Abstract

GaN crystals without cracks were successfully grown on a MOCVD-GaN/6H-SiC (MGS) substrate with a low V/III ratio of 20 at initial growth. With a high V/III ratio of 80 at initial growth, opaque GaN polycrystals were obtained. The structural analysis and optical characterization reveal that stress has a great influence on the growth of the epitaxial films. An atomic level model is used to explain these phenomena during crystal growth. It is found that atomic mobility is retarded by compressive stress and enhanced by tensile stress.

GaN has long been considered a most promising material for applications in short wavelength optoelectronics and high-power high-frequency electronics due to its excellent properties, such as a wide direct bandgap,high thermal stability and high electron velocities1,2,3. Currently, most GaN-based devices like light emitting diodes (LEDs) and laser diodes (LDs) have been commercialized by using hetero-epitaxial growth on sapphire, due to the lack of more compatible cost effective substrates. However, the large lattice mismatch (13.8%) and the large thermal expansion coefficient difference between GaN and sapphire results in a high dislocation density and residual stress, both of which seriously affect the optical and electrical performance of the fabricated devices4. A SiC substrate offers the advantages of small lattice mismatch, similar thermal expansion coefficent to GaN, and higher thermal conductivity. Thus, epitaxial growth of GaN on a SiC substrates is considered to be a very promising approach to solving these problems5,6,7,8. The thermal expansion coefficients, lattice constants, and thermal conductivity for GaN, 6H-SiC and sapphire are listed in Table 17,8,9.

Table 1. The coefficients of thermal expansion (αc, αa), lattice constants, and thermal conductivity (κ) for GaN, 6H-SiC and sapphire7,8,9.

| c (nm) | a (nm) | αc × 106 | αa × 106 | κ (w/cmK) | |

|---|---|---|---|---|---|

| GaN | 0.5186 | 0.3188 | 3.17 | 5.59 | 2.1 |

| 6H-SiC | 1.5117 | 0.3081 | 4.68 | 4.2 | 4.2 |

| Sapphire | 1.2991 | 0.4758 | 8.5 | 7.5 | 0.3 |

Lin et al. first reported the growth of 2.5–3.5 μm GaN films on a SiC substrate by molecular beam epitaxy (MBE) with a high electron mobility of 580 cm2/Vs10. The microstructure and defects in GaN films grown on a SiC substrate were also investigated11,12. Nikolaev et al. reported on GaN/6H-SiC p-n heterojunctions fabricated by the HVPE of GaN on p-doped 6H-SiC epitaxial layers grown by low temperature liquid phase epitaxy13. Insulating GaN layers doped with Zn were grown by HVPE on SiC substrates and the temperature dependence of the specific resistivity of the GaN:Zn layers was measured over the temperature range from 200 to 500 K14. H. Lahrèche et al. presented a three-step growth process that enabled them to grow high quality mirror-like GaN layers without using AlN buffer layers by MOCVD15. GaN/4H-SiC heterodiodes were fabricated where the GaN is directly grown by HVPE on off-axis 4H-SiC16. Lee et al. found that H-etching of the SiC substrate was important to eliminate stacking disorder in the GaN grown by MBE, and a high growth temperature reduced the density of screw dislocations in particular17. K. Jeganathan et al. demonstrated the growth of unstrained GaN layers on SiC-6H (0001) substrate by MBE using a double-step AlN buffer process grown at two different high temperatures with a difference of 30–50°C18. Our research group reported that GaN films were grown by HVPE on MOCVD-GaN/Al2O3 (MGA) and MOCVD-GaN/6H-SiC (MGS) samples. The strain variations were microscopically identified using Z scan Raman spectroscopy. The Raman peak (E2) shift indicates that the stress increased gradually as a function of increase in measurement depth19. The reported references mainly focused on the microstructures or defects of GaN films on a SiC substrate and the characteristics of GaN/6H-SiC p-n heterojunctions or heterodiodes grown by MBE or MOCVD. However, the influences of growth conditions and stress on GaN crystal growth with a MGS substrate grown by HVPE have not been reported. In this work, different growth conditions were tried for the growth of GaN on MGS substrates. The aim is to study the influence of stress in GaN crystals growth. We believe that this work may be helpful in understanding GaN crystal growth by HVPE on an MGS substrate.

