Abstract

About a century ago, researchers first recognized a connection between the activity of environmental microorganisms and cases of anaerobic iron corrosion. Since then, such microbially influenced corrosion (MIC) has gained prominence and its technical and economic implications are now widely recognized. Under anoxic conditions (e.g., in oil and gas pipelines), sulfate-reducing bacteria (SRB) are commonly considered the main culprits of MIC. This perception largely stems from three recurrent observations. First, anoxic sulfate-rich environments (e.g., anoxic seawater) are particularly corrosive. Second, SRB and their characteristic corrosion product iron sulfide are ubiquitously associated with anaerobic corrosion damage, and third, no other physiological group produces comparably severe corrosion damage in laboratory-grown pure cultures. However, there remain many open questions as to the underlying mechanisms and their relative contributions to corrosion. On the one hand, SRB damage iron constructions indirectly through a corrosive chemical agent, hydrogen sulfide, formed by the organisms as a dissimilatory product from sulfate reduction with organic compounds or hydrogen (“chemical microbially influenced corrosion”; CMIC). On the other hand, certain SRB can also attack iron via withdrawal of electrons (“electrical microbially influenced corrosion”; EMIC), viz., directly by metabolic coupling. Corrosion of iron by SRB is typically associated with the formation of iron sulfides (FeS) which, paradoxically, may reduce corrosion in some cases while they increase it in others. This brief review traces the historical twists in the perception of SRB-induced corrosion, considering the presently most plausible explanations as well as possible early misconceptions in the understanding of severe corrosion in anoxic, sulfate-rich environments.

INTRODUCTION

Ever since its first production roughly 4,000 years ago, iron has played a central role in human society due to its excellent mechanical properties and the abundance of its ores. Today, iron is used in much larger quantities than any other metallic material (1) and is indispensable in infrastructure, transportation, and manufacturing. A major drawback is the susceptibility of iron to corrosion. Corrosion of iron and other metals causes enormous economic damage. Across all industrial sectors, the inferred costs of metal corrosion have been estimated to range between 2% and 3% of gross domestic product (GDP) in developed countries (2, 3). These costs are to a large extent caused by corrosion of iron, due to its abundant use and particular susceptibility to oxidative damage. Estimates of the costs attributable to biocorrosion of iron lack a computed basis so that they vary widely, and definite numbers cannot be given with certainty. Still, microbially influenced corrosion (MIC) probably accounts for a significant fraction of the total costs (4–7), and, due to its effects on important infrastructure in the energy industry (such as oil and gas pipelines), costs in the range of billions of dollars appear realistic.

Protection of iron against almost all types of corrosion can be achieved by painting or other coating. However, these measures are not always technically feasible (e.g., they are difficult to implement inside pipelines or tanks) and have a limited service life (8). Alloying of iron with more active metals such as chromium, nickel, and molybdenum, on the other hand, yields stainless steels of high corrosion resistance. Still, large-scale application of stainless steels is economically not achievable to any extent. As a result, corrosion-prone carbon steel (typically ≥98% Fe0) is the most widely used metal in technical infrastructures such as oil and gas pipelines (2, 9).

Except for some cases caused by erosion or mechanical stress, the corrosion of iron is mostly an electrochemical process (10, 11), coupling metal oxidation to the reduction of a suitable oxidant. In contrast to redox reactions of nonmetals, it is not necessarily the case that iron oxidation and reduction of the oxidizing agent must occur at the same locality. Spatial separation of oxidative (anodic) and reductive (cathodic) reactions is possible as the metallic matrix allows the free flow of electrons from anodic to cathodic sites. Central to iron corrosion is the high tendency of the metal to give off electrons according to the following anodic reaction:

| (1) |

where Eo is the revised standard potential (12, 13). Hydrated ferrous ions move into solution only as long as electrons, which cannot enter the aqueous phase, are removed from the surface by a suitable chemical reactant. The most common reactant in iron corrosion is molecular oxygen (E°′ = +0.81 V), and corrosion of iron in oxic environments ultimately leads to the formation of various iron (hydr)oxides (“rust”).

In the absence of oxygen, on the other hand, the most common electron acceptors for iron oxidation are protons from dissociated water. Here, the cathodic reaction consisting of proton reduction to molecular hydrogen occurs as follows:

| (2) |

Owing to the condition of electroneutrality, the anodic and cathodic half-reactions are stoichiometrically coupled, which in the case of equations 1 and 2 yields the following net reaction:

| (3) |

Ferrous iron from equation 3 readily precipitates in most anoxic environments (e.g., as FeCO3) such that the activity a of Fe2+(aq) usually remains low, thus making reaction 3 even more favorable, e.g., ΔGenviron = −27.7 kJ (mol Fe0)−1 at a(Fe2+) = 10−3 and pH 7 (otherwise standard conditions). However, reaction 2 is “kinetically impeded” (14, 15) and particularly slow at pH > 6, where proton availability is limiting (16). Hence, iron corrosion is technically insignificant in the absence of oxygen or acid and iron constructions in many anoxic environments (e.g., marine sediment, water-logged soil) could, in principle, last for centuries.

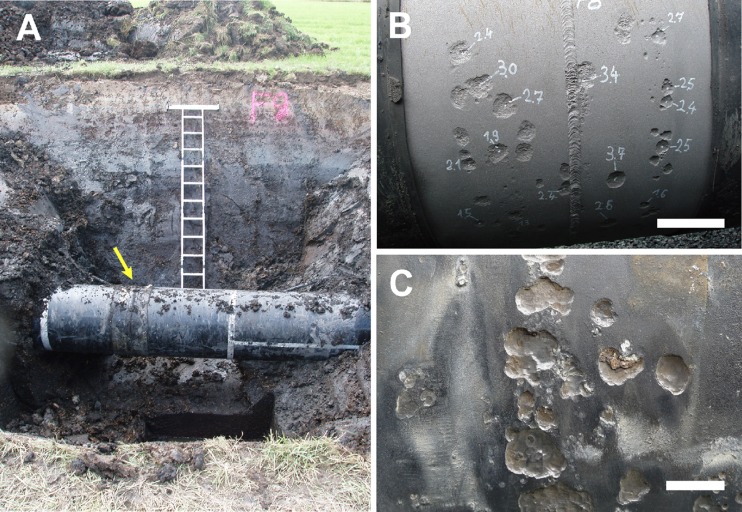

However, the scenario described above changes in the presence of microorganisms, some of which dramatically accelerate corrosion kinetics. This is particularly true in environments with little or no oxygen and pH > 6, i.e., where, from a purely chemical point of view, corrosion rates should be low. In technology, the phenomenon is referred to as (anaerobic) microbially influenced corrosion (MIC) or anaerobic biocorrosion. Figure 1 depicts a common example of MIC, viz., external corrosion under the disbonded coating of an iron pipeline in anoxic, sulfate-containing soil. Numerous ways by which microorganisms influence the corrosion of iron have been suggested (5, 17–20). Microbial corrosion in oxic environments, for instance, typically originates from localized colonization and microbial O2 consumption at iron surfaces which can trigger preferential material loss at these sites (“pitting”; 21–23). Additionally, dissolution of protective rust deposits by aerobic iron-oxidizing microorganisms can influence corrosion rates (24–26). Under anoxic conditions or in systems with only temporary O2 ingress, microbial corrosion tends to be even more pronounced. Here, corrosion results from microbial metabolic products such as organic acids (27, 28), hydrogen sulfide (12, 29, 30), or other corrosive sulfur species (31–34). In addition to these indirect effects, more-direct interactions between certain microorganisms and iron have been demonstrated (12, 35–39).

FIG 1.

External corrosion on buried gas transmission pipeline in bog soil of Germany. (A) Trench with coated carbon steel gas pipeline in water-logged, anoxic soil (1.4 mM sulfate, 17 mM dissolved inorganic carbon [DIC]). External corrosion has occurred under disbonded coating at welding sites (arrow). (B) Welding site with corrosion pits. Disbonded asphalt coating and corrosion products (FeS/FeCO3) were removed. Numbers indicate pit depth in millimeters. Bar, 20 cm. (C) Higher magnification of corrosion pits from a different site at the same pipeline. Bar, 2 cm.

Most studies have focused on the corrosive effects of sulfate-reducing bacteria (SRB), but other physiological groups such as thiosulfate-reducing bacteria (40), nitrate-reducing bacteria (41–44), acetogenic bacteria (45), and methanogenic archaea (38, 39, 46–49) have also been implicated in iron corrosion. Still, the physiological group of environmental microorganisms with a suggested key role in the anaerobic corrosion of iron consists of the SRB (5, 6, 50, 51), which are widespread in many natural as well as engineered aquatic environments. SRB gain energy for growth by reduction of sulfate to hydrogen sulfide with electrons usually derived from the degradation of organic matter or from molecular hydrogen, which is a common fermentation product in soil, sediment, and other anoxic settings (52). The suggested key function of SRB in biocorrosion is principally grounded on the following three observations. First, iron in anoxic environments containing sulfate, i.e., the electron acceptor of SRB, is particularly prone to microbial corrosion (Fig. 1) (37, 53, 54). Second, SRB, or their characteristic corrosion product FeS, are ubiquitously found on anaerobically corroded iron (54–59). Third, with corrosion rates of up to 0.9 mm Fe0 year−1 (35 mils per year [mpy]), pure laboratory-grown SRB cultures corrode iron to an extent (12, 60, 61) that matches even severe cases of corrosion in the field. Hence, field data strongly suggest a prominent role of SRB in anaerobic iron corrosion whereas laboratory investigations provide the plausible mechanistic explanations (5, 12, 51).

