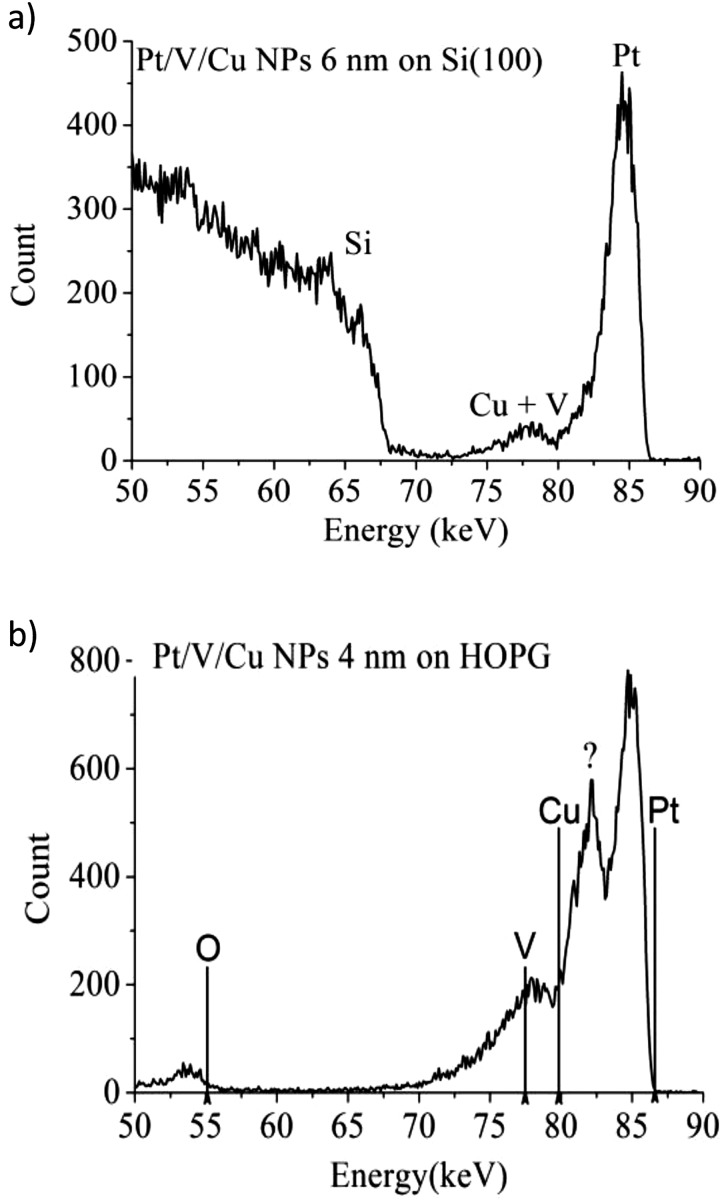

Abstract

This review examines characterization challenges inherently associated with understanding nanomaterials and the roles surface and interface characterization methods can play in meeting some of the challenges. In parts of the research community, there is growing recognition that studies and published reports on the properties and behaviors of nanomaterials often have reported inadequate or incomplete characterization. As a consequence, the true value of the data in these reports is, at best, uncertain. With the increasing importance of nanomaterials in fundamental research and technological applications, it is desirable that researchers from the wide variety of disciplines involved recognize the nature of these often unexpected challenges associated with reproducible synthesis and characterization of nanomaterials, including the difficulties of maintaining desired materials properties during handling and processing due to their dynamic nature. It is equally valuable for researchers to understand how characterization approaches (surface and otherwise) can help to minimize synthesis surprises and to determine how (and how quickly) materials and properties change in different environments. Appropriate application of traditional surface sensitive analysis methods (including x-ray photoelectron and Auger electron spectroscopies, scanning probe microscopy, and secondary ion mass spectroscopy) can provide information that helps address several of the analysis needs. In many circumstances, extensions of traditional data analysis can provide considerably more information than normally obtained from the data collected. Less common or evolving methods with surface selectivity (e.g., some variations of nuclear magnetic resonance, sum frequency generation, and low and medium energy ion scattering) can provide information about surfaces or interfaces in working environments (operando or in situ) or information not provided by more traditional methods. Although these methods may require instrumentation or expertise not generally available, they can be particularly useful in addressing specific questions, and examples of their use in nanomaterial research are presented.

INTRODUCTION

It is increasingly recognized that nanomaterials present a range of characterization challenges that have the potential to inhibit or delay the scientific and technological impact of nanoscience and nanotechnology. The incomplete characterization and under-reporting of data needed for reproducing and validating experimental findings1, 2, 3, 4, 5, 6 involving nanomaterials limits scientific understanding, slows the development of new technologies, and makes it difficult to reliably address important issues, such as product lifetimes and questions that are relevant to occupational and public health. Concerns related to adequate characterization of nanomaterials are not new, and a variety of issues have been highlighted by many research groups, multiorganizational teams of researchers, and the scientific press.2, 3, 7, 8, 9, 10, 11, 12 Challenges to appropriate characterization of many types of nanomaterials create frustration for researchers and engineers who would like to either use them for biomedical, energy, or other applications, as well as for regulatory bodies that need to understand their impact on human health and the environment.1 The incomplete characterization reports on many materials are viewed by some as a significant failure on the part of the scientific community.2

There are several reasons why complete nanomaterial characterization is not achieved, despite the inherent desire of most research groups to do high-quality research. First, nanomaterials present some unique preparation and analysis difficulties (described in following sections) that are new to some of the disciplines and researchers now involved in nanomaterials-related research. Second, because of the multidisciplinary nature of the field, not every research team has access to the range of characterization tools needed to obtain potentially important information. Third, the range of information needed to understand nanomaterials may require the application of tools and data analysis beyond the expertise of the research teams, sometimes leading to less-than-optimum application of important methods and/or incomplete understanding of the data produced. Nanoscience and nanotechnology are relatively immature fields, and the research community is just beginning to understand some of the limitations of analytical approaches that have been successfully applied in other areas.13 As understanding evolves, improvements to established methodologies, new technologies, and approaches are being developed. Thus, most of the sample preparation and characterization challenges can be addressed to differing degrees, especially when they are recognized at the outset. After exploring the nature and causes of some of the analytical challenges, we consider the ability of current- and next-generation surface analysis tools and developing capabilities to address some of the seemingly daunting materials characterization issues.

Although we focus much attention on engineered nanoparticles, many of the characterization challenges apply equally to other natural and engineered nanomaterials, as well as to areas such as atmospheric aerosols.14 In the first section, we highlight the need for the characterization of nanomaterials by showing the large and increasing impact of nanoscience and nanotechnology on science and technology around the world. The section after examines the challenges associated with nanomaterial characterization. In later sections, we explore the roles that traditional surface analysis methods can play in addressing analysis problems and show, by example, a few other methods that address questions related to characterizing nanomaterial interfaces in working environments (in situ) and determining the uniformity of coatings (intentional or accidental) on nanoparticles. The discussion and conclusion sections make recommendations, indicating approaches for overcoming synthesis and characterization challenges.

IMPACT OF NANOSCIENCE AND NANOTECHNOLOGY

The origin of nanotechnology usually is associated with a 1959 lecture by Richard Feyman.15 Possibly, the first use of the term “nanotechnology” in the scientific literature was in a 1974 paper involving “ion-sputter machining” by Taniguchi.16 The first nanotechnology journal, Nanotechnology, was launched in 1990 by the Institute of Physics in the United Kingdom. In 2000, then U.S. President Bill Clinton announced the U.S. National Nanotechnology Initiative (NNI), and Congress subsequently enacted the 21st Century Nanotechnology Research and Development Act in 2003, which significantly expanded the research focus and financial support in the area. A 2010 World Technology Evaluation Center (WTEC.org) and National Science Foundation (NSF) report, “Nanotechnology Research Directions for Societal Needs in 2020,”17 assessed the impacts of nanotechnology from 2000 to 2010 and looked toward the future. Quite appropriately, the report highlighted both the numbers of nanotechnology patent applications (growing from 224 in 1991 to nearly 13,000 in 2008) and the market size of products involving nanotechnology (approximately $91 billion in 2009). The report also notes that nanotechnology has penetrated “most production sectors of the economy” and is used in a wide range of commercial products, “including coatings, industrial chemicals, cosmetics, textiles, and magnetic storage devices, among many others.”17 The report concludes that future impacts will be both greater and more revolutionary than what has been observed to date.

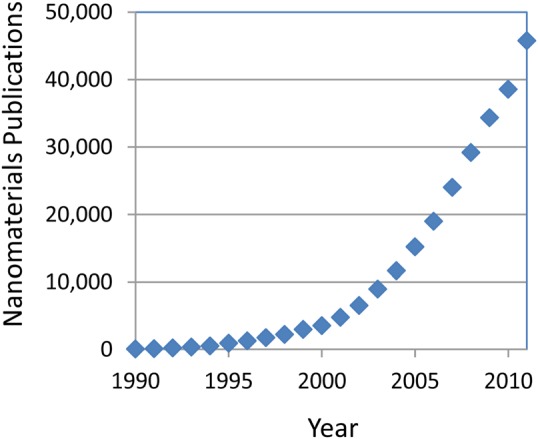

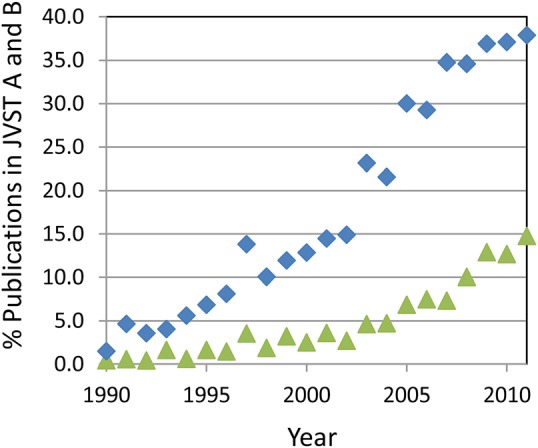

As expected, the number of publications related to nanotechnology mirrors the historical time line. Results from a Web of Science search combining the terms “nanomaterial,” “nanoparticle,” and “nanostructure” show dramatic growth in published papers (Fig. 1), from less than 100 in 1990 to almost 45,000 in 2011. Similarly, nanotechnology plays a significant role in many technical societies and has spawned new ones, as well as several journals focused on all things “nano.” Nanotechnology within the American Vacuum Society (AVS) follows a similar time line. The AVS Nanoscience and Nanotechnology Division was established in 1993. Since 1995, program activities specifically identified as “nano” have had a continuous presence in the annual AVS Symposium. By 1995, 5% of the papers in the Journal of Vacuum Science and Technology (JVST) A and JVST B were topically related to “nano” in some way with about 2% of the papers related to nanomaterials. Nano-related work in JVST grew at a nearly linear rate until 2003 when new NNI funding began appearing in significant amounts, and growth accelerated. By the end of 2011, nearly 40% of all JVST publications were linked to the key word “nano” in some way with about 15% identified as nanomaterial related using the three search terms described earlier (Fig. 2).

Figure 1.

(Color online) All “nanomaterials” publications identified by a Web of Science topic search (including: nanomaterials AND nanoparticles AND nanostructure) by year.

Figure 2.

(Color online) Percentage of publications in JVST A and B that include “nano” as a topic, ♦ as identified in the Web of Science and those focused on nanomaterials ▲.

The focus on things “nano” in the AVS and other societies occurs not only because we now have the label “nano” and due to significant funding in areas labeled nanotechnology, but the work we now call “nanotechnology” is part of a natural progression in many different areas of science coupled with development of new tools that enable researchers to see, model, and control structures at the nanometer scale.18, 19, 20 Although, in many ways, nanotechnology is not new, experimental and computational tool development enables research to be done that was not previously possible. New approaches can be taken to address previously intractable problems. Therefore, nanoscience and nanotechnology do not represent a new discipline, but rather advancements within several disciples and a convergence of concepts and ideas across disciplines.19 As such, nanotechnology introduces important new ideas and cross-fertilization that enables scientific breakthroughs and development of various new technologies.

The productive cross-fertilization of multiple disciplines also places new demands on research teams by requiring an expanded range of scientific, analytical, and other skills that are not always readily available. In addition, the fundamental nature of nanomaterials introduces characterization issues that are not routinely addressed by many analytical tools.7, 11, 13 The same characteristics of nanomaterials that make them scientifically interesting actually cause some of the analysis challenges. Nanoparticles have a physical size characteristic of biological molecules,21 and, in some ways, they can be described as having protein-like properties.7, 22 Similar to biological molecules, nanoparticles also may change their structure and properties, depending upon the physical environment.7 Particles may undergo structural transformation, dissolve, agglomerate, or pick up coatings in different environments. These behaviors complicate the ability to identify and predict properties of these materials and diminish the ability to assess the impact of these materials on the environment or their health and safety implications.

These characterization challenges are readily noted in papers, such as “Common pitfalls in nanotechnology…,”23 “The characterization bottleneck,”1 and “Discriminating the states of matter in metallic nanoparticle transformations: What are we missing?,”24 and in scientific news articles, such as “Tiny traits cause big headaches….”2 The nature of some of these “headaches” is described in the next section.

NANOMATERIAL CHARACTERIZATION SURPRISES

Research on the synthesis and properties of a range of nanomaterials takes place in the Environmental Molecular Sciences Laboratory (EMSL), a national scientific user facility sponsored by the U.S. Department of Energy's Office of Biological and Environmental Research (DOE-BER) and located at Pacific Northwest National Laboratory (PNNL), and the authors of this review paper have been associated with EMSL as staff members, research partners, or users. We have found that appropriate characterization of nanomaterials can be more difficult and, in many circumstances, more interesting than expected. Because of our long-term interest in the interactions of iron-25, 26, 27, 28 and cerium-based29, 30, 31, 32 nanoparticles in a variety of environments, many of the examples shown herein are directly derived from our work on these materials. The issues that have impacted our research are similar to those identified in a variety of studies on other materials systems.

Nanomaterials can take a variety of forms, including free-standing nano-objects (such as nanoparticles and carbon nanotubes), materials with nano-sized holes (including porous films), and other types of materials with a variety of different nanoscale structures (such as nanometer-thick layered structures). Many of the examples in this paper focus on behaviors and properties of nanoparticles. However, the detailed characterization of other types of nanomaterials often has produced results that have surprised the researchers involved in this study (described in the next section). These and other examples from the literature are used to identify some of the common issues and challenges that should be considered whenever analyzing nanomaterials.

Inconsistent behaviors and disappearing particles—cerium oxide nanoparticles

Ceria (CeO2) is used in a variety of applications, including functioning as a catalyst and catalyst support,33 serving as an antioxidant in medical treatment,34, 35 and having good ion conductivity that might prove useful for solid oxide fuel cells.36 For some applications, one of ceria's important properties is the ease at which Ce can switch oxidation states between +3 and +4. Several studies suggest that as ceria particles decrease in size, the dominant chemical state of Ce in the particles changes from +4 to +3.37

Unfortunately, published reports regarding ceria nanoparticles report properties that often contradict one another.32 We were interested in the sources of variability in measured band gaps for particles of similar size32 and the range of conflicting reports on the toxicity of ceria in biological systems.30 As summarized herein, our studies have shown that particle properties can be changed by variations in environmental conditions, the synthesis routes used to create the particles, and even seemingly inconsequential changes in well-established synthesis or sample handling processes.

Environmental and time-dependent properties

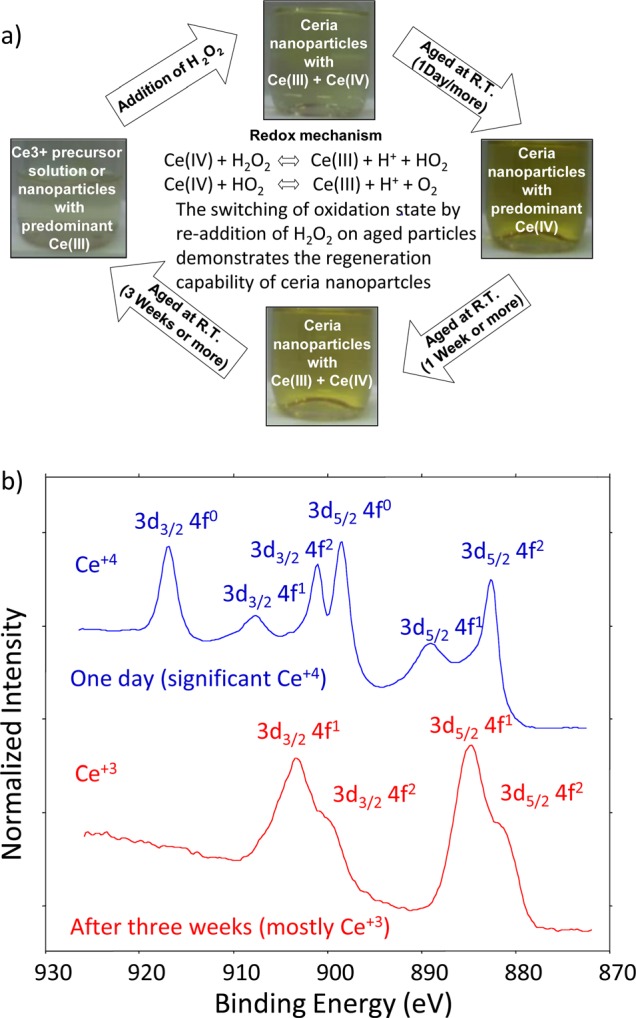

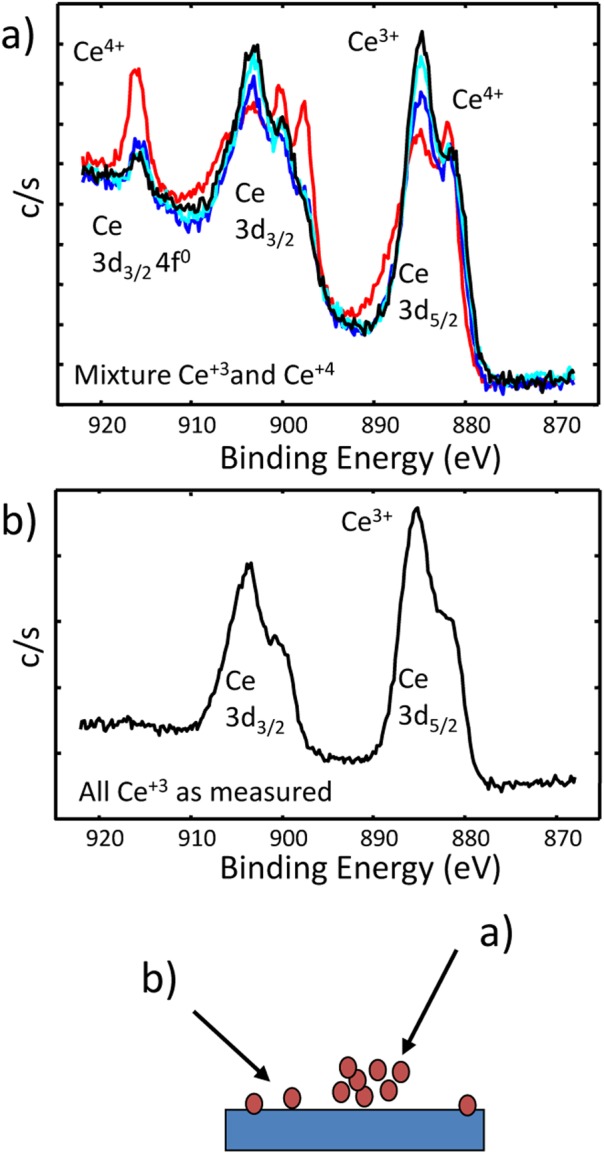

Until recently, many reports regarding nanoparticle properties in the early literature assumed that their physicochemical properties remained relatively constant after they formed. In contrast, we found that the chemical properties of 3- to 10-nm ceria particles suspended in aqueous solution changed depending on the nature of the solution and aging time32 [shown in Fig. 3a]. This work demonstrated that the oxidation state of ceria particles responds to the environment, changing from +3 to +4 [Fig. 3b] when an oxidizing agent is added and slowly reverting back to +3 as the solution ages and the oxidizing condition of the solution changes. Furthermore, it was shown that the rate of change depended on the composition of the media in which the particles were synthesized or suspended. For example, in a study of the effects of polyhydroxyls added to an aqueous solution, the kinetics of switching of oxidation states in solution was observed to be slower in basic medium compared to acidic medium.29 Taken together, these results suggest that some of the inconsistencies in particle properties reported in the literature may be related to the differing synthesis, processing, and environmental conditions experienced by particles in the different studies.

Figure 3.

(Color online) (a) Schematic representation of the regenerative capability and oxidation state switching of ceria nanoparticles in an aqueous environment. The pictures of the bottles containing the nanoparticle suspension in DI water indicate color and oxidation state changes after different aging periods. (b) XPS Ce 3d spectra from particles removed from solution after one day and three weeks. Consistent with the optical measurements and solution color, the particles were mostly Ce+4 after one day and mostly Ce+3 after three weeks. When H2O2 was added to the aged nanoparticles in solution, they switched from Ce+3 back to Ce+4. Adapted with permission from Kuchibhatla et al., J. Phys. Chem. C 116, 14108 (2012). Copyright 2012, American Chemical Society.

Contradictory biological impacts

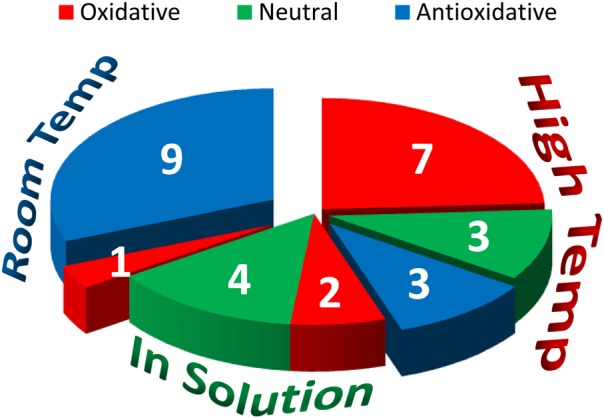

Different research reports in the literature indicate ceria nanoparticles to be oxidative or antioxidative in biological systems and to be toxic or benign depending on the particle or the biological test conducted. We examined the literature to explore the hypothesis that some of these apparently contradictory results might be due to particles differences. Although some of the published reports were too incomplete for an adequate evaluation, it was possible to determine that fundamentally different synthesis and processing routes were taken to produce the ceria particles used in different studies. Many of the ceria nanoparticles fit into one of three categories: (1) particles produced in solution at room temperature,34, 38, 39 (2) those produced by thermal hydrolysis (in the presence of various solvents/oxidizing conditions) involving heating of particles in solution,40, 41, 42 and (3) others synthesized by a variety of elevated temperature processes43, 44, 45 that involve either no solution or heating particles to elevated temperatures after synthesis (Fig. 4).

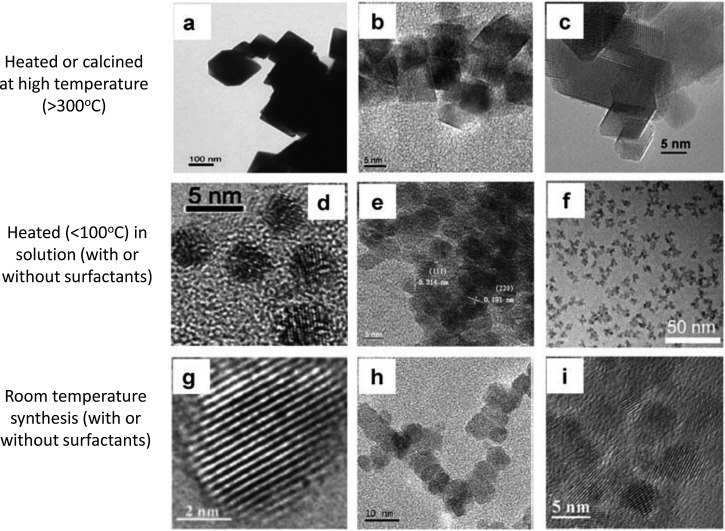

Figure 4.

Three categories of synthesis and processing approaches used to produce ceria particles: high-temperature processing (a)–(c) (Refs. 43, 44, 45), indirect heating of precursors or nanoparticles in solution (d)–(f) (Refs. 40, 41, 42), and room-temperature synthesis of nanoparticles (g)–(i) (Refs. 39, 38, 34). Adapted from Ref. 30.

When these synthesis routes were linked to the biological endpoints, it was found that in solution-based synthesis processes not involving heating produced particles that often were either nontoxic or antioxidative. Meanwhile, particles that had been heated to elevated temperatures were more likely to have undesirable effects (Fig. 5).30 Heating is likely to influence a variety of particle properties, including grain, particle size, and crystallinity. Although other factors, such as specific biological endpoint and particle coatings (deliberate or accidental), also will have impact, the literature survey suggests that synthesis route and particle history can significantly impact the biological properties of nanoparticles.

Figure 5.

(Color online) Summary of the relationships among synthesis categories and biological impacts, showing that synthesis routes have a significant impact of biological outcomes. Adapted from Ref. 30.

Detailed observations made by a University of California, Los Angeles-led research team for a set of well-characterized silica nanoparticles also highlight differences produced by a high-temperature process route, showing toxicity, while silica nanoparticles produced by low-temperature colloidal synthesis were nontoxic in a variety of tests.46 Taken together, both studies strongly indicate that synthesis and processing history can have a major impact on nanoparticle behaviors and properties. Unfortunately, because processing history, storage time, and conditions, and other information sometimes are missing in reports in the literature, it is not always possible to resolve the sources of apparently conflicting results.

Disappearing particles

In some cases, low-temperature colloidal synthesis processes, as noted, tend to produce particles with nontoxic behaviors. In the case of ceria, antioxidative behaviors often have been observed.31, 34 A significant body of work has been established by Sudipta Seal's group at the University of Central Florida for particles synthesized by a room-temperature solution process.32 Particles synthesized by this process have been observed to remain relatively stable in solution for periods of more than a year. Oddly, in-house work with particles produced by some of the same people using the same process did not have the same long-term stability, and the particles disappeared from solution in less than 60 days.30 Follow-up studies showed that switching the storage vial from glass to plastic altered some properties of the solutions, the particle lifetime, and effective diameter. We also found that variations in the precursor chemicals [from the same vendor but with different x-ray diffraction (XRD) patterns] and using different sources of deionized (DI) water for the synthesis impacted the long-term stability of the particles.30 Regardless of the specific cause of the particles' behavior changes, we note that subtle, seemingly insignificant, or unintentional changes in precursor chemicals or processes can have a significant impact on the lifetime and properties of nanoparticles.

Surprise on the surface—copper oxide nanoparticles

Copper and copper oxide nanomaterials are useful in a range of commercial applications and products, including being used as catalysts, superconductors, and lithium–ion electrodes.47 Although several studies of Cu-based nanoparticles suggest they can be toxic,48 it is recognized that as these nanoparticles age in different environments, their properties will change as a function of time.47 To assess the impacts of different chemical states of Cu nanoparticles, studies have been undertaken that include measurements of the biological response to Cu-based nanoparticles, where the particles are delivered with a known surface chemistry.

In one such study, copper oxide nanoparticles (≈42 nm primary particle size) were generated using spark discharge (Palas Karlsrühe) between opposing high-purity (99.95%) Cu rods. The aim was to generate fresh Cu (II) oxide nanoparticles for inhalation exposures. Preliminary XRD measurements revealed that the particles were a mix of metallic Cu, Cu2O, and CuO. To further characterize the nature of the particle surfaces, the material was shipped to EMSL in an argon atmosphere for x-ray photoelectron spectroscopy (XPS) analysis. At EMSL, the container was opened, and the particles were mounted on a sample holder in a glove box that was connected directly to an XPS spectrometer. Although high-energy resolution spectra focused on the Cu 2p region could answer questions about the chemical nature of the Cu, consistent with recommended practice (but not universally applied by all),49 we routinely collect large energy regions (survey spectra) to verify the nature and quality of samples provided. The high-energy resolution analysis of the Cu 2p region indicated that the particle surfaces were mostly Cu(II) (apparently, including CuO and Cu(OH)2). However, the presence of fluorine in the wide-energy survey spectra [Fig. 6a] was not expected. A higher energy resolution spectrum of the F 1s photoelectron region [Fig. 6b] found peaks that were consistent with polytetrafluoroethylene (PTFE) and CuF2. Analysis of the C 1s region [Fig. 6d] showed several carbon peaks consistent with the presence of PTFE and PTFE breakdown products.50, 51 For comparison, a spectrum from undamaged PTFE also is shown [Fig. 6c]. Not only did the particles contain an element on the surface that was unplanned, but PTFE breakdown products are known to induce acute and severe lung inflammation.52In vivo assessment of the toxicological response to these particles as CuO nanoparticles could have been misleading because the particles also were coated with PTFE and damaged PTFE.

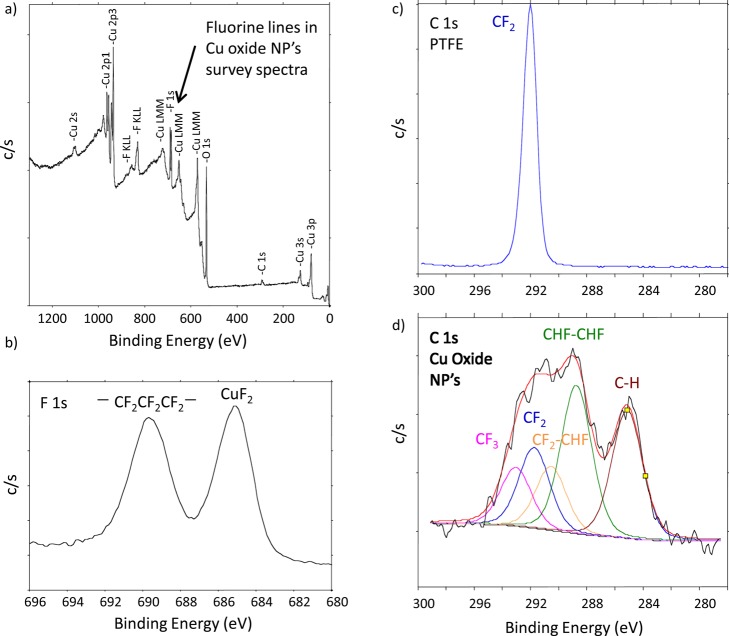

Figure 6.

(Color online) XPS spectra from Cu oxide nanoparticles and clean PTFE reference: (a) XPS survey spectra with unexpected F lines; (b) High-energy resolution F 1s region, showing photoelectron peaks consistent with the presence of PTFE and CuF2; (c) High-energy resolution spectrum C 1s region from clean PTFE, showing a photoelectron peak consistent with CF2 bonds in PTFE; and d) High-energy resolution C 1s, showing the presence of breakdown products from PTFE (e.g., CF3, CF2, CF2-CHF, CHF-CHF, along with CH from advantageous surface contamination; a small amount of C-O and C = O is possible but not included in this peak fit). XPS identified the presence of F that was not expected or desired on these particles.

Before XPS analysis was done on these particles, they had been examined by XRD and transmission electron microscopy (TEM), including energy-dispersive x-ray spectroscopy (EDS). Due to the likely thin surface coating and a noncrystalline nature of the F either in the particle or on the particle surfaces, the presence of F was not detected by these methods. Without the surface sensitive analysis (XPS, in this case), the presence of the contamination at the particle surface may have remained unrecognized. A careful evaluation of the synthesis process helped determine the source of the F and steps were made to successfully reduce the F contamination by replacing PTFE components in the generator with machinable glass. Tools with high surface sensitivity provide information regarding surface contamination that may not be detected by other methods. The XPS data provided important information critical to the development of the planned toxicology study by confirming and reinforcing the need for characterizing the surface of nanoparticles upon generation and also during exposure to properly interpret the in vivo responses.

It is easy for unexpected contamination to occur during the nanoparticle synthesis (as reinforced by another example later in this paper). Although researchers know to avoid or minimize contamination, the tools needed may not be readily available and/or are not always applied. If not detected and properly considered, the presence of contaminants in and on nanoparticles used for toxicology tests can introduce an uncontrolled variable. The toxicity of some carbon nanotubes, for example, was found to be associated with contaminants that remained from the synthesis process.53 Catalysts used in the growth of carbon nanotubes can remain as residues that make up as much as 40% of the final product weight.

Clean and dry?—surprises associated with sample processing and preparation for analysis

Many types of nanostructured materials and nanoparticles are synthesized, shipped, processed, cleaned, tested, or used in combination with solutions of various types. The interactions of nanoparticles with these solutions can have a variety of both intended and unintended consequences. Two examples from our work demonstrate related causes but differing effects.