Experimental

GaN films were grown in a home-made vertical HVPE reactor. A template with a 5 μm GaN layer grown by MOCVD on the 6H-SiC substrates was employed as the starting substrate. Ga and NH3 were used as respective gallium and nitrogen sources. HCl gas was reacted with liquid Ga at 820°C to form GaCl, which was transported to the growth zone of the reactor and reacted with NH3 at 1030°C to form GaN molecules. Nitrogen was used as the carrier gas. The reactor pressure was kept at around atmospheric pressure. In this study, two different growth conditions (A and B, shown in Table 2) were used for the growth of GaN on the MGS substrate.

Table 2. Two different growth conditions (A and B) of GaN on MGS substrate.

| Growth condition A | Growth condition B | |||

|---|---|---|---|---|

| Growth parameter | First step (20 min) | Second step (4 h) | First step (20 min) | Second step (4 h) |

| V/III | 80 | 50 | 20 | 50 |

Two sets of samples were grown under identical conditions on MGA and MGS templates. The growth temperature was 1030°C. The GaN layers on the MGA and MGS templates have the same dislocation density (6 × 108 cm−1). The gas flow rates of NH3 (800 mL/min, 1000 mL/min), HCl (10 mL/min, 20 mL/min), NH3 carrier gas (1000 mL/min), HCl carrier gas (1000 mL/min) and N2 (2000 mL/min) for growth condition A on MGA and MGS templates were the same. The gas flow rates of NH3 (400 mL/min, 1000 mL/min), HCl (20 mL/min, 20 mL/min, NH3 carrier gas (1000 mL/min), HCl carrier gas (1000 mL/min) and N2 (2000 mL/min) for growth condition B on MGA and MGS templates were the same. The heating rate and cooling rates were also the same. The surface morphology and structural quality of the as-grown GaN films were investigated by a variety of characterization techniques. AFM (Digital Instrument Dimension 3100) and FE-SEM (Hitachi S-4800) were used to investigate the surface morphology. Raman spectra of the samples were obtained by the LabRAM HR system of Horiba Jobin Yvon at room temperature using a 532 nm solid state laser as the excitation source. Photoluminescence (PL) measurements were carried out at room temperature using a 325 nm He–Cd laser as the excitation source. All samples were evaluated by high-resolution X-ray diffraction (HRXRD). The lattice parameters were determined by measuring the (002), (004) and (102), (204) peaks in a multi-diffraction ω-2θ scan.

Results and Discussion

Fig. 1 shows photographs of the GaN films grown on the MGS substrate under (a) condition A (high V/III ratio 80 at initial growth) and (b) condition B (low V/III ratio 20 at initial growth). Under growth condition A, (Fig. 1a) the surface is black and many small polycrystalline grains are observed. As shown in Fig. 1b, a 40 μm thick GaN layer with a mirror-like smooth surface was obtained on the MGS substrate under growth condition B.

Figure 1. Photographs of the GaN films grown on MGS substrate under (a) condition A and (b) condition B.

Fig. 2 shows SEM images of the surface morphology of the GaN films grown on MGS substrates under growth condition A (Fig. 2a) and B (Fig. 2b). In the image, many prismatic hexagonal grains are observed in the GaN under growth condition A, whereas for the GaN under growth condition B, a smooth pitless surface is observed. A GaN single crystal without cracks was successfully obtained under growth condition B. Using growth condition A, opaque GaN polycrystals were obtained. From the above results, we conclude that growth conditions have great influence on the MGS substrate.

Figure 2. SEM images of GaN film surface morphology grown on MGS substrate under growth condition A (a) and B (b).

