Abstract

Background: The aim of this study was to evaluate and compare the porosities in the mandibular acrylic denture bases processed by heat and microwave polymerization techniques, using two different brands of commercially available denture base resins.

Materials & Methods: Two brands of heat activated denture base resins, DPI plain and Acralyn H cross linked denture base resins designed for conventional water bath polymerization, were used to prepare 48 test specimens of mandibular acrylic denture bases. The test specimens were processed using one cycle of conventional water bath polymerization and one cycle of microwave polymerization. The absolute density of acrylic resin was used to calculate the percent mean porosity of each mandibular acrylic denture base by use of various equations.

Results: Anova analysis reveals highly significant difference between mean percent porosity values of whole denture bases of all groups. Statistics reveals that heat polymerized groups have lesser mean percent porosity values than microwave polymerized groups. It also reveals that denture bases processed with Acralyn H cross linked denture base resin have lesser mean percent porosity values than denture bases processed with DPI Plain denture base resin.

Conclusion: Specimens processed with Acralyn H cross linked denture base resin by conventional heat polymerization technique has the least mean percent porosity and specimens processed with DPI Plain denture base resin by microwave polymerization technique has the highest mean percent porosity.

How to cite the article: Kasina SP, Ajaz T, Attili S, Surapaneni H, Cherukuri M, Srinath HP. To evaluate and compare the porosities in the acrylic mandibular denture bases processed by two different polymerization techniques, using two different brands of commercially available denture base resins - an in vitro study. J Int Oral Health 2014;6(1):72-7.

Key Words: : Denture base, laboratory research, PMMA, polymerization, porosity, residual monomer

Introduction

Porosity in denture base resins remains to be a long standing problem and nearly 11% porosity was observed, based on various processing conditions. 1 Porosity in acrylic denture bases weakens acrylic resin prosthesis due to accumulation of internal stresses. Porosity can also lead to distortion and warpage of acrylic denture bases. 2

There are two major causes of porosity: Volatilization of the monomer, termed gaseous porosity, and polymerization shrinkage, termed contraction porosity. 3 Other causes of porosity include inadequate pressure, air inclusion during mixing and pouring procedures, improper mixing of powder and liquid components, 4 and residual monomer. 5

A porous denture is vulnerable to staining, calculus deposition and adherent substances. So for a denture to be hygienically acceptable it should be nonporous. 6 Porous denture is an ideal incubator for species such as Candida albicans.

Porosity in acrylic resins is of multi factorial origin. It depends partly on the type of material and partly on the method of polymerization used for processing of acrylic denture bases. Earlier studies confirmed that porosity occurs in specimens processed by short polymerization cycles. But no one study on acrylic resin porosity has considered the geometries of denture base and various combinations of different type of materials and polymerization methods. So this invitro study aims at evaluation and comparison of porosities in the acrylic mandibular denture bases processed by two different

polymerization techniques using two different brands of commercially available denture base resins.

Materials and Methods

The experimental design included four groups with 12 specimens per group. Two brands of heat activated

denture base resins, DPI plain and Acralyn H cross linked denture base resins designed for conventional water bath polymerization, were used to prepare 48 test specimens of mandibular acrylic denture bases. The test specimens were processed using one cycle of conventional water bath polymerization and one cycle of microwave polymerization (Table 1). A total of 48 mandibular edentulous master

Table 1: Type of material, method of polymerization and polymerization cycle used.

