Abstract

NiTi instruments have a high risk of separation due to torsional or flexural fatigue (cyclic fatigue). Chemomechanical preparation, cleaning procedures, chemical disinfection and sterilization cause the corrosion of endodontic instruments that may weaken the fracture resistance of the instruments.

Objective

To assess the effects of NaOCl immersion and autoclave sterilization on the cyclic fatigue resistance of ProFile, FlexMaster, Mtwo and TwistedFiles NiTi instruments (tip size 25, 0.06 taper, n=160).

Material and Methods

The instruments (n=10 for each subgroup) were dynamically immersed in NaOCl; immersed in NaOCl and sterilized in one autoclave cycle; 5 cycles immersed in NaOCl and sterilized in autoclave and not immersed in NaOCl and not sterilized (control group). Dynamic cyclic fatigue resistance was tested. The number of cycles to failure (NCF) were statistically analyzed (P<0.05).

Results

Kruskall-Wallis test indicated significant differences among the tested instruments in terms of NCF (P=0.000). The mean NCF of Mtwo (556.75) was higher than that of the Twisted File, Flexmaster and ProFile, 483.1, 376.12, 365.25, respectively. NaOCl immersion and autoclave sterilization have no effect on the NCF values of the tested instruments (P>.05).

Conclusions

Cyclic fatigue resistance of the tested NiTi instruments cannot be adversely affected by NaOCl immersion and autoclave sterilization. Production process (TwistedFiles) or design (Twisted Files, FlexMaster, Mtwo and ProFile) of the instruments can influence their cyclic fatigue resistance.

Keywords: Endodontics, Fractures, Sterilization, Stress, Sodium chloride

INTRODUCTION

Nickel-titanium (NiTi) instruments are very popular and provide many advantages during root canal treatment. However, NiTi instruments have a high risk of separation due to torsional or flexural fatigue (cyclic fatigue)23. Fractures due to cyclic fatigue occur because of metal fatigue and are more prevalent in curved root canals. The instrument rotates freely at the curvature without binding, so that the tensile and compressive stresses are concentrated at the point of maximum flexure. Resistance to fracture prior to an actual fracture is determined by the number of cycles in which an instrument operates under a specific loading condition31. When the tip or some part of the file binds in the root canal during rotation, torsional failure occurs23.

An important factor that may weaken the fracture resistance is corrosion. Chemomechanical preparation, cleaning procedures, chemical disinfection, and sterilization cause the corrosion of endodontic instruments17. Sodium hypochlorite (NaOCl) is the most commonly used irrigant in endodontic treatment2, and its active ClO- ions have the potential to increase corrosion22. NaOCl selectively removes nickel from the instrument surface and causes micropitting22. These are the areas where stress gets concentrated, forming cracks22 and increasing the probability of fatigue failure26. Environmental conditions affect crack initiation and propagation processes26. The corrosive effect of NaOCl on endodontic NiTi instruments has been studied previously only in a static mode and for long contact times, which did not simulate actual clinical conditions10.

The resistance to cyclic fatigue of NiTi rotary instruments can be increased via improvements in the manufacturing process or by the use of new alloys with superior mechanical properties. Twisted Files (SybronEndo, Orange, CA, U.S.A.), which were recently introduced, are reported to have better physical and mechanical properties than traditional NiTi instruments. They are produced with a special form of thermomechanical processing, which yields a new, heat-treated NiTi instrument that contains a martensitic phase stable superelastic alloy under clinical conditions7,13. It has been reported that the additional heating of NiTi instruments might increase their flexibility30 and microhardness5.

There have been many studies on the cyclic fatigue resistance of different NiTi rotary files having different designs or compositions7,8,13. There are also several reports related to the effect of autoclave sterilization, for either improving or degrading the surface, mechanical, and cutting properties of various NiTi rotary systems11,24,28,29. However, there is no information on the influence of both NaOCl and autoclave sterilization on the cyclic fatigue resistance of NiTi rotary instruments. Therefore, the aim of this study was to assess the effect NaOCl solution and autoclave sterilization has on the cyclic fatigue resistance of three traditional (ProFile, FlexMaster, and Mtwo) NiTi instruments and one heat-treated (Twisted Files) NiTi instrument in conditions similar to those used in clinical practice.

