Abstract

Background: As the effects of demographic transition are realised around the world, many in-dustrial societies are facing the effects of a baby boom generation, increased life expectancies, decreased birth rates and recent changes to retirement legislation with the result that older work¬ers are set to comprise a greater proportion of the labour force.

Methods: This paper reviews the evidence for the physical and cognitive factors that characterise an ageing workforce in manufacturing. From an ergonomics and human factors (E/HF) pers¬pective, characteristics of manufacturing tasks and the effects of ageing provide an insight into how the industry will have to adapt to support the user needs of the older worker in the future. The approach taken is drawn from Ilmarinen’s framework of age, experience, and work performance, from which specific E/HF issues are explored.

Results: There would appear to potential to support physical decline in older workers within manufacturing jobs through increased mechanisation and automation; however, those factors associated with cognitive human factors are less clear. Increased mechanisation and automation can place greater loads and demands on the older worker where cognitive decline is more subtle and varied between workers.

Conclusion: Using historical and contemporary findings and the relationship between age, experience, and work performance is redrawn to include both cognitive skills and physical attributes to provide recommendations for future job design and worker needs.

Keywords: Older workers, Ageing population, Ergonomics, Human factors, Manufacturing

Introduction

Manufacturing industries operate in a highly competitive environment and in the 21st century businesses are restructuring and re-engineering themselves in response to key demands and challenges. One such development is an ageing workforce that will have a direct impact on the manufacturing function of many countries over the next 50 years [1]. As a result, and following the recent global recession, companies have to be both competitive in the marketplace as well as adopt increasingly resilient manufacturing strategies to cope in volatile markets [2].

Over the last 150 years a combination of reduced infant mortality and increased life expectancy has led to a redistribution of demographics in the UK and across the developed world [3]. Population projections suggest that following the post-war baby boom of the 20th century the older population sector will continue to expand during the first quarter of the 21st century from 400 million to 1.3 billion by 2050 [4]. With these figures in mind, the mean age of workforces is expected to increase over the next 40 years. Older people represent one of the most heterogeneous groups in any society [5]. With nearly one-fifth of the population of the industrialized world soon to be beyond a traditional retirement age, businesses need to re-appraise their attitudes towards older workers [6]. From this, questions regarding the relationship of age and ability, productivity, quality of work, or health risks and safety of ageing employees represent fundamental issues that need to be explored and addressed [7].

Demographic transition

When the notion of ‘demographic transition’ was first put forward, it focussed on Europe but was predicted to spread throughout the world [8]. By comparing population data from the 1950s to the present day against projections for 2050, the effects of demographic transition can be seen to spread across Europe, United States and Asia as a process of ageing [9]. With many societies now beginning to recognise issues associated with an ageing workforce, three key causes of demographic transition are [1]:

the baby boom generation

increasing life expectancy

decreasing birth rates

The period between 1946 and 1964 witnessed a major increase in the worldwide birth rate, giving rise to the baby boom generation. With 76 million people born during this period, the size and age composition of the workforce was then determined for the following 30 years [10]. After the Second World War there was a need to open workplaces and traditional skilled male roles to large numbers of predominantly younger, unemployed male and female workers to help rebuild industries affected by the war effort. During the 1960s social security and private pension policies were designed to encourage retirement of older workers who, along with automation of manufacturing processes, were then replaced by younger less-skilled workers [11]. The ageing workforce has also been influenced by increasing life expectancies with technological and medical advances safeguarding people from dying at younger ages [8]. With a prediction that the number of workers over 45 years would increase by 7% (from 33% to 40%) between 1998 and 2008, those aged 25 to 44 years were also expected to decrease by 7% (from 51% to 44%) during the same period [10]. With birth rates declining, there has been a growing tendency for smaller family sizes such that in many countries populations have decreased whilst average ages have increased [12]. As a result, there is now a baby bust generation with more workers over 50 years of age than have been previously recorded [13].

The result of this shrinking labour supply is that there are fewer younger workers and an increasing number of older workers in the workplace who not only need to work to manufacture products but also to support the increasing retirement base of people a generation older than them [14]. These effects will be felt by different countries and their respective workforces across different time scales according to their different stages of demographic transition. This is important in the manufacturing environment as companies are increasingly required to compete in the global marketplace, but are not necessarily at the same point of global demographic transition. Strategies will focus on emerging markets together with best cost manufacture in low cost economies, customers, partners and suppliers increasingly sought abroad in order to remain competitive [2].

Workforce demographics in manufacturing

In addition to the phenomenon of demographic transition across different geographic regions, there is a clear transition across the manufacturing industry. In the UK, the spread of older employees appears to be evenly distributed across industrial sectors [15]. A review of the 10 occupations most affected by retirements in the manufacturing industry [10] illustrates that the percentage of workers over 45 years old and leaving the industry ranges from 53.1% to 74.2% with older workers typically contributing 35% to 57% of the total workforce (Table 1).

