Abstract

Okra (Abelmoschus esculentus) was dried to a moisture level of 0.1 g water/g dry matter using a microwave-assisted hot air dryer. Response surface methodology was used to optimize the drying conditions based on specific energy consumption and quality of dried okra. The drying experiments were performed using a central composite rotatable design for three variables: air temperature (40–70 °C), air velocity (1–2 m/s) and microwave power level (0.5–2.5 W/g). The quality of dried okra was determined in terms of color change, rehydration ratio and hardness of texture. A second-order polynomial model was well fitted to all responses and high R2 values (>0.8) were observed in all cases. The color change of dried okra was found higher at high microwave power and air temperatures. Rehydration properties were better for okra samples dried at higher microwave power levels. Specific energy consumption decreased with increase in microwave power due to decrease in drying time. The drying conditions of 1.51 m/s air velocity, 52.09 °C air temperature and 2.41 W/g microwave power were found optimum for product quality and minimum energy consumption for microwave-convective drying of okra.

Electronic supplementary material

The online version of this article (doi:10.1007/s13197-011-0487-9) contains supplementary material, which is available to authorized users.

Keywords: Okra, Response surface, Microwave-convective drying, Specific energy, Rehydration ratio

Introduction

Okra (Abelmoschus esculentus) or Lady’s finger, commonly known as ‘Bhindi’ in India, is an important vegetable grown throughout the tropics and warmer parts of the temperate zone. Okra is grown throughout for its fibrous pods containing round, white seeds. Okra is good source of vitamin C, vitamin A, dietary fiber, calcium and is low in saturated fat (Doymaz 2005). Each 100 g of edible portion of okra contains about 89.6 g of water, 1.9 g of protein, 0.2 g fat, 6.4 g carbohydrate, 0.7 g minerals and 1.2 g fibre (Gopalan et al. 1989). In India, 4797 thousand MT of okra was produced over an area of 452 thousand hectares during year 2009–2010 (National Horticulture Board (NHB) 2009). Fresh harvested okra is highly perishable due to very high moisture content of 88–90% wet basis. At this moisture content, the quality of okra cannot be retained for more than a week. The safe moisture content for storage of okra has been reported as 10% (Shivhare et al. 2000).

Traditionally, okra is preserved by slicing followed by sun drying. The dried okra may be used as such or ground into powder for further use. Drying is the most common method of preservation for fruits and vegetables. The removal of moisture suppresses the growth of microorganisms responsible for deterioration of quality of food products. Hot air dying, a common commercial scale drying method, addresses some of these problems. However hot air drying has drawbacks of longer drying time, high energy requirements, loss of color and nutritional properties due to longer exposure to heat and case hardening of surface (Zhang et al. 2006; Sharma and Prasad 2006a; Yongsawatdigul and Gunasekaran 1996). Microwave drying has been investigated widely in last few decades and can address many of these limitations.

Microwave drying has advantages of high drying rates, high energy efficiency, better product quality and efficient space utilization (Sutar and Prasad 2007; Dadali et al. 2007a, b; Wang and Sheng 2006; Sharma and Prasad 2006b; Maskan 2000; Sanga et al. 2000). Microwave heating is a result of dipolar interaction of water molecules inside the food material. The polar water molecules tend to align themselves according to changing electric field and heat is produced due to friction between oscillating molecules. This rapid internal heating generation causes the pressure build up and results in rapid evaporation of water (Zhang et al. 2006; Datta and Anantheswaran 2001; Prabhanjan et al. 1995). A combination of microwaves with conventional drying techniques such as hot air dying, vacuum drying, freeze drying has been investigated by many researchers for drying of fruits and vegetables such as carrots (Sutar and Prasad 2007; Prabhanjan et al. 1995), garlic (Sharma 2000), banana (Maskan 2000), apple (Funebo and Ohlsson 1998), cranberries (Yongsawatdigul and Gunasekaran 1996) and grapes (Tulasidas 1994) etc. In case of microwave-convective drying, volumetric heat generation causes moisture migration to surface which is removed by hot air. Several researchers (Sharma 2000; Funebo and Ohlsson 1998; Tulasidas 1994) have found considerable improvements in the drying processes and qualities of dried products during microwave-convective drying of foodstuffs.

The objectives of this study were to investigate the effect of drying parameters (microwave power, air temperature and speed) on the quality of dried okra and to optimize the drying conditions based on quality of dried product and specific energy consumption during process.

Materials and methods

Materials

Fresh okra was procured from the local market of Kharagpur, West Bengal (India) and stored in the refrigerator at 4 °C. All okra samples were chosen to be of similar size, shape and color. The samples were equilibrated by keeping them in ambient conditions for 2 h prior to the drying experiments. Before drying, the okra was blanched in hot water at 95 °C for 5 min. and immediately cooled in chilled water to avoid over processing (Shivhare et al. 2000). Over processing may result in loss of texture (Brennan 2006). The top and tip of blanched okra were trimmed and remaining section was cut into 2 cm slices. To determine the initial moisture content, a known weight of sample was dried in an aluminum tray at 70 °C and 100 mm mercury pressure inside the vacuum oven for 16 h (Ranganna 1986). Average of three replications was used in analysis.

