Abstract

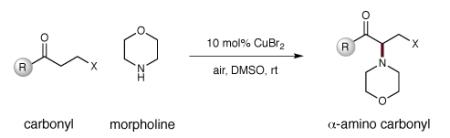

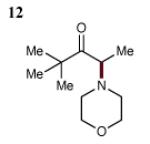

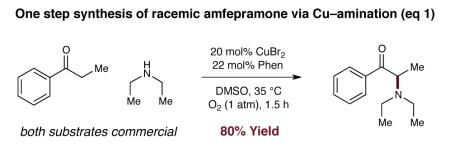

The direct α-amination of ketones, esters, and aldehydes has been accomplished via copper catalysis. In the presence of catalytic copper(II) bromide, a diverse range of carbonyl and amine substrates undergo fragment coupling to produce synthetically useful α-amino substituted motifs. The transformation is proposed to proceed via a catalytically generated α-bromo carbonyl species; nucleophilic displacement of the bromide by the amine then delivers the α-amino carbonyl adduct while the catalyst is reconstituted. The practical value of this transformation is highlighted through one-step syntheses of two high–profile pharmaceutical agents, Plavix and amfepramone.

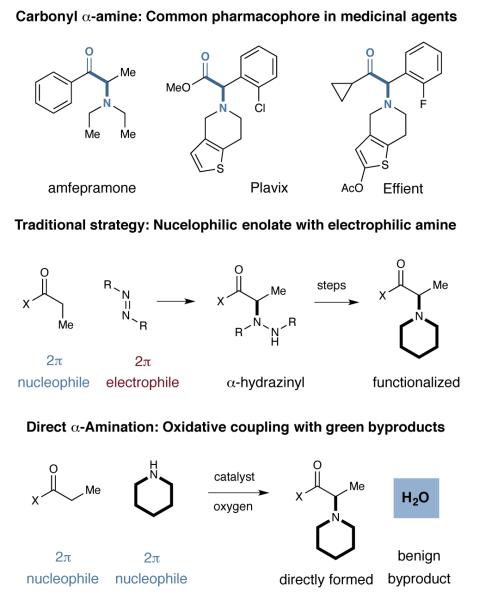

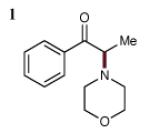

Carbonyls bearing α-amino substitution are widely represented among pharmaceutically active compounds and complex natural products1 (Figure 1). The invention of catalytic strategies toward this high-value synthon is a longstanding goal in organic synthesis, and a number of methods have been developed for the installation of specifically tailored amine substrates at the carbonyl α-position.2 For example, the catalytic α-amination of ketones and aldehydes (via enolate derivatives) often involve the use of 2π-electrophile aza-substrates to deliver α-hydrazinyl or α-oxy-amino products, two structural classes that must be chemically modified prior to natural product or medicinal chemistry applications. Slower to develop, however, have been catalytic protocols3 that allow for the merger of carbonyl-derived enolates with a generic range of nitrogen-containing structures or functionalities, a more direct strategy that would bypass the requirement for post-reaction amine modification. Conceptually, the catalytic α-coupling of amines and enolates appears to be electronically mismatched, given that both reaction partners are inherently nucleophilic and that amines readily undergo 1,2-addition with electrophilic ketones, aldehydes, esters, etc. As such, we recently questioned whether catalysis could be employed to transiently render carbonyls electrophilic at the α-position, thereby enabling the in situ addition of a broad range of nitrogen coupling partners. Herein we describe the successful conclusion of these studies and present a simple, copper(II) bromide catalysis protocol for the catalytic α-amination of aldehydes, ketones, esters, and imides with an expansive structural range of functionalized amines.

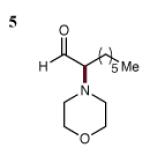

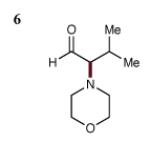

Figure 1.

Medicinal use, strategies towards α-amino carbonyls.