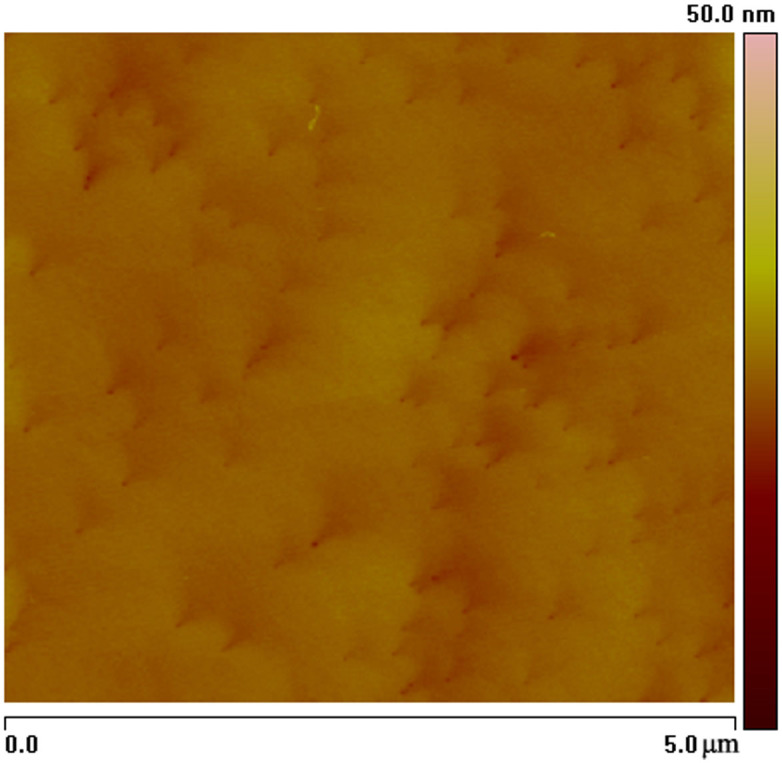

Fig. 3 shows an AFM image of the GaN (growth condition A) epilayer in an area over a 5 μm × 5 μm area. A stepped terrace structure is observed and the RMS roughness is found to be 0.860 nm.

Figure 3. AFM image of surface morphology of GaN film grown on MGS substrates obtained with growth condition B.

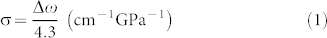

Fig. 4 shows the Raman spectrum of a GaN films grown on the MGS substrate under growth condition B. The measurement was carried out with the z (xx)  back scattering geometry. Five peaks are observed. In addition to the A1(LO) peak at 734.1 cm−1 and the E2 (high) peak at 568.7 cm−1 of GaN, the E2 (FTO) peaks of SiC are observed at 765.8 cm−1, 788.0 cm−1, and the A1 (LO) peak of SiC is observed at 964.5 cm−1. The E2 (high) phonon peak can be used to characterize the in-plane strain state of the GaN epilayer. The stress is calculated by the following equation20:

back scattering geometry. Five peaks are observed. In addition to the A1(LO) peak at 734.1 cm−1 and the E2 (high) peak at 568.7 cm−1 of GaN, the E2 (FTO) peaks of SiC are observed at 765.8 cm−1, 788.0 cm−1, and the A1 (LO) peak of SiC is observed at 964.5 cm−1. The E2 (high) phonon peak can be used to characterize the in-plane strain state of the GaN epilayer. The stress is calculated by the following equation20:

|

where σ is the biaxial stress and Δω is the E2 phonon peak shift. The E2 (high) phonon peak of stress-free GaN is believed to be located at 567.1 ± 0.1 cm−1 21. The E2 (high) phonon peak of GaN grown on the MGS substrate is at 566.92 cm−1, indicating that a tensile stress of about 0.042 GPa was present.

Figure 4. Raman spectrum of GaN film grown on MGS substrates under growth condition B.