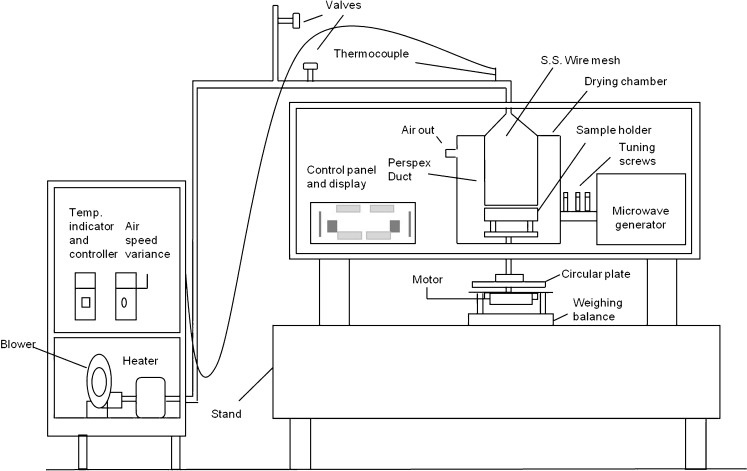

Microwave-convective drying

Okra was dried from initial moisture content of about 89% (wet basis) to a safe level of about 0.1 g water/g dry matter. The drying of okra was performed in a laboratory Microwave-Convective dryer. The schematic diagram of the system is shown in Fig. 1. A conventional microwave oven was modified by replacing the magnetron with a 2,000 W (2,450 MHz frequency) microwave generator (CobberMuegge LLC, Norwalk, CT). The microwave cavity had dimensions of 300(L) × 240(W) × 210(H) mm. Microwave generator was connected to the cavity (drying chamber) through waveguide cum tuner (CobberMuegge LLC, Norwalk, CT). Microwave generator and waveguide were selected according to size of the cavity. Power output from the generator and reflected power from the cavity were displayed by control panel. System had provision to minimize the reflected microwave power using three tuning screws on waveguide. A modified turn table was used to provide uniform heating and record on-line weight measurements. The details of turn table and weighing assembly can be found elsewhere (Sharma and Prasad 2001). The drying system had provision to regulate the air velocity, air temperature and microwave power level. A hole of 10 cm diameter was made at the centre of the top of the cavity (drying chamber) to connect the GI (galvanized iron) pipe supplying the hot air. Stainless steel mesh was placed over the hole to prevent the leakage of MW radiation. A 10 cm diameter Perspex duct having 3 mm thickness and about 10 cm length was connected to the top of the chamber for uniform supply of the hot air inside the chamber (Online Resource Fig. 6).Other constructional and operational details of the drying system can be found elsewhere (Kumar 2009).

Fig. 1.

Schematic illustration of microwave-convective drying system (Kumar, 2009)

The drying experiments were performed according to a second order central composite rotatable design (CCRD) with three variables: microwave power (P) (0.5–2.5 W/g), air temperature (T) (40–70 °C) and air velocity (V) (1–2 m/s). Microwave power levels were adjusted from the control panel of microwave generator. Air temperature inside the drying chamber was measured using a digital temperature indicator coupled with Iron-Constantan thermocouple. Air velocity was measured using a vane anemometer (ALMEMO FV A915 S120, AHLBORN, Germany) connected with a multi meter (ALMEMO 2290–2, AHLBORN, Germany). The ranges of independent variables were selected based on the review of earlier work related to microwave assisted drying of fruits and vegetables and the personal experience of the authors. The levels of variables in coded and actual units are provided in Table 1. The design includes, (I) 8 combinations at +1 and −1 level for 3 variables. (II) 6 combinations at extreme points at +1.682 and −1.682 and (III) 6 replications at center point i.e. 0 (Das 2005).

Table 1.

Levels of process variables and values of quality parameters and specific energy consumption for okra dried under various drying conditions

| Process Variables | ||||||

|---|---|---|---|---|---|---|

| Air velocity (m/s) | Air Temperature (°C) | MW Power (W/g) | Color Change ΔE | Hardness (g) | RR | Specific Energy (MJ/kg) |

| 1.8 (+1) | 63.9 (+1) | 2.1 (+1) | 29.56 | 2188.60 | 5.11 | 55.26 |

| 1.8 (+1) | 63.9 (+1) | 0.9 (−1) | 29.24 | 3020.50 | 4.97 | 98.16 |

| 1.8 (+1) | 46.1 (−1) | 2.1 (+1) | 27.13 | 2040.50 | 5.08 | 51.50 |

| 1.8 (+1) | 46.1 (−1) | 0.9 (−1) | 26.07 | 3450.70 | 4.92 | 91.23 |

| 1.2 (−1) | 63.9 (+1) | 2.1 (+1) | 28.47 | 3847.60 | 5.04 | 43.20 |

| 1.2 (−1) | 63.9 (+1) | 0.9 (−1) | 29.06 | 3106.80 | 4.86 | 80.67 |

| 1.2 (−1) | 46.1 (−1) | 2.1 (+1) | 27.55 | 2285.40 | 4.98 | 43.95 |

| 1.2 (−1) | 46.1 (−1) | 0.9 (−1) | 27.56 | 2851.50 | 4.73 | 76.73 |

| 2 (+1.682) | 55 (0) | 1.5 (0) | 29.11 | 3100.80 | 5.02 | 82.65 |

| 1 (−1.682) | 55 (0) | 1.5 (0) | 28.94 | 3040.50 | 4.84 | 56.34 |

| 1.5 (0) | 70 (+1.682) | 1.5 (0) | 29.44 | 4277.90 | 5.08 | 71.23 |

| 1.5 (0) | 40 (−1.682) | 1.5 (0) | 27.86 | 3415.10 | 4.82 | 61.14 |

| 1.5 (0) | 55 (0) | 2.5 (+1.682) | 28.34 | 2089.00 | 5.12 | 40.52 |

| 1.5 (0) | 55 (0) | 0.5 (−1.682) | 26.04 | 3840.90 | 4.72 | 96.60 |

| 1.5 (0) | 55 (0) | 1.5 (0) | 26.02 | 3120.90 | 4.96 | 67.35 |

| 1.5 (0) | 55 (0) | 1.5 (0) | 25.97 | 3095.50 | 4.93 | 70.56 |

| 1.5 (0) | 55 (0) | 1.5 (0) | 26.29 | 3096.90 | 4.98 | 67.35 |

| 1.5 (0) | 55 (0) | 1.5 (0) | 25.94 | 3115.50 | 5.00 | 70.72 |

| 1.5 (0) | 55 (0) | 1.5 (0) | 25.92 | 3120.40 | 4.9 | 67.35 |

| 1.5 (0) | 55 (0) | 1.5 (0) | 26.40 | 3105.50 | 4.94 | 67.20 |

The experiments were randomized in order to minimize the effects of unexplained variability in the observed responses. The original values as well as the code values of all variables are shown in Table 1. All experiments were performed in duplicate. A sample size of 100 g was used in each drying experiment. The dryer was run idle for 30 min with magnetron switched off to achieve a steady state before starting the experiment. To determine the moisture content during drying, weight of the sample was measured on-line at specific time intervals using electronic weighing balance with a precision of 0.01 g (Anamed Instruments, Mumbai, India). During weight measurement, the air supply and microwave generator were switched off. The drying was stopped when the sample attained a weight corresponding to moisture content of about 0.1 g water/g dry matter. The dried okra was then transferred into 400 gauge low-density polyethylene (LDPE) bags and stored in desiccators for quality analysis of dried product.

