Abstract

Background

Large-head metal-on-metal (MoM) hip arthroplasties have demonstrated poor survival. Damage at the taper-trunnion junction is a contributing factor; however, the influence of junction design is not well understood.

Questions/purposes

(1) Does taper type affect fretting, corrosion, and volumetric wear at the junction? (2) Do taper types have different wear patterns? (3) Does larger offset or head diameter increase fretting, corrosion, and wear? (4) Is the extent of fretting and corrosion associated with earlier failure?

Methods

Taper damage in 40 retrieved heads was subjectively graded for fretting and corrosion, and wear was determined with high-resolution confocal measurement. Taper types (11/13, 12/14, and Type 1) differed by angle, distal diameter, and contact length; Type 1 were thinnest and 11/13 had longer contact lengths.

Results

Fretting scores were higher in 11/13 than in Type 1 tapers. Volumetric wear and wear rates did not differ among types. Uniform, circumferential, and longitudinal wear patterns were observed in all types, but fretting, corrosion, and wear did not differ among the patterns. Head diameter and lateral offset did not correlate with fretting, corrosion, or wear. No correlation was found between fretting, corrosion, or wear and length of implantation.

Conclusions

In general, thicker tapers with longer contact lengths were associated with greater fretting scores, whereas no relationship was found among the three designs for corrosion scores or volumetric wear. This finding suggests that trunnion diameter and engagement length are important factors to consider when improving taper-trunnion junction design.

Level of Evidence

Level III, therapeutic study. See Guidelines for Authors for a complete description of levels of evidence.

Introduction

Large-head metal-on-metal (MoM) THAs have demonstrated poor performance with a significant incidence of adverse local tissue reaction [3, 13]. Worse survival and higher revision rates have been correlated to increased levels of wear caused by fretting at the taper-trunnion junction and corrosion at this same interface [7, 14]. Although the design of taper-trunnion junctions has evolved over the years, little is known about how the geometry differences and machining tolerances between the two mating components influence the performance of modern-day THAs. The problem of wear and corrosion may be exacerbated by larger head diameters that can result in increased torque at the taper-trunnion interface [11].

National registry data have drawn attention to the performance of MoM total hips. For example, the Australian registry showed that MoM conventional THAs with head diameters ≤ 32 mm performed as well as other bearing surfaces [13]. As head size exceeded 32 mm, however, MoM THAs demonstrated worse outcomes with a cumulative revision rate of 12% at 10 years. Overall, as head size increased in MoM THA, survival decreased. Furthermore, survivorship of large-diameter THAs was worse than that of hip resurfacing arthroplasties, suggesting that the presence of the head-neck taper junction may contribute significantly to their failure.

The engineering design factors of the trunnion and female taper interface that contribute to increased fretting and corrosion are not entirely clear. Multiple taper designs are currently in use commercially through several manufacturers. The taper geometry and area of contact in the female taper-trunnion interface most likely differs between the different design types. It follows that differences in these parameters may translate into variations in force distributions at the taper trunnion-junction, which could affect taper performance [4]. For example, large head diameters result in an increased moment arm and torque at the taper-trunnion coupled with design changes of the trunnion may cause excessive wear and leading to higher rates of failure [3].

Therefore, we investigated the damage at the taper-trunnion junction in retrieved large-head MoM THAs to determine the prevalence and extent of wear and corrosion and to relate these measures of tribocorrosive damage to taper design. We proposed the following questions: (1) Does taper geometry affect the presence of fretting and corrosion and the amount wear at the junction? (2) Do wear patterns differ with taper geometry? (3) Does femoral offset or head size lead to increased fretting, corrosion, and wear at the taper-trunnion junction? (4) Is the extent of fretting and corrosion associated with earlier failure of large-head MoM total hips?

Materials and Methods

We retrospectively queried our institutional review board-approved implant retrieval system to identify MoM THA implants with head diameters ≥ 36 mm. Forty femoral heads were identified from 39 patients. The cohort included three taper designs from five different manufacturers: six 11/13 tapers, 26 12/14 tapers, and eight Type 1 tapers. Taper-trunnion junctions were comprised of cobalt-chromium (CoCr) on CoCr, CoCr on titanium alloy (Ti), and Ti on Ti (Table 1). The retrievals consisted of the femoral head in all cases but trunnions for only six; therefore, our retrieval analysis focused on the female taper within the modular head. Inner sleeves were present in 19 of the femoral heads and were cold-welded to the head, so we focused our analysis on the inner most surface ignoring the sleeve/head interface.

Table 1.

