Abstract

Background:

Debonding of denture teeth from denture bases is the most common failure in removable dentures. The purpose of this study was to evaluate the effect of surface treatments on shear bond strength of denture teeth to heat-polymerized and autopolymerized denture base resins.

Materials and Methods:

In this experimental in vitro study, 60 maxillary central incisor acrylic teeth were divided into two groups. Group M was polymerized with heat-polymerized acrylic resin (Meliodent) by compression molding technique and group F was processed by autopolymerized acrylic resin (Futura Gen) by injection molding technique. Within each group, specimens were divided into three subgroups according to the teeth surface treatments (n = 10): (1) ground surface as the control group (M1 and F1), (2) ground surface combined with monomer application (M2 and F2), and (3) airborne particle abrasion by 50 μm Al2O3 (M3 and F3). The shear bond strengths of the specimens were tested by universal testing machine with crosshead speed of 5 mm/min. Data were analyzed by two-way analysis of variance (ANOVA) and Tukey's honestly significant difference (HSD) tests (P < 0.05).

Results:

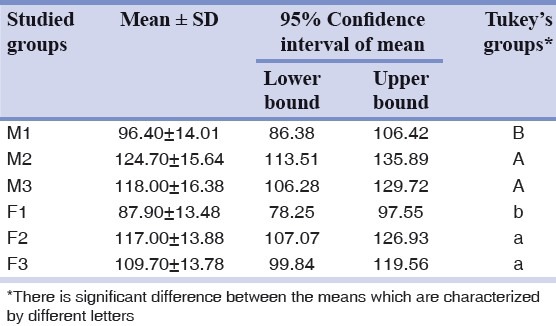

The mean shear bond strengths of the studied groups were 96.40 ± 14.01, 124.70 ± 15.64, and 118 ± 16.38 N for M1, M2, and M3 and 87.90 ± 13.48, 117 ± 13.88, and 109.70 ± 13.78 N for F1, F2, and F3, respectively. The surface treatment of the denture teeth significantly affected their shear bond strengths to the both the denture base resins (P < 0.001). However, there were no significant differences between the groups treated by monomer or airborne particle abrasion (P = 0.29). The highest percentage of failure mode was mixed in Meliodent and adhesive in Futura Gen.

Conclusion:

Monomer application and airborne particle abrasion of the ridge lap area of the denture teeth improved their shear bond strengths to the denture base resins regardless of the type of polymerization.

Keywords: Acrylic resin, dental bonding, denture bases

INTRODUCTION

One of the most widely available materials in prosthetic dentistry is polymethyl methacrylate (PMMA), a material that has been used as a denture base since 1937.[1,2] Heat-polymerized PMMA resin is used as a denture base material because of its excellent esthetics, low water sorption and solubility, relative lack of toxicity, repair ability, and simple processing technique.[3] A conventional method for curing resin is the compression molding technique.[3,4] Advantages of this method include ease of processing, its familiarity for dentists and technicians, and the lack of need for any sophisticated or expensive equipment. Disadvantages of this technique are dimensional changes and inaccuracies in the fit of the denture base. Therefore, the popularity and relative simplicity of the compression molding technique are usually overshadowed by the high processing stresses induced in the resin during polymerization.[5,6]

Another type of resin is the chemically activated or autopolymerizing resin. Chemically activated resins are much less frequently used for denture base fabrication than heat-activated resins. These materials have a higher solubility and inferior color stability due to oxidation of the amine accelerator.[7,8] Chemically activated resins, most often when compression molded, display less polymerization shrinkage than their heat-activated counterparts, which leads to greater dimensional accuracy. This could be attributed to a reduction in residual stresses that have been induced during the processing cycle.[9]

The injection molding technique when compared with the compression molding technique has a reduced processing time, lower cost, lower skin sensitivity to the evaporated monomer, and availability of the resin reservoir to compensate for acrylic resin shrinkage.[10,11]

