Abstract

Processing of raw yam (D. alata) tuber (RY) to more stable and instant form could ease the tedium in preparation, increase popularity and commercial potential of ojojo—a fried yam snack. In this study, the potential of dried okra powder (1%–5%) to reduce the sensory quality impairment in ojojo made from instant yam (D. alata) flake (YF) was tested. Inclusion of okra powder significantly increased the viscosity and increased dispersibility of reconstituted yam flour. Addition of okra powder significantly (p < 0.05) reduced the fat and increased the moisture content of ojojo. Furthermore, increasing addition of okra consistently improved the sensory acceptability of ojojo by increasing the product’s moistness and fluffiness with reduced crispiness and roughness. In conclusion, addition of 0%–2% of okra powder to reconstituted YF produced ojojo samples which compared favourably with those made from RY in terms of colour, flavour and taste.

Keywords: Dioscorea alata, Ojojo, Fried food, Snack, Instant yam flake, Descriptive profile

Introduction

Dioscorea alata L., which is commonly referred to as ‘winged yam’ or ‘greater yam’ or ‘water yam’ is the most widely distributed species of yam. The tubers of D. alata are white, brown or brownish red in colour (Lebot et al. 2005). The culinary and palatability properties of D. alata varieties vary significantly while some cook much faster than others. Traditionally, water yam is processed into boiled yam, fried yam and fried yam balls by grating the peeled tuber, mixing the grated product with spices and condiments and frying portions of it in hot oil to form little balls called ojojo (Onwueme 1978). Most D. alata have mucilage in their tissue which confers some positive attributes to their food uses. For example, in the preparation of ojojo, freshly minced okra is mixed with some grated tissue from D. alata varieties that have limited or no mucilage and this practice helps to enhance the taste and texture of the product.

Yams are primarily preserved in flour form by drying peeled and parboiled tubers. They may also be processed into snacks such as chips and French fries (Onwueme 1978; NRI 1987; Hsu et al. 2003). However, a major processing constraint of many yam varieties is the rapid discolouration of the tissue when the tuber is cut open. This rapid colour change is attributed to the oxidation of polyphenolic compounds in the flesh thereby turning its colour to yellowish or brown (Osagie and Opoku 1984; Almentros and Del Rosatio 1985). Polyphenolic oxidation is also associated with off-flavours, bitterness and deserves in some cases, special preparation (Lebot et al. 2005). This phenomenon is more predominant in D. alata than other Dioscorea sp.

The increasing demand for convenience food and reduced drudgery associated with food preparation has made various instant food products to continue to emerge in food markets. The relationship between convenience and food choice or preference has been discussed in some studies (de Boer et al. 2004; Jaeger 2006). According to Jaeger (2006), convenience in product handling, preparation and consumption is one of the factors that have increasingly determined consumer’s decision to patronize food product. Aworh (2008) reported that the inconvenience associated with processing of root and tuber products has particularly caused the development of various instant traditional root- and tuber-based food products. Ojojo is a fried snack product made from D. alata. Traditionally, the fresh peeled tuber is grated to form viscous mass which is mixed with other chopped vegetables such as onion and pepper. Sometimes okra fruits are either chopped or sliced and added during preparation to impart desirable flavour and textural characteristics to ojojo. The entire preparation process is still being carried out manually. The grating of tuber is the most tedious because it is energy and time-consuming. Processors also sustain hand injuries while squeezing the tissue against the abrasive surface of grating utensils. Therefore, scientific studies are required to reduce or eliminate such drudgery encountered in the traditional processing of ojojo. Development of a more convenient way of preparing the product would definitely be a form of value addition. Drying of fruits and vegetables materials leads to some inevitable quality impairment (Sagar and Kumar 2010). However, careful drying of grated D. alata tissue to give an easily reconstituted material would ease its handling, storage and shelf life and allow an all-year-round utilization of the dried form in food preparations.

