Abstract

Objectives

Clinical data on survival rates reveal that all-ceramic dental prostheses are susceptible to fracture from repetitive occlusal loading. The objective of this review is to examine the underlying mechanisms of fatigue in current and future dental ceramics.

Data/sources

The nature of various fatigue modes is elucidated using fracture test data on ceramic layer specimens from the dental and biomechanics literature.

Conclusions

Failure modes can change over a lifetime, depending on restoration geometry, loading conditions and material properties. Modes that operate in single-cycle loading may be dominated by alternative modes in multi-cycle loading. While post-mortem examination of failed prostheses can determine the sources of certain fractures, the evolution of these fractures en route to failure remains poorly understood. Whereas it is commonly held that loss of load-bearing capacity of dental ceramics in repetitive loading is attributable to chemically-assisted 'slow crack growth' in the presence of water, we demonstrate the existence of more deleterious fatigue mechanisms, mechanical rather than chemical in nature. Neglecting to account for mechanical fatigue can lead to gross overestimates in predicted survival rates.

Clinical significance

Strategies for prolonging the clinical lifetimes of ceramic restorations are proposed based on a crack-containment philosophy.

Keywords: dental ceramics, fatigue, fracture modes, lifetime, crowns, fixed-partial dentures

1. Introduction

Major dental restorations such as crowns and fixed-partial dentures (FDPs), as well as other biomechanical prostheses, are experiencing a rapid shift toward ceramic materials, partially for their strength and bioinertness but more so for their aesthetics.1–3 However, ceramics are brittle and susceptible to fatigue fracture in repetitive function. Although occlusal loading is nominally compressive, with bite forces supported in individual 'dome-like' structures (crowns) or in frameworks with connectors (FDPs), some tensile stresses are inevitable. Cracks tend to follow paths where these tensile stresses are greatest. While a ceramic restoration may fracture abruptly from a single intense overload, it is more likely that failure will occur cumulatively after an extended period of seemingly innocuous but lower-load biting events. Such fractures are manifest in the clinical literature as 'lifetime' or 'survival rate' data. Beyond such data lies a burning question: what are the underlying physical bases for designing next-generation ceramic materials for greater long-term performance?

The drive toward ceramic restorations is fraught with compromise.2, 4 There is a perception that ceramic crowns and FDPs are not yet as reliable as those with traditional metal-frameworks.1 The ceramics with the most desirable aesthetics, notably porcelains, tend also to have the lowest resistance to crack propagation ('toughness').5–7 Conversely, tougher ceramics such as aluminas and zirconias5, 8 are not generally aesthetic. Glass–ceramics9, 10 occupy a middle ground. Two well-grounded routes exist to overcome these countervailing tendencies. The first is to bond an aesthetic porcelain veneer onto a stiff alumina or zirconia core to provide support in flexural loading.1, 2, 11 However, the veneer remains a weak link, susceptible to chipping and delamination from the core (although as will be demonstrated later the core itself is not immune). Coefficient of thermal expansion (CTE) mismatch between veneer and core and low thermal diffusivities in most ceramics can lead to deleterious tensile stresses within the bilayer during heat treatment.12–16 The second route is to develop crack-resistant but partially translucent monolith ceramics to circumvent the need for veneering altogether—e.g. lithium disilicate glass–ceramics (IPS e.max Press or CAD by Ivoclar-Vivadent),17 or zirconias with fine grains (e.g. Lava Plus by 3M ESPE, Bruxzir by Glidewell, Allzir by New Image) or surface-infiltrated glass.18–22 Monolith ceramics also avoid weak veneer/core interfaces, minimizing the risk of delamination. In both routes, zirconia-based ceramics are emerging as materials of choice.

Given the brittleness of ceramics, it is hardly surprising that prosthetic failures do occur. Some of the more commonly observed clinical fracture modes are sketched in Fig. 1. They include cracks initiating from the contact zone at the occlusal surface,23 from the cementation surface beneath the contact,24 and from the margins of crowns and connectors in FDPs.25–31 Some examples of clinically fractured prostheses are shown in Figs. 2a to 2c, revealing fracture from a wear facet on a porcelain-veneered zirconia crown occlusal surface, a longitudinal crack initiated from the margin of a Dicor glass–ceramic crown, and a flexure crack at the connectors of a porcelain-veneered zirconia FDP. All of these cracks can result in severe damage or irrecoverable failure. Chipping fractures initiate from contact damage sites and detach at least part of the veneer from the core. Through-thickness fractures initiate from the occlusal or cementation surface beneath the contact or from the margins or connectors and can split a prosthesis in two. Clinical trials reporting survival rates for several all-ceramic systems indicate vulnerabilities to all these fractures.25–27, 32–48 Broadly speaking, porcelain-veneered systems show higher fracture rates than full-contour monoliths, FDPs more than single crowns, and glass– ceramic more than zirconia monoliths, although the variability in data from study to study can be high.

Figure 1.

Schematic diagram depicting various fracture modes in (a) crown and (b) FDP all-ceramic structures: axisymmetric outer (O) and inner (I) cone cracks, and median (M) cracks; partial cone (P) cracks; edge chipping cracks (C); radial (R) cracks at cementation surfaces; flexure (F) cracks at connectors. Linear-trace cracks (O, I, P, C, F) extend out of the plane of diagram, shaded (R, M) cracks extend within the plane of diagram.

Figure 2.

Fractures in dental prostheses. Figures (a) through (c) are clinical failures: (a) porcelain-veneered zirconia molar crown, showing crack originating from wear facet on occlusal surface; (b) longitudinal fracture from margin of Dicor crown (courtesy K. Malament); (c) connector fracture between 2 pontics of a 4-unit porcelain-veneered FDP. Figures (d) through (f) are laboratory failures of porcelain-veneered zirconia prostheses: (d) side view of veneer chipping in off-axis loaded crown, single-cycle loading with sharp point (Vickers indenter) at load 700 N; (e) post-testing section view of partial cone crack in crown veneer loaded centrally and tangentially, after 6×104 cycles with sphere indenter at 300 N (Courtesy P. Guess); (f) fracture at connector of 3-unit FDP, after 7.8×104 cycles with sphere indenter at 700 N (Courtesy C. Stappert).

The physical mechanisms of fatigue in ceramic restorative materials have not been well documented in the dental literature. The prevailing view, borrowed originally from fundamental studies in the materials science community,49, 50 is that fatigue can be accounted for by chemically-enhanced, rate-dependent crack growth in the presence of moisture.51–60 According to this viewpoint, water enters incipient fissures and breaks down cohesive bonds holding the crack walls together.49, 61 The result is so-called 'subcritical' or 'slow' crack growth (SCG) which progresses steadily over time, accelerating at higher stress levels and ultimately leading to failure. The notion is attractive because it lends itself to rigorous 'fracture mechanics' analysis in terms of explicit crack velocity equations, enabling one to predict lifetimes in terms of specified stress states.62 But recent studies in the materials science arena reveal that fatigue is more complex than just SCG. In addition to chemical degradation, there are mechanisms of mechanical degradation that can augment the fatigue process.12, 63–69 Mechanical fatigue operates exclusively in cyclic loading and cannot be inferred from static or monotonic loading tests. It can be relatively destructive, meaning that predictions based exclusively on SCG assumptions may grossly overestimate potential lifetimes. 'Fractography' 70—the microscopic analysis of post-failure restorations—can point to likely starting sources of fracture but is limited in its capacity to shed light on the fatigue mechanisms themselves, or to determine the sometimes complex evolutionary progression of competing fractures to completion.

It is important to understand the interplay between competing fracture modes in order that the best fatigue-resistant restorative ceramics may be developed. Accordingly, this article surveys the fatigue behavior of commonly used dental ceramics from a biomechanics point of view. The principal mechanisms by which chemical and mechanical fatigue occur are outlined. Simulated occlusal loading tests on model flat layer specimens (as well as on anatomically-correct prostheses), designed to represent essential features of dental ceramic layer restorations bonded to a relatively compliant dentin substrate, enable various competing fracture modes to be identified and quantified in a clinically relevant context. Strategies for prolonging the life of ceramic restorations are explored.

2. Failure Evaluation

2.1 Fracture modes

Failures in dental ceramic prostheses are usually associated with structural defects or 'flaws'. Flaws may arise during fabrication and preparation, or from post-placement chewing activity.71 They can take the form of microstructural defects within the ceramic, from machining in fabrication or sandblast damage during fitting,69, 72, 73 from wear facets and contact damage on the occlusal surface74 or cementation69 surfaces, or from micro-contacts with hard sharp objects.67 In ceramics, flaws generally assume the form of microcracks of sub-millimeter scale, often below visual detection. Valuable clues as to the origin of such flaws can be provided from post-failure fractography.70 It follows that good fabrication procedures and avoidance of preparation surface damage may be crucial elements of prosthetic dentistry. But this linking of fracture with flaw populations is to belie the essence of the failure process. Most often, newly formed cracks are 'contained'—they first arrest and subsequently extend incrementally over a long cycling period prior to ultimate failure. In natural teeth this crack 'stability' is manifest as closed fissures or 'lamellae' along the enamel walls.75–79 It is conceivable that steady crack growth could be monitored by periodic inspections of prostheses in vivo, but this is beyond the scope of normal dental practice, and in any case there is no guarantee that critical damage will be visible at the outer surface of a near-opaque restoration. Moreover, different modes of fracture can dominate under certain geometric conditions, and at different stages in the loading. Consequently, fracture evolution is complex and difficult to infer from conventional post-mortem and in vivo examinations alone.