The type of processing could affect the mechanical properties of the resins such as the bond strength between the denture teeth and the denture base resins.[2,9]

Debonding of denture teeth from denture bases is a major problem in the prosthodontic practice. Previous surveys reported that 26-33% of denture repairs are the result of debonded teeth which cause distress and increased cost for patients.[12,13] This may be related to the basic properties of the materials (teeth or denture base materials), processing factors (contaminations or curing cycle duration), and the available monomer during processing.[14,15] Attempts to increase the bond strength between acrylic resin teeth and denture base resins include grinding the glossy ground surface,[16,17] painting the ground surface of the teeth with monomer,[18,19,20] and cutting mechanical retention features in the ground surface of the teeth.[21,22,23]

Clancy and Boyer[24] compared the bond strengths of light- and heat-polymerized, and autopolymerized denture base resins to the denture teeth. In their study, the strongest bonding occurred between heat-polymerized resin and plastic teeth. The lowest bond strength was observed in light-polymerized resin. Schneider et al.[25] evaluated the bonding of two resin denture teeth to microwave and heat-processed denture bases. They obtained higher bond strength of denture teeth with the conventional heat-polymerized than the microwave-polymerized acrylic resins.

The purpose of this investigation was to evaluate the effect of surface treatments on shear bond strength of denture teeth to heat-polymerized and autopolymerized denture base resins.

The null hypotheses were: 1) there is no significant difference between the shear bond strength of the denture teeth to the two denture base resins and 2) surface treatments of the denture teeth have no effect on their bond strengths to the denture base resins.

MATERIALS AND METHODS

In this experimental in vitro study, 60 maxillary central incisor acrylic teeth (Ivoclar, Vivadent, Naturno, Italy) were divided into two groups which were processed with heat-polymerized acrylic resin (Meliodent, Heraeus-Kulzer GmbH, Wehrheim, Germany) (group M, n = 30) and autopolymerized acrylic resin (Futura Gen, Shutz-Dental, Rosbach, Germany) (group F, n = 30), respectively. Denture teeth were further subdivided into the following three subgroups with n = 10 per group: 1) M1, F1: untreated ground surface; 2) M2, F2: treated with monomer on ground surface; and 3) M3, F3: treated with airborne particle abrasion. The methyl methacrylate monomer was applied to the teeth bonding surfaces using a cotton bud for 180 s.[26,27] The airborne particle abrasion was done using 50 μm aluminum oxide particles for 30 s from a distance of 10 mm under 2 bar pressure.

The denture teeth were mounted on two sides of six triangular shaped wax models [Figure 1] and covered with silicone putty (Optosil, Heraeus-Kulzer, Leverkusen, Germany) to facilitate deflasking. Before processing, all teeth were treated according to their assigned groups.

Figure 1.

Denture teeth in triangular shaped wax model

Each model was flasked and the wax removed by boiling water. Six molds were made in this procedure for groups (M1, M2, M3, F1, F2, F3). Three molds were packed with Meliodent denture base resin and cured in a curing machine by an automatic curing device (EWL, type 5518, KaVo, Leutkirch, Germany) in accordance with the manufacturer's instructions.

The three other molds were injected with Futura Gen resin and processed using unipress machine (Shutz-Dental). The mixture was injected according to the manufacturer's instructions. After completion of the curing cycle and deflasking, the Meliodent and Futura Gen specimens were stored in distilled water at 37°C for 7 days.

Then, the shear bond strengths of the specimens were evaluated by universal testing machine (Instron Corp., Canton, MA, USA). Force was applied by a stainless steel pin, 1 mm in diameter, at an angle of 130° to the long axis of the tooth at a crosshead speed of 5 mm/min until fracture occurred. In a class I occlusion, this stimulates the average angle of contact between the maxillary and mandibular anterior teeth.[16]

The mean shear bond strength values were subjected to two-way analysis of variance (ANOVA) followed by Tukey's test. For all statistical analyses, the significance level was set at P < 0.05. The failure mode was classified as adhesive, cohesive, and mixed. No statistical analysis was performed on failure mode of the studied groups.

