Abstract

The efficient production of biofuels from cellulosic feedstocks will require the efficient fermentation of the sugars in hydrolyzed plant material. Unfortunately, plant hydrolysates also contain many compounds that inhibit microbial growth and fermentation. We used DNA-barcoded mutant libraries to identify genes that are important for hydrolysate tolerance in both Zymomonas mobilis (44 genes) and Saccharomyces cerevisiae (99 genes). Overexpression of a Z. mobilis tolerance gene of unknown function (ZMO1875) improved its specific ethanol productivity 2.4-fold in the presence of miscanthus hydrolysate. However, a mixture of 37 hydrolysate-derived inhibitors was not sufficient to explain the fitness profile of plant hydrolysate. To deconstruct the fitness profile of hydrolysate, we profiled the 37 inhibitors against a library of Z. mobilis mutants and we modeled fitness in hydrolysate as a mixture of fitness in its components. By examining outliers in this model, we identified methylglyoxal as a previously unknown component of hydrolysate. Our work provides a general strategy to dissect how microbes respond to a complex chemical stress and should enable further engineering of hydrolysate tolerance.

Keywords: biofuels, chemogenomics, plant hydrolysate, systems biology, tolerance

Introduction

Concerns over energy security, global warming, and rising petroleum prices have led to a renewed interest in the development of technologies for cost-effective production of ethanol or other biofuels from renewable resources (Hill et al, 2006; US Department of Energy, 2011). Lignocellulosic biomass, such as wood and grasses, can provide a sufficient quantity of feedstock material that can be converted into biofuels, and a variety of energy crops are currently being considered for use in the United States, such as Miscanthus giganteus (miscanthus) and Panicum virgatum (switchgrass) (Somerville et al, 2010; Youngs and Somerville, 2012). The grand challenge is to produce large quantities of a commodity chemical given economic constraints. In the case of cellulosic ethanol, technoeconomic analysis has been used to determine which steps of the production process, if optimized, can have the greatest impact on the minimum selling price (Klein-Marcuschamer et al, 2010, 2011; Kumar and Murthy, 2011; Tao et al, 2011; Vicari et al, 2012). Two critical steps are the conversion of biomass into fermentable hexose and pentose sugars (mainly glucose and xylose) and their subsequent fermentation into ethanol.

Conversion of biomass into sugars is typically a two-step process involving pretreatment and enzymatic hydrolysis. Although many variations exist, we have focused on the dilute-acid hydrolysis method, which is considered as a viable option for commercial-scale cellulosic ethanol production (Wyman et al, 2005). The high temperatures and pressures typically used for dilute-acid pretreatment result in the co-production of inhibitory compounds (derived from sugar and lignin degradation) in addition to fermentable sugars. This resulting mixture, or plant hydrolysate, contains at least 60 inhibitory compounds (Clark and Mackie, 1984; Palmqvist and Hahn-Hägerdal, 2000a, 2000b). These inhibitors have a significant impact on growth and fermentation of bacteria and yeast, thus preventing efficient biofuel production. There are three common approaches to deal with fermentation inhibitors: prevent their formation by reducing the severity of pretreatment, remove inhibitors by detoxification, or improve the tolerance of the host organism (Palmqvist and Hahn-Hägerdal, 2000a; Nilvebrant et al, 2001; Martín et al, 2007a; Parawira and Tekere, 2011; Stoutenburg et al, 2011). All three methods can be successful and are expected to have a significant economic impact (Klein-Marcuschamer et al, 2010; Tao et al, 2011), but here we will focus on improving tolerance.

There are two complementary approaches to develop more tolerant strains: laboratory evolution in the presence of plant hydrolysates and rational strain engineering (Larsson et al, 2001; Heer and Sauer, 2008; Chen, 2010; Yang et al, 2010a, 2010b; Liu, 2011; Agrawal et al, 2012; Fujitomi et al, 2012). Regardless of the approach, the resulting strains are often not fully tolerant, and further improvements in ethanol yield and productivity are needed (Keller et al, 1998; Martín et al, 2007b; Heer and Sauer, 2008). Many of these studies have focused on single inhibitory compounds present in hydrolysate or simple model mixtures as a proxy for plant hydrolysates (Palmqvist et al, 1999; Liu, 2011). Given the complexity of inhibitors in actual hydrolysate, it is challenging to predict and engineer the necessary genetic changes for tolerance based on these previous studies.

Given this challenge, we present here an experimental and computational approach to dissect the effects of complex chemical mixtures, such as plant hydrolysates, on the growth and fermentation of the bacterium Zymomonas mobilis and the yeast Saccharomyces cerevisiae. Both microbes are being considered for commercial-scale cellulosic ethanol production. Z. mobilis is currently being used as part of a DuPont industrial-scale cellulosic ethanol process ( http://www.ddce.com/), and S. cerevisiae has a long history of industrial-scale ethanol production from corn in the United States and from sugarcane in Brazil (Wheals et al, 1999).

First, we used a functional genomics approach, based on chemogenomic profiling of mutant libraries in Z. mobilis and S. cerevisiae, to identify genes that are important for growth in plant hydrolysates. Chemogenomic profiling with DNA barcodes was first pioneered in S. cerevisiae and we have recently adapted the technology for use in bacteria (Giaever et al, 2002, 2004; Oh et al, 2010; Deutschbauer et al, 2011). These previous studies, and other technologies for profiling large mutant pools, have led to key insights into the function of unknown genes and the mechanism of action of inhibitory compounds (Sassetti et al, 2001; Giaever et al, 2004; Langridge et al, 2009; Smith et al, 2009; Van Opijnen et al, 2009; Hillenmeyer et al, 2010; Deutschbauer et al, 2011). The putative hydrolysate tolerance genes that we identified are attractive targets for strain improvement programs, and we demonstrate here, by systematic overexpression of Z. mobilis tolerance genes, that we can rationally engineer improved fermentation in miscanthus hydrolysate. Most of our fitness experiments were carried out under aerobic growth conditions because this was most compatible with our high-throughput protocols. However, we did perform some experiments under anaerobic growth conditions to better match the environment of an industrial bioreactor, and identified seven additional Z. mobilis tolerance genes (see Discussion).

Second, we deconstructed the complex biological response to plant hydrolysates by obtaining individual chemogenomic profiles for each of 37 hydrolysate-derived inhibitors and in synthetic mixtures of known components. We modeled fitness in hydrolysate as a mixture of fitness in individual components and identified outliers in our model that led to the discovery of a previously unknown chemical component, methylglyoxal, which is present in our miscanthus plant hydrolysate and contributes to overall toxicity. In sum, our combined experimental and computational approach provides a general strategy for understanding how microbes respond to a complex chemical stress, for identifying critical unknown chemical components in plant hydrolysates, and for rationally engineering strains with improved hydrolysate tolerance and fermentation properties.

Results

Plant hydrolysate composition and effects on Z. mobilis growth and fermentation

To explore the natural diversity of hydrolysate composition and to determine the effect of feedstock-derived inhibitors on the growth and fermentation of Z. mobilis, we developed a microwave oven-based protocol to hydrolyze M. giganteus (miscanthus) and P. virgatum (switchgrass) plant material at high temperature and pressure. The procedure was designed to mimic, at the laboratory scale, a dilute-acid hydrolysis pretreatment method that can be used for the industrial-scale production of cellulosic biofuels (Tao et al, 2011). We prepared six hydrolysate samples from miscanthus or switchgrass grown at different field sites in Illinois and two additional hydrolysate samples from a mixture of miscanthus, from multiple field sites. All eight hydrolysate samples were analyzed using a combination of GC/MS and LC-RID/DAD; the composition of these mixtures, including 4 sugars (glucose, xylose, arabinose, and cellobiose) and 37 potential inhibitors, is shown in Supplementary Table 1. As expected, the harsh hydrolysis conditions (low pH and high temperature) resulted in the production of sugar dehydration products, such as furfural and 5-hydroxymethylfurfural (5-HMF) and their degradation products, formic acid and levulinic acid, respectively. In addition, we detected a wide variety of phenolic compounds derived from lignin degradation (Palmqvist and Hahn-Hägerdal, 2000b; Klinke et al, 2004). Based on clustering of the inhibitor and sugar concentrations, we identified three groups of samples with distinct chemical compositions: miscanthus, switchgrass, and the batch miscanthus samples (Supplementary Figure 1). Despite the different field locations, miscanthus hydrolysates were more similar to each other than switchgrass, and vice versa. By contrast, the two batch miscanthus samples (batch 1 andbatch 2) formed a third independent cluster, and this is likely explained by the higher temperature used for their processing (200°C versus 180°C) that led to higher concentrations of inhibitors (Supplementary Table 1).

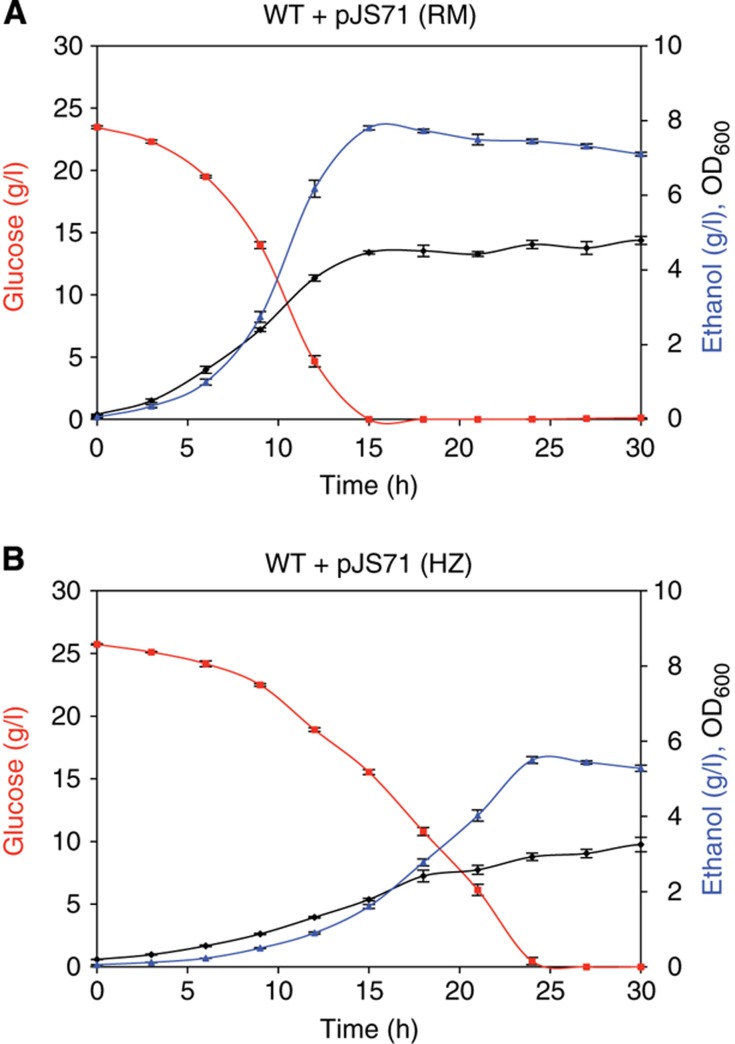

To understand the inhibitory effect of hydrolysate, we first determined the concentration of hydrolysate that, when added to rich media, significantly inhibited the growth of Z. mobilis. Consistent with their similar, but not identical, chemical compositions, all eight hydrolysate samples inhibited growth of Z. mobilis at concentrations ranging from about 8 to 20% (v/v) (Supplementary Figure 2). The most potent hydrolysate samples were the batch miscanthus that was prepared at a higher temperature, consistent with their higher inhibitor concentrations (Supplementary Table 1). We also determined the effects of plant hydrolysate on the fermentation profile of Z. mobilis by carrying out small-scale aerobic batch fermentations in the absence (Figure 1A) or presence of 8% (v/v) batch 2 hydrolysate (Figure 1B). In the presence of hydrolysate, specific ethanol productivity was reduced about three-fold (0.10 versus 0.27 g/l/h/OD600). Taken together, our hydrolysate preparations provide a complex mixture of inhibitors that serve as a model for industrial-scale dilute-acid hydrolysates.

Figure 1.

Miscanthus hydrolysate inhibits Z. mobilis growth and ethanol production. Batch fermentation profiles for wild-type Z. mobilis strain carrying an empty control plasmid (WT+pJS71) either in (A) rich media (RM) or in (B) rich media supplemented with 8% (v/v) batch 2 miscanthus hydrolysate (HZ). Data shown are the average of four replicates and error bars indicate standard deviation.

Generating a genome-wide Z. mobilis barcoded transposon library

To understand the genetic basis of hydrolysate tolerance, we first mapped 14 008 random DNA-barcoded transposon insertions in Z. mobilis ZM4 using protocols recently developed in our laboratory for Shewanella oneidensis MR-1 (Deutschbauer et al, 2011). From our collection of 14 008 mutants, we derived two Z. mobilis mutant pools of 3716 barcoded strains each that together represent 1620 of the 1892 (86%) annotated protein-coding genes (Materials and methods; Supplementary Table 2). We designed two mutant pools because it provided optimal genome-wide coverage given a limited set of barcodes (about 4200), and it allowed us to include some strains in both pools and measure them twice, which provided an internal control for experimental consistency. These mutant pools were used to perform competitive growth assays, or pooled fitness experiments, where the relative abundance of strains in our two pools was quantified (Giaever et al, 2002; Pierce et al, 2006; Oh et al, 2010). Before all experiments, we recovered the mutant pools from frozen stocks and used these cells as the starting inoculum for setting up fitness experiments in experimental conditions. By comparing strain abundance after growth in the experimental condition (END) to strain abundance in the starting inoculum (START), we calculated a log2 ratio, or strain fitness value for each mutant strain in that condition. We define ‘gene fitness’ as the average strain fitness value for insertions within that gene (see Materials and methods for details). Negative gene fitness values indicate that a gene is important for growth in the condition of interest, that is, transposon mutants of that gene should grow poorly in that condition. In contrast, positive gene fitness values indicate that the gene is detrimental to growth in the condition of interest, that is, transposon mutants of that gene have improved growth relative to the typical strain. After final data filtering, we obtained gene fitness data for 1578 of 1892 (83%) protein-coding genes. Because many genes had multiple transposon insertions (1336/1578 had >1 insertion), and because the same strain was sometimes present in both pools, we were able to make an average of 3.5 fitness measurements per gene.

We were surprised to find transposon insertions within the central 5–80% of most genes regardless of whether they were expected to be essential. In fact, we mapped insertions in 82% of predicted essential genes (Supplementary Table 3), which is not significantly less than the rate of 85% for other genes (P=0.10, Fisher’s exact test). To our knowledge, this is the first example of a large-scale transposon mutagenesis study in bacteria with this unusual distribution of insertion sites. To study this further, we first examined six mutants by PCR using primers that flanked each transposon site. Three of these mutants were in predicted essential genes (leuS::TN5, ftsZ::TN5, and rpoB::TN5), and three mutants were in non-essential genes (ZMO0759::TN5, ZMO1490::TN5, and ZMO1723::TN5). In the predicted essential gene mutants, we amplified two bands that correspond to the wild-type and mutant copies of leuS, ftsZ, and rpoB, respectively (Supplementary Figure 4A and B). By contrast, transposon insertions in non-essential genes only had a single band by PCR analysis, corresponding to the mutant copy. Mutants with two bands by PCR were classified as ‘mixed’ and were examined further by using a transposon stability assay and comparative genome hybridization (Materials and methods; Supplementary Figure 4C–L). Based on these experiments, we concluded that Z. mobilis is polyploid (i.e., has multiple copies of its main 2 Mbp chromosome), and that insertions in essential genes are heterozygous and unstable in the absence of kanamycin selection, whereas insertions in non-essential genes are homozygous and stable (Supplementary Note 1; Supplementary Figure 5). Alternatively, polyploidy might be a rare event that is selected for only when an essential gene is mutated; however, because the rate of insertion in essential genes is similar to non-essential genes, we believe that polyploidy is the normal state for Z. mobilis. In this study, we focused our single-mutant follow-up experiments on stable, homozygous KanR mutants. Although unusual, other bacteria, such as Deinococcus radiodurans, Thermus thermophilus, Synechococcus spp., Sinorhizobium meliloti bacteroids, and Epulopiscium sp. type B are known to be polyploid and to have multiple copies of their chromosome (Masters et al, 1991; Mergaert et al, 2006; Ohtani et al, 2010; Griese et al, 2011; Angert, 2012).

We validated our pooled fitness assay by growing the mutant pools in minimal media where we had a strong prediction of which genes should have fitness defects. Most of the 53 annotated amino-acid synthesis genes had strong fitness defects in minimal media and were rescued by the addition of casamino acids (CAA) (Supplementary Figure 6A–C; Supplementary Table 4). We were unable to rescue mutants of genes required for tryptophan biosynthesis (aroABCDE and trpDE), whichcan be explained because CAA does not contain tryptophan; it is lost during the preparation of CAA, which involves acid hydrolysis of casein. As a second test of auxotroph rescue, we grew the Z. mobilis transposon pools in the presence of methionine, and this specifically rescued the fitness defect ofsix genes (metCEFWXZ) all predicted to be required for methionine biosynthesis (Supplementary Figure 6C). We then carried out single-mutant follow-up studies on a metC::TN5 mutant to confirm that fitness defects in the pooled assay can be recapitulated at the single strain level (Supplementary Figure 6D). As expected, growth of metC::TN5 on minimal media could be rescued by the addition of methionine.

In addition to our biological tests, we calculated two metrics (strain and operon correlation), as previously described (Deutschbauer et al, 2011) that were used to measure overall experiment quality and to flag potential experimental errors (Supplementary Figure 6E–G). In the typical experiment, the correlation of the 1057 identical strains contained in both pools was 0.89 and the correlation of fitness between adjacent genes in the same operon was 0.50. Experiments with poor quality metrics (operon correlation <0.4 or strain correlation <0.75) were repeated, and kept if reproducible across multiple biological replicates. In sum, our validation confirms that our Z. mobilis pooled fitness assay provides accurate and biologically meaningful results that could be used to study hydrolysate tolerance.

Genome-wide fitness profiling of Z. mobilis mutants in plant hydrolysates and 37 chemical components

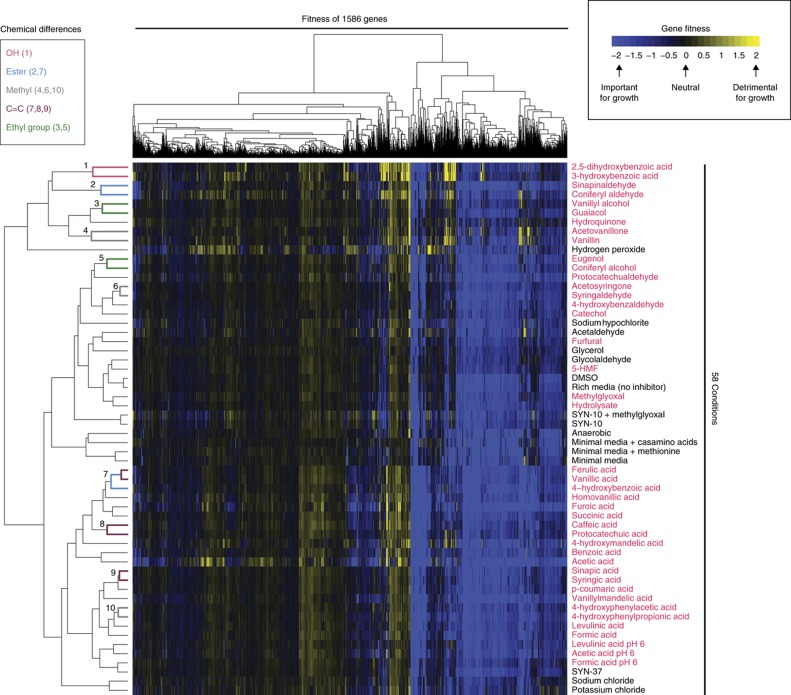

Using high-throughput culturing methods we recently developed for Shewanella oneidensis MR-1 (Deutschbauer et al, 2011), we performed 189 whole-genome mutant fitness experiments with our two Z. mobilis pools. These 189 experiments represent 58 unique experimental conditions including miscanthus and switchgrass hydrolysates, 2 types of synthetic hydrolysate mixtures (SYN-37 and SYN-10), 37 individual compounds that are present in miscanthus hydrolysate, and 11 other stress conditions (Supplementary Table 5). Most fitness experiments were performed in rich media without inhibitors and in rich media supplemented with hydrolysate or specific compounds of interest. We tested each potential growth inhibitor at several different concentrations to identify the suitable concentration for mutant fitness experiments. In general, we selected the concentration that caused about a two-fold increase in doubling time and gave a fitness pattern that was reproducibly different from the baseline rich media condition (see Materials and methods). An overview of our fitness data set is shown as a clustered heat map of average gene fitness values (Figure 2). Gene fitness values were averaged across replicate conditions, such as rich media (24 replicates) or identical concentrations of the same inhibitor. We also averaged the gene fitness values for 37 hydrolysate experiments (Supplementary Figure 7) that included both miscanthus and switchgrass samples (from single field sites or batch material). The complete, non-averaged data set can be found in Supplementary Dataset 1 and online ( http://genomics.lbl.gov/supplemental/zm4hydrolysate/).

Figure 2.

Genome-wide fitness profiling of Z. mobilis in 58 experimental conditions, including plant hydrolysate and 37 individual components of hydrolysate. Average gene fitness data are represented as a two-dimensional heat map for 1586 genes (X axis) and 58 experimental conditions (Y axis). For each transposon mutant in our pool, strain fitness is calculated as log2 ratio of (END/START). Gene fitness values are the average of per-strain fitness across all insertions within that gene and are displayed according to the color bar at the top right of the heat map. In addition, gene fitness values have also been averaged across replicate experimental conditions. Chemicals with similar structures cluster together on the Y axis (labeled 1–10) and differ by a single functional group, as colored by the key at the top left. For example, compounds 2,5-dihydroxybenzoic acid and 3-hydroxybenzoic acid (cluster 1) differ by a single hydroxyl group (see Supplementary Figure 8 for more examples). The fitness data were clustered in both dimensions by hierarchical agglomerative clustering with complete linkage. Euclidean distance was used as the distance metric for genes and Pearson’s correlation was used as the similarity metric for experimental conditions. Hydrolysate components are indicated by red text.

Two-dimensional hierarchical clustering of the averaged gene fitness data revealed two broad categories. One large group represents genes that when mutated have little or no fitness defect in the 58 conditions we tested (left half, Figure 2). Additional experimental conditions might uncover phenotypes for these mutants. The second large group had fitness defects in nearly all 58 conditions, including rich media (right half, Figure 2). With a fitness value of −1 or less, we identified 402 genes that were important for growth in rich media and 1184 that are not. Of these 402 genes, 185 (46%) are expected to be essential (see Materials and methods), while just 5% of the other 1184 genes are expected essentials (P<10−15, Fisher’s exact test). Because this large cluster of genes had negative fitness values in our baseline condition (rich media), and many are likely to be essential, they were not pursued further in this study. In addition, we found that mutants in expected essential genes were more likely to have a low abundance in our starting pool (Supplementary Figure 3B), making it more difficult to perform accurate fitness measurements on these strains.

Clustering the fitness data by condition revealed a few large groups of similar conditions, such as organic acids (Y -axis, near bottom, Figure 2). In many cases, these broad groups included chemicals of different classes, and it was not clear why they formed a cluster. However, within these broad groups, we found that chemicals with highly similar structures clustered closely (Clusters 1–10 on Y axis, Figure 2). In 10 cases, these closely related chemicals differed by a single functional group, such as a single hydroxyl, ester, methyl, or C=C group (Supplementary Figure 8). For example, cluster 1 on the Y axis contains two chemicals (2,5-dihydroxybenzoic acid and 3-hydroxybenzoic acid) that differ by a single hydroxyl group. In sum, chemicals with closely related structures had very similar fitness profiles. Our results are consistent with previous chemogenomic studies and likely reflect the underlying similarity in mechanism of action for structurally related inhibitory compounds (Hillenmeyer et al, 2010).

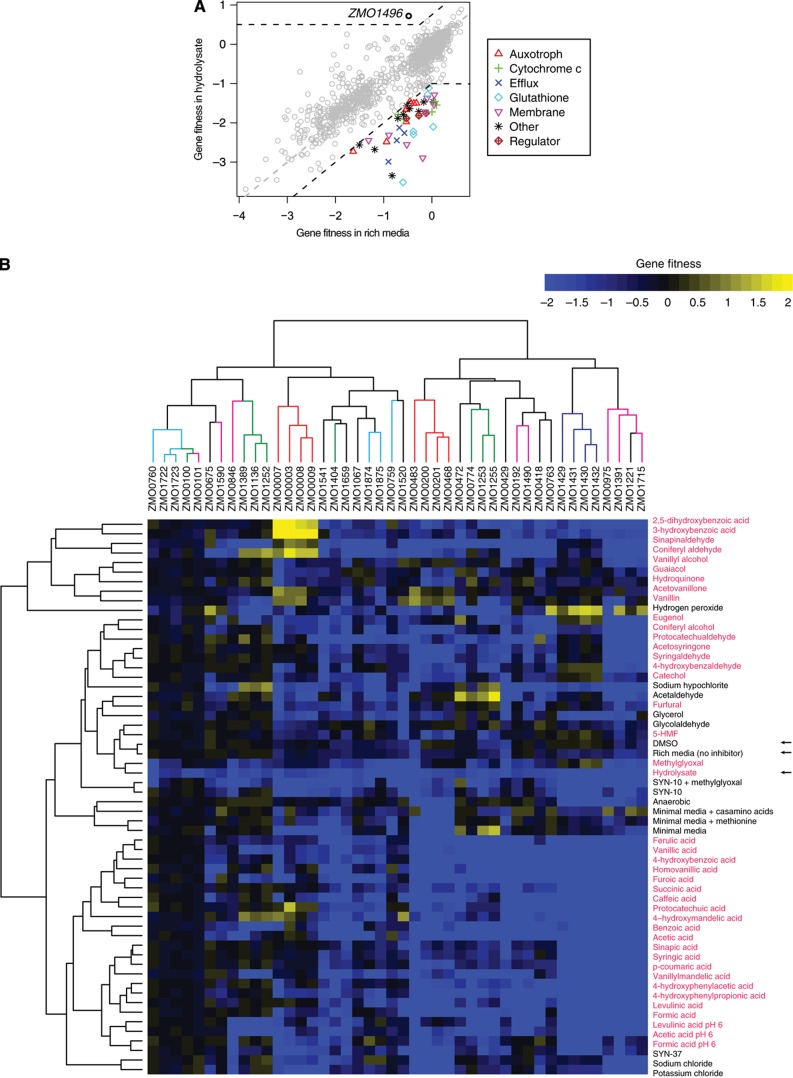

Identification of 44 putative hydrolysate tolerance genes in Z. mobilis

To identify genes that are important for growth in hydrolysate, we searched for mutants that showed a significant difference in fitness between rich media supplemented with hydrolysate and plain rich media. Based on this criterion (fitnesshydrolysate <−1 and fitnesshydrolysate<fitnessrich −1), we identified 44 putative hydrolysate tolerance genes that were further grouped into 7 functional categories (Figure 3A; Table I; Supplementary Dataset 2). In contrast, using a second criterion (fitnesshydrolysate>0.5 and fitnesshydrolysate>fitnessrich+0.75), we found only one gene, ZMO1496, that was detrimental for growth in hydrolysate, which encodes phosphoenolpyruvate (PEP) carboxylase (fitness in hydrolysate=0.72 versus rich media=−0.48). Because signal intensity on microarrays can saturate, we believe that our pooled fitness assays have a reduced sensitivity for mutants with positive fitness, which may explain why we only identified one mutant in the positive fitness category. In this study, we only pursued the negative fitness mutants.

Figure 3.

Identification of 44 Z. mobilis genes that are important for growth and 1 gene that is detrimental for growth in plant hydrolysate. (A) Scatter plot of gene fitness values in rich media (average of 24 experiments) versus gene fitness in hydrolysate (average of 37 experiments) for 1586 Z. mobilis genes. A dashed grey line indicates X=Y and dashed black lines indicate the cutoffs used to select tolerance genes. Putative tolerance genes have a more negative fitness value in hydrolysate than in rich media and are indicated by colored symbols. They are further classified based on their predicted function, as indicated in the legend. A single gene (ZMO1496), indicated by a black circle, was found to be detrimental for growth in plant hydrolysate. (B) Subset of average gene fitness data from Figure 2, showing only the fitness data for the 44 tolerance genes. The 37 hydrolysate components are indicated by red text. Arrows indicate the baseline condition without any added inhibitors (rich media), or rich media supplemented with DMSO (DMSO) or plant hydrolysate (hydrolysate). Gene fitness values are colored according to the color bar at the top right of the heat map. Each tolerance gene on the X axis is labeled by its systematic gene name (ZMOxxxx) and the clustering is colored based on predicted functional classes, as in (A). Tolerance genes were clustered by Euclidean distance, and conditions were clustered as in Figure 2.

Table 1. Table of 44 Z. mobilis hydrolysate tolerance genes identified in this study.

| Gene | Class | Annotation |

|---|---|---|

| ZMO0003 | auxo | Adenylylsulfate kinase |

| ZMO0007 | auxo | Phosphoadenosine phosphosulfate reductase |

| ZMO0008 | auxo | Sulfite reductase subunit beta |

| ZMO0009 | auxo | Sulfite reductase subunit alpha |

| ZMO0100 | reg | Transcriptional regulator, HxlR family |

| ZMO0101 | mem | NAD-dependent epimerase/dehydratase |

| ZMO0192 | mem | Peptidase M48 Ste24p |

| ZMO0200 | auxo | Anthranilate phosphoribosyltransferase |

| ZMO0201 | auxo | Glutamine amidotransferase of anthranilate synthase |

| ZMO0418 | other | Hypothetical protein |

| ZMO0429 | other | Iron-sulfur cluster assembly accessory protein |

| ZMO0468 | auxo | Anthranilate synthase component I |

| ZMO0472 | other | rpsU-divergently transcribed protein |

| ZMO0483 | auxo | Homoserine dehydrogenase |

| ZMO0675 | other | Transcriptional regulator, LysR family |

| ZMO0759 | glt | Hydroxyacylglutathione hydrolase |

| ZMO0760 | glt | Glyoxalase/bleomycin resistance protein/dioxygenase |

| ZMO0763 | other | Tetratricopeptide domain protein |

| ZMO0774 | reg | Transcriptional regulator, LysR family |

| ZMO0846 | mem | Sodium/hydrogen exchanger |

| ZMO0975 | mem | Conserved hypothetical membrane spanning protein |

| ZMO1067 | other | