Abstract

The purpose of this study was to compare the dynamic response of rear-facing child restraint systems (RFCRS) installed on the CMVSS 213 sled bench and a selection of vehicle seats. Thirty-six sled tests were conducted: three models of rear facing CRS with an anthropomorphic test device (ATD) representing a 12 month old child (CRABI) were affixed via lower anchors (LATCH), 3 point belt without CRS base, and 3 point belt with CRS base to one of three vehicle seats or the CMVSS 213 bench seat. All CRS were subjected to an identical sled acceleration pulse. Two types of matched pair analysis: “bench-to-vehicle” and “method of attachment” were conducted. Statistically significant differences were observed in the kinematic responses of the ATD and the CRS.

This is the first study to quantify differences between the regulatory bench and vehicle seats on a system level and evaluate the influence of attachment method. Our results show that the difference in RFCRS forward excursion between 3-point belt with base and LATCH installations was between 1 and 7 percent on the bench and 22 to 76 percent on the vehicle seats. When evaluating the dynamic performance of RFCRS, the use of real vehicle seats from vehicles that commonly carry children may provide valuable insight. The findings would require further confirmation using a broader selection of RFCRS and vehicle seats, before generalizable conclusions can be drawn.

INTRODUCTION

Regulations are in place worldwide to evaluate the dynamic crash performance of child restraint systems (CRS), (NHTSA 2002; ECE/R44 2008). In the United States and Canada, two very similar CRS sled tests have been implemented in federal regulations: The Federal Motor Vehicle Safety Standard (FMVSS 213) and the Canadian Motor Vehicle Safety Standard (CMVSS 213). In the 1970’s, the Highway Safety Research Institute developed a bench seat, based upon the characteristics of a 1974 Chevrolet Impala to evaluate CRS performance. The most recent changes occurred in 2002 when the NHTSA issued a new drawing package for the FMVSS 213 test bench (NHTSA 2002) in response to the Transportation Recall Enhancement, Accountability and Documentation Act (TREAD). Transport Canada adopted this revised US drawing package in 2010 with one correction. The height of the lower universal anchor bars was modified to match the cited measurements in the US and Canadian regulations.

In addition to sled tests, over the past decade, NHTSA and Transport Canada have both placed CRS’s with pediatric anthropometric test devices (ATD) in the rear seats of full scale frontal impact vehicle crash tests. Most notable from these experiments was the detachment of a few rear facing infant carriers from their base during the crash as well as certain structural disruptions (Tylko, 2009). All of the observed anomalies occurred with rear facing infant seats (RFCRS) that had passed the CMVSS 213 regulation. As a result of these findings and in effort to better align regulatory test conditions with modern day vehicle seats, Transport Canada amended the CMVSS 213 to include a 3-point belt test configuration, effective January 2012. Differences between CRS performance on the regulatory bench and in motor vehicle crash tests continued to be observed but could not be readily quantified.

The objective of this study therefore, was to investigate the system level fidelity of the CMVSS 213 bench by conducting matched pair comparisons between the regulatory bench and vehicle seats with a selection of representative rear facing infant seats. The comparisons included test parameters that described the motion of the RFCRS and numerous ATD responses, including the measures referenced by U.S. and/or Canadian regulations.

METHODS

Vehicle Selection & Test Matrix

The vehicle seats to be analyzed were selected from a list of vehicles which most frequently carry children. The NASS General Estimates System database (2006–2008) was queried for cases that met the following criteria: 1) Vehicle model year 2000+, 2) Children age 0–8 years, and 3) Rear seated. Based upon the NASS analysis, a representative seat-type was chosen from the 4-door sedan, minivan, and SUV vehicle types that encompassed a diverse range of seat geometries (i.e. bucket seat, fold down bench). A 2010 Toyota Corolla was chosen to represent a sedan seat, the 2009 Dodge Caravan second-row bench-type seat was chosen to represent the minivan category, and the 2nd row captain seat of a 2007 Ford Edge was chosen for the SUV seat.

The test matrix included a total of 36 tests conducted on the CMVSS 213 bench, the rear seat of a Toyota Corolla, a Dodge Caravan second row bench seat and a Ford Edge captain seat. Three models of RFCRS were used to conduct paired comparisons between the regulatory bench and the vehicle seats and among the three attachment methods. These models have the typical features of a RFCRS including detachable base, adjustable handle, and the option of both lower anchor and belt fixation. One model has an anti-rebound bar. The CRS models are identified as BC, MC and EE to minimize emphasis on brand comparison. The configurations for child restraint installations were selected to align with the test configurations included in the current FMVSS 213 and the amended CMVSS 213 (January 2012). The tests are identified as a function of vehicle seat and installation method in Table A1 of the Appendix.

Test Set-up

Testing was performed on a Seattle Safety 2 MN servo controlled pneumatic acceleration sled (Seattle Safety, Kent, WA, USA). The sled was programmed to produce a highly repeatable acceleration pulse that fell within the corridor specified by CMVSS 213 and produced a delta V of 48 km/h.

Child restraints were installed in the center seating position of the CMVSS 213 bench with either the lower anchors (defined throughout as LATCH) or 3-point seatbelt. The CMVSS 213 bench (Figure 1) was attached to the sled base in accordance with the regulatory drawing package. The belt was secured with a standard buckle at the inboard location on the bench (A); the belt webbing was wound on a locking webbing spool then threaded through a D-ring (B); the buckle, and looped through a locking clamp that was anchored to the frame of the bench at the bight(C). The buckle anchor was rigidly attached to the frame of the bench. The LATCH anchors were rigidly mounted to the frame and were located between the 3-point seat belt anchors. In-line load cells (Denton 9191 FL) were used to attach the LATCH webbing to the LATCH anchorages.

Figure 1.

Three-point belt installation on the CMVSS 213 compliance bench.

The Toyota Corolla buck (Figure 2) was constructed to preserve the seat/restraint characteristics and structural integrity of the rear bench seat and parcel shelf. The B-pillar, seat pan and tether anchorage were reinforced. Front row seats were removed to eliminate the confounding effects caused by front seat back interaction. The rear left seating position (behind the driver seat position) was used throughout all tests. The seat belt assemblies (including webbing and retractor) were inspected after each test and replaced at the first sign of retractor malfunction for all vehicle seats.

Figure 2.

Sample installation on Toyota Corolla buck.

The Dodge Caravan seat (Figure 3) was a second row bench seat that was rigidly fixed to the sled base plate. A complete set of 3-D measurements of belt/tether anchor, D-ring, and other key geometry were obtained prior to removal of the seat from the vehicle to ensure that seat orientation and belt geometries could be accurately reproduced when attached to the sled base. The upper anchor adjustment was set to the mid position for all tests. The legs of the bench were reinforced to preserve the structural integrity of the seat.

Figure 3.

Sample installation on Dodge Caravan seat.

The Ford Edge (Figure 4) seat was rigidly attached to a base plate which was attached to the sled. As with the Dodge Caravan, 3-D measurements were obtained prior to removing the seat from the vehicle to respect the seat orientation and belt geometries.

Figure 4.

Sample installation Ford Edge seat.

A 12-month CRABI was instrumented with tri-axial accelerometers in the head, chest and pelvis (62–2000, Endevco, CA, USA) in addition to a 6-axis load cell in the upper neck (Denton 2554A). The processing of the data was carried out following the protocols established by the Society of Automotive Engineers (SAE J-211). Optical tracking targets were placed on the lateral aspect of the head in-line with the CG of the head of the ATD.

Optical targets were placed at regular intervals along the structural members of the bench and vehicle seat. Targets were also placed in the plane defining the excursion limits defined by CMVSS 213. The seat anchorages, cushions and belts were visually inspected after each test. Video footage was closely monitored to detect signs of fatigue and damage. Tests completed at the beginning of a series were repeated at the end to ensure that any undetected seat degradation did not contribute to a variation in response (Table A2).