Table 1. Manufacturing occupations with a greater-than-average number of workers ages 45 years and older, 1998-2008 (adapted from: Dohm, 2000).

| Occupation | Total employeed N:1998 | % of employeed, 45 & older 1998 | Retiree replacement needs 1998-2008 | % of workers 45 & older leaving occcupation 1998-2008 |

| Operations and systems researchers and analysts | 212 | 37 | 54 | 74.2 |

| Supervisiors, mechanics & repairers | 259 | 42 | 69 | 68.3 |

| Industrial machine repairers | 563 | 37 | 125 | 60.4 |

| Technical writers | 73 | 37 | 12 | 59.0 |

| Winding & twisting machine operators | 53 | 42 | 12 | 55.2 |

| Crane & tower operators | 67 | 49 | 16 | 54.2 |

| Machinists | 532 | 35 | 89 | 53.8 |

| Electronic and electrical equipment assemblers | 343 | 40 | 58 | 54.7 |

| Millwrights | 83 | 57 | 22 | 53.3 |

| Upholsterers | 71 | 47 | 12 | 53.1 |

In the US, different industries are under threat where older experienced workers are approaching retirement with too few specialist younger professionals to replace them [16]. Many industries from utilities and healthcare, to insurance, financial services and public education consist of skilled workers who will soon be eligible for retirement. The situation is compounded by poor uptake and reduced recruitment into these professions in response to budget cuts, downsizing, artificial intelligence and automation as well as the increasing European retirement age.

This situation is not just restricted to white-collar professions. Those occupations already experiencing talent shortages as older workers retire are blue collar occupations, heavily reliant on skilled trades such construction, heavy manufacturing, field utility and energy personnel, skilled glass workers, mine operators, carpenters, electricians, and maintenance personnel [16]. Additional reasons contributing to the decreased numbers of new labour entrants into blue-collar professions, include the encouragement of current workers seeking a more formal education for their own children and some traditional occupations (e.g. tool and die making) being regarded as less attractive to younger workers despite an availability of jobs in these areas [10].

Further external factors that may influence demographic transition include those associated with the economy. A particular example is linked to the economic slowdown in the early 1990s. Having cut recruitment and by releasing younger workers through redundancies, newly unemployed individuals were left to compete for limited opportunities. A direct result of this has been a shortage of workers in their early thirties to take over the work of retiring specialists [6]. More recently with the latest economic crisis, graduates are remaining unemployed for longer after leaving higher education, re-employment rates are lower, and part-time employment is more common

among full-time job losers so that the resource of a full time workforce has been further compromised [17].

Given the effects of demographic transition on the manufacturing industry, it is interesting that industry managers appear to ignore the potential problems of an ageing workforce. An empirical analysis of manufacturing manager perceptions of older workers illustrated that even when companies have strategies and initiatives to address demographic change and the long-term effects are apparent, managers did not consider it an issue that required immediate attention [1]. As workforces are losing their ability to rejuvenate, demographic changes (and to an extent economic policies linked to education and retirement) may force older workers to postpone retirement and the predictions of an increasingly older labour force across many industries around the world is becoming a reality [12,18]. With managers seemingly unaware of the urgency associated with the situation [13] there is a need to raise both practitioner and researcher awareness regarding demographic transition and its effect on the labour force.

Methods

This paper reviews the evidence for the physical and cognitive human factors that are critical as we have an ageing workforce in manufacturing. The fundamental physical and cognitive characteristics of manufacturing tasks and the effects of ageing provide an insight into how the manufacturing industry will have to adapt to support the user needs of the older worker in the future. The approach taken is drawn from ergonomics/human factors (E/HF). This discipline and profession is both a science and a craft, contributing knowledge to plan for and design new equipment and systems, and also techniques and approaches to undertake user-centred (re)design of hardware, software and socio-technical systems. Thus E/HF is centrally concerned both with the impacts on people of work systems (their health, safety, satisfaction, growth, etc) and also with the impacts of people via their performance and that of the human-machine system (their reliability, effectiveness, quality etc).

E/HF takes a user-centred approach to understand user needs, user requirements, and user limitations. Various work analysis techniques (e.g. task analysis, cognitive task analysis, cognitive work analysis etc) allow E/HF experts to describe the interactions between users, technologies and their work environments at a level of detail that can be used to inform job design solutions [19,20]. This emphasis on user-centred principles is formalised in the publication of International Standard ISO:13407, Human-Centred Design Processes for Interactive Systems which outlines four fundamental factors associated with user-centred design: user involvement and task requirements; function allocation within a socio-technical system; iterative design processes; and multidisciplinary input.

Results

Human factors in the manufacturing industry

In a position paper requested by the International Ergonomics Association, design for the ageing population has recently been identified as one of the key challenges facing E/HF for the next 20 years [21]. Amongst the sectors most relevant to this concern is that of manufacturing, in all its forms. Manufacturing is a particularly interesting focus for work systems design to cope with an ageing workforce as we are dealing with 50 to 60/70 year old workers (in Europe at least) as against 60 to 80 year olds in transport systems and 70 to 90 years olds in the home, health systems and community etc. Thus there is more research evidence available on which to draw, simply because it is easier (practically and ethically) to have obtained scientific evidence regarding capabilities for the slightly younger group. Also, for example, although modern manufacturing plants in the German auto industry are much different in technology, environment and work systems from 30 years ago, the jobs and machines in a Spanish small part fabrication plant or an independent UK foundry may look very similar to those of the 1930s. Moreover, across Asia, Africa and South America there are very many small manufacturers using traditional systems and machines, alongside the gleaming modern show plants of China and South Korea. Thus, much of the literature on people’s capabilities and limitations relevant to manufacturing work of three decades ago is still relevant today.

Manufacturing industry is characterised by the use of human resources to process raw materials into finished products, through the use of machines and tools [22], even in light of the increasing use of automation, robots, supervisory control systems and virtual tools. Manufacturing jobs consist of a series of tasks with motor, perceptual and human information processing demands as well as increasingly needing conceptual and discretionary skills [23].