Demographics of retrieved implant cases and implant manufacturing information

| Demographics | Mean ± SD |

|---|---|

| Age (years) | 58 ± 14 |

| Male:female | 21:19 |

| Body mass index (kg/m2) | 29 ± 7 |

| Length of implantation (months) | 37 ± 17 |

| Head size (mm) | 46 ± 5 |

| Cup inclination (degrees) | 50 ± 11 |

| Cup anteversion (degrees) | 20 ± 11 |

| Lateral offset (mm) | 40 ± 7 |

| Taper sleeve present (number) | 19 |

| Demographics | Number |

|---|---|

| Reason for revision | |

| Aseptic loosening | 9 |

| Infection | 3 |

| Cup malposition | 2 |

| Fracture | 1 |

| Pain and noise | 1 |

| Unexplained pain | 24 |

| Manufacturer | |

| DePuy, Warsaw, IN, USA | 26 |

| Biomet, Warsaw, IN, USA | 8 |

| Wright Medical, Arlington, TN, USA | 5 |

| Zimmer, Warsaw, IN, USA | 1 |

| Taper design | |

| Type 1 | 8 |

| 11/13 | 6 |

| 12/14 | 26 |

| Taper-trunnion junction materials | |

| CoCr-CoCr | 10 |

| CoCr-Ti | 23 |

| Ti-CoCr | 1 |

| Ti-Ti | 6 |

CoCr = cobalt-chromium; Ti = titanium.

A chart review was performed to determine patient demographics and implant information (manufacturer, model, size, taper design, length of implantation, reason for revision). Thirty of the 39 patients received their primary procedure at another institution. The heads had been implanted for an average of 37 months (range, 8–76 months). Cup position and femoral offset were measured (by two of the coauthors, DN and NN). Prerevision AP and cross-table lateral radiographs were reviewed in Einzel-Bild-Roentgen-Analysis software (University of Innsbruck, Innsbruck, Austria) to measure cup inclination and anteversion, respectively. The average inclination angle for the cups was 50° ± 11°; the average anteversion angle was 20° ± 10°. Offset was determined from review of prerevision AP pelvis radiographs in Spectra IDS7 software (Spectra Medical Systems AB, Linkoping, Sweden). The radiographs were calibrated to the known diameter of the femoral head. Lateral offset was measured by measuring the perpendicular distance between the anatomic axis of the femur and the center of the femoral head. Average offset was 40 ± 7 mm.

Implants were examined visually by two independent observers (NN, DN). Tapers were viewed at magnifications up to × 30 using a Wild Type 376788 Microscope (Heerbruug, Switzerland). Gross wear and deformation within the taper were subjectively graded for fretting and corrosion using a previously published scoring system [11]. Briefly, each taper was divided into a proximal and distal segment, and corrosion and fretting scores from 1 to 4 were determined for each segment by each observer. Higher scores were indicative of worse damage. The maximum score that was achievable was 8 points for each mode (4 points per region). These scores were then combined and averaged between the two observers so that each taper had a mean fretting and mean corrosion score. To our knowledge, no studies have evaluated the reproducibility of the Goldberg scoring system; however, it is commonly used in the literature for assessing fretting and corrosion of the taper-trunnion junction.

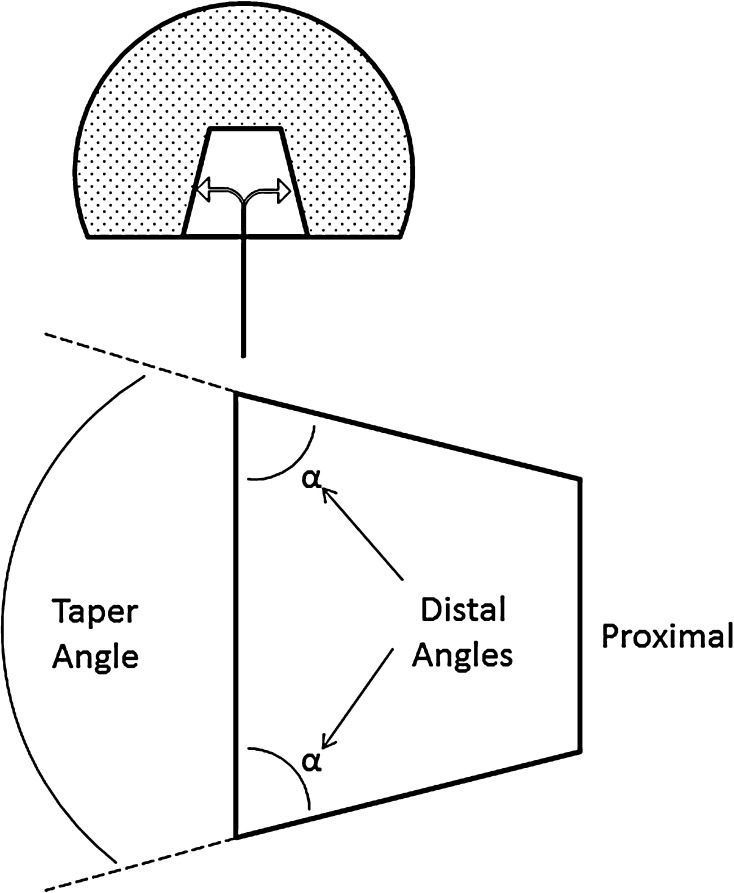

The implants were geometrically assessed using a chromatically encoded confocal measurement device (RedLux, Southamptom, UK; resolution = 3 nm) [2]. Negative molds of the female tapers were created using a high-resolution replication polymer (Microset Products, Leicestershire, UK) that has a replication resolution of 0.1 μm. These molds were scanned, creating three-dimensional point clouds. Each scan of the taper had roughly 1.5 million points. The point clouds were then analyzed using Geomagic Qualify 2012 (Morrisville, NC, USA). The point clouds were meshed with 6,700,000 triangles per female taper. Longitudinal cross-sections (resulting in a trapezoidal shape) were taken through the axis of the female taper. These cross-sections were taken at 0°, 30°, 60°, 90°, 120°, and 150° about the axis of the female taper. Distal angles of the female taper were measured from the cross-sections (Fig. 1). The average of the distal angles for each female taper was used to calculate the taper angle using Eq. 1.

|

1 |

Fig. 1.