A TraceCam optical 3D metrology system (Aicon, 3D Systems, Germany) was used to enhance measurement accuracy by ensuring repeatable installations. The system has an accuracy of ± 0.1mm + 0.15mm /m of distance to the measuring head. Since the measuring heads were within two meters of the test fixture the measurement accuracy was estimated to be of the order of ± 0.4mm.

Motion was captured at 1000 fps with four NAC video cameras (NAC Image Technology, Simi Valley, CA, USA). The views included a close-up of the left side of the child restraint, a frontal view, the right side of the bench or vehicle seat to capture forward excursion and a rear side view to capture rebound excursion. Video tracking was carried using Tema Automotive Motion Analysis software, version 3.5–012 (Photo-Sonics, Burbank, CA, USA).

Child Seat Preparation

A three sided fixture was used to locate, record and eventually copy the exact target location for all duplicate child seats of the same model. A reference angle was obtained by first measuring the angle of the interior of the shell. The location of measurement was identified by first locating a point that was 240 mm above the intersection of the seat back and the seating surface and then projecting that point horizontally to the seat back. For this measurement process, the CRS were placed on a level surface but were not placed level to ground. A laser was then used to project the seat back angle on the exterior of the shell. Targets were placed at each extremity of the shell in locations that were judged to be the most consistently visible to the cameras. A line between the two targets was used to track the seat back angle throughout the event.

Child Seat and ATD Installation

There were three types of installations for rear facing infant seats: a) with base and LATCH, b) with base and the three-point belt and c) without the base, secured with the three-point belt. All CRS used in the study were new and underwent a single test. RFCRS were installed as per the CRS manufacturer instructions. The base installations were carried out by placing the base of the infant seat in the designated seating position on the bench or vehicle seat. The TraceCam system was used to help align the child restraint center line with the 213 or vehicle seat center line. For the LATCH installation, the LATCH webbing was pulled taught until the in-line LATCH load cells recorded a value of 67N (Denton 9191 FL). Note that CMVSS 213 does not stipulate a pre-load for the LATCH however, the pre-load was adhered to so as to include an additional control of repeatability for the installations. The level of the base was checked in both the longitudinal and perpendicular planes. In some installations, without the base (Table A1), cylindrical pieces of polyethylene foam (pool noodles) were required to achieve a level base as instructed by the manufacturer. These two steps of tightening the LATCH and checking the levels were repeated until both the preload and base level conditions were met.

The three-point belt installation of the base followed a similar process to that of the LATCH installation. The base of the CRS was placed in the designated seating position and secured by alternately tightening the belt to the designated pre-load and checking the levels. CMVSS 213 stipulates a pre-load ranging from 53.5N to 67N for the lap belt portion of the three point belt and 9N to 18N for the shoulder belt. Seat belt load cells were used to record pre-load as well as dynamic load during the event (EL20, Entran Devices, NJ, USA).

A standardized protocol was followed for the installation of the CRABI ATD (Humanetics, ATD, MI, USA) in each child seat. Arms and then legs were successively raised to help seat the ATD in the CRS. The harness was applied and tightened. A webbing tension pull device was used to ensure that a 9N force applied to the top of each shoulder and the pelvis harness (50mm from the centerline) resulted in a 7mm clearance between the ATD and the belt webbing. The CRABI and carrier were then secured to the base. Levels were again checked and all pre-test target locations were recorded.

The installation without base was carried out by first securing the CRABI in the RFCRS as described above and then placing the infant carrier directly on the bench or vehicle seat. The CRS was secured to the bench or vehicle seat by alternately tightening the belt to the designated pre-loads (53.5N to 67N for the lap belt portion of the three point belt and 9N to 18N for the shoulder belt) and adjusting the RFCRS so that it was level to ground.

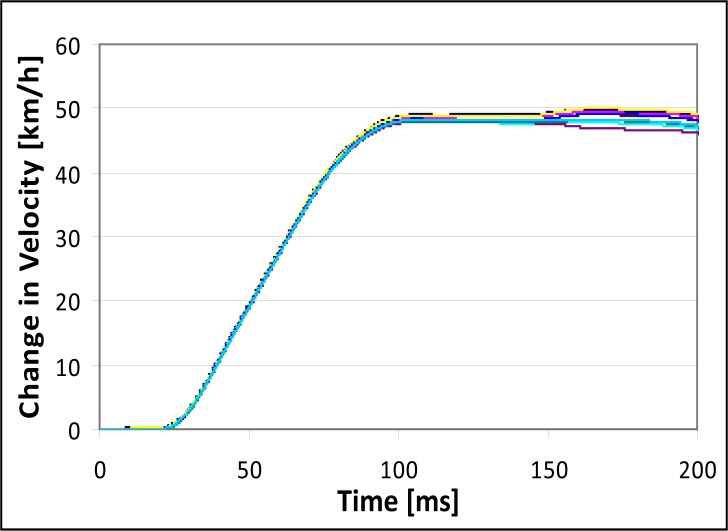

Pulse Repeatability

An overlay of 9 sled pulse accelerations reproduced with the bench and vehicle seats is presented in Figure A1 of the Appendix. The average peak acceleration for these 9 pulses was 24.4 g (Standard Deviation (SD) = 0.2g). The acceleration pulses had an average duration of 85.1 ms (SD=0.5 ms) where onset was estimated to begin at the closest value to 0.5 g and conclude at the closest value to 0.0 g. The average change in velocity was 48.9 km/h (SD = 0.8 km/h) Figure A2 of the Appendix.

Data Analysis

Matched Pair Analysis:

Unique vehicle seat tests were compared directly to the equivalent CMVSS 213 tests using a matched pair analysis. Parameters included head, chest and pelvis acceleration, neck force, HIC, belt or LATCH force, and CRS excursion and angle. The outcomes of each CMVSS 213 bench tests were subtracted from the corresponding vehicle seat test and analyzed for significance using paired parametric (t-tests) and non-parametric (Wilcoxon tests) statistical methods.

Grouped statistical analysis:

The outcome measures for the three RFCRS models and installation methods were averaged by bench/vehicle seat type. Thus, the average of the CMVSS 213 bench tests was compared to the average of tests on the Corolla, Caravan, and Edge bucks respectively. The CMVSS 213 bench tests were also compared to the average of all vehicle tests combined. Statistical significance was determined by a homoscedastic t-test using a two-tailed distribution.

The differences between the bench and vehicle seats were considered statistically significant if the p value was less than 0.05.

RESULTS

Video Capture of Bench-to-Vehicle Comparison

Important differences were observed between the motion of the CRS installed on the bench and the vehicle seats. Figure 5 presents freeze frame images recorded at peak excursion for a CRS installed with the seatbelt and the base on the CMVSS 213 bench and the Caravan, Edge and Corolla vehicle seats, respectively. The maximum change in angle ranged from 13° to 23° on the vehicle seats compared to 27° on the bench. The three CRS bases extended further, beyond the forward edges of the vehicle seats than the CRS installed on the bench.

Figure 5.

Comparison of a CRS installed on the bench, Caravan, Edge and Corolla seats with the three-point belt and the base.

Figure 6 shows a front view of a CRS installed without the base on the bench, and on the Corolla and Caravan seats. While not measured in this study, these front views illustrate the lateral rotations of the CRS. The rotations appeared to be more pronounced on the vehicle seats than on the bench at peak excursion as well as during rebound.

Figure 6.

Comparison of a CRS installed without the base on the bench, Corolla and Caravan seats with the three-point belt.

The views in Figure 7 are freeze frame images captured at peak forward excursion. When installed on the bench there appears to be little difference in the kinematics of the CRS at peak excursion whether secured with the LATCH (top left view) or the 3-point belt (top right view). However, the kinematic differences are far more pronounced when the same comparative test is conducted on the Caravan seat. The LATCH restrained infant seat in the bottom left view does not extend beyond the furthest column of targets seen in the background of the image. In contrast, when attached with the 3-point belt, the bottom right image shows the top portion of the CRS extending beyond the last column of visual targets. There is also more rotation of the CRS shell with respect to the base as the under-side of the shell can be seen lifting from the foot of the base. The shell did not separate from the base.