What is missing from clinical studies is a fundamental understanding of the various mechanisms by which flaws evolve into full-scale fractures, especially in long-term cyclic loading. One approach is to conduct laboratory tests on anatomically-correct specimens by pressing down directly at an exposed surface with an indenting plate or sphere. Examples of cracked porcelain-veneered zirconia prostheses are included in Fig. 2, for crowns loaded vertically at the edge of a buccal cusp (Fig. 2d)80, at the lingual aspect of a buccal cusp with sliding motion toward the central fossa (Fig. 2e),81 and for a 3-unit FDP loaded at the buccal cusp of the pontic (Fig. 2f).82 However, such complex structures are not amenable to simple analysis and prediction. It is accordingly expedient to conduct ex vivo tests on model brittle specimens that retain the essential material and geometrical features of crowns, but in an idealized way that enables in situ monitoring of individual or concurrent cracks from initiation to full failure. In this approach, tests are carried out on flat-layer plate83–90 and dome-like shell91–94 structures bonded to a polymeric substrate representative of a compliant dentin-like support. The undersurfaces of the test specimens can be given different preparations representative of clinical protocols, to examine the effect of surface finish. The specimens are top-surface-loaded with a spherical indenter, representative of occlusal contact. The arrangement allows for variations in contact conditions— single-cycle axial, off-axis93 and sliding,81, 95, 96 or cyclic.12, 65, 66, 74, 97–99 Generally, cracking begins at either the top occlusal or intaglio cementation surface, or sometimes, in the case of shell structures, at the margins. Damage from tests on opaque plate or shell specimens can be examined by sectioning techniques,100, 101 but such tests are data-limited and labor-intensive. Simpler and more informative are tests on systems constructed from all-transparent materials as proxies for porcelain veneer and hard ceramic monolith or core, enabling video monitoring of fracture during an actual testing cycle. The contacting sphere can be made of hard material to represent biting on a hard object, or polymer to represent chewing on soft food.102 While it is acknowledged at the outset that flat and shell model systems of this kind neglect certain important fine details, e.g. convoluted cuspal geometry and wall thickness variations, they nevertheless provide a powerful physical basis for understanding and analyzing how clinical restorative prostheses fail.

Images of top-surface contact cracks in porcelain are shown in Fig. 3, for tests in aqueous environment. The examples include half-surface and side views of sectioned flat-surface specimens in multi-cycle axial (Fig. 3a) and tangential loading (Fig. 3b) with a hard sphere. The damage is precipitated by the inordinately high local stress concentrations around the contact,103 and is most common with low-radius spheres. The contact 'footprint' is akin to a wear facet, with near-surface microplastic and microcrack damage, which can act as a precursor to occlusal cracks, of which there are several variants.5, 101, 103 In normal loading (Fig. 3a), 'outer' and 'inner' axisymmetric 'cone' cracks (O and I cracks in Fig. 1a) initiate just outside and within the contact circle and extend deep into the subsurface. The former can occur in a single heavy cycle, and thereafter grow steadily with time under load by SCG. The latter appear only after prolonged multi-cycling, and are driven mechanically by hydraulic pumping of fluid into surface microcracks.68 In sliding loading (Fig. 3b), a tangential component skews the tensile stress field, with attendant development of asymmetric, partial cone cracks (P cracks, Fig. 1a) at the trailing edge of the contact.96, 104–107 Like inner cones, partial cones grow more rapidly in multi-cycle loading, again suggestive of some hydraulic pumping. With continued cycling at sufficiently high load, cone cracks can penetrate through a veneer layer to the core interface, or even through a monolith layer to the cementation surface, with consequent delamination. In addition, 'median' cracks (M cracks, Fig. 1a) on planes containing the load axis may extend downward from more severe surface damage zones,66, 108, 109 from contacts with small spheres or sharp points. Edge chipping (C cracks, Fig. 1a) can be considered a special case of median or cone cracking in the vicinity of a top-surface edge.110 Analogous tests on model structures reveal that chipping fracture is not abrupt, but that the crack extends steadily downward with increasing load (or number of cycles) prior to instability.110

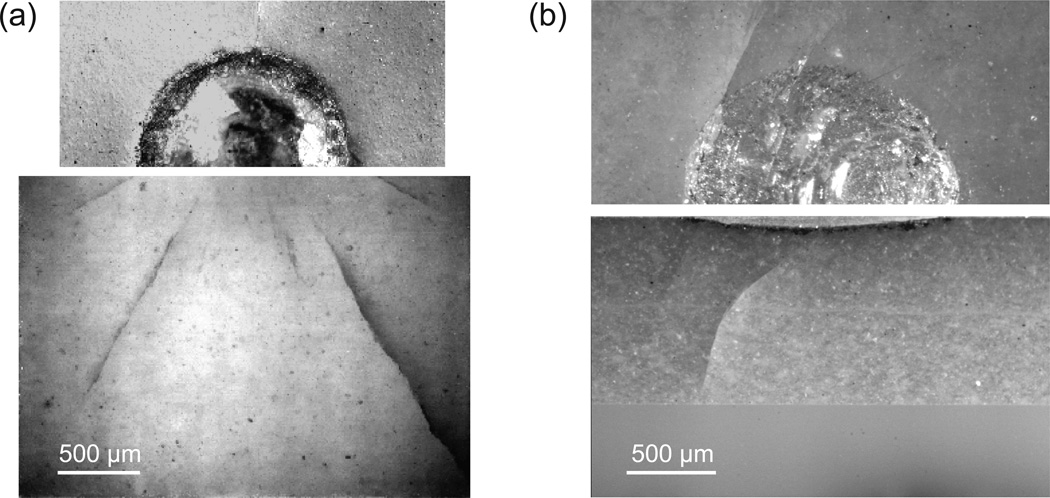

Figure 3.

Occlusal-surface damage in flat-layer porcelain specimens in contact with a hard sphere. (a) Post-indentation half-surface (top) and section view (bottom), monolith porcelain specimen (Vita Mark II, Vita Zahnfabrik) loaded axially at 5×104 cycles. Note deep-penetrating cone cracks from inner contact zone.158 (b) Post-indentation half-surface (top) and section view (bottom), flat specimen porcelain-fused-to-zirconia (LAVA, 3M ESPE) loaded tangentially at 7.8×104 cycles. Sliding direction left to right.20 Note partial cone cracks approaching porcelain/zirconia interface.

Fractures initiated away from the top-surface contact zone are shown in Fig. 4, for model transparent layer systems bonded to a dentin-like resin base. Figures 4a and 4b show side views of subsurface radial cracks (R cracks, Fig. 1a), rendered visible by interfacial interference fringes, in a glass monolith layer and glass/sapphire bilayer under load, for tests in surface loading with a hard sphere. The tensile stresses responsible for these fractures are 'flexural' in nature,85 and are much lower in magnitude than contact stresses but also much less concentrated. The radial cracks have initiated at the cementation surface beneath the contact and spread sideways and upward. Viewed from below, they are 'star-shaped' with multiple arms.87, 111 They tend to close up during unloading, causing the interference fringe patterns to disappear and thus make detection difficult. The same cracks are even harder to detect in opaque or translucent ceramics until they break through to the top surface, or until delamination occurs at either the cementation or veneer/core interface. The stress state in the shells is a little more complex.91, 112 Figures 4c and 4d show radial cracks in resin-filled glass shell structures loaded with a hard and soft sphere, respectively.91, 113 A hard contact initiates the same kind of radial cracks seen in Figs. 4a and 4b. A soft contact engulfs the top surface within a compression zone, suppressing radial cracking there and transferring tensile stresses to the margin94—the result is the same kind of longitudinal fracture, at similar failure loads, but with the cracks propagating in an opposite direction.

Figure 4.

Longitudinal fracture modes in model transparent layer structures bonded to dentin-like polymeric bases. Cracks in (a) and (b) are visible as series of interference fringes from light source. All images except (d) are in situ views with load applied axially with a hard sphere. (a) Radial crack initiated in glass layer at cementation surface.85 (b) Radial crack within sapphire core arrested at glass/sapphire interface.90 (c) Radial cracks in glass shell backfilled with epoxy resin.91 (d) Similar glass shell to (c), but now with top surface loaded off-axis with polymer disk to emulate food bolus.118 In all cases the cracks remain within a single brittle layer, increasing incrementally in size with occlusal load. Severe overload can lead to delamination or penetration into the sublayer.