MATERIAL AND METHODS

Four NiTi rotary instruments - ProFile (Dentsply Maillefer, Ballaigues, Switzerland), FlexMaster (VDW, GmbH, Munich, Germany), Twisted Files (SybronEndo, Orange, CA, U.S.A.), and Mtwo (VDW, GmbH, Munich, Germany) - were selected for the fatigue resistance test; all the instruments were of the same size (#25, 0.06 taper). Each group included 40 unused instruments that were divided into four subgroups (n=10) to evaluate different protocols.

In group 1, the instruments were dynamically immersed in 2.5% NaOCl for 5 min at room temperature. In group 2, the instruments were immersed in NaOCl, under the same conditions as in group 1, and then subjected to one cycle of autoclave sterilization (Statim 5000S, SciCan, Leutkirch im Allgäu, Germany) at a temperature of 135ºC for 32.5 min (17.5 min of sterilization and 15 min of drying). In group 3, the instruments were subjected to five cycles of the same test protocols as in group 2. In the control group, the instruments were not immersed in NaOCl and were not sterilized.

For the dynamic immersion, the endodontic instruments were attached to an endodontic motor and rotated freely at a constant speed (300 rpm for ProFile, FlexMaster, and Mtwo; 500 rpm for Twisted Files) in a small glass container with an amount of the NaOCl solution that was sufficient to be in contact with the instruments but not the shaft18. The files were rinsed with distilled water to neutralize the effect of the NaOCl and then dried.

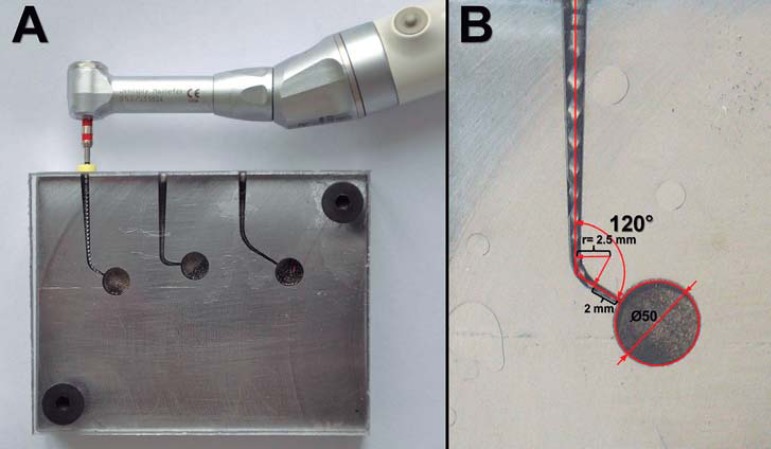

A total of 160 instruments, 40 from each subgroup, were tested for dynamic cyclic fatigue resistance. Artificial canals were constructed initially by providing a copper duplicate of each instrument to obtain accurately-sized canals. The copper duplicate was milled by increasing the original size of the instrument by 0.1 mm, using a computer numeric control machining bench (Ajan CNC, İzmir, Turkey), according to the curvature properties (60º angle, 2.5 mm radius, curvature beginning 2 mm from the tip of the file) that were chosen for this study. It was then constructed in a stainless steel block using the negative mold, using a die-sinking electrical-discharge machining process (Hartford M 65 series, She Hong Industrial Co. Ltd., Taichung, Taiwan). The depth of the artificial canal was machined to the maximum diameter of the instrument plus 0.2 mm, thus allowing the instrument to rotate freely. The artificial canal was also covered with tempered glass to prevent the instruments from slipping out and to allow observation of the instruments. The dental hand-piece was fixed to permit precise placement of each instrument inside the artificial canal and to guarantee the same three-dimensional positions of the instruments (Figures 1A, B). All the instruments except the Twisted Files were rotated at a constant speed of 300 rpm using a 16:1 contra angle and powered by a torque-controlled electric motor (X-smart, Dentsply Maillefer, Ballaigues, Switzerland) with back-and-forth axial movements until fracture occurred. The Twisted Files were rotated at a constant speed of 500 rpm, as per the manufacturer's recommendation. The amplitude of the axial movements was 3 mm, with about 2 s for every displacement. High-flow synthetic oil (DME, Gloucester, UK) was poured into the simulated canal after each file change to reduce the friction between the instrument and the metal canal walls.

