Abstract

Although stock trays often provide mechanical retention for elastomeric impression materials, manufacturers typically recommend the use of an adhesive, whether a stock or custom tray is used. The mention of the bond strength on the adhesive packaging is not available, therefore the clinician has no idea whatsoever of the ideal adhesive. The aim of this study was to evaluate the bond strength of three vinyl polysiloxane (VPS) materials, one with a poly(methyl methacrylate) autopolymerizing (PMMA) specimen and another with a light-polymerizing tray material (VLC), using the adhesive recommended by the manufacturer of the impression material, and two universal adhesives. A total of ninety specimens (15 × 15 × 20 mm) were used, 45 specimens were made in PMMA and rest 45 was made in VLC. Five paint-on adhesives (Coltene, Caulk, 3M, universal Zhermack and universal GC) were applied. Three impression materials, Affinis, Reprosil, and 3M, were mixed and injected into a perforated poly vinyl chloride cylinder. Tray specimens were positioned against the open cylinder end in contact with the VPS material. Tensile strength tests were conducted until adhesive separation failure. Mean values and standard errors of the adhesive strength were recorded in MPa for each material combination. GC paint-on universal adhesive provided significantly higher adhesive strength values.

Keywords: GC adhesive, Tensile bond strength, VPS

Introduction

In the recent era vinyl polysiloxane (VPS) impression materials are among the most popular non-aqueous elastomeric impression materials used in dentistry [1]. They provide excellent detailed surface reproduction, dimensional stability, elastic recovery and ease of manipulation [2, 3]. However the accuracy of this impression material can be rendered absolutely useless if it detaches from the impression tray while withdrawing from the undercut areas of the oral tissues.

Various tray adhesives have been introduced to strengthen the bond between tray and impression material to withstand the stresses and prevent the detachment of impression material from the tray during withdrawal from mouth. Although little information is available regarding adhesive composition for elastomeric impression materials [4]; more accurate and consistent impressions are obtained when adhesives are employed [5–8].

The adhesives recommended for silicone impression materials are composed of poly(dimethylsiloxane) and ethyl silicate. Poly(dimethylsiloxane) adheres to the silicone impression material, whereas ethyl silicate forms hydrated silica that bonds with tray material physically leading to an accurate and consistent impression. Less attention has been focused on attachment of impression materials to poly(methyl methacrylate) (PMMA) and visible light cure (VLC) tray.

A study reported that exchanging adhesives for two VPS impression materials resulted in greater bond strengths. Another investigator found that interchanging adhesives between two addition silicon materials revealed a significant increase in bond between impression material and tray. The authors concluded that the material-adhesive combination supplied by the manufacturer might not necessarily be the best [9, 10]. Different drying times have been recommended, ranging from 4 min to 72 h. Samman and Fletcher [11] found that 10 min was an optimum drying time for silicone material. Universal adhesives are commercially available, but investigators have hardly revealed the bond strength data of such products with VPS impression material and tray materials.

The objective of this study was to evaluate the tensile bond strength of five adhesives applied between three brands of VPS impression materials to two tray materials commonly used in clinical practice.

Materials and Methods

Total 90 specimens (15 × 15 × 20 mm) were fabricated (similar to those described in ADA specification #19). Forty-five specimens were fabricated in autopolymerizing poly(methyl methacrylate) (DPI, Mumbai, India) and rest 45 specimens were made in visible light polymerizing acrylic resin (Triad VLC, Dentsply Caulk, Milford, Del). A metallic eyehook was submerged into each specimen to serves as a point of attachment to the upper arm of a universal testing machine (Instron) by a key chain holder. The PMMA specimens were kept overnight for complete polymerization whereas VLC specimens were placed within the curing unit (Triad 2000; Dentsply Trubyte) for 5 min to polymerize into a hard block. The surface opposite to the eyehook attachment surface, i.e. the testing surface (15 × 15 mm) was surface hardened with 320 grit silicon carbide paper on a polishing machine (Spectrum System 1000; Leco Corp, St Joseph Mish) to standardize surface roughness for the adhesion with tray adhesive to occur. An abbreviation for the specific brand of adhesive e.g. ‘3M’ for 3M adhesive, ‘Co’ for Affinis adhesive, ‘D’ for Reprosil adhesive, ‘Z’ for universal Zhermack and ‘GC’ for universal GC adhesive was written in ink on one surface of the PMMA specimen except testing surface, for future identification of the type of adhesive used in each tray specimen.

