Abstract

Hydrogels are hydrophilic polymer-based materials with high water content and physical characteristics that resemble the native extracellular matrix. Because of their remarkable properties, hydrogel systems are used for a wide range of biomedical applications, such as three-dimensional (3D) matrices for tissue engineering, drug-delivery vehicles, composite biomaterials, and as injectable fillers in minimally invasive surgeries. In addition, the rational design of hydrogels with controlled physical and biological properties can be used to modulate cellular functionality and tissue morphogenesis. Here, the development of advanced hydrogels with tunable physiochemical properties is highlighted, with particular emphasis on elastomeric, light-sensitive, composite, and shape-memory hydrogels. Emerging technologies developed over the past decade to control hydrogel architecture are also discussed and a number of potential applications and challenges in the utilization of hydrogels in regenerative medicine are reviewed. It is anticipated that the continued development of sophisticated hydrogels will result in clinical applications that will improve patient care and quality of life.

1. Introduction

Hydrogels are three-dimensional (3D) networks consisting of hydrophilic polymer chains, which are crosslinked to form matrices with high water content (up to thousand of times their dry weight).[1] Due to their remarkable characteristics, including tunable physical, chemical, and biological properties, high biocompatibility, versatility in fabrication, and similarity to native extracellular matrix (ECM), hydrogels have emerged as promising materials in the biomedical field.[1–3] Significant progress has been made in the synthesis and fabrication of hydrogels from both natural and synthetic sources for various applications; these include regenerative medicine, drug/gene delivery, stem cell and cancer research, and cell therapy.[4–6] Naturally-derived hydrogels, such as collagen, chitosan, hyaluronic acid (HA), alginate, gelatin, elastin, chondroitin sulfate, and heparin, are appealing for biological applications due to their cell signaling and cell-interactive properties, and biodegradability.[7] However, their limitations include low mechanical properties, inability to control their degradation and structure, and potential immunogenicity. On the other hand, synthetic hydrogels, such as poly(ethylene glycol) (PEG), poly(vinyl alcohol)(PVA), poly(2-hydroxyethyl methacrylate) (PHEMA), and polyacrylamide (PAM), possess controllable degradation and microstructure, generally show high mechanical properties, but lack biological moieties.[3,7] Due to the distinct properties of each of these hydrogel classes, gels that are based on the combination of natural and synthetic polymers have attracted significant attention for biological and biomedical applications.[8]

Various crosslinking approaches, including chemical and physical, have been employed to create polymer networks and preserve their 3D structures in aqueous environments. In physically crosslinked gels, physical interactions between polymer chains prevent dissociation of the hydrogel, while in chemically crosslinked gels, covalent bonds between polymer chains create stable hydrogels. Physically crosslinked hydrogels are formed through changes in environmental conditions (e.g., pH, temperature, and ionic interactions), hydrogen bonds, and protein interactions. There has been a growing interest in using this class of hydrogels for tissue regeneration as the gelation often occurs in mild conditions and aqueous solution in the absence of chemical crosslinkers.[9] Various injectable hydrogels based on alginate, collagen, agarose, HA, and chitosan have been synthesized by using physical crosslinking approaches for engineering different tissues.[10] These gels can be confined in the damaged site and eliminate the need of invasive surgery. However, low mechanical properties of physically crosslinked hydrogels may limit their tissue engineering applications, particularly in the regeneration of load bearing tissues. Chemically crosslinked gels have been obtained by radical polymerization, chemical reactions, energy irradiation, and enzymatic crosslinking. Some examples of chemically crosslinked gels for tissue engineering applications include PHEMA, glutaraldehyde (GA) crosslinked PVA, elastin, and chitosan, UV crosslinked methacrylated gelatin and elastin, transglutaminases crosslinked fibrinogen hydrogels.[9,11–13] Generally, chemically crosslinked gels have higher mechanical properties compared to their physically crosslinked counterparts, but the residual chemical crosslinkers, organic solvents, and photoinitiator may cause cytotoxicity.

Over the past decade, complex hydrogels have been designed as a result of major breakthroughs in the field of polymer science, microscale technologies, and molecular biology.[4,6] These advances have set the framework to overcome some of the challenges in regenerative medicine by rational design of hydrogels for various medical applications. This review covers the design principles being applied to synthesize advanced hydrogels with enhanced mechanical, biological, chemical and electrical properties. Due to their important biomedical applications, particular emphasis is given to elastomeric, photo-sensitive, hybrid and shape-memory hydrogel systems. In addition, emerging techologies for controlling the micro- and nanoscale architectures of 3D hydrogel constructs and their potential applications are highlighted.

2. Advanced Hydrogels with Tunable Properties

2.1. Elastomeric Materials

Biomaterials have been used as an artificial ECM to support the regeneration of various tissues. Since elasticity is one of the major mechanical characteristics of soft tissues, significant efforts have been made to engineer elastomeric biomaterials, which mimic the ability of native tissues to extend under stress. Mimicking the non-uniform elasticity of innate tissues including skin, blood vessel, lung, cardiac, and muscle is one of the major challenges in tissue engineering. Due to the high stretchability of native tissues, thermoplastic polymers with elongation break of less than 3% fail to replicate the innate tissue elasticity, as they undergo plastic deformation under variable loading.[14] To overcome this limitation, elastomeric hydrogels have been developed for biomedical applications.[15,16] However, one of the challenges associated with these elastomeric systems is their inability to mimic non-uniform elasticity of the native tissue. For example, many of the native tissues display strain stiffening and are responsive to applied strain, which can not be easily obtained by elastomeric systems.[17]

The use of synthetic elastomers for medical devices dates back to 1890s when the rubber industry was developed. Since then, natural and synthetic rubbers, such as silicones, polyolefins, and polydienes, and polyurethanes have been widely used as elastomers to engineer various medical devices due to their biocompatibility, mechanical durability, and low cost.[15]

In the last three decades, the rise of hydrogels as a popular choice of elastomeric materials for a variety of applications has been observed.[18] In this section, we focus on natural- and synthetic-derived elastomeric hydrogels, which are particularly useful for soft tissue engineering applications. We also discuss their limitations and potential applications for engineering biomimetic tissue constructs.

2.1.1. Naturally-Derived Elastin-Based Elastomers

Elastin is one of the main elastomeric proteins in connective tissues that are exposed to repetitive strains such as major vascular vessels, aorta, skin, elastic cartilage, tendon, and lung. Elastin is the essential component that provides elasticity and resilience needed for the proper function of these tissues. For example, the presence of elastin in arterial walls facilitates the blood transfer from the heart, lowers the mechanical work performed by the heart, and preserves the steady flow of oxygen to tissues.[19] In addition, elastin fibers allow blood vessels to withstand continuous cycles of contraction and expansion over the course of a life time.[20] Elastin is also known for being the most persistent and durable protein in the human body, with a half-life of 70 years.[18]

Elastin plays a critical biological role in regulating cellular functions. Various cell-surface proteins including elastin binding protein (EBP),[21] glycosaminoglycans (GAGs),[22] and integrin αvβ3[23] have been identified as receptors for elastin and its derivatives. Binding with these receptors has been shown to facilitate various cellular interactions. For example, it was found that elastin induced the attachment and proliferation of endothelial cells (ECs) and formation of vascular networks.[24] In addition, elastin derivatives could enhance the in vitro proliferation of skin fibroblasts.[23,25] Elastin fibers in the skin were also shown to influence cellular phenotypes during wound healing processes by controlling the differentiation of proliferative dermal fibroblasts into contractile myofibroblasts to help close the wound.[26] The presence of various cell-interactive segments in elastin and its derivatives enable them to modulate cellular functions. For example, VGAPG peptide sequences in elastin facilitate the formation of epidermis layer by inducing the migration and differentiation of epidermal keratinocytes.[27] These unique features demonstrate the potential value of elastin as a biologically active molecule for engineering elastic hydrogels in tissue engineering.

Various techniques have been developed to synthesize and purify elastin molecules from natural sources to engineer elastin-based hydrogels. Elastin can be obtained by partial hydrolysis of decellularized elastin-rich tissues in animals or by expression of recombinant protein.

Decellularized Tissues as Elastin-Based Scaffolds

Natural elastin-containing scaffolds can be generated by tissue decellularization, which removes the cellular component of explant tissues by detergent, enzymatic digestions, and solvent extraction processes. Due to their stability and durability, elastin-based tissues preserve their functions and structure after decellularization. Decellularized elastic scaffolds have been used as suitable replacements of lung, bladder, artery, heart valve, skin, and vascular graft.[28–30] Despite their advantages, decellularized scaffolds have several limitations. For example, the decellularization process involves harsh reaction conditions (e.g., enzymatic, chemical, or physical treatments) that may compromise the biological and mechanical properties of the constructs, particularly when additional steps of tissue purification are used.[31] Other limitations include batch-to-batch variability, risk of pathogen transfer, inability to obtain highly purified elastic tissue, and lack of versatility and uniformity of decellularized elastic tissues.[31]

Elastin Hydrogels Made from Soluble Elastin

Hydrolyzed elastin, soluble in aqueous solvents, has been used to engineer elastic hydrogels. The insolubility of intact elastin fibers in tissues prevents their processing into elastin-based hydrogels. To solve this problem, elastic tissues have been treated with oxalic acid or potassium hydroxide to yield soluble forms of elastin (e.g., α-elastin and K-elastin).[32,33] These hydrolyzed elastin molecules have properties similar to the native tropoelastin, such as ability to coacervate as well as to regulate cell signaling via the elastin receptors. This demonstrates the potential biological value of this class of elastin derivatives for biomedical applications.