This review first gives a brief account of the historical twists in the perception of SRB-induced corrosion. We then comment on the issue of how SRB phylogeny relates to corrosion and finally discuss in detail the respective mechanisms that are currently believed to most severely affect iron in sulfate-rich environments.

SRB: LONG-KNOWN KEY PLAYERS IN ANAEROBIC IRON CORROSION

The first evidence for an involvement of SRB in anaerobic corrosion was already provided more than a hundred years ago. In 1910, Gaines reported the analysis of sulfur-rich corrosion products from anaerobically corroded iron constructions and hypothesized about a connection to the bacterial sulfur cycle (62). However, it was the work of von Wolzogen Kühr and van der Vlugt in 1934 that identified SRB as the prime cause of widespread iron pipe failures in the sulfate-rich soils of North Holland (37). Those authors proposed a purely lithotrophic microbial process, with iron as the only source of reducing equivalents. They attributed microbial corrosion to a prominent physiological trait, the utilization of cathodic hydrogen (equation 3) as the sole electron donor by SRB (37, 63). The mechanistic explanation became famous as the (classical) “cathodic depolarization theory.” Much controversy followed in the subsequent decades. Most authors initially favored the theory (6, 64–66), while only a few questioned the idea that microbial H2 scavenging would accelerate corrosion (67, 68). With the beginning of the 1960s, the hypothesis was subjected to a series of electrochemical investigations (65, 69–71). Indeed, there seemed a connection between the ability of bacterial cultures to consume cathodic hydrogen and the stimulation (“depolarization”) of the cathodic reaction in iron corrosion. However, despite the original lithotrophy-based concept of von Wolzogen Kühr and van der Vlugt, many of the later experiments were performed with lactate as an additional, organic electron donor for sulfate reduction. This greatly complicated the evaluation of obtained data. Costello (1974) convincingly demonstrated that hydrogen sulfide from organotrophic sulfate reduction (e.g., with lactate) was a cathodically active compound (29); hence, much of the electrochemical evidence for the “cathodic depolarization theory” became disputable. The previously observed acceleration of cathodic reactions in SRB cultures (65, 69–71) could now be explained by reaction between sulfide and iron rather than by microbial consumption of cathodic H2. Since then, occasional attempts to resurrect the theory have been made (38, 42, 72–74), but to date, no culture-based experiment has been able to demonstrate that bacterial consumption of cathodic hydrogen accelerates iron corrosion to any significant extent (39, 47, 67, 75). It should be stressed at this point that the study of a direct corrosive effect of SRB requires the use of essentially organic matter-free cultivation media to avoid unnecessary complication or even misinterpretation of data resulting from the corrosive effects of H2S.

In fact, it seemed at the time that much of the corrosiveness of SRB could be attributed entirely to their formation of H2S, which is a powerful cathodic and anodic reactant (29, 65, 76). H2S is known to rapidly react with metallic iron [net reaction, H2S + Fe0 → FeS + H2, ΔG° = −72.5 kJ (mol Fe0)−1], thereby forming the characteristic corrosion product iron sulfide.

In the late 1960s and early 1970s, several authors demonstrated that such biogenic iron sulfides accelerated corrosion when deposited on the metal (77–79). Interestingly, sustained corrosion by iron sulfides required the presence of active populations of SRB. The exact mechanisms in this corrosion scenario have never been fully resolved (51, 80).

Furthermore, considerable attention was given to the formation of protective (“passivating”) iron sulfide films (51, 76, 81, 82), i.e., a common phenomenon which reduces rather than accelerates the corrosion of iron by impeding the diffusion of oxidized iron (ions) from the metal surface to the bulk liquid. It is generally agreed that such thin iron sulfide layers are among the rate-controlling factors of corrosion (9, 51, 83).

Hence, until recently, SRB-induced corrosion was viewed as the result of biogenic H2S and the catalytically active iron sulfides that are formed in the process of “H2S corrosion.” In addition to these indirect effects, there remained speculation concerning the possibility of direct corrosiveness of SRB, often proposed in the elusive form of a “regeneration” of “charged” iron sulfides through microbial hydrogen consumption (55, 78, 80, 84).

In 2004, experimental evidence for a novel corrosion mechanism was furnished through isolation of SRB from enrichment cultures with metallic iron as the only electron donor (39). Apparently, sulfate reduction by these peculiar strains was directly fuelled by bacterial consumption of iron-derived electrons, without the involvement of cathodic hydrogen gas as an intermediate. In fact, while even the most efficient hydrogen-utilizing SRB did not accelerate iron corrosion compared to sterile tests when grown in organic matter-free (lithotrophic) cultures, these novel isolates accelerated iron oxidation up to 71-fold under the same conditions (12). The existence of such a direct mechanism of electron uptake had previously been considered by some investigators (55, 85) but without the availability of defined model organisms for experimental validation. Recently, the process was able to be studied in greater detail (12, 86) and the term “electrical microbially influenced corrosion” (EMIC) was proposed (12). EMIC, which is fundamentally different from the corrosive effects of biogenic H2S, can destroy metallic structures at rates of high technological relevance (Fig. 2) (12, 60).

FIG 2.

Corrosion of an iron key in the presence of Desulfovibrio ferrophilus strain IS5 (A to C) and corrosion under sterile (control) conditions (D to F). Both incubations were performed in artificial seawater medium at pH 7.3 and without addition of organic substrates (lithotrophic medium). (A to C) Electrical microbially influenced corrosion (EMIC) of the first key (A) led to substantial buildup of biogenic corrosion crust (B) and metal destruction (C) during 9 months. (D to F) Abiotic corrosion of another key (D) in sterile medium during 27 months formed minimal corrosion products (E) and led to negligible metal loss (F). Bar, 1 cm. (A) Iron key before incubation with D. ferrophilus strain IS5. (B) Iron key with biogenic corrosion crust after 9 months of incubation with pure culture of strain IS5. (C) Residual iron after removal of the crust (B) with inactivated acid (10% hexamine in 2 M HCl) revealed 80.3% (2.7 g) iron weight loss due to corrosive activity of strain IS5. Hexamine-HCl did not dissolve Fe0. (D) Iron key before sterile incubation. (E) Iron key incubated in sterile artificial seawater medium. Corrosion is much less pronounced despite 27 months of incubation. (F) Residual iron after removal of corrosion products with inactivated acid (10% hexamine in 2 M HCl) revealed 2.9% (0.09 g) iron weight loss due to abiotic corrosion. Hexamine-HCl did not dissolve Fe0.

While EMIC has so far been observed in only a limited number of highly corrosive SRB isolates (see the next section), all SRB—by definition—can influence corrosion through excretion of the chemical H2S (“chemical microbially influenced corrosion”; CMIC) if sulfate and suitable electron donors are present. In conclusion, SRB act as either direct or indirect catalysts of anaerobic iron corrosion (EMIC and CMIC, respectively) and there are species-specific differences in this respect.

WHO'S WHO IN SRB-INDUCED CORROSION? PHYLOGENETIC DISTRIBUTION AND ECOLOGICAL SIGNIFICANCE OF DIRECT CORROSION BY SRB

Sulfate-reducing bacteria are found in five phylogenetic lineages, with most isolated strains being organotrophic mesophilic Deltaproteobacteria (52). Additionally, certain Archaea exhibit a sulfate-reducing metabolism (87, 88) and archaeal thermophiles such as Archaeoglobus fulgidus may well contribute to corrosion in oil- and gas-producing facilities, particularly under conditions too hot to allow growth of their bacterial sulfidogenic counterparts (89, 90).

