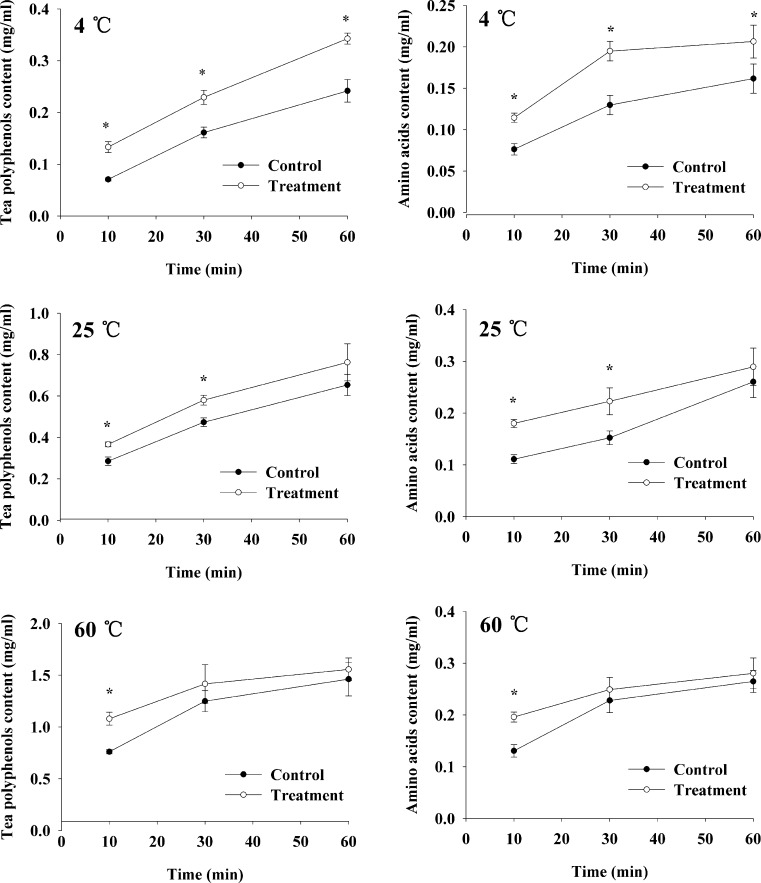

The infusion behavior of tea polyphenols and amino acids was investigated in liquor prepared with water at 4, 25, and 60 °C with regular green tea of the two processing methods in broken appearance. As shown in Fig. 3, the content of the two active components in tea liquor increased with the rising water temperature and the effects of water temperature on tea polyphenols content in liquor were more prominent than on amino acids. In most cases, the DIC processed tea produced liquor with an increased content of tea polyphenols and amino acids to a significant level (p < 0.05), especially for the liquor prepared from a shorter time infusion period like for 10 min for all the three temperatures. In a comparative study, the total tea polyphenols content was found to be lower although not significantly in the liquor prepared in cold water (room temperature) even for a long time up to 2 h than in the infusion that was prepared as a traditional way in hot water (90 °C) for 7 min for all the three main tea categories, green tea, black tea and Oolong tea (Venditti et al 2010). From the present work, the DIC technology can obviously offer a tea with a better infusion of active components if prepared in cold water like at 4 °C and at 25 °C as a room temperature condition.

Fig. 3.

Effects of instantaneous controlled pressure drop on the infusion behavior of tea polyphenols and amino acids in tea liquor compared with water at relatively lower temperature (4, 25, and 60 °C). * represents significant difference (p < 0.05) between the control and the treatment

The quality for green tea is assessed in standards as a composite of color both of the liquor and the made tea, aroma, taste, and visual appearance. In our previous study, the DIC processed tea presented a better quality as judged from the organoleptic evaluation (Wang et al 2005). As a fixation process to inactivate the endogenous enzymes and a partial rolling stage, the DIC processed tea gave a color quality more commercially acceptable. The content of chlorophyll determined in the DIC tea liquor was increased about 50% more than in the traditional one (Wang et al 2005). Although chlorophyll was not recognized as the key factor, more infusion of chlorophyll in the DIC tea liquor may have contribution to its liquor color quality.