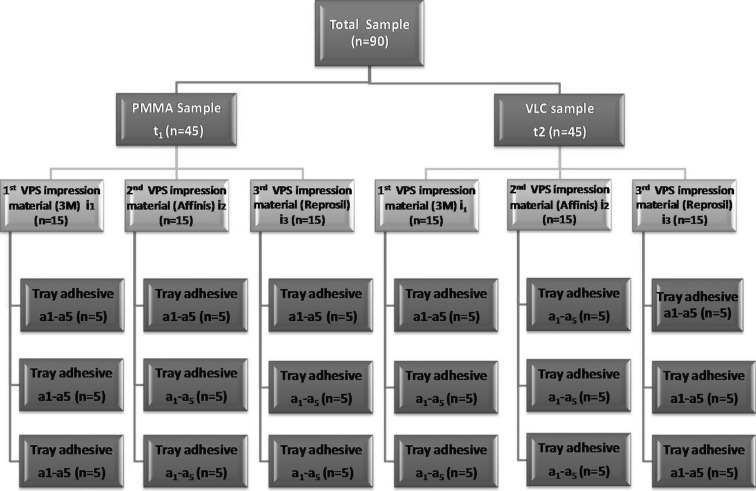

A poly vinyl chloride (PVC) hollow cylinder (15 mm in diameter and 20 mm length) was used to contain the impression material. To retain the impression material, multiple perforations within the cylinder were made with acrylic burs. Two metal screws (2.8 mm diameter) were inserted across the PVC hollow cylinder, one was put close to and across the free end of the cylinder for the attachment of a key chain holder that further attaches to the Instron machine below. The second screw was inserted across the mid portion of the cylinder so that it gets embedded within the impression material for additional mechanical retention. The 45 specimens (PMMA) were subdivided into three subgroups of 15 specimens each attached with each brand of VPS impression material in each subgroup (15 of 3M, 15 of Affinis and 15 of Reprosil). Out of the 15 specimens of 3M (i1), five samples were coated with five different brands of adhesives. The procedure was repeated twice for the remaining ten samples of this subgroup. For the second and third subgroups (15 specimens in each), same procedure was followed taking second brand (Affinis) (i2) and third brand (Reprosil) (i3) of VPS impression material respectively. For the remaining 45 (VLC) specimens (t2) same procedure was repeated (Fig. 1).

Fig. 1.