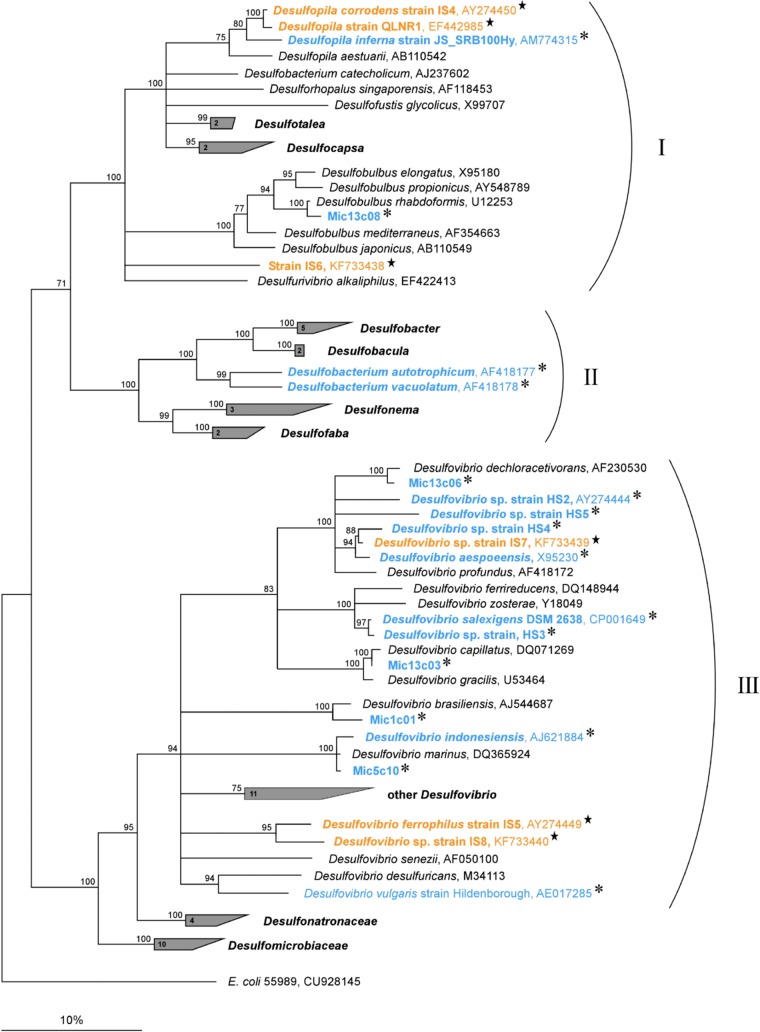

However, there is currently only a limited number of sulfate-reducing isolates for which EMIC has been demonstrated and these are, thus far, all members of the deltaproteobacterial families Desulfovibrionaceae and Desulfobulbaceae (Fig. 3, highlighted in orange). Two of the isolates, Desulfovibrio ferrophilus and Desulfopila corrodens, have been key in the recent investigations of this new type of microbe-metal interaction (12, 39, 60, 86). Such strains have probably evaded earlier discovery as they are rapidly outcompeted by “conventional” organotrophic SRB in the commonly used media that employ high concentrations of organic substrates such as lactate (91, 92). It should be emphasized in this context that many of the commonly studied organotrophic SRB do not show the capability to corrode iron directly via the EMIC mechanism (12, 39, 47). Figure 3 contains a compilation of 16 sulfate reducers (highlighted in blue) that did not corrode iron when tested under lithotrophic growth conditions, i.e., in the absence of organic electron donors. Curiously, there are only a few reports on organic matter-free enrichment cultures in the study of microbial corrosion (37, 39, 93). Still, attempts to enrich for directly corrosive SRB with iron as the only electron donor have consistently proven successful in cultures inoculated with anoxic marine sediments from a variety of geographic locations such as the North Sea, Singapore, or Vietnam (39, 49, 61).

FIG 3.

Phylogenetic tree constructed from full-length 16S rRNA gene sequences of cultivated sulfate-reducing bacteria within the Deltaproteobacteria. The tree shows SRB isolates capable of direct electron uptake (EMIC; orange and ★) and hydrogenotrophic SRB that cannot corrode iron by the EMIC mechanism (blue and *). Other SRB (black) were not tested on Fe0. All depicted SRB corrode iron via the CMIC mechanism in the presence of suitable electron donors and sulfate. The tree does not include all cultivated SRB. I, Desulfobulbaceae; II, Desulfobacteraceae; III, Desulfovibrionaceae. The tree was calculated based on maximum likelihood with the ARB software package and SILVA database (126, 127). Branching with bootstrap values below 75 is not depicted. The scale bar represents a 10% difference in sequence similarity. “Mic” isolates are from Mori et al. (2010) (47). The figure was adapted from Enning (2012) (61).

Interestingly, Dinh et al. (2004) and Uchiyama et al. (2010) isolated corrosive methanogenic archaea by omission of sulfate from otherwise similar enrichments with iron (39, 48). Methanobacterium-like strain IM1 (39) and Methanococcus maripaludis strain KA1 (48) were shown to corrode iron by direct electron uptake, and the involvement of similar methanogenic strains in anaerobic biocorrosion in sulfate-limited environments seems likely. We expect the number of sulfate-reducing and methanogenic isolates with the capability of EMIC to grow significantly if more researchers embrace the concept of lithotrophic cultivation.

The molecular mechanisms that enable certain SRB to withdraw electrons directly from iron are currently unknown. Likewise, there is presently no information as to whether this is a genetically fixed trait or whether conventional hydrogenotrophic SRB can also adapt to iron utilization when exposed to it over long periods of time (12). It is assumed that direct electron uptake from iron involves outer membrane redox proteins such as c-type cytochromes (39), found in other microorganisms that interact with extracellular electron donors (94, 95) and acceptors (96, 97). This is certainly an exciting area for future research with possible synergies with other topics in the developing scientific discipline of “electromicrobiology.”

Generally, microbial uptake of electrons from extracellular surfaces is a widespread and ecologically significant process in many environments (98–101). In the context of microbial corrosion, it is particularly interesting to question the evolutionary roots and ecological significance of direct electron uptake. Significant quantities of anthropogenic metallic iron have been present on Earth for only approximately 4,000 years and would thus represent a rather recent electron donor in the evolution of microbial physiologies. Metallic iron originating from meteorites or deep subsurfaces (102, 103), on the other hand, is very rare, although the idea of an evolution coupled to such minerals is certainly fascinating.

Still, we speculate that the EMIC mechanism may in fact represent an evolutionarily undirected physiological trait. Microbes have evolved a multitude of physiological strategies to exploit other (non-Fe0) solid electron donors, acceptors, and electrical mediators. For example, it has previously been shown that addition of semiconductive iron minerals to syntrophic microbial cultures can accelerate the rates of substrate turnover, indicating complex bioelectric interactions between microbes and iron minerals (98, 99). Similarly, recent reports describe the existence of filamentous sulfate-reducing bacteria that conduct electrons internally over centimeter distances (101) to couple distant biogeochemical processes (100). Interestingly, SRB with the ability of direct electron uptake from iron (Fe0) appear to be abundant in nature. In a previous study, more than 107 cells per gram wet weight were counted in marine anoxic sediments, despite the apparent absence of man-made iron constructions (12). We hence hypothesize that the remarkable ability of certain SRB to withdraw electrons from metallic iron is in fact derived from their ability to accept electrons from other biotic and abiotic external surfaces (12).

EMIC VERSUS CMIC—EMERGING THEORIES IN SRB-INDUCED CORROSION

Obviously, there is no single, generalized explanation for SRB-induced corrosion. Yet a causal understanding of the basic underlying mechanisms and principles is possible. Generally, abiotic corrosion of iron in anoxic, circumneutral environments is a very slow process if proton reduction to H2 (equation 2) is the most important cathodic (i.e., electron-accepting) reaction (Fig. 2D to F). However, there are particular environments that support proliferation of sulfate-reducing bacteria which, once present in sufficient numbers, can profoundly affect metal corrosion. Corrosion may proceed 70 to 90 times faster in the presence of SRB than under conditions of sterile control experiments (12, 104; compare also Fig. 2A to C with Fig. 2D to F).

The aforementioned “classical” cathodic depolarization theory by von Wolzogen Kühr and van der Vlugt (37) attributed such metal damage to the microbial consumption of cathodic hydrogen. In fact, this model declared microbial H2 uptake to be a necessary prerequisite for hydrogen-forming corrosion (equation 3; Fe0 + 2 H+ → Fe2+ + H2) to proceed in the first place (37, 63). However, the validity of the model is questionable. Under environmental conditions, anaerobic corrosion of iron according to equation 3 is generally thermodynamically feasible, even in the absence of anaerobic microorganisms that remove the reaction product H2 (12, 85, 86, 104). It is rather the limiting availability of protons, as well as the kinetically impeded formation of H2 on iron, that explains the low rates of anaerobic corrosion under sterile, circumneutral conditions (e.g., as shown in Fig. 2D to F). In fact, experiments with hydrogen-consuming SRB and iron as the only electron donor consistently showed that SRB were capable of using cathodic hydrogen as a substrate but that this did not affect iron corrosion to any significant extent (39, 47, 67, 75, 86). In conclusion, kinetic considerations and empirical studies have explicitly demonstrated that microbial consumption of H2 cannot and does not accelerate iron corrosion.