Design Plan

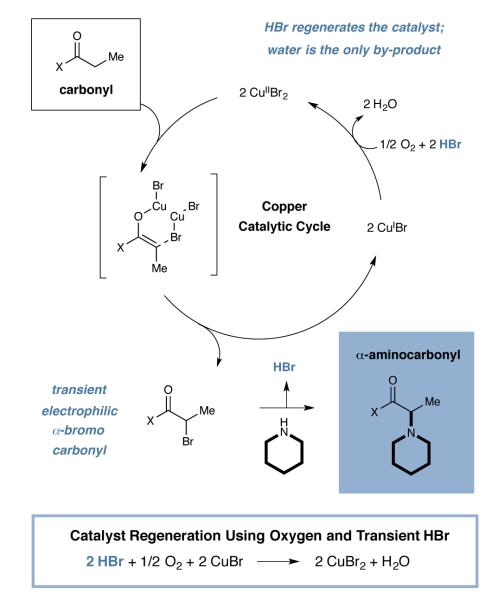

Drawing inspiration from the powerful Buchwald-Hartwig4 and Chan-Lam5 cross-coupling strategies, in which secondary amines are merged with aryl halides or boronic acids to generate aryl amine adducts, we envisioned an analogous direct fragment coupling of carbonyls and secondary amines en route to α-amino carbonyl synthons (Figure 1). An ongoing area of research in our lab is the invention of reactions that use copper catalysis to install high-value α-carbonyl functionality. Toward this end, we have demonstrated the ability of copper(I) to catalyze the α-arylation of enol-silanes in the presence of diaryliodonium salts.6 Additionally, the synergistic merger of copper(I) catalysis with enamine catalysis has led to the development of methods for the enantioselective α-arylation,7 α-vinylation,8 α-oxygenation,9 and α-trifluoromethylation10 of aldehyde substrates. On this basis, the proposed mechanism for the carbonyl amination is presented in Scheme 1. We postulated that in the presence of catalytic copper(II) bromide, a diverse range of carbonyl substrates would undergo bromination at the α-position11 via a copper-bound enolate to generate an α-bromo carbonyl along with two molecules of copper(I) bromide and an equivalent of HBr.12,13,14 Facile nucleophilic displacement of the α-C=O bromide functionality by a secondary amine would then deliver the α-amino carbonyl adduct along with a second equivalent of HBr. Oxygen-mediated reoxidation of copper(I) bromide in the presence of HBr would reconstitute the copper(II) bromide catalyst. Importantly, we recognized that water would be the only molecular by-product of this proposed catalytic cycle.

Scheme 1.

Design of Cu(II)-catalyzed carbonyl–amine coupling.

Results

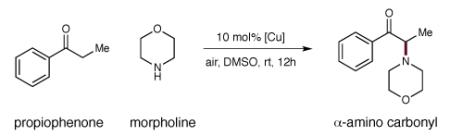

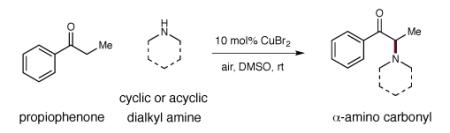

Our evaluation of the proposed carbonyl–amine fragment coupling began with exposure of propiophenone and morpholine to a series of copper catalysts (Table 1). The reaction was performed under an ambient air atmosphere to provide the oxygen necessary for catalyst turnover. As expected, the most suitable catalyst was copper(II) bromide, which delivered the α-amino carbonyl product in 68% yield (entry 1). By comparison, copper(II) chloride and copper(I) bromide were significantly less effective at mediating this transformation (entries 2 and 3, 2% and 31% yield). Although we postulated the intermediacy of an α-bromo carbonyl species, we recognized that an alternative mechanism might involve C–N bond formation via reductive elimination from a transient copper(III) species.15,16 To distinguish these pathways, the coupling was evaluated with a series of Cu(II) salts that did not contain halogens (e.g. Cu(OTf)2, Cu(TFA)2), and indeed, no desired amination products were observed in any case.17 Moreover, while the use of catalytic copper(II) bistrifluoroacetic acid provided no observable product (entry 4, 0% yield), addition of 30 mol% lithium bromide led to a substantial recovery of catalytic efficiency (entry 5, 50% yield). These findings lend support to the existence of the crucial α-bromocarbonyl intermediate as depicted in Scheme 1. While extended reaction times did not lead to an improvement in overall efficiency (entry 6, 62% yield), the choice of solvent significantly influenced the coupling yield (entries 7–10, 45–93% yield), with DMSO proving to be the optimal reaction medium, presumably due to solvent stabilization of the transient copper enolate species (entry 10, 93% yield).18