Studies and reviews investigating normative decline in physiological fitness, cognitive ability and health parameters associated with chronological age, illustrate a broad consensus in the scientific community that performance on many measures generally declines as age increases [24]. A traditional view of the relationship between age and performance is based on a ‘decremental’ model of human performance that occurs during the second half of adulthood and proposes that after reaching a peak of fitness and ability, performance diminishes [25]. Whilst this model has high face validity and has been adopted by decision makers, it has been argued that it does not apply to real working environments [1]. The model is derived from laboratory experiments and studies in real settings have not always illustrated similar decremental effects in line with increased age. There is evidence that other factors beyond age influence the performance of a worker, with performance scores significantly varying within age as opposed to across age cohorts [26]. It has also been argued that older technology users often bring with them a wealth of experience, prior training and enhanced mental models of processes that may support them in various tasks [24]. In a humourous, non-scientific book, [27] exemplifies this, drawing upon a number of authors to suggest that “… the markets are in reality 22-27 year old business school graduates … reporting to bosses perhaps five years senior …they generally possess the mentality … of secondary school students (quoting Kevin O’Rourke) … [that] … researchers have now shown that brain cells do not disappear in large numbers with the normal ageing process … we are slower than we used to be in learning new skills … but experience allows us to apply that learning to better effect … [and in] vocabulary, verbal memory, spatial orientation and inductive reasoning people performed best between 40 and 65 … and outscored their performance in their own 20s” (quoting Barbara Strauch).

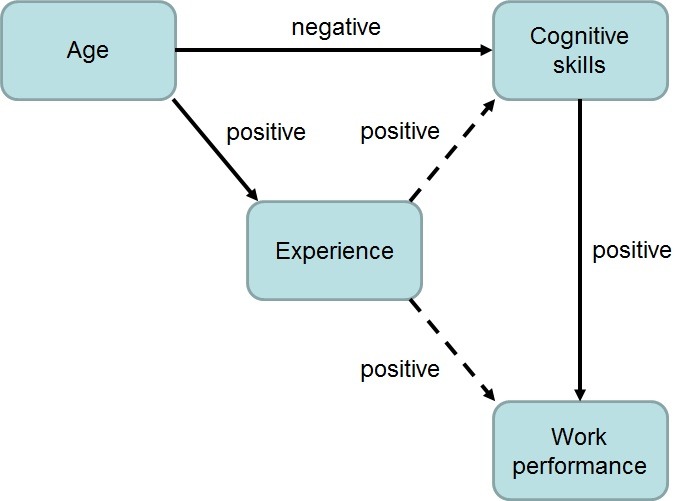

In order to better understand the capabilities and limitations of older workers, the interactions between experience, work performance, and ageing have been modelled by [7] (Fig. 1).

Fig. 1.

Age, experience, and work performance (adapted from: Ilmarinen, 2001)

In this model, experience (which is assumed to be a function of age) supports cognitive skills and work performance. Age is assumed to have a negative impact on cognitive skills which in turn has a positive impact on work performance and so experience is a key factor in mediating work performance for older workers. The association of experience to cognitive skills and work performance is mutually exclusive so if experience improves or maintains cognitive skills, the emphasis lies in this direction and the association of experience and work performance is weaker [7]. This model helps explain why job performance does not necessarily diminish with age and with an understanding and effective use of experience (e.g. from life-experience or previous work and training) older workers can improve their performance in work life.

With older workers set to comprise a greater proportion of the future workforce, a human centered approach will become increasingly important. With this in mind a more detailed interpretation of the physical and cognitive characteristics of manufacturing tasks, effects of ageing and the subsequent effect on the manufacturing task is considered. With recent initiatives in the UK to raise the retirement ages for male and female workers, older workers are evolving into an important sector of the employment market but this has largely occurred without full consideration of their user (or worker) needs across various physiological and cognitive factors.

Older workers: Physiological and biomechanical human capabilities in manufacturing

Assembly tasks are one of the most common activities in many manufacturing and processing industries characterized by precision demands [28] repetitive movements of the arms, hands, and fingers exertion of grip, axial and torque forces [29] and, in instances when large pieces are assembled, workers may also have to lift and/or support heavy objects [30].

Assembly tasks typically involve intensive use of different hand tools [31]. Although the use of powered hand tools is common in many industrial work situations, simple hand tools are still common [29]. Screwdrivers are widely used in a number of occupations such as electronics assembly and automobile assembly, maintenance and repair activities and construction work [32,33]. In addition, fastening screws with a screwdriver requires both dexterity and tactile feedback. Working with a manual screwdriver requires forearm torque strength, muscle control and endurance capacity [34].

Depending on the type of machine and machine tool use in a particular manufacturing plant, the demands on the workforce may include [35]:

a high degree of muscular coordination and manipulative accuracy (constant, rapid, highly complex and dextrous movements of different limbs in space and time, with a high degree of rhythm and timing). Often characterised by fine, intricate, subtle and controlled movements

considerable muscular coordination required (controlled manipulation of machine controls requiring high level of manual dexterity)

physical co-ordination required (use of hand tools, gauges and machine controls requires manual dexterity or agility of limb movements)

little demand on muscular co-ordination or manual dexterity to operate manually machine controls or hand tools to any degree of precision

task requires no manual dexterity (any movements required are commonplace, everyday movements).

Maximum physical and muscle strength is generally reported between 20 to 30 years of age [11] and declines by 15% to 50% as the individual ages [36]. The decline in physical strength is gradual until 40 to 50 years of age and increases thereafter. The capacity to perform work requiring muscle effort over a period of time declines substantially after 50 years of age however, this effect reduced or was neglible in industrial populations [37]. Such declines in strength also vary greatly across different muscle groups. Muscles of the lower-body tend to exhibit the greatest decline relative to upper-body muscle groups, both within and between individuals [38]. Being weaker and vulnerable to musculoskeletal disorders or injury is a key factor in the perceptions that older workers have of their own abilities in the workplace [15]. However, muscle endurance appears to decline at a slower rate than actual muscle strength [36] even if workers use qualitative interpretations of their abilities by reporting that their bodies are ‘slowing down’ [15].

