Abstract

The main objective of this study was to increase the shelf life of fruits through vacuum packing. Papaya fruits were pretreated with waxing, oil application, purafil packets, tissue paper wrapping given along with control and were packed in 150 gauge thickness polyethylene film bags under vacuum and another set of these samples under without vacuum. The fruits were then stored at room and refrigerated temperature and analyzed for chemical changes. Results showed that the shelf life of the fruits increased under vacuum packing with room and refrigeration temperatures for one and four weeks respectively. The fruits packed without any pretreatment in 150 gauge polyethylene bags maintained the quality with minimum changes followed by waxing, purafil and oil application. During storage moisture, acidity, Vitamin C and total sugar decreased whereas reducing sugar and total soluble solids (TSS) increased during storage. The sensory qualities declined with the period of storage and temperature differences. The study concluded that vacuum packaging and refrigeration conditions increased the shelf life of the papaya fruits.

Keywords: Papaya, Pretreatments, Vacuum, Storage temperature, Chemical constituents, Shelf life

Introduction

In India, papaya is cultivated on an area of 68,000 ha with a total production of 2.15 million tones (Ravindran et al. 2007). Mature fruits are being utilized on a commercial scale in the preparation of candy or tutti-frutti, a product in great demand in bakeries and confectionaries. Ripe fruits can be utilized in the manufacture of “ready-to-serve” papaya juice drink and mixed jam. These fruits are easily deteriorated due to respiration after harvesting. Over the last decade, papaya fruit handling and ripening research has been considered as importance. The importance is due to the increase of worldwide consumer’s awareness for this fruit and subsequently expansion in production and exports (Al Eryani-Raquup et al. 2009). Various post – harvest treatment methods are employed to increase the biological stability and to extend the shelf life of products. According to Khurdiya (1995) the available losses can be reduced by post – harvest management. In all, pretreatments, low temperature and packaging are most important. Proper storage of fresh produce and preservation can add to the value of the processed products and also made available throughout the year. The simplest most common means of modifying the internal gaseous atmosphere is vacuum pack. The product is placed in a pack made from film of low oxygen permeability and air is evacuated and the package is sealed. An evacuated pack collapses around the product so that the pressure inside is seldom much less than that of atmospheric pressure. This process is widely used for packaging oxygen – sensitive products (Stevens 1994). Vacuum packaged products are available in the markets which include fresh fruits and vegetables, freshly prepared fruits and vegetables, red meat, fresh and precooked sea foods (Day 1990). Refrigeration is the most reliable and time test method available for extending the fresh condition of fruits and vegetables as it checks destructive activities of decay causing microorganisms and also slows down the normal process of deterioration. Ali et al. (1994) showed that papaya fruits are susceptible to chilling injury in 10 to 15 °C. According to Pastrana et al. 2010 the ripe fruits stored at 25 °C had more β carotene and rutin compared to fruits stored at 1 °C low (chilling ) temperature negatively affected major carotenoids. Dadjie and Deland (1993) stated that coatings are mainly exert their effects on skin resistance to diffusion of the permanent gases by blocking a greater or lesser proportion of the pores of the fruit surface. Removing the ethylene from the atmosphere slows the maturation of fruits and reduces spoilage.

Based on these a study was undertaken to evaluate the effect of pretreatments, storage temperature and vacuum on the shelf life of papaya.

Materials and methods

In this study fully matured but unripe papaya (Carica papaya L.) was used. Polyethylene bags (6” × 8”) 150 gauge thickness was used as packaging material. Pretreatments were given to fruits and denoted as below:

T1- control (without any packing; fruit as such)

T2- fruits without any pretreatment, packed with polyethylene bag.

T3- waxing

T4-oil application

T5- packed with purafil packets (Purafil is an ethylene absorbent consists of potassium permanganate impregnated with silica gel),

T6- tissue paper wrapping (as cushioning effect & prevent mechanical damage which leads to deterioration).