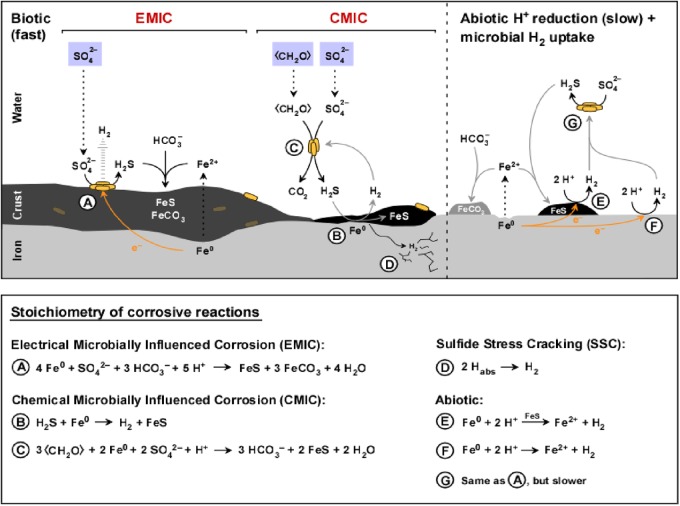

EMIC, on the other hand, circumvents the slow, abiotic formation of cathodic hydrogen (equation 3) and allows SRB to utilize iron more efficiently as an electron donor by direct uptake of electrons from iron oxidation (Fe0 → Fe2+ + 2 e−). Specialized “electron-consuming” sulfate reducers can corrode iron progressively and at very high rates (Fig. 2A to C). Here, the anodic dissolution of iron results from electron consumption by sulfate reduction (Fig. 4A), i.e., a cathodic reaction that is kinetically impossible at room temperature and in the absence of biological catalysis. EMIC by SRB is characterized by the formation of large amounts of inorganic corrosion products at a distinct stoichiometry (Fig. 4, reaction A). Microbial oxidation of 4 moles of Fe0 to Fe2+ is coupled to the reduction of only 1 mole of sulfate. Consequently, H2S from this reaction precipitates 1 mole of FeS (which is highly insoluble) whereas the remaining 3 moles of Fe2+ precipitate as nonsulfidic iron minerals, e.g., with carbonate, which is abundant in produced waters and other anoxic environments. Enning et al. (2012) recently calculated that less than 4% (wt/wt) of these biogenic corrosion products is actually biomass, while the remainder consists of inorganic ferrous minerals and other mineral precipitates (12). The same study (12) further demonstrated that the bulky black crusts formed through EMIC (compare Fig. 2B) are electrically conductive and hence that direct contact between corrosive SRB and the metal is not a necessary condition for corrosion. Instead, electrons flow from the corroding iron (4 Fe0 → 4 Fe2+ + 8 e−) through the electroconductive mineral crust to the crust-attached cells reducing sulfate (8 e− + SO42− + 10 H+ → H2S + 4 H2O). Venzlaff et al. (2012) performed linear sweep voltammetry on such corrosive SRB biofilms before and after inactivation of the crust-attached cells with a biocide, showing that a cathodic acceleration of iron corrosion indeed required the presence of viable electron-consuming SRB (86). The flow of electrons from the metal to the SRB is believed to be mainly mediated by iron sulfide minerals (see reference 12 for more information), which have long been known for their semiconductor properties (105, 106). Still, the discovery of a similar mechanism in certain methanogenic archaea (see the previous section and references 39, 47, and 48) demonstrated that the ability to corrode iron by direct electron uptake seems to be principally independent of the presence of iron sulfides (which are not formed in methanogenic cultures). It is noteworthy that, due to an imbalance between electrons entering cells and their consumption by sulfate reduction, some of the tested SRB strains that are capable of EMIC may initially even form (rather than consume) molecular hydrogen from iron in a shunt reaction (39, 61).

FIG 4.

Schematic illustration of different types of iron corrosion by sulfate-reducing bacteria (SRB) at circumneutral pH. Biotic and abiotic reactions are shown. Depicted biotic reactions tend to be much faster than abiotic corrosion reactions. SRB attack iron via electrical microbially influenced corrosion (EMIC) or chemical microbially influenced corrosion (CMIC). Stoichiometry of the illustrated reactions is given in the lower panel of this figure. Please note that all depicted processes may occur simultaneously on corroding metal surfaces but differ in rates and relative contributions to corrosion. (A) Specially adapted lithotrophic SRB withdraw electrons from iron via electroconductive iron sulfides (EMIC). Excess of accepted electrons may be released as H2 (via hydrogenase enzyme). Participation of possibly buried (encrusted) SRB in sulfate reduction and hydrogen release is currently unknown. (B) Biogenic, dissolved hydrogen sulfide reacts with metallic iron. (C) Overall representation of CMIC. Organotrophic SRB produce hydrogen sulfide which reacts with metallic iron. (D) Sulfide stress cracking (SSC) of iron due to biogenic hydrogen sulfide. (E) Catalytic iron sulfides may accelerate reduction of H+ ions to H2. (F) Slow, kinetically impeded reduction of H+ ions to H2 at iron surfaces. (G) Consumption of H2 from reaction E or F by SRB does not accelerate the rate of H2 formation (no “cathodic depolarization”; see the text). Note that CMIC quantitatively depends on the availability of biodegradable organic matter (here schematically shown as carbon with the oxidation state of zero, CH2O).

CMIC results from the sulfidogenic degradation of organic matter in anoxic environments (Fig. 4, reaction C). Even though most corrosion studies have focused on the effects of sulfide formed by microbial reduction of sulfate, it should be noted that other microbial processes such as the dissimilatory reduction of thiosulfate or sulfite can also produce significant amounts of corrosive sulfide (40) and, hence, CMIC. Intracellular oxidation of organic compounds by SRB (107, 108) is coupled to generation of sulfide, which, upon diffusion out of the cell, stoichiometrically reacts with metallic iron (Fig. 4, reaction B). For instance, oxidation (corrosion) of 1 g Fe0 via the CMIC mechanism requires the complete oxidation of 0.8 g acetate, a common environmental substrate of SRB (for the calculation, use equation C in Fig. 4).

Biogenic sulfide may initially stimulate the anodic part of the corrosion reaction by chemisorption and direct reaction with metallic iron (65, 109, 110). However, once the metallic surface is covered with inorganic corrosion products such as FeS, cathodic reactions become more important drivers of metal oxidation (81). It has been suggested that such cathodic stimulation results from biogenic dissolved sulfides (29, 83, 104, 111). Accordingly, sulfide anions act as a shuttle for bound (uncharged) protons, thereby increasing the availability of protons as electron acceptors at cathodic sites (83, 85, 112). In principle, reduction of sulfide-bound protons should occur at the metal and at FeS surfaces alike, but the latter may provide a particularly large cathodic surface area (Fig. 4, reaction B) whereas the former may become increasingly inaccessible due to coverage with organic and inorganic “biofilm.” Rapid hydrogen evolution from “H2S reduction” with iron has been observed in both the presence (30) and the absence (39, 83, 85) of SRB. The rates of corrosion in organotrophically grown sulfide-producing cultures differ greatly but can be high. Hubert et al. (2005) observed corrosion rates of up to 0.4 mm Fe0 year−1 (16 mpy) in packed-bed bioreactors fed with a continuous inflow of lactate-containing medium (43). However, given the nature of the microbial inoculum (produced-water enrichments), corrosion may not have entirely been the result of biogenic H2S (CMIC); the presence of microorganisms capable of the EMIC mechanisms in these tests cannot be excluded. Most studies performed with pure laboratory-grown SRB cultures have reported lower corrosion rates in media with organic electron donors (6, 104, 113, 114).

SRB inflict damage on metal infrastructure in yet another way as hydrogen sulfide decelerates (poisons) the combining of hydrogen atoms into molecular hydrogen at the metal surface (115). This leads to the diffusion of a higher fraction of hydrogen atoms into the metal matrix. Combining of absorbed atomic hydrogen molecules into hydrogen gas (H2) within the metal—often along internal inclusions (116)—causes embrittlement of the metal (Fig. 4, reaction D). Cracking of metals under conditions of mechanical stress (e.g., in pressurized pipes) as a consequence of sulfide attack is known as sulfide stress cracking (SSC).

THE ROLE OF FeS IN IRON CORROSION

Iron sulfides (FeS) are the characteristic products of SRB-induced corrosion. They usually occur as part of a mixture of mineral and organic deposits found on anaerobically corroded iron constructions. Besides its central role in EMIC and CMIC (Fig. 4, reactions A and B, respectively), the presence of biogenic FeS may also, at least temporarily, lead to the protection of iron against corrosion. This is explained by the formation of tightly adherent FeS films on the metal surface, most likely by direct reaction of dissolved sulfide with metallic iron (76, 82, 110). Such films act as an effective process barrier by impeding the diffusion of ferrous ions from the metal anode to the aqueous environment (76, 117). Impediment (“polarization”) of the anodic half-reaction (Fe0 → Fe2+ + 2 e−) has been frequently observed in cultures of organotrophically grown SRB (69, 71, 84). In organic matter-free cultures, where the predominant corrosive mechanism is EMIC, no significant slowdown of corrosion due to crust formation has been observed to date. Newman et al. (1992) stated that formation of protective FeS films occurs when dissolved sulfide concentrations exceed the concentration of dissolved ferrous ions at the unreacted metal surface, i.e., usually at high concentrations of dissolved sulfide (76). Rupture of the FeS film and local reexposure of metallic iron results in rapid pitting corrosion (localized metal dissolution) unless additional sulfide seals the exposed site. In the light of the dual role of FeS films in corrosion, it is not surprising that corrosion rates in sulfidic SRB cultures (CMIC) span at least 2 orders of magnitude (see reference 12 for a compilation of reported EMIC and CMIC corrosion rates). Particularly severe and progressive CMIC has been demonstrated in lactate-based media with high concentrations of ferrous salts (118, 119); their scavenging of H2S probably prevents formation of the protective FeS film and instead deposits fine suspensions of the mineral on the metal.

It has been reported that crystalline iron sulfides stimulate iron corrosion in sterile, sulfide-free incubations (77, 79, 120, 121). This is most likely due to catalysis by FeS of the chemical (abiotic) reduction of protons (Fig. 4, reaction E). The role of FeS in SRB-induced corrosion was emphasized by several authors (77, 78, 80), but the exact mechanisms are apparently complex and insufficiently understood (51). Newman et al. (1991) found the stimulatory effect of FeS to be small upon closer inspection and stated that the increased cathodic surface area provided by FeS was probably more important than its catalytic properties (81). Indeed, corrosion by FeS has so far been reported only for chemically prepared fine suspensions of the minerals (77–79, 120). Venzlaff et al. (2012) found the corrosive effect of FeS to be negligible in compact crusts formed by marine lithotrophic SRB (86). Further studies on the exact mechanisms and contribution of FeS to anaerobic corrosion are needed.

RELEVANCE OF DIFFERENT CORROSION PROCESSES

An issue of considerable technological interest is the relevance of the individual corrosion processes and their long-term rates of anaerobic metal destruction. Typical corrosion rates of unprotected steel in permanently anoxic environments range from 0.2 to 0.4 mm Fe0 year−1 (8 to 16 mpy) (see references 12 and 18 and Fig. 1). This can in principle be explained by CMIC (Fig. 4, reaction B); corrosion rates as high as 0.4 mm Fe0 year−1 (16 mpy) were reported in anoxic sulfidogenic cultures of SRB grown with organic substrates (43, 122). However, CMIC was usually far less pronounced in laboratory tests (6, 104, 113, 114), probably due to the formation of protective FeS deposits.