Table 1.

Initial Studies towards α-Amination of Carbonyls

| entry | [Cu] catalyst | solvent | yielda |

|---|---|---|---|

| 1 | CuBr2 | MeCN | 68% |

| 2 | CuCl2 | MeCN | 2% |

| 3 | CuBr | MeCN | 31% |

| 4 | Cu(TFA)2 | MeCN | 0% |

| 5b | Cu(TFA)2 | MeCN | 50% |

| 6c | CuBr2 | MeCN | 62% |

| 7 | CuBr2 | CHCl3/EtOAc | 45% |

| 8 | CuBr2 | THF | 67% |

| 9 | CuBr2 | DMF | 71% |

| 10 | CuBr2 | DMSO | 93%d |

GC yield using Bn2O as an internal standard.

With 30 mol% LiBr.

Performed over 24 hours.

Isolated Yield.

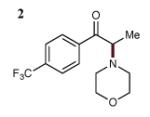

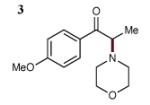

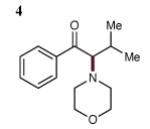

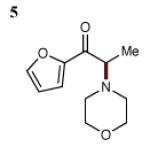

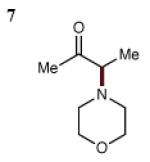

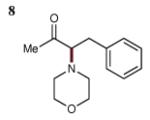

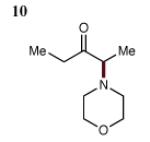

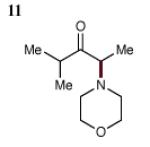

With optimized conditions in hand, we next sought to define the scope of the carbonyl coupling partner. As shown in Table 2, electron-rich and -poor aryl ketones readily undergo fragment coupling with morpholine (entries 2 and 3, 92% and 78% yield). More specifically, the efficient conversion of electron deficient ketones was achieved at sub-ambient temperatures to prevent product decomposition, while systems that involve a π-rich aryl ring require elevated temperatures. This disparity is attributed to the rate differential in both the ketone enolization and amine nucleophilic addition steps. It is important to note that electron-rich aromatic systems do not undergo Friedel-Crafts bromination under these catalytic conditions.19 Heteroaromatic ketones are also productive coupling partners, delivering α-amino ketones in high yield (entries 5 and 6, 92% and 82% yield). Moreover, steric bulk at the carbonyl β-position is well-tolerated (entry 4, 73% yield). Efficient α-amination of aliphatic ketones was found to require the introduction of a co-catalyst – such as NiBr2, ZnBr2 or MgI2 – to facilitate the ketone enolization event.20 Under these modified conditions, the coupling of non-symmetrical methyl, alkyl substituted ketones proceeds with high efficiency and regiocontrol to introduce the morpholine group exclusively at the internal methylene position (entry 7, 71% yield).21,22 Moreover, α-amino ketone adducts that could be susceptible to 1,2-elimination are readily accessed without any observable product degradation (entries 8 and 9, 61% and 63% yield). Notably, the use of 3-pentanone leads to monoamination adducts exclusively (entry 10, 50% yield), while the incorporation of sterically demanding alkyl substituents (isopropyl, tert-butyl), on the ketone substrate leads to selective amination at the less hindered methylene position in moderate to good yield (entries 11 and 12, 41% and 75% yield).

Table 2.

