Abstract

There has been no established chemical bonding between custom tray resin and the elastomeric impression materials without the use of manufacturer’s recommended specific tray adhesive. The present study was aimed to compare the bond strength of the manufacturer recommended tray adhesives with the universal tray adhesives using the medium body consistency vinyl polysiloxane (VPS) material and custom tray made of autopolymerising resin and visible light cure (VLC) resin. A total 90 cubicle specimens of autopolymerising resin and 90 specimens of VLC resin were tested for its tensile bond strength. Effectiveness of universal tray adhesive was compared with manufactured tray adhesive. Each of these specimens was then subjected to tensile load in hounsefield universal testing machine at a cross head speed of 5 mm/min and the results were compared and evaluated using one way analysis of variance and post hoc Tuckey’s test. Analysis of bond strength revealed that the universal tray adhesive showed better strength and was statiscally significant when compared to the manufacture supplied tray adhesive. Comparison between both the groups, VLC resin showed better bond strength as compared to autopolymerizing resin. Universal tray adhesive had better tensile bond strength than the manufacturers recommended tray adhesive with the medium body viscosity VPS impression material for both autopolymerising and VLC tray resin.

Keywords: Elastomeric impression material, Tray adhesive, Universal adhesive, VLC resin tray material, Autopolymerising tray resin, Tensile bond strength

Introduction

Fabrication of any prosthesis requires a dimensionally accurate impression. With proper material selection and manipulation accurate impressions can be made conveniently of the hard and soft oral tissues [1]. Accurate registration of oral structures require an accurate impression material, an accurate impression tray to support the material and a means of bonding or attaching the set material to the tray [2]. The use of a custom impression tray enhances the dimensional accuracy of the impression and subsequently the fabricated prosthesis by allowing a more uniform thickness of impression material. Dies obtained by using custom tray are more accurate than those obtained by using a stock tray [3]. An impression made with an elastic impression material must be securely attached to the tray to assure an accurate impression. If the material pulls away from the tray during removal from the mouth, the completed impression may fail to return to its original shape and dimension, resulting in a distorted die, wax pattern and casting [4, 5].

Each class of elastomeric impression materials has its own specific adhesives for application on impression trays. Both manufacturer recommended tray adhesives and universal tray adhesives are available these days [6]. With the advent of the universal tray adhesive many clinicians have started using this adhesive but the studies regarding their efficacy is not known. With the above background the present study aims at evaluating and comparing the bond strength of universal versus adhesives supplied by the manufacturer on autopolymerising resin and visible light cure (VLC) resin.

Methodology

Three commonly available medium bodied vinyl polysiloxane (VPS) impression materials with corresponding adhesives and two universal adhesives were evaluated with poly methylmethacrylate (PMMA) resin and visible light cure resin.

Materials used

| Tray materials | Type | Lot no. | Manufacturer |

|---|---|---|---|

| Poly methylmethacrylate resin (Fig. 1) | Autopolymerizing | NA | DPI |

| VLC resin (Fig. 2) | Light polymerizing | 080218 | DP dental |

| Impression material | Type | Lot no. | Manufacturer |

|---|---|---|---|

| 3M ESPE (Fig. 3) | Medium viscosity | 6KWW171 | 3M ESPE (USA) |

| Aquasil (Fig. 4) | Medium viscosity | 061121 | Dentsply int (USA) |

| Affinis (Fig. 5) | Medium viscosity | 0078924 | Coltene wholedent int (USA) |

| Adhesives | Type | Lot no. | Manufacturer |

|---|---|---|---|

| 3M ESPE VPS tray adhesive (Fig. 6) | Paint on adhesive for 3M ESPE | 239016 | 3M ESPE (USA) |

| Caulk | Paint on adhesive for Aquasil | 070604 | Dentsply caulk |

| Affinis | Paint on adhesive for Affinis | 70375 | Coltene wholedent (USA) |

| Zhermack Universal adhesive (Fig. 7) | Paint on Universal | 60444 | Zhermack (Italy) |

| Universal VPS GC dhesive | Paint on type | 0604061 | GC America Inc (USA) |

Fig. 1.

Materials for group A (autopolymerizing resin)

Fig. 2.

Materials for group B (VLC resin)

Fig. 3.

Materials for subgroup I (3M ESPE)

Fig. 4.

Materials for subgroup II (Dentsply)

Fig. 5.

Materials for subgroup III (Affinis)

Fig. 6.