Tea polyphenols and theanine, an amino acid especially found in tea with a content of more than the half amount of the total free amino acids, have attracted great interest for their role in the health function that tea plays (Almajano et al 2008; Kimura et al 2007; Hong-Suk et al 2008). The present experiments demonstrated that the DIC processed tea offered a better infusion of these two active components in all the three shapes and prepared with water of different temperature than the traditional tea, which would inevitably favorable both for tea quality and health function. Quite interestingly, the two active components were more accessibly infused into the liquor prepare in water of lower temperature for DIC processed tea. In green tea, more catechins can be extracted if the same leaves were infused with water at a higher temperature (Sharma et al 2005). However, catechins as phenolic compound would easily get decreased in hot condition and liquid state. Both green tea catechins and theaflavins were observed to be vulnerable to degradation by temperature elevation (Su et al 2003). Brewing tea in lower temperature water may prevent such decrease and thus would offer tea liquor with greater health function capacity. Furthermore, cold liquor may give a special taste like iced tea popular globally. From this study, the DIC processed tea may be capable of brewing tea in water of a lower temperature by modifying its microstructure. It could be believed that a cold-brewing tea would be possible after more optimization work.

Conclusions

Instantaneous controlled pressure drop (DIC) can efficiently modify the microstructural properties of material tea leaves. Proper operation of the DIC process can facilitate both the chemical quality and the appearance properties of green tea. DIC process can be applied as a technology in green tea processing as the fixation process to inactivate endogenous enzymes and a partial rolling stage.

Capable of obtaining a desirable cell disruption within intact tea leaves, DIC process can overcome the contradiction between rolling process and visual appearance which would often confront the traditional green tea processing with tender material leaves. It is prominently workable as a potential technology for quality and famous green tea.

DIC process can improve the infusion character of tea components prepared both in the traditional brewing way and in water of lower temperatures. More active components may be held in a cold brewing manner by DIC processed tea and the application of DIC process may be capable of manufacturing cold-brewing tea as a new product.

Acknowledgements

The authors thank Prof. Hong Jian in the Zhejiang University Center of Analysis & Measurement for his kind assistance and technical support in the microstructural observations.

References

- Allaf K, Maache-Rezzoug Z, Louka N (2000) French patent, WO/1999/042003

- Almajano MP, Carbo R, Jimenez J. Antioxidant and antimicrobial activities of tea infusions. Food Chem. 2008;108:55–63. doi: 10.1016/j.foodchem.2007.10.040. [DOI] [Google Scholar]

- Amor BB, Allaf K. Impact of texturing using instant pressure drop treatment prior to solvent extraction of anthocyanins from Malaysian Roselle (Hibiscus sabdariffa) Food Chem. 2009;115:820–825. doi: 10.1016/j.foodchem.2008.12.094. [DOI] [Google Scholar]

- Chen YQ, Ni DJ, Ding XF. Effect of different rolling methods on quality of Luzheng famous tea. J Huazhong Agr Univ. 1996;15(4):401–403. [Google Scholar]

- Chen QS, Zhao JW, Liu MH. Determination of total polyphenols content in green tea using FT-NIR spectroscopy and different PLS algorithms. J Pharmaceut Biomed. 2008;46:568–573. doi: 10.1016/j.jpba.2007.10.031. [DOI] [PubMed] [Google Scholar]

- Emmel A, Mathias AL, Wypych F. Fractionation of Eucalyptusgrandis chips by dilute acid-catalysed steam explosion. Bioresource Technol. 2003;86:105–115. doi: 10.1016/S0960-8524(02)00165-7. [DOI] [PubMed] [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ), Tea: Determination of free amino acids content, GB/T 8314–2002

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ), Determination of total polyphenols and catechins content in tea GB/T 8313–2008