Figure 7.

Comparison of a CRS installed on the bench and Caravan seat with the LATCH and three-point belt.

Data Analysis

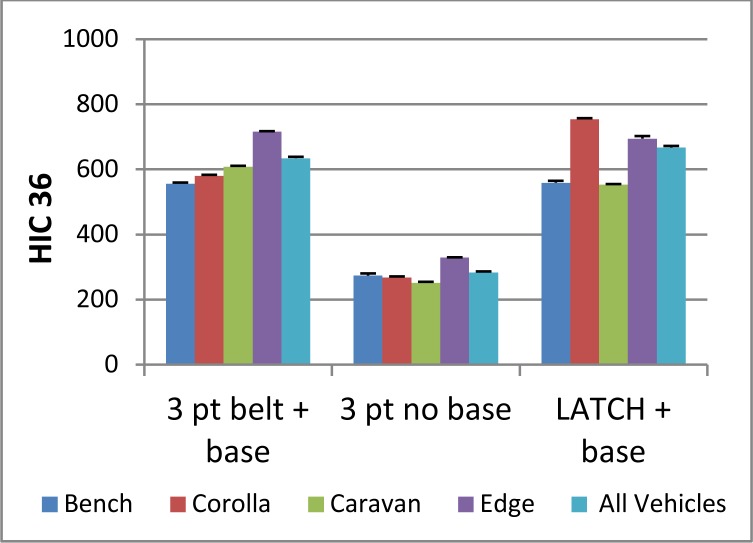

Statistical results for the matched pair analysis are presented in Table A3. A summary of the statistically significant results are presented below in Table 1. Two of the 14 variables evaluated for the rear facing infant CRS with base, secured with the 3-point belt, were sufficiently different between the vehicle seats and the CMVSS 213 bench to achieve statistical significance. Pelvis acceleration was 5.4 g (SD =5.1 g, p=0.013) higher on the vehicle seats than on the bench. Similarly, HIC36 was on average 74.8 units (SD = 80.2, p=0.023) higher on the vehicle seats than on the bench. Neck resultant force was 104.0 N (SD=139 N) lower on the vehicle seat compared to the bench, but this result was not statistically significant (p=0.055).

Table 1.

Summary of statistically significant matched pair analysis results.

| Difference(Vehicle – Bench) | |||

| Mean | SD | P value | |

| 3 point belt with base | |||

| Pelvis resultant acc. (g) | 5.4 | 5.1 | 0.013 |

| HIC36 | 75 | 80 | 0.023 |

| 3 point belt without base | |||

| Head resultant acc. (g) | 5.7 | 6.0 | 0.022 |

| CRS up. excursion (mm) | 49 | 62 | 0.044 |

| Change in CRS angle | 4.3 | 5.1 | 0.038 |

| LATCH with base | |||

| Head resultant acc. (g) | 6.8 | 6.9 | 0.019 |

| HIC36 | 108 | 124 | 0.031 |

| Head 3ms clip (g) | 5.9 | 6.9 | 0.034 |

| Left LATCH force (N) | 191 | 82 | 0.000 |

| CRS up. excursion (mm) | −36 | 14 | 0.000 |

| CRS low. excursion (mm) | −33 | 12 | 0.000 |

The RFCRS installed without the base and secured with the three point belt yielded three statistically significant results. On average, the head resultant acceleration was 5.7 units (SD 6.0, p=0.022) higher on the vehicle seat as compared to the bench. Forward excursion of the upper seat back of the CRS was on average, 49 mm (SD 61.9, p=0.044) higher on the vehicle seats as compared to the bench. Similarly, the maximum change in CRS angle was greater on the vehicle seats by an average 4.3 degrees (SD= 5.1, p=0.038). Shoulder belt force trended higher on the vehicle as compared to the bench, but this difference was not statistically significant (p=0.098).

Rear facing infant CRS secured with LATCH, resulted in statistically significantly differences for 6 of the 14 variables in the vehicle seat to bench comparisons. Head acceleration measures were higher on the vehicle seats as compared to the bench The differences were as follows: Head resultant acceleration 6.8 g (SD=6.9, p=0.019); HIC36 108 (SD=124, p=0.031); HIC36 108.2 (SD=124.4, p=0.031); 3ms head acceleration clip 5.9 g (SD=6.9 g, p=0.034). The left LATCH anchor force was also 191 N greater (SD=82.1 N, p=0.000) on vehicle seats. Conversely, measures of CRS motion were lower on the vehicle seat as compared to the bench: Upper and lower CRS seatback excursions were on average 36 mm (SD=14, p=0.000) and 33 mm (SD=12, p=0.000) lower on the vehicle seats as compared to the bench.

Results of the homoscedastic t-test analysis using a two-tailed distribution for the ATD responses and the CRS motion are tabulated in Tables A4 and A5, respectively. Grouped analysis comparing the average results obtained on the bench to the average results of all vehicle tests combined did not demonstrate statistical significance for any of the ATD responses. The motion of the CRS installed with LATCH and base was sufficiently different on the bench (compared to the vehicle seats) to result in a statistically significant t-test value for the upper and lower seatback excursions (p = 0.0004, 0.0001) and the maximum angle of seatback rotation (p = 0.0044).

Method of Attachment Comparison

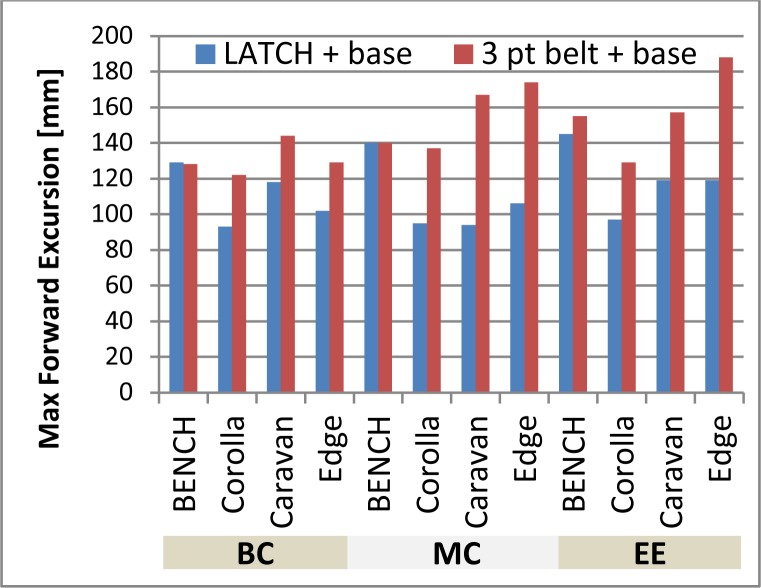

Results for installations with base are presented separately from the excursion results for installations without the base to facilitate comparisons. Figure 8 compares the peak excursions measured with the video tracking for the three models of rear facing CRS (identified as BC, MC and EE), attached to the bench and vehicle test seats with the LATCH+ base or 3-point belt + base. Two observations can be made of these results. The first is that the peak excursions of CRS installed on the bench with the LATCH were greater than the excursions on any of the vehicle seats. The second point to note is that, while the excursions of CRS installed with the 3-point belt and base were greater than the CRS installed with the LATCH in all three vehicle tests, there was no difference between the two types of installations when tested on the bench.

Figure 8.

Maximum forward excursion of the CRS (LOWER CRS target) recorded as a function of installation, where BC, MC, EE refer to CRS models.

Figure 9 illustrates the difference in excursion for the two modes of installation with base. Each colored bar represents the difference between two installations for the same model of CRS on the 213 bench and each vehicle seat. There was no discernible difference in excursion for any of the infant seats tested on the bench, shown on the left of the figure. However, when these same infant seats were tested on the vehicle seats, installations with 3-point belts were found to have greater excursions than LATCH installations.

Figure 9.

Differences in peak forward excursions (LOWER CRS target) recorded for CRS installed with the 3-point belt with base as compared to LATCH with base by CRS model and vehicle seat.

