Abstract

Background: The aim of this study was to assess physical properties of dietetic chocolate milk produced by stevia as a sugar replacer and inulin. Along with having prebiotic effect, inulin can also participate in enhancing textural properties of beverages. Therefore, this novel food will be useful for all people especially for diabetics.

Methods: This study was carried out in Quality Control Laboratory of Food Science and Technology Department, Health and Nutrition Faculty, Tabriz University of Medical Science, during 2011-2012. The assay was performed on nine treatments with three replications. Sugar was substituted with stevia in two proportions of sucrose to stevia; 50:50 and 0:100. Inulin, in four levels of 0%, 2%, 4% and 6%, was added to the treatments of 50% and 100% stevia. The control sample contained no stevia and no inulin, such as commercial ones. Precipitation amount and viscosity were measured 24 hours after production. Data analyzed by one-way ANOVA, at the significant level of 0.05, using SPSS software ver. 17.

Results: Sugar replacement with stevia caused significant increase in precipitation and significant decrease in viscosity (P<0.05), whereas using inulin in formulation significantly decreased precipitation and increased viscosity (P<0.05). The sample containing 100% stevia and 6% inulin revealed a viscosity with a non-significant difference with the control (P>0.05). The sample containing 50% stevia and 6% inulin had the lowest precipitation while having a non-significantly difference with the control.

Conclusion A thickener agent, such as inulin, should be used in the chocolate milk sweetened by stevia to improve physical properties of the product.

Keywords: Chocolate milk, Dietary, Stevia, Inulin, Physical properties

Introduction

Type 2 diabetes mellitus (DM) is a disease with a globally rising prevalence, mainly due to modern lifestyle with high levels of sugar and fat in the diet [1]. So nowadays, there is an increasing tendency to low caloric foods prepared by high intensity non-nutritive sweeteners.

Stevia is a zero calorie natural sweetener, which is 250-300 times sweeter than sugar. It is extracted from Stevia rebaudiana bertoni leaves, a sweet plant native to northeastern Paraguay and commercially available in many countries. The sweetness is due to presence of many glycosides in the leaf extract, such as stevioside. Therefore, concentration amounts of extracted glycosides determine the exact level of sweetness [2,3]. On the contrary, of artificial sweeteners, stevia not only does not lead to health problems, but also causes several good medicinal effects on the body, including its anti-diabetic activity [3]. It is claimed that stevia treats obesity and high blood pressure and has a negligible effect on blood glucose [4]. Moreover, it is safe and there is no evidence for its health risk or birth defects [5].

Because of very few dietetic dairy products in Iran, we sought to assess production of a diabetic chocolate milk prepared using stevia. We also used inulin to enhance textural properties of dietetic chocolate milk. High intensity sweeteners after replacing sucrose, diminish the viscosity and bulking properties [6]. Among different kinds of flavored milks, chocolate milk is the most popular one. It is formulated with ingredients such as milk, sucrose, cocoa powder, and some hydrocolloids that are added to improve consistency and to prevent sedimentation of cocoa particles [7]. Physical properties of chocolate milk are very important and should be controlled by industrialists [8].

There is a wide variation between viscosities of commercial samples; however, there are different opinions about the favorable viscosity of chocolate milk [9]. Some persons believe that chocolate milk should have the same viscosity as normal milk. Other people prefer a thick, more viscous product. When a small percentage of stabilizers are added, the chocolate milk will be more viscous than simple milk. Development of a high viscosity that the chocolate milk pours like syrup is not desirable. Acceptance of a slightly increased viscosity to inhibit creaming is typical, but a heavy, viscous product should probably be criticized by the evaluators [9,10]. The sedimentation of cocoa solids in chocolate milk is a disadvantage of appearance. The industrialists should consider the amount of sedimentation, the quality or fineness of cocoa sediment, and the ease or resistance with which it remixes with the milk. Villegas et al. employed three types of inulin in milk and studied about their differences in thickness and creaminess. They reported that with adding 8% of long-chain inulin to skim milk, the product would have a desired creaminess and thickness [11]. Inulin bifidogenic nature appears in concentration of 6% [12], so our product will be a novel food with dietetic and prebiotic effects.