The pretreated fruits were packed in polyethylene bag without vacuum. Another set of pretreated fruits were kept under vacuum. For vacuum packing the polyethylene bag was sealed with the fruits leaving small gap (about 1 cm wide) for evacuating air from the bag. The air in the bag was removed by vacuum pump with a pressure of 300–350 mm of Hg, which made the bag completely collapsed around the fruit and sealed.

These pretreated and packed fruits (with and without vacuum) were kept at room temperature (36 °C) and another set were kept at refrigeration temperature at 20 °C in order to prevent chilling injury.

The moisture content was assessed by drying in hot air oven at 70 °C for 24 h (Ranganna 1995). Total soluble solids (TSS) were recorded by hand refractometer. Acidity was determined by titration method (Ranganna 1995) and the results expressed as percentage of citric acid. Vitamin C content was determined by titulometric method with 2.6- dichloro indophenol (Ranganna 1995), with 4% oxalic acid. The total and reducing sugar were analyzed by Shaffer – somogy titration method as per the procedure of Ranganna (1995). The sensory analysis (9 to 1 scale) were done by 10 untrained judges as per the procedure of Watts et al. (1989).The data on the chemical characters of the samples, packaging and storage statistically analyzed by Factorial Completely Randomized design (FCRD).

Results and discussion

The data collected on pretreatment and packaging of fruits and their impact on the chemical changes revealed that the control sample and tissue paper wrapped deteriorated within two days itself whereas the vacuum packed sample shelf life remained good up to one and four weeks at room and refrigerated temperature respectively with slight physiological changes (Table 1). The values are highly significantly different in room and refrigeration temperatures. The refrigerated samples had a better in quality and minimum chemical changes compared to that of ambient temperature. The statistical data revealed that there was a significant difference between temperatures. The statistical data revealed that there was 0.01% significance In the pretreatments, without any treatment samples (T2) with vacuum were best followed by waxing (T3), purafil packets (T5) and oil application (T4).

Table 1.

Effect of pretreatments and vacuum packing on chemical changes of papaya

| Storage period (weeks) | Treatments | Room temperature (mean) | Storage period (weeks) | Refrigeration temperature (mean) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Moisture (g%) | TSS (°brix) | Acidity (g%) | Vitamin C (mg %) | Reducing sugar (g%) | Total sugar (g%) | Moisture (g%) | TSS (°brix) | Acidity (g%) | Vitamin C (mg%) | Reducing sugar (g%) | Total sugar (g%) | |||

| 0 | Initial | 90.6 | 6.1 | 0.15 | 20.8 | 3.3 | 5.5 | 0 | 85.5 | 6.3 | 0.17 | 22.2 | 3.6 | 5.6 |

| I | T1 (Control) | – | – | – | – | – | – | IV | – | – | – | – | – | – |

| T2(without treatment) | 80.3 | 6.2 | 0.11 | 20.2 | 3.5 | 5.1 | 80.8 | 6.6 | 0.11 | 20.2 | 4.05 | 5.3 | ||

| T3 (Waxing) | 80.2 | 6.5 | 0.11 | 20.1 | 3.6 | 5.1 | 80.8 | 6.7 | 0.10 | 20.1 | 4.0 | 5.3 | ||

| T4 (Oil film) | 79.8 | 6.7 | 0.09 | 19.7 | 3.6 | 5.04 | 80.5 | 6.9 | 0.08 | 19.8 | 4.1 | 5.2 | ||

| T5 (Purafil) | 79.9 | 6.6 | 0.10 | 19.8 | 3.6 | 5.10 | 80.8 | 6.8 | 0.10 | 19.9 | 4.1 | 5.3 | ||

| T6 (Tissue paper) | – | – | – | – | – | – | – | – | – | – | – | – | ||

| SED | .192 | .0563 | .0007 | .0478 | .0212 | .0259 | 1.6171 | .0744 | .0113 | .0313 | .0217 | .0254 | ||

| CD | .38** | .12** | .01** | .09** | .04** | .01** | 3.19** | .15** | .02** | .06** | .04** | .05** | ||

**The CD values are highly significant at P ≤ 0.01. Each value is the mean for three replicates

The control and tissue paper wrapped fruits deteriorated because of higher respiratory rate, water loss, physiological changes which occurred very faster rate compared to other treatments. Statistically (0.01%) it was proved that these two samples significantly differed from others. In the tissue paper covered fruits, the paper stick on the fruits because of moisture produced by the fruits and thus deteriorated by fungal attack.