The pictorial cross-section of a negative mold of a female taper depicts the distal and taper angles.

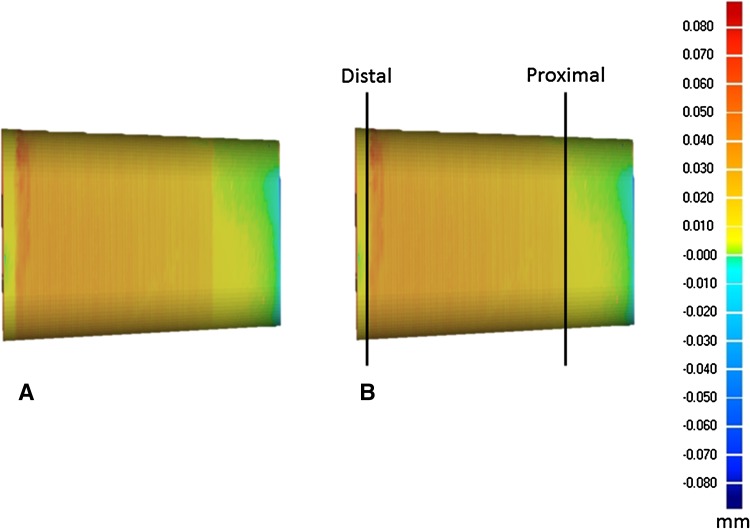

The contact length along which the trunnion engaged with the female taper was also measured. This was done by determining the most distal and most proximal positions of visible wear that included either corrosion or imprinting marks from the opposing surface. Planes perpendicular to the female taper axis were then placed at the distal and proximal wear positions, and the distance between these two planes was calculated (Fig. 2). The diameter of the taper at the most distal position of visible wear was also measured by cross-sectioning the taper with a plane perpendicular to the axis of the taper. The cross-section was then fit with a circle using a best-fit method.

Fig. 2A–B.

(A) An image of a scanned taper shows the region where the trunnion engaged with the taper (orange). (B) Distal and proximal planes are positioned at the points where engagement ends.

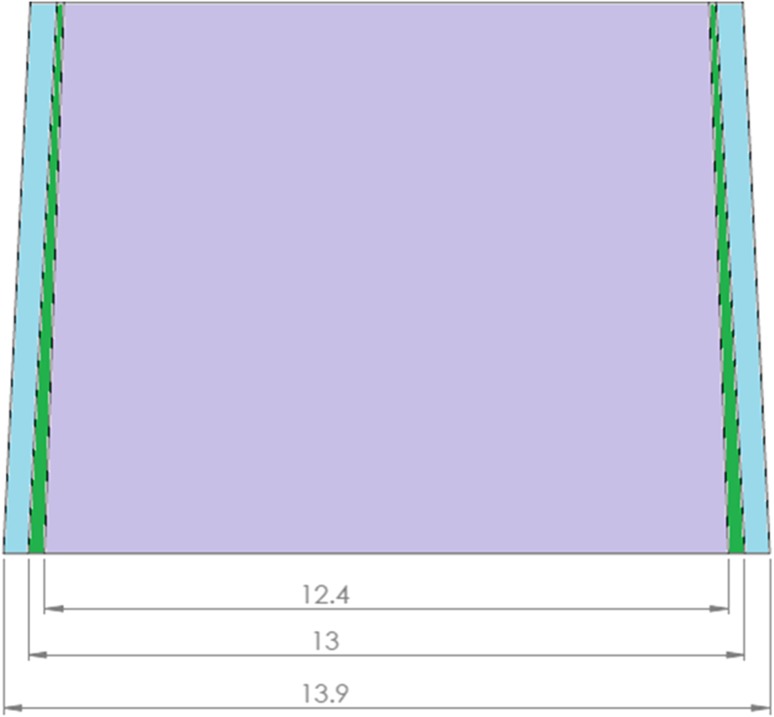

Descriptively, the taper angles, distal diameter, and contact length differed among the three taper designs (Table 2). Type 1 tapers were the thinnest, followed by 11/13, then 12/14 (Fig. 3). Type 11/13 tapers had the longest contact length, whereas the contact length of Type 1 and 12/14 were similar (Table 2).

Table 2.

Geometric differences were found among the three taper designs

| Taper design | Taper angle (degrees) | Distal diameter (mm) | Contact length (mm) |

|---|---|---|---|

| Type 1 | 4.0 ± 0.1*,† | 12.4 ± 0.3* | 12.4 ± 4.8† |

| 11/13 | 6.0 ± 0.01* | 13.0 ± 0.2* | 19.0 ± 1.6* |

| 12/14 | 5.6 ± 0.2 | 13.9 ± 0.4 | 13.3 ± 3.5 |

Values are mean ± SD; * significant different from 12/14, p < 0.05; †significant different from 11/13, p < 0.05.