Quality analysis

Color, rehydration ratio and texture (hardness) were studied as quality parameters of dried okra, using the standard procedures discussed below.

Color

The color of a food product is one of the most important quality factors and plays a significant role in its appearance and consumer acceptability. The colors of the samples were determined using a Chroma meter (Konica Minolta Sensing, Inc.) in terms of L (whiteness/darkness), a (redness/greenness), b (yellowness/blueness) and color difference (ΔE). Color difference was calculated using Eq. 1.

|

1 |

ΔE indicates the degree of overall color change of a sample in comparison to color values of an ideal sample having color values of L*, a*, b*. Fresh okra was taken as ideal sample. Five color measurements were replicated for each sample and the average values of L, a, and b were reported.

Rehydration ratio

Rehydration ratio (RR), a measure of rehydration characteristics of dried okra, was determined by immersing dried okra samples in distilled water in ratio 1:30 (w/w) at room temperature, 30 °C. Weight of the samples were measured every hour for first 6 h and then after 24 h (Adedeji et al. 2008). Subsequently, the rehydrated samples were drained, excess moisture removed using tissue paper and weighed. Rehydration ratio was calculated as the ratio of weight of final rehydrated samples to the dry weight of the sample. Three replications were done for each sample and average value was calculated.

Texture (hardness)

Hardness of dried okra was determined using a texture analyzer (Model TA-XT2i,Texture Technologies Corp., Stable Microsystems Ltd, UK,) fitted with a 25 kg load cell. Compression test was carried out to generate a plot of force (g) vs. time (s) which was used to obtain hardness values. A 75 mm diameter compression plate (P/75) was used to compress the dehydrated okra slice to 30% of its original thickness (Giri and Prasad 2007). The test speed of probe was 2 mm/s during compression. The hardness was expressed as peak force (g) in the first compression. The mean value of five replicates was taken.

Specific energy consumption

Amount of energy consumed in any operation is an important aspect in evaluating a process. Specific energy consumption, defined here as the energy utilized to remove a unit mass of water during drying, was calculated for all drying conditions as suggested by Sharma and Prasad (2006b). Energy consumption was calculated by estimating the energy required by different components of the drying system: blower, heater, magnetron, turn table and water pump. Specific energy consumption during microwave-convective drying process, E, was calculated using Eq. 2.

|

2 |

where, E1 = energy required to heat the air, MJ; E2 = energy requirement of the air blower, MJ; E3 = energy requirement of the microwave generator, MJ; E4 = energy requirement for turn table, MJ; E5 = energy requirement of water pump for cooling system of microwave generator, MJ and We = amount of moisture removed, kg. Details of the calculations can be found elsewhere (Online Resource).

Analysis of data and optimization technique

Response surface method (RSM) was used to determine the relative contributions of variables (P, T and V) to various responses (quality parameters and specific energy) under study. Response surface methodology (RSM) is a statistical procedure used for optimization of multivariate problems. RSM helps in determining the relationship between one or more measured responses and multiple input variables. Other advantage of RSM is that it can provide statistically acceptable results with fewer number of experiments (Kaur et al. 2009).

A second-order polynomial equation (Eq. 3) was used for analysis of experimental data and to relate response function to coded variables (Jain et al. 2011; Giri and Prasad 2007; Balusu et al. 2005).

|

3 |

where, ‘β’ is the regression coefficient, ‘y’ is the response, k the number of variables studied in the experiment, ‘xis’ are coded process variables, and ‘E’ is random error. Higher values of β indicate the higher importance of variable and vice-versa. The regression analysis and analysis of variance (ANOVA) were conducted for fitting the model and to find the statistical significance of the model terms. A statistical package, Design Expert, version 7.0 (Stat-Ease 2000) was used to analyze data, perform RSM and to obtain three dimensional (3-D) graphs of response. Numerical optimization of process variables based on the multiple responses was performed using Design-Expert 7.0 software. Desired goals (minimization of color change, hardness and specific energy and maximization of rehydration ratio) were used to perform optimization of factors and the response. An overall composite function (D(x)), also known as desirability function, was calculated for optimization of multiple responses (Giri and Prasad 2007; Myers and Montgomery 1995) using Eq. 4.

|

4 |

where, Yi (i = 1, 2… n) are the responses and ‘n’ is the total number of responses in the study. The value of ‘D’ ranges from zero to one. The ‘D’ is a composite function describing how desirable (well matched) the responses are at a particular level of independent factors (variables). The program of the software seeks to find the values of variables, which can result in maximum value of desirability function (Yadav et al. 2010). There is possibility of two or more than two maximums due to curvature in response surface (Giri and Prasad 2007).

Results and discussion

Estimated regression coefficients of the polynomial models (Eq. 3) for all process variables and all responses are presented in Table 2. Coefficients V, T and M represent ‘βki’; V2, T2, M2 represent ‘βii’ and VT, VM and TM represent ‘βkij’ (linear, quadratic and interaction regression coefficients of model). The values of corresponding R2 (coefficient of determination) and Coefficient of variation (CV) are also included in the table. The R2 value is an indicative of degree of fit and can be is defined as the ratio of the explained variation to the total variation (Giri and Prasad 2007).

Table 2.