Waxing reduces the water loss and respiration changes because all the O2 with in the fruit cannot be replaced as quickly as before waxing because of the coating. All fruits and vegetables are covered naturally in a cuticle, which is a barrier to gas exchange. The cuticle is very permeable to O2, slightly more permeable to CO2 and several magnitudes more permeable to water vapour. Unwaxed fruits have pores in their surface through which most the diffusion of O2 and CO2 offers. During the process of waxing a lightly adhering thin film of the coating substances is applied to the surface of the fruit. The surface coating is often relatively impermeable to O2 and CO2. Research on edible coating has been intense in recent years due to good quality and convenience. It acts as barrier and also a natural material. In this present study edible oil was used for coating. According to Wijewardane and Guleria (2009) application of neem oil(2%) significantly reduced the fruit rot caused by Penicillum expansum. In general the coating of wax and oil treatments caused significant decrease in physiological loss in weight, and titratable acidity.

Harod and Satunku (1975) studied ethylene is a hormone which is responsible for catalyzing various reactions and metabolic activities which leads hasten the ripening process, which ultimately leads to senescence. It is possible to absorb the ethylene by chemicals. Among the chemicals purafil proved to be the most effective ethylene absorbent (Mahajan and Chopra 1994). In this present study also purafil showed the best results.

Even though these pretreatments increased the shelf life of the produce, sometimes anaerobic conditions leads to off flavour production which is the indication of deterioration. So in the present study without any pretreatment (T2) was best compared to all.

In the pretreatments, without any pretreatment samples (T2) with vacuum had the moisture content of 80.38 and 80.87 per cent; 0.11 and 0.11 g per cent of acidity; 20.23 and 20.21 mg per cent of vitamin C; 5.13 and 5.39 g per cent of total sugar; 6.28 and 6.67°brix; 3.58 and 4.05 per cent of total sugar. In the treatment of waxing (T3) the moisture, TSS, acidity, vitamin C, reducing and total sugar changed into 80.28 and 80.85per cent, 6.52 and 6.72°brix, 0.11 and 0.10 g per cent, 20.10 and 20.16 mg/ 100 g, 3.67 and 4.07 g per cent and 5.12 and 5.36 g per cent. Oil applied fruits (T4) showed faster changes in chemical characteristics compared to that of waxing(T3) and purafil packets (T5) kept samples.

Moisture loss is primarily due to transpiration and respiration. Water is lost by transpiration due to differences in vapour pressure of water in the atmosphere and the vegetable surface. The shelf life extending in the refrigerated temperature was more because anaerobic atmosphere and optimum packaging film lead to low condensation preventing moisture loss during storage. The packaging material used in this study prevented moisture loss more successfully. According to Perez-Gregorio et al. (2011) the water loss was occurred after 16 days of storage under vacuum in fresh cut onion. There was a slight increase in the TSS, which did not affect the quality of the papaya. Since per cent soluble solids act as a rough index of the amount of sugars in fruits and vegetables, it would be expected that these values would increase rapidly during ripening and then decrease due to respiration. The acidity levels in fruits and vegetables could affect their flavour and acceptability. Ghanta (1994) reported that ascorbic acid content of papaya was same during early stages and it was low during ripening stages. The similar results were observed in this study. Low temperature was found to have pronounced effect in reducing respiration rate because of which the ascorbic acid was retained to a greater extent. According to Ana Sofia Rodrigues et al. 2010, the post harvest treatment (UV and ethylene) and storage conditions had no significant modifications in total levels of anthocyanin pigments after 6 months of storage in red onion bulbs but after 7 months of storage anthocyanin content was reduced between 40 to 60%.