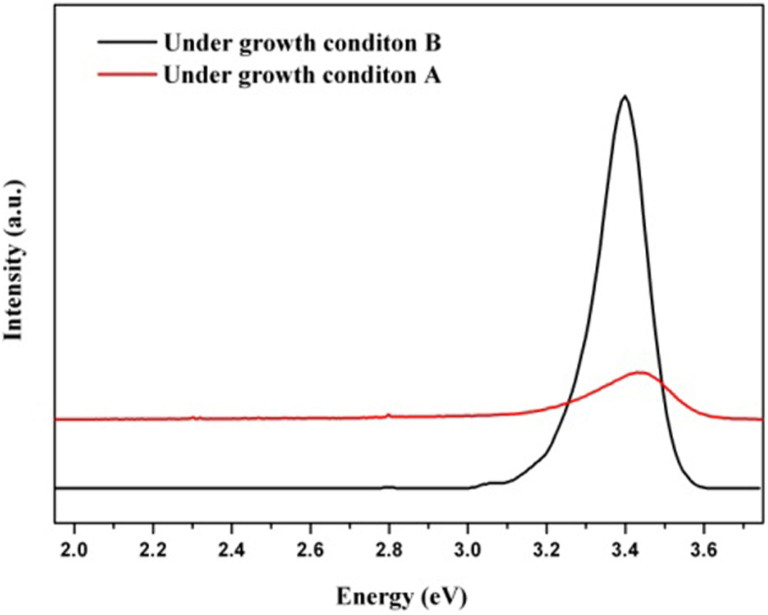

The optical characteristics of the samples were obtained using PL measurements at room temperature (Fig. 5). The strong band-edge emission peaks of the GaN films grown on the MGS substrate can be observed near 3.399 eV. No yellow luminescence around 2.21 eV was observed. The luminescence peak of stress-free GaN is located at 3.471 eV22,23. The PL peaks of the samples exhibit a 72 meV red-shift with respect to those of completely relaxed bulk GaN, and indicate that the stress in GaN grown on the MGS substrate is tensile in nature. The narrow peak for the GaN film grown on the MGS substrate indicates that the crystalline quality of this layer is good. In contrast to the intensity obtained from the sample grown under growth condition B, the PL intensity from the polycrystalline GaN sample under growth condition A is very low. This observation implies that the concentration of non-radiative recombination centers is high.

Figure 5. PL spectra of the GaN film grown on MGS substrates under growth conditions A and B.

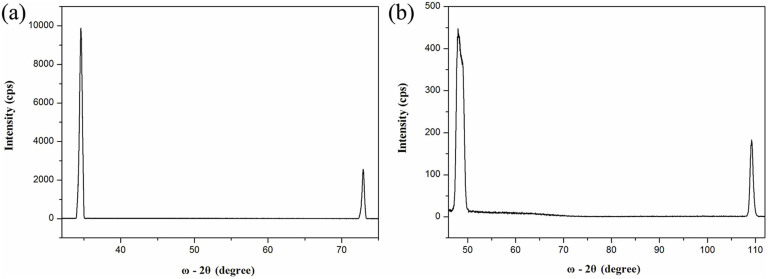

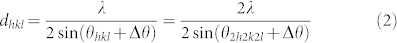

Fig. 6 shows the XRD ω-2θ scan of the GaN film grown on the MGS substrate. The GaN (002), (004) and (102), (204) diffraction peak positions were used to calculate the lattice constants c and a by using the following equations24,25:

|

|

where (h k l) are the indices of the diffraction plane, θh k l is the measured angular position of the (h k l) reflection, Δθ is the zero error of the instrument, and λ is the X-ray wavelength (0.154 nm for Cu Kα1 radiation). The in-plane strain was obtained by using the formula (4):

|

The strain-to-stress conversion is performed using the expression:

|

where σ is the in-plane stress, M (MSiC = 602 GPa26, MGaN = 478 GPa26) is the biaxial elastic modulus, and ε is the in-plane strain. The lattice constants of strain-free GaN are a0 = 0.31892 nm and c0 = 0.51850 nm27. The calculated lattice constants, strains and stresses are listed in Table 3. It can be seen that the GaN film on the MGS substrate has a smaller c value and larger a value compared to the strain-free parameters given the reference27. According to the calculated results, it can be concluded that the residual stress in GaN films grown on the MGS substrate is tensile in nature. The results are in agreement with the Raman and PL results.

Figure 6. Diffraction peaks (ω-2θ scan) for planes (a) (002), (004) and (b) (102), (104) (b) of GaN film grown on MGS substrate under growth condition B.

Table 3. Calculated lattice constants, strains and stresses.

| Grown on MGS substrate | Free standing GaN27 | |

|---|---|---|

| c (nm) | 0.51843 | 0.51850 |

| a (nm) | 0.31899 | 0.31892 |

| ε | 0. 022% | - |

| σ | 0.132 GPa | - |

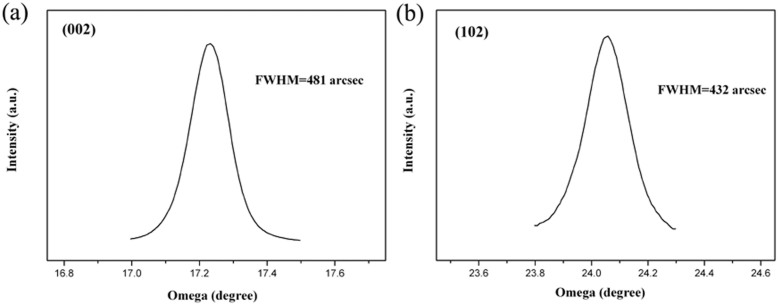

In addition, an HRXRD rocking curve for the (002) symmetric and (102) asymmetric planes of the GaN epilayer was performed to determine the crystal quality. The FWHM values of the symmetric (002) and asymmetric (102) diffraction line are 481 and 432 arcsec, respectively (Fig. 7).