Fig. 3.

Type 1 tapers were found to be the thinnest (purple) followed by 11/13 (green), then 12/14 (blue), which can be seen by stacking geometric representations on top of each other. The average distal diameters are described in millimeters.

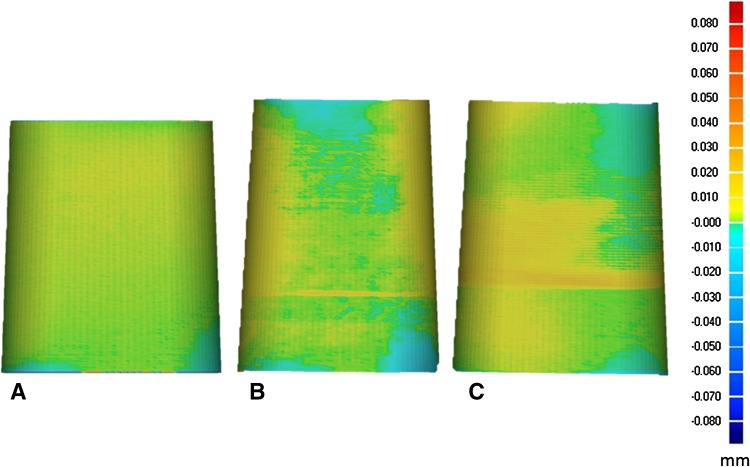

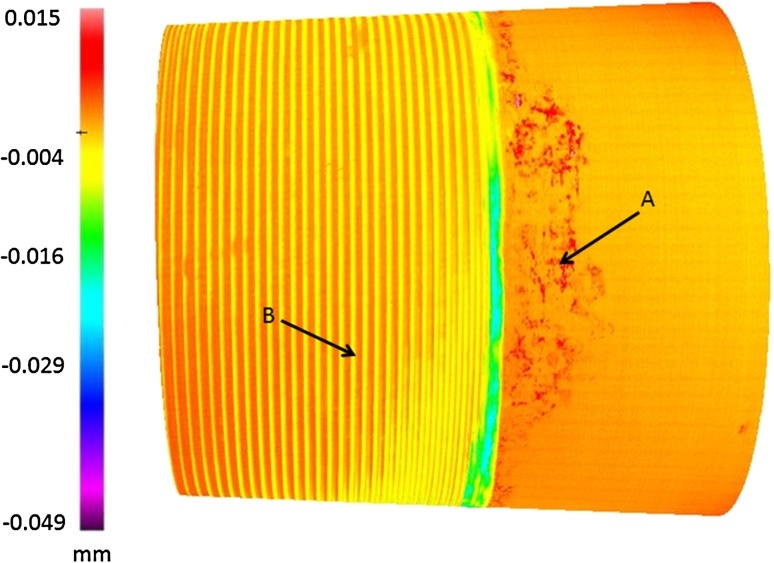

To determine wear of the female tapers, a reference taper was created for each retrieved implant by fitting cones using a best-fit algorithm to the unworn areas of the female taper. We classified unworn areas as region of the cones that did not have visible corrosion, pitting, or imprinting of the trunnion. Two implants (one 12/14 and one Type 1 taper) were excluded from this part of the analysis because they were too worn to reliably fit a reference taper. The retrieved female taper was then compared with the reference taper to obtain dimensional deviations, which were depicted colorimetrically. The colorimetric deviation maps were visually categorized into groups by one observer (KS). Three groups were found: uniform, circumferentially asymmetric, and longitudinally asymmetric. Uniform patterns depicted wear distributed uniformly both circumferentially and longitudinally along the taper (Fig. 4A). Circumferential asymmetry described wear distributed unequally around the circumference of the taper (Fig. 4B). Longitudinal asymmetry described wear distributed unequally along the axis of the taper (Fig. 4C).

Fig. 4A–C.

Colorimetric deviations maps of the female tapers reflect material loss (red) versus material deposition (blue). The deviations were categorized into three groups: uniform deviations (A), circumferentially asymmetrical deviations (B), and longitudinally asymmetrical deviations (C).

Volumetric wear of the contact area was determined by subtracting the volume of the retrieved female taper bounded by the previously described distal and proximal wear planes from the volume of the reference taper bounded by the same planes. A positive volume difference indicated material lost; a negative volume difference indicated material gained. Volumetric wear rate was determined by dividing the volumetric wear measured on each female taper by the implant’s length of implantation. The volumetric wear rate was also normalized by the contact length of the female tapers.

Linear relationships between groups were found using Spearman rank correlation. Continuous variables were compared using a Kruskal-Wallis one-way analysis of variance followed by appropriate Dunn’s pairwise, Tukey’s, or Shapiro-Wilk post hoc analysis. To compare categorical data, a Fisher’s exact test was used. Statistical significance was set at p < 0.05.