RESULTS

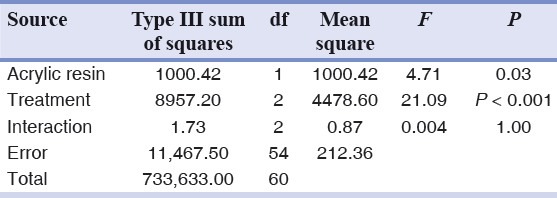

Table 1 presents the mean and standard deviation of the studied groups. Two-way ANOVA demonstrated that the shear bond strength was significantly affected by the type of acrylic resin (F = 4.71, P = 0.03) and the surface treatment (F = 21.09, P < 0.001), but the interaction between these two factors was not statistically significant (F = 0.004, P = 1.00) [Table 2].

Table 1.

Mean and standard deviation of the studied groups

Table 2.

Two-way ANOVA

Tukey's honestly significant difference (HSD) multiple comparison test revealed that the control groups had significantly lower bond strength than the treated groups (P < 0.001), but there was no significant difference between the bond strengths of groups treated by monomer or airborne particle abrasion (P = 0.29) [Table 1].

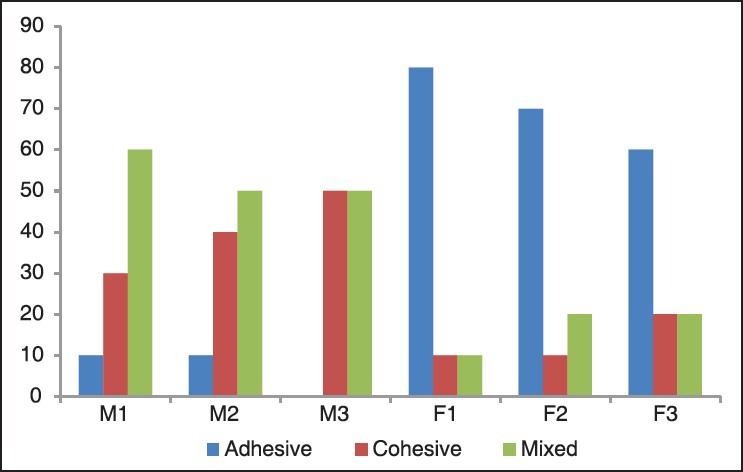

Failure mode was predominantly mixed in the Meliodent groups, whereas adhesive failure was reported for Futura Gen specimens [Figure 2].

Figure 2.

The failure mode of the studied groups

DISCUSSION

According to the results of the present study, there was significant difference between the shear bond strengths of the denture teeth to the two denture base resins and surface treatment of the denture teeth affected the bond strength significantly. Thus, the null hypotheses were rejected.

Some studies have reported that the bond strength of acrylic teeth to denture base resin is due to the diffusion and polymerization of monomer across the teeth base interface to form an interpenetrating polymer network. The efficiency of the attainment of such bond depends primarily on the rate at which the monomer diffuses from the base resin mixture. Higher diffusion rate of the monomer of a denture base polymer mixture into the acrylic resin polymer teeth is achieved with increasing polymerization temperature.[18,26,27,28]

Injection molding does not have any heat conduction as with the conventional water bath technique, thus the bond strength of the denture teeth in the Meliodent group was higher than that in the Futura Gen group.