In relation to fine motor skills, the relationship between motor behavior and environmental stimuli is important [18]. Psychomotor performance is commonly measured according to response times or accuracy as a function of task complexity and stimulus-response processes. Simple response times and fine motor performance on a newly acquired task show that older people have slower responses than younger people and that response times increase more after 60 year of age [39]. However, task complexity is also an important factor. A single emergency stop button system controlling the table and spindle on a computer numerical controlled (CNC) turning centre illustrated that whilst a performance decline occurred in older workers it could still be maintained well into old age [36]. For a process with a double emergency stop button system (one controlling the spindle and one controlling the table) performance was found to decline for the older worker partly due to task complexity [38]. Evidence of incompatible responses increased the response times for older workers as they found it more demanding to adapt to a change in emergency stop button (from ‘big, red and round button’ to ‘small, purple and square button’) due to the incompatible notion of the emergency stop [38]. This also supports the notion that older workers may be anchored to prior mental models, where traditional designs have more salience over new designs [24].

In addition to muscle strength and fine motor skill tasks, other physiological functions that are reported to decline predictably with age include bone density, pulmonary oxygen uptake, exercise capacity, visual acuity and resistance to heat and cold stress [11]. Estimated decreases in oxygen uptake of 20% to 30% occur between the ages of 20 to 49 years of age [40]. This in itself is an integrated measure of cardio-respiratory fitness but may also directly impact on physical endurance in older workers especially in physically demanding manufacturing workplaces. Environmental conditions also appear to affect older workers more than younger workers. More specifically, older people have a reduced ability to maintain a constant body temperature in hostile work environments where increases in heat and humidity were key factors. Environmental pollutants (e.g. dust) can also affect the respiratory efficiency of older workers to a greater extent than younger workers. Other factors indirectly associated with work may affect older workers more than younger workers. Difficulties in commuting and travel to (field) work, and on-call working [41] act to compound the effects of the work process by placing greater physical demands on older workers before they start work; something which is particularly evident in manufacturing support industries such as catering and cleaning on premises [15]. Shift working, especially including night working, also seems to have greater effects on older workers than their younger colleagues. It is important, therefore, to consider the full work system and organisational environment when evaluating the consequences of physiological and biomechanical stressors for an ageing workforce.

Whilst older workers face specific challenges in the workplace due to declining motor and psychomotor skills, the ability to work successfully is the result of many integrated factors [11]. For example, older users involved in word-processing and computer use, despite slower input rates and reaction times related to psychomotor skills, are able to compensate through increased scanning behaviours than younger workers [13]. Likewise, training and practice enhance both physical (and cognitive) performance of older workers [42]. In this respect training, practice and experience can be seen to enhance older worker performance, in some cases out-performing younger workers, despite established age-related decline.

With the exception of more traditional manufacturing technologies, flexible ways to support older workers may be developed through automated processes, however with the expansion of information technologies, many manufacturing workplaces are characterised by greater cognitive demands. For this reason, age-related cognitive issues in manufacturing are addressed next in providing an understanding of the impacts on and of the future older workforce.

Older workers: Cognitive issues in manufacturing

Cognitive human factors in manufacturing encompass perceptual (e.g. sensing, judging), conceptual (e.g. abstracting, calculating, inferring) and discretionary skills (e.g. decision making, independent action). In a similar way to motor skills, perceptual, conceptual and discretionary skills can be classified across factors associated with machine tool operation [35]:

the monitoring of sounds, vibrations and other signals or judging surface finish, depth of cut, metal flaws, sharpness or cutting tool

understanding and translating abstract, symbolic information in the form of drawings layouts, planning sheets, programmes

the decisions operators make about tool, speeds and feeds, sequence of operations or improvising.

Cognitive human factors in manufacturing span perceptual skills involving touch, hearing and vision; perception, memory, judgements; and conceptual and discretionary skills involving spatial abilities, decision-making and problem solving. Two nearly ubiquitous effects of the ageing process are a decreased function in hearing and vision. Older adults tend to suffer from moderate hearing loss with age with difficulties in hearing higher frequencies and specific loss of auditory acuity in the normal speech range [43]. The ability to discriminate frequency deteriorates in a linear fashion between 25 to 55 years of age, after which a greater differential is required especially for the higher frequencies [44]. The effects of ageing on hearing difficulties are reported to increase after 55 years of age, and it is likely that traditional noise-polluted industrial environments (as often found in manufacturing) exacerbate this [38]. The process is affected by many factors such as work exposure, diet and genetic influences, but by the age of 50 years there is often sufficient loss of hearing to cause impairment [44]. The context for speech interpretation is important for older workers as cueing-in on information such as diagnostics evidence and interpreting verbal instructions are two important aspects of manufacturing process [45].