Results

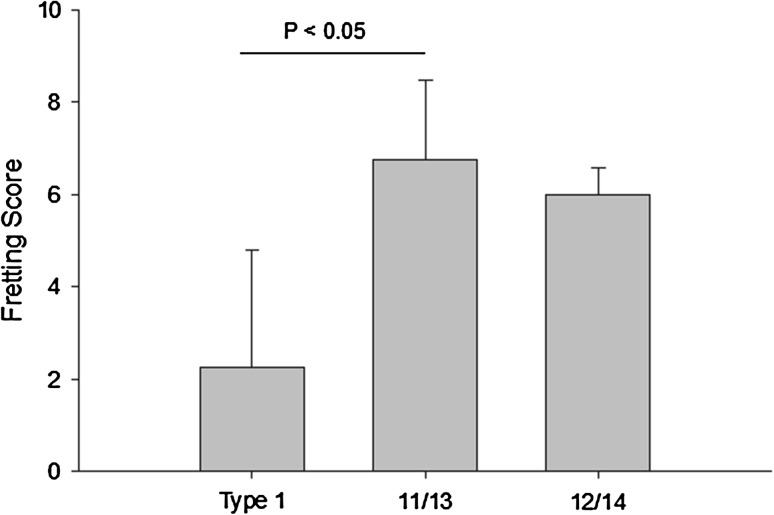

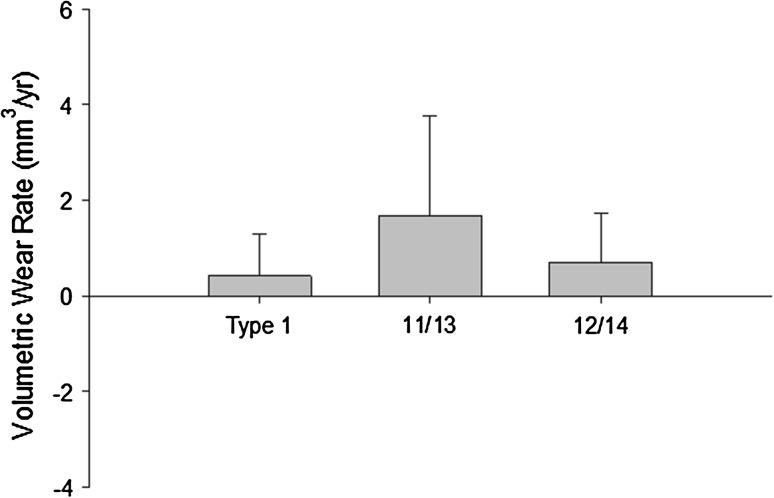

In general, thicker tapers with longer contact lengths were associated with greater fretting scores, whereas no relationship was found among the three designs for corrosion scores or wear. Type 1 tapers demonstrated a mean fretting score of 3 ± 2, 11/13 a score of 6 ± 2, and 12/14 5 ± 2. Fretting scores were significantly higher in 11/13 tapers than Type 1 tapers (p = 0.005) (Fig. 5). Corrosion scores for Type 1 tapers were 4 ± 2, 11/13 tapers 6 ± 1, and 12/14 tapers 5 ± 2 (p = 0.45). The volumetric wear and volumetric wear rates among the three taper designs did not differ (p = 0.38 and 0.15, respectively; Fig. 6).

Fig. 5.

Fretting was less in Type 1 than in 11/13 tapers.

Fig. 6.

Although not significant, Type 1 and 12/14 tapers had lower volumetric wear rates than 11/13 tapers.

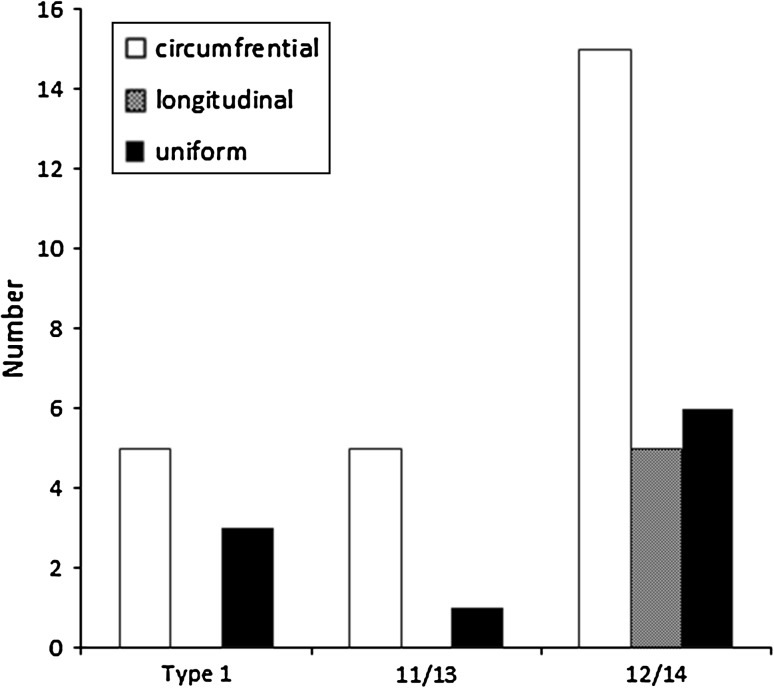

The three wear patterns were distributed among the taper geometries (Fig. 7); however, the distributions did not differ (p = 0.58). Type 1 tapers exhibited only uniform (n = 3) and circumferential (n = 5) patterns. Type 11/13 had only uniform (n = 1) and circumferential (n = 5) patterns. Type 12/14 exhibited all three patterns: uniform (n = 6), circumferential (n = 15), and longitudinal (n = 5). No differences were found in fretting scores (p = 0.05), corrosion scores (p = 0.27), volumetric wear (p = 0.06), or volumetric wear rate (p = 0.08) among the wear patterns.