Several elastin-based hydrogels have been synthesized from solubilized elastin for engineering different tissues such as skin,[32,34,35] cartilage,[36,37] and blood vessels.[38] For example, α-elastin hydrogels have been fabricated through chemical crosslinking approaches using various types of crosslinking agents.[32,34,40] Highly porous and elastic hydrogels were also engineered by crosslinking α -elastin with glutaraldehyde (GA)[34] and hexamethylene diisocyanate (HMDI)[32] under high pressure CO2. The fabricated hydrogels facilitated the infiltration, attachment, and growth of 3T3 fibroblasts within the 3D structure of the hydrogels.[32,34] In addition, the combination of α-elastin with poly caprolactone (PCL) promoted chondrocyte adhesion and proliferation.[36,39] Regeneration of cartilage tissue has also been achieved by using composite hydrogels containing K-elastin, alginate, and collagen.[37] Chondrocytes isolated from porcine and human were embedded inside the hydrogel composite and subsequently implanted in nude mice. After 12 weeks of implantation, cartilage-specific components including proteoglycans, collagen, and elastin fibers were formed within the engineered tissues which closely mimicked the native articular cartilage.[37] Despite its extensive use in tissue engineering, animal-derived soluble elastin is a heterogeneous mixture of peptides which are partially crosslinked and may not have adequate cell binding sites.[41] In addition, the clinical use of animal-derived proteins is often restricted due to the risk of pathogen transfer and immunological rejection.[42]

Recombinant Elastin-Based Hydrogels

Elastin-based elastomers can be also produced from various recombinant elastin proteins (e.g., recombinant elastin like polypeptides (ELP) and recombinant human tropoelastin). These proteins are obtained via the expression of recombinant DNA in different hosts including plants,[43–45] yeast,[46,47] and Escherichia coli (E. coli).[48]

Recently, human recombinant tropoelastin (rhTE) has been used to generate elastic rhTE-based hydrogels. Previously, rhTE was obtained in very low yield by construction of an expression vector containing the cDNA sequence of an isoform of human tropoelastin.[49] To enhance the production yield, Martin and Weiss developed a 2210-bp synthetic human TEL-encoding gene (SHEL) which contained codons optimized for maximum expression of rhTE in commercial yields.[50] This rhTE has been processed into a variety of promising hydrogels for tissue engineering applications.[27]

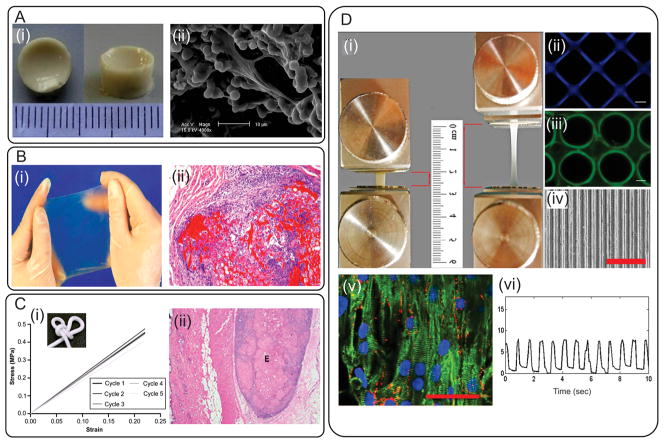

Elastic rhTE-based hydrogels with excellent cell-interactive properties have been created by using various approaches including, enzymatic crosslinking using yeast lysyl oxidase (PPLO),[51] chemical crosslinking,[52,53] using a fungal copper amine oxidase,[54] physical crosslinking,[55] and UV crosslinking.[13,56] For example, rhTE were chemically crosslinked by GA (Figure 1Ai)[52] or bis(sulfosuccinimidyl) suberate (BS3) (Figure 1Bi)[57] to generate hydrogels in various forms such as sheets, sponges, and tubes. The fabricated hydrogels promoted in vitro attachment, proliferation, and growth of dermal fibroblast cells (Figure 1Aii).[52] Furthermore, cellular penetration within the 3D structures of these hydrogels was significantly promoted by increasing the level of porosity and average pore sizes of the gels through the incorporation of GAGs[58] and the use of high pressure CO2.[52] In addition, the BS3 crosslinked rhTE hydrogels, that were implanted subcutaneously in guinea pigs, exhibited high biocompatibility and stability up to 13 weeks of culture (Figure 1Bii).[57] A physical crosslinking approach was also used to generate rhTE hydrogels by increasing the pH of protein solutions, which facilitated the self-assembly of rhTE spherules in a sol-gel transition process.[55] This approach eliminated the use of chemical or enzyme crosslinkers. The resulting hydrogel was highly flexible and elastic with compressive modulus of about 1.7 MPa over 5 cycles (Figure 1Ci). These hydrogels also facilitated the attachment and proliferation of dermal fibroblast in vitro and were stable for two weeks after intradermal injection into rats (Figure 1Cii).[55] Recently, a highly elastic photocrosslinkable hydrogel, methacrylated tropoelastin (MeTro), with tunable physical properties has been synthesized by functionalization of rhTE with methacrylate groups and subsequent UV crosslinking.[13] This approach was used to control the physical properties of resulting hydrogels including swelling behavior, porosity, and mechanical properties by altering the methacrylation degree and MeTro concentration. The fabricated MeTro hydrogels displayed high resilience, reversible deformation with low energy loss following cyclic compressions, and substantial extensibility up to 400% before rupture (Figure 1Di). In addition, in vitro studies showed that MeTro hydrogels supported cellular attachment and growth in both 2D and 3D culture environment.[13] Micropatterns were then created on the surface of these elastic hydrogels with microscale technology to fabricate micropatterned MeTro hydrogels, which were used to align cardiomyocytes (CMs) isolated from rat hearts (Figure 1Dii–iv).[56] The in vitro studies demonstrated that these microfabricated MeTro hydrogels successfully promoted all the characteristics of CMs including attachment, spreading, alignment, phenotype and synchronized beating, which ultimately led to the formation of highly functionalized cardiac tissues (Figure 1Dv–vi).[56] rhTE-based elastomeric hydrogels have shown unique mechanical and biological properties[59] and exhibited potential advantages compared to animal-derived hydrolyzed soluble elastin. First, rhTE is synthesized using a highly reproducible recombinant technology, which eliminates the batch-to-batch variations associated with soluble elastin derived from animal sources. Second, as shown by the animal studies using rhTE-based hydrogels, rhTE carries little risk of immunological rejection upon implantation.[59] Third, the abundance of cell-responsive peptides on rhTE molecules[23] significantly promotes biological properties of rhTE-based biomaterials as compared to soluble elastin.

Figure 1.

Examples of naturally-derived elastin-based hydrogels. A) GA crosslinked rTE/elastin hydrogels produced under high pressure CO2; i) structure of the hydrogel after swelling, ii) SEM image of dermal fibroblast cells penetrated and attached within the 3D structure of the gel. Reproduced with permission.[52] Copyright 2010, Elsevier B.V. B) BS3 crosslinked rTE gel; i) an image from an elastic hydrogel sheet, (ii) hematoxylin and eosin-stained sample explanted after 13 weeks of implantation (hydrogel is shown in bright red). Reproduced with permission.[57] Copyright 2004, Elsevier B.V. C) Physically crosslinked rTE gel; i) representative stress–strain curves over 5 cycles, the resulting gel could be tied in a knot, demonstrating its high flexibility, ii) a hematoxylin and eosin-stained explant showing the injection site (the elastic deposit is marked with an E). Reproduced with permission.[55] Copyright 2009, Elsevier B.V. D) Methacrylated rTE gel; i) image of an elastic MeTro gel before and after stretching, ii–iv) formation of patterns with various geometries on MeTro gel by using different microfabrication techniques, v) immunostaining of CM markers on MeTro gel on day 8 of culture, gel stained for sarcomeric α-actinin (green)/connexin-43 (red)/nuclei (blue) (scale bar = 50 μm), vi) beating behavior of CMs on micropatterned MeTro gel. Reproduced with permission[13] Copyright 2013, Elsevier B.V; Reproduced with permission.[56] Copyright 2013, John Wiley & Sons, Inc.

2.1.2. Synthetic Elastomers

Synthetic degradable elastomers have received significant attention for tissue engineering applications, particularly for soft tissue regeneration. Their unique features include 3D crosslinked networks, which mimic the structure of naturally-derived elastic materials, high elasticity and flexibility, biodegradability, and mechanical properties similar to those of native soft tissues.[16] In addition, the physical properties of these elastomers can be adjusted by changing their processing conditions. The synthesis and preparation of synthetic degradable elastomers have been comprehensively reviewed elsewhere.[15,16] In this section, we introduce several examples of the synthetic elastic materials and composites, which can be used to form elastic hydrogels.

Elastin-like Polypeptides (ELPs)

ELPs containing repetitive amino acids have been synthesized and extensively used to engineer highly elastic hydrogels.[60,61] This class of polymers possesses promising properties for tissue engineering including tunable degradation rates and similarity to native ECM. In addition, their fabrication method allows the incorporation of bioactive peptide moieties within their structures during polymer synthesis.

ELP-based elastomers have been fabricated for the regeneration of blood vessels, cartilage, ocular, and liver tissues.[60,61] For example, cell-laden ELP hydrogels were fabricated by Betre et al. for cartilage repair.[62] To form these injectable cell-laden hydrogels, temperature-triggered coacervation of ELPs was used to encapsulate chondrocytes. The resulting gels facilitated the growth and proliferation as well as the formation of cartilage ECM (e.g., deposition of glycosaminoglycans and collagen).[62] These ELP-based hydrogels also facilitated the in vitro differentiation of human adipose-derived adult stem cells into chondrocytes without the addition of chondrogenic growth factors.[63] Despite the suitable biological properties, these coacervated ELP hydrogels lacked mechanical stability and stiffness, which limited their tissue engineering applications. To fabricate ELP-based gels with higher mechanical properties, researchers have chemically crosslinked a lysine containing ELP by using β-[tris(hydroxymethyl)phosphino]propionic acid (THPP) under physiological conditions.[64–67] The THPP-crosslinked ELP hydrogels supported cell penetration and formation of ECM after injection into an osteochondral defect using a goat model. However, their fast degradation rate was an issue.[67] ELPs containing lysine were also crosslinked using various types of crosslinking agents such as tris-succinimidyl aminotriacetate[66] and bis(sulfosuccinimidyl) suberate.[68]

The unique properties of ELP-based hydrogels, such as their tunable degradation and mechanical properties, and low toxicity, make them a promising class of materials for biomedical applications. However, in vivo biocompatibility of ELP-based hydrogels is still unknown as there are only few in vivo studies on these materials. Therefore, it is crucial to study the immune response against a comprehensive library of ELPs prior to clinical application. It is expected that more systematic approaches for engineering ELPs with controlled biological properties will be developed. Microengineered technologies can also be used to tailor the properties and architectures of ELP-based materials to further advance the potential applications of this class of polymers in regenerative medicine.

Poly(glycerol sebacate) (PGS)

PGS has been synthetized by polycondensation of glycerol and sebacic acid,[69] and used as a promising polyester-based elastomer for soft tissue engineering applications. PGS has been used in various forms including sheets, porous scaffolds, electrospun fibers, and microfabricated constructs for the regeneration of soft tissues such as vascular,[70] cardiac,[71] retinal,[72] cartilage,[73] and neural[74] tissues. Despite having promising properties, PGS has limited water uptake capacity (approximately 2%), which constrains its utility as a hydrogel for soft tissue engineering applications. The hydrophilicity of PGS can be improved by incorporating additional carboxyl groups in PGS backbone[75] or by its copolymerization with PEG.[76–78] Recently, poly(glycerol sebacate citrate) (PGSC) was synthesized by thermally curing citric acid and PGS mixture in a mold.[75] The biodegradation and mechanical properties of elastomeric PGSC scaffolds were controlled by its composition as well as the thermal curing time. The presence of hydroxyl groups in the backbone of PGSC improved the water uptake properties of the elastomer, which can be beneficial for tissue regeneration.[75] Our group has also demonstrated the synthesis of highly elastic PGS-co-PEG copolymers with controlled swelling behaviors.[76] The mechanical properties and degradation of resulting elastomers were finely tuned by changing the water uptake properties of the hydrogels. The elastic modulus of PGS-co-PEG was in the range of 13 kPa to 2.2 MPa, depending on the concentration of PEG incorporated within the copolymer. In addition, the presence of PEG in the polymer network resulted in a 15-fold increase in water uptake capability and a 6-fold increase in elongation as compared with PGS elastomers. The PGS-co-PEG copolymers supported the growth and proliferation of 3T3 fibroblasts over 10 days of culture, demonstrating the suitability of synthesized elastomers for tissue engineering applications.[76]

Due to their tunable physical properties, PGS-based materials are promising candidates for engineering soft tissues, particularly cardiovascular tissues. Despite significant progress in utilizing PGS elastomers for tissue regeneration, there are still some challenges including their fast degradation rate (several weeks), which limits their applications for engineering tissues that require longer time to regenerate (several months to years). In addition, PGS polymers produce acidic degradation products, which causes cytotoxicity in vitro.[74,79] However, in vivo assessment of PGS-based scaffolds showed little to mild inflammation.[73,80,81] It has been shown that increasing the crosslinking density can improve the in vitro cytocompatibility of PGS-based elastomers.[79,82] Other limitations of PGS for soft tissue engineering applications include difficulties in achieving non-linear elastic behavior similar to native soft tissue and their inability to be used as a 3D environment for cellular encapsulation due to their harsh processing conditions (e.g., high temperature).