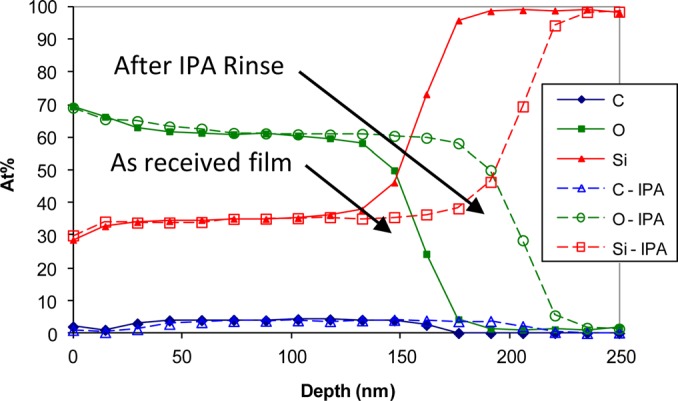

Apparent changes in thickness of nanoporous films due to solvent treatment

In earlier work, nanoporous silica films were examined as a method to create low-k dielectric materials for advanced high-density integrated circuits. These films were synthesized, processed, and cleaned in a variety of ways. Ion sputter profiling and XPS analysis were applied to obtain an estimate of relative layer thickness. As part of these studies, we found that films exposed to isopropyl alcohol (IPA) appeared to be thicker than those not exposed to IPA. The samples exposed to IPA had been removed from solution, dried, and placed in vacuum for several hours before being subjected to Ar ion sputtering.54 Figure 7 shows the apparent changes in film thickness. Based upon the sputter time to expose the interface, the exposure to IPA appeared to thicken the films. Our initial assumption was that the IPA exposure altered the film in some way that likely altered the sputter rate and caused the apparently thickening. To explain the observation, several different hypotheses regarding changes in the film structure or chemistry and/or deposition of material within the porous structures were considered and tested before we concluded that some IPA was retained in the nanostructured films even after drying for several hours in air and vacuum. Thus, the apparent differences in thickness were due to additional mass being included in the film. Eventually, we learned that leaving the samples in vacuum for more than 48 h would remove the retained liquid, and the time to sputter through the films for unexposed and IPA-exposed films became consistent.54 Capillary forces were sufficiently strong to retain significant amounts of a highly volatile solvent after hours in air and vacuum.

Figure 7.

(Color online) Sputter depth profiles of plasma processed p-OSG film before and after exposure to IPA. Based on comparison to the sputter rate for SiO2 the apparent thickness was approximately 157 nm with no IPA exposure and 205 nm after IPA exposure. From Gaspar et al., Surf. Interface Anal. 37, 417 (2005), Copyright 2005, John Wiley & Sons, Ltd.

Removing nanoparticles from solution without destroying important information

For many types of detailed analyses, it is necessary to remove particles from synthesis, process, or testing solution prior to analysis. As outlined by Nurmi et al.,26 there are several factors that need to be taken into consideration including: (1) removing residual solutes to minimize deposition of salts or other solution species, (2) removing solvent and cosolvents in a manner that minimizes aggregation and interference with the measurement process, (3) eliminating nonstructural water or other solvent without significantly altering particle phases, (iv) minimizing erosion of original surface coatings by dissolution or abrasion, and (v) avoiding reactions with the medium or its contaminants that may occur upon exposure to oxygen and other potentially reactive species that will alter the samples either immediately or as a function of time. Two different particles extraction processes are described herein that highlight the need to tailor the extraction process to the particle type and analysis objectives.

A variety of extraction or immersion processes are used as reported in the literature. Techane et al.55 described the process they used to remove Au nanoparticles coated with a self-assembled monolayer (SAM) from the solution. In this case, the objective was to remove the particles from the solution where the SAM was grown on the particles, minimizing any organic residue from excess 16-mercaptohexadecanoic acid (C16-COOH) thiol remaining in the solution. The process for removing the particles from the AuNP C16 COOH-SAM solution and depositing the particles on a substrate for XPS analysis involved several steps, including dialyzing the solution three times, concentrating the particles by centrifugation, and multiple deposits of solution on a clean silicon substrate. The samples were stored under N2 gas until surface analysis measurements were conducted, usually within about 2 h.55 This procedure produced SAM-coated Au nanoparticles consistent with good-quality coatings found on Au flat surfaces.

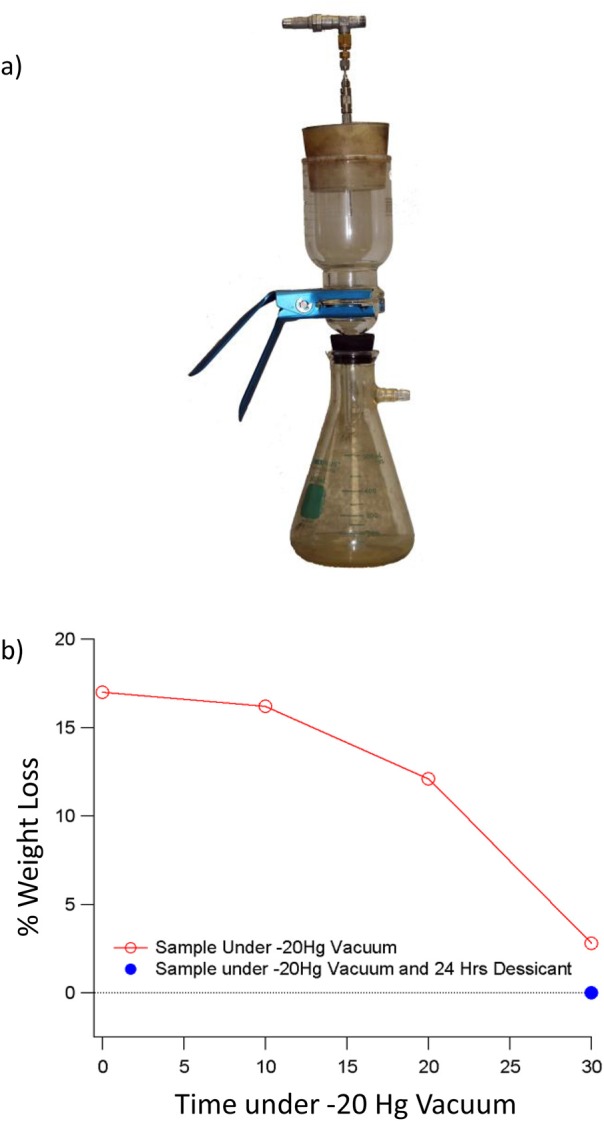

Our research conducted on metal-core oxide-shell Fe nanoparticles (nano-Fe0), which focused on understanding the impact of variations in nanoparticle synthesis, composition, and structure on the reduction of contaminants in groundwater,27 had somewhat different analysis objectives and required a different sample preparation method. Because the particles were reacting with both the water and contaminants in the water, we needed to stop the reaction to obtain the desired analysis. In the work's early stages, a “flash” drying process was developed to extract particles from solution as part of a method to “quench” particles into a stable state at different times during the reaction process. The aim was to stop the reaction or aging process and minimize solution contaminants remaining on the particles. The drying process26 involved removing the particles from solution in a glove box using a standard vacuum filtration apparatus assembled with a 0.02-μm PTFE filter and a vacuum pump capable of producing −20 mm Hg. After pouring the nanoparticle suspension onto the filter, approximately 30 s were needed to remove the original solvent. Then, the filtrate was washed three times with acetone (or other hygroscopic solvent), each time using just enough to completely cover the filtered nanoparticles. After washing, the vacuum was maintained until the particle layer appeared dry (typically 5–10 min). At this stage, most types of nano-Fe0 were a loose powder that was readily transferred to a container for storage or testing.

Although the samples appeared dry using this procedure, electrochemical measurements made on particles showed that they continued to change as a function of time. A range of thermal analysis, mass spectrometry, and other measurements demonstrated that a variable amount of water was retained in the sample (even though the powder appeared dry). Slightly different types of particles retained variable amounts of moisture, in some cases up to nearly 20 wt. % of the sample. The thermal analysis helped the development of a revised drying procedure that involved simple but important changes. After the third and final wash with solvent, the top of the Büchner funnel was sealed with a silicone stopper [Fig. 8a], and a vacuum gauge was used to adjust the pressure inside the funnel to −20 mm Hg. This condition was maintained for 30 min as it was determined this was sufficient time for removal of most of the residual solvent [shown in Fig. 8b]. The vacuum was relieved without disrupting the layer of nanoparticles on the filter by slowly opening a needle valve on a stainless-steel tube that pierced the silicone stopper. The flash-dried powder usually was transferred to an amber vial and stored (loosely capped) in a vacuum desiccator containing a 50/50 mix of Drierite® and activated charcoal.26 This process removed most of the moisture from the samples (some additional moisture was removed by storage in the desiccator), effectively stopped the changes observed in the electrochemical studies due to storage time, and also increased the reproducibility of other experiments.

Figure 8.

(Color online) (a) Image of filter and pump arrangement used to “flash dry” nanoparticles removed from aqueous solution for detailed. (b) Graph showing percent weight (moisture) loss as a function of drying time under −20 mm Hg vacuum (open circles). Without the vacuum assist, variable amounts of moisture often were retained in the collection of particles. As shown by the horizontal line, an additional 2 to 3% of moisture could be removed by storing the particles for 24 h in a desiccator filled with 50:50 anhydrous calcium sulfate and activated charcoal. Reprinted with the permission from Nurmi et al., J. Nanopart. Res. 13, 1937 (2010). Copyright 2010, Springer Science and Business Media.

Both the nanoporous film and nanoparticle immersion results highlight the fact that capillary forces can be quite effective at retaining a range of solvents within various types of nanostructures. For the nano-Fe0 studies, it was particularly important to effectively stop the changes taking place when the particles were in the solution to relate the physical behaviors of the particles to the particle reactivity and surface chemistry when ex situ measurements were conducted.28

NANOMATERIAL PROPERTIES AND CHARACTERIZATION CHALLENGES

The following summary highlights general areas or analysis challenges important for many types of nanomaterial characterization, including the importance of surfaces and interfaces; enhanced significance of synthesis, handling, processing, and storage conditions; and the dynamic nature of nanosized objects. A variety of effects have been grouped into topics as shown in Fig. 9 and Table Table I..

Figure 9.

(Color online) Properties of nanoparticles that often introduce characterization challenges; also see Table Table I..

Table I.

Challenges associated with characterization of nanoparticles.

| Nanomaterial surfaces and interfaces control properties |

|

| “Equivalent” nanoparticles usually are not |

|

| Nano-sized objects are dynamic: they change with time and respond to their environment |

|

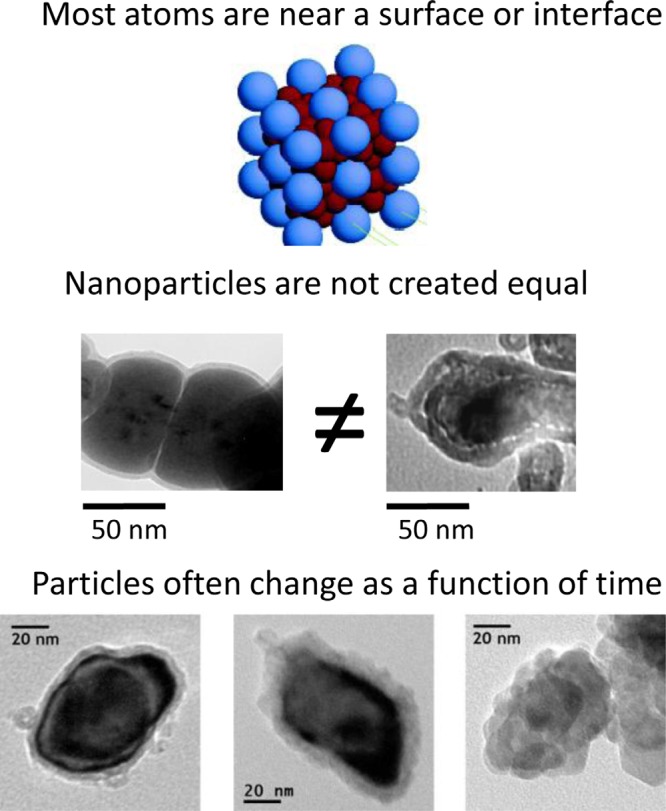

Nanomaterial surfaces and interfaces control many material properties

It is widely recognized that as particle size decreases, surfaces and interfaces begin to dominate and control the properties of nanostructured materials. However, the chemical and physical nature of these surfaces and interfaces often are not measured or reported. Grainger and Castner10 point out that over the past 40 years, surface scientists have obtained detailed knowledge about the behavior of surfaces, including the important role of deliberate and accidental surface layers. They note that the rigor needed to understand the chemistry of other surfaces also is required to understand and control properties of nanoparticles and other nanomaterials. Such “nanosurface” analysis10 has been extensively used to characterize supported nanoparticle catalysts but generally unused to characterize unsupported nanoparticles in biomedical and other applications. Because of the significant fraction of atoms or molecules associated with surfaces and interfaces of nanomaterials, surface impurities, surface enrichment or depletion, and surface contamination10 on nanomaterial properties can dominate material properties. For example, the electrical characteristics of Si nanowires are highly dependent on the nature of the environment and wire surface.56 The nature and impact of surfaces may depend upon the application and properties of interest. However, Karakoti and coworkers12 note that the importance of nanoparticle surface chemistry, especially as applied to toxicology, has been significantly underemphasized.