The aim of this study was to explore effect of sugar substitution with stevia and adding different concentrations of inulin on viscosity and sedimentation of chocolate milk, which are two important physical parameters of that.

Materials and Methods

Materials

The assay employed Frutafit® HD (a native inulin/oligofructose, extracted from chicory root) from Sensus company (Netherland), PROVLadd CM 1722 (a creamy white weight free following powder consisting of carrageenan blend, used as a natural stabilizer for milk products) from PROVISCO (Swiss), Stevia SU200 (Steviol Glycoside, white powder, 240 times cane sugar, Compared with the solution of 2% cane sugar) from SteviaPac, (Singapore) and cocoa powder (Kayseri, Turkey). Sugar and low fat milk (1.5% fat) were purchased from local market.

Methods

Preparation of Samples

The samples were prepared in Quality Control Laboratory of Food Science and Technology Department, Health and Nutrition Faculty, Tabriz University of Medical Science, during 2011-2012.The base formulation of chocolate milk contained 8% of sucrose, 1.5% of cocoa powder, and 0.03% of stabilizer (w/w). Because of replacing stevia sweetener, the concentration of sucrose was various, but the cocoa powder and the stabilizer concentrations were constant. Table 1 shows the concentration of the sweeteners and inulin in the nine formulations. Premixes of dry ingredients (a ratio of sugar to stevia sweetener, cocoa powder, stabilizer, and inulin in some of treatments) were added to the low-fat milk. Then the samples were heated up at 74 ±2°C during 15 min, under constant agitation in order to disperse the stabilizer and other dry materials. After heating up at 74±2°C, the temperature was kept constant for about 15 seconds in order to pasteurize the samples [13,14]. Chocolate milks were stored at 4±1°C, for 24 hours, to be ready for assessment.

Table 1. Concentration of sweetener and inulin in the nine formulations.

| Treatment | Abbreviation | Sweetener (ratio of the Sucrose:Stevia) | Inulin (w/w%) |

| 1 | T1 | 100:0 | 0 |

| 2 | T2 | 50:50 | 0 |

| 3 | T3 | 0:100 | 0 |

| 4 | T2a | 50:50 | 2 |

| 5 | T2b | 50:50 | 4 |

| 6 | T2c | 50:50 | 6 |

| 7 | T3a | 0:100 | 2 |

| 8 | T3b | 0:100 | 4 |

| 9 | T3c | 0:100 | 6 |

Experimental Design

This study was carried out on nine treatments with three replications. Sucrose was substituted with stevia in two proportions of sucrose to stevia; 50:50 and 0:100. Inulin, in four levels of 0%, 2%, 4% and 6%, was added to the treatments using 50% and 100% of stevia. The control sample contained no stevia and no inulin, such as commercial ones.

Apparent Viscosity Measurement

Apparent viscosity of chocolate milks was measured at 4 ±1°C through the use of a rotational viscometer (DVII + LV, Brookfield, Middleboro, MA, USA), equipped with a LV1 spindle. Measurements were carried out at 140 rpm.

A fixed volume (500 mL) of each sample was used for the apparent viscosity measurements in a 600 mL beaker [13]. The samples were stored in refrigeration (4 ±1°C) for 24 h before being rheologically measured.

Precipitation Measurement

After one day storage in refrigeration (4 ±1°C), precipitation amount of samples were measured by the way described earlier [8]. Since all tubes had the same height and volume, it was preferred to report the precipitation rates just in millimeter, rather than reporting the proportion of precipitation to the tube height.

Statistical Analysis

Data were reported as mean (standard deviation) and their analysis was implemented by one-way analysis of variance, at the significant level of 0.05, using SPSS software ver. 17. The Duncan's post-hoc test was used for paired comparison between the groups.

Results

Our findings showed that there was at least one significant difference (P<0.05) between the treatments for apparent viscosity and for amount of sedimentation.