The stimulation of corrosion by iron monosulfides (Fig. 4, reaction E), on the other hand, was generally rather low (≤0.06 mm Fe0 year−1 [≤2.5 mpy]) with fine suspensions of the minerals (77, 79, 85) and negligible with more-compact crusts (86).

Electrical microbially influenced corrosion (EMIC; Fig. 4, reaction A), on the other hand, led to progressive oxidation of metallic iron even in the complete absence of organic electron donors (Fig. 2). Corrosion rates of up to 0.9 mm Fe0 year−1 (36 mpy) have been reported for long-term incubations during months when alkalization of cultivation media due to biocorrosion (compare Fig. 4, reaction A) was prevented by using small iron specimens in large quantities of fluid (12, 61). However, in vitro corrosion rates alone are an insufficient indicator of the relevance of the individual corrosion processes in situ. SRB capable of the EMIC mechanism corrode iron at technically highly relevant rates and would hence make for interesting targets of field surveys to better evaluate the significance of this corrosion mechanism. However, currently available strains are apparently not more closely related to each other than they are to other conventional SRB (compare Fig. 3), so a molecular detection of “EMIC SRB” as a group based on the 16S rRNA gene does not seem to be a promising application at this point. The analysis of corrosion products was proposed as another useful indicator (37). CMIC and EMIC produce corrosion products with inherently different relative amounts of sulfidic and nonsulfidic iron. While CMIC produces FeS as the sole mineral product, FeS accounts for only about 25% of the total iron minerals formed by the EMIC mechanism (see reference 12; compare also equations A and C in Fig. 4). This was used to quantitatively infer the contribution of EMIC to total SRB-induced corrosion from corrosion product analysis (12). Indeed, it was demonstrated that serious corrosion damage of buried iron coupons in permanently anoxic marine sediment of the German North Sea was solely due to EMIC (12). More work needs to be done to better understand the relative contributions of EMIC and CMIC in different anoxic environments. Interestingly, evaluation of the original corrosion product ratios provided by von Wolzogen Kühr and van der Vlugt (1934) (37) suggests that EMIC may have accounted for 75% to 91% of the corrosion damage in their freshwater enrichments. It is tempting to speculate that early researchers had already cultivated unidentified lithotrophic SRB capable of direct electron uptake from metallic iron.

CONCLUDING REMARKS

This brief review discusses the microbial mechanisms that lead to progressive corrosion of iron in anoxic, sulfate-rich environments. Principally, two scenarios must be distinguished. First, chemical microbially influenced corrosion (CMIC) of iron by hydrogen sulfide from microbial sulfate reduction occurs with “natural” organic substrates. Second, SRB corrode iron by direct utilization of the metal itself (Fig. 2A to C). This always occurs via direct electron uptake and in only a limited number of recently discovered SRB strains. Still, such electrical microbially influenced corrosion (EMIC) is assumed to be widespread (12, 39) and of considerable technical relevance.

CMIC and EMIC are the likely primary processes that drive iron corrosion in sulfate-containing anoxic environments. However, there are particular situations in which SRB-induced biocorrosion can be further exacerbated. Ingress of molecular oxygen (32–34, 51) into previously anoxic systems can lead to the formation of highly corrosive sulfur species from the partial oxidation of dissolved H2S and biogenic FeS deposits at steel surfaces (123–125). This can even further impair metals that have already been damaged by SRB.

A better understanding of SRB-induced biocorrosion is envisioned to ultimately aid in the design of better MIC prevention and mitigation strategies for a variety of iron constructions with exposure to sulfate-containing anoxic waters, including oil and gas pipelines, ballast water tanks, steel pilings in marine applications, and, more recently, offshore wind farms.

ACKNOWLEDGMENTS

We are grateful to Friedrich Widdel for fruitful discussions. We thank Rebecca Ansorge for her technical support.

Funding for this work was provided through the Max Planck Society.

Footnotes

Published ahead of print 6 December 2013

REFERENCES

- 1.U.S. Geological Survey 2011. Mineral commodity summaries 2011. U.S. Geological Survey, Washington, DC: http://minerals.usgs.gov/minerals/pubs/mcs/2011/mcs2011.pdf [Google Scholar]

- 2.Koch GH, Brongers MPH, Thompson NG, Virmani YP, Payer JH. 2001. Corrosion cost and preventive strategies in the United States. FHWA-RD-01-156. CC Technologies Laboratories, NACE International, Dublin, OH [Google Scholar]

- 3.Kruger J. 2011. Cost of metallic corrosion, p 15–20 In Revie RW. (ed), Uhlig's corrosion handbook, 3rd ed. Wiley, Hoboken, NJ [Google Scholar]

- 4.Beaver JA, Thompson NG. 2006. External corrosion of oil and natural gas pipelines. In Cramer SD, Covino BSJ. (ed), ASM handbook, vol 13C Corrosion: environments and industries (#05145) ASM International, Materials Park, OH [Google Scholar]

- 5.Beech IB, Sunner IA. 2007. Sulphate-reducing bacteria and their role in corrosion of ferrous materials, p 459–482 In Barton LL, Hamilton WA. (ed), Sulphate-reducing bacteria: environmental and engineered systems, 1st ed. Cambridge University Press, Cambridge, United Kingdom [Google Scholar]

- 6.Booth GH. 1964. Sulphur bacteria in relation to corrosion. J. Appl. Bacteriol. 27:174–181. 10.1111/j.1365-2672.1964.tb04825.x [DOI] [Google Scholar]

- 7.Flemming HC. 1994. Microbial deterioration of materials—fundamentals—economical and technical overview. Mater. Corrosion 45:5–9. 10.1002/maco.19940450105 [DOI] [Google Scholar]

- 8.Grundmeier G, Schmidt W, Stratmann M. 2000. Corrosion protection by organic coatings: electrochemical mechanism and novel methods of investigation. Electrochim. Acta 45:2515–2533. 10.1016/S0013-4686(00)00348-0 [DOI] [Google Scholar]

- 9.Sun W, Pugh DV, Ling S, Reddy RV, Pacheco JL, Nisbet RS, Nor NM, Kersey MS, Morshidi L. 2011. Understanding and quantifying corrosion of L80 carbon steel in sour environments, paper 11063. Abstr. NACE Corrosion 2011 Conf. Expo, Houston, TX [Google Scholar]

- 10.Revie RW. 2011. Uhlig's corrosion handbook, 3rd ed, vol 3 Wiley, New York, NY [Google Scholar]

- 11.Whitney WR. 1903. The corrosion of iron. J. Am. Chem. Soc. 25:394–406 [Google Scholar]

- 12.Enning D, Venzlaff H, Garrelfs J, Dinh HT, Meyer V, Mayrhofer K, Hassel AW, Stratmann M, Widdel F. 2012. Marine sulfate-reducing bacteria cause serious corrosion of iron under electroconductive biogenic mineral crust. Environ. Microbiol. 14:1772–1787. 10.1111/j.1462-2920.2012.02778.x [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Rickard D, Luther GW. 2007. Chemistry of iron sulfides. Chem. Rev. 107:514–562. 10.1021/cr0503658 [DOI] [PubMed] [Google Scholar]

- 14.Kaesche H. 2003. Corrosion of metals: physicochemical principles and current problems. Springer, Berlin, Germany [Google Scholar]

- 15.Bockris JOM, Reddy AKN. 1970. Modern electrochemistry. Plenum, New York, NY [Google Scholar]

- 16.Piron DL. 1994. The electrochemistry of corrosion. NACE Press, Houston, TX [Google Scholar]

- 17.Videla HA. 2001. Microbially induced corrosion: an updated overview. Int. Biodeterior. Biodegradation 48:176–201. 10.1016/S0964-8305(01)00081-6 [DOI] [Google Scholar]

- 18.Jack TR. 2002. Biological corrosion failures, p 881–898 In Shipley RJ, Becker WT. (ed), ASM handbook, vol 11 Failure analysis and prevention ASM International, Materials Park, OH [Google Scholar]

- 19.Lewandowski Z, Beyenal H. 2009. Mechanisms of microbially influenced corrosion, p 35–64 In Flemming HC, Murthy PS, Venkatesan R, Cooksey KE. (ed), Marine and industrial biofouling. Springer, Berlin, Germany [Google Scholar]

- 20.Hamilton WA. 2003. Microbially influenced corrosion as a model system for the study of metal microbe interactions: a unifying electron transfer hypothesis. Biofouling 19:65–76. 10.1080/0892701021000041078 [DOI] [PubMed] [Google Scholar]

- 21.Little BJ, Lee JS. 2007. Microbiologically influenced corrosion. Wiley, Hoboken, NJ [Google Scholar]

- 22.Lee WC, de Beer D. 1995. Oxygen and pH microprofiles above corroding mild-steel covered with a biofilm. Biofouling 8:273–280. 10.1080/08927019509378280 [DOI] [Google Scholar]

- 23.Gu JD, Ford TE, Mitchell R. 2011. Microbiological corrosion of metallic materials, p 549–557 In Revie RW. (ed), Uhlig's corrosion handbook. Wiley, New York, NY [Google Scholar]

- 24.Little B, Wagner P, Hart K, Ray R, Lavoie D, Nealson K, Aguilar C. 1998. The role of biomineralization in microbiologically influenced corrosion. Biodegradation 9:1–10. 10.1023/A:1008264313065 [DOI] [PubMed] [Google Scholar]