In all cases in Figs. 3 and 4 the fractures remain contained within the brittle outerlayer. Once radial cracks break through the shell thickness they progress slowly but inexorably with continued cycling around the side walls, under the influence of SCG.114, 115 The ensuing full fractures have all the essential characteristics of the clinical failures depicted in Fig. 1. Even contacts that produce no evidence of surface damage in a single load cycle can lead to catastrophic crack growth over time. Severe overloads can lead to delamination or even penetration of the cracks into the dentin-like sublayer.91

2.2 Strength data

Fatigue evaluation of individual dental ceramics has been conducted using standard flexure testing methodologies. The most common method is to break flat bars or disks, and to evaluate the maximum tensile stress S ('strength') as a function of number of cycles n. The advantage of such testing is simplicity in specimen preparation and data accumulation. A useful variant is first to bond the bar or plate to a dentin-like polymer base and then load the top surface sinusoidally with a hard sphere at a specified frequency until a radial crack abruptly initiates at the cementation surface, as in the arrangement of Fig. 4a. Such a supported layer structure is one step closer to the clinical reality of crown/dentin configurations. A video camera placed beneath the bilayer specimens enables detection of radial crack initiation, even in opaque materials.111

Strength data obtained in this way are shown in Fig. 5, for fine-grain zirconia plates (Prozyr Y-TZP, Norton, East Granby, CT) of thickness 0.6 mm loaded at frequency 10 Hz.63, 67 The symbols represent intaglio surfaces subjected to different treatments: high polish (1 µm diamond paste), sandblasted (50 µm alumina particles), and pre-indented with a sharp Vickers diamond at 0.1 and 10 N (approximately 1 µm and 10 µm half-diagonal impressions, i.e. on a scale typical of linear scratching from an errant hard particle). The data points indicate individual tests, the straight lines predicted strength falloffs due exclusively to chemically-assisted crack growth, and the curved lines empirical data fits. Several conclusions may be drawn from Fig. 5: (i) polished surfaces diminish in strength by about a factor of two or more over the cyclic range (equivalent to 5 years or more at normal biting frequency), consistent with expectation from SCG; (ii) sandblasting degrades the strength of the zirconia, in this case by about a third relative to polished surfaces, indicative of the introduction of microcracks from the particle abrasion, but still consistent with SCG69; (iii) contact with individual hard particulates causes a more rapid strength drop, indicative of superposed mechanical degradation.69, 97, 116 Comparative strength tests in monotonically sustained loading over equivalent test durations show no such deviations from linear SCG predictions, providing diagnostic confirmation of a mechanical fatigue component.67

Figure 5.

Strength of dental zirconia ceramic (Prozyr Y-TZP) plates bonded to a polycarbonate base in flexural loading, as a function of cycles to failure at frequency 10 Hz. Data shown for surfaces in polished, sandblasted and point-load-indented states. Linear trendlines are in accord with degradation from chemically-assisted slow crack growth in presence of water. Downward deviations from these linear trendlines indicate superposed degradation from mechanical fatigue. From.67

These trends are representative of all dental ceramics—it is just the vertical positions on the plot that differ. Typically, the strength levels for alumina-based ceramics and lithium disilicate glass-ceramics are about one half to one third those for zirconia, while the levels for porcelain are about an order of magnitude lower.117

2.3 Lifetime data

Strength testing tells only part of the fatigue story. Crack initiation at a maximum tensile stress does not necessarily signify 'failure' of a complex clinical layer system. As demonstrated in Figs. 3 and 4, newly formed cracks arrest within the layer interior. Additional cycling, or single-cycle overload, is then required to drive the cracks to full penetration through the layer and outward to the edges or margins. It is in this context that transparent model structures such as those in Fig. 4 provide a powerful means for following all stages of fracture in cyclic loading, culminating in materials databases and predictive fracture mechanics relations that enable estimates of lifetimes for more clinically representative all-ceramic systems.12, 65, 69, 118

To illustrate, Fig. 6 plots through-section crack depth versus number of cycles for flat glass plates of thickness 1 mm bonded to a thicker dentin-like polymer base (cf. Fig. 4a) and loaded with an axial force at its top surface by a hard sphere at frequency 1 Hz.65, 66 The surfaces of the glass plate were abraded with SiC grit (analogous to flaws and defects in porcelain) to provide starting flaws for the fractures. Figure 6a plots growth behavior for downward-extending cracks initiating at the top surface—outer and inner cone cracks and median cracks in axial loading, partial cones in sliding loading. Figure 6b shows behavior for upward-extending radial cracks initiating at the intaglio surface. Vertical portions of some of the lines indicate abrupt initiation at later stages of the cycling. For reference, the line for outer cone cracks in Fig. 6a is entirely consistent with SCG, indicated by the dashed line. Inner cones and median cracks do not initiate until much later in the cyclic history, but then overtake the outer cones with accelerated penetration. In sliding contact, partial cones initiate much earlier, and lead to even more premature failure. The strong upward deviation of the inner and partial cone and median cracks from the trendline for outer cone cracks is indicative of a mechanical component in the fatigue response. The subsurface radial cracks in Fig. 6b also initiate later in the cyclic history, but then extend nearly parallel to the SCG trendline in Fig. 6a.

Figure 6.

Crack depth through layer section versus number of cycles for a monolith flat glass plate of thickness 1 mm bonded to a thicker polycarbonate base and loaded with an axial force 120 N at its top surface with a hard sphere of radius 1.6 mm at frequency 1 Hz (cf. Fig. 4a). (a) Cone and median cracks initiated at glass top surface. (b) Radial cracks initiated at glass bottom surface. Solid inclined line indicates expected growth rate due solely to SCG, for token crack initiated to depth 0.5 mm on first cycle. Vertical dashed lines indicate abrupt initiation stages.66

In all cases in Fig. 6, there is substantial stable crack extension between crack initiation and final layer penetration, meaning that even well-developed cracks can be contained within the structure during the oral history. Such plots usefully demonstrate the interplay between different fracture modes. A mode that dominates in single-cycle loading can be completely overtaken by a competing mode after continued cycling. The absolute and even relative positions of these curves can shift around with changes in biting force, material system, internal residual stress states, and layer thickness, with resultant crossovers in dominant fracture mode.65, 69, 118 In actual curved-surface prostheses, post-initiation fracture stability becomes less pronounced with declining smaller tooth size, until ultimately failure may occur spontaneously from a newly initiated crack, i.e. without the stable phase.91, 113 The testing methodology is readily extended to trilayers, with the critical crack configuration now defined by intersection with the internal veneer/core interface (e.g. Fig. 4b).12 Top-surface veneer cracks can then cause delamination at the interface, while bottom-surface core cracks are more likely to penetrate abruptly across the interface into the veneer.119 In the context of prosthetic failures, little of the complex crack history evident in data sets such as those in Fig. 6 is amenable to inference from in vivo inspection of outer surfaces or ex vivo inspection of remaining parts, and certainly not from any single-cycle tests.

Data such as those in Fig. 6, in combination with fracture mechanics and finite element modeling, facilitate the derivation of explicit relations for critical bite forces for full layer penetration in terms of important clinical material properties (notably elastic modulus and toughness) and geometrical dimensions (contact dimensions, layer thickness, curvature).12, 65, 66, 69, 112, 118, 120 These relations, in conjunction with data extrapolations, enable lifetime predictions for any given clinically relevant ceramic layer configuration to be plotted on 'damage maps' as critical number of cycles versus bite force. Examples are shown in Figs. 7a and 7b for flat porcelain-veneered lithium disilicate and zirconia ceramic layers cemented to a dentin base (porcelain thickness 1 mm), and in Figs. 7c and 7d for their lithium disilicate and zirconia monolith counterparts, in each case with net layer thickness 1.5 mm and axial loading with opposing porcelain or enamel surface of radius 5 mm. The linear plots represent occlusal surface cone cracks and cementation subsurface radial cracks, all showing progressive declines in sustainable bite forces with increasing cycling. In the case of the veneered layers, failure is dominated by cone cracks, with a switch from outer to inner at longer cycling times. In the monoliths, no plots are shown for cone cracks, since none form at all at the load range and sphere size represented, meaning that radial cracks comprise the more likely source of fracture. With due acknowledgement of approximations in the analyses and uncertainties in fracture parameters, estimates of critical biting forces over any given number of cycles are probably not more accurate than ± 25%. Again, the curves in Fig. 7 will shift around with changes in key material and geometric variables (Sect. 4). Notwithstanding these caveats, fracture maps of the kind in Fig. 7 provide valuable quantitative insight into the prospective lifetimes of prescribed material systems.

Figure 7.

Bite force to penetrate layer thickness versus number of cycles for flat layer structures of net thickness 1.5 mm bonded to dentin and loaded axially with a porcelain sphere (or opposing tooth) of radius 5 mm. Trendlines evaluated from fracture mechanics lifetime equations, in conjunction with data extrapolation from Fig. 6.118 Estimates for (a) lithium disilicate and (b) zirconia cores veneered with 1 mm porcelain, and (c) lithium disilicate and (d) zirconia monoliths. Trendlines can shift according to key material and geometrical conditions.

The data in Fig. 7 correspond to normal loading along a tooth axis with a relatively blunt contact. Loading with a sphere of smaller radius is not likely to shift the radial crack plots substantially, but can exacerbate the onset of microplasticity at the top surface, with consequent increased likelihood of median cracking and accelerated wear (see Sect. 3). Superposition of a sliding component can produce partial cones and biting on a hard contact can induce median cracks (Fig. 6a), each of which can dominate the failure process under certain conditions. Not specifically represented in Figs. 6 and 7 is edge chipping, from loading with a sharp point close to the side wall of a prosthesis. While no systematic fatigue data appear to have been reported for chipping fracture, we may expect similar falloffs in critical bite force with cycling as in Fig. 7, i.e. a reduction of two or three over an equivalent loading year. Data for the critical bite force to induce chipping fracture from a hard, sharp contact in single-cycle loading are shown for selected dental ceramics in Fig. 8.110, 121 For small edge distances, critical force levels can be much lower than those for axial fracture modes, especially in porcelains, accounting for the prevalence of chipping in veneered restorations.

Figure 8.

Critical bite forces to form chipping fractures from sharp contacts in dental ceramic materials, as function of distance from side wall. Lines from chipping equations from fits to data on flat monolith and anatomically-correct crown specimens.110,121 The relative locations of the lines highlight the toughness of zirconia ceramics and weakness of porcelains, with alumina and lithium disilicate intermediate.