With regard to visual function, older adults often suffer declines in depth perception; static and dynamic acuity; light, contrast and glare sensitivity; size of useful field-of-view and speed of smooth pursuit eye movement [46]. Visual acuity (the ability of the eye to discriminate detail) is at its greatest in early teenage years and diminishes more rapidly after 50 years of age [47,48]. Decreases in the elasticity of the lens lead to a reduction in the speed of accommodation and an average near point of 50cm for a 50 year old compared to 12.5cm for a 30 year old [49]. The average 60 year old requires three times more light than the average 20 year old to see the same level of detail [47]. Other research considers the interaction of visual attention and age highlighting three main categories; sustained, divided and selective attention tasks. Whilst differences in signal detection accuracy in age groups were found, no consistent age-by-vigilance decremental interaction with regard to sustained visual attention was reported [38]. However reported declines occur where attention is divided amongst tasks (such as monitoring more than one machine or several quality dimensions) in all but the simplest of tasks [50]. Likewise, evidence supports the observation that older people cope poorly with divided attention tasks however differences between younger and older counterparts regarding selective visual attention were only found in uncertain or novel situations such as searching for quality defects or errors in the syntax of CNC programmes [51]. With regard to problem-solving, there are general increases in capacity until the ages of 40 to 50 years, after which an experiential related decline occurs [52]. In relation to more modern manufacturing, there could be problems for older workers with increased use of CAD, virtual models, LCD and other display technologies especially where older workers have to use visual attention with a novel display [53].

Of particular importance to manufacturing, spatial ability is one of the mental processes that is especially sensitive to age [11]. In an investigation into the spatial abilities of older workers through the interpretation of orthographic drawings, older engineers performed significantly worse in the task compared to younger engineers [54]. There has been significant research relating to fundamental cognitive skills required for discretionary tasks, reporting that inductive reasoning, numeric ability, word fluency and working memory decline with age [23]. Whilst spatial and verbal working memory are reported to account for the largest proportion of age-related differences between older and younger people [55] working memory does not appear to decline in relation to storage capacity, but rather processing efficiency [52]. In a similar way to perceptual skills, the decline in abilities involving divided and selective attention tasks appear to be exaggerated by abstract and novel situations and increasing task complexity [23]. More specifically, older workers appear to have more problems following step-by-step protocols (provided by instructors or in written instructions) than younger people although there seemed to be no significant difference in problem solving performance when an older worker was asked to call upon experience and familiarity [55].

Whilst changes in physical and mental function are inevitable, they do not necessarily lead to reduced performance and productivity in workers [11]. Older people maintain the ability to learn, with evidence of neural plasticity, however, the process takes more time, especially with complex material [56]. Learned skills such as vocabulary and language use are maintained unimpaired until late in life whereas skills that depend on rapid processing, accurate logical thought and spatial ability are markedly affected as people become older [47]. The wealth of knowledge and experience built up and possessed by older workers over a number of years can offset some of the declines reported. This might be particularly important in modern distributed manufacturing networks, virtual manufacturing and supply chain integration, for instance in terms of the importance of collaboration, co-operation and mutual understanding in collaborative engineering [57]. In some cases physiological or psychological shortcomings in older workers might be compensated by familiarity and experience, alongside other mediating factors such as assistive technologies, training and prior education, although these effects have rarely been formally investigated in the workplace.

Discussion

Physical and cognitive decline can vary greatly between individuals due to the heterogeneous nature of aging itself and the multitude of factors such as lifestyle, health, nutrition, individual differences, work and exercise [24]. This sets a challenge for equipment, job and work organization design as there is no typical older worker to design for. What is needed is a clear approach (such as user-centered approaches adopted in human factors) to develop solutions that meet user needs. By comparing traditional and contemporary views, approaches to designing the ergonomics of manufacturing systems can be examined in a structured fashion to assist in understanding and designing for older work needs.

A historical comparison of skills on the then new numerically controlled (NC) and conventional machines across six observations [58] can still provide a basis for developing contemporary recommendations:

NC involves diminished operator activity and physical effort

NC involves fewer demands on motor skills, and a reduction in the associated perceptual demands related to precision and accuracy of movement

NC involves a change in perceptual demands associated with vigilance and machine monitoring

NC reduces the amount of processing of symbolic information in the form of drawings and planning instructions, and the degree and extent of calculations and other conceptual demands

NC reduces the number of decisions an operator has to make

NC can see an overall reduction in skill demands, enabling an operator to control more than one machine.

Whilst it might be assumed that NC diminishes activity and effort in manufacturing jobs in the physical sense, it is suggested that overall activity was probably increased [35]. Flexible ways to mechanise and automate many workstations may decrease challenges from the physically demanding working conditions of some manufacturing environments for the older workers [1]. With physical declines associated with older workers discussed previously, this would appear to be a positive factor for both the ageing worker and also the employing organisation from health and safety, performance, staff retention and business resilience perspectives. However, whilst there may be some load reductions from motor skills and perceptual demands, these are probably found in manufacturing environments where older workers might have problems of adapting to new technologies and interfaces [23].

With respect to discretionary skills, reducing the number of decisions older workers may have to make is one solution [35]; however, the rise of advanced manufacturing technologies and integrated control of the entire shop floor has placed new demands on both workers and managers in areas such as sequencing and scheduling [59]. Despite scheduling operations being critical to maintaining overall manufacturing system performance, when compared with process control, far less research has been conducted in relation to cognitive ergonomics in manufacturing although there has been more general research into issues associated with local control for manufacturing and industrial workforces [59].

As operatives often work on more than one machine, this appears to support the final hypothesis. With the rise of individually controlled CNC machines this has meant where an operator used to manually control machines, there are now there are many more situations where a single worker is responsible for an entire manufacturing cell. Whilst Davis [58] attributes the enabling of operators to control more than one machine as an overall skill demand reduction, the knock-on effect of mechanisation and automation for cognitive human factors must be appreciated [59]. With the changing nature of physical and cognitive human factors within manufacturing, it appears likely that the older worker will need to adapt to more technologically intense manufacturing environments in the future [23].