Polyurethanes (PU)

Since the 1980s, PU materials have been widely used for engineering cardiovascular devices including vascular prostheses, cardiac valves, the total artificial hearts, blood bags, and small diameter grafts for bypass surgeries. Due to their long-term stability, PU-based scaffolds have been utilized for long-term implantation. Tuning biodegradability and durability of PU-based materials is an essential step for their tissue engineering applications. Significant efforts have been made to synthesize a new class of biodegradable PUs for engineering various tissues including vascular grafts,[83] neural tissue,[84] bone,[85] and cardiac muscle.[86,87] These biodegradable PU-based polymers have been synthesized by incorporating chain extenders or soft segments (e.g., caprolactone, lactides, amino acids, and PEG) in PU backbone to induce degradability and in some cases hydrophilicity. For example, Zhang et al. synthesized a series of photocrosslinkable PU hydrogels containing PEG and PCL as the soft segment, lysine diisocyanate (LDI) as the hard segment, and 2-hydroxyethyl methacrylate (HEMA) as the chain terminator.[88] The physical properties of fabricated elastic PU hydrogels were tuned by changing the ratio of PCL/PEG in the soft segment. For example, increasing the amount of PEG enhanced the swelling ratio and degradation rate but reduced the mechanical properties of fabricated PU hydrogels. The fabricated PU hydrogels had swelling ratio in the range of 3.2–66%, elastic modulus ranging from 17–34 MPa, and fracture strain of 5–61% when the ratio of PEG/PCL was changed from 0/100 to 50/50. The PU hydrogels supported mouse chondrocyte attachment and proliferation.[88] Recently, an injectable amine-functionalized PU/PEG block co-hydrogel was synthesized and exhibited its highest elastic modulus at 37 °C.[89] The fabricated composite supported in vitro growth of smooth muscle cells. The results of in vivo test exhibited significant inflammatory response 3 days post-implantation with the presence of recruited ED-1 positive macrophages but the amount of inflammation decreased 4 weeks after implantation.[89] In another recent study, highly elastic PU-based biomaterials, with extensibility of more than 1100%, were fabricated by the solution blending of sodium alginate and an aqueous solution of cationic PU to form cationic dispersions-sodium alginate nanoparticles.[90] Incorporating sodium alginate into PU network improved the mechanical strength as well as the hydrophilicity of the composite network.[90] Similarly, Huang et al. combined a hierarchical PU scaffold with a cell-laden hydrogel composed of gelatin, alginate, and fibrinogen by using a rapid prototyping technique to form 3D vascular constructs.[91] The external PU scaffold provided adequate mechanical support while the internal hydrogel construct supported adipose-derived stem cell growth and proliferation in vitro. The fabricated PU/cell-laden hydrogel was also found to be stable and biocompatible after two weeks of implantation in the abdominal cavity of nude mice.[91]

These results together indicate that biodegradable PU-based composite hydrogels are promising elastic biomaterials for tissue engineering. These highly elastic materials have shown proper durability and good biocompatibility in vitro by supporting cellular adhesion and proliferation during culture. However, the in vivo evaluation of biodegradable PU-based scaffolds demonstrated limited stability and consequently mechanical failures. In addition, the toxic degradation products of PUs (e.g., aromatic diisocyanates) can cause cytotoxicity.[92] To address this problem, aromatic diisocyanates have been replaced with aliphatic ones such as lysine diisocyanates for the synthesis of bioresorbable PU.[93,94] However, more investigation on the in vivo response to biodegradable PU-based materials and their susceptibility to biodegradation is required.

Composite Elastomers

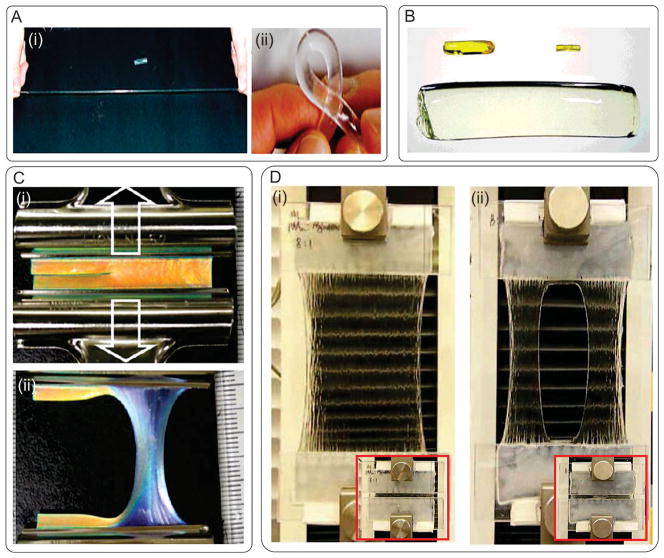

Various types of composite elastomers have been developed including nanocomposite hydrogels (Figure 2A),[95,96] polyrotaxane gel (Figure 2B),[97] double network (DN) gels,[98] hydrophobic bilayers (PDGI)/polyacrylamide (PAAm) (Figure 2C),[99] and PAAm/alginate composite gel[100] (Figure 2D). For example, polymer/clay nanocomposites composed of N-isopropylacrylamide and hectorite clay Laponite XLG were formed by free radical polymerization of the polymer in an aqueous suspension of clay. The resulting hydrogel had tensile modulus in the range of 270–300 kPa and elongation of up to 1300%. The fabricated nanocomposite gels could also withstand high levels of deformation in twisting, bending, and knotting[95] (Figure 2A). In another study, highly elastic hydrogels were formed by ionic crosslinking in combination with physically associated triblock copolymer chains, but these hydrogels could only recover up to 50% of their initial deformation.[101] To solve this problem, Haque et al. incorporated lamellar PDGI in a hydrophilic PAAm matrix as reversible sacrificial bonds to dissociate upon deformation with large energy dissipation.[99] The fabricated hydrogel was highly elastic with a tensile strength of 38 kPa and strain of 2200%. The hydrogel fully recovered its original length within several minutes after stress removal (Figure 2C). Despite their high recovery capability, these PDGI/PAAm gels had lower fracture energy compared to DN gels. Recently, a highly stretchable and tough hydrogel was synthesized by mixing ionically crosslinked alginate, and covalently crosslinked PAAm (Figure 2D).[100] The fabricated hydrogels were able to stretch more than 20 times of their initial length. The hydrogel sheets were also shown to be notch-insensitive and fully recovered after mechanical stretching caused by dropping a metal ball on the hydrogel membrane.[100]

Figure 2.

Examples of composite elastomers. A) N-isopropylacrylamide/clay nanocomposite hydrogel; i) with high level of elongation and ii) torsion. Reproduced with permission.[95] Copyright 2002, John Wiley & Sons, Inc. B) Volume change of a superabsorbent polyrotaxane gel swelled to 45 times the initial weight; before volume change, in dried state, and in swollen state (up to 400% of its dry weight). Reproduced with permission.[97] Copyright 2001, John Wiley & Sons, Inc. C) Crack resistance of a PDGI/PAAm gel; (i) hydrogel with an initial sharp crack along the longitudinal direction, (ii) the hydrogel was stretched perpendicular to the crack direction up to a strain of 3. Reproduced with permission.[99] Copyright 2011, American Chemical Society. D) Highly stretchable alginate/acrylamide gel; i) the gel was glued to two rigid clamps and stretched up to 21 times its initial length, ii) a notch was cut into the gel before stretching to 17 times its initial length. Reproduced with permission.[100] Copyright 2012, Nature Publishing Group.

2.2. Photosensitive Hydrogels

Hydrogels can be crosslinked or degraded by utilizing various approaches such as ionic interactions, pH stimulation, and light exposure.[102] Photosensitive hydrogels have been extensively used for a wide range of tissue engineering applications. In this section, we will discuss about polymer networks, which can be either generated or degraded by UV light exposure.

2.2.1. Photocrosslinkable Gels

To form hydrogels via exposure to light, a photocurable hydrogel precursor is mixed with a photoinitiator and then exposed to light that initiates the crosslinking reaction.[2] Although a range of light wavelengths can be used, ultraviolet (UV) light is most commonly used to induce the photoinitiator to generate free radicals. The activated functional groups then form covalent bonds with free radicals to create crosslinked networks.[103,104] Subsequently, unreacted polymer is washed out upon completion of the crosslinking process. Photocrosslinkable hydrogels offer a number of advantages over other types of crosslinking schemes. For example, they enable controlled spatial crosslinking of the hydrogel to control the microarchitecture of the resulting material,[105–107] which can be used to modulate cellular behavior (e.g., adhesion, migration, and differentiation).[108,109] In addition, photocrosslinking is a simple, rapid, and cost effective technique.[2,6] Despite these attractive features, photocroslinkable hydrogels also demonstrate some drawbacks. For instance, the formation of free radicals upon UV exposure may lead to DNA damage and impair cellular function.[2] In addition, in vivo gelation of photocrosslinkable hydrogel is challenging due to the limited light penetration through the tissues.

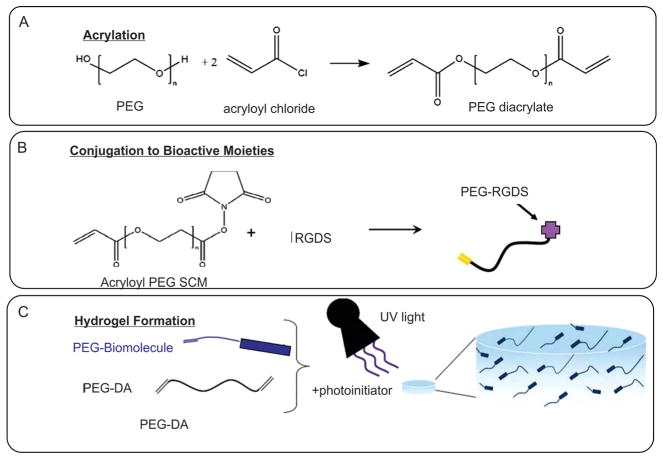

Materials with both synthetic and natural origins have been modified with photocrosslinkable functional groups.[107] For instance, PEG[110–112] and PHEMA[113] were chemically modified by methacrylate groups to synthesize photocrosslinkable hydrogels (Figure 3). Similarly, naturally-derived materials, such as alginate,[114] dextran,[115] agarose,[116] heparin,[117] hyaluronan,[118–121] chitosan,[122] collagen,[123] and gelatin[12,119,124–126] were methacrylated to yield photocurable gels. These photocrosslinkable hydrogels were used as robust 3D environments to engineer biomimetic cell-laden hydrogels for different tissue engineering applications. For instance, 3T3 fibroblast cells were encapsulated within photocurable gelatin hydrogels to test the biocompatibility of the gels.[12,127] Similarly, macrophages,[110] human umbilical vein endothelial cells (HUVECs)[107] and hepatocytes[111] were tested for their cellular response within photocrosslinkable gels based on PEG, gelatin, and HA.