Fig. 7.

Circumferentially asymmetric and uniform wear patterns were present in all taper designs; however, only 12/14 tapers demonstrated longitudinal asymmetry.

Femoral head size did not correlate with fretting score (p = 0.11), corrosion score (p = 0.61), volumetric wear (p = 0.28), or volumetric wear rate (p = 0.97). Similarly, the femoral offset did not correlate with fretting score (p = 0.70), corrosion score (p = 0.37), volumetric wear (p = 0.41), or volumetric wear rate (p = 0.35).

The extent of taper fretting (p = 0.68), corrosion (p = 0.54), volumetric wear (p = 0.30), and volumetric wear rate (p = 0.12) were not associated with earlier revisions in this series.

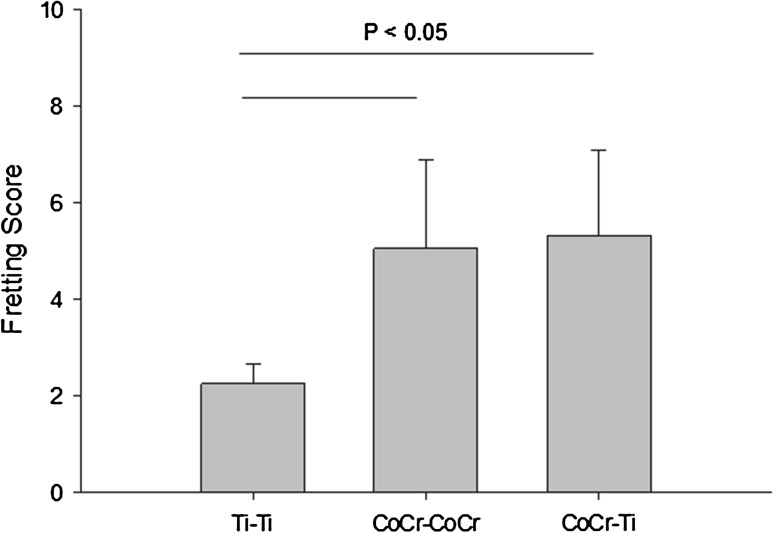

A large, unexpected heterogeneity in the material compositions of the tapers and trunnions was present within the cohort of retrieved implant, including dissimilar metal taper-trunnion junctions. Specifically the Biomet M2A heads greater than 40 mm in diameter had Ti tapers but a CoCr articular surface. Twenty-three had CoCr tapers with Ti trunnions, 10 had CoCr tapers with CoCr trunnions, six had Ti tapers with Ti trunnions, and one had a Ti taper with a CoCr trunnion. The Ti-Ti junctions had less fretting than CoCr-CoCr and CoCr-Ti junctions (p = 0.008; Fig. 8). No difference occurred in corrosion scores (p = 0.33), wear volume (p = 0.69), or wear rate (p = 0.63) among different material compositions.

Fig. 8.

Taper-trunnions with Ti-Ti junctions had lower fretting scores than those with CoCr-CoCr or CoCr-Ti junctions.

Discussion

Higher failure rates in MoM THAs are associated with the destructive but often silent local tissue reactions that can occur with implants using these bearings. Large-head MoM total hips have demonstrated higher than acceptable early failure rates in both small cohorts of patients [3] and large national registries [9, 13]. These clinical findings suggest that the taper-trunnion junction, with its potential for fretting and corrosion and subsequent release of wear debris or corrosion byproducts, plays a critical role in the failures of these implants. However, the contribution of the female taper of these large heads has only recently become a topic of interest [5, 7, 14]. Our intent was to elucidate the parameters that may lead to damage at the taper-trunnion junction.

Our study has several limitations. First, this is a retrospective retrieval study in which we examined a small group of failed implants. The cohort was heterogeneous in terms of the implant manufacturer, taper-trunnion geometry, metallic alloys, and reason for revision. Therefore, the results may overestimate the prevalence of damage at the taper-trunnion junction because we selected for failed implants with a relatively short lifespan. The small size and heterogeneity also preclude us from drawing firm conclusions because our data set is underpowered for some of our observations. Second, most revisions involved retention of the femoral stem component, leaving only the femoral head available for analysis. Lack of information on the male trunnion may underestimate the total amount of damage at the taper-trunnion junction. Third, we did not examine the head and acetabular cup bearing surfaces; however, Langton et al. [12] showed that taper volumetric wear rates in MoM implants are unaffected by bearing surface wear rates. Fourth, the Goldberg scoring system for fretting and corrosion is subjective and relies on the grader’s judgment to distinguish between corrosion products and organic depositions; however, with more severe levels of corrosion, it is easy to determine the difference resulting from surface topography. It is important to note that the to our knowledge, the reproducibility of the Goldberg scoring system has not been evaluated; as mentioned earlier, it is commonly used in the tribocorrosion literature for assessing fretting and corrosion of the taper-trunnion junction, but its reproducibility, in fact, is unknown. Finally, our wear measurements were made using an indirect method using a polymeric mold. This technique inherently adds error and reduces the resolution of the subsequent scanning from 20 nm to 100 nm. However, this measurement technique is similar to coordinate measuring machine measurement [2].