Development of alternative materials such as Futura Gen (PMMA) is a breakthrough in denture base materials used for prosthetic dentistry. The advantages of Futura Gen include less shrinkage, outstanding denture adhesion characteristics, less processing time, and ease of polishing. The manufacturer claims that the quality of this material has been improved because of modification and binding ability which has resulted in higher bond strength. In addition, the lack of a monomer results in higher strength compared to that of heat-cured resin.[10,11] Production of Futura Gen is a success for overcoming the disadvantages of autopolymerized PMMA. According to the manufacturer, due to changing of the initiator system and replacement of changed copper and barbituric acid ions, instead of the tertiary amine, the amount of residual monomer in Futura Gen is similar to that of heat-polymerized resin.[10]

In similar studies on the bond strengths of denture teeth to different types of denture base resins, heat-polymerized acrylic resins showed the highest bonding values in comparison to autopolymerized or light-polymerized acrylic resins, which is in agreement with this study.[16,24,25] On the contrary, Vallitue[29] suggested that heat-polymerized PMMA did not adhere to the acrylic resin tooth better than the autopolymerizing PMMA.

The results of this study showed that the surface treatment with monomer is an effective method for improving the bond strength between denture teeth and denture base resins. Acrylic teeth treated with monomer failed predominantly in the cohesive and mixed modes in Meliodent groups, which is in agreement with the findings of previous studies on the benefits of chemical locks.[16,17] The monomer that was applied to the tooth surface before packing provided a solvent effect on the tooth surface which favored a more effective diffusion of the monomer of the denture base polymer across the tooth denture base interface and formed interpenetrating polymer networks.[30,31]

One of the technical factors that contribute to the bond strength of denture tooth to denture base resin is ridge lap surface contamination with wax or tinfoil substitute residues, which can be cleaned with monomer application before packing PMMA into the mold.[14,15]

The airborne particle abrasion of the denture teeth ground surface improved significantly the shear bond strength compared to untreated samples. Although these results are in agreement with some studies,[20,25] however, there are other studies which have shown that airborne particle abrasion or grinding decreases the bond strength of the treated teeth to denture bases.[1,17] Other studies have reported that teeth base roughening with cutting or abrasive rotary instruments or aluminum oxide air abrasion provides slightly higher bond strength values than those achieved without surface modification, or with cavity preparation or monomer etching.[21,22]

It has been shown that the use of mechanical retention is a primary means of securing the bond strength between acrylic resin teeth and the denture base resins. The airborne particle abrasion increases the surface area of the ridge lap portion of the denture teeth and, hence, improves their bond strengths to denture base resins.[29,30,31]

In this study, most of the Futura Gen specimens (F1 > F2 > F3) showed adhesive failure, but failure mode of the Meliodent specimens was predominantly mixed (adhesive and cohesive) (M1 > M2 and M3) [Figure 2].

Hatim and Hasan[26] demonstrated that the failure modes are mostly adhesive in all types of selected acrylic teeth with heat-polymerized resins and mixed for microwave acrylic denture bases. Fletcher-Stark et al.[28] showed adhesive debonding between the acrylic denture teeth and light-polymerized resin without a bonding agent. But when a bonding agent was used with light- and heat-polymerized denture base resins, mixed and cohesive failures were observed.

Mechanical fatigue, thermal cycling, and chewing simulation were not considered in the present study; therefore, the results of the present study should be interpreted with caution.

CONCLUSION

Within the limitations of this study, these conclusions can be drawn:

Treatment of the ridge lap surface of denture teeth by monomer or by airborne particle abrasion significantly improved their bond strengths to the denture base resins.

There was no significant difference between applying monomer or airborne particle abrasion in improvement of the bond strength.

The bond strength of the denture teeth to the studied denture base resins was significantly different.

The failure mode was predominantly adhesive with Futura Gen and mixed in Meliodent.

ACKNOWLEDGMENTS

The authors thank the Vice-chancellery of Shiraz University of Medical Sciences for supporting the research (Grant# 91-01-03-4960). They would also like to thank Dr. Sh. Hamedani (DDS, Msc) for his editorial assistance.