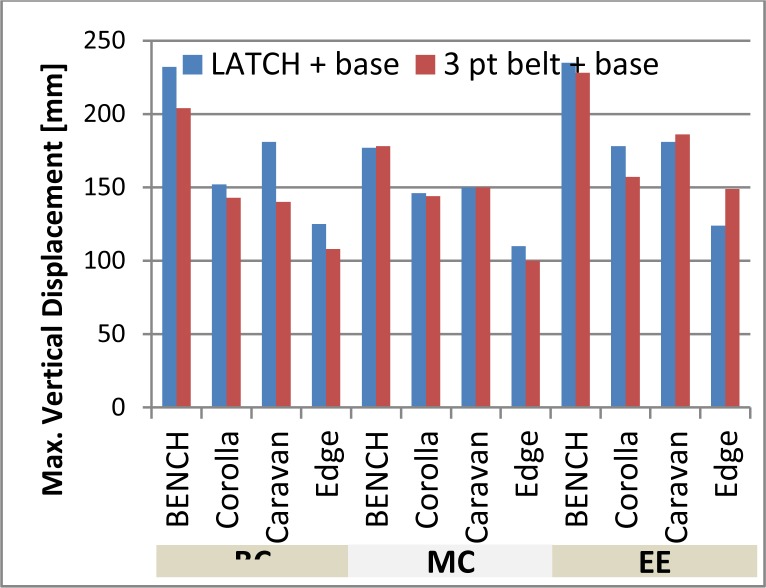

Peak vertical displacements of the upper and lower targets on the CRS are shown in Figures 10 and 11 respectively, for rear facing infant seats installed with the base. For each model of child seat, peak vertical displacement was greater for the upper target than for the lower target and all vertical displacements were consistently greater when installed on the 213 bench.

Figure 10.

Maximum vertical displacement of the UPPER CRS target as a function of installation, where BC, MC, EE refer to CRS models.

Figure 11.

Maximum vertical displacement of the LOWER CRS target as a function of installation, where BC, MC, EE refer to CRS models.

Peak forward excursions of the lower optical target for CRS installations without base are shown in Figure 12. Regardless of whether or not the RFCRS was installed on the bench or a vehicle seat, all peak forward excursions for NO base installations (Figure 12) were greater than any single peak forward excursion for RFCRS installations with the base (Figure 8)

Figure 12.

Maximum forward excursion of the CRS (LOWER target) installed without the base where, BC, MC, EE refer to CRS models.

As noted previously, differences in rotation were found to be statistically significant for the LATCH and no base configurations. However, as can be observed in Figure 13, the differences in the magnitude of peak rotations were small.

Figure 13.

Peak seatback rotation calculated from film analysis for each installation method and test seat.

The average measurements of rotation for the three RFCRS models installed with the bases were all in the order of 60 degrees while the RFCRS installed without the bases tended to be just below 60 degrees.

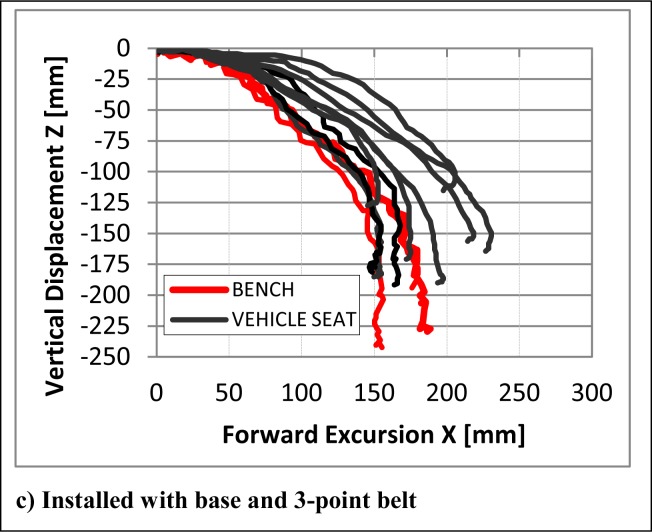

Figure 14 illustrates the 2D motion of the upper target on the CRS, up to the moment of peak excursion, for rear facing infant seats installed without the base and for the two modes of installation with the base. In Figure 14 (a), the upper target on the three models of infant seats installed on the regulatory bench without the base, moved further down into the cushion and exhibited lower forward excursions than most of the CRS installed on the three types of vehicle seats. When installed with the base and secured to the regulatory bench with the LATCH as shown in Figure 14 (b), the upper targets on the three models of CRS tended to display greater forward excursions and greater vertical displacements when installed on the 213 bench. This trend was reversed when the 3 CRS models were installed with the 3-point seat belt. As shown in Figure 14 (c), forward excursions were generally smaller on the bench than on the vehicle seats. Vertical displacements tended to be greater on the bench than on the vehicle seats for most of the forward motion and at peak forward excursion.

Figure 14.

Comparison of displacement path of the UPPER target for rear facing infant seats installed on the bench and vehicles seats.

ATD Responses

The differences in head acceleration parameters were statistically significant between the bench and certain vehicle seat installations however even when these differences were statistically significant, the difference was small. For example, the mean difference in HIC36 values for the LATCH with base installation was 108.2 while the mean difference in HIC36 values for the 3-point belt with base installation was 74.8. The magnitude of these differences represented only 7.5% of the allowable limit (HIC36 = 1000) for the installation with 3-point belt and 10.8% of the limit for LATCH installations (Table A3).

The mean HIC36 values obtained for the three CRS models are plotted in Figure 15 as a function of installation method and test seat. While HIC36 values were clearly lower for the installations without base, results within each type of installation method category were mixed, with HIC36 values for the bench trending lower than for the vehicle seats. The Edge seat, represented by the fourth bar, was consistently greater than the bench values represented by the first bar, for all installation modes. In contrast, the Corolla HIC36 value was greater than the bench for the LATCH installation by almost 200 units but comparable for the 3-point belt installations. Similar patterns were observed for the average head resultant acceleration 3ms clip shown in Figure 16.

Figure 15.

Average HIC36 values for the complete sample

Figure 16.

Average head resultant acceleration 3 ms clips for the complete sample.

These findings suggest that the differences, however subtle, are likely caused by a combination of factors including seat stiffness, seat and belt anchor geometry.

The mean chest acceleration resultant 3 ms clips shown in Figure 17 appeared to be unaffected by installation method or CRS model.

Figure 17.

Average chest resultant acceleration 3 ms clips for the complete sample.

DISCUSSION

Match paired comparisons were carried out with three models of rear facing child restraints installed on the CMVSS 213 compliance bench and three popular models of automotive seats frequently used by North American families. The study compared ATD responses and the motion of the child restraints, installed on the 213 bench, to equivalent installations on vehicle seats. Three modes of installation were examined: Rear facing infant seat installed with the LATCH and the base; with the 3-point belt and the base; and installed with the 3-point belt without the base. All of the ATD response parameters, with the exception of the neck force and pelvis acceleration are included as injury criteria in the U.S. or Canadian regulatory requirements. The regulations limit the maximum allowable rotation and the motion of the ATD head with respect the upper edge of the CRS but there is no limit for excursion.

The acceleration measures appeared to be effective at confirming that the RFCRS systems were exposed to comparable inertial loads in the paired comparisons. However, these measures did not appear to be sensitive enough to detect differences in the motions that were observed across the installation methods and vehicle seat/bench combinations included in this study. Similar uniformity of acceleration responses have previously been observed in vehicle crash testing with larger child ATDs (Tylko, 2012).

Both the excursion and rotation at peak forward excursion differed significantly for the child restraints that were installed on the bench compared to installation on the vehicle seats for either LATCH or 3-point belt without the base. Child restraints with LATCH installations moved an average of 36 mm further forward on the bench compared to the vehicle seats while CRS installed with the 3-point belt without the base were displaced 49 mm less forward on the bench.