| Group | Material | Brand | Method | Polymerization Cycle |

| 1 | Heat cure denture base resin | DPI Plain | Heat | Water bath polymerization – 74oC for 2 hours and 100oC for 1 hour6 |

| 2 | Heat cure denture base resin | Acralyn HCrosslinked | Heat | Water bath polymerization – 74oC for 2 hours and 100oC for 1 hour6 |

| 3 | Heat cure denture base resin | DPI Plain | Microwave | Microwave polymerization – 13 minutes at 85 to 100 Watts and 90 seconds at 500 Watts36,45 |

| 4 | Heat cure denture base resin | Acralyn HCrosslinked | Microwave | Microwave polymerization – 13 minutes at 85 to 100 Watts and 90 seconds at 500 Watts36,45 |

casts were obtained using standard mandibular edentulous silicone mold (Figure 1 & 2 ). The master specimen, mandibular edentulous denture base was fabricated with heat cure acrylic resin with standard dimensions ( Figure 3 ). This master specimen was used as template in fabrication of all the 48 test specimens of this study. The master specimen is sealed to the master cast with modeling wax and master specimen was sprayed with lubricating spray ( Figure 4 ). The master specimen along with master cast was flasked in a fiber glass reinforced plastic flask for microwave curing and in brass flask for conventional water bath curing. Three pour technique was used for flasking for

Figure 1: Standard Mandibular Edentulous Silicone Mold.

Figure 2: Master Cast obtained from Silicone Mold.

Figure 3: Fabrication of Wax pattern over Master Cast.

Figure 4: Master Specimen over Master Cast.

in the ratio of 1:1 was used for all the three pours during the flasking procedures. Once the plaster sets, lower and upper member of flasks were separated and mould space was created for fabrication o test specimens (Figure 5 & 6 ). All the test specimens were numbered and subjected to porosity analysis ( Figure 7 ).

Figure 5: Denture Flask after trial closure for Water Bath Curing.

Figure 6: Denture Flask after trial closure for Microwave Curing.

Figure 7: Heat Cured Acralyn H Specimens.

Porosity analysis:

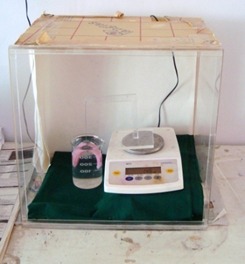

Digital analytical balance was used to weigh each specimen in air and then in water ( Figure 8 ). The absolute density of acrylic resin (1.198 ± 0.01 gm/cc) was used to calculate the percent mean porosity by use of various equations. 9

Figure 8: Weighing Whole Denture Base in Water.

Wa = g (dr - da ) (vsp - vip) --- 1

Ww = g (dr - dw ) (vsp - vip) + g (da - dw ) vip --- 2

% of porosity = vip / vsp × 100 --- 3

Where Wa = specimen weight in air

Ww = specimen weight in water

g = gravitational constant

dr = density of acrylic resin

da = density of the air

dw = density of water

Vsp = specimen volume

Vip = internal porosity volume

In the first equation, specimen volume minus volume of internal porosity was determined using the following known values: d r = 1.198 6 ±0.01 g/ml, d a = 1.23 Kg/m 3 , d w = 1000 Kg/m 3 and g = 9.8066 m/sec 2 . Having solved the first equation for specimen volume minus volume of internal porosity, this value was used in the second equation, along with W w measured, to determine the volume of internal porosity. With known values for

specimen volume minus volume of internal porosity, the specimen volume was calculated. As the specimen volume and internal porosity volume were known, total percent porosity was calculated using the third equation.

Results

Descriptive analysis of mean percent porosity of all groups reveals that heat polymerized groups have lesser mean percent porosity values than microwave polymerized groups. It also reveals that denture bases processed with Acralyn H cross linked denture base resin have lesser mean percent porosity values than denture bases processed with DPI Plain deture base resin (Table-2).

Table 2: Descriptive Analysis of mean percent porosity values of whole denture bases of all groups.

| N | Mean | Std. Deviation | Minimum | Maximum | |

| 1. DPI PLAIN- HEAT | 12 | .976983 | .0013141 | .9754 | .9793 |

| 2. ACRALYN H CROSS LINKED- HEAT | 12 | .816158 | .0015453 | .8138 | .8188 |

| 3. DPI-PLAIN- MICROWAVE | 12 | 3.756642 | .0059996 | 3.7534 | 3.7754 |

| 4. ACRALYN H CROSS LINKED- MICROWAVE | 12 | 2.818108 | .0016273 | 2.8153 | 2.8204 |

| Total | 48 | 2.091973 | 1.2550499 | .8138 | 3.7754 |

Anova analysis reveals highly significant difference between mean percent porosity values of whole deture bases of all groups, where F value of 2308515.245 was found significant at .000 level (Table-3).

Table 3: ANOVA Analysis of mean percent porosity values of whole denture bases of all groups

| Sum of Squares | df | Mean Square | F | Sig. | |

| Between Groups | 74.032 | 3 | 24.677 | 2308515.245 | .000 |

| Within Groups | .000 | 44 | .000 | ||

| Total | 74.032 | 47 |

Scheffe’s Analysis for whole denture bases of all groups reveals that group 2 specimens processed with Acralyn H cross linked denture base resin by conventional heat polymerization technique has the least mean percent porosity and group 3 specimens processed with DPI Plain deture base resin by microwave polymerization technique has the highest mean percent porosity (Table-4).

Table 4: Scheffe’s Analysis of mean percent porosity values of whole denture bases of all groups

| Groups | N | Subset for alpha =.05 | |||

| 1 | 2 | 3 | 4 | ||

| 2. ACRALYN H CROSS LINKED-HEAT | 12 | .816158 | |||

| 1. DPI PLAIN- HEAT | 12 | .976983 | |||

| 4. ACRALYN H CROSS LINKED- MICROWAVE | 12 | 2.818108 | |||

| 3. DPI PLAIN- MICROWAVE | 12 | 3.756642 | |||

| Uses Harmonic Mean Sample Size =12.000. | |||||

Discussion

Results of the present study showed that denture bases processed with Acralyn H cross linked denture base resin by both heat and microwave polymerization have lesser mean percent porosity than denture bases processed with DPI Plain denture base resin. So it appears that material formulation may have more of an effect on porosity irrespective of the method of polymerization employed. This finding is consistent with other research that demonstrated that porosity depends not only on the method of polymerization, but also on the type of acrylic resin used for the study. 1 , 2 , 7 - 10

The cross linking agent present in the Acralyn H cross linked denture base resin may be the contributing factor in reducing the percent mean porosity of the denture bases. A cross linking agent is incorporated into the liquid component to increase the resistance of denture base to deformation. Glycol dimethacrylate commonly is used as cross linking agent in poly (methyl methacrylate) denture base resins. Glycol dimethacrylate is chemically and structurally similar to methyl methacrylate and therefore may be incorporated into growing polymer chains. Although methyl methacrylate possesses one double bond per molecule, glycol dimethacrylate possesses two double bonds per molecule. As a result, an individual molecule of glycol dimethacrylate acts as a bridge that unites two polymer chains. If sufficient glycol dimethacrylate is included in the mixture, several interconnections may be formed resulting in netlike structure which provides increased resistance to deformation. 4 Poly (methyl methacrylate) has a high vapor pressure and processing temperatures above 100.8 o c would result in vaporization of monomer leading to porosity in the processed acrylic resin

denture bases. Bafile et al reported that the monomer formulated for microwave polymerization could contain dimethacrylates which are either triethylene glycol or tetraethylene glycol having a reactive group on each end. Dimethacrylates have low vapor pressures, and hence allowed processing even at elevated temperatures of 100.8 0 C to 150.8 0 C without danger of producing porosity. 9 So, less porosity shown by Acralyn H cross linked denture base resin used in the present study can be attributed to the incorporation of dimethacrylates as cross linking agent in its liquid component. Floyd A. Peyton, analysed the influence of temperature on four different products which include Crystolex 102, Densene 33, Lang, and Lucitone denture base resins and found that the intensity of porosity varied among all these products at different temperatures with all other factors being held constant. 11 This is evidence to indicate that all products are not the same in their behavior during processing.

This study also showed that the whole acrylic resin denture bases processed by microwave polymerization have greater mean percent porosity than the whole acrylic resin denture bases processed by conventional heat polymerization. This can be explained on the basis that microwaves act directly on the MMA monomers inside the resin dough, and rises the temperature very fast. According to De Clerck’s study microwaves easily surpass the boiling temperature of monomer resulting in vaporization of monomer and porosity in the resin. 12 De Clerck’s observations were supported by other studies conducted to measure the temperature of acrylic dough processed under microwave energy. Kimura et al measured the temperature of approximately 130 0 C in both the dough and gypsum mold, during the processing of a heat curing material at 500 W power in microwave oven. 8 Suzuki using a similar method to process 2mm thick specimen of a new microwave curing material, recorded a maximum temperature of 125 0 C after 3 minutes irradiation. He considered that the relatively high temperature involved was due to generation of heat within the dough. Al doori et al have shown temperature reading for every 1-2 min, recording peak temperature of upto 13 0 0 C after 12-18 min at 70W power. 13 The second reason for denture bases processed by microwave polymerization having greater mean percent porosity than the denture bases processed by conventional heat

polymerization could be because of inadequate pressure applied to the microwave curable flask during curing. According to various studies the external pressure applied on the trial closures range from 1500-4500 psi, 14 but the Packing pressure cannot exceed 1200 psi without danger of breaking the microwave curable plastic flask. 15 W.F.E.Yau et al conducted a study to correlate the effect of packing pressure on porosity and concluded that adequate clamp pressure prevents gaseous porosity irrespective of polymerization cycle used. 14 T.E. Donovan et al also found that the specimens polymerized under pressure exhibited almost no porosity at the macroscopic level, while those cured at ambient pressures demonstrated extensive porosity. 16 These results are also in agreement with findings of Bafile et al who investigated the porosity of a conventional heat-activated denture base resin polymerized by both microwave energy and a conventional heat method. These authors confirmed that the groups of microwave processed specimens showed a significantly higher mean porosity. No significant differences were found in mean porosity between the group processed by the conventional heat method and the groups of microwave-processed specimens that used a monomer formulated for microwave polymerization. 9

Conclusion

specimens processed with Acralyn H cross linked denture base resin by conventional heat polymerization technique has the least mean percent porosity and specimens processed with DPI Plain deture base resin by microwave polymerization technique has the highest mean percent porosity.

Clinical Significance

Porosity in acrylic resin is a complex phenomenon and appears to depend on various factors. Porosity in acrylic denture bases weakens acrylic resin prosthesis due to accumulation of internal stresses. Porosity can also lead to distortion and warpage of acrylic denture bases. According to this study porosity appears to depend not only on the polymerization method but also on the type of acrylic resin

used depending on its formulation.

Footnotes

Source of Support: Nil

Conflict of Interest: None

Contributor Information

Sitaram Prasad Kasina, Department of Prosthodontics, St. Joseph Dental College, Duggirala, Eluru, Andhra Pradesh, India.

Tarannum Ajaz, Department of Prsothodontics, Purvanchal Institute of Dental Sciences, Gida, Gorakhpur, Uttar Pradesh, India.

Sirisha Attili, Department of Prosthodontics, St. Joseph Dental College, Duggirala, Eluru, Andhra Pradesh, India.

Hemchand Surapaneni, Department of Prosthodontics, Dr Sudha & Nageswara Rao Siddhartha Institute of Dental Sciences, Chinaoutpalli, Gannavaram, Andhra Pradesh, India.

Muralikrishna Cherukuri, Department of Prosthodontics, St. Joseph Dental College, Duggirala, Eluru, Andhra Pradesh, India.

H P Srinath, Department of Prosthodontics, St Joseph Dental College, Duggirala, Eluru, Andhra Pradesh, India.

References

- 1.JC Keller, EP Lautenschlager. Porosity reduction and its associated effect on the diametral tensile strength of activated acrylic resins. J Prosthet Dent. 1985;53:374–379. doi: 10.1016/0022-3913(85)90516-5. [DOI] [PubMed] [Google Scholar]

- 2.S Yannikakis, A Zissis, G Polyzois, A Adreopoulos. Evaluation of porosity in microwave processed acrylic resin using a photographic method. J Prosthet Dent. 2002;87:613–619. doi: 10.1067/mpr.2002.124490. [DOI] [PubMed] [Google Scholar]

- 3.RV Noort. Introduction to dental materials, 1st ed. London:Mosby. 1994 [Google Scholar]

- 4.KJ Anusavice. Phillip’s Science of dental materials, 11th ed. St. Louis:Elsevier. 2004 [Google Scholar]

- 5.DR Beech. Molecular weight distribution of denture base acrylic. J Dent. 1975;3:19–24. doi: 10.1016/0300-5712(75)90019-6. [DOI] [PubMed] [Google Scholar]

- 6.materials Final report of the workshop on clinical requirements of ideal denture base. The Academy of Denture Prosthetics. J Prosthet Dent. 1968;20:101–105. doi: 10.1016/0022-3913(68)90132-7. [DOI] [PubMed] [Google Scholar]

- 7.MA Compagnoni, DB Barbosa, RF Souza, AC Pero. The effect of polymerization cycles on porosity of microwave processed denture base resin. J Prosthet Dent. 2004;91:281–285. doi: 10.1016/j.prosdent.2004.01.006. [DOI] [PubMed] [Google Scholar]

- 8.H Kimura, F Teracka, H Ohnishi, T Saito, M Yato. Application of microwave for dental technique (part I).Dough forming and curing of acrylic resin. J Osaka Univ Dent Sch. 1983;23:43–49. [PubMed] [Google Scholar]

- 9.M Bafile, N Gerald, Graser, ML Myers, EK Li. Porosity of denture resin cured by microwave energy. J Prosthet Dent. 1991;66:269–274. doi: 10.1016/s0022-3913(05)80061-7. [DOI] [PubMed] [Google Scholar]

- 10.JF Wolfaardt, CP Jones, P Fatti. The occurrence of porosity in a heat cured poly (methyl methacrylate) denture base resin. J Prosthet Dent. 1986;55:393–400. doi: 10.1016/0022-3913(86)90128-9. [DOI] [PubMed] [Google Scholar]

- 11.FA Peyton. Packing and processing denture base resins. J Am Dent Assoc. 1950;40:520–527. doi: 10.14219/jada.archive.1950.0089. [DOI] [PubMed] [Google Scholar]

- 12.JP Declerck. Microwave polymerization of acrylic resins used in dental prostheses. J Prosthet Dent. 1987;57:650–658. doi: 10.1016/0022-3913(87)90353-2. [DOI] [PubMed] [Google Scholar]

- 13.DA Doori, R Huggett, JF Bates, SC Brooks. A comparison of denture base acrylic resins polymerised by microwave irradiation and by conventional water bath curing systems. Dent Mater. 1988;4:25–32. doi: 10.1016/s0109-5641(88)80084-8. [DOI] [PubMed] [Google Scholar]

- 14.WF Yau, YY Cheng, RK Clark, TW Chow. Pressure and temperature changes in heat cured acrylic resin during processing. Dent Mater. 2002;18:622–629. doi: 10.1016/s0109-5641(01)00092-6. [DOI] [PubMed] [Google Scholar]

- 15.B Levin, JL Sanders, PV Reitz. The use of microwave energy for processing acrylic resins. J Prosthet Dent. 1989;61:381–383. doi: 10.1016/0022-3913(89)90150-9. [DOI] [PubMed] [Google Scholar]

- 16.TE Donovan, RG Hurst, WV Campagni. Physical properties of acrylic resin polymerized by four different techniques. J Prosthet Dent. 1985;54:522–524. doi: 10.1016/0022-3913(85)90425-1. [DOI] [PubMed] [Google Scholar]