The reducing sugar increased and total sugar decreased during storage. The decrease in sugar content is due to their subsequent utilization via glycolysis for maintenance of respiration over longer period of storage. Sugars, acids and their interactions are important to sweetness, sourness and overall flavour intensity. Changes in reducing sugars, total sugars and sucrose were parallel and the general trend was a decrease with time at each storage conditions. Reduction in the loss of sugars was probably the result of decreased respiration rate. In this study chemical changes were altered slightly due to vacuum packing fruits than control which was deteriorated easily.

In the present study, refrigeration temperature (20 °C) plays an important role because the phsico chemical characteristics of stored papaya fruits was provided an effective control in reducing moisture loss, maintained firmness, delayed changes in soluble solid, reducing and total sugar concentrations during the storage period. The acidity declined throughout the storage period though at a slower rate in refrigerated stored samples compared to fruits stored at room temperature. Similar results were also obtained in study conducted in Eksotika II papaya fruits by Muhammad et al. 2011.Statiscally the refrigeration temperature samples were good (P ≤ 0.01) up to four weeks compared to room temperature which deteriorated at one week itself.

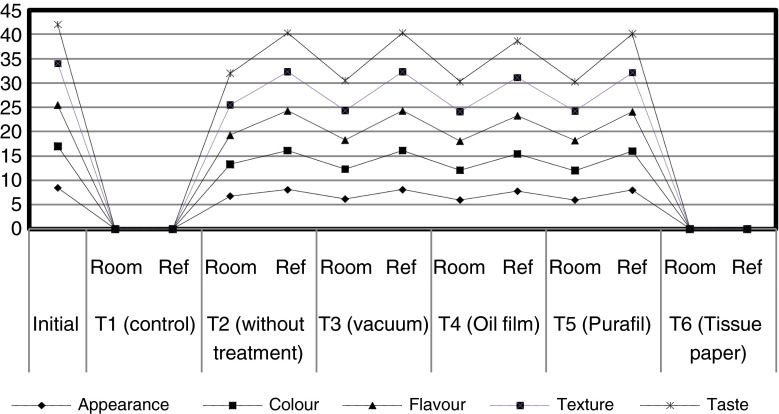

The sensory evaluation was done in the unripe papaya, in the form of salad. The papaya skin was removed and sliced, pepper powder and salt was mixed and given for sensory evaluation. All the pretreated fruits were similar in all aspects except control and tissue wrapped fruits which were spoiled by fungal attack. The qualities of raw papaya were ranked 8.5 in all sensory qualities except taste (8.0). During storage, in room temperature stored papaya scored 6.2, 6.1, 5.95, 6.0 and 6.1 in appearance, colour, flavor, texture and taste respectively (Fig. 1). There was no significant difference among treatments. When increasing the storage period the scores declined. According to Mahajan et al. (2009) the sensory quality of guava improved up to 2 weeks of storage and sharp decline was observed in sensory qualities in 4th week of storage even in refrigeration temperature. In this study also there was a significant difference (P ≤ 0.01) in room and refrigerated storage samples. The scores were 7.8, 7.7, 7.8, 7.7 and 7.6 in appearance, colour, flavor, texture and taste respectively even after 4th week of storage.

Fig. 1.

Sensory qualities of stored papaya

Summary

It was summarized that papaya packed without any treatment under vacuum in 150 gauge thickness polyethylene bags was found to be good for papaya followed by waxing, purafil packets and oil film treatment. Hence this study proved that fruits pretreated and kept under vacuum with refrigeration temperature had better efficiency in relating the quality attributes and increase the market value.