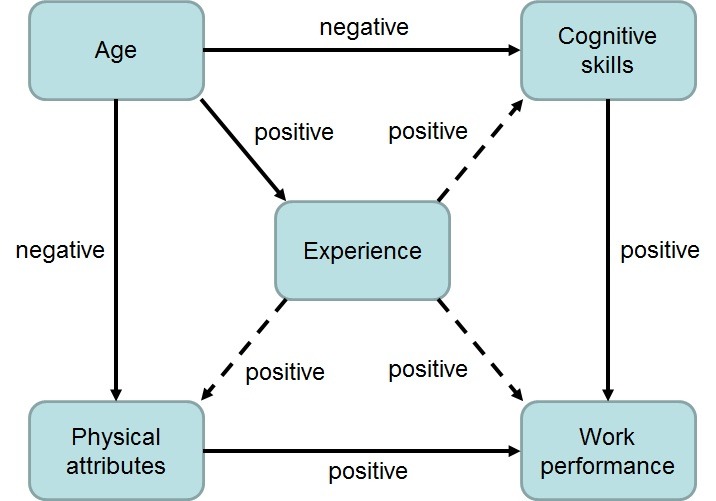

In order to understand the potential capabilities and limitations of older workers in a structured fashion, it is useful to return to the model of age, experience and work performance [7]. The original focus was on cognitive skills and the representation can be expanded to include physical attributes and cognitive skills (Fig. 2).

Fig. 2.

Cognitive skills, physical attributes, experience, and work performance

In this representation experience now offers potential mediation to physical attributes as well as cognitive skills and workers may be aware of their limitations and compensate for weaknesses so that overall performance is maintained. In the same way as age is assumed to have a negative impact on cognitive skills, it has a similar effect on physical attributes for the older worker. With the evidence reviewed, physical well-being tends to diminish after 50 years of age with little scope for improvement. Building on the principles in the original representation, if experience is a limited resource it now forms the basis of a mutually exclusive relationship between cognitive skills and physical attributes, as well as work performance. This helps to focus future research efforts along with educating younger workers about the limitations of older workers as well as older workers themselves with regard to how different processes impact on their overall work performance.

Conclusion

This paper has explored demographic transition and physical and cognitive human factors of an ageing workforce in relation to manufacturing roles. Whilst general physical declines associated with age are well researched, there is less literature on industrial workplaces. There would appear to potential to support physical decline in older workers within manufacturing jobs through increased mechanisation and automation; however, those factors associated with cognitive human factors however are less clear. Increased mechanisation and automation can place greater loads and demands on the older worker where cognitive decline is more subtle and varied between workers. Whilst negative correlations may exist between the cognitive, perceptual and conceptual characteristics of manufacturing jobs, evidence relating to discretionary skills is inconclusive as the wealth of knowledge and experience of older workers can offer a degree of compensation. With older workers set to comprise a greater proportion of labor forces around the world and with managers seemingly unaware of the urgency associated with the situation, E/HF is centrally concerned both with the impacts on people of work systems and also with the impacts of people via their performance within the wider socio-technical system. From the historical and contemporary evidence reviewed, many aspects of manufacturing have changed little over the last century however with advanced manufacturing processes E/HF has an important contribution to make in and developing techniques and approaches to undertake user-centered (re)design of hardware, software and socio-technical systems to support older workers’ needs.

Acknowledgments

The authors declare that there is no conflict of interest.

References

- [1].Thun JH, Großler A, Miczka Miczka, S S. The impact of the demographic effects of an ageing workforce in German industrial firms. J Manuf Tech Manage. 2007;18(8):985–999. [Google Scholar]

- [2].Zhang WJ, van Luttervelt CA. Toward a resilient manufacturing system. CIRP Annals Manuf Tech. 2011;60(1):469–472. [Google Scholar]

- [3]. Coleman R. Living longer: The New Context for Design, The Design Council: London. 1–55; 2001.

- [4]. Summers A. Living Longer – The context for new design. The Design Council: London; 2001.

- [5]. Bullock WC, Smith BH. Expanding user populations. Interface’87: Human Implications of Product Design, Proceedings of the 5th Symposium on Human Factors and Industrial Design in Consumer Products. Human Factors & Ergonomics Society, Consumer Products, Rochester, New York, May 13-15, 1987. pp. 123–128; 1987.

- [6].Tempest S, Barnatt C, Coupland C. Grey advantage: New strategies for the old. Long Ran Plan. 2002;35:475–492. [Google Scholar]

- [7].Ilmarinen JE. Aging workers. Occup Env Med. 2001;58:546–552. doi: 10.1136/oem.58.8.546. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [8]. Malmberg B, Lindh T. Forecasting global growth by age structure projections. Scand Work Pap Econ 2004; No. 2004: 5.

- [9]. United Nations (2005). World Population Ageing 1950-2050. United Nations; Population Division DESA, http://www.un.org/esa/population/publications/worldageing19502050 [Accessed: 28/03/12].

- [10]. Dohm A. Gaugeing the labor force effects of retiring baby-boomers. Monthy Lab Rev July 2000, 17–25.

- [11].Silverstein M. Meeting the challenges of an aging workforce. Am J Ind Med. 2008;51:269–280. doi: 10.1002/ajim.20569. [DOI] [PubMed] [Google Scholar]

- [12]. Buck H, Dworschak B. Aging and work in Europe. In: H Buck, B Dworschak (Eds.), Ageing and Work in Europe: Strategies at Company Level and Public Policies in Selected European Countries. Stuttgart; 2003.

- [13].Reed K, Doty DH, May DR. The impact of aging on self-efficacy and computer skill acquisition. J Manag Issue. 2005;25:212–228. [Google Scholar]

- [14]. Kochling A. Human resource maangement under conditions of demographic change. In: H Buck, B Dworschak (Eds.), Ageing and Work in Europe: Strategies at Company Level and Public Policies in Selected European Countries. Stuttgart; 2003.