Figure 1.

A) Cyclic fatigue testing device and the used canal type B) Trajectory of the size 25/.06 instrument and curvature properties of artificial root canal

The time-to-fracture was recorded visually with a 1/100-s chronometer. The number of cycles to failure (NCF) was determined by converting the time required to fracture the instrument into decimal units and then multiplying the time by the number of rotations per minute. The NCF values (n=40) obtained from four subgroups with different protocols were averaged to calculate the mean NCF value for each instrument (ProFile, FlexMaster, Twisted Files and Mtwo). The length of each fractured tip was also recorded.

Statistical analysis

Bartlett's test showed that the data did not provide preconditions of homogeneity of variance (P<0.05) and were not normally distributed according to Anderson-Darling test (P<0.05). Thus, the significances among the tested instruments were statistically analyzed with Kruskall-Wallis test (P=0.05).

RESULTS

Kruskall-Wallis test indicated significant differences among the tested instruments in terms of NCF, P=0.000. The mean NCF of Mtwo (556.75) was higher than that of the Twisted File, Flexmaster and ProFile, 483.1, 376.12, 365.25, respectively (Table 1).

Table 1.

The mean (SD) number of cycles to failure (NCF)* and fragment lengths in mm (SD) of tested NiTi instruments

| Tested NiTi instruments | NCF (SD) | Fragment length (mm) (SD) |

| ProFile (n=40) | 365.25 (75.64)c | 2.5 (0.4) |

| FlexMaster (n=40) | 376.12 (63.38)c | 2.6 (0.4) |

| Twisted File (n=40) | 483.1 (133.85)b | 2.5 (0.5) |

| Mtwo (n=40) | 556.75 (78.58)a | 2.7 (0.3) |

SD=Standard deviation;

different letters in the same column indicate statistically significant difference

Kruskal-Wallis test showed that NaOCl immersion and autoclave sterilization have no effect on the NCF values of the tested instruments (P>.05), when the effects of NaOCl immersion and autoclave sterilization on each instrument were searched (Table 2).

Table 2.

Mean (SD) of the number of cycles to failure (NCF) and fragment lengths in mm (SD) of tested NiTi instruments according to the groups

| NiTi instruments | Groups | NCF (SD) | Fragment length mm (SD) |

| ProFile (n=40) | Control | 396.5 (77.46) | 2.6 (0.4) |

| 5 min %2.5 NaOCl | 385.5 (76.03) | 2.4 (0.5) | |

| 5 min %2.5 NaOCl + sterilization | 359 (73.25) | 2.5 (0.6) | |

| 5X (5 min %2.5 NaOCl + sterilization) | 320 (61.55) | 2.6 (0.2) | |

| FlexMaster (n=40) | Control | 379 (70.54) | 3 (0.4) |

| 5 min %2.5 NaOCl | 378 (53.39) | 2.5 (0.4) | |

| 5 min %2.5 NaOCl + sterilization | 374 (70.82) | 2.7 (0.3) | |

| 5X (5 min %2.5 NaOCl + sterilization) | 373.5 (67.37) | 2.5 (0.4) | |

| Twisted File (n=40) | Control | 551.2 (118.78) | 2.4 (0.4) |

| 5 min %2.5 NaOCl | 526.5 (105.8) | 2.4 (0.2) | |

| 5 min %2.5 NaOCl + sterilization | 439 (148.16) | 2.6 (0.4) | |

| 5X (5 min %2.5 NaOCl + sterilization) | 415.7 (126.21) | 2.5 (0.2) | |

| Mtwo (n=40) | Control | 599.5 (79.46) | 2.8 (0.2) |

| 5 min %2.5 NaOCl | 560 (56.81) | 2.7 (0.2) | |

| 5 min %2.5 NaOCl + sterilization | 553 (87.94) | 2.6 (0.2) | |

| 5X (5 min %2.5 NaOCl + sterilization) | 514.5 (73.76) | 2.6 (0.2) |

SD=Standard deviation

There were no statistically significant differences among the tested instruments in terms of the length of fractured segments, (P>.05) (Table 1). The mean lengths of the separated segments as measured from the instruments' tips were 2.7, 2.6, 2.5 and, 2.5 mm for Mtwo, FlexMaster, Twisted File and Profile, respectively (Table 1).