Regression coefficients of polynomial model for process variables (in coded units)

| Variables/Factors | Estimated Coefficients | |||

|---|---|---|---|---|

| ΔE | RR | H | Specific Energy | |

| Constant | 26.101 | 4.951 | 3123.850 | 68.433 |

| V-Air Velocity | −0.026 | 0.057 | −94.428 | 7.020 |

| T-Air Temperature | 0.782 | 0.052 | 218.678 | 2.259 |

| M-Microwave Power | 0.340 | 0.103 | −367.122 | −18.145 |

| VT | 0.398 | −0.014 | −262.450 | 0.937 |

| VM | 0.248 | −0.016 | −302.100 | −1.547 |

| TM | −0.165 | −0.011 | 235.650 | −0.982 |

| V2 | 0.966 | −0.002 | −109.890 | 0.294 |

| T2 | 0.833 | 0.006 | 164.414 | −0.875 |

| M2 | 0.317 | −0.005 | −147.261 | −0.101 |

| R2 | 0.92 | 0.93 | 0.83 | 0.99 |

| CV (%) | 1.89 | 0.87 | 10.82 | 3.12 |

The results of ANOVA analysis are shown in Table 3. It can be observed that models for all responses are highly significant with p ≤ 0.05. The R2 values are high (>0.9) for all models of responses (Table 2) except for hardness (R2 = 0.83). The value of CV should be less than 10% (Giri and Prasad, 2007) and were observed to be less than 4% for all models except for that of hardness (10.82%). This indicates that model for hardness is not adequate.

Table 3.

ANOVA results of different models

| Variables/Factors | F-value | ||||

|---|---|---|---|---|---|

| df | ΔE | RR | Hardness | Specific Energy | |

| Model | 9 | 13.73*** | 13.89*** | 5.38*** | 130.24*** |

| V-Air Velocity | 1 | 0.03 | 23.76*** | 1.11 | 149.22*** |

| T-Air Temperature | 1 | 30.70*** | 19.91*** | 5.96** | 15.46*** |

| M-Microwave Power | 1 | 5.82** | 78.30*** | 16.80*** | 997.05*** |

| VT | 1 | 4.65* | 0.82 | 5.03** | 1.56 |

| VM | 1 | 1.80 | 1.15 | 6.66** | 4.25* |

| TM | 1 | 0.80 | 0.55 | 4.05* | 1.71 |

| V2 | 1 | 49.42*** | 0.02 | 1.59 | 0.28 |

| T2 | 1 | 36.78*** | 0.24 | 3.56* | 2.45 |

| M2 | 1 | 5.32*** | 0.20 | 2.85 | 0.03 |

| Residual | 10 | ||||

| Lack of Fit | 5 | 12.15*** | 1.84 | 1673.03*** | 2.05 |

| Pure Error | 5 | ||||

| Total | 19 | ||||

***Significant at p < 0.01, **p < 0.05, *p < 0.1

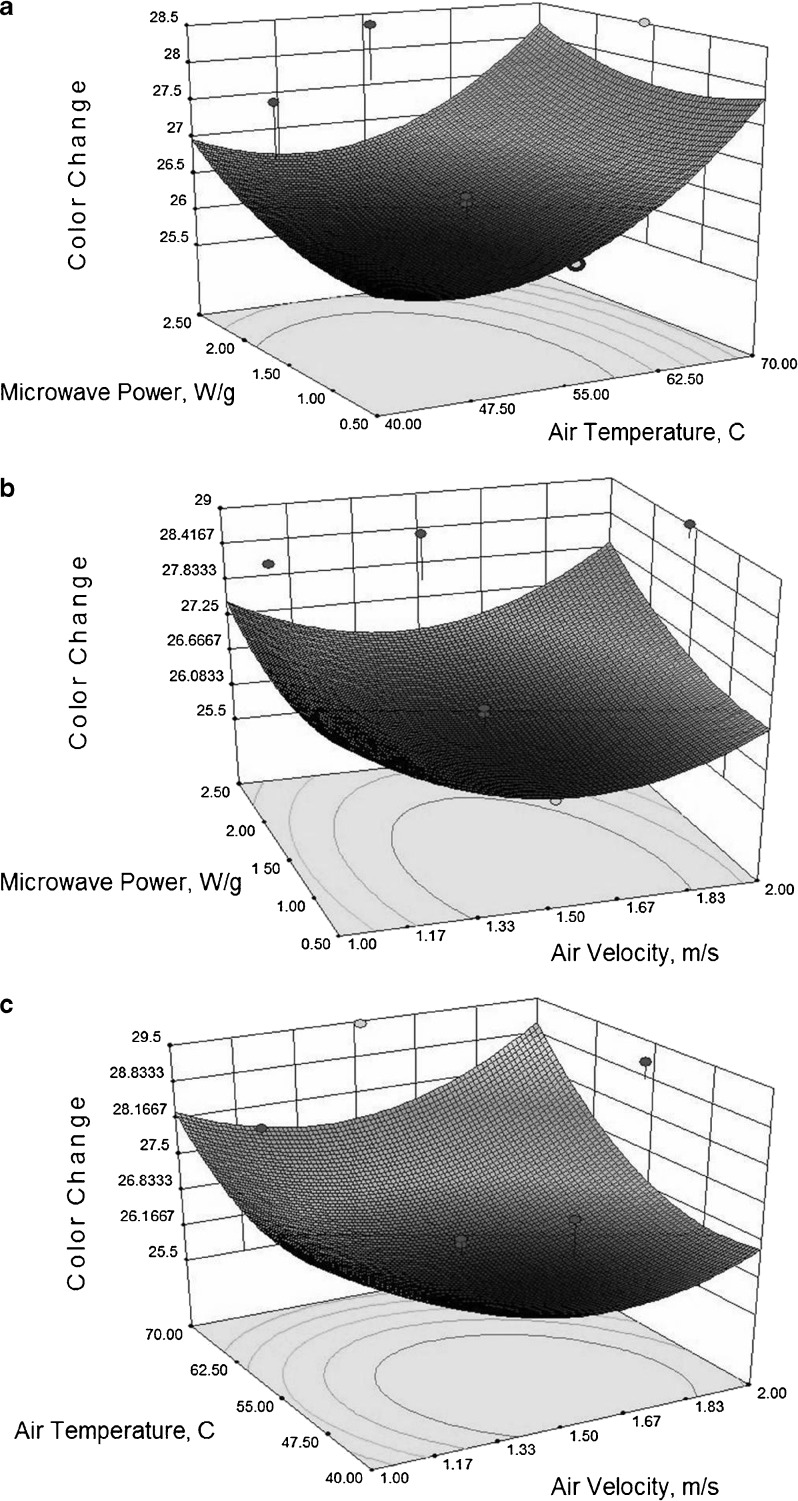

Color characteristics of dried okra

The color change of the dried okra samples was determined in terms of ΔE, which ranged from 25.92 to 29.56 for different drying conditions. The range for L-value was from 20.29 to 26.25. The values of color difference ΔE are given in the Table 1. Values of L, a, b are provided in Online Resource Table A2. It can be observed from Table 3 that microwave power and air temperature had significant effect (p ≤ 0.05) on color change. The coefficient of air velocity is not significant (p > 0.05). The variability of color change with change in air temperature and microwave power level is shown in Fig. 2. Among all process variables, air temperature has maximum effect on color change as indicated by regression coefficient and F-value.

Fig. 2.

Response surface plot showing effect of different drying parameters on color change (a) microwave power and air temperature at 1.5 m/s air velocity (b) microwave power and air velocity at 55 °C air temperature (c) air temperature and air velocity at 1.5 W/g microwave power

The regression equation of color change (ΔE) relating to actual levels of drying parameters was found as (Eq. 5):

|

5 |

R2 value for this model was found as 0.92, indicating a good model fit. With increase in temperature, there was significant increase in color change. The effect of microwave power was less significant but at higher microwave power levels, color difference was higher. Sharma and Prasad (2006a) also observed that dried garlic was darker when higher air temperatures and microwave power levels were used during microwave assisted drying.

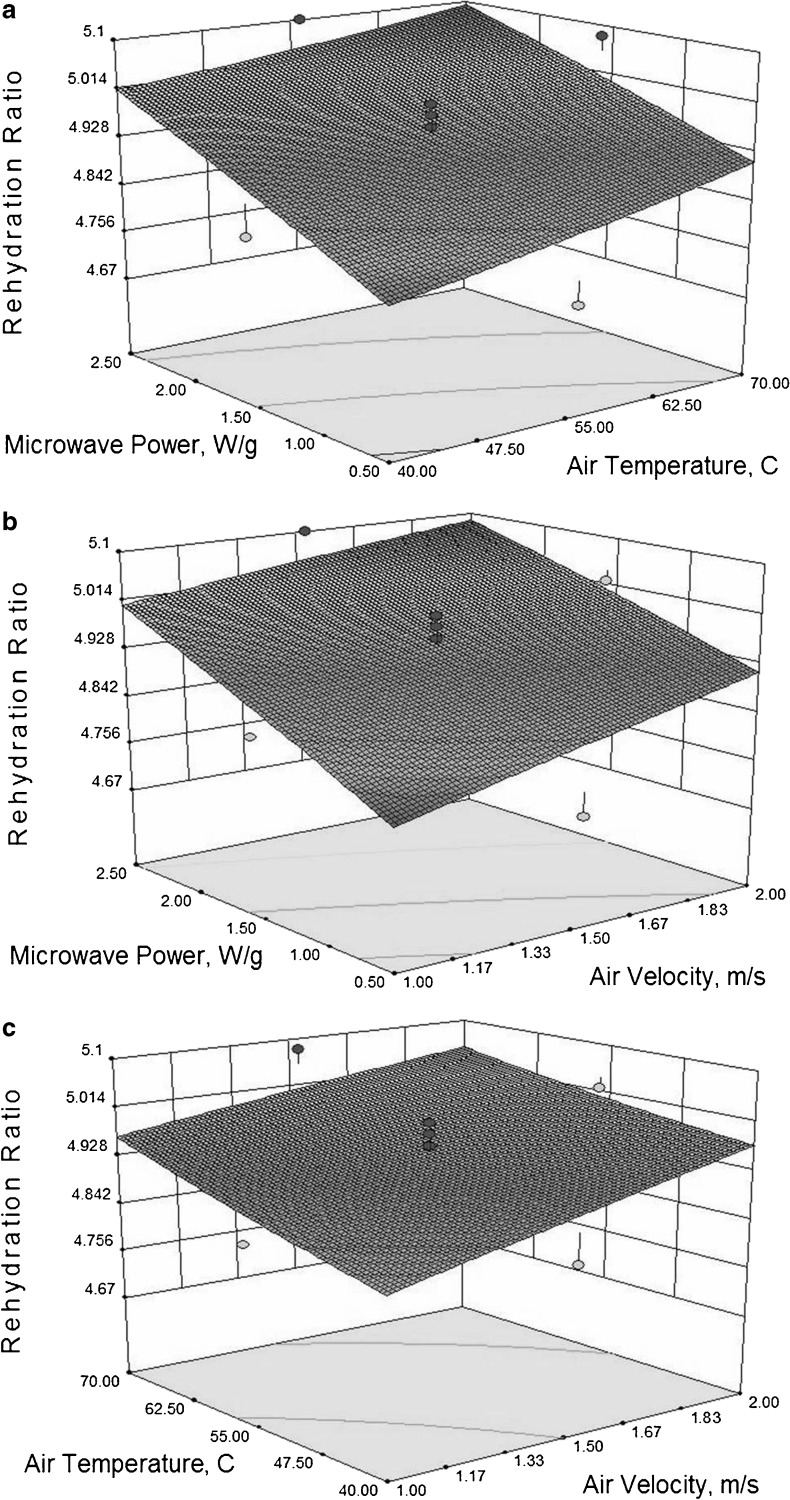

Rehydration ratio (RR)

Values of RR for okra samples dried in various conditions were found to be in the range of 4.72–5.12 (Table 1). All three drying parameters: air velocity, air temperature and microwave power level had significant effect on rehydration ratio (p ≤ 0.01). The regression coefficient is positive and maximum for microwave power level, which indicates better rehydration properties for okra dried at high microwave power levels. This can be a result of high internal pressure development at high microwave power levels. The higher microwave power generates large internal heat and creates a flux of rapidly escaping water vapors. This phenomenon causes opening of pores in the structure and prevents shrinkage, which results in improved rehydration properties (Giri and Prasad 2007). El-Din and Shouk (1999) observed that rehydration characteristics of okra dried using microwave oven were better than those of okra dried using conventional oven. The rehydration ratios for microwave dried okra were observed in the range of 5.59–6.14 (El-Din and Shouk 1999).