- 25.McBeth JM, Little BJ, Ray RI, Farrar KM, Emerson D. 2011. Neutrophilic iron-oxidizing “Zetaproteobacteria” and mild steel corrosion in nearshore marine environments. Appl. Environ. Microbiol. 77:1405–1412. 10.1128/AEM.02095-10 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Starosvetsky D, Armon R, Yahalom J, Starosvetsky J. 2001. Pitting corrosion of carbon steel caused by iron bacteria. Int. Biodeterior. Biodegradation 47:79–87. 10.1016/S0964-8305(99)00081-5 [DOI] [Google Scholar]

- 27.Pak KR, Lee HJ, Lee HK, Kim YK, Oh YS, Choi SC. 2003. Involvement of organic acid during corrosion of iron coupon by Desulfovibrio desulfuricans. J. Microbiol. Biotechnol. 13:937–941 [Google Scholar]

- 28.Iverson WP. 1987. Microbial corrosion of metals. Adv. Appl. Microbiol. 32:1–36. 10.1016/S0065-2164(08)70077-7 [DOI] [Google Scholar]

- 29.Costello JA. 1974. Cathodic depolarization by sulphate-reducing bacteria. S. Afr. J. Sci. 70:202–204 [Google Scholar]

- 30.Cord-Ruwisch R, Widdel F. 1986. Corroding iron as a hydrogen source for sulfate reduction in growing cultures of sulfate-reducing bacteria. Appl. Microbiol. Biotechnol. 25:169–174. 10.1007/BF00938942 [DOI] [Google Scholar]

- 31.Park HS, Chatterjee I, Dong X, Wang SH, Sensen CW, Caffrey SM, Jack TR, Boivin J, Voordouw G. 2011. Effect of sodium bisulfite injection on the microbial community composition in a brackish-water-transporting pipeline. Appl. Environ. Microbiol. 77:6908–6917. 10.1128/AEM.05891-11 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Hardy JA, Brown JL. 1984. The corrosion of mild steel by biogenic sulfide films exposed to air. Corrosion 40:650–654. 10.5006/1.3593903 [DOI] [Google Scholar]

- 33.Jack TR, Wilmott A, Stockdale J, Van Boven G, Worthingham RG, Sutherby RL. 1998. Corrosion consequences of secondary oxidation of microbial corrosion. Corrosion 54:246–252. 10.5006/1.3284850 [DOI] [Google Scholar]

- 34.Lee W, Lewandowski Z, Morrison M, Characklis WG, Avci R, Nielsen PH. 1993. Corrosion of mild steel underneath aerobic biofilms containing sulfate-reducing bacteria. Part I: at high dissolved oxygen concentrations. Biofouling 7:217–239 [Google Scholar]

- 35.Van Ommen Kloeke F, Bryant RD. 1995. Localization of cytochromes in the outer membrane of Desulfovibrio vulgaris (Hildenborough) and their role in anaerobic biocorrosion. Anaerobe 1:351–358. 10.1006/anae.1995.1038 [DOI] [PubMed] [Google Scholar]

- 36.Mehanna M, Basseguy R, Delia ML, Bergel A. 2009. Role of direct microbial electron transfer in corrosion of steel. Electrochem. Commun. 11:568–571. 10.1016/j.elecom.2008.12.019 [DOI] [Google Scholar]

- 37.von Wolzogen Kühr CAH, van der Vlugt LS. 1934. The graphitization of cast iron as an electrobiochemical process in anaerobic soil. Water 18:147–165 [Google Scholar]

- 38.Daniels L, Belay N, Rajagopal BS, Weimer PJ. 1987. Bacterial methanogenesis and growth from CO2 with elemental iron as the sole source of electrons. Science 237:509–511. 10.1126/science.237.4814.509 [DOI] [PubMed] [Google Scholar]

- 39.Dinh HT, Kuever J, Mußmann M, Hassel AW, Stratmann M, Widdel F. 2004. Iron corrosion by novel anaerobic microorganisms. Nature 427:829–832. 10.1038/nature02321 [DOI] [PubMed] [Google Scholar]

- 40.Magot M, Ravot G, Campaignolle X, Ollivier B, Patel BKC, Fardeau ML, Thomas P, Crolet JL, Garcia JL. 1997. Dethiosulfovibrio peptidovorans gen. nov., sp. nov., a new anaerobic slightly halophilic, thiosulfate-reducing bacterium from corroding offshore oil wells. Int. J. Syst. Bacteriol. 47:818–824. 10.1099/00207713-47-3-818 [DOI] [PubMed] [Google Scholar]

- 41.Xu D, Li Y, Song F, Gu T. 2013. Laboratory investigation of microbiologically influenced corrosion of C1018 carbon steel by nitrate reducing bacterium Bacillus licheniformis. Corros. Sci. 77:385–390. 10.1016/j.corsci.2013.07.044 [DOI] [Google Scholar]

- 42.De Windt W, Boon N, Siciliano SD, Verstraete W. 2003. Cell density related H2 consumption in relation to anoxic Fe(0) corrosion and precipitation of corrosion products by Shewanella oneidensis MR-1. Environ. Microbiol. 5:1192–1202. 10.1046/j.1462-2920.2003.00527.x [DOI] [PubMed] [Google Scholar]

- 43.Hubert C, Nemati M, Jenneman G, Voordouw G. 2005. Corrosion risk associated with microbial souring control using nitrate or nitrite. Appl. Microbiol. Biotechnol. 68:272–282. 10.1007/s00253-005-1897-2 [DOI] [PubMed] [Google Scholar]

- 44.Vik EA, Janbu AO, Garshol F, Henninge LB, Engebretsen S, Kuijvenhoven C, Oliphant D, Hendriks WP. 2007. Nitrate-based souring mitigation of produced water—side effects and challenges from the Draugen produced water re-injection pilot, paper SPE 106178 SPE International Symposium on Oilfield Chemistry, Houston, TX [Google Scholar]

- 45.Dowling NJE, Brooks SA, Phelps TJ, White DC. 1992. Effects of selection and fate of substrates supplied to anaerobic bacteria involved in the corrosion of pipe-line steel. J. Ind. Microbiol. 10:207–215. 10.1007/BF01569768 [DOI] [Google Scholar]

- 46.Larsen J, Rasmussen K, Pedersen K, Soerensen K, Lundgaard T, Skovhus TL. 2010. Consortia of MIC bacteria and archaea causing pitting corrosion in top side oil production facilities, paper 10252. Abstr. NACE Corrosion 2010 Conf. Expo, Houston, TX [Google Scholar]

- 47.Mori K, Tsurumaru H, Harayama S. 2010. Iron corrosion activity of anaerobic hydrogen-consuming microorganisms isolated from oil facilities. J. Biosci. Bioeng. 110:426–430. 10.1016/j.jbiosc.2010.04.012 [DOI] [PubMed] [Google Scholar]

- 48.Uchiyama T, Ito K, Mori K, Tsurumaru H, Harayama S. 2010. Iron-corroding methanogen isolated from a crude-oil storage tank. Appl. Environ. Microbiol. 76:1783–1788. 10.1128/AEM.00668-09 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 49.Dinh HT. 2003. Microbiological study of the anaerobic corrosion of iron. Ph.D. thesis. University of Bremen, Bremen, Germany [Google Scholar]

- 50.Hamilton WA. 1985. Sulphate-reducing bacteria and anaerobic corrosion. Annu. Rev. Microbiol. 39:195–217. 10.1146/annurev.mi.39.100185.001211 [DOI] [PubMed] [Google Scholar]

- 51.Lee W, Lewandowski Z, Nielsen PH, Hamilton WA. 1995. Role of sulfate-reducing bacteria in corrosion of mild steel: a review. Biofouling 8:165–194. 10.1080/08927019509378271 [DOI] [Google Scholar]

- 52.Muyzer G, Stams AJM. 2008. The ecology and biotechnology of sulphate-reducing bacteria. Nat. Rev. Microbiol. 6:441–454. 10.1038/nrmicro1892 [DOI] [PubMed] [Google Scholar]

- 53.Bødtker G, Thorstenson T, Lillebø BLP, Thorbjørnsen BE, Ulvøen RH, Sunde E, Torsvik T. 2008. The effect of long-term nitrate treatment on SRB activity, corrosion rate and bacterial community composition in offshore water injection systems. J. Ind. Microbiol. Biotechnol. 35:1625–1636. 10.1007/s10295-008-0406-x [DOI] [PubMed] [Google Scholar]

- 54.Li S, Kim Y, Jeon K, Kho Y. 2000. Microbiologically influenced corrosion of underground pipelines under the disbonded coatings. Met. Mater. 6:281–286. 10.1007/BF03028224 [DOI] [Google Scholar]

- 55.Ferris FG, Jack TR, Bramhill BJ. 1992. Corrosion products associated with attached bacteria at an oil field water injection plant. Can. J. Microbiol. 38:1320–1324. 10.1139/m92-217 [DOI] [Google Scholar]

- 56.Jack TR, Wilmott MJ, Sutherby RL. 1995. Indicator minerals formed during external corrosion of line pipe. Mater. Perform. 34:19–22 [Google Scholar]

- 57.Païssé S, Ghiglione JF, Marty F, Abbas B, Gueuné H, Sanchez Amaya JM, Muyzer G, Quillet L. 2013. Sulfate-reducing bacteria inhabiting natural corrosion deposits from marine steel structures. Appl. Microbiol. Biotechnol. 97:7493–7504. 10.1007/s00253-012-4464-7 [DOI] [PubMed] [Google Scholar]