Figure 7. HRXRD rocking curves of GaN film grown on MGS substrate under growth condition B: (a) (002) ω-scans and (b) (102) ω-scans.

Nucleation during HPVE is a complex process, which is usually dependent on temperature, substrate surface, gas flow rate, etc. The lattice perfection improved as the growth temperature increased, and the lattice quality and stoichiometry both reached optimum conditions as the N:Ga ratio approached a fixed value at a given growth temperature28. The diffusion barriers for a-plane and m-plane surfaces are different: on the a-plane surface, Ga ad-atoms exhibit substantially a smaller diffusion barriers along the c-axis, while on the m-plane surface, the Ga ad-atoms exhibit a substantially larger diffusion barriers along the c-axis29. In order to study the influence of stress in GaN crystals grown by HVPE on MGS substrates, the GaN growth process was in all cases carried out at the same growth temperature, Ga-pane growth surface, and gas flow rate. Both growth conditions A and B were used to grow GaN on a MGA substrate, and mirror-like smooth GaN films were obtained19,30. The stress condition in GaN grown on a MGA substrate is compressive in nature19, while on a MGS substrate it is tensile in nature. Therefore, we think that the different growth results obtained for the MGS substrate under conditions A and B are relevant to the stress present in the films.

The critical steps (V/III ratio = 80 for A and V/III = 20 ratio for B) in GaN growth for 20 min at 1030°C have been characterized by SEM (Fig. 8). Fig. 8a and Fig. 8b show SEM images of the GaN films grown on the MGA substrate. A continuous GaN layer was formed under growth conditions A and B. A lower V/III ratio enhances the three dimensional (3D) growth mode and a higher V/III ratio improves two dimensional (2D) growth mode31,32. For the MGA substrate, both 3D GaN nucleation layers with a low V/III ratio and 2D GaN nucleation layers with a high V/III ratio form coherent GaN films at the initial growth stage under compressive stress.

Figure 8.

SEM images of GaN films grown on the MGA substrate under growth condition A (a) and B (b) with growth time of 20 min. SEM images of GaN films grown on the MGS substrate under growth condition A (c) and B (d) with growth time of 20 min. The cross-sectional SEM images of GaN films grown on the MGS substrate under growth condition A (e) and B (f) with growth time of 20 min.

Fig. 8c and Fig. 8d show SEM images of GaN films grown on the MGS substrate. It can be seen that the GaN nucleation layers have been coalesced and continuous films are formed under growth condition A (Fig. 8c). Only a few pits were observed. However, many GaN islands were observed and the islands cannot coalescence with each other under growth condition B (Fig. 8d). Due to the tensile stress on GaN grown on the MGS substrate, the 3D GaN nucleation layers with low V/III ratio coalesce in the first growth step and smooth GaN films are formed with a high V/III ratio in the second step. However, the coalescence of 2D GaN nucleation layers with a high V/III ratio in the first growth step does not occur and prismatic hexagonal polycrystalline grains are formed instead. Fig. 8e and Fig. 8f show cross-sectional SEM images of GaN films grown on the MGS substrate. These results also confirmed that the growth mode is 2D under growth condition A and 3D under growth condition B for GaN grown on the MGS substrate.

Ad-atom surface mobility is considered to be a key parameter controlling the surface morphology33. It has been reported that stress in the film during growth can alter the surface mobility of ad-atoms and consequently the growth mode, thereby vastly influencing the surface morphology34,35,36,37. In the early stages, the GaN coalesces into islands. Then the islands are incorporated together by the Ga ad-atoms. The average diffusion length of the Ga ad-atoms plays an important role in the coalescence of the islands. The 3D growth mode usually produces many isolated islands because of the short diffusion length of the Ga ad-atoms38. The Ga ad-atoms only diffuse on the surface of the island, which allows the island structure to dominate. High dislocation density and rough surface morphology result. On the contrary, the 2D growth mode usually produces a smooth surface because of the long diffusion length of the Ga ad-atoms. The ad-atoms diffuse until they are incorporated into the island edges and allow the island to grow in the horizontal direction to form a smooth surface. The dislocations were bent, which dramatically reduced the threading dislocation density38.