Manufacturer recomended adhesives (3M ESPE, Dentsply, Affinis)

Fig. 7.

Universal adhesives (GC, Zhermack)

The study was carried in the following manner:

- Preparation of custom tray specimens.

- Autopolymerizing tray specimens

- VLC resin custom tray specimens

Preparation of poly vinyl chloride (PVC) pipe samples.

Preparation of the assembly.

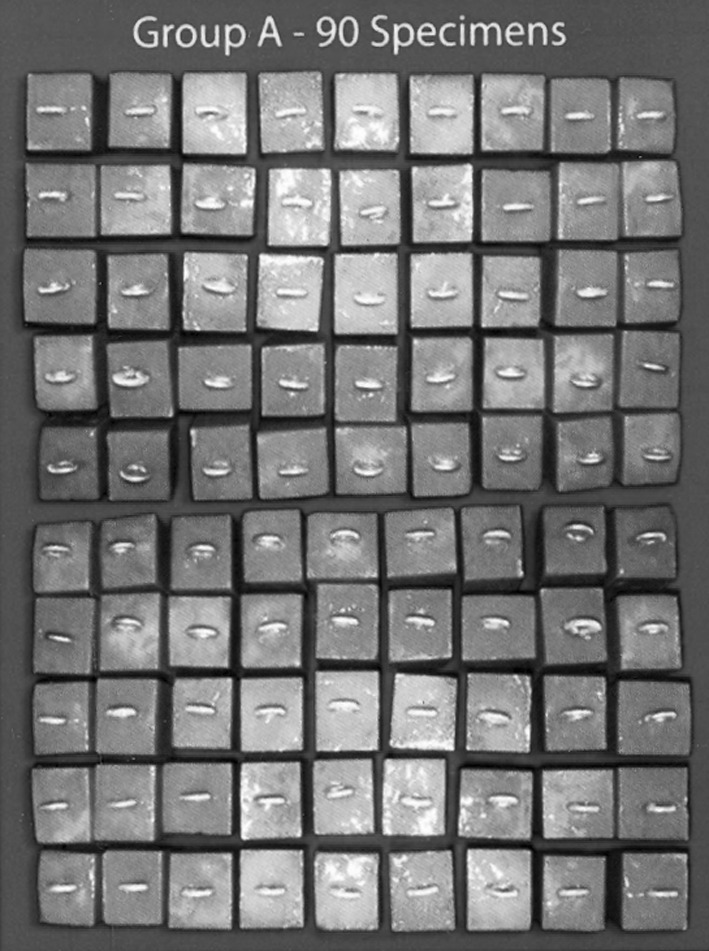

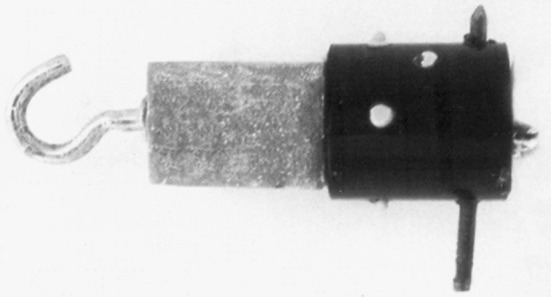

Preparation of Autopolymerizing Custom Tray Specimens (90 Samples; Fig. 8)

Fig. 8.

Specimens of group A (autopolymerizing resin)

Autopolymerizing custom tray specimens were obtained from a metal mold (15 × 15 × 20 mm3) made of stainless steel. 90 cubical specimens were made 24 h prior to testing of the samples. The mold consisted of two plates of which the upper plate had window measuring (15 × 15 × 20 mm3). A thin film of Vaseline (White petroleum jelly, KIM Chemicals Ltd) was applied on the walls to facilitate easy removal of the specimens. The PMMA resin (Dentsply) was mixed according to manufacturers recommended polymer monomer ratio (3:1) and poured into the prepared mold (Fig. 9). The tray material was then allowed to polymerize. Once the resin had polymerized, the samples were retrieved and finished (Fig. 10). The test surface was left untouched and was polished with silicone carbide paper (80 grit) before the tray adhesive application [2]. For the attachment of the hook on the opposite side of test surface, preparation was done with the help of straight fissure bur (Fig. 10). After the preparation, the eye hook was attached into the prepared site and sealed with the custom autopolymerizing tray material. Rests of the samples were fabricated in the same manner.

Fig. 9.

Filling of the mold with the autopolymerizing tray

Fig. 10.