Scope of the Ketone Coupling Component.

93% Yield |

92% Yielde |

78% Yieldb |

73% Yieldc |

85% Yield |

82% Yielde |

71% Yielda,f |

61% Yielda,g |

63% Yielda,g |

50% Yielda,d,f,i,j |

41% Yielda,h |

75% Yielda,b,g |

The cited yields are of material isolated by column chromatography.

Conducted under 1 atm of O2.

Conducted at 60 °C.

Conducted at 50 °C.

Conducted at 10 °C.

Conducted at 5 °C.

ZnBr2 was employed as cocatalyst.

NiBr2 was employed as cocatalyst.

MgI2 was employed as cocatalyst.

NaI was employed.

THF was substituted as solvent. See supporting information for experimental details.

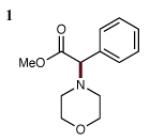

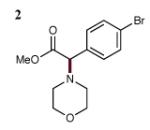

We anticipated that our catalytic carbonyl–amine fragment coupling should also be compatible with a range of non-ketonic carbonyls. Indeed, a series of α-aryl esters bearing a diverse array of aryl substituents readily undergo morpholine incorporation in the presence of catalytic CuBr2 to generate α-amino esters with good efficiency (Table 3, entries 1–4, 70–91% yield). Notably, the reaction is compatible with an aryl bromide motif (entry 2, 91% yield); i.e. no undesired Buchwald-Hartwig coupling product was observed using our standard conditions. A survey of ester substrates revealed the importance of the α-aryl group in enabling efficient coupling under these conditions. More specifically, the inductive effect of the aryl group promotes rapid ester enolization, a critical step that engenders the subsequent bromination–amine addition pathway that is not possible at this time with α-aliphatic esters. However, aliphatic aldehydes, which we presumed would have a propensity to undergo non-productive enamine formation,23 serve as highly suitable coupling partners24 in this α-carbonyl functionalization reaction (entries 5 and 6, 75% and 67% yield).

Table 3.

Scope of the Ester and Aldehyde Component.

The cited yields are of material isolated by column chromatography.

Conducted under 1 atm of O2.

Conducted at 70 °C.

Conducted at rt.

MeCN was substituted as solvent. See supporting information for experimental details.

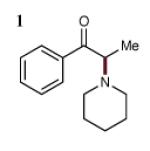

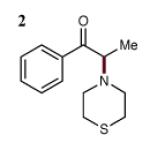

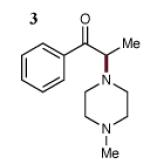

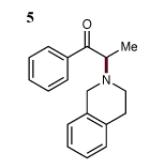

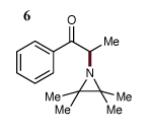

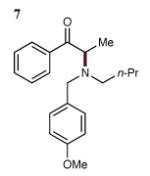

A defining attribute of this new α-amination protocol is its potential to provide direct access to a broad array of amine groups at the carbonyl α-position. As shown in Table 4, a wide range of synthetically useful secondary amines is readily employed in this transformation. For example, cyclic amines of various ring sizes readily participate to deliver the α-cyclic amino product in high yield (entries 1–6, 71–90% yield). Differentially protected acyclic alkyl amines also serve as

|

|

efficient coupling partners when elevated reaction temperatures are employed along with sodium iodide as an additive (entries 7–9, 61–74% yield). Addition of sodium iodide presumably allows the intermediate α-bromocarbonyl to undergo a Finkelstein substitution to generate a more electrophilic α-iodocarbonyl, thereby accelerating the subsequent amine displacement step.

Table 4.

Scope of the Amine Coupling Component.

88% Yield |

87% Yieldb |

75% Yield |

82% Yield |

90% Yield |

71% Yieldc |

74% Yielda,d |

70% Yielda,d |

74% Yielda,d |

The cited yields are of material isolated by column chromatography.

Conducted at 60 °C.

Conducted at 50 °C.

Conducted at 40 °C.

NaI was employed. See supporting information for experimental details.