Sample distribution

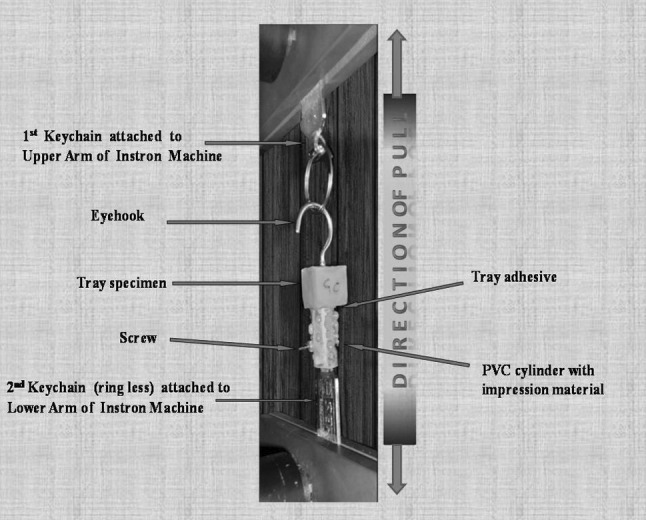

The testing surface of the specimen was cleaned with brush; a thin single coat of tray adhesive was applied and left for 10 min for the solvent to evaporate according to the manufacturer’s specifications. The perforated PVC hollow cylinder was then centrally placed in contact with the testing surface of the specimen. The impression material was dispensed onto the testing surface of the specimen through the other free end of the PVC cylinder till the cylinder fills completely and held in position till impression material set (Fig. 2). Each specimen was then attached to the universal testing machine (Instron 5567, USA) with the two key chain holders in their respective positions and crosshead speed of 5 mm/min using 2,500 kg load cell set at full scale load and slowly but gradually pulled apart till the separation of the impression material from the testing surface of the specimen happens. The readings were recorded (Figs. 3, 4). The values obtained were divided by the area of adhesion of the cylinder with the specimen and tensile bond strength was calculated in megapascal (MPa) by the formula:

|

Fig. 2.

Sample attached with key chain holder on one end and the other end without key ring

Fig. 3.

Tensile test specimen assembly secured to universal testing machine (Instron)

Fig. 4.

Sample placed within the Instron machine

The failure site was classified as occurring at specimen/adhesive interface, adhesive/impression material interface, a mixed failure occurring at both interfaces and absolutely cohesive failure of the impression material (Table 1).

Table 1.

Impression materials, tray adhesives and tray materials studied

| Description of materials studied | ||||

|---|---|---|---|---|

| Group | Trade name | Type | Lot. no. | Manufacturer |

| Impression material | ||||

| i1 | 3M | Medium viscosity | 388840 | 3M ESPE, Germany |

| i2 | Affinis | Medium viscosity | 0184193 | Coltene, Whaledent, Mahwah, NJ |

| i3 | Reprosil | Medium viscosity | 100714 | Dentsply Caulk, Milford, Del |

| Tray adhesive | ||||

| a1 | 3M | Paint-on recommended for 3M | 419032 | 3M ESPE, AG Dental products, Germany |

| a2 | Coltene | Paint-on recommended for Affinis | 0192622 | Coltene, Whaledent, Mahwah, NJ |

| a3 | Caulk | Paint-on recommended for Reprosil | 091104 | Dentsply Caulk, Milford, De, USA |

| a4 | Universal VPS (Zhermack) | Paint-on universal | 84966 | Zhermack, Confident Sales India Pvt. Ltd. Bangalore |

| a5 | Universal VPS (GC) | Paint-on universal | 0911021 | GC (VPS) GC Asia Dental Pvt. Ltd. Hyderabad |

| Tray material | ||||

| t1 | DPI RR cold cure | Autopolymerizing poly(methyl methacrylate) (PMMA) | 10103 | Dental product of India (DPI), Burmah Trading Corp. Mumbai |

| t2 | Triad | Light polymerizing acrylic resin (VLC) | 090501B | Dentsply Caulk, Milford, Del |

Results

The data were analyzed using SPSS software. The first analysis was a three way analysis of variance (ANOVA). The software also provided mean and standard deviation for mean affects one way (specimen, impression materials and adhesives), two way and three way interactions

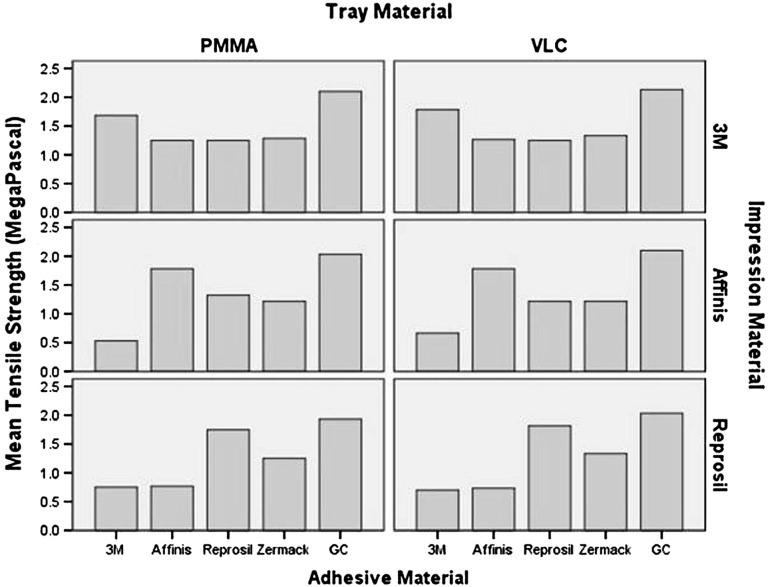

The ANOVA revealed significant variations among these three materials. The three way ANOVA confirmed no significant difference between the effect of tray materials on tensile strength (p > 0.05) (Table 2). There was a significant (p < 0.05) interaction between impression materials and adhesives. The calculated adhesive tensile bond strength for the adhesive and impression material combinations and the summary of statistical differences are displayed in Fig. 5.

Table 2.

Tests between subjects-effects for tensile bond strength [analysis of variance (ANOVA)]

| Source | Sum of squares | Degrees of freedom | Mean square | F | Significance |

|---|---|---|---|---|---|

| Overall average | 178.703 | 1 | 178.703 | 9302.627 | 0.000 |

| Tray# | 0.021 | 1 | 0.021 | 1.102 | 0.298 |

| Impression material | 0.792 | 2 | 0.396 | 20.614 | 0.000 |

| Adhesives | 10.984 | 4 | 2.746 | 142.941 | 0.000 |

| Tray# × impression material | 0.002 | 2 | 0.001 | 0.047 | 0.955 |

| Tray# × adhesives | 0.025 | 4 | 0.006 | 0.332 | 0.856 |

| Impression material × adhesives | 8.225 | 8 | 1.028 | 53.52 | 0.000 |

| Tray# × Impression material × adhesives | 0.060 | 8 | 0.008 | 0.392 | 0.920 |

| Residual | 1.153 | 60 | 0.019 | ||

| Total | 199.965 | 90 |

Fig. 5.

Mean tensile bond strength of various tray adhesives between different groups of impression materials and tray materials

All specimens with universal GC adhesive demonstrated cohesive failure of the impression material except GC adhesive with Affinis impression material with PMMA specimen, GC adhesive with Reprosil impression material with PMMA specimen and GC adhesive with Reprosil impression material with VLC specimen showed a mixed failure at both the adhesive/specimen interface and at the adhesive/impression material interface.

3M impression material with Reprosil and Zhermack adhesive with PMMA and VLC specimens; Affinis impression material with Zhermack adhesive with PMMA specimen, demonstrated an adhesive/impression material interface failure.

3M impression material with 3M adhesive, Affinis adhesive with PMMA and VLC specimens, 3M impression material with adhesive with PMMA specimen, and Affinis impression material with 3M adhesive with PMMA and VLC specimens, Reprosil impression material with 3M, Affinis, Zhermack adhesive with PMMA and VLC trays showed a specimen/adhesive interface failure.

All combinations with universal GC adhesives revealed greatest tensile bond strength (2.05 MPa) whereas 3M adhesive showed to be the lowest (1.01 MPa). The differences between the adhesives were statistically significant (p < 0.05).

Discussion

Various investigators have reported that the tensile strength between tray adhesive and VPS impression material ranged from 0.13 to 2.1 MPa depending on the tray/impression material [5, 7, 9–14, 18, 22]. Dixon et al. [23] observed that Triad custom impression tray material exhibited highest mean adhesive tensile bond strength than Fastray (PMMA) material. In this study the mean tensile bond strength of PMMA tray was 1.39 MPa and of VLC tray was 1.42 MPa which were statistically not significant (p < 0.05). The increased values in this study may be due to the addition of modifiers of the adhesives or the compositional variations of the impression materials of different brands which requires further investigations to reveal these conclusions. Previous investigators have formulated their samples with variation in surface area of the testing surface, length of cylinder, number and diameter of perforation in the cylinder which has not been compared in this study and could be the reason for the disparity in the values among previous studies done, which requires further investigations to reveal these conclusions [15–19, 24, 25].

Corso et al. [20] observed that perforated trays for PVS impression materials augment the effect of tray adhesive to prevent detachment of the impression material while removing from undercuts on the dimensional stability of impression material which may be the reason for the variation in results in this study. MacSween et al. [21] revealed that auto-mix medium-body addition reaction silicone material (Extrude) produced the greatest peel bond strengths on perforated test surface (1.56 MPa). In this study we observed that GC adhesive surpassed all the brands tested for tensile strength (2.05 MPa).

Conclusions

Within the limitations of the experimental conditions of this in vitro study, no significant difference in adhesive strength was noted as a function of tray material. Amongst the adhesives used, GC unveiled the greatest tensile bond strength with all combinations than those (adhesives) supplied by the manufacturer of the impression materials. Among the three impression materials studied 3M demonstrated highest tensile strength. Effect of interchanging adhesives among different impression material on tensile strength revealed 3M impression material with GC adhesive to be superior most. Therefore in our clinical practice the knowledge of adhesive strength of various impression materials with certain adhesive is of utmost important for the success of the prosthodontic procedure and final result. From this study it can be concluded that GC adhesive can be employed with any of the three impression materials used to attain maximum result without the need of the adhesive supplied by the manufacturer of the respective impression materials.

Contributor Information

Surender Kumar, Email: drsurender_kum@yahoo.co.in.

Udey Vir Gandhi, Email: dentalavenue07@gmail.com.

Saurav Banerjee, Email: sauravbnrj@gmail.com.

References

- 1.Frazier KB, Mjör IA. The teaching of all ceramic restorations in North American dental schools: materials and techniques employed. J Esthet Dent. 1997;9(2):86–93. doi: 10.1111/j.1708-8240.1997.tb00922.x. [DOI] [PubMed] [Google Scholar]

- 2.Craig RG, Urquiola NJ, Liu CC. Comparison of commercial elastomeric impression materials. Oper Dent. 1990;15(3):94–104. [PubMed] [Google Scholar]

- 3.Chee WW, Donovan TE. Polyvinyl siloxane impression materials a review of properties and techniques. J Prosthet Dent. 1992;68(5):728–732. doi: 10.1016/0022-3913(92)90192-D. [DOI] [PubMed] [Google Scholar]

- 4.Phillips RW, Skinners EW. Skinner’s science of dental materials. 8. Philadelphia: W.B. Saunders Co; 1982. p. 150. [Google Scholar]

- 5.Nicholson JW, Porter KH, Dolan T. Strength of tray adhesives for elastomeric impression materials. Oper Dent. 1985;10(1):12–16. [PubMed] [Google Scholar]

- 6.Tjan AH, Whang SB. Comparing effect of tray treatment on the accuracy of dies. J Prosthet Dent. 1987;58(2):175–178. doi: 10.1016/0022-3913(87)90172-7. [DOI] [PubMed] [Google Scholar]

- 7.Grant BE, Tjan AH. Tensile and peel bond strengths of tray adhesives. J Prosthet Dent. 1988;59(2):165–168. doi: 10.1016/0022-3913(88)90009-1. [DOI] [PubMed] [Google Scholar]

- 8.Bomberg TJ, Goldfogel MH, Hoffman W, Jr, Bomberg SE. Considerations for adhesion of impression materials to impression trays. J Prosthet Dent. 1988;60(6):681–684. doi: 10.1016/0022-3913(88)90398-8. [DOI] [PubMed] [Google Scholar]

- 9.Sulong MZ, Setchell DJ. Properties of the tray adhesive of an addition polymerizing silicone to impression tray materials. J Prosthet Dent. 1991;66(6):743–747. doi: 10.1016/0022-3913(91)90407-N. [DOI] [PubMed] [Google Scholar]

- 10.Sandrik JL, Vacco JL. Tensile and bond strength of putty-wash elastomeric impression materials. J Prosthet Dent. 1983;50(3):358–361. doi: 10.1016/S0022-3913(83)80092-4. [DOI] [PubMed] [Google Scholar]

- 11.Samman JM, Fletcher A. A study of impression tray adhesives. Quintessence Int. 1985;16(4):305–309. [PubMed] [Google Scholar]

- 12.Payne JA, Pereira BP. Bond strength of two nonaqueous elastomeric impression materials bonded to two thermoplastic resin tray materials. J Prosthet Dent. 1995;74(6):563–568. doi: 10.1016/S0022-3913(05)80306-3. [DOI] [PubMed] [Google Scholar]

- 13.Bindra B, Heath JR. Adhesion of elastomeric impression materials to trays. J Oral Rehabil. 1997;24(1):63–69. doi: 10.1046/j.1365-2842.1997.00458.x. [DOI] [PubMed] [Google Scholar]

- 14.Dixon DL, Breeding LC, Bosser MJ, Nafso AJ. The effect of custom tray material type and surface treatment on the tensile bond strength of an impression material/adhesive system. Int J Prosthodont. 1993;6(3):303–306. [PubMed] [Google Scholar]

- 15.Hogan WR, Agar JR. The bond strength of elastomer tray adhesives to thermoplastic and acrylic resin tray materials. J Prosthet Dent. 1992;67(4):541–543. doi: 10.1016/0022-3913(92)90087-Q. [DOI] [PubMed] [Google Scholar]

- 16.Ellam AH, Smith DC. The relative effectiveness of adhesives for polysulphide impression materials. Br Dent J. 1966;120(3):135–138. [PubMed] [Google Scholar]

- 17.Cho GC, Donovan TE, Chee WW, White SN. Tensile bond strength of polyvinyl siloxane impressions bonded to a custom tray as a function of drying time: part I. J Prosthet Dent. 1995;73(5):419–423. doi: 10.1016/S0022-3913(05)80068-X. [DOI] [PubMed] [Google Scholar]

- 18.Peregrina A, Land MF, Wandling C, Johnston WM. The effect of different adhesives on vinyl polysiloxane bond strength to two tray materials. J Prosthet Dent. 2005;94(3):209–213. doi: 10.1016/j.prosdent.2005.06.011. [DOI] [PubMed] [Google Scholar]

- 19.Chew CL, Chee WW, Donovan TE. The influence of temperature on the dimensional stability of poly (vinyl siloxane) impression materials. Int J Prosthodont. 1993;6(6):528–532. [PubMed] [Google Scholar]

- 20.Corso M, Abanomy A, Di Canzio J, Zurakowski D, Morgano SM. The effect of temperature changes on the dimensional stability of polyvinyl siloxane and polyether impression materials. J Prosthet Dent. 1998;79(6):626–631. doi: 10.1016/S0022-3913(98)70068-X. [DOI] [PubMed] [Google Scholar]

- 21.MacSween R, Price RB. Peel bond strength of five impression material tray adhesives. J Can Dent Assoc. 1991;57(8):654–657. [PubMed] [Google Scholar]

- 22.Chai JY, Jameson LM, Moser JB, Hesby RA. Adhesive properties of several impression material systems part I. J Prosthet Dent. 1991;66(2):201–209. doi: 10.1016/S0022-3913(05)80048-4. [DOI] [PubMed] [Google Scholar]

- 23.Dixon DL, Breeding LC, Bosser MJ, Nafso AJ. The effect of custom tray material type and adhesive drying time on the tensile bond strength of an impression material/adhesive system. Int J Prosthodont. 1994;7(2):129–133. [PubMed] [Google Scholar]

- 24.Maruo Y, Nishigawa G, Oka M, Minagi S, Irie M, Suzuki K. Tensile bond strength between custom tray and elastomeric impression material. J Dent Mater. 2007;26(3):323–328. doi: 10.4012/dmj.26.323. [DOI] [PubMed] [Google Scholar]

- 25.Abdullah MA, Talic YF. The effect of custom tray material type and fabrication technique on tensile bond strength of impression material adhesive systems. J Oral Rehabil. 2003;30(3):312–317. doi: 10.1046/j.1365-2842.2003.01023.x. [DOI] [PubMed] [Google Scholar]