In the present study the potential of using an instant dried form of water yam as an ingredient in ojojo preparation was evaluated. In order to make up for any loss in the mucilaginous contents of water yam due to drying, varying quantities of okra powder were added. The effect of okra powder addition on the functional properties of YF was determined while the ojojo sample produced from fresh water yam was also used as control to determine the effect of okra addition on the moisture and fat contents and sensory qualities of fried balls. Because of the constraints of rapid discoloration after peeling of some D. alata varieties, the white-fleshed variety of D. alata which is more resistant to oxidation was used for this study.

Materials and methods

Materials

Dormant tubers of white fleshed D. alata tubers and fresh okra pods purchased from a local market in Abeokuta, Nigeria were used for this investigation.

Preparation of yam flakes and okra powder

Okra pods were washed sliced to about 2 cm thick and dried at about 60 °C in locally fabricated cabinet dryer for up to 3 h. Drying okra at this temperature gives high quality dried slices (Pendre et al. 2011). The dried slices were milled and sieved through 0.1 mm screen to give okra powder. Yam tubers were washed, peeled and carefully grated using the local stainless steel grater. The grated samples were thinly spread on stainless steel trays for drying in a cabinet dryer thermostatically set at a temperature of 60 °C until the moisture contents were below 12% (wet basis). The dried flakes were then cooled, pulverized and packaged in sealed high density polythene bags and kept under a dry cool condition.

Dispersibility

Dispersibility was determined by the modified method of Kulkarni et al. (1991). Ten grams of flour were weighed into a 250 ml measuring cylinder and distilled water was added to reach a volume of 100 ml. The set up was stirred vigorously and allowed to settle for 3 h. Percent dispersibility was calculated as ratio of dispersed column divided by the initial column volume. Analyses were done in triplicate.

Viscosity

The reconstituted samples were placed in a 500 ml measuring cylinder and viscosity was measured rotational viscometer (Model DV-E, Brookfield Inc. UK). The viscosity of the samples was measured with a spindle size of 5, at rotational speed of 100 rpm and at room temperature (29 ± 2 °C). The spindle rotates for 5 min before making the measurement and the torque reading was >10%. Viscosity values were recorded in centipoises (cP). Analyses were done in triplicate.

Preparation of ojojo

Raw yam tuber was peeled, washed, grated and mixed with condiment, before dip frying. On the other hand, to prepare ojojo from YF, okra powder was mixed with YF at about 0%–5% w/w. Mixing with water was done to give a blend of about 70% moisture content (wet basis) using Kenwood electric blender (Model KM800) at medium speed. To each of the sample, condiment (about 2 g salt and 5 g chopped onion per 100 g of grated RY or reconstituted YF) was added. About 10 g of the RY grates or reconstituted YF mixes were deep-fried in hot vegetable oil at 160°C for 11 min. Fried products were drained in a stainless steel mesh and allowed to equilibrate at room temperature.

Fat and moisture content of ojojo samples

The fat and moisture content of water yam, flour and fried ojojo were estimated in triplicate according to AOAC methods 221.03 and 934.06, respectively (AOAC 1990). Analyses were done in triplicate.

Sensory evaluation

Sensory evaluation of ojojo was performed using quantitative descriptive analysis (QDA) and hedonic rating. For hedonic rating, samples of coded ojojo were served warm to twenty untrained panelists to rate their preference for appearance, texture, taste, flavour and overall acceptability using a five point scale of 1 (extremely like) and 5 (extremely dislike). Quantitative descriptive analysis of ojojo was done following the procedure described by Stone and Sidel (1993). Eight trained panelists participated in the evaluation. The descriptive terms were derived after initial free choice profiling where the panelists were asked to describe the sample by using descriptive terms that were suitable for the samples. The descriptors were used for the development of a ‘score card’ that consisted of all attributes on a 15 cm scale each. Evaluations were done in a sensory laboratory with individual booths under fluorescent lightening, similar to daylight. Three-digit coded samples were served warm in porcelain plates and panelists were asked to indicate the perceived intensities of the attributes by drawing a vertical line on the scale and writing the code number. Distilled water was used for rinsing and biscuit cracker for cleansing the palate in-between two evaluations (Ramassamy and Nuggehalli 2004).