Footnotes

Source of Support: Nil

Conflict of Interest: None declared

REFERENCES

- 1.Huggett R, John G, Jagger RG, Bates JF. Strength of the acrylic denture base tooth bond. Br Dent J. 1982;153:187–90. doi: 10.1038/sj.bdj.4804883. [DOI] [PubMed] [Google Scholar]

- 2.Takahashi Y, Chai J, Takahashi T, Habu T. Bond strength of denture teeth to denture base resins. Int J Prosthodont. 2000;13:59–65. [PubMed] [Google Scholar]

- 3.Memon MS, Yunus N, Razak AA. Some mechanical properties of a highly cross-linked, microwave-polymerized, injection-molded denture base polymer. Int J Prosthodont. 2001;14:214–8. [PubMed] [Google Scholar]

- 4.Salim S, Sadamori S, Hamada T. The dimensional accuracy of rectangular acrylic resin specimens cured by three denture base processing methods. J Prosthet Dent. 1992;67:879–81. doi: 10.1016/0022-3913(92)90606-b. [DOI] [PubMed] [Google Scholar]

- 5.Bahrani F, Safari A, Vojdani M, Karampoor G. Comparison of hardness and surface roughness of two denture bases polymerized by different methods. World J Dent. 2012;3:171–5. [Google Scholar]

- 6.Nogueira SS, Ogle RE, Davis EL. Comparison of accuracy between compression- and injection-molded complete dentures. J Prosthet Dent. 1999;82:291–300. doi: 10.1016/s0022-3913(99)70083-1. [DOI] [PubMed] [Google Scholar]

- 7.Garfunkel E. Evaluation of dimensional changes in complete dentures processed by injection-pressing and the pack-and-press technique. J Prosthet Dent. 1983;50:757–61. doi: 10.1016/0022-3913(83)90085-9. [DOI] [PubMed] [Google Scholar]

- 8.Ono T, Kita S, Nokubi T. Dimensional accuracy of acrylic resin maxillary denture base polymerized by a new injection pressing method. Dent Mater J. 2004;23:348–52. doi: 10.4012/dmj.23.348. [DOI] [PubMed] [Google Scholar]

- 9.Ali IL, Yunus N, Abu-Hassan MI. Hardness, flexural strength, and flexural modulus comparisons of three differently cured denture base systems. J Prosthodont. 2008;17:545–9. doi: 10.1111/j.1532-849X.2008.00357.x. [DOI] [PubMed] [Google Scholar]

- 10.Drees S. Polymers used in dental prostheses. [Last cited on 2008 Mar]. Available from: http://www.Schuetzdental.de/FG- Material-Safety-Data- Sheet.333.0.html .

- 11.Powers JM, Sakaguchi RL. 12th ed. Philadelphia: Mosby Elsevier; 2006. Craig's restorative dental materials; pp. 513–43. [Google Scholar]

- 12.Vallittu PK, Lassila VP, Lappalainen R. Evaluation of damage to removable dentures in two cities in Finland. Acta Odontol Scand. 1993;51:363–9. doi: 10.3109/00016359309040587. [DOI] [PubMed] [Google Scholar]

- 13.Darbar UR, Huggett R, Harrison A. Denture fracture-a survey. Br Dent J. 1994;7(176):342–5. doi: 10.1038/sj.bdj.4808449. [DOI] [PubMed] [Google Scholar]

- 14.Kawara M, Carter JM, Ogle RE, Johnson RR. Bonding of plastic teeth to denture base resins. J Prosthet Dent. 1991;66:566–71. doi: 10.1016/0022-3913(91)90525-2. [DOI] [PubMed] [Google Scholar]

- 15.Caswell CW, Norling BK. Comparative study of the bond strengths of three abrasion-resistant plastic denture teeth bonded to a cross-linked and a grafted, cross-linked denture base material. J Prosthet Dent. 1986;55:701–8. doi: 10.1016/0022-3913(86)90447-6. [DOI] [PubMed] [Google Scholar]

- 16.Sorensen SE, Fjeldstad E. Bonding of plastic teeth to acrylic denture base material. J Dent Res. 1961;40:776–9. [Google Scholar]