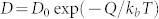

The diffusion of an ad-atom on a flat surface is by far the most important kinetic process in film growth39. The diffusion coefficient is the measure of the ad-atom mobility. Ad-atom surface diffusion processes exhibit a characteristic diffusion length L, which is connected to the average atomic lifetime on the surface τ and the diffusion coefficient D ( ). The process follows the Arrhenius equation:

). The process follows the Arrhenius equation:  , where kB is the Boltzmann constant, T is the temperature, and Q is the surface diffusion activation energy associated with the diffusion barrier40,41. The investigation of Jang et al. showed that the vacancy migration energy barrier (Em) is independent of pressure and remains almost constant42. So the activation energy barrier (Q), as the sum of vacancy formation enthalpy (

, where kB is the Boltzmann constant, T is the temperature, and Q is the surface diffusion activation energy associated with the diffusion barrier40,41. The investigation of Jang et al. showed that the vacancy migration energy barrier (Em) is independent of pressure and remains almost constant42. So the activation energy barrier (Q), as the sum of vacancy formation enthalpy ( ) and the migration energy barrier (

) and the migration energy barrier ( ), increases with increasing pressure43. The Q value with compressive stress is greater than that of the stress-free state. The Q value with tensile stress is less than that of the stress-free state. Therefore, it can be concluded that atomic mobility is influenced differently depending on the type of stress. The atomic mobility is retarded by compressive stress, but it is enhanced by tensile stress. A lower V/III ratio enhanced the 3D growth mode by increasing atomtic mobility, and a higher V/III ratio improved the 2D growth mode due to increased ad-atom mobility31. The stress condition in GaN grown on a 6H-SiC substrate is tensile in nature. For the MGS substrate, condition B (an increasing V/III ratio) was introduced in order to stabilize the atomic mobility and a smooth surface was obtained. Condition A (a decreasing V/III ratio) can caused disorder in the atomic mobility and opaque GaN polycrystals were obtained.

), increases with increasing pressure43. The Q value with compressive stress is greater than that of the stress-free state. The Q value with tensile stress is less than that of the stress-free state. Therefore, it can be concluded that atomic mobility is influenced differently depending on the type of stress. The atomic mobility is retarded by compressive stress, but it is enhanced by tensile stress. A lower V/III ratio enhanced the 3D growth mode by increasing atomtic mobility, and a higher V/III ratio improved the 2D growth mode due to increased ad-atom mobility31. The stress condition in GaN grown on a 6H-SiC substrate is tensile in nature. For the MGS substrate, condition B (an increasing V/III ratio) was introduced in order to stabilize the atomic mobility and a smooth surface was obtained. Condition A (a decreasing V/III ratio) can caused disorder in the atomic mobility and opaque GaN polycrystals were obtained.

Conclusions

The effect of stress on the growth of GaN films has been investigated. The atomic mobility is influenced differently depending on the type of stress, and consequently the growth mode is changed during GaN growth. It is found that 3D GaN nucleation layers grown at a low V/III ratio coalesced in the first growth phase and a GaN crystal was obtained on the MGS substrate. With a high V/III ratio in the initial growth step, opaque GaN polycrystals were obtained. Our work is helpful for understanding the growth of GaN crystals by HVPE on 6H-SiC substrate. GaN polycrystals can be avoided on the MGS substrate by using suitable growth conditions.

Author Contributions

X.H. and Y.W. designed experiment. L.Z. wrote the main manuscript text. J.Y. carried out SEM measurements. Y.S., H.Z., Y.D. and Y.T. grew the sample. All authors reviewed the manuscript.

Acknowledgments

This work was supported by National Basic Research Program of China (2011CB301904), NSFC (Contract 51321091), IIFSDU (2012JC007), China Postdoctoral Science Foundation funded project (2012M521331), Special Fund from Postdoctoral Innovation Research Program of Shandong Province (201203062). Thanks to Prof. Robert I. Boughton, Bowling Green State University, for linguistic advice.

References

- Ponce F. A. & Bour D. P. Nitride-based semiconductors for blue and green light-emitting devices. Nature 386, 351–359 (1997). [Google Scholar]

- Ehrentraut D. & Sitar Z. Advances in Bulk Crystal Growth of AlN and GaN. MRS Bull. 34, 259–265 (2009). [Google Scholar]

- Feezell D. F., Schmidt M. C., DenBaars S. P. & Nakamura S. Development of Nonpolar and Semipolar InGaN/GaN Visible Light-Emitting Diodes. MRS Bull. 34, 318–323 (2009). [Google Scholar]

- Nakamura S. et al. InGaN/GaN/AlGaN-Based Laser Diodes Grown on GaN Substrates with a Fundamental Transverse Mode. Jpn. J. Appl. Phys. 37, L1020–1022 (1998). [Google Scholar]