Figure 3.

Schematic for generation of photocrosslinkable hydrogels. A) Modification of PEG polymer with photocrosslinkable acrylate groups. B) Conjugation of biological molecules to photocrosslinkable PEG polymer precursor. C) Formation of hydrogel upon exposure to UV light. Reproduced with permission.[112] Copyright 2011, Wiley Periodical Inc.

Micropatterning using photocrosslinkable gels is a common strategy to modulate cellular behavior. For example, micropatterned gelatin-based hydrogels enabled guidance and alignment of different cell types, such as 3T3 fibroblasts, C2C12 skeletal muscle cells, cardiac side population (CSP) cells, and HUVECs.[128] These technologies will be discussed in details in Section 3. Photocrosslinkable hydrogels allow temporal and spatial control over structural, mechanical, and degradation of the fabricated constructs. For example, in one study methacrylated HA gel was first crosslinked by a Michael-type addition reaction with dithiothreitol (DTT) and then its mechanical stiffness was tuned by additional UV crosslinking.[129] It was shown that the substrate stiffness affected differentiation of MSCs, seeded on the surface of the hydrogel.

Due to their ability to generate micro- and nanostructures, as well as their tunable chemical, biological and mechanical properties, photocrossinkable hydrogels have been extensively used in tissue engineering research. However, the next generation of photocrosslinkable hydrogels could further benefit from novel strategies for in situ crosslinking of these hydrogels within the human body.

2.2.2. Photodegradable Gels

Hydrogel structures can be controlled both spatially and temporally to modulate material properties and therefore their biological response.[130] When photodegradable gels are exposed to irradiation, light-triggered reactions induce dissociation of the crosslinks in the polymer chain and therefore its degradation in the exposed region. This results in either complete degradation or local decrease in the crosslinking density, which influences the physical properties of the gel and subsequently cellular behaviors.[131] For example, the degradation of cell-encapsulated hydrogels can facilitate the deposition of the ECM by the cells as well as guide cellular migration within the hydrogel.

The most commonly used photodegradable functional groups are nitrobenzyl ether,[130] poly(t-butyl acrylate),[132] 4-[4-(1-Hydroxyethyl)-2-methoxy-5-nitrophenoxy] butanoic acid,[133] and bis(4-(dimethylamino)phenyl)(4-vinylphenyl)methyl leluco cyanide.[134] Photodegradable hydrogels from different synthetic sources have been fabricated by the incorporation of the above listed groups to the polymer backbone.[132,133,135–142] For example, the migration of stem cells was guided within photodegradable PEG-based hydrogels.[143] In addition to their bulk degradation ability, photodegradable hydrogels can also be patterned by irradiating light through photomasks to generate specific patterns for modulating or directing cellular migration. In one study, directed migration of fibrosarcoma cells within photodegradable hydrogels was investigated.[130] In another report, DeForest et al. controlled the architecture of PEG-based photodegradable hydrogels, which led to the modulation of the adhesion, spreading, and migration of 3T3 fibroblasts.[144]

Generally, photodegradation enables tuning the hydrogel structure and properties spatially and temporally and offers unique opportunities to control cellular function in 3D environments. But tissue engineering applications of photodegradable hydrogels have been less explored. In addition, similar to their photocrosslinkable counterparts, sensitivity of cells to irradiation may be a concern for cell encapsulation; therefore the process should be optimized.[142] It is expected that photodegradable hydrogels to be utilized to direct cellular behavior dynamically and control local microenvironments for different tissue engineering applications ranging from directed migration of neurons, formation of cardiac fibers, and photorelease of biological molecules.

2.3. Reinforced Composite Hydrogels

Hydrogels are generally made from a single polymer network. But no single polymer holds all the required mechanical and biological properties for tissue engineering applications. Therefore, strategies are being employed to improve the properties of hydrogels, mainly by incorporating different entities to create composite hydrogel matrices.[145–147] These strategies include incorporation of secondary polymers as well as various nanostructures into the main hydrogel. In this section, we will discuss the fabrication and characterization of these composite hydrogels.

2.3.1. Polymer-Composite Hydrogels

The simplest way to create composite materials is by mixing different materials (‘physical blending’). As polymers used to fabricate hydrogels are hydrophilic, they are generally compatible with one another, and miscible in aqueous solutions. For example, alginate hydrogels are widely used in various bioengineering applications.[148] However, alginate alone may not induce the desired cellular response. Therefore, ECM proteins such as collagen and fibronectin, or cell-responsive synthetic polymers such as polylysine are often mixed with alginate to regulate its cell-interactive properties.[149,150] In addition, mechanical properties of the alginate hydrogels were enhanced by incorporating other natural or synthetic polymers (e.g., chitosan, poly(vinyl alcohol) (PVA) and poly(acrylic acid)(PAA)) into hydrogels.[151–153] There are other types of polymer-composite hydrogels utilizing more elaborate strategies to incorporate a secondary polymeric network, such as hybrid networks, interpenetrating polymer networks (IPNs), and semi-IPNs.

Hybrid Hydrogels

One critical drawback of incorporating secondary polymers via physical blending is that only limited amounts of the polymers can be included within the hydrogel network. Often, inadequate inclusion of the secondary polymers within the hydrogels leads to phase separation.[154,155] Therefore, co-polymerization schemes are employed to covalently link the secondary polymers to the hydrogel, and ultimately create fully integrated “hybrid” hydrogels with a wide range of properties. For example, photocrosslinkable hydrogels are commonly prepared by UV-induced radical polymerization of reactive species containing double carbon-carbon bonded functional groups (e.g., vinyl, acrylic and methacrylic).[156,157] Secondary polymers containing those groups can readily undergo copolymerization to form hybrid hydrogels. For example, HA, a polysaccharide component of natural ECM, is made photocrosslinkable by conjugating methacrylated functional groups, and incorporated into PEG hydrogels.[158]

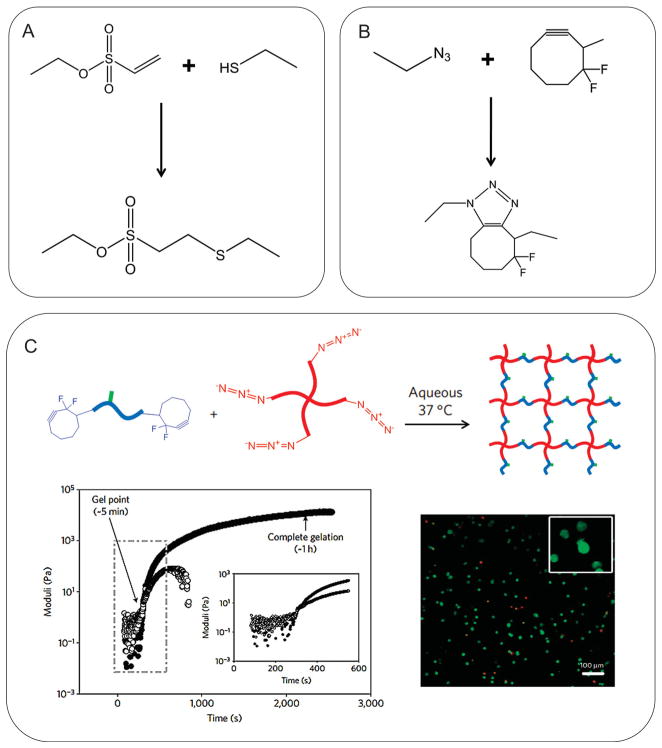

Recently, more biocompatible and selective chemical reactions have been used to create hybrid hydrogels. For example, Lutolf and Hubbell first employed a Michael-type addition reaction to engineer hydrogels using thiol- and vinyl-functionalized PEG molecules (Figure 4A).[159] This thiol-based Michael reaction was especially useful to prepare hydrogels for biological applications as the reaction took place in physiological pH and buffers and in the absence of potentially toxic initiators.[135,160–162] Furthermore, “click” chemistry, which has gained recognition in recent years as a highly bio-orthogonal and facile reaction between alkyne and azide groups, has also been explored to fabricate hydrogels.[162–164] Especially, the biocompatibility of the click chemistry was achieved by the recent development of “copper-free” method (i.e., cycloaddition reaction between cyclooctyne and azide), which circumvented the use of cytotoxic copper catalyst (Figure 4B).[164,165] For example, DeForest et al. utilized the copper-free click chemistry to create PEG-polypeptide hybrid hydrogel (Figure 4C).[166] The reaction between tetraazide-functionalized 4-arm PEG and bis(difluorocyclooctyne)-functionalized polypeptide resulted in hydrogel formation under physiological conditions. The viability of cells encapsulated in the hydrogel was well maintained.[166]

Figure 4.

Biocompatible click-based hydrogels. A) A Michael-type addition between thiol and vinyl sulfone. B) A “copper-free” click chemistry between azide and difluorinated cyclooctyne. Both reactions occurred under physiological conditions. C) Cell-encapsulating hydrogel was fabricated by copper-free click chemistry between 4-arm PEG-tetrazide and bis(difluorocyclooctyne)-polypeptide. Reproduced with permission.[166] Copyright 2009, Nature Publishing Group.

IPN and Semi-IPN Hydrogels

IPNs date back to early 20th century, when Aylsworth first created IPN materials by introducing phenol-formaldehyde resins to natural rubber network.[167] The primary purpose for developing IPN has been to improve the fracture resistance of a material, which otherwise may be too weak or brittle.[168] It is well known that the IPN materials demonstrate enhanced mechanical toughness by efficiently transferring externally applied stress to the secondary polymer network.[98,168] The major distinction of IPN hydrogels from hybrid hydrogels is that the secondary polymers are not covalently conjugated to the hydrogel. Rather, the secondary polymers are placed within the hydrogel already formed, and then allowed to undergo polymerization to form the secondary polymer network. Therefore, the secondary network becomes interlocked within the hydrogel.[169] Semi-IPN hydrogel is another class of polymer-composite hydrogels, in which the secondary polymers are not crosslinked, but only “trapped” within the polymer network.[169]

The strategy of creating IPN hydrogel is continuously explored as a popular mode of structurally reinforcing hydrogels. For example, Gong et al. engineered IPN hydrogel with PAAm and poly(2-acrylamido-2-methylpropanesulfonic acid) (PAMPS), which demonstrated extremely high tensile strength as compared with the single network of PAAM or PAMPS (i.e., 10 to 20 fold increase in fracture stress).[170] Sun et al. have recently reported similar findings, in which by introducing ionically crosslinked alginate network to PAAm network, the resulting IPN hydrogels showed significant stretchability.[100]

There are efforts to create IPNs in order to add different physical characteristics to the hydrogels, rather than focusing purely on the mechanical properties. For example, poly(N-isopropylacrylamide) (PNIPAm) and PAAm networks are often incorporated to engineer IPN hydrogels with temperature- and pH-sensitivity, respectively.[171,172] In addition, Lin et al. introduced electrically conductive polyaniline (PANI) network to non-conductive PAAm hydrogel, and demonstrated that the resulting PANI/PAAm IPN hydrogel showed improved electrical field sensitivity as compared with PAAm hydrogel.[173]

2.3.2. Nanocomposite Hydrogels

With the rapid development of nanotechnologies in recent years, extensive research efforts are being made to develop nanoparticles (NPs) for various biomedical applications.[174] NPs can be engineered from a variety of sources (e.g., polymers, minerals, metals, and semiconductors) and into different shapes (e.g., spheres, rods, shells, wires, and tubes).[174–176] In addition, chemical modification strategies are available to further modulate the properties of NPs.[177] Due to this diverse array of NPs with distinct physical and chemical properties, research efforts are being made to incorporate various types of NPs into hydrogel systems to create reinforced nanocomposite hydrogels.