Hole drilled at the marked point for the attachement of screw

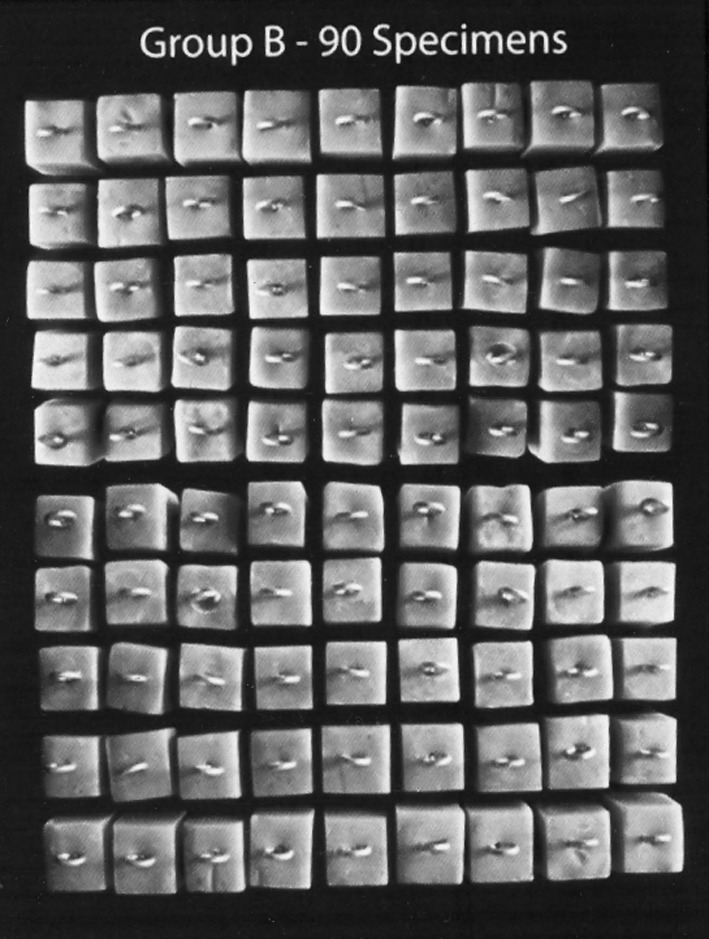

Preparation of VLC Resin Custom Tray Specimens (90 Samples; Fig. 11)

Fig. 11.

Specimens of group B (VLC resin)

The VLC resin (W+P Dental, Germany) was available in the form of sheets and was moulded into stainless steel mold to obtain 90 flat square specimens. The eye hooks were inserted into the centre of each specimen and were allowed to light cure to polymerize in the light cure unit (Kulzer, Dentacolor XS). Once the material is polymerized, the test surface was polished with silicone carbide paper (80 grit) before the tray adhesive application.

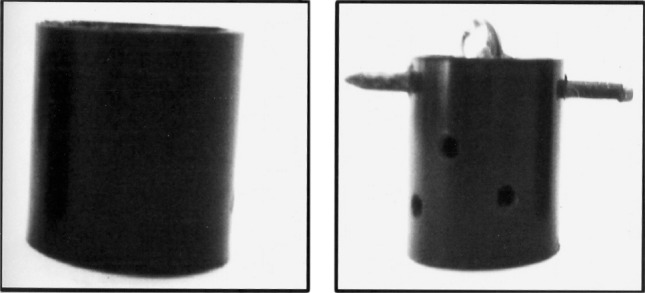

Preparation of Polyvinyl Chloride Open Cylinders (90 Samples: for Housing of Impression Material

Uniform size specimens in the form of open cylinders (15 mm diameter and 20 mm height) were obtained from the piece of intact PVC pipe to serve for the housing of impression material. The cylinder was perforated from No. 2 size straight fissure carbide bur at 5 different locations to provide additional mechanical retention (Fig. 12). To attach a hook, a metal rod was passed into two centred holes of cylinder from one side to other at its lower end to provide retention for an eye hook that will serve as second point of attachment to testing machine.

Fig. 12.

Poly vinyl chloride cylinder specimens

Preparation of the Assembly

PVC pipe housing was centrally placed in contact with surface of tray specimen. The metal rod and hook was inserted at the open end of the cylinder. The assembly was fixed and stabilized with cyano-acrylate adhesive (Fig. 13). This assembly was used for the fabrication of stone index thus serving for orientation of rest of the samples.

Fig. 13.

Bonded sample

All the test samples was grouped and tested as following.