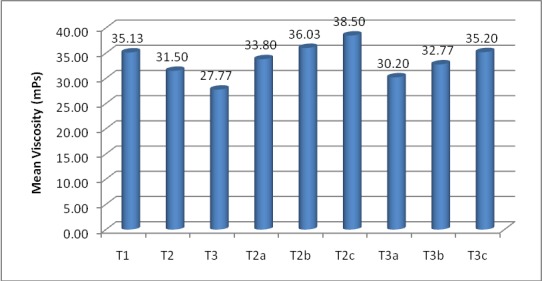

The Duncan post hoc analysis for apparent viscosity revealed that there were no significant differences among the T1 (as control), T2a and T3c, and the other treatments are significantly different from the treatment 1. T3 (with complete replacement of sucrose, and without inulin) had the lowest viscosity and T2c (partial replacement of sucrose, and containing 6% of inulin) had the maximum viscosity.

The results (Fig. 1) indicated that by replacing 50% of sugar with stevia and adding 4% and 6% inulin (respectively in T2b and T2c) and also by replacing 100% of sucrose with stevia and adding 6% inulin, these products had the viscosity like or slightly higher than that of control (T1).

Fig. 1.

Effect of inulin and stevia on apparent viscosity of chocolate milk, at 4±1°C. The data presented are the mean of three replicate trials

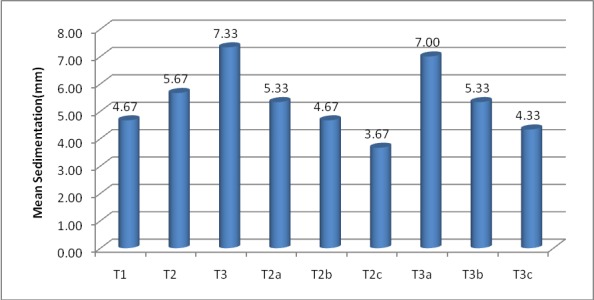

On the other hand, the results showed that adding inulin decreased the amount of sedimentation of chocolate milk (Table 2). There were no significant difference among T2b, T2c, T3c and T1. Sedimentation of all treatments is comparable in Fig. 2.

Table 2. Viscosity and sedimentation of chocolate milks, 24h after production, in 4±1°C* .

| Treatment** | Viscosity (mPa.s) | Sedimentation (mm) |

| T1 | 35.13±0.94ef | 4.67±0.57ab |

| T2 | 31.50±0.87bc | 5.67±0.57c |

| T3 | 27.77±0.72a | 7.33±0.57d |

| T2a | 33.80±1.04de | 5.33±0.57bc |

| T2b | 36.03±1.20f | 4.67±0.57ab |

| T2c | 38.50±1.06g | 3.67±0.57a |

| T3a | 32.20±0.70b | 7.00±1.00d |

| T3b | 32.77±0.72cd | 5.33±0.57bc |

| T3c | 35.20±0.95ef | 4.33±0.57ab |

* All values are mean of three replicate trials ± standard deviation; the values shown with different letters in a column are significantly different (P< 0.05).

** Identification of treatments in Table 1

Fig. 2.

Effect of inulin and stevia on sedimentation of chocolate milk, 24 h after production. The data presented are the mean of three replicate trials

Discussion

As a comparison among treatments, the results indicated that the apparent viscosity from T1 to T3 (because of reducing the sucrose) gradually decreased. From T2a to T2c, and from T3a to T3c (because of increasing amount of inulin) the apparent viscosity gradually increased. Shikhata and Bajva studied about a low calorie functional milk drink using long-chain inulin and sucralose as fat and sugar substitutes, respectively. Sugar replacement considerably decreased total solids, total soluble solids, viscosity, and sensory scores. However, increase in inulin from 0 to 8% significantly improved these parameters [15]. Because of the hygroscopic nature of inulin, it forms a gel-like network with the liquid phase of milk. The water binding capacity of inulin powder, with specific gravity of about 1.35 and molecular weight of 1,600, is about 2:1 [16]. Sucrose replacing with high intensity sweeteners (such as stevia in this study) diminishes the bulking properties that sucrose provides to foods [6]. The results indicated the same behavior of viscosity and sedimentation among the treatments. The decline of precipitation was due to the increased viscosity by adding inulin.

Using inulin as a texture modifier caused a noticeable improvement in the viscosity of the dietetic chocolate milk. The final product would be such as the control one, in apparent viscosity and amount of precipitation, by 100% sweetener replacement using 6% of inulin, or by 50% sweetener replacement using 4% or 6% of inulin. Overall, increase in inulin quantity raised the viscosity and sedimentation, whereas replacement of sucrose with stevia considerably caused declines. Besides being used as a stabilizer, bulk improver, or texture modifier, inulin is a prebiotic ingredient and has many health promoting effects.