Of particular interest is the observation that forward excursions for LATCH and 3-point belt installations on the regulatory bench were comparable in magnitude but when installed on any vehicle test seat, the excursions with 3-point belt attachments were always greater than for LATCH. Indeed, the difference in CRS forward excursion between 3-point belt with base and LATCH installations (Figure 9) was between 1 and 7 percent on the bench and 22 to 76 percent on the vehicle seats. While it is clear that there is a reduction in excursion with LATCH as compared to belts in these specific vehicle seats and RFCRS the study did not evaluate the benefit of reduced excursions in the field.

Vertical displacements were always greater on the bench as compared to the vehicle seats regardless of child restraint model or installation method. Glass (2002) developed a protocol to test the compressive stiffness of the CRS sled test buck and any vehicle seat cushion. The authors found that the cushion stiffness of the regulatory bench was comparable to the average vehicle up to 80 mm of displacement, but from 80 to 120 mm of displacement the average vehicle seat was substantially stiffer than the bench.

In this study, the effect of the soft cushion appeared to restrain the forward motion of the CRS and influence the peak change in rotation. The length of the seat cushion may also have influenced rotation. The two dimensional tracking of the upper targets shown in Figure 14 display the differences in trajectory recorded for the three attachment methods.

The tracking of the installation without base shown in the top trace (14 a) suggests that when installed on the bench, the CRSs had a tendency to sink further into the cushion than the CRS installations on the vehicle seat. The deceleration of the CRS may have been aided by the interaction of the bottom surface of the shell with the gummy, vinyl cover of the bench. When compared to the vehicle seat installations these same CRS tended to sink less and travel further forward.

The trajectories of the CRS, installed on the vehicle seats with the base and the three point belt, shown in the bottom graph (14 c) were more widely distributed than the same installations on the bench. In fact, the distribution of CRS installed with the base and the three-point belts on the vehicles seats was wider than any other installation. Since belt loads were controlled for all installations, the shape and most notably the scatter of the trajectories were likely caused by the interaction between the bases of the CRSs and the seat cushions. The relatively stiffer vehicle seat cushion and lower friction seat upholstery allowed the CRSs to slide further forward before initiating rotation. The material properties and shape of the bottom of the base could also have had an effect on the interaction with the vehicle seat cushion and ultimately, the extent of forward motion and scatter that was observed. The soft, gummy surface of the vinyl covering of the bench may have masked these effects since the trajectories for the bench installations are grouped close together until peak excursions were approached.

Lastly, the middle graph (14 b) displaying the trajectories for LATCH installations suggests that the LATCH for vehicle seats limits the excursion and consequently reduces the interaction of the CRS base with the seat cushion. The scatter observed for the three-point belt installations in the lower graph (14 c) was not apparent for LATCH installations on the vehicle seats.

The difference between trajectories for individual CRS models installed on the bench and the vehicle seats was quite noteworthy for certain installations. Further studies are needed to explain the effect that restraint and seat characteristics such as cushion stiffness, upholstery material and, how tightly the upholstery fits to the seat cushion may have on the dynamic response of the CRS. The characteristics of the bottom of the base and CRS shell may also warrant further consideration.

In a study conducted to quantify the relationship between vehicle interior geometry and child restraint systems, Sherwood et al. (2005, 2006) found that there was generally no clearance between the RFCRS and front seat when the front seat was adjusted at the mid- seat track position. Based on a small number of tests carried out by the NHTSA, Sherwood surmised that further research was needed to quantify the interactions. Transport Canada investigated the interaction of rear facing child seats with the interior of motor vehicles in full frontal barrier crash tests (Tylko, 2011). In 35/127 frontal crash tests, the top of the dummy head was observed to have contacted the seatback of the driver or front passenger seat. There were five cases where the impacts resulted in head accelerations ≥ 80 g and in each of these cases the RFCRS had been installed with the bases and secured with the seat belt. In contrast, of the 20 RFCRS installed with LATCH in second row seats, none were found to have recorded elevated head accelerations (≥ 80g). The study demonstrated that large forward excursions of the rear facing CRS increased the likelihood of interaction with the vehicle interior and elevated head responses. These findings have important implications for this study since significant differences in excursions were observed for RFCRS installed on the compliance bench when compared to RFCRS installed on vehicles seats.

The CMVSS 213 regulations have no limits for the forward excursion of the rear facing child restraint. The regulations require that the angle of the CRS seatback not rotate beyond 70 degrees; and that the CG of the head not extend beyond the upper limit of the seatback. The results obtained in this study suggest that of all the measurement parameters considered, the motion of the CRS, and more precisely the forward excursion may be an important parameter in the comparison of CRS installations.

Over the past 10 years, great strides have been made in the reduction of child fatalities and injuries as motor vehicle crash occupants. As reported by Arbogast and Durbin (2013), in 2009 1,314 child occupants aged 0–14 years died in motor vehicle crashes in the United States representing a 41% decrease from 1996 (NHTSA 2010). Despite these gains, motor vehicle crashes persist as the leading cause of death for young people in the US, and for each fatality approximately 18 children are hospitalized and over 400 receive medical treatment for injuries sustained in a crash (CDC NCIPC WISQARS 2010). Specific to our results herein, use of RFCRS have been shown to reduce fatal injury by 71% for infants less than one year of age in passenger cars and by 58% in light trucks (Hertz 1996). Our line of research examines one component the vehicle seat surrogate used in RFCRS in North America of the multi-faceted motor vehicle crash child protection effort. As we seek to refine the regulations, we must be cognizant of the current effectiveness of CRS in reducing mortality and morbidity, and ensure that the changes we make to safety systems will yield increased safety benefits for children.

LIMITATIONS

The study was restricted to three common rear facing child restraint models and three common automotive seats. The results are therefore based on a relatively small sample of all possible combinations of child restraint, vehicle seats, and installation methods. The sled testing was conducted with an acceleration pulse that was within the corridor specified by the CMVSS 213 for purposes of repeatability and to provide reference to regulatory test results. The pulse was not intended to represent any actual passenger vehicle deceleration crash pulse. Similarly in an effort to maintain similitude with the CMVSS 213 regulatory test protocol and avoid potentially confounding effects, a front seat was not included in the study. The rebound response could not be evaluated since there was no constraint placed on the acceleration pulse beyond the corridor when rebound generally occurs.

Future work will focus on identifying the principal characteristics of the 213 bench that contribute the observed differences in child restraint response. These may include belt anchorage geometries, foam stiffness properties as well as material properties and fit of the bench cushion covers.

CONCLUSION

The rear facing infant seat matched pair tests suggest important performance differences between the bench and the vehicle seats that were dependent upon the method of fixation. LATCH installations were found to result in lower forward excursions than 3-point belt with base installations on all three vehicle seats included in the sample but this difference was either absent or reversed for installations on the regulatory bench.

Given that child restraints must perform reliably and effectively in complex environments, involving a variety of belt anchorages, vehicle seat characteristics, and interior occupant compartment profiles, the need to develop a test device and test criteria that are representative of these conditions appears clear. The use of motor vehicle seats attached to the sled buck in research testing can provide valuable comprehensive insight into the likely performance of a CRS in the field.

Acknowledgments

The authors would like to acknowledge the National Science Foundation (NSF) Center for Child Injury Prevention Studies at the Children’s Hospital of Philadelphia (CHOP) for sponsoring this study and its Industry Advisory Board (IAB) members for their support, valuable input and advice. The authors gratefully acknowledge the technical expertise of the sled staff at PMG Technologies.

APPENDIX

Table A1.