Mineral NPs

The earliest attempt to reinforce materials with NPs was made by Usuki et al., who incorporated mont-morillonite, a type of natural silicate mineral (“clay”) NPs, into nylon-6.[178] The fabricated nanocomposites showed significant improvement in tensile strength.[178] Since then, various types of clay NPs have been used as prominent composite materials.[179] The inorganic clay NPs are often modified with polymers to render them hydrophilic, and therefore increase solubility and interaction with polymers.[180] The organic clay NPs are also being used to reinforce hydrogels. For example, Kokabi et al. engineered PVA hydrogel reinforced with organic-substituted clay NPs.[181] The resulting PVA-clay nanocomposite hydrogels showed enhanced tensile strength and diminished microbial penetration, while maintaining high water absorbency.[181]

Polymeric NPs

Synthetic polymeric NPs, such as dendrimers and micelles, which are widely used as drug delivery systems, have also been incorporated into hydrogels to utilize their drug releasing capability, as well as enhance their mechanical properties. In one study, Xiao et al. covalently incorporated micelles, made from self-assembly of block copolymers, in PAAm hydrogel.[182] Mechanical properties of the micelle-linked PAAm hydrogel could be controlled by the amount of micelles, in which 2-fold increase in tensile stress and 4-fold increase in Young’s modulus were observed when the micelle concentration was doubled, from 7.5 to 15 mg mL−1. In another study, Desai et al. developed a photocurable PEG hydrogel crosslinked with polyaminoamine dendrimers, and demonstrated cytocompatibility, controlled swelling and degradation by modification of dendrimers (i.e., chain length and charge density).[183]

Metallic NPs

With increasing popularity of hydrogels in various areas of biomedical engineering, there is a growing need to engineer hydrogels with tunable properties (e.g., electrical and optical properties) to meet specific needs. Metallic NPs hold great promise as reinforcing elements to engineer composite hydrogels with unique characteristics, since they possess properties that are not commonly found in polymers or inorganic materials. For example, gold nanoparticles (AuNPs) are actively explored as biosensors, as they possess useful electronic and optical properties (e.g., quantized capacitance and surface plasmon resonance).[184] Pardo-Yisar et al. utilized a “breathing” mechanism to introduce AuNPs into hydrogels, in which PAAm hydrogel was first dehydrated by organic solvent, then followed by swelling in aqueous media containing AuNPs.[185] The resulting AuNP/PAAm composite hydrogels demonstrated significant increase in electrical conductivity. Silver nanoparticles (AgNPs) are also well known for their unique antibacterial activity. Therefore, AgNP-incorporated hydrogels are currently being investigated for their use as antibacterial wound dressing.[186]

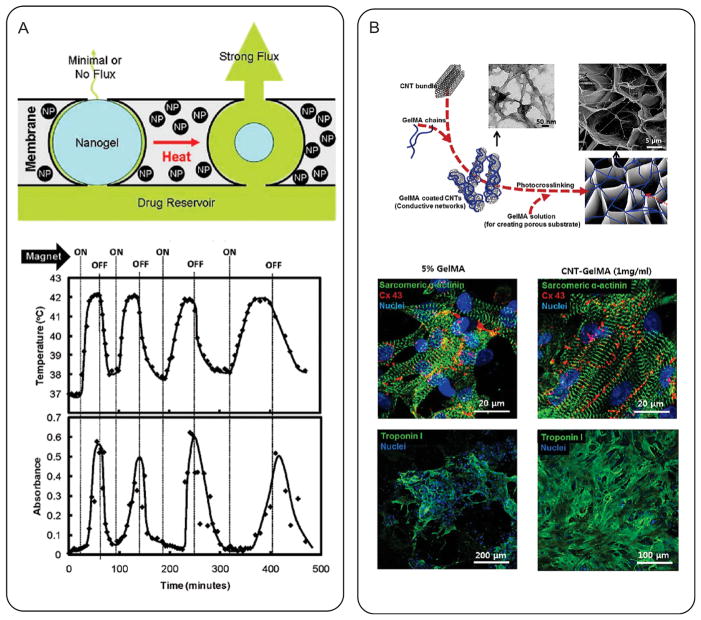

Magnetic nanoparticles (MNPs), such as iron oxide and gadolinium, are the most widely investigated class of metallic NPs for biomedical applications.[187,188] They have been mainly used as contrast agents for magnetic resonance imaging (MRI), with several products already commercially available.[187] Strategies of coating MNPs with hydrogels have been explored to increase their hydrophilicity and biocompatibility, as well as reduce non-specific protein adsorption. For example, Yi et al. utilized a sol-gel reaction to coat iron oxide MNPs with silica hydrogel.[189] Another interesting aspect of MNPs is their ability to produce heat under applied magnetic field (“magnetocaloric effect”).[190] Therefore, MNP-loaded hydrogels are currently being explored in hyperthermia-based cancer therapies (e.g., thermal ablation and temperature-sensitive drug delivery).[188,191,192] For example, Hoare et al. developed a composite film consisting of thermosensitive PNIPAm hydrogel and iron oxide MNPs.[193] They demonstrated that magnetic-induced hyperthermia from iron oxide MNPs caused the volumetric change of PNIPAm hydrogel, thereby inducing the release of cancer drugs (Figure 5A). In another study, Meenach et al. showed that magnetization of PEG-MNP composite hydrogels generated enough heat to kill glioblastoma cells.[194]

Figure 5.

Nanocomposite hydrogels as bioactuators. A) A magnetic triggered composite film consisting of iron oxide MNPs and PNIPAm hydrogels. The magnetic-induced hyperthermia from the iron oxide MNPs caused shrinkage of PNIPAm hydrogel, inducing the release of cancer drugs. Reproduced with permission.[193] Copyright 2009, American Chemical Society. B) CNTs were embedded in GelMA hydrogel to engineer electrically conductive tissue engineering scaffold. CMs on CNT-GelMA composite hydrogels displayed enhanced electrophysiological functions (identified with the expression of various cardiac markers including sarcomeric α-actinin, connexin 43, and troponin I), compared to pure GelMA hydrogels. Reproduced with permission.[195] Copyright 2013, American Chemical Society.

Carbon-based NPs

Carbon-based NPs (CBNs), such as carbon nanotubes (CNTs) and graphene, have gained worldwide popularity in recent years for their excellent multi-functional nature (i.e., mechanical strength, electrical, thermal, and optical conductivity). Therefore, extensive research efforts are under way to utilize their unique and favorable properties to create CBN-based composite materials for a variety of applications, including high-strength materials, nanoscale electronic circuitry, sensors, and actuators.[196–198] CBNs are also being investigated to reinforce hydrogels for biomedical applications. For example, Tong et al. demonstrated a twofold increase in tensile stress of PVA hydrogels by incorporating CNTs (0.05 wt%).[199] Similarly, Zhang et al. reported a 2-fold increase in tensile stress of PVA-graphene oxide (GO) composite hydrogel when GO was increased up to 0.8 wt%.[200]

Hydrogels commonly used in biomedical applications are not conductive towards thermal, optical and electrical stimuli, as they are made from non-conductive polymers. However, there is a growing need for conductive hydrogels to be used as biosensors, actuators and tissue engineering scaffolds. Therefore, CBNs are considered as highly promising materials to engineer conductive stimuli-responsive hydrogels. For example, Zhang et al. developed an electrical- and pH-responsive actuator based on graphene-PAAm composite hydrogel.[201] Shin et al. also demonstrated increased electrical conductivity of methacrylated gelatin (GelMA) hydrogel by incorporating CNTs. The resulting CNT-GelMA composite hydrogel was successfully used as a tissue engineering scaffold to mediate enhanced electrophysiological function of CMs (Figure 5B).[195]

Overall, as hydrogels have become a popular choice of materials used in several areas of bioengineering, strategies of encompassing various components to develop composite hydrogels with tunable properties are expected to be continuously explored. Traditionally, the composite strategies are often employed to engineer hydrogels with enhanced mechanical strength and function. Also, commonly used reinforcing materials have been mostly limited to polymers. However, more extensive research efforts are now being made to impart hydrogels with various properties (e.g., electrical and optical conductivity), with added emphasis on engineering multifunctional hydrogels to tailor to specific needs and complexities often required for present and future challenges. For this purpose, the recent advances in nanotechnology and development of various types of nanomaterials have made it possible to engineer nanocomposite hydrogels, which are likely to attain greater popularity than polymer-based composite hydrogels. This can be due to the fact that the nanomaterials often possess highly specialized and favorable functions that are not commonly found in polymers.

2.4. Shape Memory and Self-Assembled Hydrogels

Shape memory hydrogels (SMHs) are a class of smart biomaterials with multiple shape capability. These hydrogels can vary their shapes when exposed to an external stimulus such as temperature or pH.[202–205] In this section, we review the fundamental mechanisms of shape memory hydrogel formation with their advantages and shortcomings. Particularly, we review the properties of hydrogels with stimuli-responsiveness, self-healing, and shape-memory characteristics. Finally, we point out applications of SMH in regenerative tissue-engineering strategies, particularly of those that are responsive to temperature changes with enhanced control-release and mechanical properties pertinent to biomedical applications and medical devices.[206]

Repeating units such as macrobiomolecules, polysaccharides, and nucleic acids make up the basic building blocks in living organisms. In their native environment, these repeating units are responsible for directing various cellular functions such as morphogenesis, proliferation, migration, and metabolic activity.[207–209] These building blocks are stable at a broad range of temperature gradients but undergo biophysical changes when they are exposed to their thermal transition temperatures (TT), which trigger the reversible transition from a firm state to a softer, rubbery form. This non-linear and specific behavior happens due to cumulative cooperative interactions of the repeating units (e.g., macrobiomolecules, polysaccharides, and nucleic acids). That is, under alteration of temperature, the intermolecular and intramolecular interactions undergo conformational and structural changes. This physiological observation has been introduced artificially in biomaterial design strategies to stimulate a response in natural or synthetic polymers.[210–212]

Among the variables studied to modify the response of polymers and hydrogels, thermal stimulation is the one that causes the largest conformational and structural responses. SMHs are created when these conformational responses are reversible; this reversibility occurs via supramolecular bonds formed by hydrogen bonds, van der Waals interactions, π–π interactions, or metal complexes. These interactions serve to build up network chains from non-covalent interactions between monomers, or non-covalently associate polymer chains together.[213–215] The non-covalent bonds can be combined in different ways to produce SMH networks with adaptable wettability,[216] swelling capability,[217] permeability,[218,219] and sol-gel transition properties.[220] Merging transient, reversible, non-covalent physical bonds with stable chemical bonds is a feature of SMHs that arises during its mechanism of formation.