3. Discussion

The fracture mechanics approach advocated here offers a uniquely powerful base for evaluating fatigue properties of dental ceramics, with clear physical insight into a multitude of fracture modes. These competing modes have gone largely unconsidered in the dental community. The dental materials literature is replete with strength data from standardized single-cycle flexure tests on bar or disk specimens. Strength tests can be differently done, and some of the protocols may resemble the clinical situation more closely than others, but this does not mean that any one method is better—all can provide useful means of ranking materials. However, such tests do not come close to representing the long-term behavior of real prostheses. Single-cycle strength tests provide information only at the left axis of S–n diagrams such as Fig. 5, and therefore exclude information on those more deleterious fracture modes governed by mechanical degradation at later stages of cycling. Even S–n diagrams are limited in their usefulness, especially in crown configurations where the tensile stress states consist of a complex mixture of contact, flexural and membrane components and are sufficiently inhomogeneous as to cause newly initiated cracks to undergo the stages of arrest and stable propagation evident in Fig. 6. Simulated 'crunch-the-crown' tests with hard indenters, analogous to those represented in Figs. 3 and 4, take us a step closer to real restoration geometries, although proper caution needs to be exercised in linking laboratory observations to clinical situations 24. The widely popular techniques of finite element modeling can usefully map out such complex stress states, but are inadequate to account for the stable fracture phase without the laborious incorporation of crack extension subroutines into the code.113, 122, 123 Nor can fractographic studies, so useful in identifying fracture origins, reveal much about the complex route from crack initiation to ultimate failure. Ideally, evaluations of lifetimes ultimately rest with tests on anatomically-correct specimens under conditions that replicate actual oral function, such as those in mouth-motion simulators,81, 82, 95, 124, 125 but these offer limited insight into the roles of the many controlling fatigue variables.

Lifetime fracture maps of the kind shown in Fig. 7, as well as delineating the regions of dominance for different fracture modes, provide guidelines for designing dental ceramic systems. In porcelain-veneered structures with lithium disilicate (Fig. 7a) and zirconia (Fig. 7b) cores, occlusal surface cracks (particularly inner cones) are dominant over the cycle range. In lithium disilicate monolith (Fig. 7c) and zirconia monoliths (Fig. 7d), radial (or margin) fracture dominates. Generally, zirconia-based monolithic or veneered structures are more damage resistant than are glass–ceramic-based, reflecting a higher toughness for the former material. Veneered structures have inferior lifetime characteristics relative to monoliths, partly because the weak porcelain is more susceptible to surface cracking and partly because the cracks have a smaller thickness to traverse to an interface. An important requirement in design is to maintain the lifetime trendlines above the range of natural bite forces, with maxima estimated variously between 100 N and 600 N.95, 126, 127 The veneered structures in Figs. 7c and 7d come close to violating this requirement, especially if porcelain chipping is factored in, indicative of an inherently vulnerable system.

Given our emphasis on mechanical fatigue in the long-term response of dental ceramics, some comment on the physical nature of the responsible mechanisms is called for. Mechanical degradation can manifest itself in periodic flexure testing, as in the S–n data in Fig. 5. For surfaces subject to point-contact damage, strength loss is due to degradation from internal friction followed by microcracking at weak interfaces within a near-surface damage zone.103, 128, 129 More pronounced mechanical fatigue occurs once the cracks enter the stage of stable propagation, e.g. in the c–n crack growth data for inner or partial cone and median cracks in Fig. 6. The principal underlying mechanism is then hydraulic pumping of aqueous solution into the fissures,68 a kind of 'fracking'. A simple diagnostic in traditional fatigue testing for distinguishing mechanical from chemical (SCG) processes is to compare c–n data obtained in cyclic versus steady or monotonic loading over comparable test durations: in single-cycle loading, outer cone and radial crack data sets remain parallel to the SCG growth trendlines, while inner and partial cone cracks and (usually) median cracks do not appear at all.68

The bioengineering approach to lifetime evaluations described herein provides a strong physical basis for designing next-generation materials for dental prostheses. The key is a sound understanding of the roles of material and geometrical variables in damage accumulation in repetitive loading. Changes in these variables are manifested as shifts of different segments in the trendlines of Fig. 7. Materials design involves balancing several factors, which have been documented in the literature: (i) material properties,3, 12, 61, 65, 69, 91, 118, 130–136 (ii) microstructure,1, 10, 137–140 (iii) residual stresses,13, 15, 16, 135, 141–145 (iv) monolithic versus veneered structures,18, 19, 21, 22, 146 (v) layer thickness,12, 65, 90, 135, 147, (vi) tooth contact conditions,12, 65, 66, 94, 148 (vii) tooth size and shape,91, 149 (viii) dentine, enamel and adhesive modulus,86, 150–157 (ix) surface state.63, 69, 91

4. Conclusions

Model layer structures loaded with spherical indenters enable identification of clinically relevant fracture modes in layered dental prosthetic structures. Some of these modes are not easily inferred from conventional post-mortem examinations of failed parts.

Ceramics are susceptible to loss of load-bearing capacity in cyclic loading, i.e. fatigue, amounting to declines in strength or critical bite force amounting to a factor of 2 or more over an equivalent one-year biting history.

Part of fatigue is due to well-documented chemically-assisted slow crack growth (SCG), but more deleterious is degradation by mechanical processes such as hydraulic pumping and internal friction at microcrack walls. Some fractures, most notably inner cone cracks, do not appear at all in static or monotonic loading.

Strength tests in cyclic flexure provide information on the stresses needed to initiate cracks, but are restrictive in information relating subsequent stable crack growth to ultimate failure.

In situ fracture tests on transparent layer structures, coupled with rigorous fracture mechanics analysis of crack extension from initiation through stable growth to failure, facilitate construction of lifetime damage maps for common prosthetic material combinations.

Monolith structures are more resilient than their veneered counterparts. Zirconia is the most fatigue-resistant of the current dental ceramics.

Acknowledgements

Funding was provided by the United States National Institute of Dental and Craniofacial Research (Grant 2R01 DE017925), National Science Foundation (Grant CMMI-0758530), and by NIST. Thanks are due to Petra Guess, Christian Stappert, and Kenneth Malament for providing images for Fig. 2.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- 1.Kelly JR. Dental ceramics: current thinking and trends. Dental Clinics of North America. 2004;48:513–530. doi: 10.1016/j.cden.2004.01.003. [DOI] [PubMed] [Google Scholar]

- 2.Rekow D, Thompson VP. Engineering long term clinical success of advanced ceramic prostheses. Journal of Materials Science: Materials in Medicine. 2007;18:47–56. doi: 10.1007/s10856-006-0661-1. [DOI] [PubMed] [Google Scholar]

- 3.Giordano R, McLaren EA. Ceramics overview: classification by microstructure and processing methods. Compendium of Continuing Education in Dentistry. 2010;31:682–684. 6, 8 passim; quiz 98, 700. [PubMed] [Google Scholar]

- 4.Giordano RA. Dental ceramic restorative systems. Compendium of Continuing Education in Dentistry. 1996;17:779–782. 84–6 passim; quiz 94. [PubMed] [Google Scholar]

- 5.Peterson IM, Pajares A, Lawn BR, Thompson VP, Rekow ED. Mechanical characterization of dental ceramics by Hertzian contacts. Journal of Dental Research. 1998;77:589–602. doi: 10.1177/00220345980770041201. [DOI] [PubMed] [Google Scholar]

- 6.Peterson IM, Wuttiphan S, Lawn BR, Chyung K. Role of microstructure on contact damage and strength degradation of micaceous glass-ceramics. Dental Materials. 1998;14:80–89. doi: 10.1016/s0109-5641(98)00013-x. [DOI] [PubMed] [Google Scholar]

- 7.Scherrer SS, Kelly JR, Quinn GD, Xu K. Fracture toughness (K Ic) of a dental porcelain determined by fractographic analysis. Dental Materials. 1999;15:342–348. doi: 10.1016/s0109-5641(99)00055-x. [DOI] [PubMed] [Google Scholar]

- 8.Denry I, Kelly JR. State of the art of zirconia for dental applications. Dental Materials. 2008;24:299–307. doi: 10.1016/j.dental.2007.05.007. [DOI] [PubMed] [Google Scholar]

- 9.Holand W, Rheinberger V, Apel E, van 't Hoen C, Holand M, Dommann A, et al. Clinical applications of glass-ceramics in dentistry. Journal of Materials Science: Materials in Medicine. 2006;17:1037–1042. doi: 10.1007/s10856-006-0441-y. [DOI] [PubMed] [Google Scholar]

- 10.Holand W, Kappert H, Peschke A, Schweiger M, Watzke R. Ceramics as biomaterials for dental restoration. Expert Review of Medical Devices. 2008;5:729–745. doi: 10.1586/17434440.5.6.729. [DOI] [PubMed] [Google Scholar]

- 11.Heintze SD, Rousson V. Survival of zirconia- and metal-supported fixed dental prostheses: a systematic review. The International Journal of Prosthodontics. 2010;23:493–502. [PubMed] [Google Scholar]

- 12.Hermann I, Bhowmick S, Zhang Y, Lawn BR. Competing fracture modes in brittle materials subject to concentrated cyclic loading in liquid environments: trilayer structures. Journal of Materials Research. 2006;21:512–521. [Google Scholar]