Statistical analysis of data

One way analysis of variance (ANOVA) was performed to test the significance of differences between sample means. Duncan’s Multiple Range Test was applied to separate the significantly different means of parameters. SPSS (Statistical Package for Social Scientist) version 10.0 was used for data analysis. The charts were drawn using Microsoft Excel 2007 Package.

Results and discussion

Functional properties of reconstituted yam flakes

The mean values of the functional properties of reconstituted dried yam flakes (YF) supplemented with okra powder are shown in Table 1. One-way ANOVA shows that the addition of okra powder to the YF caused significant differences in the dispersibility of the reconstituted YF. Dispersibility is the ease with which the reconstituted food powder becomes distributed as a particulate in the bulk liquid phase (Shittu and Lawal 2007). The addition of okra increased the dispersibility of the reconstituted sample, which may be attributed to the presence of mucilage in the okra powder. Mucilage consists of polysaccharides that have high affinity for binding water (Nilufar et al. 1993). Okra powder addition was found to proportionately increase the dispersibility of yam flakes and this corroborates with the viscosity data (Table 1). The increased viscosity with the addition of okra powder is expected to enhance the textural quality of ojojo as highly viscous water yam mash is preferred for preparation of ojojo (Onwueme 1978).

Table 1.

Effect of okra powder on functional properties of reconstituted yam flakes, fat, moisture content and sensory acceptability scores of ojojo

| Okra powder (%) | Reconstituted yam flake | Deep fried ojojo | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Dispersibility (%)a | Viscosity (cP)a | Fat (%)a | Moisture (%)a | Colourb | Flavourb | Textureb | Tasteb | Overall acceptabilityb | |

| 0 | 31.3 ± 4.9a | 1034.7 ± 32.1a | 25.6 ± 1.4e | 16.1 ± 4.5a | 1.1 ± 0.3a | 1.7 ± 0.7a | 1.8 ± 0.6ab | 1.8 ± 0.6ab | 1.5 ± 0.5a |

| 1 | 36.3 ± 6.9b | 1164.0 ± 34.1b | 24.8 ± 2.3d | 17.0 ± 3.3a | 1.4 ± 0.5ab | 2.2 ± 0.4ab | 2.5 ± 0.6ab | 1.9 ± 0.6ab | 1.9 ± 0.6ab |

| 2 | 42.3 ± 3.3c | 2189.3 ± 35.0c | 24.2 ± 3.6d | 17.3 ± 5.2a | 1.8 ± 0.4bc | 2.0 ± 0.8ab | 1.9 ± 0.6ab | 1.8 ± 0.6ab | 1.8 ± 0.8ab |

| 3 | 60.0 ± 6.7d | 2370.7 ± 28.7d | 23.4 ± 5.6c | 24.0 ± 4.5b | 2.1 ± 0.7c | 2.7 ± 0.7bc | 2.2 ± 0.4b | 2.2 ± 0.6b | 2.3 ± 0.5b |

| 4 | 68.5 ± 4.7e | 2704.0 ± 20.1e | 22.1 ± 4.7b | 29.4 ± 6.5c | 2.4 ± 0.8c | 2.6 ± 0.8bc | 2.5 ± 1.1b | 1.9 ± 1.1ab | 2.2 ± 0.8b |

| 5 | 71.8 ± 9.1f | 2849.3 ± 15.2f | 20.0 ± 4.5a | 40.3 ± 3.9d | 3.6 ± 1.3d | 3.0 ± 0.9c | 1.9 ± 0.6ab | 3.0 ± 0.9c | 3.3 ± 1.1c |

aMeans value (n = 3)

bMean values (n = 20)

Means values followed by the same alphabet in each column are not significantly different at p < 0.05