The effect of air temperature and microwave power level on rehydration ratio is shown in Fig. 3. The quadratic model fitted to the data was found to be significant with p-value less than 0.05. Equation relating actual levels of drying parameters to RR is given by Eq. 6 and had a high R2 of 0.93 (Table 2):

|

6 |

Fig. 3.

Response surface plot showing effect of different drying parameters on rehydration ratio (a) microwave power and air temperature at 1.5 m/s air velocity (b) microwave power and air velocity at 55 °C air temperature (c) air temperature and air velocity at 1.5 W/g microwave power

RR values increased with increase in hot air temperature and air velocities.

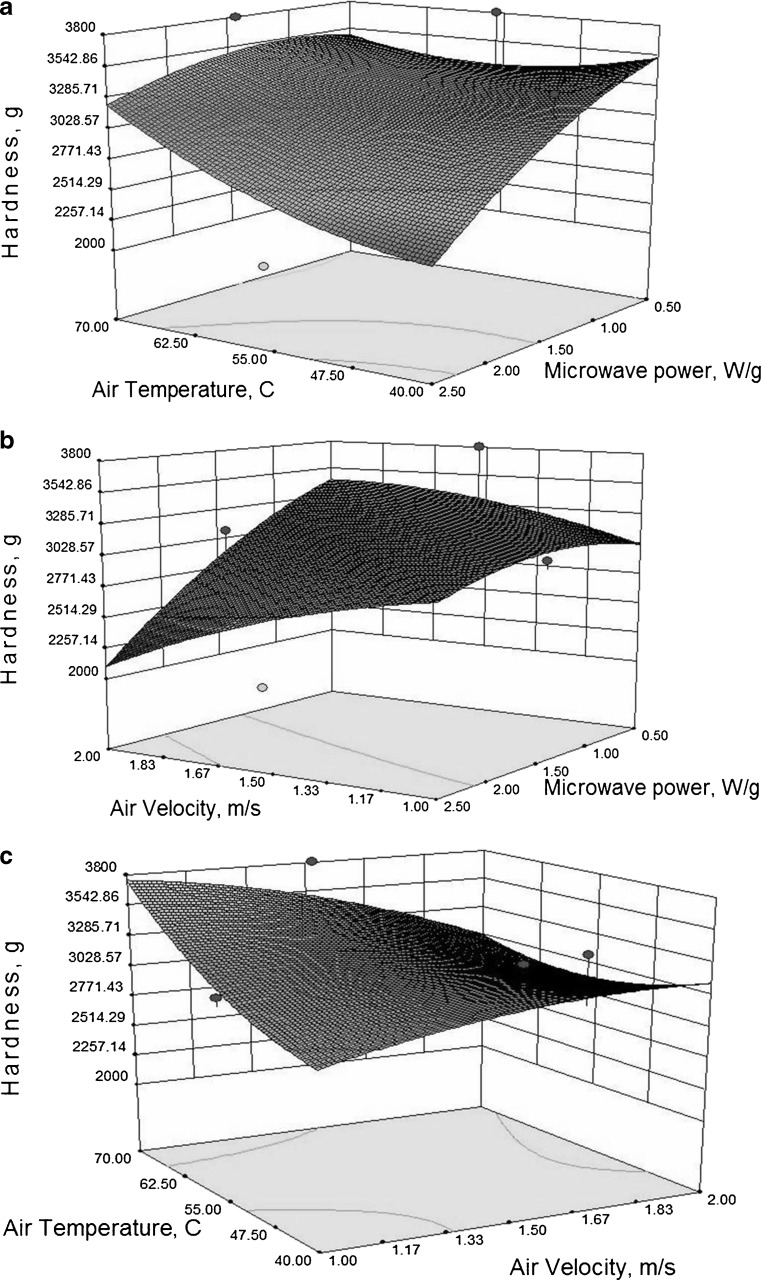

Texture (hardness)

The hardness values of okra dried under various conditions ranged between 2040.5 and 4277.9 g (Table 1). It was observed from ANOVA analysis (Table 3) that regression coefficients of microwave power and air temperature were significant (p ≤ 0.05), whereas the coefficient of air velocity (V) was insignificant (p > 0.05). The hardness of dried okra was found increasing with rise in air temperature. The effect of air temperature and microwave power level on hardness is illustrated in Fig. 4.

Fig. 4.

Response surface plot showing effect of different drying parameters on hardness (a) microwave power and air temperature at 1.5 m/s air velocity (b) microwave power and air velocity at 55 °C air temperature (c) air temperature and air velocity at 1.5 W/g microwave power

The following regression equation (R2 = 0.83) was obtained for hardness relating to actual levels of drying parameters (Table 2).