Group A: Polymethyl methacrylate resin

| Subgroup I (3M ESPE) | 3M ESPE adhesive (recommended by manufacturers) Zermack Universal adhesive GC Universal adhesive |

| Subgroup II (Aquasil) | Caulk adhesive (recommended by manufacturer) Zermack Universal adhesive GC Universal adhesive |

| Subgroup II (Affinis) | Coltene (recommended by manufacturer) Zermack Universal adhesive GC Universal adhesive |

Group B: Visible light cure resin

| Subgroup I (3M ESPE) | 3M ESPE adhesive (recommended by manufacturers) Zermack Universal adhesive GC Universal adhesive |

| Subgroup II (Aquasil) | Caulk adhesive (recommended by manufacturer) Zermack Universal adhesive GC Universal adhesive |

| Subgroup II (Affinis) | Coltene (recommended by manufacturer) Zermack Universal adhesive GC Universal adhesive |

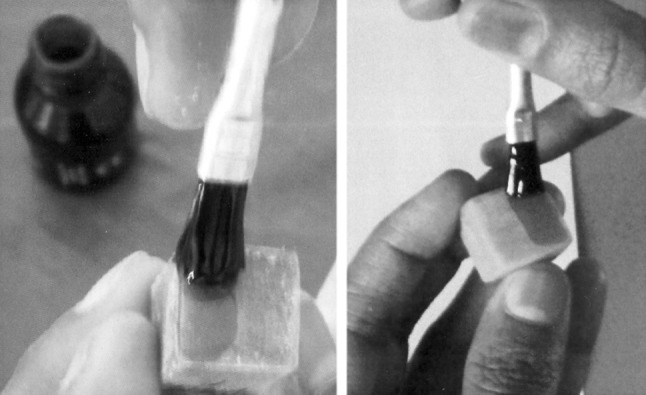

From the above mentioned groups, ten specimens each was coated with adhesive recommended by manufacturers of the respective impression materials and from the other 20 specimens ten each will be coated with each of the two universal adhesives and allowed to dry for the prescribed time of 15 min (Fig. 14).

Fig. 14.

Application of the tray adhesive

The PVC open cylinder was then placed on acrylic specimen in the stone index which was stabilized with the help of rubber bands. After 15 min of tray adhesive drying time, the impression material was automixed [7] and dispensed into the cylinder from one end till the excess came out from the vents ensuring proper dispensing of material without any voids.