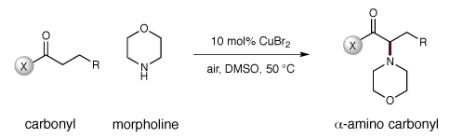

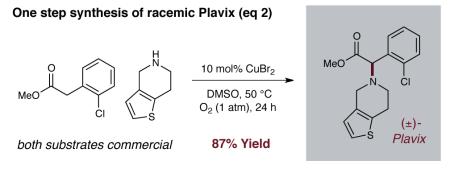

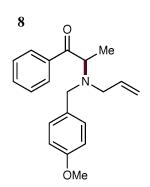

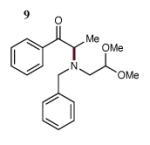

Given the operational simplicity and broad generality of this amine coupling protocol, we sought to demonstrate the utility of this new catalytic process for the production of high-profile medicinal agents. As shown in equation 1, we have developed a one-step racemic synthesis of the appetite suppressant amfepramone in 80% yield using an analogous Phen•CuBr2 catalyst, an operation that is complete in less than two hours.25 Moreover, we have also demonstrated a one-step route to the antiplatelet agent Plavix (eq 2).26 Formation of this blockbuster drug was accomplished in 87% yield from inexpensive commercial materials using our standard CuBr2 catalysis protocol.27

Finally, to demonstrate the preparative utility of this new amine coupling process, we performed the union of morpholine and propiophenone on a 37 mmol scale to generate 7.1 g (87% yield) of the desired α-amination product (cf. Table 2, entry 1, 93% yield).

In conclusion, we have developed a generic approach to the synthesis of complex α-amino carbonyls via the direct copper-catalyzed coupling of carbonyls and functionalized secondary amines. This process provides a useful alternative to standard “atom transfer” approaches to the installation of amine functionality at the carbonyl α-position. This simple yet versatile method, which readily tolerates a range of functionality on the carbonyl and amine reaction components, has been applied to rapid syntheses of two prominent pharmaceutical agents. Studies toward a catalytic asymmetric variant of this new transformation are ongoing.28

Supplementary Material

Acknowledgement

Financial support was provided by the NIGMS (R01 GM103558-01) and kind gifts from Merck, Amgen and Abbvie.

Footnotes

Supporting Information Available. Experimental procedures and spectral data are provided. This material is available free of charge via the Internet at http://pubs.acs.org.

References

- 1 (a).Meltzer PC, Butler D, Deschamps JR, Madras BK. J. Med. Chem. 2006;49:1420–1432. doi: 10.1021/jm050797a. [DOI] [PMC free article] [PubMed] [Google Scholar]; (b) Carrol FI, Blough BE, Abraham P, Mills AC, Holleman JA, Wolchenhauer SA, Decker AM, Landavazo AK, McElroy T, Navarro HA, Gatch MB, Forster MJ. J. Med. Chem. 2009;52:6768–6781. doi: 10.1021/jm901189z. [DOI] [PubMed] [Google Scholar]; (c) Bouteiller C, Becerril-Ortega J, Marchand P, Nicole O, Barre L, Buisson A, Perrio C. Org. Biomol. Chem. 2010;8:1111–1120. doi: 10.1039/b923255a. [DOI] [PubMed] [Google Scholar]; (d) Meyers MC, Wang J-L, Iera JA, Bang J-K, Hara T, Saito S, Zambetti GP, Appella DH. J. Am. Chem. Soc. 2005;127:6152–6153. doi: 10.1021/ja045752y. [DOI] [PubMed] [Google Scholar]; (e) Ando R, Sakaki T, Morinaka Y, Takahashi C, Tamao Y. 1994. EP 603769 A1 19940629. [DOI] [PubMed]

- 2 (a).For a review of such methods, see: Janey JM. Angew. Chem. Int. Ed. 2005;44:4292–3300. doi: 10.1002/anie.200462314. Vilaivan T, Bhanthumnavin W. Molecules. 2010;15:917–958. doi: 10.3390/molecules15020917.