Others have noted57 that adsorption is a spontaneous process on high surface energy materials that reduces the free energy of nanoparticles. Consequently, thermodynamics drives the formation of many types of adlayers on particles during synthesis, processing, and storage. In relation to biological systems, Jones et al.57 observed that adsorbate layers on nanomaterials, not the virgin nanomaterial chemistry, are increasingly thought to be the primary surface that interacts with biological components. The segregation of components during synthesis or in different environments also can create materials for which the surface is significantly different from the bulk material. An excellent example where such segregation was unexpected has been observed during the formation of organic aerosols.58

As shown by the Cu oxide nanoparticle study, where F was identified by XPS, efforts must be made to characterize nanoparticle surfaces because the presence of unexpected contaminants or the unanticipated surface enrichment of a component species would make the nature of the particles significantly different than expected. In many circumstances, nanomaterials synthesis involves using surfactants to control particle shape59 during growth, and different types of chemicals are used during synthesis or processing. Residue from these processes23 may remain on particle surfaces or in the solutions in which many particles are stored and shipped. Often, the routinely applied analytical methods cannot identify such adlayers on particle surfaces. Consequently, lack of surface characterization contributes to the uncertainly and variability of results in the literature. Detailed reporting of synthesis, processing, and storage processes also can assist efforts to track down possible differences in particle behaviors.

“Equivalent” nanoparticles usually are not—nanoparticles are not created equal

When we compared the ability of two types of Fe metal-core oxide-shell nanoparticles (nano zero-valent iron) created by different synthesis processes to reduce CCl4, we found the reaction rates and reaction pathways to vary significantly.27, 60 In further work, we identified residue from different salts that could be used to synthesize particles61 by the “same” process significantly altered the properties of particles. As described previously, we found that ceria particles can behave differently, even when we have attempted to produce them using an identical process,30 and differences in the toxicity of particles that are the same material but have been processed in different ways now are well established.30, 46 Subtle differences, as well as not-so-subtle differences, in materials synthesis, processing, and storage (time, temperature, and light) may effectively make “similar” nanomaterials have different characteristics (some of which are not readily identified by most characterization methods).

Two observations from the Nanotechnology Characterization Laboratory (NCL) of the National Cancer Institute further emphasize some important issues.23, 62 Similar to our challenges to reproduce the formulation of ceria particles, they frequently observe batch-to-batch variation in particle properties. They report measurements on chemically attached polyethylene glycol, or PEGylated, gold nanoparticles, where a series of important measurements produced identical results, but only one batch produced highly inflammatory lung lesions. A highly detailed analysis eventually showed a difference in the degree of PEG coating between the batches, which impacted the degree of plasma protein binding.23, 62 Another important observation made by NCL staff over the years is that many researchers use commercial materials and the manufacturer specifications at face value without further testing.23 Because of history, shipping, storage, and other effects, this is a highly questionable practice. Particles made and characterized at one time and location are often not identical for the same material at a different time or location.

Properties of nanosized objects are dynamic—they often change with time and environment

In an article on metal nanoparticle catalysts, Somorjai and Park63 comment: “The restructuring of the surface coincides with the mobility of the adsorbate; thus the surface, both the metal and the adsorbate, has to be dynamic for catalytic reactions to occur.” Similar observations were made regarding the activity of catalysts associated with the growth of nanofibers.64, 65 It is possible to observe shape changes for nanoparticles during electron microscopy.66 It may be important to think of nanoparticles as dynamic, rather than static, objects. Many studies have shown the dynamic nature of natural and engineered nanoparticles, especially for particles smaller than 10 nm,67, 68 which has many different types of manifestations and implications. In particular, they can change with time, may be altered by proximity to other particles or surfaces, can be easily damaged during analysis, and frequently change in response to their environment.

Particle shapes can change

In reviewing structure and shape changes for nanosized particles, Yacaman et al.66 noted that different configurations for a nanoparticle have very similar energy, thereby making shape transformation easy and common. The types of energies we commonly apply during analysis will provide energy adequate to stimulate such changes.7 It may be appropriate to consider the dynamic nature of particles an essential characteristic that gives rise to important chemical properties as previously noted.63, 65

Particles dissolve, grow, and adsorb material from the environment

The high surface energy of many types of particles is lowered by growing57 or dissolving.69 Particles also may assemble into larger units57, 70 that may be easy (soft agglomerates) or difficult (aggregates) to break apart. As noted, to reduce surface energy, most particles naturally adsorb material from their environment.57 When nanoparticles are placed into biological media, a protein coating (corona) forms around the particles that may be tens of nm thick.71 The protein corona forms quickly, and the composition is influenced by the size of the nanoparticles.72 In many environments, even single-material nanoparticles quickly become core-shell particles, either by adsorbing material from the environment or reacting with that environment (e.g., oxidation/corrosion).28

Environmentally induced changes in structure and chemistry (including sample preparation and processing)

In addition to forming surface coatings, the environment can alter either physical structure or chemistry of a nanoparticle. Changes in the chemical state of ceria nanoparticles have been found to vary due to the presence of peroxide in the solution in which they are suspended.32 The crystalline nature of ZnS nanoparticles was observed to change when the particles' environment varied from wet to dry.73 As expected, oxide-shell metal-core iron nanoparticles oxidize in water, impacting their ability to reduce contaminants such as CCl4.28

The impact of environmentally induced particle changes has implications in at least two different ways: impacts on sample preparation and analysis and how they may transform in their “native” or working environments. Many surface analysis methods require placing samples in environments (often vacuum) that differ from those in which the samples are normally found. This can alter the particles and needs to be considered as part of the analysis and sample preparation process. Issues associated with sample handling and removal of samples from the natural environment to the analysis environment also apply here. The deliberate need to stop a process in the environment of interest was the focus on the flash-drying study noted earlier.26 The need to remove components from the solution environment that were not associated with the particles was a focus of both the flash-drying process and the extraction process of the SAM-coated Au nanoparticles.55

There also are broader implications of environmental-induced transformation, both for application and aspects of analysis. Wiesner et al.67 commented on the “Ubiquity and Mutability of Nano-Sized Materials in the Environment.” It is important to realize that nanomaterials (especially nanoparticles) may change in some ways if their local environment changes during incorporation into a product, they are introduced into a biological system, or they are released into the natural environment. Cohen et al.74 noted the importance of comprehending particle–media interaction to understand the particle dose delivered to cells for either toxicological impacts or pharmaceutical purposes. The need to understand particles and their transformations in the native environment underscores the demand for various types of in situ real-time measurements.

The nature of sample preparation must be linked directly to analysis and the testing to be conducted. To examine the reaction intermediates during a catalysis reaction, Krier et al.75 conducted a study that combined both of the two preceding issues. They noted that organic ligands typically are used to stabilize nanoparticles during synthesis, and these remain on the particles after synthesis. However, the presence of an organic capping agent may block a significant fraction of active sites when the particles are intended for catalysis studies. Their specific study focused on the application of sum frequency generation-vibrational spectroscopy (SFG-VS). They observed that the capping layer produced a strong signal that inhibited measurement of the reaction intermediates of interest. They tested both solvent cleaning and ultraviolet (UV) cleaning for removing the capping layers and found that both cleaning processes enabled the collection of the needed SFG signals. They further noted that the solvent cleaning process did not remove the entire capping layer, while the UV cleaning enabled complete removal. However, the solvent cleaning produced particles that were stable under reaction conditions, while the UV-cleaned particles had significant aggregation and were effectively unstable, actually complicating the study objectives. In this case, the “partial” cleaning produced the most useful material and stable material.

Proximity effects

The properties of individual or isolated nanoparticles may change as they are in contact or near surfaces or other nanoparticles.7, 22 This behavior can be used to create materials with tuned properties76 or as the physical basis of a nanoscale ruler.77 Implications of proximity effects related to sample mounting78, 79 include substrate interactions, particle charging, coupling of quantum states, and spacing impacts on electronic and magnetic properties of the effective composite. We have found, for example, that the chemical state observed by XPS may depend upon the concentration of particles loaded onto a substrate as shown in Fig. 10. The ceria particles examined were deposited on a silicon wafer by placing a drop of solution on the substrate in a glove box and letting the solution evaporate. After the solvent evaporated, a nonuniform distribution of particles formed on the surface. XPS analysis of portions of the deposit with a low density indicated Ce+3 [Fig. 10b], while the portion of the deposit with a higher density contained at least some Ce+4 [Fig. 10a]. When we first observed this behavior, we asked a few others if they had ever observed similar behaviors. One group agreed that they had observed something very similar on a different substrate, but they thought something had gone wrong with the measurement. We think this behavior is a proximity or environmental effect. In the region of higher particle density, the particles were interacting with each other (ceria nanoparticles with other ceria nanoparticles). Meanwhile, for the region of lower particle density, ceria nanoparticles had greater interaction with the substrate.

Figure 10.

(Color online) Ce 3d XPS spectra from ceria nanoparticles deposited on a Si substrate. Based on optical data, we would expect the ceria to be mostly Ce+3. The deposition process produced regions of high (a) and low (b) particle density. The XPS photoelectron spectrum from the higher density of particles differed (some Ce+4) from the lower density region (only Ce+3).