- [15].Buckle P, Woods V, Oztug O, Stubbs D. Understanding the design of the workplace for the older worker: A Case Study In: Bust P, (Ed.) London: Taylor & Francis; 2008. 3–7 [Google Scholar]

- [16].Rappaport A, Bancroft E, Okum L. The ageing workforce raises new talent management issues for employers. J Organisational Excellence. 2003;23(1):55–66. [Google Scholar]

- [17]. Farber HS. (2010) Job Loss and unemployment in the 21st century: The great recession in labor marketperspective, https://www.frbatlanta.org/documents/news/conferences/10CHCS_farber.pdf [accessed 28/03/12].

- [18].Sluiter JK. High-demand jobs: Age-related diversity in work ability? Appl Ergon. 2006;37:429–440. doi: 10.1016/j.apergo.2006.04.007. [DOI] [PubMed] [Google Scholar]

- [19]. Kirwan B, Ainsworth LK. A Guide to Task Analysis. Taylor & Francis Ltd: London; 1993.

- [20].Militello LG, Hutton RJB. Applied Cognitive Task Analysis (ACTA): a practitioner’s toolkit for understanding cognitive task demands. Ergonomics. 1998;41(11):1618–1641. doi: 10.1080/001401398186108. [DOI] [PubMed] [Google Scholar]

- [21].Dul J, Bruder R, Buckle P, Carayon P, Falzon P, Marras WS, Wilson JR, van der Doelen B. A strategy for human factors/ergonomics: Developing the discipline and profession. Ergonomics. 2012;55(4):377–395. doi: 10.1080/00140139.2012.661087. [DOI] [PubMed] [Google Scholar]

- [22]. Sirca AD. (2008) Reconfigurable Manufacturing Systems. http://ebookbrowse.com/oradea-sirca-anca-reconfigurable-manufacturing-systems-pdf-d62097440 [Accessed: 28/03/12].

- [23].Rogers WA, Fisk AD. Toward a psychological science of advanced technology design for older adults. Psycholog Sci. 2010;65B(6): Psycholog Sci 2010; 65B(6). doi: 10.1093/geronb/gbq065. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [24].Pattison M, Stedmon AW. Inclusive design and human factors: designing mobile phones for older usersIn: EL Waterworth, J Waterworth, (Eds), Special Issue of Psychnology – Designing technology to meet the needs of the older user. Psychnology. 2006;4(3):267–284. [Google Scholar]

- [25].Welford AT. Causes of slowing of performance with age. Interdiscip Top Gerontol. 1977;11:43–51. [Google Scholar]

- [26].Smith J, Baltes PB. Differential psychological aging. Aging Soc. 1993;13:551–587. [Google Scholar]

- [27]. Krugman P. (2010) Sex and drugs and markets’ role. The Conscience of a Liberal http://krugman.blogs.nytimes.com/2010/10/30/sex-and-drugs-and-markets-role/ [accessed: 28/3/12].

- [28].Wartenberg C, Dukic T, Falck AC, Hallbeck S. The effect of assembly tolerance on performance of a tape application task: A pilot study. Int J Ind Ergon. 2004;33:369–379. [Google Scholar]

- [29].Kong YK, Lowe BD, Lee SJ, Krieg EF. Evaluation of handle shapes for screw driving. Appl Ergon. 2008;39:191–198. doi: 10.1016/j.apergo.2007.05.003. [DOI] [PubMed] [Google Scholar]

- [30].Hakkanen M, Viikari-Juntura E, Takala EP. Effects of changes in work methods on musculoskeletal load: An intervention study in the trailer assembly. Appl Ergon. 1997;28:99–108. doi: 10.1016/s0003-6870(96)00040-3. [DOI] [PubMed] [Google Scholar]

- [31].Lin JH, McGorry RW, Chang CC, Dempsey PG. Effects of user experience, working posture and joint hardness on powered nut-runner torque reactions. Ergonomics. 2007;50:859–876. doi: 10.1080/00140130701237618. [DOI] [PubMed] [Google Scholar]

- [32].Cederqvist T, Lindberg M. Screwdrivers and their use from a Swedish construction industry perspective. Appl Ergon. 1993;24:148–157. doi: 10.1016/0003-6870(93)90002-q. [DOI] [PubMed] [Google Scholar]

- [33].Chang CH, Wang MJJ. Evaluating the effects of activation mode, torque and horizontal operating distance on hand–arm response while operating pneumatic screwdrivers. Int J Ind Ergon. 2001;28:171–179. [Google Scholar]

- [34].Dianat I, Haslegrave CM, Stedmon AW. Short and longer duration effects of protective gloves on hand performance capabilities and subjective assessments in a screw-driving task. Ergonomics. 2010;53(12):1468–1483. doi: 10.1080/00140139.2010.528453. [DOI] [PubMed] [Google Scholar]

- [35].Hazlehurst RJ, Bradbury RJ, Corlett EN. A comparison of the skills of machinists on numerically controlled and conventional machines. Occup Psychol. 1969;43(3/4):169–182. [Google Scholar]

- [36].Spirduso WW, Gilliam Macrae P. Motor performance and aging In: JE Birren, KW Schaie (Eds), Handbook of the Psychology of Aging. San Diego: Academic Press; 1990. 183–200 [Google Scholar]

- [37]. Millanvoye M. Ageing of the organism before sixty years of age. In: J.C. Marquie, D. Paumes Cau-Bareille, and S., Volkoff (Eds.), Working with Age. Taylor & Francis Ltd: London. pp. 133–161; 1998.