- 3 (a).Matsuda N, Hirano K, Satoh T, Miura M. Angew. Chem. Int. Ed. 2012;51:11827–11831. doi: 10.1002/anie.201206755. [DOI] [PubMed] [Google Scholar]; (b) Miura T, Morimoto M, Murakami M. Org. Lett. 2012;14:5214–5217. doi: 10.1021/ol302331k. [DOI] [PubMed] [Google Scholar]; (c) Wei Y, Lin S, Liang F. Org. Lett. 2012;14:4202–4205. doi: 10.1021/ol301871s. [DOI] [PubMed] [Google Scholar]; (d) Lamani M, Prabhu KR. Chem. Eur. J. 2012;18:14638–14642. doi: 10.1002/chem.201202703. [DOI] [PubMed] [Google Scholar]; (e) Tian J-S, Loh T-P. Chem. Commun. 2011;47:5458–5460. doi: 10.1039/c1cc11102g. [DOI] [PubMed] [Google Scholar]; (f) Tian J-S, Ng KWJ, Wong J-R, Loh T-P. Angew. Chem. Int. Ed. 2012;51:9105–9109. doi: 10.1002/anie.201204215. [DOI] [PubMed] [Google Scholar]

- 4 (a).Guram AS, Rennels RA, Buchwald SL. Angew. Chem. Int. Ed. 1995;34:1348–1350. [Google Scholar]; (b) Louie J, Hartwig JF. Tetrahedron Lett. 1995;36:3609–3612. [Google Scholar]

- 5 (a).Chan DMT, Monaco KL, Wang RP, Winters MP. Tetrahedron Lett. 1998;39:2933. [Google Scholar]; (b) Lam P, Clark CG, Saubern S, Adams J, Winters MP, Chan DM, Combs T, A. Tetrahedron Lett. 1998;39:2941. [Google Scholar]; (c) Lam P, Vincent G, Bonne D, Clark CG. Tetrahedron Lett. 2003;44:4927. [Google Scholar]

- 6.Harvey JS, Simonovich SP, Jamison CR, MacMillan DWC. J. Am. Chem. Soc. 2011;133:13782–13785. doi: 10.1021/ja206050b. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Allen AE, MacMillan DWC. J. Am. Chem. Soc. 2011;133:4260–4263. doi: 10.1021/ja2008906. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8 (a).Skucas E, MacMillan DWC. J. Am. Chem. Soc. 2012;134:9090–9093. doi: 10.1021/ja303116v. [DOI] [PMC free article] [PubMed] [Google Scholar]; (b) Stevens JM, MacMillan DWC. J. Am. Chem. Soc. 2013;135:11756–11759. doi: 10.1021/ja406356c. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Simonovich SP, Van Humbeck JF, MacMillan DWC. Chem. Sci. 2012;3:58–61. doi: 10.1039/c1sc00556a. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Allen AE, MacMillan DWC. J. Am. Chem. Soc. 2010;132:4986–4987. doi: 10.1021/ja100748y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.King LC, Ostrum GK. J. Org. Chem. 1964;29:3459–3461. [Google Scholar]

- 12 (a).Kochi JK. J. Am. Chem. Soc. 1955;77:5274–5278. [Google Scholar]; (b) Kosower EM, Wu GS. J. Org. Chem. 1963;28:633–638. [Google Scholar]; (c) Kojima Y, Usui K, Kawaguchi S. Bull. Chem. Soc. Jpn. 1972;45:3127–3130. [Google Scholar]; (d) Kojima Y, Kawaguchi S. Bull. Chem. Soc. Jpn. 1972;45:1293–1299. [Google Scholar]

- 13.An alternative mechanism for the bromination of ketones involves reductive elimination of a bromide from the copper bound enolate to form the desired α-bromocarbonyl and Cu(0). Under these reaction conditions, we recognize that such a mechanism could be operable. For further mechanistic information see ref. 12(a) and 12(b).

- 14.A reviewer has postulated an alternative mechanism for the bromination step which involves the intermediacy of a Copper(III)Br2 bound enolate, that could undergo addition to another molecule of Copper(II)Br2 via a one electron pathway to form the desired α-bromocarbonyl.

- 15 (a).For examples of amination reactions following this mechanism, see: Yamamoto H, Maruoka K. J. Org. Chem. 1980;45:2739–2740. Alberti A, Canè F, Dembech P, Lazzari D, Ricci A, Seconi G. J. Org. Chem. 1996;61:1677–1681. doi: 10.1021/jo9512315. Canè F, Brancaleoni D, Dembech P, Ricci A, Seconi G. Synthesis. 1997:545–548. del Amo CL, Dubbaka SR, Krasovskiy A, Knochel P. Angew. Chem. Int. Ed. 2006;45:7838–7842. doi: 10.1002/anie.200603089. Kienle M, Dubbaka SR, del Amo V, Knochel P. Synthesis. 2007:1272–1278.

- 16.In the absence of oxygen and amine, a trace amount of α-bromopropiophenone was detected. The reaction of propiophenone with super-stoichiometric amounts of copper(II) bromide, however, generated a quantitative yield of α-bromopropiophenone.

- 17.A survey of various copper(II) salts was undertaken. These included: Cu(OTf)2, Cu(TFA)2, Cu(BF4)2, Cu(NO3)2, Cu(ClO4)2, CuCO3, Cu(OAc)2, Cu(HCO2)2. In all cases no detectable amount of product was formed.

- 18.A variant of Table 1, entry 10, was preformed under a nitrogen atmosphere. We observed a total of 4% amination product. This result is strongly indicative that oxygen is required for catalyst turnover.

- 19 (a).For selected examples of CuBr2 brominations of aromatic rings, see: Yang L, Lu Z, Stahl SS. Chem. Commun. 2009;45:6460–6462. doi: 10.1039/b915487f. Song Y-F, van Albada GA, Tang J, Mutikainen I, Turpeinen U, Massera C, Roubeau O, Costa JS, Gamez P, Reedijk J. Inorg. Chem. 2007;46:4944–4950. doi: 10.1021/ic070057n. Bhatt S, Nayak SK. Synth. Commun. 2007;37:1381–1388.

- 20.Wei HX, Jasoni RL, Shao H, Hu J, Pare PW. Tetrahedron. 2004;60:11829–11835. [Google Scholar]

- 21.The chlorination of 2-butanone has been shown to occur regioselectively to produce 3-chloro-2-butanone when using CuCl2, please see: Kosower EM, Cole WJ, Wu G-S, Cardy DE, Meisters G. J. Org. Chem. 1963;23:630–633.

- 22.The substituted enolate derived from 2-butanone is substantially more π-nucleophilic, a feature that likely contributes to selective bromination and thereafter amination at the butanone 3-position. Mayr nucleophile index values for enol silanes are consistent with this finding: Mayr H, Kempf B, Ofial AR. Acc. Chem. Res. 2003;36:66–77. doi: 10.1021/ar020094c.

- 23.Mukherjee S, Yang JW, Hoffmann S, List B. Chem. Rev. 2007;107:5471–5569. doi: 10.1021/cr0684016. [DOI] [PubMed] [Google Scholar]

- 24.Products isolated after an in situ Wittig olefination.

- 25.Silverstone T. Drugs. 1992;43:820–836. doi: 10.2165/00003495-199243060-00003. [DOI] [PubMed] [Google Scholar]

- 26.Li J-J, Johnson DS, Sliskovic DR, Roth BD. Contemporary Drug Synthesis. Wiley; Hoboken: 2004. [Google Scholar]

- 27.The use of air as the terminal oxidant in this case resulted in diminished yield.

- 28.Preliminary efforts towards an asymmetric catalytic version of this reaction have demonstrated feasibility but not levels of efficiency or selectivity that would be deemed worthy of disclosure. We hope to overcome such limitations in the near future.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.