- 13.Swain MV. Unstable cracking (chipping) of veneering porcelain on all-ceramic dental crowns and fixed partial dentures. Acta Biomaterialia. 2009;5:1668–1677. doi: 10.1016/j.actbio.2008.12.016. [DOI] [PubMed] [Google Scholar]

- 14.Mainjot AK, Schajer GS, Vanheusden AJ, Sadoun MJ. Residual stress measurement in veneering ceramic by hole-drilling. Dental materials. 2011;27:439–444. doi: 10.1016/j.dental.2010.12.002. [DOI] [PubMed] [Google Scholar]

- 15.Baldassarri M, Stappert CF, Wolff MS, Thompson VP, Zhang Y. Residual stresses in porcelain-veneered zirconia prostheses. Dental materials. 2012;28:873–879. doi: 10.1016/j.dental.2012.04.019. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Meira JB, Reis BR, Tanaka CB, Ballester RY, Cesar PF, Versluis A, et al. Residual stresses in Y-TZP crowns due to changes in the thermal contraction coefficient of veneers. Dental materials. 2013;29:594–601. doi: 10.1016/j.dental.2013.03.012. [DOI] [PubMed] [Google Scholar]

- 17.Holand W, Schweiger M, Frank M, Rheinberger V. A comparison of the microstructure and properties of the IPS Empress 2 and the IPS Empress glass-ceramics. Journal of Biomedical Materials Research. 2000;53:297–303. doi: 10.1002/1097-4636(2000)53:4<297::aid-jbm3>3.0.co;2-g. [DOI] [PubMed] [Google Scholar]

- 18.Zhang Y, Kim JW. Graded structures for damage resistant and aesthetic all-ceramic restorations. Dental materials. 2009;25:781–790. doi: 10.1016/j.dental.2009.01.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Zhang Y, Chai H, Lawn BR. Graded structures for all-ceramic restorations. Journal of Dental Research. 2010;89:417–421. doi: 10.1177/0022034510363245. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Zhang Y, Kim JW. Graded zirconia glass for resistance to veneer fracture. Journal of Dental Research. 2010;89:1057–1062. doi: 10.1177/0022034510375289. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Zhang Y, Sun MJ, Zhang D. Designing functionally graded materials with superior load-bearing properties. Acta Biomaterialia. 2012;8:1101–1108. doi: 10.1016/j.actbio.2011.11.033. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Zhang Y. Overview: damage resistance of graded ceramic restorative materials. Journal of the European Ceramic Society. 2012;32:2623–2632. doi: 10.1016/j.jeurceramsoc.2012.02.020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Sailer I, Gottnerb J, Kanelb S, Hammerle CH. Randomized controlled clinical trial of zirconia-ceramic and metal-ceramic posterior fixed dental prostheses: a 3-year follow-up. The International Journal of Prosthodontics. 2009;22:553–560. [PubMed] [Google Scholar]

- 24.Kelly JR. Clinically relevant approach to failure testing of all-ceramic restorations. The Journal of Prosthetic Dentistry. 1999;81:652–661. doi: 10.1016/s0022-3913(99)70103-4. [DOI] [PubMed] [Google Scholar]

- 25.Malament KA, Socransky SS. Survival of Dicor glass-ceramic dental restorations over 14 years. Part II: effect of thickness of Dicor material and design of tooth preparation. The Journal of Prosthetic Dentistry. 1999;81:662–667. doi: 10.1016/s0022-3913(99)70104-6. [DOI] [PubMed] [Google Scholar]

- 26.Malament KA, Socransky SS. Survival of Dicor glass-ceramic dental restorations over 14 years: Part I. Survival of Dicor complete coverage restorations and effect of internal surface acid etching, tooth position, gender, and age. The Journal of Prosthetic Dentistry. 1999;81:23–32. doi: 10.1016/s0022-3913(99)70231-3. [DOI] [PubMed] [Google Scholar]

- 27.Malament KA, Socransky SS. Survival of Dicor glass-ceramic dental restorations over 16 years. Part III: effect of luting agent and tooth or tooth-substitute core structure. The Journal of Prosthetic Dentistry. 2001;86:511–519. doi: 10.1067/mpr.2001.119415. [DOI] [PubMed] [Google Scholar]

- 28.Esquivel-Upshaw JF, Young H, Jones J, Yang M, Anusavice KJ. Four-year clinical performance of a lithia disilicate-based core ceramic for posterior fixed partial dentures. The International Journal of Prosthodontics. 2008;21:155–160. [PubMed] [Google Scholar]

- 29.Sax C, Hammerle CH, Sailer I. 10-year clinical outcomes of fixed dental prostheses with zirconia frameworks. International Journal of Computerized Dentistry. 2011;14:183–202. [PubMed] [Google Scholar]

- 30.Kern M, Sasse M, Wolfart S. Ten-year outcome of three-unit fixed dental prostheses made from monolithic lithium disilicate ceramic. The Journal of the American Dental Association. 2012;143:234–240. doi: 10.14219/jada.archive.2012.0147. [DOI] [PubMed] [Google Scholar]

- 31.Schmitter M, Mussotter K, Rammelsberg P, Gabbert O, Ohlmann B. Clinical performance of long-span zirconia frameworks for fixed dental prostheses: 5-year results. Journal of Oral Rehabilitation. 2012;39:552–557. doi: 10.1111/j.1365-2842.2012.02311.x. [DOI] [PubMed] [Google Scholar]

- 32.Oden A, Andersson M, Krystek-Ondracek I, Magnusson D. Five-year clinical evaluation of Procera AllCeram crowns. The Journal of Prosthetic Dentistry. 1998;80:450–456. doi: 10.1016/s0022-3913(98)70010-1. [DOI] [PubMed] [Google Scholar]

- 33.Taskonak B, Sertgoz A. Two-year clinical evaluation of lithia-disilicate-based all-ceramic crowns and fixed partial dentures. Dental Materials. 2006;22:1008–1013. doi: 10.1016/j.dental.2005.11.028. [DOI] [PubMed] [Google Scholar]

- 34.Marquardt P, Strub JR. Survival rates of IPS empress 2 all-ceramic crowns and fixed partial dentures: results of a 5-year prospective clinical study. Quintessence International. 2006;37:253–259. [PubMed] [Google Scholar]

- 35.Sailer I, Feher A, Filser F, Gauckler LJ, Luthy H, Hammerle CH. Five-year clinical results of zirconia frameworks for posterior fixed partial dentures. The International Journal of Prosthodontics. 2007;20:383–388. [PubMed] [Google Scholar]

- 36.Valenti M, Valenti A. Retrospective survival analysis of 261 lithium disilicate crowns in a private general practice. Quintessence International. 2009;40:573–579. [PubMed] [Google Scholar]

- 37.Wolfart S, Eschbach S, Scherrer S, Kern M. Clinical outcome of three-unit lithium-disilicate glass-ceramic fixed dental prostheses: up to 8 years results. Dental Materials. 2009;25:e63–e71. doi: 10.1016/j.dental.2009.05.003. [DOI] [PubMed] [Google Scholar]

- 38.Larsson C, Vult von Steyern P. Five-year follow-up of implant-supported Y-TZP and ZTA fixed dental prostheses. A randomized, prospective clinical trial comparing two different material systems. The International Journal of Prosthodontics. 2010;23:555–561. [PubMed] [Google Scholar]

- 39.Beuer F, Stimmelmayr M, Gernet W, Edelhoff D, Guh JF, Naumann M. Prospective study of zirconia-based restorations: 3-year clinical results. Quintessence International. 2010;41:631–637. [PubMed] [Google Scholar]

- 40.Roediger M, Gersdorff N, Huels A, Rinke S. Prospective evaluation of zirconia posterior fixed partial dentures: four-year clinical results. The International Journal of Prosthodontics. 2010;23:141–148. [PubMed] [Google Scholar]

- 41.Etman MK, Woolford MJ. Three-year clinical evaluation of two ceramic crown systems: a preliminary study. The Journal of Prosthetic Dentistry. 2010;103:80–90. doi: 10.1016/S0022-3913(10)60010-8. [DOI] [PubMed] [Google Scholar]

- 42.Crisp RJ, Cowan AJ, Lamb J, Thompson O, Tulloch N, Burke FJ. A clinical evaluation of all-ceramic bridges placed in patients attending UK general dental practices: three-year results. Dental Materials. 2012;28:229–236. doi: 10.1016/j.dental.2010.12.004. [DOI] [PubMed] [Google Scholar]

- 43.Larsson C, Vult Von Steyern P. Implant-supported full-arch zirconia-based mandibular fixed dental prostheses. Eight-year results from a clinical pilot study. Acta Odontologica Scandinavica. 2013;71:1118–1122. doi: 10.3109/00016357.2012.749518. [DOI] [PubMed] [Google Scholar]

- 44.Ortorp A, Kihl ML, Carlsson GE. A 5-year retrospective study of survival of zirconia single crowns fitted in a private clinical setting. Journal of Dentistry. 2012;40:527–530. doi: 10.1016/j.jdent.2012.02.011. [DOI] [PubMed] [Google Scholar]

- 45.Raigrodski AJ, Yu A, Chiche GJ, Hochstedler JL, Mancl LA, Mohamed SE. Clinical efficacy of veneered zirconium dioxide-based posterior partial fixed dental prostheses: five-year results. The Journal of Prosthetic Dentistry. 2012;108:214–222. doi: 10.1016/S0022-3913(12)60165-6. [DOI] [PubMed] [Google Scholar]