References

- Al Eryani-Raquup A, Mahmud TMM, Syed Omer SR, Mohamed Zaki AR, Al Eryani AR. Effect of calcium and chitosan treatments on controlling anthracnose and post harvest quality of papaya. Int J Agrl Res. 2009;4(2):53–68. doi: 10.3923/ijar.2009.53.68. [DOI] [Google Scholar]

- Ali ZM, Lazan H, Ishak SN, Selamat MK. The biochemical basis of accelerated softening in papaya following storage at low temperature. Hortic Abstr. 1994;64(4):431. [Google Scholar]

- Dadjie BK, Deland DJ. Reducing gas exchange of fruit with surface coatings. Post Harvest Biol Tech. 1993;3:269–284. doi: 10.1016/0925-5214(93)90062-8. [DOI] [Google Scholar]

- Day B. Perspective of modified atmospheric packaging of fresh produce in western Europe in proceedings of CAP’90 fifth International Conference on Controlled/ modified / vacuum packaging, San Jose, California, January17–19. Princeton: Schotland Business Research Inc; 1990. [Google Scholar]

- Ghanta PK. Physico-chemical changes in papaya cv. Tanchi during fruit development and maturity. South Indian Horticulture. 1994;42(4):231–235. [Google Scholar]

- Harod N, Satunku DK (1975) Controlled atmosphere for fresh fruits and vegetables – Why and When, AVI Pub Co. Inc

- Khurdiya Non – thermal method for preservation of fruits and vegetables: A critical approval. J Food Sci Technol. 1995;32(6):441–452. [Google Scholar]

- Mahajan BVC, Chopra SK. Studies on the storage of apple packed with ethylene absorbent. Indian Food Packer. 1994;XLVIII(3):11–14. [Google Scholar]

- Mahajan BVC, Sharma SR, Dhall RK. Optimization of storage temperature for maintaining quality of guava. J Food Sci Technol. 2009;46(6):604–605. [Google Scholar]

- Muhammad MTM, Sijam K, Siddiqui Y. Effect of chitosan coatings on yhe physic chemical characteristics of Eksotika II papaya (Carica papaya L.) fruit during cold storage. Food Chem. 2011;124(2):620–626. doi: 10.1016/j.foodchem.2010.06.085. [DOI] [Google Scholar]

- Pastrana DMR, Yahia EM, Gonzalez-Aguilar GA. Phenoloic and carotenoid profiles of papaya fruit (Carica papaya L.) and their contents under low temperature storage. J Sci Food Agrl. 2010;90(14):2358–2365. doi: 10.1002/jsfa.4092. [DOI] [PubMed] [Google Scholar]

- Perez-Gregorio MR, Garcia-Falcon MS, Simal-Gandhara J. Flavonoids changes in fresh cut onions during storage in different packaging systems. Food Chem. 2011;124:652–658. doi: 10.1016/j.foodchem.2010.06.090. [DOI] [Google Scholar]

- Ranganna S. Manual analysis of fruits and vegetable products. New Delhi: Tata Mc Graw Hill publishing Co. Ltd; 1995. [Google Scholar]

- Ravindran C, Kohli A, Srinivasa Murthy BN. Fruit production in India. Chron Horticult. 2007;47(2):21–26. [Google Scholar]

- Rodrigues AS, Perez-Gregorio MR, Garcia-Falcon MS, Simal-Gandara J, Almeida DPF (2010) Effect of post harvest practices on flavonoid content of red and white onion cultivars. Food control 21:878–884

- Stevens TWC. Vacuum skin packaging technology providing the competitive advantage, 5th Food conference, 26–29, July. Kualalumbur. 1994;1994:145–146. [Google Scholar]

- Watts BM, Ylimaki GL, Jeffery LE, Elias LG. Basic sensory method for food evaluation. Ottawa: International development Research Centre IDRC; 1989. [Google Scholar]

- Wijewardane RMNA, Guleria SPS. Effect of post-harvest coating treatments on apple storage quality. J Food Sci Technol. 2009;46(6):549–553. [Google Scholar]