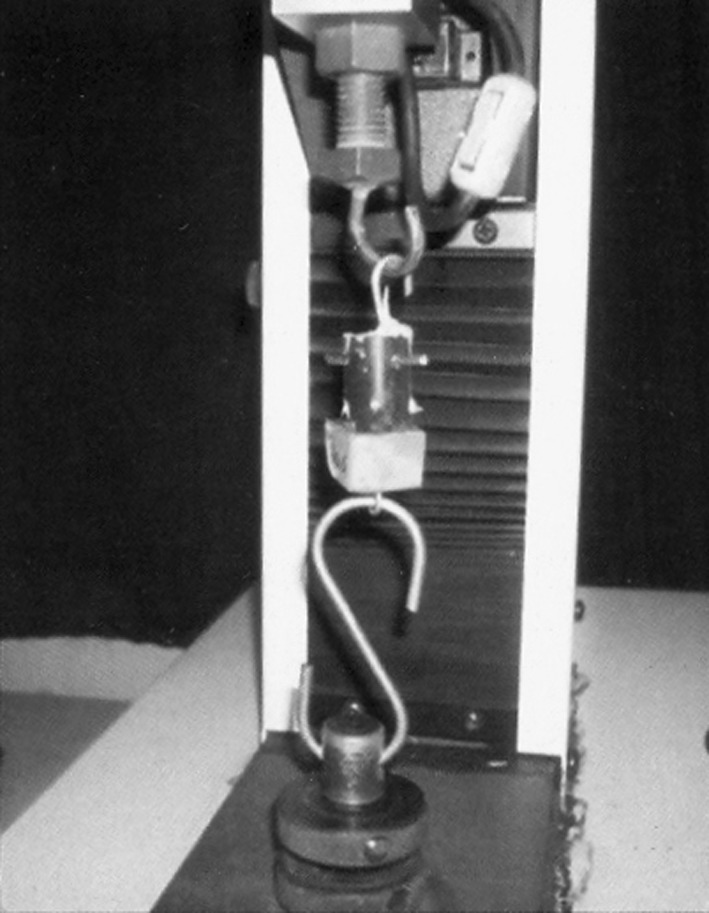

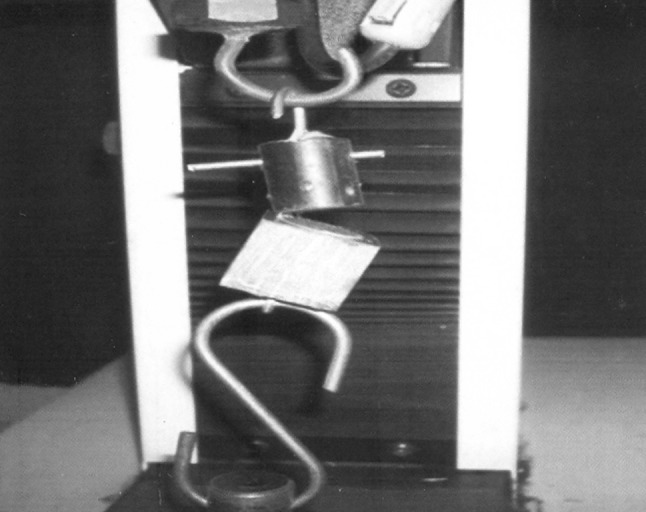

The impression material was then allowed to polymerize in accordance with the respective manufacturer recommendation time. After polymerization, the stone index was separated and the excess if any was removed carefully from the specimen with the help of BP blade. The assembly was then attached to the Hounsfield Universal testing machine by means of metal hook at one end of the tray specimen and the hook attachment of the cylinders on the other end (Figs. 15, 16). The same procedures were carried out for all the subgroups.

Fig. 16.

Group B sample attached to the universal testing machine

Fig. 15.

Group A sample attached to the universal testing machine

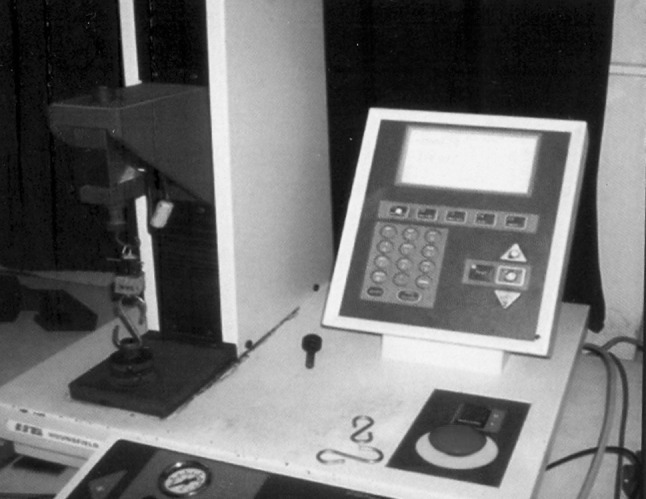

The specimens were then tested in tensile mode for its debonding force at a crosshead speed of 5 mm per minute using 500 kg load all set at full scale load until separation failure occurred (Fig. 17).

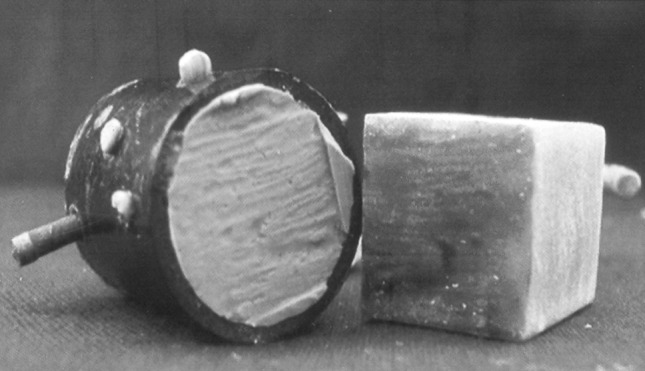

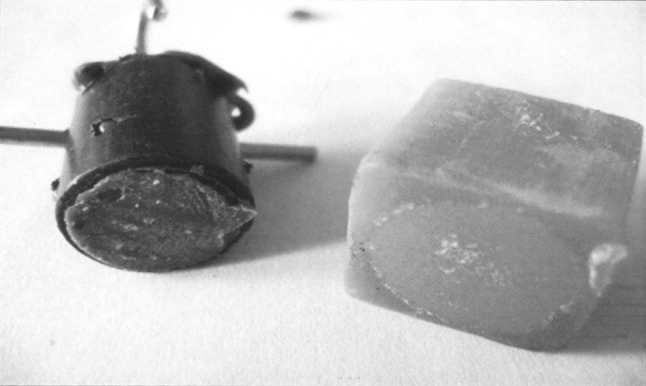

All the values were then recorded for the force at which the separation failure occurred (Figs. 18, 19). The force was measured in kgF which was then calculated for its tensile bond strength using the formula:

Fig. 17.