DISCUSSION

In the literature, there is still a debate regarding the impact of torsional stress and metal fatigue on the fracturing of NiTi rotary instruments. A number of studies have stated that fatigue is the predominant mechanism in material failure6,25. On the other hand, some authors have hypothesized that torsional failure occurs more frequently than flexural fatigue1,23.

The fatigue life of an instrument is determined by the radius and angle of curvature, which are associated with the diameter of the instrument in the region of maximum bending3. Thus, as the diameter of the instrument increases and the curvature radius of the canal decreases, the fatigue resistance of the rotary instruments decreases29. Other factors related to cyclic fatigue are the design and cross section of the instrument27,31, the working speed, torque and sterilization procedures4,5 and clinical usage3,8.

To simulate clinical conditions, the test protocol chosen for this study included dynamic immersion in 2.5% NaOCl, a maximum of five cycles of autoclave sterilization, and dynamic cyclic fatigue resistance testing. To remain within a realistic time-frame of clinical practice and considering the mean life of the control instruments (between 1 min, 51.36 s for Mtwo; and 1 min, 13.06 s for ProFile), 5 min was selected as the contact time of the solution with the instrument. The shaft of the instrument was not immersed in the irrigation solution, as is the case in root canal instrumentation procedures. This also served the purpose of avoiding galvanic corrosion phenomena4. A dynamic model that incorporates cyclic axial movement not only provides better simulation of the clinical environment but also lengthens the lifespan of the rotary files, because the compressive and tensile stresses are distributed along the instruments14,16. However, the NCF values obtained in the present study were lower than those obtained in other studies that used a dynamic model16,31. Those studies used an artificial canal that was not constructed based on the specific dimensions of each file group to ensure a suitable file trajectory. Therefore, the canal design they used may have affected the fatigue life and resulted in a wide variation in the fatigue life of the instruments tested, as was claimed by Plotino, et al.21 (2009).

The number of times that rotary instruments can be reused is suggested to vary between 1 and 109,12, depending on the canal conditions and the type of instrument usage. Clinicians often recycle NiTi files owing to economic considerations11. In the present study, reuse for five times was simulated by five cycles of NaOCl immersion and autoclave sterilization.

In a recent study, Pedullà, et al.18 (2011) reported that static or dynamic immersion in 5% NaOCl did not significantly reduce the cyclic fatigue resistance of Twisted Files, Mtwo, or Revo S SU. The authors attributed this to the location of the corrosion. If the corrosion is not in the maximum stress area, then, the instrument's resistance to cyclic fatigue probably cannot be reduced18. In another study, ProFile and RaCe instruments showed a reduction in fatigue resistance after immersion in a heated NaOCl solution for 1 h19.

In the present study, the results showed no significant difference for the instruments made of traditional NiTi alloy (ProFile, FlexMaster and Mtwo) before and after NaOCl immersion and autoclave sterilization. The findings of other studies that investigated autoclave sterilization effects on NiTi instruments were in agreement with the present results11,20. On the other hand, Viana, et al.29 (2006) reported that the NCF of ProFile rotary instruments (25, 0.06) increased by 16% after five autoclave cycles in a temperature range 122-128ºC. Furthermore, it has been demonstrated that the five cycles of autoclave sterilization increased the microhardness of the NiTi endodontic instruments5.