Ease of sample damage

The energies associated with chemical binding, particle bending or fracture, and charge buildup become roughly equal and less than those associated with analysis methods for nanoparticles.7, 21 One consequence of the similar energies is that particles are easily damaged during analysis or upon exposure to the environmental conditions of the analysis method. Samples have been observed to melt upon exposure to an electron beam,80 change oxidation upon x-ray81 or electron beam exposure,82 and sputter at enhanced rates.83

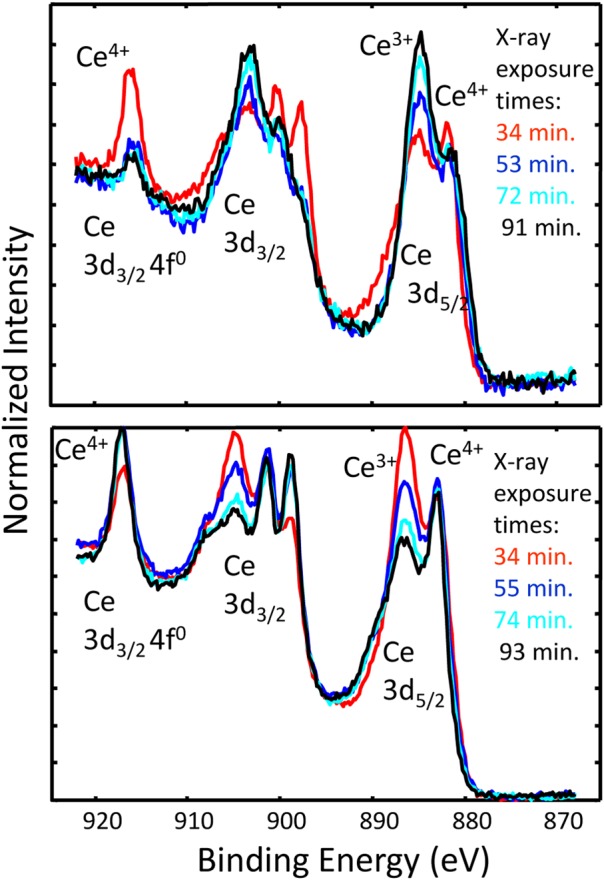

During XPS analysis of ceria nanoparticles, we discovered that the type of damage observed could change depending on the synthesis process used to create the particles. For the higher particle density, multiple spectra are shown in Fig. 10a. This set of spectra is presented again in Fig. 11a, showing that although the Ce+4 signal never totally went away, it decreased upon x-ray exposure.81 In contrast, a set of spectra in Fig. 11b shows an example of the Ce+4 increasing with time. We believe that the different damage processes are due to differences in the synthesis of the particles. In the first example showing damage-related reduction, the sample synthesis included the use of toluene, where a residue on the particle surface produced a locally reducing environment upon x-ray exposure. The second set of particles was synthesized in an aqueous solution containing no added organics, and an oxidizing environment was produced upon radiation.

Figure 11.

(Color online) Changes in the Ce 3d XPS spectra collected as a function of time for (a) particles formed in an aqueous solution, containing some amount of organic (toluene) (after Ref. 81), or (b) particles synthesized in a solution with no added organic. The 3–5 nm diameter particles produced in the solution with toluene (a) tended to become reduced upon x-ray exposure, while 10–14 nm particles formed in aqueous solution without added organics (b) tended to become oxidized upon x-ray exposure.

These and many other observations7 highlight that nanomaterials in various forms are easily damaged during analysis, and the nature of the damage may be altered by the specific nature of the particles and the environment where the damage takes place.

Time-dependent behaviors

For all of the preceding reasons, the properties and characteristics of nanoparticles frequently alter with time, a process sometimes called “aging.”28, 32, 47 This time dependence can be influenced by the synthesis process, exposure to light, storage conditions, temperature, and other aspects of the sample environment. Consequently, true characterization of nanoparticles might be considered a four-dimensional challenge60 with the axes being space, composition or structure, time, and environment. Although this might seem to present an overwhelming challenge for nanoparticle analysis and application, the rate of change is sufficiently slow in many cases as to be of no concern, and, in other circumstances, aging of nanoparticles presents an opportunity to tune particles for desired properties and lifetime or life cycle. Because the time scales of change can range from fractions of seconds to many years, the impact of any changes depends on the particle, environment, and nature of the study or application being considered.

Understanding these and other characteristics of nanoparticles and other nanomaterials enables researchers to design the types of analyses and characterization needed for specific research activities. It is clear, for example, that characterization of objects months or years before application or use may not provide useful information,4 unless the reliability of that information is confirmed. Understanding the changes a particle will undergo in particular environmental conditions is useful for determining the time frame and handling needed for a specific experiment. Keeping and reporting detailed records of the date of synthesis, storage times, and conditions, and times of analyses will facilitate the understanding of similarities and differences between studies. Because of environmental impact on particle properties and behaviors, it is important to monitor particles in the actual environment of interest, to the extent possible.11 Because the information available from such in situ measurements is often incomplete and less detailed than desired, it usually is important to combine real-time in situ measurements with a range of ex situ measurements, where sample handling has been carefully planned and appropriate integration of results is undertaken (we have attempted such integration in our Fe metal-core oxide-shell work26, 27, 28).

ROLE OF SURFACE ANALYSIS IN SUITE OF INFORMATION NEEDS

Incomplete characterization impacts several aspects of nanomaterials research, including the reproducibility of research results, the process of scaling production to meet manufacturing needs, and human health and environmental risk assessment.4, 10, 57, 84 Several different research, regulatory, economic development, and standards-related communities have worked to identify the minimum measurements needed to adequately characterize nanomaterials. Stefaniak et al.4 have examined 28 of these lists to understand the most critical needs related to metrological challenges and the development of nanoscale reference materials. As might be expected, particle size, surface area, particle composition (bulk), surface chemistry, agglomeration/aggregation, surface charge, and surface reactivity are prominent on many lists. Additional features, such as particle stability, solubility in biological media, and surface structure, are critical but less commonly discussed.

In a perspective article, Grainger and Castner10 observed that the information and experience obtained from surface science often is not integrated into studies of nanomaterials. In an impressive review of stabilization and functionalization of iron oxide nanoparticles for biomedical applications, Amstad et al.85 summarized the information needs and wide range of tools that have been applied to gather relevant data. Although they note the value of XPS for certain types of adsorbate measurements, surface sensitive methods generally play a minor role in these studies. It is our view that surface analysis methods of various types are underused as important components in the suite of tools needed for appropriate nanomaterial characterization. Although we have applied a range of methods to characterize the Fe metal-core oxide-shell nanoparticles,27 XPS became one of the few core methods applied in almost every circumstance to assure consistency and verify that contamination or other changes in the particles surface had not taken place.

The underuse of surface analysis methods for characterization of nanomaterials may have multiple sources. First, because the most common surface analysis tools have surface sensitivity in only one dimension and usually do not have the resolution to examine individual particles, some researchers do not consider applying the tools. A second possible reason is that these tools can require instrument access, as well as appropriate care in sample preparation and analysis, that may exceed the expertise available to prepare samples, collect data, and understand results. If applied or interpreted inappropriately, incorrect, inconsistent, or misleading results may be produced. A variety of research groups are demonstrating the application and value of these tools, as well as expanding types of information that can be obtained from these tools.

Information available from common surface analysis methods

The range of useful information about nanomaterials that can be obtained from data collected using traditional surface analysis methods exceeds what generally is expected by many analysts. The information available from several surface analysis methods is summarized in Table Table II.. These surface sensitive analysis methods can be applied in two somewhat different modes. For example, in many circumstances, it is highly useful to simply recognize the presence or absence of contaminants or to confirm the chemical state of elements present in the nanomaterial. Such uses dominate the literature, and their importance cannot be understated. However, with additional thoughtful analysis, an expanded range of information can be extracted—even from what was initially collected as qualitative data. In earlier reviews and summaries focused on XPS,78 nanoparticles, carbon nanotubes,60, 79 and nanomaterials,7, 86, 87 we provided many examples of how the most available surface analysis methods can be applied for nanomaterial characterization. Here, we highlight important underlying concepts, discuss some recent applications.

Table II.

Characteristics of common surface analysis methods and types of information available for nanomaterials.

| Surface analysis methods | Information available | Probe | Detected | Lateral resolution | Information depth | Depth resolution |

|---|---|---|---|---|---|---|

| Electron Spectroscopies | ||||||

| X-ray photoelectron spectroscopy |

|

X-rays | Photoelectrons | ≈2 mm System dependent | ≈10 nm | ≈2 nm |

| Auger electron spectroscopy |

|

Electrons (∼3 to 20 kV) | Auger electrons | ≈10 nm | ≈10 nm | ≈2 nm |

| Incident Ion Methods | ||||||

| Secondary ion mass spectrometry |

|

Ions (∼3 – 20 kV) | Sputtered ions | ≈50 nm (inorganic)> 200 nm (organic) | ≈1 nm | ≈1 nm (inorganic)≈10 nm (organic) |

| Low-energy ion scattering |

|

Ions(∼2 to 10 kV) | Elastically scattered ions | ≈100 mm | ≈10 nm | ≈0.1 nm |

| Medium-energy ion scattering |

|

Ions(50–200 kV) | Elastically scattered ions | 10 mm (TOF)1 mm (ESA) | ∼10 s nm | ≈0.1 nm |

| Scanning Probe Microscopies | ||||||

| Scanning tunneling microscopy |

|

Stylus | Tunneling current | ≈1 nm | ≈10 nm | |

| Atomic force microscopy |

|

Stylus | Force or displacement | ≈1 nm | ≈10 nm | |

X-ray photoelectron spectroscopy

Because evidence suggests that XPS is the most common surface analysis method applied to nanomaterials,88 we will highlight several examples of its application. It is important to recognize that although XPS is highly used and can provide valuable information, as normally applied in the laboratory, it requires placing a sample in ultrahigh vacuum and involves the analysis of many particles supported on a substrate. Strengths and limitations of XPS and other methods are noted in Table Table III..

Table III.

Strengths and limitations of primary methods discussed in this review.

| Technique | Strengths | Limitations or issues |

|---|---|---|

| XPS |

|

|

| AES |

|

|

| SIMS |

|

|

| LEIS |

|

|

| MEIS |

|

|

| AFM |

|

|

| STM |

|

|

| SFG-VS |

|

|

| NMR |

|

|

The nanostructure of a material impacts the peak intensities, peak energies, and structure (including background signals) of x-ray-excited photoelectron peaks.78 It is possible to invert the process and use details of the XPS peak shape and intensity to learn about the nanostructure of the materials being examined. The surface and structural sensitivity in XPS comes from the short distances that the excited photoelectrons can travel before losing the energy that identifies them as photoelectrons. The contribution to the detected signal from a depth z into the material is attenuated by material covering the layer closer to the surface. Although the equation is only approximately valid, the relationship between depth into a sample and signal strength can be usefully expressed as

| (1) |

where dIz is the intensity of the detected signal at depth z, I1 is the intensity that would have been produced if the layer were at z = 0 (the outer surface), L is the photoelectron attenuation lengths, θ is the angle of the detected electron relative to the surface normal, and dz is the thickness of the layer. The information depths from which detectable signal intensities can be extracted are typically in the range of 1–20 nm. Because L depends on energy, Eq. 1 demonstrates both the energy and angle dependence of the signal intensity from depth z. Applying the surface sensitivity of XPS, including the energy dependences of L and the impact of angle, a range of information can be extracted from XPS spectra,78 including surface composition and chemical state, presence and nature of functional groups, enrichment or depletion of elements at the surface, presence and thickness of coatings55, 89, 90 or contaminants (and reaction rates),91 and average nanoparticle size (if less than 10 nm).92, 93 It is also possible to use XPS to determine the electrical characteristics of particles or coatings and the distribution of Lewis and Brønsted acid sites on zeolite surfaces.79

A variety of methods can be used to extract the thickness of coatings on particles or flat films from XPS data—all effectively based on Eq. 1.89, 90, 91, 94, 95, 96 Computer algorithms using different approaches are available for layer thickness and structure determination, including MultiQuant™,95, 96, 97, 98 which looks at the impact of different particle shape and surface layer models on photoelectron peak signal strength, and quases,94, 99, 100, 101, 102 which considers the impacts of the surface nanostructure on signal strength and the related background signals around photoelectron peaks. Using simulation of electron spectra for surface analysis (SESSA)103 and Topofactor90 approaches to determine the thickness of coating on nanoparticles is discussed in more detail in an example to follow. The impact of particle shape depends somewhat on size. For those larger than 30 or 40 nm in diameter, the particles are effectively objects with curved surfaces, and the analytical approach to determining coating thickness will vary with particle shape but is independent of particle size. For smaller particles, for which photoelectrons can traverse the whole particle, it is necessary to know the particle size and shape to accurately relate signal strength to a layer or coating structure.78, 90