Sample getting debonded on universal testing machine

|

where F is the maximum force at which separation failure occurred in kgF, A is area of adhesion, i.e. area of the circle (3.14 × r2) in mm2, and r is the radius of the circle [i.e. r = diameter of circle/2, r = 15/2 = 7.5 mm].

Fig. 18.

Debonded sample after tensile loading (Group A)

Fig. 19.

Debonded sample after tensile loading (Group B)

All the values were measured in mega pascals (MPa) and the data was analyzed and tested for its significance using one way ANOVA and post hoc Tukey’s test.

Results

Tables 1 and 2 depicts the statistics of group A and group B that is autopolymerizing tray material and vlc tray resin with three different subgroups of medium body VPS impression material treated with its own tray adhesive and with two universal adhesive. ANOVA showed the F values for Subgroup I, II, III, which were statistically significant. The post hoc Tukey’s test showed p < 0.001 for comparison between manufacturer supplied adhesives with universal adhesives (Zhermack and GC) and hence, was statistically significant. The comparison between universal adhesives that is Zhermack versus GC for subgroup I, II, III not statistically significant.

Table 1.

Comparison of adhesives in Group A

| Adhesive | Subgroup I (3M ESPE) | Subgroup II (Aquasil) | Subgroup III (Affinis) | |

|---|---|---|---|---|

| 1. Manufacturer supplied | 0.43 ± 0.04 | 0.77 ± 0.06 | 0.41 ± 0.03 | |

| 2. Universal adhesive (Zhermack) | 0.70 ± 0.12 | 1.14 ± 0.05 | 0.92 ± 0.04 | |

| 3. Universal adhesive—GC | 0.90 ± 0.05 | 1.16 ± 0.05 | 0.89 ± 0.09 | |

| ANOVA | ||||

| F | 90.26 | 171.9 | 494.1 | |

| p | <0.001 | <0.001 | <0.001 | |

| Difference between groups (p values) | ||||

| 1–2 | <0.001 | <0.001 | <0.001 | |

| 1–3 | <0.001 | <0.001 | <0.001 | |

| 2–3 | <0.001 | 0.74, NS | 0.17, NS | |

One way ANOVA: multiple group comparison; Post hoc Tukey’s test: groupwise comparison

Table 2.

Comparison of adhesives in Group B

| Adhesive | Subgroup I (3M ESPE) | Subgroup II (Aquasil) | Subgroup III (Affinis) | |

|---|---|---|---|---|

| 1. Manufacturer supplied | 0.44 ± 0.04 | 0.91 ± 0.11 | 0.23 ± 0.05 | |

| 2. Universal adhesive (Zhermack) | 1.08 ± 0.07 | 1.41 ± 0.08 | 0.98 ± 0.09 | |

| 3. Universal adhesive—GC | 1.06 ± 0.07 | 1.39 ± 0.06 | 0.99 ± 0.03 | |

| ANOVA | ||||

| F | 343.3 | 108.2 | 376.6 | |

| P | <0.001, HS | <0.001, HS | <0.001, HS | |

| Difference between groups (p values) | ||||

| 1–2 | <0.001, HS | <0.001, HS | <0.001, HS | |

| 1–3 | <0.001, HS | <0.001, HS | <0.001, HS | |

| 2–3 | 0.71, NS | 0.83, NS | 0.96, NS | |

Table 3 depicts the t values and p values within the subjects of Group A and Group B tray material. The t value results were not statistically significant, whereas post hoc Tukey’s test showed p values which were statistically significant.

Table 3.