- 17.Morrow RM, Matvias FM, Windeler AS, Fuchs RJ. Bonding of plastic teeth to two heat-curing denture base resins. J Prosthet Dent. 1978;39:565–8. doi: 10.1016/s0022-3913(78)80195-4. [DOI] [PubMed] [Google Scholar]

- 18.Büyükyilmaz S, Ruyter IE. The effects of polymerization temperature on the acrylic resin denture base-tooth bond. Int J Prosthodont. 1997;10:49–54. [PubMed] [Google Scholar]

- 19.Geerts GA, Jooste CH. A comparison of the bond strengths of microwave- and water bath-cured denture material. J Prosthet Dent. 1993;70:406–9. doi: 10.1016/0022-3913(93)90075-y. [DOI] [PubMed] [Google Scholar]

- 20.Mosharraf R, Pooya E, Maleky V. The evaluation of an Iranian denture tooth (Marjan) bond strength with denture base resins in four different preparing methods. J Islamic Dent Asso Iran. 2001;37:49–59. [Google Scholar]

- 21.Bragaglia LE, Prates LH, Calvo MC. The role of surface treatments on the bond between acrylic denture base and teeth. Braz Dent J. 2009;20:156–61. doi: 10.1590/s0103-64402009000200012. [DOI] [PubMed] [Google Scholar]

- 22.Patil SB, Naveen BH, Patil NP. Bonding acrylic teeth to acrylic resin denture bases: A review. Gerodontology. 2006;23:131–9. doi: 10.1111/j.1741-2358.2006.00129.x. [DOI] [PubMed] [Google Scholar]

- 23.Mosharraf R, Mechanic N. Comparison of the effects of four pre-bonding preparation methods on the bond strength between a multilithic tooth and denture base resin. Dent Res J. 2007;4:102–5. [Google Scholar]

- 24.Clancy JM, Boyer DB. Comparative bond strengths of light-cured, heat-cured and autopolymerizing denture resins to denture teeth. J Prosthet Dent. 1989;61:457–62. doi: 10.1016/0022-3913(89)90014-0. [DOI] [PubMed] [Google Scholar]

- 25.Schneider RL, Curtis ER, Clancy JM. Tensile bond strength of acrylic resin denture teeth to a microwave- or heat-processed denture base. J Prosthet Dent. 2002;88:145–50. doi: 10.1067/mpr.2002.127898. [DOI] [PubMed] [Google Scholar]

- 26.Hatim NA, Hasan RH. Bond strength of different artificial tooth manufacturing to microwave cured acrylic denture base. Al Rafidain Dent J. 2010;10:8–16. [Google Scholar]

- 27.Vojdani M, Rezaei S, Zareeian L. Effect of chemical surface treatments and repair material on transverse strength of repaired acrylic denture resin. Indian J Dent Res. 2008;19:2–5. doi: 10.4103/0970-9290.38923. [DOI] [PubMed] [Google Scholar]

- 28.Fletcher-Stark ML, Chung KH, Rubenstein JE, Raigrodski AJ, Mancl LA. Shear bond strength of denture teeth to heat- and light-polymerized denture base resin. J Prosthodont. 2011;20:52–9. doi: 10.1111/j.1532-849X.2010.00639.x. [DOI] [PubMed] [Google Scholar]

- 29.Vallittu PK. Bonding of resin teeth to the polymethyl methacrylate denture base material. Acta Odontol Scand. 1995;53:99–104. doi: 10.3109/00016359509005954. [DOI] [PubMed] [Google Scholar]

- 30.Civjan S, Huget EF, de Simon LB. Modifications of the fluid resin technique. J Am Dent Assoc. 1972;85:109–12. doi: 10.14219/jada.archive.1972.0269. [DOI] [PubMed] [Google Scholar]

- 31.Can G, Kansu G. An evaluation of the bond strength of plastic teeth to acrylic denture base material. Ankara Univ Hekim Fak Derg. 1990;17:97–101. [PubMed] [Google Scholar]