- Edmonda J. et al. High efficiency GaN-based LEDs and lasers on SiC. J. Cryst. Growth 272, 242–250 (2004). [Google Scholar]

- Harle V. et al. GaN-Based LEDs and Lasers on SiC. Phys. Stat. Sol. a 180, 5–13 (2000). [Google Scholar]

- Liu L. & Edgar J. H. Substrates for gallium nitride epitaxy. Mater. Sci. Eng. R 37, 61–127 (2002). [Google Scholar]

- Nikitina I. P., Sheglov M. P., Melnik, Yu V., Irvine K. G. & Dmitriev V. A. Residual strains in GaN grown on 6H-SiC. Diamond Relat. Mater. 6, 1524–1527 (1997). [Google Scholar]

- Ponce F. A., Krusor B. S., Major, Jr J. S., Plano W. E. & Welch D. F. Microstructure of GaN epitaxy on SiC using AlN buffer layers. Appl. Phys. Lett. 67, 410–412 (1995). [Google Scholar]

- Lin M. E., Swerdlov B., Zhou G. L. & Morkoc H. A comparative study of GaN epilayers grown on sapphire and SiC substrates by plasma-assisted molecular-beam epitaxy. Appl. Phys. Lett. 62, 3479–3481 (1993). [Google Scholar]

- Nikitina I. P. & Dmitriev V. A. X-ray differential diffractometry applied to GaN grown on SiC. Inst. Phys. Conf. Series 141, 431–436 (1995). [Google Scholar]

- Melnik Y. V., Nikitina I. P., Nikolaev A. E. & Dmitriev V. A. Structural properties of GaN grown on SiC substrates by hydride vapor phase epitaxy. Diamond Relat. Mater. 6, 1532–1535 (1997). [Google Scholar]

- Nikolaev A. E., Rendakova S. V. & Nikitina I. P. GaN grown by hydride vapor phase epitaxy on p-type 6H-SiC layers. J. Electron. Mater 27, 288–291 (1998). [Google Scholar]

- Kuznetsov N. I., Nikolaev A. E., Zubrilov A. S., Melnik, Yu V. & Dmitrieva V. A. Insulating GaN:Zn layers grown by hydride vapor phase epitaxy on SiC substrates. Appl. Phys. Lett. 75, 3138–3140 (1999). [Google Scholar]

- Lahrèche H. et al. Buffer free direct growth of GaN on 6H–SiC by metalorganic vapor phase epitaxy. J. Appl. Phys. 87, 577–584 (2000). [Google Scholar]

- Danielsson E. et al. Fabrication and characterization of heterojunction diodes with HVPE-grown GaN on 4H-SiC. IEEE Trans. Electr. Dev. 48, 444–449 (2001). [Google Scholar]

- Lee C. D., Ramachandran V., Sagar A., Feenstra R. M. & Greve D. W. Properties of GaN epitaxial layers grown on 6H-SiC(0001) by plasma-assisted molecular beam epitaxy. J. Electron. Mater. 30, 162–169 (2001). [Google Scholar]

- Jeganathan K., Shimizu M. & Okumura H. Growth of Strain Free GaN Layers on 6H-SiC (0001) by Plasma-Assisted Molecular Beam Epitaxy. Phys. Status. Solidi. c 1, 143–147 (2002). [Google Scholar]

- Zhang L. et al. Comparison of the strain of GaN films grown on MOCVD-GaN/Al2O3 and MOCVD-GaN/SiC samples by HVPE growth. J. Cryst. Growth 334, 62–66 (2011). [Google Scholar]

- Tripathy S., Chua S. J., Chen P. & Miao Z. L. Micro-Raman investigation of strain in GaN and AlxGa1−xN/GaN heterostructures grown on Si(111). J. Appl. Phys. 92, 3503–3510 (2002). [Google Scholar]

- Goni A. R., Siegle H., Syassen K., Thomsen C. & Wagner J. M. Effect of pressure on optical phonon modes and transverse effective charges in GaN and AlN. Phys. Rev. B 64, 035205 (2001). [Google Scholar]

- Kasic A. et al. Highly homogeneous bulk-like 2″ GaN grown by HVPE on MOCVD-GaN template. J. Cryst. Growth 275, e387–e393 (2005). [Google Scholar]