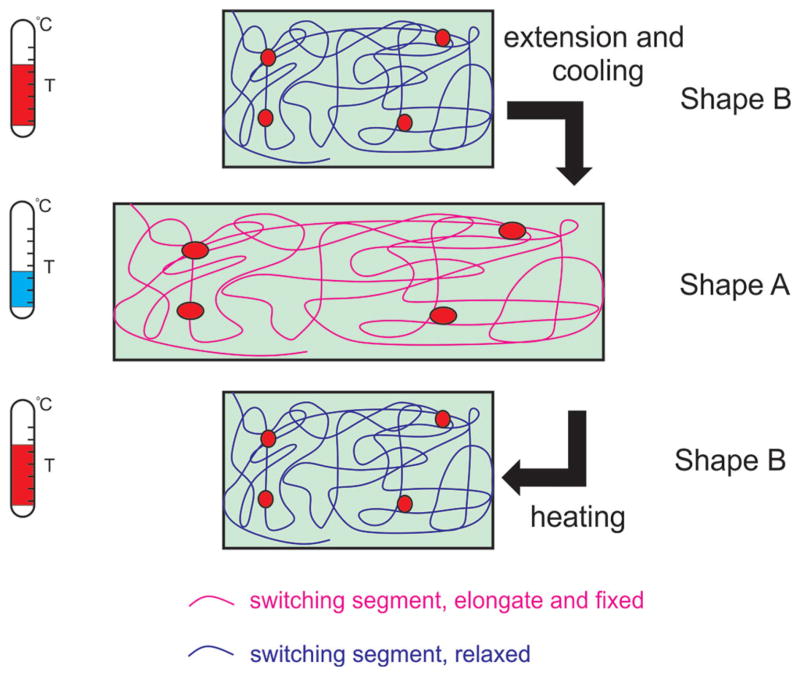

The mechanism of SMH formation can be described as follows. When reversible supramolecular crosslinks and permanent covalent crosslinks are heated to a critical TT, the physical crosslinks dissociate, the network deforms, and only the permanent covalent crosslinks are responsible for an elastic response.[221] Decreasing the temperature below TT causes association of the physical molecular crosslinks; thus, deforming the hydrogel and locking it. Raising the temperature again above TT dissociates the physical molecular crosslinks, releasing stored elastic energy of the permanent crosslinks, and restoring the hydrogel back to its original shape (Figure 6).[222]

Figure 6.

Molecular mechanism of temperature-responsive SMHs. The left panels represent the TT related to the switching of conformational structure. The right panel represents the conformational change of the SMH from shape B to shape A upon cooling, and back from shape A to shape B upon application of heat. The covalent chemical bonds are represented by the red dots and the physical non-covalent bonds by the entangled lines. Reproduced with permission.[222] Copyright 2013, American Chemical Society.

As mentioned above, one important advantage of SMHs is that they rely on the synergistic interplay between networks forming chemical and physical connections.[223] Chemical networks are connected together by covalent chemical bonds; physical networks on the other hand, are connected by transient non-covalent interactions (e.g., hydrophobic or electrostatic interactions). Both chemical and physical crosslinks have advantages and disadvantages. Chemical networks are strong and can be considered permanent. This feature is important for applications that require tough and highly connected networks, but may be detrimental if the hydrogel has to be reprocessed or recycled. On the other hand, the reversibility physical crosslinked networks greatly enhance reprocessing and recycling capabilities. Nonetheless, physical crosslinks are hard to customize, and their applications are specific to polyelectrolyte or biopolymer systems.[213] The combination of these chemical and physical crosslinks offers several advantages to SMHs. First, the reversibility of the physical crosslinked networks in SMHs enable their utilization as sensors,[224] actuators,[225–228] and controlled release platforms.[229] Second, SMHs exhibit self-healing properties;[221] when the network is ruptured, unassociated molecular bonds display a tendency to re-associate if they are brought into close proximity with each other. Third, the SMHs are customizable as they can form strong materials under favorable conditions, but easily de-coupled or de-crosslinked when exposed to temperatures below their TT. Forth, SMHs can be considered as composite hydrogels combining polymers and nanoparticles with specific “memory” characteristics. The detailed chemistry and characteristics of these composite hydrogels have been previously described in Section 2.3.

Temperature-responsive SMHs present promise as delivery vehicles of multiple bioactive molecules or growth factors due to their unique self-healing properties.[230–232] Once the SMH is stimulated, it can modify its shape and selectively attract or release a pre-determined set of biomolecules. For example, Ozadin-Ince et al. developed a coaxial nanofilm with a hydrogel core and a p(tert-butyl acrylate-co-diethylene glycol divinyl ether) shape memory shell to form temperature activated nanotubes using vapor phase deposition.[233] The temperature response of the coaxial nanofilm was then studied through release of encapsulated fluorescent dye. Burst release of fluorescent dye (fluorescein-5-thiosemicarbazide, FTSC) occurred due to the stress applied by the shape memory outer layer when activated at elevated temperatures.[233]

Temperature-responsive SMHs have also been used as smart hydrogels for cell and growth factor encapsulation. For example, Wang et al. developed a biodegradable, partially crosslinked alginate hydrogel with shape-memory properties at body temperature for minimally invasive surgical applications.[234] In this paper, 90% of recombinant insulin-like growth factor-1 (IGF-1) that was encapsulated in these hydrogels was released over several days in vitro, allowing skeletal muscle cell survival, proliferation, and migration within the scaffold over a 28-day period. In another study, a temperature-sensitive hydrogel composed of 2-acrylamido-2-methylpropanosulfonic acid (AMPS), NIPAm, and acrylamide (AAm) was synthesized to selectively bind proteins from serum samples.[224] The AMPS was chosen as a protein complex monomer based on the affinity of sulfonic acid groups to amide groups of bovine serum albumin (BSA). In addition, NIPAm was introduced as a temperature-sensitive material to bind and release BSA upon temperature changes. The shape-memory properties of the fabricated hydrogel combined with charge interactions enabled selectively reorganization and adsorption of BSA from a real serum sample.[224]

A near-infrared light responsive polymer-nanorod composite with a TT in the range of body temperature was also employed for the control-release of anti-cancerous drugs such as doxorubicin.[227] In vitro studies on these composite microspheres demonstrated a ~90% reduction in the activity of cancerous T6–17 cells when the release of doxorubicin was triggered from microspheres exposed to near-infrared light. Due to their high surface area, the microspheres facilitated cumulative release of drug;[227] however their applicability for clinical application such as cancer treatment remains to be proven.

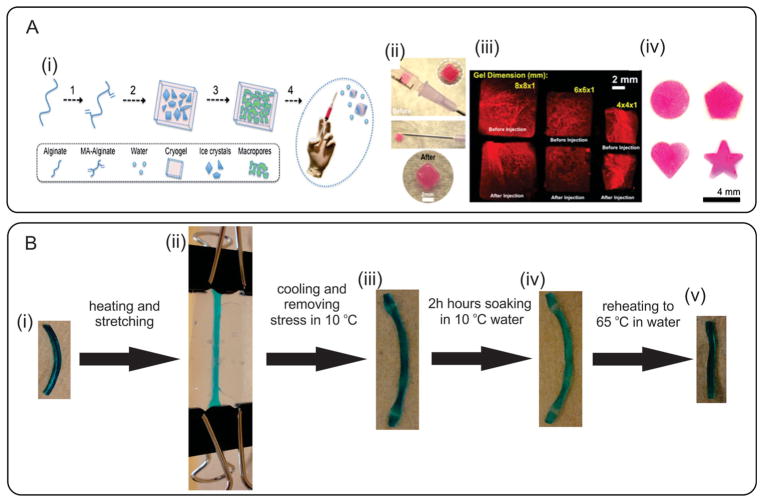

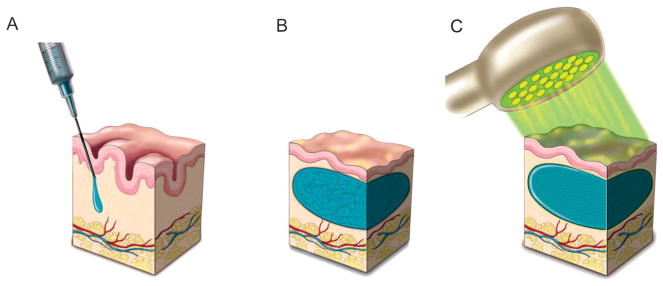

Injectable Smart Hydrogels

Recently, SMHs with tunable mechanical characteristics have shown promise as injectable hydrogels. For example, Bencherif et al. developed injectable macroporous alginate scaffolds with well-defined shape-memory properties (Figure 7Ai–iv).[235] These injectable hydrogels were highly compressible and could withstand reversible deformations up to 90% strain upon in vivo injection by a using conventional needle–syringe technique. Moreover, the fabricated hydrogels were employed as a delivery vehicle for biomolecules such as bovine serum albumin (BSA) as well as cells. Recently, shear-thinning hydrogels have been also proposed as injectable biomaterials at physiological conditions.[236,237] These hydrogels can be injected by application of shear stress during injection and quickly self-heal after removal of shear. In one study, shear-thinning hydrogels were made from small peptides and used to improve the immune response of H1N1 influenza vaccines.[238]

Figure 7.

Representative examples of SMHs. A) Formation of injectable SMHs: i) cryogelation process: 1) alginate is chemically modified to allow radical polymerization; 2) MA-alginate is added to a chemical initiator at −20 °C to allow ice crystal formation; 3) cryogelation takes place followed by thawing of ice crystals; and 4) conventional needle–syringe injection of preformed cryogels; ii) Photographs showing placement of a cryogel in a syringe (before injection) and hydrogel recovery (after injection); iii) MA-alginate gels with various sizes and shapes. Fluorescent square-shaped gels were syringe injected and showed complete geometric restoration after injection; iv) Cryogels prepared with different geometric shapes. Reproduced with permission.[235] Copyright 2012, National Academy of Sciences. B) Shape-memory behavior of highly stretchable hydrogels: i) The original length of the hydrogel is 26.3 mm; ii) The hydrogel heated in 65 °C water and stretched to 45.2 mm; iii) The shape of the hydrogel immediately after cooling to 10 °C; iv) After 24 h soaking in 10 °C water, the length of hydrogel decreased to 43.0 mm; v) After reheating hydrogel in 65 °C water without any external stress, the length recovered to 26.0 mm. Reproduced with permission.[239] Copyright 2009, American Chemical Society.