Test matrix n= 9

| RFCRS MODEL | CMVSS 213 | COROLLAA | CARAVAN | EDGE | INSTALLATION | |

|---|---|---|---|---|---|---|

| REAR FACING INFANT | BC | 002_0001 | 002_0010 | 002_0020 | 002–0031 | LATCH |

| MC | 002_0004 | 002_0013 | 002_0023 | 002–0034 | LATCH | |

| EE | 002_0007 | 002_0016 | 002_0026 | 002–0037 | LATCH | |

| BC | 002_0002 | 002_0011 | 002_0021 | 002–0032 | 3 pt BELT + BASE | |

| MC | 002_0005 | 002_0014 | 002_0024 | 002–0035 | 3 pt BELT + BASE | |

| EE | 002_0008 | 002_0017 | 002_0027 | 002–0038 | 3 pt BELT + BASE | |

| BC | 002_0003 | 002_00121 | 002_0022 | 002–00331 | 3 pt BELT NO BASE | |

| MC | 002_00401 | 002_00151 | 002_00251 | 002–00361 | 3 pt BELT NO BASE | |

| EE | 002_0009 | 002_00181 | 002_00281 | 002–0039 | 3 pt BELT NO BASE |

Note

Cylindrical pieces of polyethylene foam (pool noodles) were required to achieve a level base during installation.

Figure A1.

Acceleration pulse repeatability

Figure A2.

Delta V for the nine sled runs

Table A2.

Rear facing infant seat repeat test pairs with percent error analyzed for outcomes of interest

| Test No | Order | Seat | CRS Model | Head g | Neck R. Force N | Chest R. Acc. g | Pelvis Acc. R g | HIC 36 | ISO Left or Torso Belt | ISO Right or Lap Belt | Upper Target Forward Excursion mm | Lower Target Forward Excursion mm | Initial Angle | Max Angle | Max Change in Angle |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SD11-002_0010 | Primary | Corolla | BC | 66 | 1258 | 49 | 69 | 502 | 4229 | 3993 | 124 | 93 | 39.1 | 58.2 | 19.1 |

| SD11-002_0019 | Repeat | Corolla | BC | 69 | 1249 | 49 | 68 | 545 | 4584 | 3986 | 117 | 86 | 38.8 | 58.2 | 19.4 |

| % Error | 4% | 1% | 0% | 1% | 8% | 8% | 0% | 6% | 8% | 1% | 0% | 1% | |||

| SD11-002_0020 | Primary | Caravan | BC | 62 | 1268 | 50 | 77 | 613 | 4255 | 4106 | 160 | 118 | 39.4 | 63.3 | 23.9 |

| SD11-002_0029 | Repeat | Caravan | BC | 64 | 1224 | 55 | 77 | 685 | 4356 | 4512 | 156 | 113 | 39.9 | 62.2 | 22.2 |

| % Error | 3% | 4% | 9% | 0% | 11% | 2% | 9% | 3% | 5% | 1% | 2% | 7% | |||

| SD11-002_0021 | Primary | Caravan | BC | 56 | 1234 | 49 | 68 | 595 | 3795 | 1732 | 175 | 144 | 40.7 | 62.5 | 21.8 |

| SD11-002_0030 | Repeat | Caravan | BC | 58 | 1325 | 54 | 72 | 600 | 4415 | 1626 | 180 | 143 | 41.3 | 64.3 | 23.1 |

| % Error | 3% | 7% | 9% | 6% | 1% | 14% | 7% | 3% | 0% | 1% | 3% | 5% | |||

Table A3.

Matched pair analysis results for infant CRS where SD = standard deviation and SE = standard error.

| Difference (Vehicles – Bench) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 3-POINT BELT WITH BASE | N | Mean | SD | SE | Min | Max | t | p value |

| Head Resultant Acceleration | 9 | 2.1 | 5.9 | 2.0 | −7.0 | 11.0 | 1.1 | 0.313 |

| Neck Resultant Force | 9 | −104.0 | 139.0 | 46.3 | −286.0 | 107.0 | −2.2 | 0.055 |

| Chest Resultant Acceleration | 9 | 2.4 | 4.3 | 1.4 | −4.0 | 8.0 | 1.7 | 0.129 |

| Pelvis Resultant Acceleration | 9 | 5.4 | 5.1 | 1.7 | −1.0 | 15.0 | 3.2 | 0.013 |

| HIC | 9 | 39.6 | 55.6 | 18.5 | −50.0 | 117.0 | 2.1 | 0.065 |

| HIC36 | 9 | 74.8 | 80.2 | 26.7 | −71.0 | 193.0 | 2.8 | 0.023 |

| Head 3ms Clip | 9 | 0.7 | 6.1 | 2.0 | −9.0 | 11.0 | 0.3 | 0.751 |

| Chest 3ms Clip | 9 | 2.6 | 4.0 | 1.3 | −3.0 | 8.0 | 1.9 | 0.094 |

| Shoulder Belt Force | 9 | 182.7 | 1026.7 | 342.2 | −1739 | 2040 | 0.5 | 0.608 |

| Lap Belt Force | 9 | −773.8 | 1298.4 | 432.8 | −3518 | 455.0 | −1.8 | 0.112 |

| CRS Up Seatback Excursion | 9 | −0.7 | 7.7 | 2.6 | −36 | 51 | −0.3 | 0.788 |

| CRS Low Seatback Excursion | 9 | 1.5 | 4.1 | 1.4 | −26 | 34 | 1.1 | 0.308 |

| Max change in CRS angle | 9 | −2.2 | 8.3 | 2.9 | −13.2 | 16.1 | −0.8 | 0.452 |

| 3-POINT BELT NO BASE | N | Mean | SD | SE | Min | Max | t | p value |

| Head Resultant Acceleration | 9 | 5.7 | 6.0 | 2.0 | −4 | 13 | 2.8 | 0.022 |

| Neck Resultant Force | 9 | −2.9 | 120.1 | 40.0 | −140 | 240 | −0.1 | 0.944 |

| Chest Resultant Acceleration | 9 | 1.6 | 5.0 | 1.7 | −6 | 12 | 0.9 | 0.378 |

| Pelvis Resultant Acceleration | 9 | 0.1 | 6.1 | 2.0 | −7 | 11 | 0.05 | 0.958 |

| HIC | 9 | −17.8 | 38.9 | 13.0 | −66 | 36 | −1.4 | 0.208 |

| HIC36 | 9 | 19 | 43.5 | 14.5 | −42 | 107 | 1.3 | 0.227 |

| Head 3ms Clip | 9 | 3.7 | 5.8 | 1.9 | −5 | 12 | 1.9 | 0.095 |

| Chest 3ms Clip | 9 | 0.9 | 4.7 | 1.6 | −5 | 11 | 0.6 | 0.586 |

| Shoulder Belt Force | 9 | 307.8 | 493 | 164 | −420 | 1139 | 1.9 | 0.098 |

| Lap Belt Force | 9 | −81.2 | 760 | 253 | −1304 | 847 | −0.3 | 0.757 |

| CRS Up Seatback Excursion | 9 | 49.2 | 62 | 20.7 | −12 | 141 | 2.3 | 0.044 |

| CRS Low Seatback Excursion | 9 | 35.8 | 53 | 17.7 | −13 | 120 | 2.0 | 0.078 |

| Max change in CRS angle | 9 | 4.3 | 5.1 | −4.1 | 10.2 | 2.4 | 0.038 | |

| LATCH WITH BASE | N | Mean | SD | SE | Min | Max | t | p value |

| Head Resultant Acceleration | 9 | 6.8 | 6.9 | 2.3 | −7.0 | 15.0 | 2.9 | 0.019 |

| Neck Resultant Force | 9 | −53.4 | 94.9 | 31.6 | −204.0 | 62.0 | −1.7 | 0.129 |

| Chest Resultant Acceleration | 9 | −0.9 | 4.6 | 1.5 | −11.0 | 3.0 | −0.6 | 0.575 |

| Pelvis Resultant Acceleration | 9 | 2.7 | 6.5 | 2.2 | −5.0 | 15.0 | 1.2 | 0.251 |

| HIC | 9 | −8.8 | 102.3 | 34.1 | −176.0 | 157.0 | −0.3 | 0.803 |

| HIC36 | 9 | 108.2 | 124.4 | 41.5 | −143.0 | 309.0 | 2.6 | 0.031 |

| Head 3ms Clip | 9 | 5.9 | 6.9 | 2.3 | −7.0 | 14.0 | 2.5 | 0.034 |

| Chest 3ms Clip | 9 | −0.7 | 3.9 | 1.3 | −8.0 | 5.0 | −0.5 | 0.622 |

| Left LATCH Anchor Force | 9 | 190.9 | 82.1 | 27.4 | 37.0 | 284.0 | 7.0 | 0.000 |

| Right LATCH Anchor Force | 9 | −142.1 | 272.4 | 90.8 | −556.0 | 201.0 | −1.6 | 0.156 |

| CRS Up Seatback Excursion | 9 | −36.1 | 14.3 | 4.9 | −60.0 | −6 | −7.6 | 0.000 |

| CRS Low Seatback Excursion | 9 | −33.1 | 12.1 | 4.1 | −48 | −11 | −8.2 | 0.000 |

| Max change in CRS angle | 9 | −1.2 | 5.9 | 2.0 | −10.2 | 8.5 | −0.6 | 0.557 |

Note: In terms of significance or non-significance of the difference between matched pairs, Wilcoxon matched-pairs signed-ranks tests were in exact agreement with the t-test results (data not shown).