- Gogova D., Talik E., Ivanov I. G. & Monemar B. Large-area free-standing GaN substrate grown by hydride vapor phase epitaxy on epitaxial lateral overgrown GaN template. Physica B: Condensed Matter. 371, 133–139 (2006). [Google Scholar]

- Zheng X. H. et al. Method for measurement of lattice parameter of cubic GaN layers on GaAs (001). J. Cryst. Growth 250, 345–348 (2003). [Google Scholar]

- Qu S. et al. Influence of the growth temperature of AlN buffer on the quality and stress of GaN films grown on 6H–SiC substrate by MOVPE. J. Alloys Compd. 502, 417–422 (2010). [Google Scholar]

- Goldberg Y., Levinshtein M. & Rumyantsev S. Silicon carbide (SiC). Wiley 93–147 (2001). [Google Scholar]

- Shan W. et al. Strain effects on excitonic transitions in GaN: Deformation potentials. Phys. Rev. B 54, 13460 (1996). [DOI] [PubMed] [Google Scholar]

- Zhou X., Murdick D., Gillespie B. & Wadley H. Atomic assembly during GaN film growth: Molecular dynamics simulations. Phys. Rev. B 73, 045337 (2006). [Google Scholar]

- Lymperakis L. & Neugebauer J. Large anisotropic adatom kinetics on nonpolar GaN surfaces: Consequences for surface morphologies and nanowire growth. Phys. Rev. B 79, 241308 (2009). [Google Scholar]

- Shao Y. L. et al. Influence of GaCl carrier gas flow rate on properties of GaN films grown by hydride vapor-phase epitaxy. J. Alloys. Compd. 509, 6212–6216 (2011). [Google Scholar]

- Kim S. et al. Two-step growth of high quality GaN using V/III ratio variation in the initial growth stage. J. Cryst. Growth 262, 7–13 (2004). [Google Scholar]

- Zhao D. G., Jiang D. S., Zhu J. J., Liu Z. S. & Zhang S. M. The influence of V/III ratio in the initial growth stage on the properties of GaN epilayer deposited on low temperature AlN buffer layer. J. Cryst. Growth 303, 414–418 (2007). [Google Scholar]

- Zywietz T., Neugebauer J. & Scheffler M. Adatom diffusion at GaN (0001) and (0001) surfaces. Appl. Phys. Lett. 73, 487–489 (1998). [Google Scholar]

- Yam K., Low L. L., Oh S. A. & Hassan Z. Gallium Nitride: An Overview of Structural Defects, Optoelectronics-Materials and Techniques. InTech 107, (2011). [Google Scholar]

- Fujii H. et al. Impact of growth temperature, pressure, and strain on the morphology of GaN films. III-V Nitrides MRS Proceedings 449, 227 (1997). [Google Scholar]

- Deville J. P. & Hanbücken M. Stress and Strain in Epitaxy: Theoretical Concepts. Measurements and Applications. Elsevier 3, (2001). [Google Scholar]

- Waltereit P., Brandt O., Trampert A., Ramsteiner M. & Reiche M. Influence of AlN nucleation layers on growth mode and strain relief of GaN grown on 6H–SiC (0001). Appl. Phys. Lett. 74, 3660–3662 (1999). [Google Scholar]

- Sun X. J. et al. In situ observation of two-step growth of AlN on sapphire using high-temperature metal–organic chemical vapour deposition. CrystEngComm 15, 6066–6073 (2013). [Google Scholar]

- Zhang Z. Y. & Lagally M. G. Atomistic Processes in the Early Stages of Thin-Film Growth. Science 276, 377–383 (1997). [DOI] [PubMed] [Google Scholar]

- Ploch S. Wernicke T., Dinh D. V., Pristovsek M. & Kneissl M. Surface diffusion and layer morphology of (11–22) GaN grown by metal-organic vapor phase epitaxy. J. Appl. Phys. 111, 033526 (2012). [Google Scholar]

- Lymperakis L. & Neugebauer J. Large anisotropic adatom kinetics on nonpolar GaN surfaces: Consequences for surface morphologies and nanowire growth. Phys. Rev. B 79, 241308 (2009). [Google Scholar]

- Jang J. W., Kwon J. H. & Lee B. J. Effect of stress on self-diffusion in bcc Fe: An atomistic simulation study. Scripta Mater. 63, 39–42 (2010). [Google Scholar]

- Bouville M. The role of stress and diffusion in structure formation in semiconductors. The University of Michigan (2004). [Google Scholar]