NaOCl immersion and autoclave sterilization also had no significant influence on the cyclic fatigue life of the heat-treated instruments (Twisted Files). In contrary, Hilfer, et al.11 (2011) found that repeated autoclaving significantly reduced the mean NCF of 25/.06 Twisted Files. As they explained it, 135ºC is too low a temperature to produce a heat treatment effect, because it is known that such changes require a temperature of at least 170ºC, and that the maximum fatigue resistance can be obtained at 430-440ºC15. Furthermore, multiple autoclave cycles have been reported to increase the depth of NiTi file surface irregularities, causing fatigue propagation1,28. On the other hand, Plotino, et al.20 (2012) suggested that autoclave sterilization might improve the mechanical properties of instruments (K3 XF protypes, SybronEndo) that are manufactured using a type of heat treatment. The quality of manufacturing processes and different thermal treatments influence the performance of NiTi rotary instruments because NiTi is an alloy that is very sensitive to both the thermal and mechanical (machining) stresses that can occur during the manufacturing process20. A better arrangement of the crystal structure and changes in the percentage of phases of the alloy obtained via thermal treatment provide improvements in superelastic and plastic behaviors20. In the production process of Twisted Files, R-phase heat treatment technology modifies the crystalline structure, making it finer than that of traditionally processed materials, and it maximizes the flexibility and resistance to breakage without affecting the superelasticity16. Although Plotino, et al.20 (2012) reported that this new manufacturing technology enhanced the mechanical properties of instruments, the results of the present study did not confirm this finding. The traditional NiTi instrument, Mtwo, showed better cyclic fatigue resistance than the other traditional instruments, ProFile and FlexMaster, and the heat-treated instrument, Twisted Files. Twisted Files showed better cyclic fatigue resistance than ProFile and FlexMaster, as reported previously16. Oh, et al.16 (2010) demonstrated that Twisted Files have fewer surface defects (microfractures) because of twisting, and a smaller cross-sectional area than ProFile instruments, characteristics that might result in their better fatigue resistance. However, scanning electron micrography (SEM) micrographs revealed wrinkle-like grooves because of twisting on the flute faces of Twisted Files, which may increase their level of stress during instrumentation31.

All tested instruments fractured at the point of the maximum flexure within the curved part of the artificial canal where the stress concentrates. As expected, the lengths of the fractured segments of the instruments were not influenced by the NaOCl immersion and autoclave sterilization.

CONCLUSION

The comparison within the conditions of this study showed that cyclic fatigue resistance of the tested NiTi instruments cannot be adversely affected by NaOCl immersion and autoclave sterilization. Production process (TwistedFiles) or design (Twisted Files, FlexMaster, Mtwo and ProFile) of the instruments can influence their cyclic fatigue resistance. However, further studies investigating the different factors which can affect the instruments cyclic fatigue resistance, fracture modes and different apparatus design with more similar features to root dentine are necessary.

ACKNOWLEDGEMENTS

We would like to thank Assistant Professor Dr. Özgür Koşkan for statistical analyses.

REFERENCES

- 1.Alapati SB, Brantley WA, Svec TA, Powers JM, Nusstein JM, Daehn GS. SEM observations of nickel-titanium rotary endodontic instruments that fractured during clinical Use. J Endod. 2005;31:40–43. doi: 10.1097/01.don.0000132301.87637.4a. [DOI] [PubMed] [Google Scholar]

- 2.Arruda MP, Carvalho JR, Junior, Miranda CE, Paschoalato C, Silva SR. Cleaning of flattened root canals with different irrigating solutions and nickel-titanium rotary instrumentation. Braz Dent J. 2009;20:284–289. doi: 10.1590/s0103-64402009000400004. [DOI] [PubMed] [Google Scholar]

- 3.Bahia MG, Buono VT. Decrease in the fatigue resistance of nickel-titanium rotary instruments after clinical use in curved root canals. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2005;100:249–255. doi: 10.1016/j.tripleo.2004.10.013. [DOI] [PubMed] [Google Scholar]

- 4.Berutti E, Angelini E, Rigolone M, Migliaretti G, Pasqualini D. Influence of sodium hypochlorite on fracture properties and corrosion of ProTaper Rotary instruments. Int Endod J. 2006;39:693–699. doi: 10.1111/j.1365-2591.2006.01134.x. [DOI] [PubMed] [Google Scholar]

- 5.Chaves Craveiro de Melo M, Guiomar de Azevedo Bahia M, Lopes Buono VT. Fatigue resistance of engine-driven rotary nickel-titanium endodontic instruments. J Endod. 2002;28:765–769. doi: 10.1097/00004770-200211000-00005. [DOI] [PubMed] [Google Scholar]