- 46.Reich S, Schierz O. Chair-side generated posterior lithium disilicate crowns after 4 years. Clinical Oral Investigations. 2013;17:1765–1772. doi: 10.1007/s00784-012-0868-0. [DOI] [PubMed] [Google Scholar]

- 47.Rinke S, Schafer S, Lange K, Gersdorff N, Roediger M. Practice-based clinical evaluation of metal-ceramic and zirconia molar crowns: 3-year results. Journal of Oral Rehabilitation. 2013;40:228–237. doi: 10.1111/joor.12018. [DOI] [PubMed] [Google Scholar]

- 48.Gehrt M, Wolfart S, Rafai N, Reich S, Edelhoff D. Clinical results of lithium-disilicate crowns after up to 9 years of service. Clinical Oral Investigations. 2013;17:275–284. doi: 10.1007/s00784-012-0700-x. [DOI] [PubMed] [Google Scholar]

- 49.Wiederhorn SM, Bolz LH. Stress corrosion and static fatigue of glass. Journal of the American Ceramic Society. 1970;53:543–548. [Google Scholar]

- 50.Wiederhorn SM. Subcritical crack growth in ceramics. In: Bradt RC, Lange FF, Hasselman DPH, editors. Fracture Mechanics of Ceramics. Vol. 2. New York: Plenum Press; 1974. pp. 613–646. [Google Scholar]

- 51.Morena R, Beaudreau GM, Lockwood PE, Evans AL, Fairhurst CW. Fatigue of dental ceramics in a simulated oral environment. Journal of Dental Research. 1986;65:993–997. doi: 10.1177/00220345860650071901. [DOI] [PubMed] [Google Scholar]

- 52.Fairhurst CW, Lockwood PE, Ringle RD, Twiggs SW. Dynamic fatigue of feldspathic porcelain. Dental Materials. 1993;9:269–273. doi: 10.1016/0109-5641(93)90073-y. [DOI] [PubMed] [Google Scholar]

- 53.White SN, Zhao XY, Zhaokun Y, Li ZC. Cyclic mechanical fatigue of a feldspathic dental porcelain. The International Journal of Prosthodontics. 1995;8:413–420. [PubMed] [Google Scholar]

- 54.Pan LS, Matsuzawa M, Horibe S. Stress rate dependence of fracture strength in pre-cracked zirconia ceramics. Materials Science and Engineering: A. 1998;244:199–206. [Google Scholar]

- 55.Studart AR, Filser F, Kocher P, Gauckler LJ. In vitro lifetime of dental ceramics under cyclic loading in water. Biomaterials. 2007;28:2695–2705. doi: 10.1016/j.biomaterials.2006.12.033. [DOI] [PubMed] [Google Scholar]

- 56.Taskonak B, Griggs JA, Mecholsky JJ, Jr, Yan JH. Analysis of subcritical crack growth in dental ceramics using fracture mechanics and fractography. Dental Materials. 2008;24:700–707. doi: 10.1016/j.dental.2007.08.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 57.Mitov G, Lohbauer U, Rabbo MA, Petschelt A, Pospiech P. Investigations of subcritical crack propagation of the Empress 2 all-ceramic system. Dental Materials. 2008;24:267–273. doi: 10.1016/j.dental.2007.05.010. [DOI] [PubMed] [Google Scholar]

- 58.Gonzaga CC, Cesar PF, Miranda WG, Jr, Yoshimura HN. Slow crack growth and reliability of dental ceramics. Dental Materials. 2011;27:394–406. doi: 10.1016/j.dental.2010.10.025. [DOI] [PubMed] [Google Scholar]

- 59.Griggs JA, Alaqeel SM, Zhang Y, Miller AW, 3rd, Cai Z. Effects of stress rate and calculation method on subcritical crack growth parameters deduced from constant stress-rate flexural testing. Dental Materials. 2011;27:364–370. doi: 10.1016/j.dental.2010.11.016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 60.Mitov G, Gessner J, Lohbauer U, Woll K, Muecklich F, Pospiech P. Subcritical crack growth behavior and life data analysis of two types of dental Y-TZP ceramics. Dental Materials. 2011;27:684–691. doi: 10.1016/j.dental.2011.03.010. [DOI] [PubMed] [Google Scholar]

- 61.Lawn BR. Second ed. Cambridge: Cambridge University Press; 1993. Fracture of Brittle Solids. [Google Scholar]

- 62.Wiederhorn SM. Dependence of lifetime predictions on the form of the crack propagation equation. In: Taplin DMR, editor. Fracture 1977: Fourth International Conference on Fracture. Vol. 3. Waterloo, Canada: University of Waterloo Press; 1977. pp. 893–902. [Google Scholar]

- 63.Zhang Y, Lawn BR, Rekow ED, Thompson VP. Effect of sandblasting on the long-term performance of dental ceramics. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2004;71:381–386. doi: 10.1002/jbm.b.30097. [DOI] [PubMed] [Google Scholar]

- 64.Zhang Y, Pajares A, Lawn BR. Fatigue and damage tolerance of Y-TZP ceramics in layered biomechanical systems. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2004;71:166–171. doi: 10.1002/jbm.b.30083. [DOI] [PubMed] [Google Scholar]

- 65.Bhowmick S, Zhang Y, Lawn BR. Competing fracture modes in brittle materials subject to concentrated cyclic loading in liquid environments: bilayer structures. Journal of Materials Research. 2005;20:2792–2800. [Google Scholar]

- 66.Zhang Y, Bhowmick S, Lawn BR. Competing fracture modes in brittle materials subject to concentrated cyclic loading in liquid environments: monoliths. Journal of Materials Research. 2005;20:2021–2029. [Google Scholar]

- 67.Zhang Y, Lawn BR. Fatigue sensitivity of Y-TZP to microscale sharp-contact flaws. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2005;72:388–392. doi: 10.1002/jbm.b.30174. [DOI] [PubMed] [Google Scholar]

- 68.Zhang Y, Song JK, Lawn BR. Deep-penetrating conical cracks in brittle layers from hydraulic cyclic contact. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2005;73:186–193. doi: 10.1002/jbm.b.30195. [DOI] [PubMed] [Google Scholar]

- 69.Zhang Y, Lawn BR, Malament KA, Van Thompson P, Rekow ED. Damage accumulation and fatigue life of particle-abraded ceramics. The International Journal of Prosthodontics. 2006;19:442–448. [PubMed] [Google Scholar]

- 70.Scherrer SS, Quinn JB, Quinn GD, Wiskott HW. Fractographic ceramic failure analysis using the replica technique. Dental Materials. 2007;23:1397–1404. doi: 10.1016/j.dental.2006.12.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 71.Denry I. How and when does fabrication damage adversely affect the clinical performance of ceramic restorations? Dental Materials. 2013;29:85–96. doi: 10.1016/j.dental.2012.07.001. [DOI] [PubMed] [Google Scholar]

- 72.Cho S-J, Hockey BJ, Lawn BR, Bennison SJ. Grain-size and R-curve effects in the abrasive wear of alumina. Journal of the American Ceramic Society. 1989;72:1249–1252. [Google Scholar]

- 73.Xu HHK, Jahanmir S. Simple technique for observing subsurface damage in machining of ceramics. Journal of the American Ceramic Society. 1994;77:1388–1390. [Google Scholar]

- 74.Kim JW, Kim JH, Thompson VP, Zhang Y. Sliding contact fatigue damage in layered ceramic structures. Journal of Dental Research. 2007;86:1046–1050. doi: 10.1177/154405910708601105. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 75.Bodecker CF. Enamel of the teeth decalified by the celloidin method and examined with ultra-violet light. Dental Reviews. 1906;20:317–337. [Google Scholar]

- 76.Sognnaes RF. The organic elements of the enamel; the gross morphology and the histological relationship of the lamellae to the organic framework of the enamel. Journal of Dental Research. 1950;29:260–269. doi: 10.1177/00220345500290030201. [DOI] [PubMed] [Google Scholar]

- 77.Bodecker CF. Enamel lamellae and their origin. Journal of Dental Research. 1953;32:239–245. doi: 10.1177/00220345530320021301. [DOI] [PubMed] [Google Scholar]

- 78.Osborn JW. Dental Tissues. In: JW Osborn., editor. Dental Anatomy and Embryology. Oxford: Blackwell; 1981. [Google Scholar]

- 79.von Koenigswald W, Rensberger JM, Pretzschner HU. Changes in the tooth enamel of early paleocene mammals allowing increased diet diversity. Nature. 1987;328:150–152. doi: 10.1038/328150a0. [DOI] [PubMed] [Google Scholar]

- 80.Zhang Y, Chai H, Lee JJ, Lawn BR. Chipping resistance of graded zirconia ceramics for dental crowns. Journal of Dental Research. 2012;91:311–315. doi: 10.1177/0022034511434356. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 81.Guess PC, Bonfante EA, Silva NRFA, Coelho PG, Thompson VP. Effect of core design and veneering technique on damage and reliability of Y-TZP-supported crowns. Dental Materials. 2013;29:307–316. doi: 10.1016/j.dental.2012.11.012. [DOI] [PubMed] [Google Scholar]

- 82.Baldassarri M, Zhang Y, Thompson VP, Rekow ED, Stappert CF. Reliability and failure modes of implant-supported zirconium-oxide fixed dental prostheses related to veneering techniques. Journal of Dentistry. 2011;39:489–498. doi: 10.1016/j.jdent.2011.04.006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 83.Wuttiphan S, Lawn BR, Padture NP. Crack suppression in strongly-bonded homogeneous/heterogeneous laminates: a study on glass/glass-ceramic bilayers. Journal of the American Ceramic Society. 1996;79:634–640. [Google Scholar]