Acknowledgments

This study was made possible by financial support of The Research Vice-Chancellor of Tabriz University of Medical Sciences (Tabriz, Iran). The authors gratefully thank Mr Hosein Rhmanpour Arjmand (Department of Food Science and Technology, Faculty of Health and Nutrition, Tabriz University of Medical Sciences) for his useful recommendations and providing laboratory facilities. The authors declare that there is no conflict of interests.

References

- [1].Vyoma A, Anita K, Rajbir S. Sensory and Nutritional Evaluation of Sweet Milk Products Prepared Using Stevia Powder for Diabetics. Ethno Med. 2010;4:9–13. [Google Scholar]

- [2].Prakash I, Dubois GE, Clos JF, Wilkens KL, Fosdick LE. Development of rebiana, a natural, non-caloric sweetener. Food Chem Toxicol. 2008;46:S75–S82. doi: 10.1016/j.fct.2008.05.004. [DOI] [PubMed] [Google Scholar]

- [3].Varanuj C, Chatchai M. Stevioside and related compounds: Therapeutic benefits beyond sweetness. Pharmacol Ther. 2009;121:41–54. doi: 10.1016/j.pharmthera.2008.09.007. [DOI] [PubMed] [Google Scholar]

- [4].Tadhani MB, Patel VH, Subhash R. In vitro antioxidant activities of Stevia rebaudiana leaves and callus. J Food Compos Anal. 2007;20:323–329. [Google Scholar]

- [5].Brusick DJ. A critical review of the genetic toxicity of steviol and steviol glycosides. Food Chem Toxicol. 2008;7:83–91. doi: 10.1016/j.fct.2008.05.002. [DOI] [PubMed] [Google Scholar]

- [6].Stamp JA. Sorting out the alternative sweeteners. Cereal Food World. 1990;35:395–400. [Google Scholar]

- [7].Manuel OR, Jorge FV. The physicochemical and rheological properties of a milk drink flavoured with cajeta, a Mexican caramel jam. Int J Dairy Technol. 2011;64:294–304. [Google Scholar]

- [8].Mueller WS. Factors to be Considered in Selecting Chocolate-Flavored Milk. J Dairy Sci. 1939;22:623–636. [Google Scholar]

- [9].Mario Y, Duran L, Costell E. Rheological and optical properties of commercial chocolate milk beverages. J Food Eng. 2002;51:229–234. [Google Scholar]

- [10]. Clark S, Costello M, Drake M, Bodyfelt F. The Sensory Evaluation of Dairy Products. 2nd ed. Springer. New York; 2009.

- [11].Villegas B, Carbonell I, Costell E. Inulin Milk Beverages: Sensory Differences in Thickness using R-INDEX Analysis of the Ranking Data. J Sens Stud. 2007;22:377–393. [Google Scholar]

- [12].Coussement PA. Inulin and oligofructose: Safe intakes and legal status. J Nutr. 1999;129:1412–1417. doi: 10.1093/jn/129.7.1412S. [DOI] [PubMed] [Google Scholar]

- [13].Reis1 FR, Bellarmino de Pereira-Netto A, Meira Silveira JL, Isidoro Haminiuk ChW, Bileski Cândido LM. Apparent Viscosity of a Skim Milk Based Dessert: Optimization through Response Surface Methodology. Food Nutr Sci. 2011;2:90–95. [Google Scholar]

- [14].Sangeeta P, Thom H, Olena K, Hilton D. Ultra-high-temperature processing of chocolate flavoured milk. J Food Eng. 2010;96:179–184. [Google Scholar]

- [15]. Mittal Sh, Bajva U. Effect of fat and sugar substitution on the quality characteristics of low calorie milk drinks. J Food Sci Technol [serial on the Internet] 2011 [cited 2011 January 28]. Available from www.springerlink.com/index/A51537783N2H35NL.pdf [DOI] [PMC free article] [PubMed]

- [16]. Silva RF. Use of inulin as a natural texture modifier. Cereal Food W.