- Haddad J, Allaf K. A study of the impact of instantaneous controlled pressure drop on the trypsin inhibitors of soybean. J Food Eng. 2007;79(1):353–357. doi: 10.1016/j.jfoodeng.2006.01.066. [DOI] [Google Scholar]

- Hampton MG. Production of black tea. In: Willson KC, Califford MN, editors. Tea: cultivation to consumption, Chapter 14. London: Chapman & Hall; 1992. pp. 459–511. [Google Scholar]

- Hong-Suk C, Kim S, Lee SY. Protective effect of the green tea component, L-theanine on environmental toxins-induced neuronal cell death. NeuroToxicology. 2008;29(4):656–662. doi: 10.1016/j.neuro.2008.03.004. [DOI] [PubMed] [Google Scholar]

- Hu JC (1997) Primary processing of green tea. In: Shi Zhaopeng (ed) Tea processing, Chapter 3. China Agriculture Press, Beijing, pp 27–79

- Kamal IM, Sobolik V, Kristiawan M. Structure expansion of green coffee beans using instantaneous controlled pressure drop process. Innov Food Sci Emerg. 2008;9(4):534–541. doi: 10.1016/j.ifset.2008.01.004. [DOI] [Google Scholar]

- Kimura K, Makoto O, Lekh RJ. L-Theanine reduces psychological and physiological stress responses. Biol Psychol. 2007;74(1):39–45. doi: 10.1016/j.biopsycho.2006.06.006. [DOI] [PubMed] [Google Scholar]

- Liu QG, Shen SR, Zhang ZZ (2003) Chemistry of green tea processing. In: Wan Xiaochun (ed) Tea biochemistry, Chapter 5. China Agriculture Press, Beijing, pp 219–247

- Oszmianski J, Michał W, Aneta W. Influence of apple pure’e preparation and storage on polyphenol contents and antioxidant activity. Food Chem. 2008;107:1473–1484. doi: 10.1016/j.foodchem.2007.10.003. [DOI] [Google Scholar]

- Rezzoug SA, Boutekedjiret C, Allaf K. Optimization of operating conditions of rosemary essential oil by fast controlled pressure drop process using response surface methodology. J Food Eng. 2005;71:9–17. doi: 10.1016/j.jfoodeng.2004.10.044. [DOI] [Google Scholar]

- Sharma V, Gulati A, Ravindranath SD. Extractability of tea catechins as a function of manufacture procedure and temperature of infusion. Food Chem. 2005;93:141–148. doi: 10.1016/j.foodchem.2004.10.016. [DOI] [Google Scholar]

- Su YL, Leung LK, Huang CZY. Stability of tea theaflavins and catechins. Food Chem. 2003;83:189–195. doi: 10.1016/S0308-8146(03)00062-1. [DOI] [Google Scholar]

- Venditti E, Bacchetti T, Tiano L, Carloni P, Greci L, Damiani E. Hot vs. cold water steeping of different teas: do they affect antioxidant activity? Food Chem. 2010;119:1597–1604. doi: 10.1016/j.foodchem.2009.09.049. [DOI] [Google Scholar]

- Wang YF, Yang XF, Ren P, et al. Application of instantaneous controlled pressure drop on tea processing. J Tea Sci. 2005;25(4):311–314. [Google Scholar]

- Yang YQ, Yin J. The mathematical model of tea rolling. J Tea Sci. 2003;23(1):38–40. [Google Scholar]

- Yang XQ, Feng LY (2006) A method for tea manufacture by applying instantaneous controlled pressure drop. China Patent, CN 200410067803

- Ye BC (1997) Primary processing of Oolong tea. In: Shi Zhaopeng (ed) Tea processing, Chapter 6. China Agriculture Press, Beijing, pp 157–182

- Yuan DS. Technology in primary white tea processing. In: Yuan DS, editor. Chinese white tea, Chapter 4. Xiamen: Xiamen University Press; 2006. pp. 42–54. [Google Scholar]