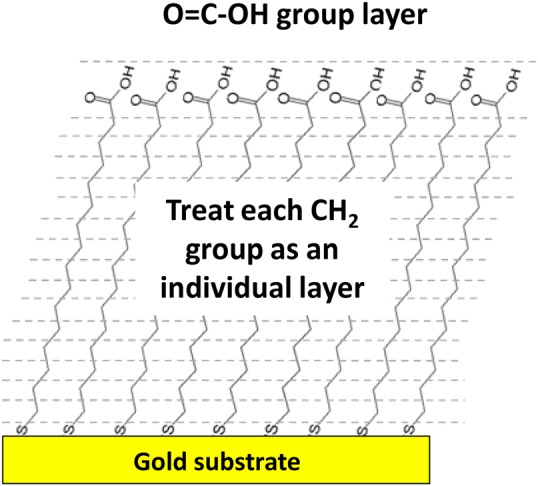

One of the recent tools for assisting the application of Auger electron spectroscopy (AES) and XPS is SESSA.103 In the initial form, the program provides important physical information to allow simulation of AES and XPS spectra from flat surfaces and (nano)-layered structures. Although a new version explicitly incorporating three-dimensional nanostructures, such as particles and wires, is being developed, Techane et al.55 modeled a C16 COOH-SAM adsorbed onto Au nanoparticles (AuNPs) using the flat surface version. This was done by constructing a “model” spherical nanoparticle made up of concentric cylinders with “flat” surfaces with a SAM coating (Fig. 12) at varying angles with respect to the axis of the analyzer as shown in Fig. 13.

Figure 12.

(Color online) Schematic model for the carboxylic-terminated SAM on a flat gold surface that was used in the SESSA calculations. Reprinted with permission from Techane et al., Anal. Chem. 83, 6704 (2011). Copyright 2011, American Chemical Society.

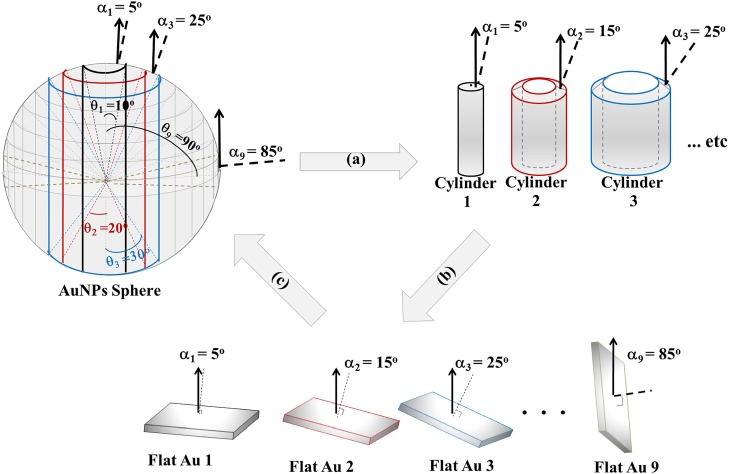

Figure 13.

(Color online) For application of SESSA to predict the signal strengths from SAM-coated Au nanoparticles, the particles were modeled as multiconcentric cylinders, where each cylinder surface has an average photoelectron take-off angle of ai. The XPS detector is positioned at 0° from the central axis of the AuNP. (a) The sphere is divided into nine concentric cylinders. (b) The end of each cylinder is modeled as a flat surface tiled relative to the axis of the spectrometer with infinite thickness of gold, and (c) the surface composition of each flat Au sample is weighted by its geometric factor then summed together to find the AuNP surface composition. Reprinted with permission from Techane et al., Anal. Chem. 83, 6704 (2011). Copyright 2011, American Chemical Society.

The study involved experimental measurements and SESSA modeling of XPS photoelectron signal strengths from two systems: (1) the SAM layer on a flat Au surface as a function of electron takeoff angle and (2) SAM-coated nanoparticles. SESSA was used to simulate both the angle variation of signals from the flat surface and the signals from spherical nanoparticles. In the initial form, SESSA can calculate signal strengths from a layered surface and the layer structure for the SAM on a flat Au surface. Figure 12 shows the SAM structure used in SESSA. The SESSA calculations as a function of angle then were compared to those observed experimentally. Appropriate agreement between the model and experiment was obtained when a small amount of surface contamination was included in addition to the SAM layer and Au substrate. As indicated in Fig. 13, a nanoparticle was approximated as a series of cylinders where the detected photoelectron signals will have different takeoff angles. For both the flat surface and nanoparticle, the SAM thickness and relative surface roughness (RSA) in SESSA were optimized to determine the best agreement between simulated and experimental surface composition. As summarized by Techane et al.,55 a SAM thickness of 0.11 nm/CH2 group, an RSA of 1.05, and a 0.15-nm CH2-contamination overlayer (total film thickness = 2.15 nm) provided the best agreement with the experimental XPS data. After applying the appropriate area weighting factors and summing the SESSA flat surface compositions, the most applicable results for the C16 COOH-SAM thickness and surface roughness on the AuNPs were determined to be 0.09 nm/CH2 group and 1.06 RSA with a 0.15-nm CH2-contamination overlayer (total film thickness = 1.85 nm). The 0.3 nm difference in SAM thickness between the flat Au and AuNP surfaces suggests that the SAM's alkyl chains may be slightly more tilted or disordered on the AuNP surfaces. SESSA and other detailed analysis approaches can provide a remarkable amount of information about the details of nanoparticles89, 104 and are especially useful when this type of information is required. However, these analysis methods are not yet easy to apply to “routine” samples. Sometimes, less rigorous methods can provide useful information as well.

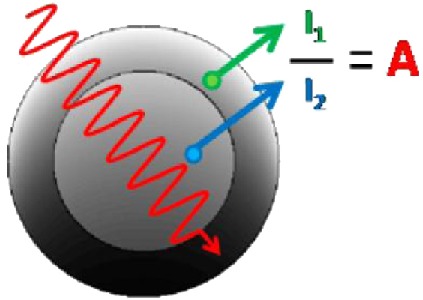

Shard has developed a simple approach for analyzing XPS data to obtain the thickness of coatings on nanoparticles.90, 105 The method involves measuring peak intensity ratios (Fig. 14), knowing the general structure and approximate particle diameters. It can be applied using either analytical formulas or a simple graphical method. Shard has applied the method105 to the data from Techane et al.55 (as analyzed using SESSA) using the ratio for the C 1s and Au 4f photoelectron peak ratios and relevant photoelectron attenuation lengths. The coating thickness calculated by the simple approach is 1.74 nm. As the simple calculation does not include the contributions of the O- and S-containing layers at the top and bottom of the SAM, it can be concluded that the 1.74-nm thickness compares quite well with the 1.85-nm total shell thickness determined by detailed calculations of Techane et al.55 using SESSA. The advantage of the simple method is that it is fast and simple to use. However, for cases when more detail is required, such as core–shell particles with multilayers or an outer contaminant layer, numerical simulations still are preferred.

Figure 14.

(Color online) Schematic diagram showing the relationships of peak intensity ratios (a) and shell thickness' of nanoparticles based upon knowledge of the radius of the nanoparticles. Reprinted with permission from Shard, J. Phys. Chem. C 116, 16806 (2012). Copyright 2012, American Chemical Society.

We have used the procedure described by Shard105 to examine Ag nanoparticles that were produced for a National Institute of Environmental Health Sciences (NIEHS) Consortium that is examining the toxicology of nanoparticles. During the course of the initial research with the particles, we learned the Ag particles had been formed around 7- to 8-nm Au cores. The presence of Au also had been identified in the XPS survey spectra. Au was observed by XPS in particles nominally 20 nm in diameter but was not observed in particles exceeding 100 nm in diameter. Before we could obtain any microscopy evidence of the Au cores, we used Shard's simple method to check the consistency of the XPS results with the assumption of the presence of a 7- to 8-nm Au core within ∼20-nm Ag particles.

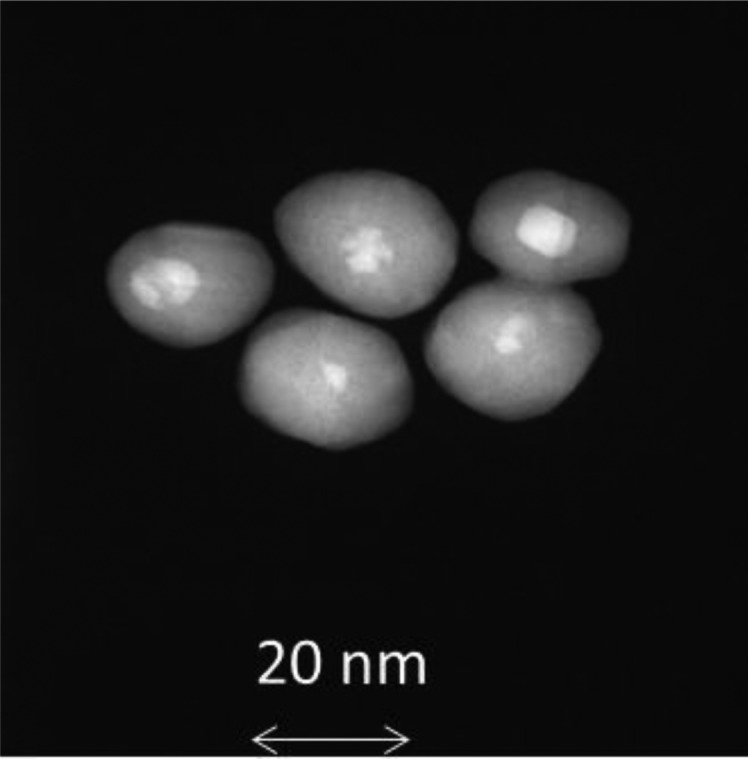

Based on a standard atomic percent calculation, the apparent atom ratio of Ag to Au for the 20-nm particles was approximately 64. This value becomes parameter A in Shard's approach.105 The second important factor in determining the coating thickness is the ratio of electron attenuation lengths for Au and Ag photoelectrons in the particle shell. For the Ag-shell Au-core particles, B = L(Ag in Ag)/L(Au in Ag), where L(Ag in Ag) is the attenuation length of Ag photoelectrons in the Ag shell (overlayer) and L(Au in Ag) is the attenuation length for Au (from the substrate) in the Ag shell. It is possible to calculate an approximate value using B ≈ (Eo/Es)0.75 as noted in earlier work,90, 106 but attenuation lengths and electron mean free path lengths can be calculated using several methods and sources, including National Institute of Standards and Technology databases107 and the formulas contained in computer codes, such as quases.100 Using the experimental value of A and the calculated value of B, Eq. (6) of Ref. 105 was applied to calculate the thickness of the overlayer normalized by the attenuation length (L(Ag in Ag)), assuming the data was from a flat sample (see Table Table IV.). The conversion from the flat film calculation to the spherical nanoparticle geometry was done using the average Topofactor of 0.67 that applies to particles significantly larger than L(Ag in Ag). Multiplying the corrected (but normalized) thickness by L(Ag in Ag) produces the estimate of the particle shell's thickness. The shell thickness determined by this calculation was 5.5 nm. Assuming an 8-nm Au core surrounded by a 5.5-nm-thick shell produces a particle size of ≈19 nm—quite consistent with a nominal size of 20. A later set of scanning TEM (STEM) measurements (Fig. 15) confirmed the presence of the Au core in most particles.