- 6.Cheung GS, Darvell BW. Fatigue testing of a NiTi rotary instrument Part 2: Fractographic analysis. Int Endod J. 2007;40:619–625. doi: 10.1111/j.1365-2591.2007.01256.x. [DOI] [PubMed] [Google Scholar]

- 7.Gambarini G. Cyclic fatigue of nickel-titanium rotary instruments after clinical use with low- and high-torque endodontic motors. J Endod. 2001;27:772–774. doi: 10.1097/00004770-200112000-00015. [DOI] [PubMed] [Google Scholar]

- 8.Gambarini G. Cyclic fatigue of ProFile rotary instruments after prolonged clinical use. Int Endod J. 2001;34:386–389. doi: 10.1046/j.1365-2591.2001.00259.x. [DOI] [PubMed] [Google Scholar]

- 9.Gambarini G, Grande NM, Plotino G, Somma F, Garala M, De Luca M, et al. Fatigue resistance of engine-driven rotary nickel-titanium instruments produced by new manufacturing methods. J Endod. 2008;34:1003–1005. doi: 10.1016/j.joen.2008.05.007. [DOI] [PubMed] [Google Scholar]

- 10.Haikel Y, Serfaty R, Wilson P, Speisser JM, Allemann C. Mechanical properties of nickel-titanium endodontic instruments and the effect of sodium hypochlorite treatment. J Endod. 1998;24:731–735. doi: 10.1016/S0099-2399(98)80163-5. [DOI] [PubMed] [Google Scholar]

- 11.Hilfer PB, Bergeron BE, Mayerchak MJ, Roberts HW, Jeansonne BG. Multiple autoclave cycle effects on cyclic fatigue of nickel-titanium rotary files produced by new manufacturing methods. J Endod. 2011;37:72–74. doi: 10.1016/j.joen.2010.09.011. [DOI] [PubMed] [Google Scholar]

- 12.Inan U, Gonulol N. Deformation and fracture of Mtwo rotary nickel-titanium instruments after clinical use. J Endod. 2009;35:1396–1399. doi: 10.1016/j.joen.2009.06.014. [DOI] [PubMed] [Google Scholar]

- 13.Larsen CM, Watanabe I, Glickman GN, He J. Cyclic fatigue analysis of a new generation of nickel titanium rotary instruments. J Endod. 2009;35:401–403. doi: 10.1016/j.joen.2008.12.010. [DOI] [PubMed] [Google Scholar]

- 14.Li UM, Lee BS, Shih CT, Lan WH, Lin CP. Cyclic fatigue of endodontic nickel titanium rotary instruments: static and dynamic tests. J Endod. 2002;28:448–451. doi: 10.1097/00004770-200206000-00007. [DOI] [PubMed] [Google Scholar]

- 15.Mize SB, Clement DJ, Pruett JP, Carnes DL., Jr Effect of sterilization on cyclic fatigue of rotary nickel-titanium endodontic instruments. J Endod. 1998;24:843–847. doi: 10.1016/S0099-2399(98)80015-0. [DOI] [PubMed] [Google Scholar]

- 16.Oh SR, Chang SW, Lee Y, Gu Y, Son WJ, Lee W, et al. A comparison of nickel-titanium rotary instruments manufactured using different methods and cross-sectional areas: ability to resist cyclic fatigue. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2010;109:622–628. doi: 10.1016/j.tripleo.2009.12.025. [DOI] [PubMed] [Google Scholar]

- 17.O'Hoy PY, Messer HH, Palamara JE. The effect of cleaning procedures on fracture properties and corrosion of NiTi files. Int Endod J. 2003;36:724–732. doi: 10.1046/j.1365-2591.2003.00709.x. [DOI] [PubMed] [Google Scholar]

- 18.Pedullà E, Grande NM, Plotino G, Pappalardo A, Rapisarda E. Cyclic fatigue resistance of three different nickel-titanium instruments after immersion in sodium hypochlorite. J Endod. 2011;37:1139–1142. doi: 10.1016/j.joen.2011.04.008. [DOI] [PubMed] [Google Scholar]