|

7 |

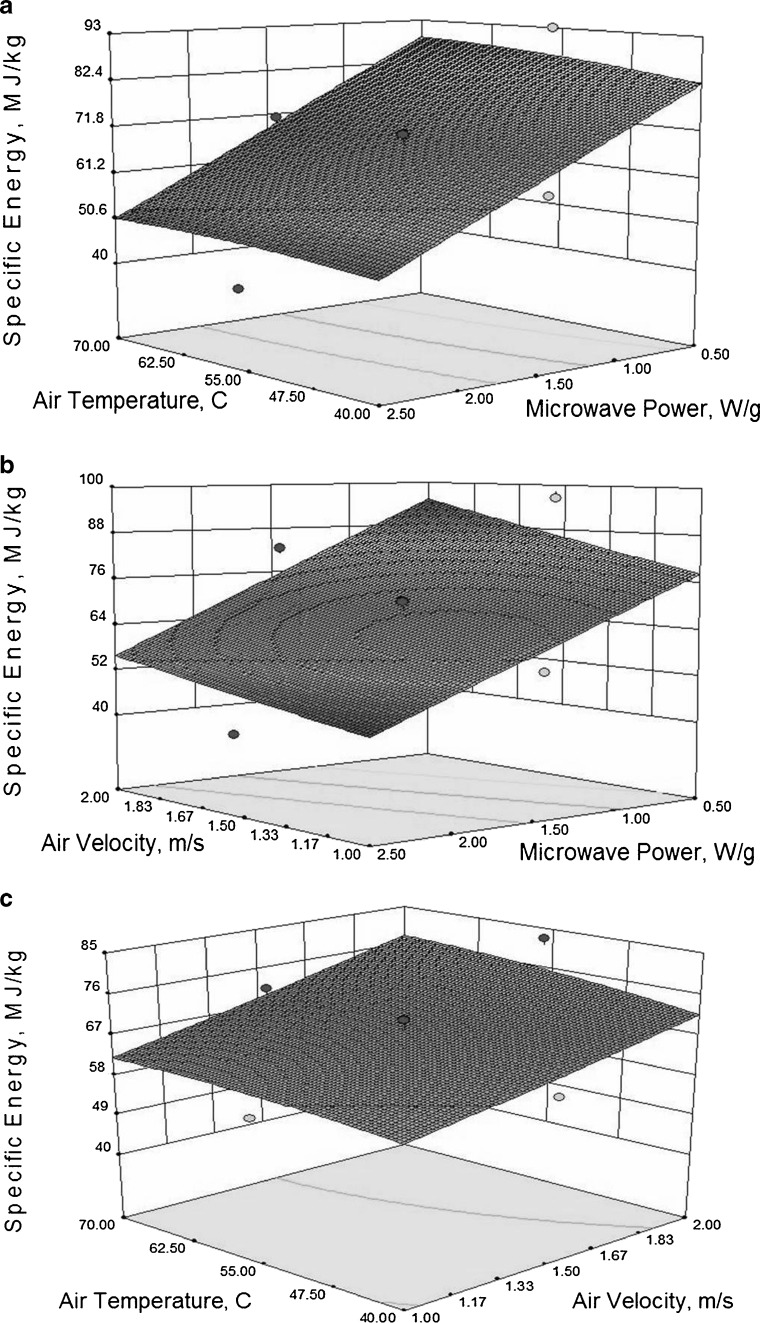

Specific energy consumption

The specific energy requirement for drying of okra under different drying conditions was estimated from Eq. 2. The values of specific energy required in all drying experiments are given in Table 1 (details provided in Online Resource Table A1). Only air temperature and microwave power level had significant effect on specific energy consumption (p ≤ 0.05). Effect of process parameters on specific energy is shown in Fig. 5.

Fig. 5.

Response surface plot showing effect of different drying parameters on specific energy consumption (a) microwave power and air temperature at 1.5 m/s air velocity (b) microwave power and air velocity at 55 °C air temperature (c) air temperature and air velocity at 1.5 W/g microwave power

The regression coefficient of microwave power level was found negative and highest among all drying variables. This indicates that specific energy consumption reduced substantially with increase in microwave power level. This behavior was observed because of considerable decrease in drying time, which reduces the total energy requirements. Similar results were obtained by Sharma and Prasad (2006b) for microwave-convective drying of garlic. The regression equation (Eq. 8) obtained for specific energy relating to actual levels of drying parameters (R2 = 0.99).

|

8 |

Optimization of microwave-convective drying of okra

The desired goals (objectives) for each parameter and response were assigned to each variable and response to adjust the shape of its particular desirability factor (Table 4). All factors (variables and responses) were equally weighed.

Table 4.

Optimization criteria for different factors and responses

| Responses | Goal | Lower Limit | Upper Limit |

|---|---|---|---|

| Air velocity (m/s) | in range | 1 | 2 |

| Air Temp. (°C) | in range | 40 | 70 |

| MW Power (W/g) | in range | 0.50 | 2.50 |

| Color Change (ΔE) | minimize | 25.92 | 29.56 |

| Rehydration Ratio | maximize | 4.72 | 5.12 |

| Hardness (g) | minimize | 2040.5 | 4277.90 |

| Specific Energy (MJ/kg) | minimize | 40.52 | 98.16 |

Optimum values of process variables, obtained for maximum desirability function (0.87) using Design expert 7.0 were: 1.51 m/s air velocity, 52.09 °C air temperature and 2.41 W/g microwave power level. The values of color change, rehydration ratio and hardness for okra dried at these drying conditions were predicted as 27.25, 5.09 and 2040.5 g respectively. A specific energy requirement of about 40.52 MJ/kg was predicted for drying of okra under these conditions.

Conclusion

Okra was dried from initial moisture content of about 8.0 g to 0.1 g water/g dry matter using microwave-assisted hot air drying technique. Drying experiments were performed by varying the process variables: air temperature (40–70 °C), air velocity (1–2 m/s) and microwave power level (0.5–2.5 W/g) using a central composite rotatable design. The drying parameters were optimized based on quality of dried okra and energy used during drying process. The air temperature and microwave power had significant effect on all drying parameters and energy consumption; however the effect of microwave power was more predominant. The values of rehydration ratio and hardness for different dried samples ranged from 4.72 to 5.12 and 2040.5 to 4277.9 g respectively. Specific energy consumption reduced considerably with increase in microwave power level, primarily due to reduction in drying time. The drying conditions of 1.51 m/s air velocity, 52.09 °C air temperature and 2.41 W/g microwave power were found optimum for microwave-convective drying of okra.

Electronic supplementary material

(PDF 1270 kb)

Acknowledgement

Authors are thankful to (Late) Prof. H. Das, Indian Institute of Technology, Kharagpur for allowing use of colorimeter in the experiments.

References

- Adedeji AA, Gachovska TK, Ngadi MO, Raghavan GSV. Effect of pretreatments on drying characteristics of okra. Dry Technol. 2008;26(10):1251–1256. doi: 10.1080/07373930802307209. [DOI] [Google Scholar]

- Balusu R, Paduru RR, Kuravi SK, Seenayya G, Reddy G. Optimization of critical medium components using response surface methodology for ethanol production from cellulosic biomass by Clostridium thermocellum SS19. Process Biochem. 2005;40(9):3025–3030. doi: 10.1016/j.procbio.2005.02.003. [DOI] [Google Scholar]

- Brennan JG. Food processing handbook. Germany: Wiley-VCH Weinheim; 2006. [Google Scholar]

- Dadali G, Apar DK, Özbek B. Color change kinetics of okra undergoing microwave drying. Dry Technol. 2007;25(5):925–936. doi: 10.1080/07373930701372296. [DOI] [Google Scholar]