- 58.Nemati M, Voordouw G. 2000. Identification and characterization of sulfate-reducing bacteria involved in microbially influenced corrosion in oil fields, paper 00126. Abstr. NACE Corrosion 2000 Conf. Expo, Orlando, FL [Google Scholar]

- 59.Zhang T, Fang HHP. 2001. Phylogenetic diversity of a SRB-rich marine biofilm. Appl. Microbiol. Biotechnol. 57:437–440. 10.1007/s002530100770 [DOI] [PubMed] [Google Scholar]

- 60.Beese P, Venzlaff H, Srinivasan J, Garrelfs J, Stratmann M, Mayrhofer KJJ. 2013. Monitoring of anaerobic microbially influenced corrosion via electrochemical frequency modulation. Electrochim. Acta 105:239–247. 10.1016/j.electacta.2013.04.144 [DOI] [Google Scholar]

- 61.Enning D. 2012. Bioelectrical corrosion of iron by lithotrophic sulfate-reducing bacteria. Ph.D. thesis. University of Bremen, Bremen, Germany [Google Scholar]

- 62.Gaines R. 1910. Bacterial activity as a corrosive influence in the soil. J. Ind. Eng. Chem. 2:128–130. 10.1021/ie50016a003 [DOI] [Google Scholar]

- 63.von Wolzogen Kühr CAH. 1961. Unity of anaerobic and aerobic iron corrosion process in the soil. Corrosion 17:119–125 [Google Scholar]

- 64.Butlin KR, Adams ME, Thomas M. 1949. Sulphate-reducing bacteria and internal corrosion of ferrous pipes conveying water. Nature 163:26–27. 10.1038/163026a0 [DOI] [PubMed] [Google Scholar]

- 65.Horvath J, Solti M. 1959. Beitrag zum Mechanismus der anaeroben Korrosion der Metalle im Boden. Mater. Corros. 10:624–630. 10.1002/maco.19590101007 [DOI] [Google Scholar]

- 66.Starkey RL. 1946. Sulfate reduction and the anaerobic corrosion of iron. Antonie Van Leeuwenhoek 12:193–203 [DOI] [PubMed] [Google Scholar]

- 67.Spruit CJP, Wanklyn JN. 1951. Iron sulphide ratios in corrosion by sulphate-reducing bacteria. Nature 168:951–952. 10.1038/168951a0 [DOI] [PubMed] [Google Scholar]

- 68.Wanklyn JN, Spruit CJP. 1952. Influence of sulphate-reducing bacteria on the corrosion potential of iron. Nature 169:928–92914941089 [Google Scholar]

- 69.Booth GH, Tiller AK. 1960. Polarization studies of mild steel in cultures of sulphate-reducing bacteria. Trans. Faraday Soc. 56:1689–1696. 10.1039/tf9605601689 [DOI] [Google Scholar]

- 70.Booth GH, Tiller AK. 1962. Polarization studies of mild steel in cultures of sulphate-reducing bacteria. Part 3. Halophilic organisms. Trans. Faraday Soc. 58:2510–2516 [Google Scholar]

- 71.Tiller AK, Booth GH. 1962. Polarization studies of mild steel in cultures of sulphate-reducing bacteria. Part 2. Thermophilic organisms. T. Faraday. Soc. 58:110–115 [Google Scholar]

- 72.Pankhania IP, Moosavi AN, Hamilton WA. 1986. Utilization of cathodic hydrogen by Desulfovibrio vulgaris (Hildenborough). J. Gen. Microbiol. 132:3357–3365 [Google Scholar]

- 73.Bryant RD, Jansen W, Boivin J, Laishley EJ, Costerton JW. 1991. Effect of hydrogenase and mixed sulfate-reducing bacterial populations on the corrosion of steel. Appl. Environ. Microbiol. 57:2804–2809 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 74.Bryant RD, Laishley EJ. 1990. The role of hydrogenase in anaerobic biocorrosion. Can. J. Microbiol. 36:259–264. 10.1139/m90-045 [DOI] [Google Scholar]

- 75.Hardy JA. 1983. Utilization of cathodic hydrogen by sulphate-reducing bacteria. Br. Corros. J. 18:190–193 [Google Scholar]

- 76.Newman RC, Rumash K, Webster BJ. 1992. The effect of pre-corrosion on the corrosion rate of steel in neutral solutions containing sulfide: relevance to microbially influenced corrosion. Corros. Sci. 33:1877–1884. 10.1016/0010-938X(92)90190-E [DOI] [Google Scholar]

- 77.Booth GH, Elford L, Wakerley DS. 1968. Corrosion of mild steel by sulphate-reducing bacteria: an alternative mechanism. Br. Corros. J. 3:242–245. 10.1179/000705968798326073 [DOI] [Google Scholar]

- 78.King RA, Miller JDA. 1971. Corrosion by sulphate-reducing bacteria. Nature 233:491–492. 10.1038/233491a0 [DOI] [PubMed] [Google Scholar]

- 79.King RA, Miller JDA, Smith JS. 1973. Corrosion of mild steel by iron sulphides. Br. Corros. J. 8:137–141. 10.1179/000705973798322251 [DOI] [Google Scholar]

- 80.Smith JS, Miller JDA. 1975. Nature of sulphides and their corrosive effect on ferrous metals: a review. Br. Corros. J. 10:136–143. 10.1179/000705975798320701 [DOI] [Google Scholar]

- 81.Newman RC, Webster BJ, Kelly RG. 1991. The electrochemistry of SRB corrosion and related inorganic phenomena. ISIJ Int. 31:201–209. 10.2355/isijinternational.31.201 [DOI] [Google Scholar]

- 82.Sun W, Nešić S. 2007. A mechanistic model of H2S corrosion of mild steel, paper 07655. Corrosion 2007. http://www.corrosioncenter.ohiou.edu/nesic/papers/FullText/conference-91.pdf [Google Scholar]

- 83.Nešić S. 2011. Carbon dioxide corrosion of mild steel, p 229–245 In Revie RW. (ed), Uhlig's corrosion handbook, 3rd ed. Wiley, Hoboken, NJ [Google Scholar]

- 84.Tiller AK. 1983. Electrochemical aspects of corrosion: an overview, p 54–65 In Microbial corrosion. The Metals Society, Teddington, United Kingdom [Google Scholar]

- 85.Widdel F. 1992. Microbial corrosion, p 277–318 In Finn RK, Prave P, Schlingmann M, Crueger W, Esser K, Thauer R, Wagner F. (ed), Biotechnology focus 3. Hanser, Munich, Germany [Google Scholar]

- 86.Venzlaff H, Enning D, Srinivasan J, Mayrhofer K, Hassel AW, Widdel F, Stratmann M. 2012. Accelerated cathodic reaction in microbial corrosion of iron due to direct electron uptake by sulfate-reducing bacteria. Corros. Sci. 66:88–96. 10.1016/j.corsci.2012.09.006 [DOI] [Google Scholar]

- 87.Ollivier B, Cayol JL, Fauque G. 2007. Sulphate-reducing bacteria from oil field environments and deep-sea hydrothermal vents, p 305–328 In Barton LL, Hamilton WA. (ed), Sulphate-reducing bacteria. Cambridge University Press, Cambridge, United Kingdom [Google Scholar]

- 88.Stetter KO, Lauerer G, Thomm M, Neuner A. 1987. Isolation of extremely thermophilic sulfate reducers: evidence for a novel branch of archaebacteria. Science 236:822–824. 10.1126/science.236.4803.822 [DOI] [PubMed] [Google Scholar]

- 89.Duncan KE, Gieg LM, Parisi VA, Tanner RS, Green Tringe S, Bristow J, Suflita JM. 2009. Biocorrosive thermophilic microbial communities in Alaskan north slope oil facilities. Environ. Sci. Technol. 43:7977–7984. 10.1021/es9013932 [DOI] [PubMed] [Google Scholar]

- 90.Islam S, Karr EA. 2013. Examination of metal corrosion by Desulfomicrobium thermophilum, Archaeoglobus fulgidus, and Methanothermobacter thermautotrophicus. BIOS 84:59–64. 10.1893/0005-3155-84.2.59 [DOI] [Google Scholar]

- 91.Miranda-Tello E, Fardeau ML, Fernández L, Ramírez F, Cayol JL, Thomas P, Garcia JL, Ollivier B. 2003. Desulfovibrio capillatus sp. nov., a novel sulfate-reducing bacterium isolated from an oil field separator located in the Gulf of Mexico. Anaerobe 9:97–103. 10.1016/S1075-9964(03)00064-7 [DOI] [PubMed] [Google Scholar]

- 92.Feio MJ, Zinkevich V, Beech IB, Llobet-Brossa E, Eaton P, Schmitt J, Guezennec J. 2004. Desulfovibrio alaskensis sp. nov., a sulphate-reducing bacterium from a soured oil reservoir. Int. J. Syst. Evol. Microbiol. 54:1747–1752. 10.1099/ijs.0.63118-0 [DOI] [PubMed] [Google Scholar]

- 93.Sherar BWA, Power IM, Keech PG, Mitlin S, Southam G, Shoesmith DW. 2011. Characterizing the effect of carbon steel exposure in sulfide containing solutions to microbially induced corrosion. Corros. Sci. 53:955–960. 10.1016/j.corsci.2010.11.027 [DOI] [Google Scholar]

- 94.Appia-Ayme C, Guiliani N, Ratouchniak J, Bonnefoy V. 1999. Characterization of an operon encoding two c-type cytochromes, an aa3-type cytochrome oxidase, and rusticyanin in Thiobacillus ferrooxidans ATCC 33020. Appl. Environ. Microbiol. 65:4781–4787 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 95.Strycharz SM, Glaven RH, Coppi MV, Gannon SM, Perpetua LA, Liu A, Nevin KP, Lovley DR. 2011. Gene expression and deletion analysis of mechanisms for electron transfer from electrodes to Geobacter sulfurreducens. Bioelectrochemistry 80:142–150. 10.1016/j.bioelechem.2010.07.005 [DOI] [PubMed] [Google Scholar]

- 96.Butler JE, Young ND, Lovley DR. 2010. Evolution of electron transfer out of the cell: comparative genomics of six Geobacter genomes. BMC Genomics 11:40. 10.1186/1471-2164-11-40 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 97.Shi L, Squier TC, Zachara JM, Fredrickson JK. 2007. Respiration of metal (hydr)oxides by Shewanella and Geobacter: a key role for multihaem c-type cytochromes. Mol. Microbiol. 65:12–20. 10.1111/j.1365-2958.2007.05783.x [DOI] [PMC free article] [PubMed] [Google Scholar]

- 98.Kato S, Hashimoto K, Watanabe K. 2012. Microbial interspecies electron transfer via electric currents through conductive minerals. Proc. Natl. Acad. Sci. U. S. A. 109:10042–10046. 10.1073/pnas.1117592109 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 99.Nakamura R, Kai F, Okamoto A, Newton GJ, Hashimoto K. 2009. Self-constructed electrically conductive bacterial networks. Angew. Chem. Int. Ed. Engl. 48:508–511. 10.1002/anie.200804750 [DOI] [PubMed] [Google Scholar]

- 100.Nielsen LP, Risgaard-Petersen N, Fossing H, Christensen PB, Sayama M. 2010. Electric currents couple spatially separated biogeochemical processes in marine sediment. Nature 463:1071–1074. 10.1038/nature08790 [DOI] [PubMed] [Google Scholar]

- 101.Pfeffer C, Larsen S, Song J, Dong MD, Besenbacher F, Meyer RL, Kjeldsen KU, Schreiber L, Gorby YA, El-Naggar MY, Leung KM, Schramm A, Risgaard-Petersen N, Nielsen LP. 2012. Filamentous bacteria transport electrons over centimetre distances. Nature 491:218–221. 10.1038/nature11586 [DOI] [PubMed] [Google Scholar]

- 102.Deutsch ER, Rao KV, Laurent R, Seguin MK. 1977. New evidence and possible origin of native iron in ophiolites of eastern Canada. Nature 269:684–685. 10.1038/269684a0 [DOI] [Google Scholar]

- 103.Haggerty SE, Toft PB. 1985. Native iron in the continental lower crust: petrological and geophysical implications. Science 229:647–649. 10.1126/science.229.4714.647 [DOI] [PubMed] [Google Scholar]

- 104.Cord-Ruwisch R. 2000. Microbially influenced corrosion of steel, p 159–173 In Lovley DR. (ed), Environmental microbe-metal interactions. ASM Press, Washington, DC [Google Scholar]

- 105.Braun F. 1875. Ueber die Stromleitung durch Schwefelmetalle. Ann. Phys. 229:556–563 [Google Scholar]

- 106.Pearce CI, Pattrick RAD, Vaughan DJ. 2006. Electrical and magnetic properties of sulfides. Rev. Min. Geochem. 61:127–180. 10.2138/rmg.2006.61.3 [DOI] [Google Scholar]

- 107.Pereira IAC, Ramos AR, Grein F, Marques MC, da Silva SM, Venceslau SS. 2011. A comparative genomic analysis of energy metabolism in sulfate reducing bacteria and archaea. Front. Microbiol. 2:69. 10.3389/fmicb.2011.00069 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 108.Rabus R, Hansen T, Widdel F. 2006. Dissimilatory sulfate- and sulfur-reducing prokaryotes, p 659–768 In Dworkin M, Schleifer K-H, Stackebrandt E. (ed), The prokaryotes. Springer, New York, NY [Google Scholar]

- 109.Iofa ZA, Batrakov VV, Cho-Ngok-Ba 1964. Influence of anion adsorption on the action of inhibitors on the acid corrosion of iron and cobalt. Electrochim. Acta 9:1645–1653. 10.1016/0013-4686(64)80091-8 [DOI] [Google Scholar]

- 110.Shoesmith DW, Taylor P, Bailey MG, Owen DG. 1980. The formation of ferrous monosulfide polymorphs during the corrosion of iron by aqueous hydrogen sulfide at 21°C. J. Electrochem. Soc. 127:1007–1015. 10.1149/1.2129808 [DOI] [Google Scholar]

- 111.Ma HY, Cheng XL, Li GQ, Chen SH, Quan ZL, Zhao SY, Niu L. 2000. The influence of hydrogen sulfide on corrosion of iron under different conditions. Corros. Sci. 42:1669–1683. 10.1016/S0010-938X(00)00003-2 [DOI] [Google Scholar]

- 112.Wikjord AG, Rummery TE, Doern FE, Owen DG. 1980. Corrosion and deposition during the exposure of carbon steel to hydrogen sulfide-water solutions. Corros. Sci. 20:651–671. 10.1016/0010-938X(80)90101-8 [DOI] [Google Scholar]

- 113.Beech IB, Cheung CWS, Chan CSP, Hill MA, Franco R, Lino AR. 1994. Study of parameters implicated in the biodeterioration of mild steel in the presence of different species of sulfate-reducing bacteria. Int. Biodeterior. Biodegradation 34:289–303. 10.1016/0964-8305(94)90089-2 [DOI] [Google Scholar]

- 114.Gaylarde CC. 1992. Sulfate-reducing bacteria which do not induce accelerated corrosion. Int. Biodeterior. Biodegradation 30:331–338. 10.1016/0964-8305(92)90037-O [DOI] [Google Scholar]

- 115.Elboujdaini M. 2011. Hydrogen-induced cracking and sulfide stress cracking, p 183–194 In Revie RW. (ed), Uhlig's corrosion handbook, 3rd ed. Wiley, Hoboken, NJ [Google Scholar]

- 116.Radkevych OI, Pokhmurs'kyi VI. 2001. Influence of hydrogen sulfide on serviceability of materials of gas field equipment. Mater. Sci. 37:319–332. 10.1023/A:1013275129001 [DOI] [Google Scholar]

- 117.Hansson EB, Odziemkowski MS, Gillham RW. 2006. Formation of poorly crystalline iron monosulfides: surface redox reactions on high purity iron, spectroelectrochemical studies. Corros. Sci. 48:3767–3783. 10.1016/j.corsci.2006.03.010 [DOI] [Google Scholar]

- 118.Adams ME, Farrer TW. 1953. The influence of ferrous iron on bacterial corrosion. J. Appl. Chem. 3:117–120 [Google Scholar]

- 119.Lee W, Characklis WG. 1993. Corrosion of mild steel under anaerobic biofilm. Corrosion 49:186–199. 10.5006/1.3316040 [DOI] [Google Scholar]

- 120.Mara DD, Williams DJA. 1972. Polarisation of pure iron in the presence of iron sulfide minerals. Br. Corros. J. 7:94–95. 10.1179/000705972798323198 [DOI] [Google Scholar]

- 121.Stumper R. 1923. Inorganic chemistry: the corrosion of iron in the presence of iron sulphuret. C. R. Hebd. Seances Acad. Sci. 176:1316–1317 [Google Scholar]

- 122.Bell RG, Lim CK. 1981. Corrosion of mild and stainless steel by four tropical Desulfovibrio desulfuricans strains. Can. J. Microbiol. 27:242–245. 10.1139/m81-036 [DOI] [PubMed] [Google Scholar]

- 123.MacDonald DD, Roberts B, Hyne JB. 1978. Corrosion of carbon steel during cyclical exposure to wet elemental sulfur and atmosphere. Corros. Sci. 18:499–501. 10.1016/S0010-938X(78)80042-0 [DOI] [Google Scholar]

- 124.Nielsen PH, Lee W, Lewandowski Z, Morison M, Characklis WG. 1993. Corrosion of mild steel in an alternating oxic and anoxic biofilm system. Biofouling 7:267–284. 10.1080/08927019309386259 [DOI] [Google Scholar]

- 125.Schaschl E. 1980. Elemental sulfur as a corrodent in deaerated, neutral aqueous solutions. Mater. Perform. 19:9–12 [Google Scholar]

- 126.Ludwig W, Strunk O, Westram R, Richter L, Meier H, Yadhukumar Buchner A, Lai T, Steppi S, Jobb G, Forster W, Brettske I, Gerber S, Ginhart AW, Gross O, Grumann S, Hermann S, Jost R, König A, Liss T, Lussmann R, May M, Nonhoff B, Reichel B, Strehlow R, Stamatakis A, Stuckmann N, Vilbig A, Lenke M, Ludwig T, Bode A, Schleifer K-H. 2004. ARB: a software environment for sequence data. Nucleic Acids Res. 32:1363–1371. 10.1093/nar/gkh293 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 127.Pruesse E, Quast C, Knittel K, Fuchs BM, Ludwig WG, Peplies J, Glöckner FO. 2007. SILVA: a comprehensive online resource for quality checked and aligned ribosomal RNA sequence data compatible with ARB. Nucleic Acids Res. 35:7188–7196. 10.1093/nar/gkm864 [DOI] [PMC free article] [PubMed] [Google Scholar]