- [38].Ellis RD, Pines E, Allaire JC. Performance implications of older workers in technological manufacturing environments: a task-analysis/human reliability perspect-ive. Int J Comp Integr Manuf. 1999;12(2):104–112. [Google Scholar]

- [39].Smith CD, Walton A, Loveland AD, Umberger GH, Kryscio RJ, Gash DM. Memories that last in old age: motor skill learning and memory preservation. Neurobiol Aging. 2005;26:883–890. doi: 10.1016/j.neurobiolaging.2004.08.014. [DOI] [PubMed] [Google Scholar]

- [40].Wang CY, Haskell WL, Farrell SW, LaMonte MJ, Blair SN, Curtin LR, Hughes JP, Burt VL. Cardiorespiratory fitness levels among US adults 20–49 years of age: Findings from the 1999–2004 National Health and Nutrition Examination Survey. Am J Epid. 2010;171(4):426–435. doi: 10.1093/aje/kwp412. [DOI] [PubMed] [Google Scholar]

- [41]. Cebola N, Golightly D, Wilson JR. The on-call system of work: A framework to understand and manage the risks. Proceedings of the IEHF Annual Conference, 16-19 April, Blackpool; 2012.

- [42].Wagner N, Hassanein K, Head M. Computer use by older adults: A multi-disciplinary review. Comp Hum Behav. 2010;26(5):870–882. [Google Scholar]

- [43].Brant LJ, Fozard JL. Age changes in pure –tone hearing thresholds in a longitudinal study of normal human aging. J Acoust Soc Am. 1990;88(2):813–820. doi: 10.1121/1.399731. [DOI] [PubMed] [Google Scholar]

- [44].Takeda S, Morioka I, Miyashita K, Okumura A, Yoshida Y, Matsumoto K. Age variation in the upper limit of hearing. Europ J Appl Physiol Occup Physiol. 1992;65(5):403–408. doi: 10.1007/BF00243505. [DOI] [PubMed] [Google Scholar]

- [45].Pearson JD, Morell CH, Gordon-Salant S, Brant LJ, Metter EJ, Klein LL, Fozard JL. Gender differences in a longitudinal study of age-associated hearing loss. J Acoust Soc Am. 1995;97(2):1196–1205. doi: 10.1121/1.412231. [DOI] [PubMed] [Google Scholar]

- [46].Kosnik W, Winslow L, Kline D, Rasinski K, Sekuler R. Visual changes in daily life throughout adulthood. J Gerontol. 1988;43:63–70. doi: 10.1093/geronj/43.3.p63. [DOI] [PubMed] [Google Scholar]

- [47].Haigh R. The ageing process: A challenge for design. Appl Ergon. 1993;24(1):9–14. doi: 10.1016/0003-6870(93)90153-z. [DOI] [PubMed] [Google Scholar]

- [48]. Steenbekkers LPA, Dirken JM, van Beijsterveldt CEM. Design-relevant fun-ctional capacities of the elderly, assessed in the Delft Gerontechnology project. In P Seppala, T Luopajarvi, CH Nygard, M Mattila (Eds.), From Experience to Innovation - IEA '97. Proceedings of the 13th Triennial Congress of the International Ergonomics Association, Tampere, Finland, June 29-July 4, 1997. pp. 612–614; 1998.

- [49].Ishihara K, Ishihara S, Nagamachi M, Osaki H. Difficulties for elderly people caused by age-related yellowing vision In: McCabe P. Ed. London: Taylor & Francis Ltd; 2002. 579–581 [Google Scholar]

- [50].McDowd JM, Craik FIM. Effects of aging and task difficulty on divided attention performance. J Exp Psychol Hum Percept Perform. 1988;14:267–280. doi: 10.1037/0096-1523.14.2.267. [DOI] [PubMed] [Google Scholar]

- [51].Plude DJ, Doussard-Roosevelt JA. Aging, selective attention, and feature integration. Psychol Aging. 1989;4:98–105. doi: 10.1037/0882-7974.4.1.98. [DOI] [PubMed] [Google Scholar]

- [52]. Norris B, Smith S, Peebles L. Older Adult data–The handbook of measurements and capabilities of the Older Adult –data for design safety. Department of Trade and Industry, UK; 2000.

- [53].Hitchcock DR, Lockyer S, Cook S, Quigley C. Third age usability and safety - An ergonomics contribution to design. Int J Hum Comp Stud. 2001;55(4):635–643. [Google Scholar]

- [54].Salthouse TA. Mental exercise and mental aging: Evaluating the validity of the ‘use it or lose it’ hypothesis. Perspect Psychol Sci. 2006;1(1):68–87. doi: 10.1111/j.1745-6916.2006.00005.x. [DOI] [PubMed] [Google Scholar]

- [55].Morrell RW, Park DC. The effects of age and task variables on the performance of procedural assembly tasks. Psychol Aging. 1993;8:389–399. doi: 10.1037//0882-7974.8.3.389. [DOI] [PubMed] [Google Scholar]

- [56]. Kandel ER, Schwartz JH, Jessell TM. Principles of Neural Science. 4th ed. McGraw-Hill: New York; 2000.

- [57].Patel H, Pettitt M, Wilson JR. Factors of collaborative working: A framework for a collaboration model. Appl Ergon. 2012;43:1–26. doi: 10.1016/j.apergo.2011.04.009. [DOI] [PubMed] [Google Scholar]

- [58].Davis LE. Automation and job design. Ind Relat. 1962;2(1):65–70. [Google Scholar]

- [59].Wilson JR. Support of opportunities for shop floor involvement through Informa-tion and communication technologies. AI & Soc. 2003;17(2):114–133. [Google Scholar]