Group A vs. Group B

| Adhesives | Group A (AP resin) | Group B (VLC) | Mean difference | A vs. B | |

|---|---|---|---|---|---|

| t value | p value | ||||

| Subgroup I (3M ESPE) | |||||

| Manufacturer supplied | 0.43 ± 0.04 | 0.44 ± 0.04 | 0.01 | 0.56 | 0.58 |

| Universal adhesive–Zhermack | 0.70 ± 0.12 | 1.08 ± 0.07 | 0.38 | 8.95 | <0.001 |

| Universal adhesive–GC | 0.90 ± 0.05 | 1.06 ± 0.07 | 0.16 | 5.61 | <0.001 |

| Subgroup II (Aquasil) | |||||

| Manufacturer supplied | 0.77 ± 0.06 | 0.91 ± 0.11 | 0.15 | 3.76 | <0.01 |

| Universal adhesive–Zhermack | 1.14 ± 0.05 | 1.41 ± 0.08 | 0.27 | 8.43 | <0.001 |

| Universal adhesive–GC | 1.16 ± 0.05 | 1.39 ± 0.06 | 0.22 | 9.14 | <0.001 |

| Subgroup III (Affinis) | |||||

| Manufacturer supplied | 0.41 ± 0.03 | 0.23 ± 0.05 | 0.09 | 5.01 | <0.001 |

| Universal adhesive–Zhermack | 0.92 ± 0.04 | 0.98 ± 0.09 | 0.06 | 1.93 | <0.001 |

| Universal adhesive–GC | 0.89 ± 0.05 | 0.99 ± 0.03 | 0.10 | 5.31 | <0.001 |

Discussion

The bond strength of an impression material to tray is essential and is achieved with the use of various means of mechanical retention and/or chemical adhesion. To obtain an accurate impression, the impression material must be securely attached to the tray. If the material is not secured to tray firmly while retrieving from the mouth will result in improper impression and therefore cause distorted die, wax pattern and casting [6, 7]. As the mechanical locking factor of the impression material with the custom tray is minimum, some means of bonding should be there for securing the impression to the custom tray [8].

The use of impression tray adhesive in retaining the elastomeric impression material has definite benefits. Davis et al. [9, 10] investigated the bonding properties of elastomeric tray adhesive. They concluded that since the bonding is not adequate and as the material goes into the undercut, a considerable amount of force is required to pull away the material. The surface preparation of the custom tray especially with the silicone carbide paper significantly affected the retention, by increasing the bond strength of the impression material with the adhesive [11]. It is a routine procedure to apply a tray adhesive as it controls the direction of polymerization shrinkage of the material towards the custom tray side. The impression adhesives used for silicone impression materials contain polydimethyl-siloxane or a similar reactive silicone, and ethyl silicate. Polymethylsiloxane of adhesives bonds to the silicone impression material whereas ethylsilicate forms a hydrated silica that bonds to the impression tray material physically.The volatile solvent in the form of ethyl acetate reacts with the autopolymerising tray material to create microporosites on the tray material so that the adhesive physically and mechanically bonds with it [12].

Previous literature reported that the material adhesive combination supplied by the manufacturer might not necessarily be the best [13]. Universal adhesives have now started to replace the manufacturer’s adhesive [13]. Paint-on adhesive on medium body VPS is found to be effective [14]. Considering this fact, the study is done to test the effectiveness of the universal adhesives (GC America, Zhermack) with the three commonly available medium consistency VPS impression material (3M, Dentsply and Affinis) with their respective tray adhesives using the custom autopolymerising tray resin and visible light cure tray material.

Other investigators have reported values for tensile strength of VPS elastomeric impression materials ranging from 0.2 to 2.1 MPa depending on the tray impression materials used [13]. Thus the mean adhesive values (0.2–1.41 MPa) found in this study were similar to those reported. Based on these findings, and the published work of other investigators, it is not possible to define a threshold bond-strength value, but it may be assumed that a stronger bond between impression material and tray material will result in a reduced probability of interface failure with concomitant loss of accuracy in the subsequent fabrication of the prosthesis. Craig and Powers reported maximum tear force/length values for VPS impression materials ranging from 1,500 to 4,300 N/m. Given this range, the adhesives appears to be the weak link, which is consistent with the clinical observation that failure is periodically observed at the adhesive/tray or adhesive/impression material interface [13].

In this study, the bonding of each impression material to autopolymerizing acrylic resin was compared with the VLC tray material group, polyvinyl siloxane showed statistically significantly higher bond strengths to the VLC tray material than to the acrylic resin (p < 0.001) except for 3M ESPE impression material which is not statistically significant (p = 0.58). The results of this study compare favorably with those reported by Abdullah and Talic [2]. Among the impression material adhesive combination, the universal adhesive (Zhermack) consistently demonstrated higher adhesive strength with all the impression materials tested with the exception of the 3M ESPE impression material for both autopolymerizing and VLC resin tray material. Universal adhesive (GC) demonstrated high tensile bond strength with autopolymerizing resin. This could be attributed to the addition of modifiers (solvents) in the form of petroleum spirits, toluene and benzene in very less concentration [Universal VPS adhesive, GC America, Inc]. This could possibly impact the resulting strength but this may not explain why one of the universal adhesives resulted in higher adhesive values.