Our goal was to determine the contribution of trunnion design on fretting and corrosion damage and the amount and rate of wear at the taper-trunnion junction. Our data demonstrate that thicker tapers with longer contact lengths such as the 11/13 taper may be more prone to higher fretting damage. Specifically, our findings suggest a relationship between damage to the inner taper and the area of contact: the larger amount of available surface area, the greater the area over which fretting can occur. Although volumetric wear rates were not significantly different, they did reflect the extent of fretting observed on the taper. The large variation in wear rates may also reflect the contribution of corrosion, which was fairly uniform among taper designs. Corrosion can occur at any point along the female taper where synovial fluid is present (Fig. 9), regardless of where the trunnion is engaged [6]. Therefore, corrosion may be overshadowing the trends seen in fretting caused by taper-trunnion engagement.

Fig. 9.

The colormetric scan of this taper shows corrosion beyond the contact area: (A) areas of corrosion pitting and (B) areas where the trunnion had imprinted onto the taper.

The wear patterns provide an indication of how the tapers were loaded in vivo, assuming that most of the wear is from contact. Regardless of design, most tapers showed uniform or circumferential patterns, consistent with them being loaded uniformly or just circumferentially at the base of the taper. Only 12/14 tapers exhibited longitudinal asymmetry. These patterns were previously described by Bishop in a small cohort of patients undergoing THA [1]. In the same study, these investigators used an analytical model to demonstrate that radial stresses at the junction are uniform after a large impacting load was applied through a point where the center of the trunnion coincided with the head center. However, if the initial impaction force was too low or offset from the center of the trunnion, asymmetrical radial stresses occurred. This finding is consistent with both circumferential and longitudinal asymmetry. The wear patterns were also consistent with the corrosion observed on the tapers. Corrosion was most severe at the distal end of the tapers, as has been previously reported [11].

Our finding that a thinner and shorter taper is more beneficial than a longer, thicker taper disagrees with other studies in the literature. These studies suggest that a larger moment is applied to the taper-trunnion connection as the head diameter and the moment arm of the contact load passing through the hip increases [12]. Thus, a longer, thicker taper should be beneficial. However, we found no effect of offset and head diameter on fretting, corrosion, or wear. This may indicate two things. First, the proposed effect of offset and head diameter may not cause drastic changes in performance of the taper-trunnion junction. In fact, Goldberg et al. [11] found that once stem rigidity and length of implantation were considered, neither head diameter nor neck length (not contact length) predicted fretting or corrosion. Second, the effect of head diameter on loading may not have been as pronounced for our cohort, for which head diameter was always ≥ 36 mm, than if we had included smaller heads in our study [8].

Our finding that fretting, corrosion, and wear did not correlate with length of implantation is not similar to literature. Gilbert et al. found that corrosion correlated with length of implantation of devices implanted on average of 29.5 months [10]. Goldberg et al. also found that both fretting and corrosion correlated with length of implantation in implants revised at an average of 44.2 months [11]. Because our implants were implanted for longer periods of time than this, we too expected to see correlations with length of implantation. However, these studies did not take into account the differences in taper designs, which may be a contributing factor.

An unexpected finding was the influence of material composition. The Ti-Ti interfaces had the least amount of fretting when compared with the CoCr-CoCr and CoCr-Ti interfaces. This may be counterintuitive given that Ti has a lower modulus and is less resistant to fretting [11], but on the other hand, it might reflect the ability for Ti-Ti to form a better “cold weld,” thus reducing micromotion at the junction. However, all of the Ti-Ti junctions in our cohort were Type 1 tapers, so the geometry effects may be confounding this finding.

We found that fretting, corrosion, and wear of taper-trunnion junctions in large-diameter MoM THAs depend on trunnion geometry. Our results suggest that smaller diameter trunnions with shorter engagement lengths against the opposing taper surfaces will likely have lower amounts of fretting and corrosion damage and subsequently wear. This is not to say that clinicians should necessarily choose small, short trunnions, but our data do suggest that trunnion diameter and engagement length are important factors to consider as designers attempt to improve the performance of taper-trunnion junctions regardless of the types of bearing surfaces used.

Acknowledgments

We thank Stephanie Tow for her assistance with this project.

Footnotes

One of the authors (TW) received institutional support from Synthes Spine, West Chester, PA, USA, and Stryker, Mahwah, NJ, USA. One of the authors (DEP) is a consultant for Mako, Ft. Lauderdale, FL, USA, and Stryker. One or more of the authors has a royalty agreement with Mako (DEP) and Mathys, Bettlach, Switzerland (TW). One of the authors (TW) has ownership interest in Exactech, Gainesville, FL, USA.

All ICMJE Conflict of Interest Forms for authors and Clinical Orthopaedics and Related Research editors and board members are on file with the publication and can be viewed on request.

Clinical Orthopaedics and Related Research neither advocates nor endorses the use of any treatment, drug, or device. Readers are encouraged to always seek additional information, including FDA-approval status, of any drug or device prior to clinical use.

This work was performed in the Mary and Fred Trump Institute for Implant Analysis (Hospital for Special Surgery, New York, NY, USA).

Each author certifies that his or her institution approved the human protocol for this investigation, that all investigation were conducted in conformity with ethical principle of research, and that informed consent for participation in the study was obtained.

References

- 1.Bishop NEH. High friction moments in large hard-on-hard hip replacement bearings in conditions of poor lubrication. J Orthop Res. 2013;31:807–813. doi: 10.1002/jor.22255. [DOI] [PubMed] [Google Scholar]

- 2.Bolland B, Maul C, Cook RB, Roques A, Wood R, Latham JM. Profiling tapers for retrieval analysis of metal on metal modular heads. Bone Jt J Orthop Proc Suppl. 2013;95:139. [Google Scholar]

- 3.Bolland BJRF, Culliford DJ, Langton DJ, Millington JPS, Arden NK, Latham JM. High failure rates with a large-diameter hybrid metal-on-metal total hip replacement: clinical, radiological and retrieval analysis. J Bone Joint Surg Br. 2011;93:608–615. doi: 10.1302/0301-620X.93B5.26309. [DOI] [PubMed] [Google Scholar]

- 4.Cales B, Stefani Y. Risks and advantages in standardization of bores and cones for heads in modular hip prostheses. J Biomed Mater Res. 1998;43:62–68. doi: 10.1002/(SICI)1097-4636(199821)43:1<62::AID-JBM7>3.0.CO;2-K. [DOI] [PubMed] [Google Scholar]

- 5.Chana R, Esposito C, Campbell PA, Walter WK, Walter WL. Mixing and matching causing taper wear: corrosion associated with pseudotumour formation. J Bone Joint Surg Br. 2012;94:281–286. doi: 10.1302/0301-620X.94B2.27247. [DOI] [PubMed] [Google Scholar]

- 6.Collier JP, Surprenant VA, Jensen RE, Mayor MB. Corrosion at the interface of cobalt-alloy heads on titanium-alloy stems. Clin Orthop Relat Res. 1991;271:305–312. [PubMed] [Google Scholar]

- 7.Cooper H, Della Valle CJ, Berger RA, Tetreault M, Paprosky WG, Sporer SM, Jacobs JJ. Corrosion at the head-neck taper as a cause for adverse local tissue reaction after total hip arthroplasty. J Bone Joint Surg Am. 2012;94:1655–1661. doi: 10.2106/JBJS.K.01352. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Dyrkacz RMR, Brandt J-M, Ojo OA, Turgeon TR, Wyss UP. The influence of head size on corrosion and fretting behaviour at the head-neck interface of artificial hip joints. J Arthroplasty. 2013;28:1036–1040. doi: 10.1016/j.arth.2012.10.017. [DOI] [PubMed] [Google Scholar]

- 9.Garellick G, Karrholm J, Rogmark C, Herberts P. Goteborg, Sweden: Swedish Hip Arthroplasty Register Annual Report; 2010. Available at: www.shpr.se/Libraries/Documents/AnnualReport-2010-2-eng.sflb.ashx. Accessed May 28, 2013.

- 10.Gilbert JL, Buckley CA, Jacobs JJ. In vivo corrosion of modular hip prosthesis components in mixed and similar metal combinations. The effect of crevice, stress, motion, and alloy coupling. J Biomed Mater Res. 1993;27:1533–1544. doi: 10.1002/jbm.820271210. [DOI] [PubMed] [Google Scholar]

- 11.Goldberg JR, Gilbert JL, Jacobs JJ, Bauer TW, Paprosky W, Leurgans S. A multicenter retrieval study of the taper interfaces of modular hip prostheses. Clin Orthop Relat Res. 2002;401:149–161. doi: 10.1097/00003086-200208000-00018. [DOI] [PubMed] [Google Scholar]

- 12.Langton DJ, Sidaginamale R, Lord JK, Nargol AVF, Joyce TJ. Taper junction failure in large-diameter metal-on-metal bearings. Bone Jt Res. 2012;1:56–63. doi: 10.1302/2046-3758.14.2000047. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Mercer D, Bergman N. Hip and Knee Arthroplasty Annual Report 2011. Adelaide, Australia: University of Adelaide SA Australia: Austrialian Orthopaedic Association National Joint Replacement Registry; 2011.

- 14.Meyer H, Mueller T, Goldau G, Chamaon K, Ruetschi M, Lohmann CH. Corrosion at the cone/taper interface leads to failure of large-diameter metal-on-metal total hip arthroplasties. Clin. Orthop. 2012;470:3101–3108. doi: 10.1007/s11999-012-2502-5. [DOI] [PMC free article] [PubMed] [Google Scholar]