- 19.Peters OA, Roehlike JO, Baumann MA. Effect of immersion in sodium hypochlorite on torque and fatigue resistance of nickel-titanium instruments. J Endod. 2007;33:589–593. doi: 10.1016/j.joen.2007.01.007. [DOI] [PubMed] [Google Scholar]

- 20.Plotino G, Costanzo A, Grande NM, Petrovic R, Testarelli L, Gambarini G. Experimental evaluation on the influence of autoclave sterilization on the cyclic fatigue of new nickel-titanium rotary instruments. J Endod. 2012;38:222–225. doi: 10.1016/j.joen.2011.10.017. [DOI] [PubMed] [Google Scholar]

- 21.Plotino G, Grande NM, Cordaro M, Testarelli L, Gambarini G. A review of cyclic fatigue testing of nickel-titanium rotary instruments. J Endod. 2009;35:1469–1476. doi: 10.1016/j.joen.2009.06.015. [DOI] [PubMed] [Google Scholar]

- 22.Sarkar NK, Redmond W, Schwaninger B, Goldberg AJ. The chloride corrosion behaviour of four orthodontic wires. J Oral Rehabil. 1983;10:121–128. doi: 10.1111/j.1365-2842.1983.tb00106.x. [DOI] [PubMed] [Google Scholar]

- 23.Sattapan B, Nervo GJ, Palamara JE, Messer HH. Defects in rotary nickel-titanium files after clinical use. J Endod. 2000;26:161–165. doi: 10.1097/00004770-200003000-00008. [DOI] [PubMed] [Google Scholar]

- 24.Schafer E. Effect of sterilization on the cutting efficiency of PVD-coated nickel-titanium endodontic instruments. Int Endod J. 2002;35:867–872. doi: 10.1046/j.1365-2591.2002.00586.x. [DOI] [PubMed] [Google Scholar]

- 25.Shen Y, Cheung GS, Peng B, Haapasalo M. Defects in nickel-titanium instruments after clinical usePart 2: Fractographic analysis of fractured surface in a cohort study. J Endod. 2009;35:133–136. doi: 10.1016/j.joen.2008.10.013. [DOI] [PubMed] [Google Scholar]

- 26.Shen Y, Qian W, Abtin H, Gao Y, Haapasalo M. Effect of environment on fatigue failure of controlled memory wire nickel-titanium rotary instruments. J Endod. 2012;38:376–380. doi: 10.1016/j.joen.2011.12.002. [DOI] [PubMed] [Google Scholar]

- 27.Turpin YL, Chagneau F, Vulcain JM. Impact of two theoretical cross-sections on torsional and bending stresses of nickel-titanium root canal instrument models. J Endod. 2000;26:414–417. doi: 10.1097/00004770-200007000-00009. [DOI] [PubMed] [Google Scholar]

- 28.Valois CR, Silva LP, Azevedo RB. Multiple autoclave cycles affect the surface of rotary nickel-titanium files: an atomic force microscopy study. J Endod. 2008;34:859–862. doi: 10.1016/j.joen.2008.02.028. [DOI] [PubMed] [Google Scholar]

- 29.Viana AC, Gonzalez BM, Buono VT, Bahia MG. Influence of sterilization on mechanical properties and fatigue resistance of nickel-titanium rotary endodontic instruments. Int Endod J. 2006;39:709–715. doi: 10.1111/j.1365-2591.2006.01138.x. [DOI] [PubMed] [Google Scholar]

- 30.Yahata Y, Yoneyama T, Hayashi Y, Ebihara A, Doi H, Hanawa T, Suda H. Effect of heat treatment on transformation temperatures and bending properties of nickel-titanium endodontic instruments. Int Endod J. 2009;42:621–626. doi: 10.1111/j.1365-2591.2009.01563.x. [DOI] [PubMed] [Google Scholar]

- 31.Yao JH, Schwartz SA, Beeson TJ. Cyclic fatigue of three types of rotary nickel-titanium files in a dynamic model. J Endod. 2006;32:55–57. doi: 10.1016/j.joen.2005.10.013. [DOI] [PubMed] [Google Scholar]