Table IV.

Parameters used to calculate the shell thickness for Ag-shell Au-core nanoparticles using XPS signal strengths.

| Parameter | Description or unit | Value |

|---|---|---|

| A | Ag/Au atom ratio | 64 |

| B | Attenuation length ratio | 0.82 |

| T | Normalized flat surface thickness | 5.1 |

| Topo | Topofactor | 0.67 |

| L | Attenuation length (nm) | 1.6 |

| Shell thickness | nm | 5.5 |

| Particle diameter (assuming 8 nm core) | nm | 19 |

Figure 15.

STEM dark field images of Ag-shell Au-core nanoparticles clearly show the presence of Au cores in most particles.

The analysis depth of XPS included in Table Table II. is based upon the most common x-ray sources for laboratory-based instruments. By using alternative energies, particularly those associated with synchrotrons, it is possible to extend the depth of analysis and to use x-ray energy as a method of tuning the analysis depth. Haverkamp et al.108 used this approach to understand the complex core-shell structure of IrO2, RuO2, Sb2O5, and SnO2 electrocatalyst nanoparticles.

It is useful to note that accurate knowledge of attenuation lengths is likely the most important limitation on the ability to accurately determine layer thicknesses of both films and on nanoparticles. The accuracy of these lengths is likely no better than 10% at one standard deviation.107, 109 Furthermore, the attenuation length information is normally applied to thin films (“nano” in one dimension), not for objects of “nano” size in three dimensions. The uncertainty in attenuation lengths limits overall accuracy of the analysis but still allows a great deal of information to be extracted.

Auger electron spectroscopy

Because both XPS and electron-induced AES involve detection of electrons of similar energies, many of the considerations described for XPS apply to AES. However, as generally defined, AES involves an incident electron beam with a spatial resolution that can sometimes be used to collect information about individual nanoparticles. It can be of importance to recognize that because AES involves electron excitation, issues of electron backscattering and transmission through a particle mean some additional parts of the sample may be stimulated to produce Auger electrons, which will limit the actual spatial resolution.110 Analysts have a tendency to look at a scanning electron image available in an AES instrument and assume, when collecting AES data from a feature identified in the image, that the entire signal is derived only from the area where the electron beam strikes. When the electron beam penetrates through a nanoparticle or other nanosized feature below or into the surrounding material, the Auger signals produced and detected usually come from both the nanofeature and surrounding region.

When the potential issues are understood, AES can be quite effective in providing information about nanostructured material, and it has been particularly useful in combination with other methods. Liang et al.111 were interested in the formation of what they called “Cu2O nanodots” for possible chemical or photochemical applications. AES was used to examine the nature of the nanodots formed on a SrTiO3 substrate after deposition using oxygen plasma assisted molecular beam epitaxy. In the AES instrument, it was possible to obtain secondary electron images of the nanodots, along with AES maps for Cu, Ti, and O (shown in Fig. 5 from Ref. 79). One objective of the AES analysis was to determine if a Cu2O wetting layer was observed between the Cu2O nanodots. This wetting layer was not observed. The secondary electron images and AES maps showed that nanodots could be formed with differing shapes. This process was also examined as a function of the amount of material deposited combining AES with atomic force microscopy (AFM) (Fig. 6 of Ref. 79).

As another example, AES was teamed with scanning electron microscopy (SEM) and TEM to examine the location of a composite organic–inorganic nanoparticle on leukemia cells. The combined technique provided reliable, high-resolution information about the nanoparticles and how they bind to cell surface antigens.79, 112

Secondary ion mass spectrometry

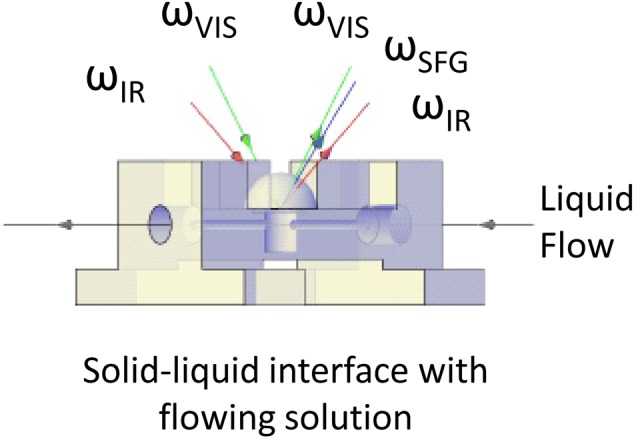

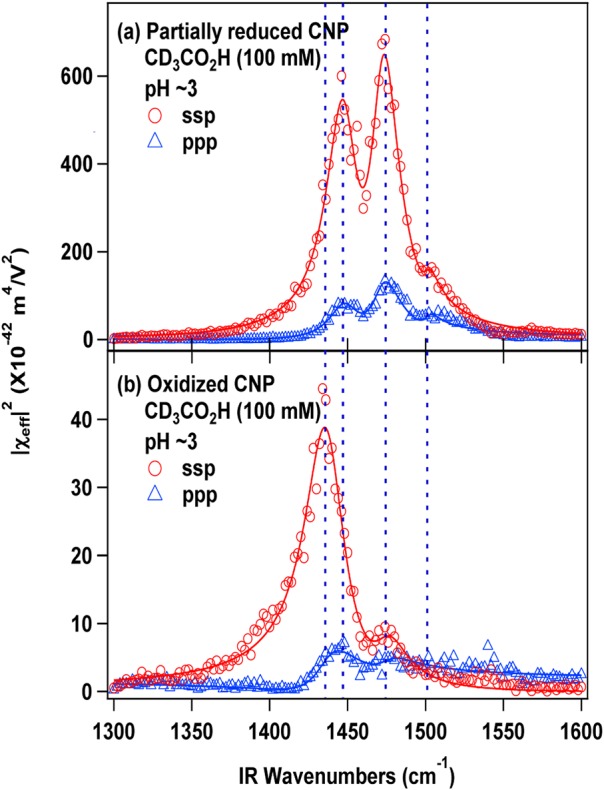

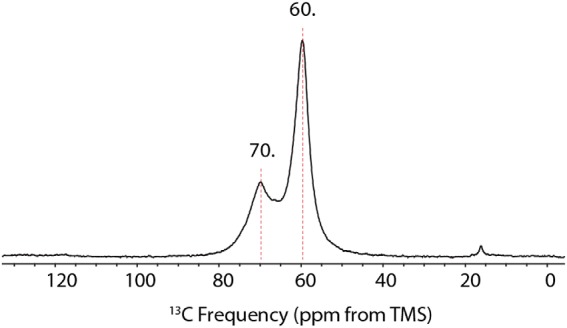

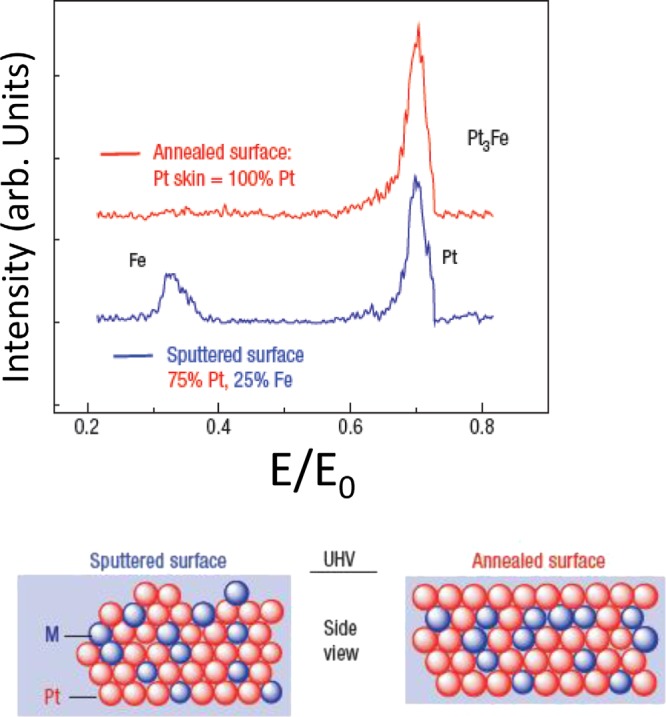

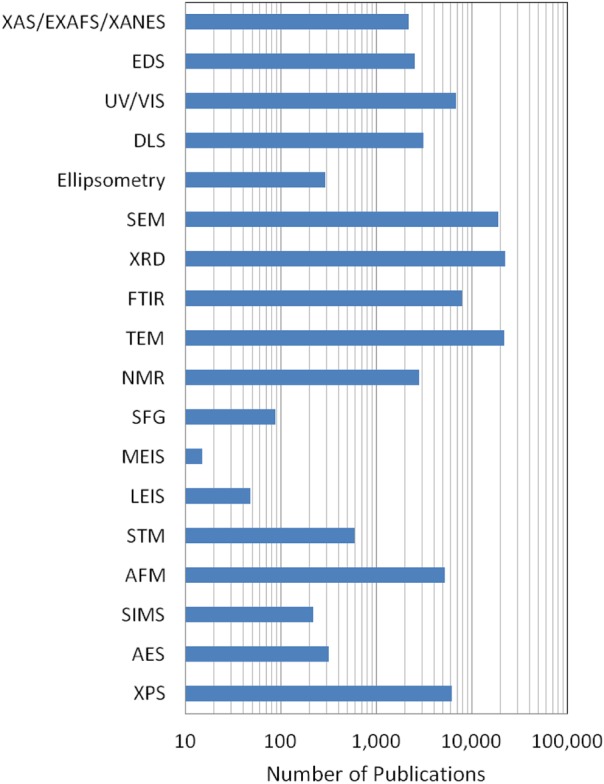

During secondary ion mass spectrometry (SIMS), measurements, primary ion beams with energies between 3 and 20 keV are incident on the surface, and the ions removed (sputtered) from the surface are detected. Surface selectivity arises from the depth of the region where the sputtered ions arise. Using cluster ion beams has enhanced the surface sensitivity and, for some materials, minimized the region of damage, allowing sputter depth profiles of organic layers.113, 114 To extract surface molecular information, SIMS is used in a “static” mode that involves a low density and low total dose of ions, so the surface damage and alteration are minimized. Both atomic and molecular secondary ions are used to extract the surface information.115 Like the electron spectroscopies, SIMS is useful for obtaining information about surface layers, functional groups added to the surface, and contamination. Two differences between the electron spectroscopies and SIMS are: (1) the high sensitivity (HS) of time-of-flight SIMS (TOF-SIMS) to many trace elements and functional groups and (2) the changes (damage) induced to the surface due to ion sputtering. The functional group sensitivity has been usefully applied in many ways. For example, TOF-SIMS has been used to examine peptides conjugated to Au nanoparticles as part of a protein kinase assay116 and to examine a multilayer, plasma-produced organic coating deposited on alumina nanoparticles.117 For relatively large nanoparticles produced during welding, SIMS with sputter profiling has been used to examine the complex layers that form on the particles.118 Unlike XPS, which often infers chemistry indirectly from binding energy shifts, SIMS has the advantage of measuring molecular fragments directly.