- Dadali G, Apar DK, Özbek B. Estimation of effective moisture diffusivity of okra for microwave drying. Dry Technol. 2007;25(9):1445–1450. doi: 10.1080/07373930701536767. [DOI] [Google Scholar]

- Das H. Empirical model development. In: Food Processing Operations Analysis, Asian Books Private Limited, New Delhi; 2005. [Google Scholar]

- Datta AK, Anantheswaran RC. Handbook of microwave technology for food applications. New York-Basel: Marcel Dekker; 2001. [Google Scholar]

- Doymaz I. Drying characteristics and kinetics of okra. J Food Eng. 2005;69(3):275–279. doi: 10.1016/j.jfoodeng.2004.08.019. [DOI] [Google Scholar]

- El-Din M, Shouk A. Comparative study between microwave and conventional dehydration of okra. Grasas y Aceites. 1999;50(6):454–459. doi: 10.3989/gya.1999.v50.i6.694. [DOI] [Google Scholar]

- Funebo T, Ohlsson T. Microwave-assisted air dehydration of apple and mushroom. J Food Eng. 1998;38(3):353–367. doi: 10.1016/S0260-8774(98)00131-9. [DOI] [Google Scholar]

- Giri SK, Prasad S. Optimization of microwave-vacuum drying of button mushrooms using response-surface methodology. Dry Technol. 2007;25(5):901–911. doi: 10.1080/07373930701370407. [DOI] [Google Scholar]

- Gopalan C, Sastri BVR, Balasubramanian SC. Nutritive value of Indian foods. Indian Council of Medical Research, Hyderabad: National Institute of Nutrition; 1989. [Google Scholar]

- Jain SK, Verma RC, Murdia LK, Jain HK, Sharma GP. Optimization of process parameters for osmotic dehydration of papaya cubes. J Food Sci Technol. 2011;48(2):211–217. doi: 10.1007/s13197-010-0161-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kaur S, Sarkar BC, Sharma HK, Singh C. Optimization of enzymatic hydrolysis pretreatment conditions for enhanced juice recovery from guava fruit using response surface methodology. Food Bioprocess Technol. 2009;2(1):96–100. doi: 10.1007/s11947-008-0119-1. [DOI] [Google Scholar]

- Kumar D (2009) Studies on Microwave-Convective drying of okra. M. Tech. Thesis, Kharagpur: Indian Institute of Technology, Kharagpur, Agricultural and Food Engineering Department

- Maskan M. Microwave/air and microwave finish drying of banana. J Food Eng. 2000;44(2):71–78. doi: 10.1016/S0260-8774(99)00167-3. [DOI] [Google Scholar]

- Myers RH, Montgomery DC. Response surface methodology: process and product optimization using designed experiments. New York: John Willey & Sons; 1995. [Google Scholar]

- National Horticulture Board (NHB) (2009) Ministry of Agriculture, Government of India. http://nhb.gov.in/OnlineClient/rptProduction.aspx. Accessed March 12, 2011

- Prabhanjan DG, Ramaswamy HS, Raghavan GSV. Microwave-assisted convective air drying of thin layer carrots. J Food Eng. 1995;25(2):283–293. doi: 10.1016/0260-8774(94)00031-4. [DOI] [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. New Delhi: Tata McGraw-Hill; 1986. [Google Scholar]

- Sanga E, Mujumdar AS, Raghavan GSV. Principles and applications of microwave drying. In: Drying Technology in Agriculture and Food Sciences. New Hampshire: Science Publishers, Inc; 2000. pp. 253–289. [Google Scholar]

- Sharma GP (2000) Microwave convective drying of garlic cloves. PhD Thesis, Kharagpur: Indian Institute of Technology, Kharagpur, Agricultural and Food Engineering Department

- Sharma GP, Prasad S. Drying of garlic (Allium sativum) cloves by microwave-hot air combination. J Food Eng. 2001;50(2):99–105. doi: 10.1016/S0260-8774(00)00200-4. [DOI] [Google Scholar]

- Sharma GP, Prasad S. Optimization of process parameters for microwave drying of garlic cloves. J Food Eng. 2006;75(4):441–446. doi: 10.1016/j.jfoodeng.2005.04.029. [DOI] [Google Scholar]

- Sharma GP, Prasad S. Specific energy consumption in microwave drying of garlic cloves. Energy. 2006;31(12):1921–1926. doi: 10.1016/j.energy.2005.08.006. [DOI] [Google Scholar]

- Shivhare US, Gupta A, Bawa AS, Gupta P. Drying characteristics and product quality of okra. Dry Technol. 2000;18(1):409–419. doi: 10.1080/07373930008917712. [DOI] [Google Scholar]

- Design expert user’s guide. Minneapolis: Stat-Ease Inc.; 2000. [Google Scholar]

- Sutar PP, Prasad S. Modeling microwave vacuum drying kinetics and moisture diffusivity of carrot slices. Dry Technol. 2007;25(10):1695–1702. doi: 10.1080/07373930701590947. [DOI] [Google Scholar]

- Tulasidas TN (1994) Combined convective and microwave drying of grapes. PhD Thesis, Quebec, Canada: McGill University, Departmental of Agriculture Engineering

- Wang J, Sheng K. Far-infrared and microwave drying of peach. LWT-Food Sci Technol. 2006;39(3):247–255. doi: 10.1016/j.lwt.2005.02.001. [DOI] [Google Scholar]

- Yadav DN, Rajan A, Sharma GK, Bawa AS. Effect of fiber incorporation on rheological and chapati making quality of wheat flour. J Food Sci Technol. 2010;47(2):166–173. doi: 10.1007/s13197-010-0036-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yongsawatdigul J, Gunasekaran S. Microwave vacuum drying of cranberries: part I. energy use and efficiency. J Food Process Pres. 1996;20(2):121–143. doi: 10.1111/j.1745-4549.1996.tb00850.x. [DOI] [Google Scholar]

- Zhang M, Tang J, Mujumdar AS, Wang S. Trends in microwave-related drying of fruits and vegetables. Trends Food Sci Technol. 2006;17(10):524–534. doi: 10.1016/j.tifs.2006.04.011. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

(PDF 1270 kb)