Table A4.

Grouped analysis results for infant ATD responses where SD = standard deviation and t-test is homoscedastic t-test using a two-tailed distribution.

| 3 point belt + base | Head Acc. R (no rebound) g | Neck F Resultant N | Pelvis Acc. R g | HIC | HIC 15 | HIC 36 | Head 3 ms Clip | Chest 3 ms Clip | |

|

| |||||||||

| Average FMVSS 213 Bench | 59 | 1408 | 60 | 654 | 313 | 559 | 57 | 46 | |

| Average Corolla | 60 | 1465 | 66 | 672 | 316 | 581 | 57 | 52 | |

| Average Caravan | 56 | 1175 | 62 | 687 | 315 | 608 | 55 | 45 | |

| Average Edge | 67 | 1273 | 67 | 722 | 421 | 714 | 62 | 48 | |

| Average All Vehicles | 61 | 1304 | 65 | 694 | 351 | 634 | 58 | 49 | |

|

| |||||||||

| SD FMVSS 213 Bench | 4 | 55 | 8 | 60 | 29 | 66 | 4 | 3 | |

| SD Corolla | 4 | 101 | 9 | 68 | 52 | 73 | 3 | 4 | |

| SD Caravan | 1 | 62 | 6 | 24 | 27 | 15 | 2 | 2 | |

| SD Edge | 0 | 68 | 2 | 64 | 47 | 70 | 4 | 3 | |

| SD All Vehicles | 5 | 145 | 6 | 53 | 65 | 79 | 3 | 4 | |

|

| |||||||||

| t-test FMVSS vs. Corolla | 0.7640 | 0.4535 | 0.4077 | 0.7489 | 0.9353 | 0.7213 | 1.0000 | 0.1066 | |

| t-test FMVSS vs. Caravan | 0.3280 | 0.0083 | 0.7506 | 0.4541 | 0.9121 | 0.3291 | 0.3127 | 0.7498 | |

| t-test FMVSS vs. Edge | 0.0615 | 0.0577 | 0.2483 | 0.2500 | 0.0375 | 0.0493 | 0.1528 | 0.3306 | |

| t-test FMVSS vs. All Vehicles | 0.4680 | 0.1046 | 0.3797 | 0.3819 | 0.2001 | 0.1776 | 0.8110 | 0.2554 | |

|

| |||||||||

| 3 point belt + no base | Average FMVSS 213 Bench | 42 | 653 | 48 | 324 | 152 | 274 | 41 | 42 |

| Average Corolla | 44 | 728 | 47 | 284 | 151 | 267 | 40 | 42 | |

| Average Caravan | 45 | 662 | 44 | 269 | 166 | 251 | 44 | 41 | |

| Average Edge | 50 | 767 | 45 | 333 | 209 | 329 | 48 | 46 | |

| Average All Vehicles | 47 | 719 | 45 | 296 | 175 | 282 | 44 | 43 | |

|

| |||||||||

| SD FMVSS 213 Bench | 6 | 61 | 9 | 38 | 51 | 46 | 6 | 7 | |

| SD Corolla | 6 | 13 | 6 | 46 | 44 | 57 | 3 | 4 | |

| SD Caravan | 6 | 60 | 2 | 43 | 41 | 51 | 5 | 4 | |

| SD Edge | 1 | 118 | 3 | 25 | 14 | 26 | 0 | 1 | |

| SD All Vehicles | 5 | 81 | 4 | 45 | 40 | 54 | 5 | 4 | |

|

| |||||||||

| t-test FMVSS vs. Corolla | 0.7014 | 0.1637 | 0.8445 | 0.3147 | 0.9807 | 0.8828 | 0.8071 | 0.9476 | |

| t-test FMVSS vs. Caravan | 0.5646 | 0.8648 | 0.5523 | 0.1762 | 0.7242 | 0.5962 | 0.5359 | 0.8400 | |

| t-test FMVSS vs. Edge | 0.1405 | 0.2331 | 0.6645 | 0.7327 | 0.1843 | 0.1602 | 0.1613 | 0.4270 | |

| t-test FMVSS vs. All Vehicles | 0.3330 | 0.2031 | 0.6719 | 0.3438 | 0.5211 | 0.7990 | 0.4626 | 0.8499 | |

|

| |||||||||

| LATCH + base | Average FMVSS 213 Bench | 60 | 1340 | 58 | 712 | 318 | 559 | 57 | 49 |

| Average Corolla | 68 | 1316 | 61 | 805 | 444 | 753 | 57 | 49 | |

| Average Caravan | 61 | 1299 | 60 | 596 | 301 | 553 | 65 | 46 | |

| Average Edge | 71 | 1245 | 61 | 707 | 448 | 694 | 66 | 50 | |

| Average All Vehicles | 66 | 1287 | 61 | 703 | 398 | 667 | 63 | 48 | |

|

| |||||||||

| SD FMVSS 213 Bench | 4 | 151 | 4 | 88 | 52 | 159 | 4 | 4 | |

| SD Corolla | 6 | 76 | 14 | 45 | 110 | 122 | 4 | 3 | |

| SD Caravan | 5 | 37 | 8 | 51 | 28 | 46 | 6 | 2 | |

| SD Edge | 8 | 98 | 6 | 90 | 131 | 104 | 10 | 8 | |

| SD All Vehicles | 7 | 72 | 8 | 107 | 113 | 122 | 5 | 5 | |

|

| |||||||||

| t-test FMVSS vs. Corolla | 0.1079 | 0.8220 | 0.7478 | 0.2017 | 0.1757 | 0.1722 | 0.9723 | 1.0000 | |

| t-test FMVSS vs. Caravan | 0.7897 | 0.6886 | 0.7188 | 0.1387 | 0.6449 | 0.9574 | 0.1388 | 0.3127 | |

| t-test FMVSS vs. Edge | 0.1276 | 0.4189 | 0.5106 | 0.9555 | 0.2216 | 0.2933 | 0.2358 | 0.8523 | |

| t-test FMVSS vs. All Vehicles | 0.0728 | 0.6074 | 0.4872 | 0.8944 | 0.1362 | 0.3640 | 0.1365 | 0.8138 | |

Table A5.