Chemical composition of ojojo

The results showing the effect of increasing okra concentration on the fat content and moisture content of ojojo are presented in Table 1. The fat and moisture contents of the products ranged between 20.0 to 26.0% and 16.0 and 40.33%, respectively. There was a significant difference in the moisture and fat content of the fried products. The fat content reduced significantly (P < 0.05) with increased okra concentration, whereas the moisture content of ojojo sample increased significantly with increasing okra powder concentration. The fat content reduced by a factor of 21.8% as the okra content increased from 0 to 5%. With the increasing consciousness of food manufacturers and consumers on the health implications of food products, the reduction in fat content with increased okra concentration is definitely an advantage (Bullens 1994; Katz 2000). It has been reported that reducing fat consumption to the recommended 30% level could increase average life expectancy by 3–4 months (Browner et al. 1991). Increased moisture content with increasing okra concentration could reduce the shelf-stability by increasing the susceptibility of ojojo to microbial spoilage. It should however be stated that moist core is an attribute that is well accepted for ojojo. This increased moisture content with increased okra concentration could be attributed to the higher water retention capacity of okra powder compared to yam flakes. The high content of polysaccharide gums in food materials leads to enhanced water retention (Lee et al. 2002).

Sensory acceptability

The sensory acceptability of the ojojo samples with different levels of okra powder addition is shown in Table 1. The colour, flavour, texture and taste attributes differed significantly (p < 0.05). Generally, the acceptability scores of ojojo from reconstituted yam flakes (YF) decreased with increased okra concentration. Samples containing up to 2% of okra powder compared favorably with ojojo from raw un-dried yam (RY). The scores of colour, taste and flavour of ojojo from reconstituted YF with 0%–2% okra powder compared favorably with those prepared from un-dried raw yam (RY). Likewise, the textural characteristics of ojojo with 3%–5% okra powder compared favourably with those prepared from RY.

Sensory descriptive profile

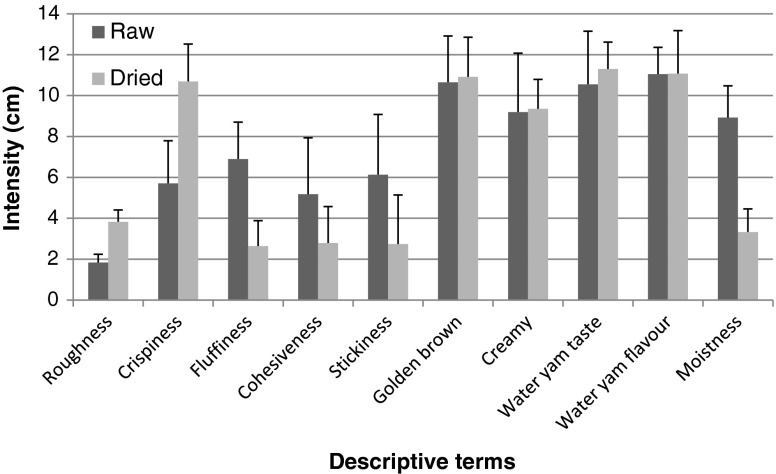

Figure 1 shows the comparative sensory profile of ojojo samples made from raw (RY) and dried water yam flake (YF) without okra substitution. The most intense sensory attribute of ojojo samples from RY are the golden brown color, water yam taste and flavor. The intensity of golden brown and water yam taste slightly increased for YF. The taste and flavour characteristics of the ojojo samples from YF and RY were not significantly different. However, these samples had significantly different textural attributes (p < 0.05) except cohesiveness. The roughness and crispiness of ojojo from RY were significantly lower (p < 0.05) while the fluffiness, stickiness and moistness of product were significantly higher (p < 0.05) than YF. With the increased roughness and crispiness, and reduced fluffiness, cohesiveness, stickiness and moistness, drying of yam has made ojojo from YF inferior compared with RY. In order to make up for the quality impairment ojojo from YF, functional ingredients must be introduced into the preparation.

Fig. 1.