SMHs with Enhanced Mechanical Properties

Temperature-responsive SMHs nanocomposites with enhanced mechanical properties have also been investigated. For example, a reinforced SHM was produced by introducing reinforcing networks of cellulose whiskers (CCW) isolated from cotton into poly(vinyl acetate).[240] Upon immersion in artificial cerebrospinal fluid at 37 °C, the nanocomposites showed an adaptable change in elastic modulus, which made them suitable substrates for intracortical electrodes.[240]

In another study, highly stretchable SMHs were produced by covalently crosslinking quad-polymers of N,N-dimethylacrylamide (DMA), 2-(N-ethylperfluoro-octanesulfonamido) ethyl methacrylate (FOSM), hydroxyethyl acrylate, and 2-cinnamoyl-oxyethyl acrylate (Figure 7Bi–v).[239] These hybrid hydrogels, containing physical and covalent crosslinks, exhibited high mechanical strength, elasticity, extensibility, and fracture toughness, with potential applications for ligament or tendon repair.[241] Anthamatten et al. also synthesized copolymers of methyl acrylate (MA), methyl methacrylate (MMA), and iso-bornyl acrylate (IBoA) by adjusting their TT between 28 °C and 55 °C to form highly stretchable SMHs.[242] The developed materials demonstrated fully recoverable strains at 807% for a TT of 28 °C, at 663% for a TT of 37 °C, and at 553% for a TT of 55 °C. Due to their recoverable high-strain, these SMHs may be useful as cardiac patches or synthetic blood vessels.

Various temperature-responsive SMHs have been explored in the medical devices industry with applications in aneurysm treatment,[243] blood clot removal,[244] stents,[245,246] and dialysis needles.[247] Lately, there have been examples of temperature-responsive polymers with promising clinical applications in minimally invasive gastrointestinal surgery.[248] Minimally invasive surgeries can benefit from devices that can change their geometry or shape when placed inside the body. For example, Kratz et al. utilized thermoplastic temperature-responsive polymers for designing intelligent devices, which could be programmed by the clinician to individually adapt their shifting geometry and response temperature to the patients’ needs.[248] In this study, multiblock copolymers were synthesized from biocompatible poly(ω-pentadecalactone), as the hard backbone, and PCL as the crystallizable controlling unit. This polymer network was then used to develop an intelligent temperature-responsive drainage pigtail catheter for gastroenterology applications.[248]

Overall, SMHs hold promise as robust biomedical platforms that can be rationally designed since their structure is controlled by reversible crosslinks. Once created, they can be reversibly disassembled, as their hybrid structures could spontaneously reassemble in one, two or multiple steps. Fundamental research in the area of temperature-responsive SMHs aims to develop materials that can be either light-stimulated remotely or highly compressible to be injected via minimally invasive surgeries. SMHs could also envisioned to be triggered by pH[249] or by shear stress.[250] Therefore, in the future, there may be opportunities for the use of biodegradable and biocompatible medical devices made from SMHs to perform complex movements in the fields of cardiovascular surgery or gastroenterology.

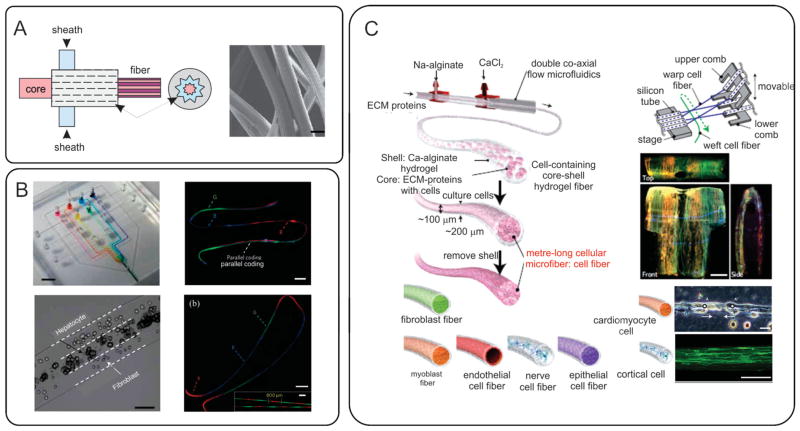

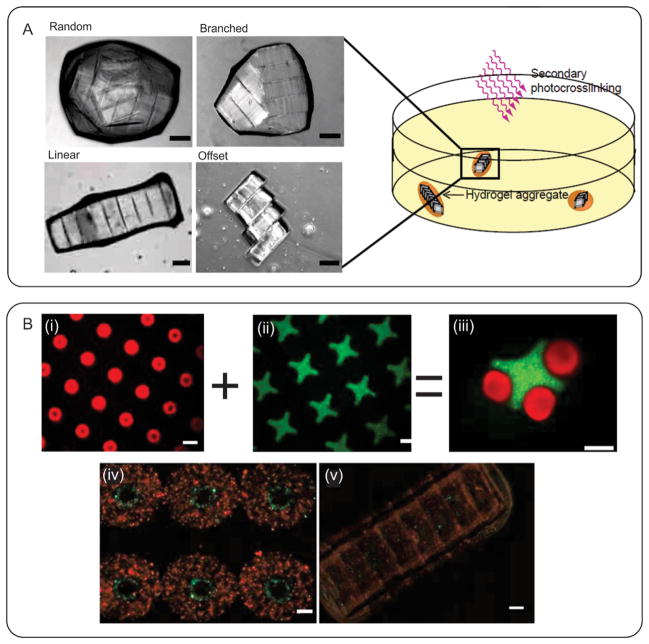

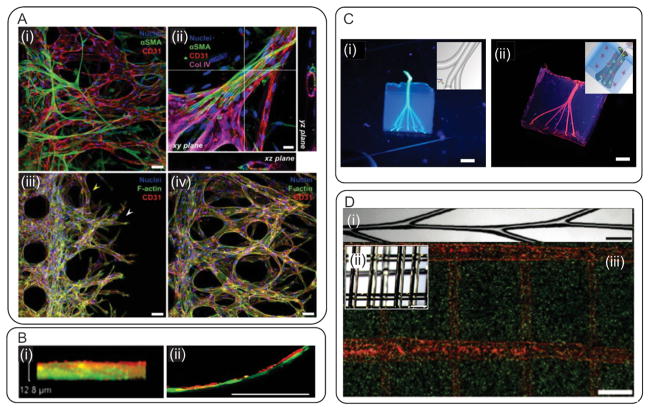

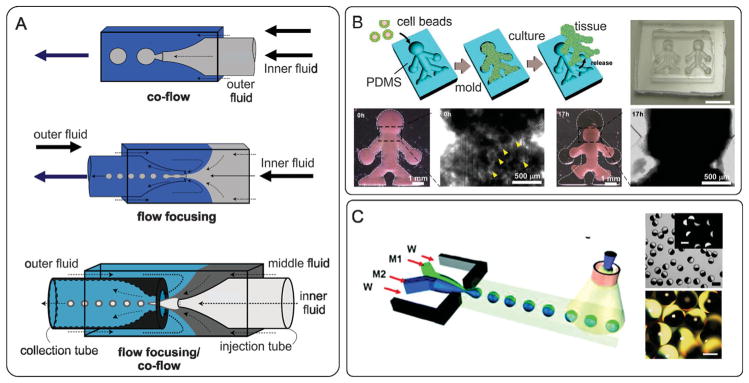

3. Emerging Technologies for Engineering Hydrogel Constructs

Hydrogel constructs with controllable architectural features, at the micro- and nanoscale, have been shown to be useful in directing cell behavior, tissue formation and may be powerful tools for tissue engineering applications. Over the past decades, many research groups have tried to adopt techniques from various engineering fields for the fabrication of hydrogel constructs with controlled architecture.[251–256] However, factors such as low mechanical properties of hydrogels as well as the biocompatibility of the employed chemicals and the fabrication process, should be considered in utilization of these methods. Here, we review the emerging techniques, which can be used to control the geometrical features as well as the distribution of cells and biomolecules within fabricated hydrogel constructs.

3.1. Microfabrication

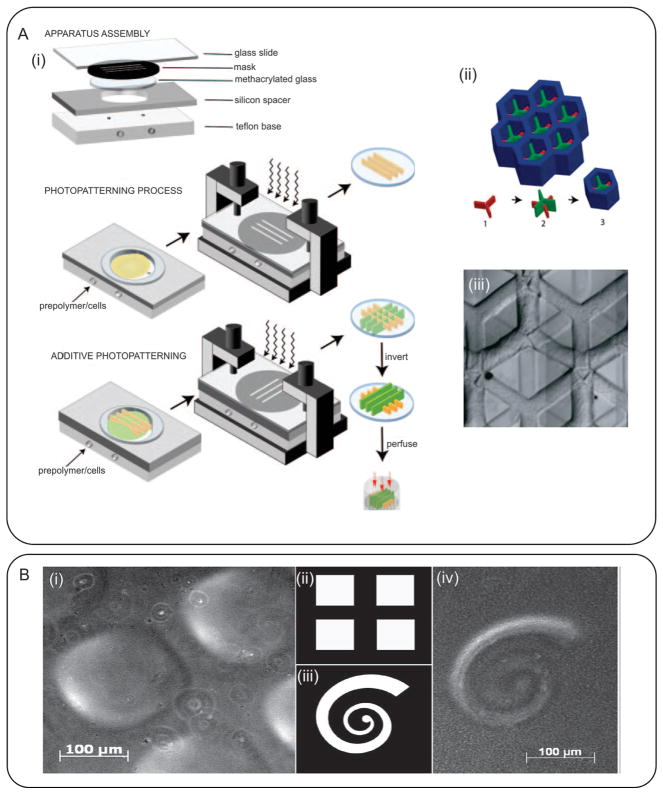

3.1.1. Photopatterning

Photolithography, or photopatterning, is one of the techniques that has found popularity in the creation of microfabricated hydrogels.[252] This approach was originally developed for the fabrication of micron-sized features for micro electromechanical systems (MEMS) applications. In photopatterning, a mask is first created, which contains the pattern to be implemented. Certain areas of the mask are kept transparent allowing the light to pass and certain areas are opaque, blocking the light. Upon light irradiation, the hydrogel areas corresponding to the transparent regions of the mask are crosslinked to form the micropatterns, whereas the remaining uncrosslinked parts (under the opaque parts of the mask) are washed out in the washing step.[256] As expected, this photopatterning technique is only applicable to microfabricate photocrosslinkable hydrogels. Recently, researchers have conjugated acrylamide- or acrylate-based groups to prepolymer backbone, which make these hydrogels photocrosslinkable. Some examples of these hydrogels include PEG diacrylate (PEGDA),[257,258] PEG-dimethacrylates (PEGDM),[259] GelMA,[260] gelatin methacrylamid,[261] methacrylated HA,[262] and MeTro.[13,263] To form a polymerized network, a photoinitiator is usually used which forms free radicals upon light irradiation and initiates the polymerization reaction.

During the photopatterning process, the entire thickness of the hydrogel layer is usually crosslinked with no control over the crosslinking depth. The resolution of the features depends on the quality of the employed photomask and the illumination system. However, a resolution down to few microns is readily achievable. Another important property that can limit the dimensions of the microfabricated hydrogel constructs is their aspect ratio (i.e., the ratio between their height and width). Since hydrogels are not usually mechanically strong, high aspect ratio features may collapse.