- 84.Jung YG, Wuttiphan S, Peterson IM, Lawn BR. Damage modes in dental layer structures. Journal of Dental Research. 1999;78:887–897. doi: 10.1177/00220345990780040901. [DOI] [PubMed] [Google Scholar]

- 85.Chai H, Lawn BR, Wuttiphan S. Fracture modes In brittle coatings with large interlayer modulus mismatch. Journal of Materials Research. 1999;14:3805–3817. [Google Scholar]

- 86.Lee KS, Rhee Y-W, Blackburn DH, Lawn BR, Chai H. Cracking of brittle coatings adhesively bonded to substrates of unlike modulus. Journal of Materials Research. 2000;15:1653–1656. [Google Scholar]

- 87.Deng Y, Lawn BR, Lloyd IK. Characterization of damage modes in dental ceramic bilayer structures. Journal of Biomedical Materials Research. 2002;63:137–145. doi: 10.1002/jbm.10091. [DOI] [PubMed] [Google Scholar]

- 88.Lawn BR, Deng Y, Lloyd IK, Janal MN, Rekow ED, Thompson VP. Materials design of ceramic-based layer structures for crowns. Journal of Dental Research. 2002;81:433–448. doi: 10.1177/154405910208100615. [DOI] [PubMed] [Google Scholar]

- 89.Lawn BR, Deng Y, Miranda P, Pajares A, Chai H, Kim DK. Overview: damage in brittle layer structures from concentrated loads. Journal of Materials Research. 2002;17:3019–3036. [Google Scholar]

- 90.Deng Y, Miranda P, Pajares A, Guiberteau F, Lawn BR. Fracture of ceramic/ceramic/polymer trilayers for biomechanical applications. Journal of Biomedical Materials Research Part A. 2003;67:828–833. doi: 10.1002/jbm.a.10161. [DOI] [PubMed] [Google Scholar]

- 91.Qasim T, Bush MB, Hu X, Lawn BR. Contact damage in brittle coating layers: influence of surface curvature. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2005;73:179–185. doi: 10.1002/jbm.b.30188. [DOI] [PubMed] [Google Scholar]

- 92.Qasim T, Bush MB, Hu X-Z. The influence of complex surface geometry on contact damage in curved brittle coatings. International Journal of Mechanical Sciences. 2006;48:244–248. [Google Scholar]

- 93.Qasim T, Ford C, Bush MB, Hu X, Lawn BR. Effect of off-axis concentrated loading on failure of curved brittle layer structures. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2006;76:334–339. doi: 10.1002/jbm.b.30373. [DOI] [PubMed] [Google Scholar]

- 94.Qasim T, Ford C, Bush MB, Hu X, Malament KA, Lawn BR. Margin failures in brittle dome structures: relevance to failure of dental crowns. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2007;80:78–85. doi: 10.1002/jbm.b.30571. [DOI] [PubMed] [Google Scholar]

- 95.DeLong R, Douglas WH. Development of an artificial oral environment for the testing of dental restoratives: bi-axial force and movement control. Journal of Dental Research. 1983;62:32–36. doi: 10.1177/00220345830620010801. [DOI] [PubMed] [Google Scholar]

- 96.Zhang Y, Kim JW, Kim JH, Lawn BR. Fatigue damage in ceramic coatings from cyclic contact loading with a tangential component. Journal of the American Ceramic Society. 2008;91:198–202. [Google Scholar]

- 97.Guiberteau F, Padture N, Cai H, BR L. Indentation fatigue: a simple cyclic Hertzian test for measuring damage accumulation in polycrystalline ceramics. Philosophical Magazine. 1993:1003–1016. [Google Scholar]

- 98.Kim JH, Kim JW, Myoung SW, Pines M, Zhang Y. Damage maps for layered ceramics under simulated mastication. Journal of Dental Research. 2008;87:671–675. doi: 10.1177/154405910808700706. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 99.Kim JW, Kim JH, Janal MN, Zhang Y. Damage maps of veneered zirconia under simulated mastication. Journal of Dental Research. 2008;87:1127–1132. doi: 10.1177/154405910808701210. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 100.Guiberteau F, Padture NP, Lawn BR. Effect of grain size on Hertzian contact in alumina. Journal of the American Ceramic Society. 1994;77:1825–1831. [Google Scholar]

- 101.Lawn BR, Padture NP, Cait H, Guiberteau F. Making ceramics "ductile". Science. 1994;263:1114–1116. doi: 10.1126/science.263.5150.1114. [DOI] [PubMed] [Google Scholar]

- 102.Lawn BR, Lee JJ, Constantino PJ, Lucas PW. Predicting failure in mammalian enamel. Journal of the Mechanical Behavior of Biomedical Materials. 2009;2:33–42. doi: 10.1016/j.jmbbm.2008.05.007. [DOI] [PubMed] [Google Scholar]

- 103.Lawn BR. Indentation of ceramics with spheres: a century after Hertz. Journal of the American Ceramic Society. 1998;81:1977–1994. [Google Scholar]

- 104.Lawn BR. Partial cone crack formation in a brittle material loaded with a sliding indenter. Proceedings of the Royal Society of London. 1967;A299:307–316. [Google Scholar]

- 105.Lawn BR, Wiederhorn SM, Roberts DE. Effect of sliding friction forces on the strength of brittle materials. Journal of Materials Science. 1984;19:2561–1569. [Google Scholar]

- 106.Ren L, Janal MN, Zhang Y. Sliding contact fatigue of graded zirconia with external esthetic glass. Journal of Dental Research. 2011;90:1116–1121. doi: 10.1177/0022034511412075. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 107.Ren L, Liu L, Bhowmick S, Gerbig YB, Janal MN, Thompson VP, et al. Improving fatigue damage resistance of alumina through surface grading. Journal of Dental Research. 2011;90:1026–1030. doi: 10.1177/0022034511408427. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 108.Lawn BR, Swain MV. Microfracture beneath point indentations in brittle solids. Journal of Materials Science. 1975;10:113–122. [Google Scholar]

- 109.Chai H, Lawn BR. Failure of brittle layers on polymeric substrates from Vickers indentation. Scripta Materialia. 2006;55:335–358. [Google Scholar]

- 110.Chai H, Lawn BR. A universal relation for edge chipping from sharp contacts in brittle materials: a simple means of toughness evaluation. Acta Materialia. 2007;55:2555–2561. [Google Scholar]

- 111.Rhee Y-W, Kim H-W, Deng Y, Lawn BR. Contact-induced damage in ceramic coatings on compliant substrates: fracture mechanics and design. Journal of the American Ceramic Society. 2001;84:1066–1072. [Google Scholar]

- 112.Chai H, Lee JJ, Kwon JY, Lucas PW, Lawn BR. A simple model for enamel fracture from margin cracks. Acta Biomaterialia. 2009;5:1663–1667. doi: 10.1016/j.actbio.2008.11.007. [DOI] [PubMed] [Google Scholar]

- 113.Rudas M, Qasim T, Bush MB, Lawn BR. Failure of curved brittle layer systems from radial cracking in concentrated surface loading. Journal of Materials Research. 2005;20:2812–2819. [Google Scholar]

- 114.Lee CS, Kim DK, Sanchez J, Miranda P, Pajares A, Lawn BR. Rate effects in critical loads for radial cracking in ceramic coatings. Journal of the American Ceramic Society. 2002;85:2019–2024. [Google Scholar]

- 115.Kim JW, Thompson VP, Rekow ED, Jung YG, Zhang Y. Fracture modes in curved brittle layers subject to concentrated cyclic loading in liquid environments. Journal of Materials Research. 2009;24:1075–1081. doi: 10.1557/jmr.2009.0081. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 116.Padture NP, Lawn BR. Contact fatigue of a silicon carbide with a heterogeneous grain structure. Journal of the American Ceramic Society. 1995;78:1431–1438. [Google Scholar]

- 117.Zhang Y, Lawn B. Long-term strength of ceramics for biomedical applications. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2004;69:166–172. doi: 10.1002/jbm.b.20039. [DOI] [PubMed] [Google Scholar]

- 118.Lawn BR, Bhowmick S, Bush MB, Qasim T, Rekow ED, Zhang Y. Failure modes in ceramic-based layer structures: a basis for materials design of dental crowns. Journal of the American Ceramic Society. 2007;90:1671–1683. [Google Scholar]

- 119.Kim JW, Bhowmick S, Hermann I, Lawn BR. Transverse fracture of brittle bilayers: relevance to failure of all-ceramic dental crowns. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2006;79:58–65. doi: 10.1002/jbm.b.30511. [DOI] [PubMed] [Google Scholar]

- 120.Lawn BR, Lee JJW. Analysis of fracture and deformation modes in teeth subjected to occlusal loading. Acta Biomaterialia. 2009;5:2213–2221. doi: 10.1016/j.actbio.2009.02.001. [DOI] [PubMed] [Google Scholar]

- 121.Chai H, Lee JJ, Lawn BR. On the chipping and splitting of teeth. Journal of the Mechanical Behavior of Biomedical Materials. 2011;4:315–321. doi: 10.1016/j.jmbbm.2010.10.011. [DOI] [PubMed] [Google Scholar]

- 122.Chai H, Lawn BR. Hydraulically pumped cone fracture in brittle solids. Acta Materialia. 2005;53:4237–4244. [Google Scholar]