Effect of drying water yam on the sensory profile (n = 8) of ojojo

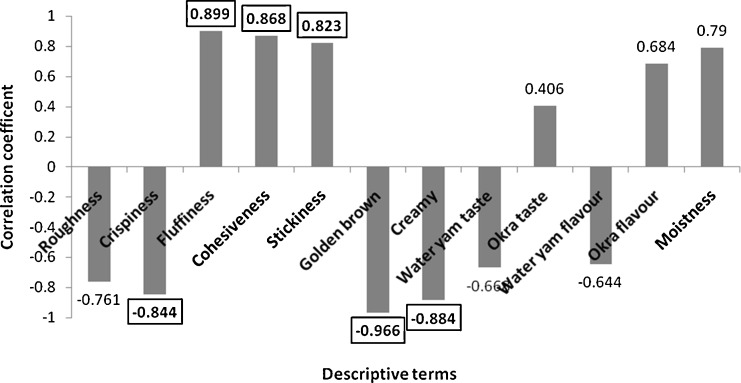

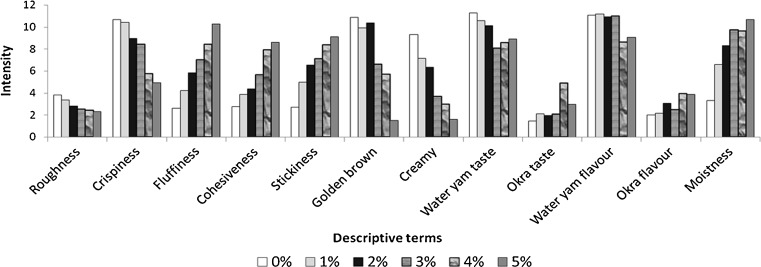

The introduction of dried okra powder as ingredient in this study was expected to reduce some of the losses in sensory quality attributes. In order to appreciate the relationships between individual sensory attribute and the overall acceptability of ojojo samples supplemented with okra powder, linear correlation analysis was performed. The result shown in Fig. 2 indicates that appearance and textural attributes of the products had more significant correlations (p < 0.05) with overall acceptability than the taste and flavor notes. Specifically, the fluffiness, cohesiveness, stickiness and moistness were found to be the most important sensory attributes that could positively influence the acceptability of ojojo. Therefore, in any product development study for ojojo, these attributes should be given close marking. Moreover, the significant negative correlations of crispiness, brownness, and creaminess with the overall acceptability in the products indicate that these attributes should be reduced as much as possible to enhance the acceptability of the product. Our findings further showed that addition of okra consistently improved the quality of ojojo by increasing the products moistness and fluffiness while it reduced crispiness and roughness (Fig. 3).

Fig. 2.

Correlation coefficients of sensory descriptive terms with the overall acceptability of ojojo samples. Correlation coefficients values in boxes are significant at 95% confidence limit

Fig. 3.

Effect of okra powder addition on the sensory profile (n = 8) of ojojo

Conclusions

Based on the findings of this study, it can be concluded that increased okra powder concentration from 0 to 5% significantly reduced the fat content of ojojo by about 21.8%. Conversion of RY to YF by drying caused significant reduction in fluffiness and increased crispiness of ojojo. The fluffiness, cohesiveness, stickiness, moistness, crispiness, brownness and creaminess were found to be the most important sensory attributes influencing the acceptability of ojojo. Although, addition of 0%–2% okra powder improved the colour, flavour and taste characteristics of ojojo, inclusion of 3%–5% okra powder gave ojojo samples that had similar textural quality with those prepared from RY.