Grouped analysis results for infant ATD responses where SD = standard deviation and TTEST is homoscedastic TTEST using a two-tailed distribution.

| 3 point belt + base | ISO Left or Shoulder Belt | ISO Right or Lap Belt | Upper Seatback Excursion | Lower Seatback Excursion | Initial RFCRS Angle | Max Angle | Max Change Angle | |

|

| ||||||||

| Average FMVSS 213 Bench | 1895 | 4286 | 176 | 141 | 37 | 64 | 27 | |

| Average Corolla | 1174 | 3913 | 159 | 129 | 40 | 63 | 23 | |

| Average Caravan | 2838 | 2133 | 201 | 156 | 37 | 67 | 30 | |

| Average Edge | 2220 | 4492 | 192 | 163 | 38 | 59 | 21 | |

| Average All Vehicles | 2078 | 3513 | 184 | 150 | 38 | 63 | 25 | |

|

| ||||||||

| SD FMVSS 213 Bench | 767 | 304 | 18 | 13 | 6 | 5 | 0 | |

| SD Corolla | 199 | 133 | 8 | 8 | 1 | 3 | 2 | |

| SD Caravan | 1311 | 1299 | 28 | 12 | 4 | 11 | 10 | |

| SD Edge | 651 | 344 | 35 | 31 | 6 | 2 | 4 | |

| SD All Vehicles | 1037 | 1261 | 30 | 23 | 4 | 7 | 7 | |

|

| ||||||||

| TTEST FMVSS vs. Corolla | 0.2411 | 0.1553 | 0.2427 | 0.2745 | 0.4441 | 0.8426 | 0.0547 | |

| TTEST FMVSS vs. Caravan | 0.3558 | 0.0959 | 0.2644 | 0.2245 | 0.8878 | 0.6574 | 0.6849 | |

| TTEST FMVSS vs. Edge | 0.6059 | 0.4813 | 0.5169 | 0.3453 | 0.8652 | 0.2460 | 0.1471 | |

| TTEST FMVSS vs. All Vehicles | 0.7589 | 0.1208 | 0.5675 | 0.4672 | 0.6975 | 0.8548 | 0.3623 | |

|

| ||||||||

| 3 point belt + no base | Average FMVSS 213 Bench | 1618 | 2582 | 248 | 227 | 41 | 55 | 14 |

| Average Corolla | 1964 | 2722 | 256 | 235 | 43 | 62 | 19 | |

| Average Caravan | 2594 | 1867 | 268 | 232 | 39 | 58 | 19 | |

| Average Edge | 1586 | 3484 | 266 | 241 | 39 | 56 | 17 | |

| Average All Vehicles | 2048 | 2691 | 263 | 236 | 41 | 59 | 18 | |

|

| ||||||||

| SD FMVSS 213 Bench | 484 | 574 | 56 | 48 | 2 | 7 | 4 | |

| SD Corolla | 551 | 305 | 5 | 5 | 1 | 2 | 1 | |

| SD Caravan | 303 | 300 | 25 | 19 | 4 | 4 | 4 | |

| SD Edge | 216 | 558 | 33 | 29 | 3 | 2 | 3 | |

| SD All Vehicles | 552 | 784 | 22 | 18 | 3 | 4 | 3 | |

|

| ||||||||

| TTEST FMVSS vs. Corolla | 0.4612 | 0.7335 | 0.1571 | 0.3355 | 0.1475 | 0.2909 | 0.8623 | |

| TTEST FMVSS vs. Caravan | 0.0517 | 0.1514 | 0.2444 | 0.7144 | 0.4082 | 0.2063 | 0.8633 | |

| TTEST FMVSS vs. Edge | 0.9230 | 0.1227 | 0.4053 | 0.4724 | 0.3202 | 0.3308 | 0.9191 | |

| TTEST FMVSS vs. All Vehicles | 0.2697 | 0.8067 | 0.2593 | 0.4911 | 0.6693 | 0.5826 | 0.9334 | |

|

| ||||||||

| LATCH + base | Average FMVSS 213 Bench | 3771 | 3905 | 176 | 140 | 38 | 63 | 26 |

| Average Corolla | 3961 | 3543 | 153 | 111 | 37 | 61 | 24 | |

| Average Caravan | 3885 | 3678 | 126 | 95 | 40 | 60 | 20 | |

| Average Edge | 4039 | 4069 | 140 | 109 | 37 | 56 | 19 | |

| Average All Vehicles | 3962 | 3763 | 140 | 105 | 38 | 59 | 21 | |

|

| ||||||||

| SD FMVSS 213 Bench | 323 | 288 | 7 | 6 | 4 | 1 | 3 | |

| SD Corolla | 277 | 491 | 7 | 14 | 4 | 3 | 2 | |

| SD Caravan | 300 | 273 | 6 | 2 | 1 | 3 | 2 | |

| SD Edge | 332 | 261 | 6 | 9 | 4 | 3 | 2 | |

| SD All Vehicles | 271 | 390 | 13 | 11 | 3 | 3 | 3 | |

|

| ||||||||

| TTEST FMVSS vs. Corolla | 0.4825 | 0.3457 | 0.0187 | 0.0532 | 0.7419 | 0.2384 | 0.5268 | |

| TTEST FMVSS vs. Caravan | 0.6772 | 0.3768 | 0.0007 | 0.0024 | 0.3994 | 0.1599 | 0.0510 | |

| TTEST FMVSS vs. Edge | 0.3725 | 0.5066 | 0.0026 | 0.0110 | 0.7317 | 0.0356 | 0.0338 | |

| TTEST FMVSS vs. All Vehicles | 0.4245 | 0.5321 | 0.0004 | 0.0001 | 0.9933 | 0.0044 | 0.0806 | |

Footnotes

DISCLAIMER

The views presented are those of the authors and not necessarily the views of CHOP, the NSF or of the IAB members.

This paper shall not be construed as an endorsement, warranty, or guarantee, expressed or implied, on the part of Transport Canada for any evaluated material, product, system or service described herein. Readers should not infer that Transport Canada’s evaluation is for any purpose or characteristic other than as stated herein. All information in this document is for information purposes only and is not intended to provide any specific advice. Any reliance on or use of the information contained in this document is at the user’s sole risk and expense. Any actions or decisions should be based on independent research.

REFERENCES

- Arbogast KB, Durbin D. Epidemiology of child motor vehicle crash injuries and fatalities. In: Crandall JR, Myers BS, Meany DF, Schmidtke SZ, editors. Pediatric Injury Biomechanics: Archive and Textbook. Springer; New York: 2013. [Google Scholar]

- Centers for Disease Control and Prevention (CDC) National Center for Injury Prevention and Control Web-based Injury Statistics Query and Reporting System. http://www.cdc.gov/injury/wisqars. Accessed 2010.

- ECE/R44 2008. Uniform provisions concerning the approval of restraining devices for child occupants of power-driven vehicles. Addendum 43: Regulation No. 44. U. NATIONS.

- Glass W. 2002. Technical report on the FMVSS 213 crash pulse and test bench analysis. N. A. W. C. A. Division. Docket NHTSA-02-11707.

- Government of Canada 2012. Motor Vehicle Restraint Systems and Booster Cushions Safety Regulations SOR/210-90.

- Hertz E. 1996 Revised estimates of child restraint effectiveness. NHTSA Research note: www-nrd.nhtsa.dot.gov/pubs/96855.pdf. Accessed 10 July 2012.

- NHTSA “Federal Motor Vehicle Safety Standards; Child Restraint Systems.”. 2002 National Highway Traffic Safety Administration Docket No. NHTSA–02-11707-3. [Google Scholar]

- Sherwood CP, Abdelilah Y, Crandall JR. Quantifying the relationship between vehicle interior geometry and child restraints systems. 50th Annual AAAM Conference; October 16–18, 2006; pp. 381–396. [PMC free article] [PubMed] [Google Scholar]

- Sherwood CP, Gopalan S, Abdelilah Y, Marshall RJ, Crandall JR. Vehicle interior interactions and kinematics of rear facing child restraints in frontal crashes. 49th Annual AAAM Conference; September 12–14, 2005; pp. 215–228. [PMC free article] [PubMed] [Google Scholar]

- Tylko S, Bussières A. Responses of the Hybrid III 5th Female and 10-year-old ATD Seated in the Rear Seats of Passenger Vehicles in Frontal Crash Tests, IRCOBI September 2012, Dublin, Ireland.

- Tylko S. Interactions of Rear Facing Child Restraints with the Vehicle Interior During Frontal Crash Tests. 22nd Enhanced Vehicle Safety Conference; Washington, DC. June 2011; Paper Number 11-0406. [Google Scholar]

- Tylko S. 2009. Internal Research Report - Results of Rear Facing Infant Seat Testing. T. Canada, Minister of Transport. ASFB-2009-01.