Conclusion

This study on the tensile bond strength using three medium body viscosity VPS (3M, Dentsply & Affinis) treated with their own adhesives and universal adhesives (Zhermack & GC) were compared to the two tray materials (autopolymerizing resin and VLC resin).

Among the group A (autopolymerizing resin tray material) universal tray adhesives showed the better strength as compared to the manufacturer recommended adhesive.

Among the group B (VLC resin tray material) universal tray adhesive (Zhermack) showed the better strength as compared to the manufacturer recommended adhesive and universal adhesive GC.

Among both the groups, group B (VLC resin tray material) gave better bond strength with the universal tray adhesive.

References

- 1.Donovan TE, Chee WW (2004) A review of contemporary impression materials and techniques. Dent Clin N Am 48:445–70 [DOI] [PubMed]

- 2.Abdullah MA, Talic YF. The effect of custom tray material type and fabrication technique on tensile bond strength of impression material adhesive systems. J Oral Rehabil. 2003;30:312–317. doi: 10.1046/j.1365-2842.2003.01023.x. [DOI] [PubMed] [Google Scholar]

- 3.Payne JA, Pereira BP. Bond strength of two non aqueous elastomeric impression materials bonded to two thermoplastic resin tray materials. J Prosthet Dent. 1995;74(6):563–568. doi: 10.1016/S0022-3913(05)80306-3. [DOI] [PubMed] [Google Scholar]

- 4.Nicholson JW, Porter KH, Teresa D. Strength of tray adhesives for elastomeric impression materials. Oper Dent. 1985;10:12–16. [PubMed] [Google Scholar]

- 5.Johnson GH, Craig RG. Accuracy of addition silicones as a function of technique. Prosthet Dent. 1986;55:197–203. doi: 10.1016/0022-3913(86)90342-2. [DOI] [PubMed] [Google Scholar]

- 6.Bomberg TJ, Goldfogel MH, Hoffman W, Bomberg SE. Considerations for adhesion of impression materials to impression trays. J Prosthet Dent. 1988;60:681–684. doi: 10.1016/0022-3913(88)90398-8. [DOI] [PubMed] [Google Scholar]

- 7.Cullen DR, Sandrik JL. Tensile strength of elastomeric impression materials, adhesive and cohesive bonding. J Prosthet Dent. 1989;62:142–145. doi: 10.1016/0022-3913(89)90300-4. [DOI] [PubMed] [Google Scholar]

- 8.Chee WWL, Donovan TE. Polyvinyl siloxane impression materials. A review of properties and techniques. J Prosthet Dent. 1992;68:728–732. doi: 10.1016/0022-3913(92)90192-D. [DOI] [PubMed] [Google Scholar]

- 9.Davis GB, Moser JB, Brinsden GI. The bonding properties of elastomer tray adhesives. J Prosthet Dent. 1976;36:278–285. doi: 10.1016/0022-3913(76)90183-9. [DOI] [PubMed] [Google Scholar]

- 10.Grant BE, Tjan AHL. Tensile and peel bond strengths of tray adhesive. J Prosthet Dent. 1988;59:165–168. doi: 10.1016/0022-3913(88)90009-1. [DOI] [PubMed] [Google Scholar]

- 11.Craig RG, Powers JM. Restorative dental materials. 11. St. Louis: Mosby; 2001. pp. 330–389. [Google Scholar]

- 12.Phillips RW, Skinner EW (1982) Skinner’s science of dental materials, 8th edn. WB Saunders, Philadelphia, pp 150–54

- 13.Peregrina A, Land MF, Wandlig C, Johnstone WH. The effect of different adhesives on vinyl polysiloxane bond strength to two tray materials. J Prosthet Dent. 2005;94:209–213. doi: 10.1016/j.prosdent.2005.06.011. [DOI] [PubMed] [Google Scholar]

- 14.Anthony HLT, Sung BW. Comparing effects of tray treatment on the accuracy of dies. J Prosthet Dent. 1987;58:175–178. doi: 10.1016/0022-3913(87)90172-7. [DOI] [PubMed] [Google Scholar]