- 123.Barani A, Keown AJ, Bush MB, Lee JJ, Chai H, Lawn BR. Mechanics of longitudinal cracks in tooth enamel. Acta Biomaterialia. 2011;7:2285–2292. doi: 10.1016/j.actbio.2011.01.038. [DOI] [PubMed] [Google Scholar]

- 124.Coelho PG, Bonfante EA, Silva NR, Rekow ED, Thompson VP. Laboratory simulation of Y-TZP all-ceramic crown clinical failures. Journal of Dental Research. 2009;88:382–386. doi: 10.1177/0022034509333968. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 125.Stappert CF, Baldassarri M, Zhang Y, Hanssler F, Rekow ED, Van PT. Reliability and fatigue failure modes of implant-supported aluminum-oxide fixed dental prostheses. Clinical Oral Implants Research. 2012;23:1173–1180. doi: 10.1111/j.1600-0501.2011.02281.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 126.Demes B, Creel N. Bite force, diet, and cranial morphology of fossil hominids. Journal of Human Evolution. 1988;17:657–670. [Google Scholar]

- 127.Phillips RW. Skinnerɴs Science of Dental Materials. Philadelphia: W.B. Saunders; 1991. [Google Scholar]

- 128.Cai H, Kalceff M, Hooks B, Lawn B, Chyung K. Cyclic fatigue of a mica-containing glass-ceramic at Hertzian contacts. Journal of Materials Research. 1994:2654–2661. [Google Scholar]

- 129.Padture NP, Lawn BR. Fatigue in ceramics with interconnecting weak interfaces: a study using cyclic Hertzian contacts. Acta Metallurgica. 1995;43:1609–1617. [Google Scholar]

- 130.Chevalier J, Cales B, Drouin JM. Low-temperature aging of Y-TZP ceramics. Journal of the American Ceramic Society. 1999;82:2150–2154. [Google Scholar]

- 131.Chevalier J, Olagnon C, Fantozzi G. Crack propagation and fatigue in zirconia-based composites. Composites Part A: Applied Science and Manufacturing. 1999;30:525–530. [Google Scholar]

- 132.Lawn BR, Deng Y, Thompson VP. Use of contact testing in the characterization and design of all-ceramic crownlike layer structures: a review. The Journal of Prosthetic Dentistry. 2001;86:495–510. doi: 10.1067/mpr.2001.119581. [DOI] [PubMed] [Google Scholar]

- 133.Deng Y, Lawn BR, Lloyd IK. Damage characterization of dental materials in ceramic-based crown-like layer structures. In: Gong Y, Pan W, editors. High-Performance Ceramics. Vol. 224. 2002. pp. 453–457. 2001:Proceedings. [Google Scholar]

- 134.Chevalier J. What future for zirconia as a biomaterials? Biomaterials. 2006;27:534–543. doi: 10.1016/j.biomaterials.2005.07.034. [DOI] [PubMed] [Google Scholar]

- 135.Hermann I, Bhowmick S, Lawn BR. Role of core support material in veneer failure of brittle layer structures. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2007;82:115–121. doi: 10.1002/jbm.b.30712. [DOI] [PubMed] [Google Scholar]

- 136.Kim JW, Covel NS, Guess PC, Rekow ED, Zhang Y. Concerns of hydrothermal degradation in CAD/CAM zirconia. Journal of Dental Research. 2010;89:91–95. doi: 10.1177/0022034509354193. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 137.Mackert JR, Jr, Evans AL. Effect of cooling rate on leucite volume fraction in dental porcelains. Journal of Dental Research. 1991;70:137–139. doi: 10.1177/00220345910700020801. [DOI] [PubMed] [Google Scholar]

- 138.Denry IL, Mackert JR, Jr, Holloway JA, Rosenstiel SF. Effect of cubic leucite stabilization on the flexural strength of feldspathic dental porcelain. Journal of Dental Research. 1996;75:1928–1935. doi: 10.1177/00220345960750120301. [DOI] [PubMed] [Google Scholar]

- 139.Apel E, Deubener J, Bernard A, Holand M, Muller R, Kappert H, et al. Phenomena and mechanisms of crack propagation in glass-ceramics. Journal of the Mechanical Behavior of Biomedical Materials. 2008;1:313–325. doi: 10.1016/j.jmbbm.2007.11.005. [DOI] [PubMed] [Google Scholar]

- 140.Culp L, McLaren EA. Lithium disilicate: the restorative material of multiple options. Compendium of Continuing Education in Dentistry. 2010;31:716–722. 22,24-5. [PubMed] [Google Scholar]

- 141.Tholey MJ, Swain MV, Thiel N. Thermal gradients and residual stresses in veneered Y-TZP frameworks. Dental Materials. 2011;27:1102–1110. doi: 10.1016/j.dental.2011.08.001. [DOI] [PubMed] [Google Scholar]

- 142.Mainjot AK, Schajer GS, Vanheusden AJ, Sadoun MJ. Influence of cooling rate on residual stress profile in veneering ceramic: measurement by hole-drilling. Dental Materials. 2011;27:906–914. doi: 10.1016/j.dental.2011.05.005. [DOI] [PubMed] [Google Scholar]

- 143.Belli R, Monteiro S, Jr, Baratieri LN, Katte H, Petschelt A, Lohbauer U. A photoelastic assessment of residual stresses in zirconia-veneer crowns. Journal of Dental Research. 2012;91:316–320. doi: 10.1177/0022034511435100. [DOI] [PubMed] [Google Scholar]

- 144.Mainjot AK, Schajer GS, Vanheusden AJ, Sadoun MJ. Influence of zirconia framework thickness on residual stress profile in veneering ceramic: measurement by hole-drilling. Dental Materials. 2012;28:378–384. doi: 10.1016/j.dental.2011.11.009. [DOI] [PubMed] [Google Scholar]

- 145.Mainjot AK, Schajer GS, Vanheusden AJ, Sadoun MJ. Influence of veneer thickness on residual stress profile in veneering ceramic: measurement by hole-drilling. Dental Materials. 2012;28:160–167. doi: 10.1016/j.dental.2011.11.008. [DOI] [PubMed] [Google Scholar]

- 146.Zhang Y, Ma L. Optimization of ceramic strength using elastic gradients. Acta Materialia. 2009;57:2721–2729. doi: 10.1016/j.actamat.2009.02.037. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 147.Bhowmick S, Melendez-Martinez JJ, Zhang Y, Lawn BR. Design maps for failure of all-ceramic layer structures in concentrated cyclic loading. Acta Materialia. 2007;55:2479–2488. doi: 10.1016/j.actamat.2006.11.042. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 148.Bhowmick S, Melendez-Martinez JJ, Hermann I, Zhang Y, Lawn BR. Role of indenter material and size in veneer failure of brittle layer structures. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2007;82:253–259. doi: 10.1002/jbm.b.30728. [DOI] [PubMed] [Google Scholar]

- 149.Barani A, Keown AJ, Bush MB, Lee JJ, Lawn BR. Role of tooth elongation in promoting fracture resistance. Journal of the Mechanical Behavior of Biomedical Materials. 2012;8:37–46. doi: 10.1016/j.jmbbm.2011.11.014. [DOI] [PubMed] [Google Scholar]

- 150.Scherrer SS, de Rijk WG. The fracture resistance of all-ceramic crowns on supporting structures with different elastic moduli. The International Journal of Prosthodontics. 1993;6:462–467. [PubMed] [Google Scholar]

- 151.Scherrer SS, de Rijk WG, Belser UC, Meyer JM. Effect of cement film thickness on the fracture resistance of a machinable glass-ceramic. Dental Materials. 1994;10:172–177. doi: 10.1016/0109-5641(94)90028-0. [DOI] [PubMed] [Google Scholar]

- 152.Xu HH, Smith DT, Jahanmir S, Romberg E, Kelly JR, Thompson VP, et al. Indentation damage and mechanical properties of human enamel and dentin. Journal of Dental Research. 1998;77:472–480. doi: 10.1177/00220345980770030601. [DOI] [PubMed] [Google Scholar]

- 153.Chai H, Lawn BR. Role of adhesive interlayer in transverse fracture of brittle layer structures. Journal of Materials Research. 2000;15:1017–1024. [Google Scholar]

- 154.Kim JH, Miranda P, Kim DK, Lawn BR. Effect of an adhesive interlayer on the fracture of a brittle coating on a supporting substrate. Journal of Materials Research. 2003;18:222–227. [Google Scholar]

- 155.Kim JW, Bhowmick S, Chai H, Lawn BR. Role of substrate material in failure of crownlike layer structures. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2007;81:305–311. doi: 10.1002/jbm.b.30666. [DOI] [PubMed] [Google Scholar]

- 156.Zhang Y, Kim JW, Bhowmick S, Thompson VP, Rekow ED. Competition of fracture mechanisms in monolithic dental ceramics: flat model systems. Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2009;88:402–411. doi: 10.1002/jbm.b.31100. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 157.Ma L, Guess PC, Zhang Y. Load-bearing properties of minimal-invasive monolithic lithium disilicate and zirconia occlusal onlays: finite element and theoretical analyses. Dental Materials. 2013;29:742–751. doi: 10.1016/j.dental.2013.04.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 158.Kim DK, Jung Y-G, Peterson IM, Lawn BR. Cyclic fatigue of intrinsically brittle ceramics in contact with spheres. Acta Materialia. 1999;47:4711–4725. [Google Scholar]