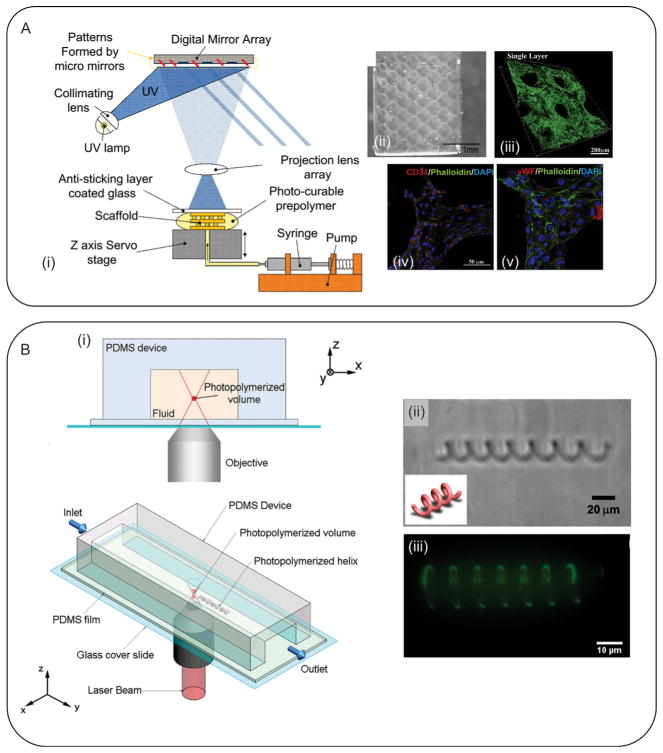

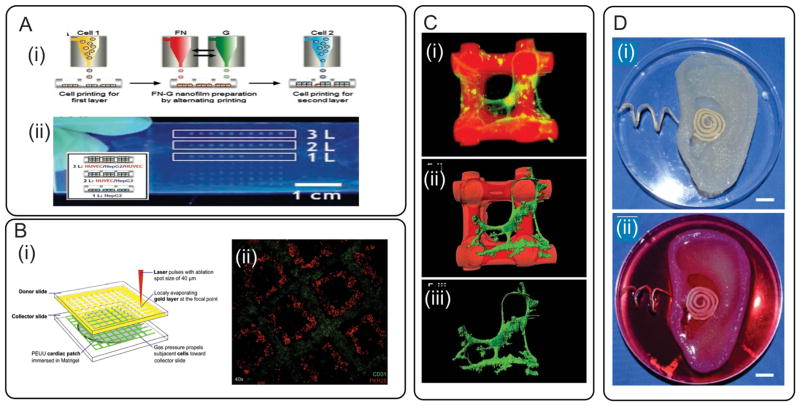

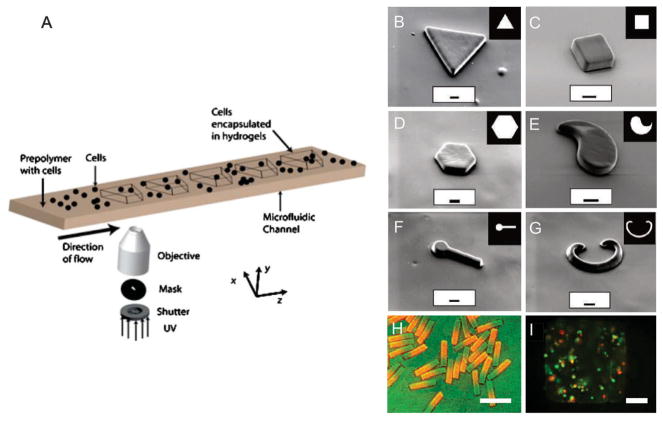

Photopatterning is a versatile technique and allows precise spatial control over the cellular microenvironment. In addition, it allows the fabrication of 3D cell-laden constructs or patterning of different cells through sequential photopatterning of hydrogels containing various cell types. In a notable study, Tsang et al. photopatterned complex 3D structures by successive crosslinking of PEGDA containing different chemicals using three different photomasks (Figure 8A).[257] In addition, they encapsulated primary hepatocytes as a model for liver-on-a-chip research. To control the height of the constructs, the height of the reservoir was changed by means of removable spacers. Cells stayed viable after the fabrication and showed a higher albumin and urea secretion in comparison with unpatterned cells.[257] In another study, Nichol et al. fabricated low aspect ratio HUVEC-laden GelMA constructs through UV crosslinking of the hydrogel and showed high cell viability after the fabrication process.[260] They characterized the hydrogel properties as a function of the UV exposure time and noticed that the mechanical properties were directly related to the UV exposure time and methacrylation degree. In a follow up study, Aubin et al. fabricated lines of cell-laden GelMA hydrogels with different widths and demonstrated that the widths of the patterned lines had a significant impact on the morphology of the cells.[128] Using a similar approach, biomolecules were patterned within photocrosslinkable hydrogels[264] or spatial patterns with different mechanical properties were created.[265] Such patterns can be used to direct cellular activity, migration, and differentiation, which will be further discussed in the following sections.

Figure 8.

Photopatterning of hydrogel constructs. A) Fabrication of cell-laden PEGDA constructs for liver tissue engineering; i,ii) schematic of the additive photopatterning process, in which different cell-laden hydrogels were photocrosslinked sequentially using different photomasks to create a 3D construct, iii) Micrograph image of a typical fabricated cell-laden hydrogel construct. Reproduced with permission.[257] Copyright 2007, The Federation of American Societies for Experimental Biology. B) Typical structures fabricated by degrading the surface of hydrogels; the hydrogel surface under 100 μm (i) squares and (iii) spiral masks were partially degraded and swell to form positive features observed in (i) and (iv). Reproduced with permission.[266] Copyright 2010, American Chemical Society.

Photodegradable hydrogels can also be used for the fabrication of microscale features within hydrogel constructs. For example, Wong et al. formed a photodegradable hydrogel through conjugating photodegradable ortho-nitrobenzyl (o-NB) groups to PEG.[132] They used photomasks to fabricate microchannels and microwells within the fabricated hydrogels. In addition, they could locally adjust the swelling properties of photodegradable hydrogels. As a result, the photodegraded area was swollen and formed a 3D microstructure (Figure 8B). In another study, Chiu et al. sandwiched a layer of photodegradable PEG-co(L-lactide) diacrylate (PEG-PLLA-DA) between layers of PEGDA.[266] A photomask was then used to selectively irradiate UV light to degrade a pattern within PEG-PLLA-DA layer. Upon the exposure of the construct to high pH conditions, the photopatterned regions were dissolved quickly and 3D microchannels were formed.[266] One of the limitations of this technique is the inability to encapsulate cells within the fabricated construct due to the use of a basic environment.

Photopatterning technique is easy-to-use and does not require sophisticated equipment. For photopatterning of hydrogel constructs, one needs a light source, a photo mask, and a photocrosslinkable hydrogel mixed with a photoinitiator. However, a key challenge is determining the suitable UV exposure time. Longer exposure times are found to affect cellular viability and activity or potentially might result in phenotype variation. Another limitation of this method is the fabrication of only planar constructs. Moreover, controlling cell distribution requires the use of multiple photomasks, which is challenging due to the need to align the photopatterns with the masks before each exposure.

3.1.2. Soft Lithography and Molding

Soft lithography and molding have been widely used in the creation of microfabricated hydrogel constructs.[267] Molds can be fabricated from various materials including plastics, polymers, and metals. However, elastomers such as polydimethylsiloxane (PDMS) and polymers such as poly(methyl methacrylate) (PMMA) have found more popularity.[256] This is due to their ease of microfabrication, biocompatibility, and hydrophobic surface property, which helps the detachment of crosslinked hydrogels from the mold. In addition, coating the mold with temperature responsive hydrogels, such as PNIPAm, have been shown to facilitate hydrogel removal from the mold.[268] Molding has been used for the fabrication of both physically and chemically crosslinkable hydrogels. The fabrication of 3D constructs using molding can be achieved by independent fabrication of multiple layers and their subsequent assembly.

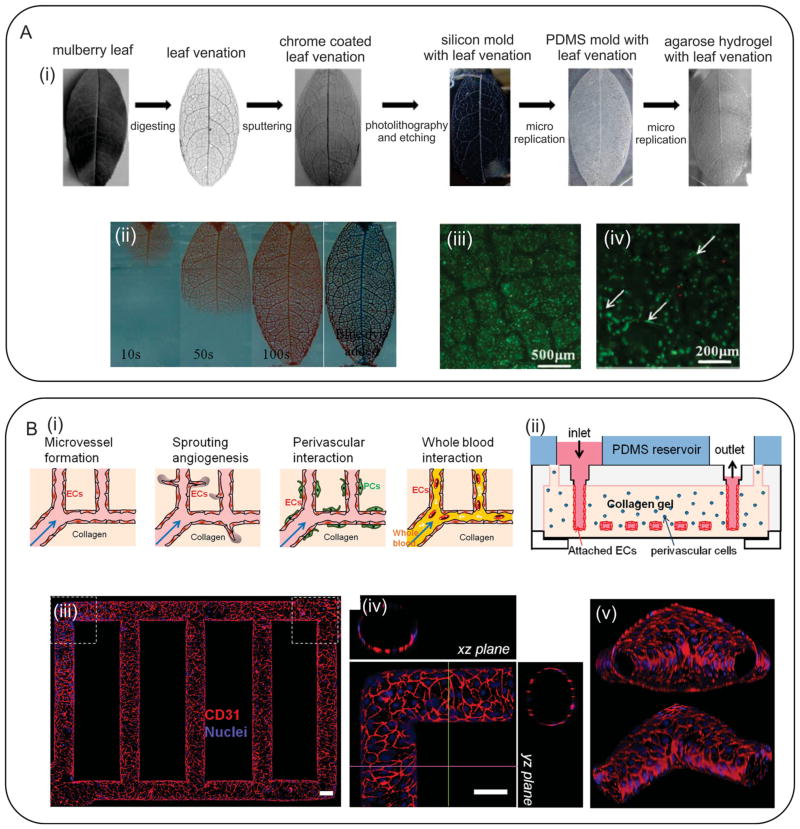

He et al. employed a microreplication method followed by a molding process to fabricate biomimetic perfusable microvascular networks.[269] They digested the soft tissue of a leaf and sputtered its veins with a layer of chrome. The sputtered leaf was used as a photomask in a soft lithography process to fabricate a negative PDMS mold, which was then utilized for the fabrication of agarose hydrogels (Figure 9A). Collagen solution containing ECs was injected within the patterned microchannels. In addition, HepG2 cells were encapsulated within the agarose hydrogel to form a liver-like structure containing perfusable channels. The in vitro results indicated that the presence of the microvascular network resulted in high cellular viability over 3 days of culture.[269] Zheng et al. fabricated microvessel networks within 3D collagen gel by using an injection technique (Figure 9B).[270] They encapsulated human umbilical arterial smooth muscle cells (HUASMCs) as well as human brain vascular pericytes (HBVPCs) within the collagen layer. The channels were also seeded with HUVECs to form functional microvessels. The hydrogel constructs were then cultured for 14 days to study the effects of cell-cell interactions on angiogenesis and sprouting. They observed that HUVECs tend to form cylindrical lumens within the channels. Our groups also used micromolding technique to form microchannels within PDMS samples and used them as molds for fabricating grooved MeTro and GelMA hydrogels.[56] The fabricated constructs were then used to align CMs within the fabricated micropatterns.

Figure 9.