References

- Almentros VP, Del Rosatio RR. Phenolic content and polyphenoloxidase activity related to browning in yam (Dioscorea alata Linn) Phil Agric. 1985;68:44–452. [Google Scholar]

- Official methods of analysis. 15. Washington, DC: Association of Official Analytical Chemists; 1990. [Google Scholar]

- Aworh OC (2008) The role of traditional food processing technologies in national development: the West African experience (Chapter 3). In: Robertson GL, Lupien JR (eds) Using food science and technology to improve nutrition and promote national development. International Union of Food Science and Technology

- Browner WS, Westernhouse J, Tice JA. What if Americans ate less fat? A quantitative estimate of the effect on mortality. J Am Med Assoc. 1991;265:3285–3291. doi: 10.1001/jama.1991.03460240081032. [DOI] [PubMed] [Google Scholar]

- Bullens C. Reduced-fat Cheddar: aspects of process and ingredient effect. World Ingred. 1994;1:28–31. [Google Scholar]

- De Boer M, McCarthy M, Cowan C, Ryan I. The influence of lifestyle characteristics and beliefs about convenience food on the demand for convenience foods in the Irish market. Food Qual Prefer. 2004;15:155–165. doi: 10.1016/S0950-3293(03)00054-5. [DOI] [Google Scholar]

- Hsu CL, Hurang SL, Chen W, Weng YM, Tseng CY. Qualities and antioxidant properties of bread as affected by the incorporation of yam flour in the formulation. Int J Food Sci Tech. 2003;39:231–238. doi: 10.1046/j.0950-5423.2003.00770.x. [DOI] [Google Scholar]

- Jaeger SR. Non-sensory factors in sensory science research. Food Qual Prefer. 2006;17:132–144. doi: 10.1016/j.foodqual.2005.03.004. [DOI] [Google Scholar]

- Katz F. Research priorities move toward health and safe. Food Technol. 2000;54:42–46. [Google Scholar]

- Kulkarni KD, Kulkarni DN, Ingle UM. Sorghum malt-based weaning formulations: preparation, functional properties, and nutritive value. Food Nutr Bullet. 1991;13:322–327. [Google Scholar]

- Lebot V, Malapa R, Molisale T, Marchand JL. Physico-chemical characterization of yam (Dioscorea alata L.) tubers from vanatu. Gen Res Crop Evol. 2005;53:1199–1208. doi: 10.1007/s10722-005-2013-2. [DOI] [Google Scholar]

- Lee MH, Baek MH, Cha DS, Park HJ, Lim ST. Free thaw stabilization of sweet potato starch gel by polysaccharides gums. Food Hydrocol. 2002;16:345–352. doi: 10.1016/S0268-005X(01)00107-2. [DOI] [Google Scholar]

- Nilufar N, Mosihuzzaman M, Dey SK. Analysis of free sugar and dietary fibre of some vegetables of Bangladesh. Food Chem. 1993;46:397–400. doi: 10.1016/0308-8146(93)90011-4. [DOI] [Google Scholar]

- NRI Greater yam (Dioscorea alata) Root Crops. 1987;37:308. [Google Scholar]

- Onwueme IC. The tropical tuber crops: yams, cassava. Sweet potato and cocoyams. Chichester: Wiley; 1978. pp. 215–225. [Google Scholar]

- Osagie AU, Opoku AR. Enzymatic browning of yams (Dioscorea species) Niger J Biochem. 1984;1:25–29. [Google Scholar]

- Pendre NK, Nema PK, Sharma, HP, Rathore SS, Kushwah SS (2011) Effect of drying temperature and slice size on quality of dried okra (Abelmoschus esculentus (L.) Moench). J Food Sci Technol, Online First™ [DOI] [PMC free article] [PubMed]

- Ramassamy R, Nuggehalli SS. The effect of the concentration of batter made from chickpea (cicer arientium L.) flour on the quality of a deep-fried snack. Int J Food Sci Technol. 2004;39:755–762. doi: 10.1111/j.1365-2621.2004.00841.x. [DOI] [Google Scholar]

- Sagar VR, Kumar PS. Recent advances in drying and dehydration of fruits and vegetables: a review. J Food Sci Technol. 2010;47:15–26. doi: 10.1007/s13197-010-0010-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shittu TA, Lawal MO. Factors affecting instant properties of powdered cocoa beverages. Food Chem. 2007;100:91–98. doi: 10.1016/j.foodchem.2005.09.013. [DOI] [Google Scholar]

- Stone H, Sidel JS. Sensory evaluation practices. California: Academic; 1993. [Google Scholar]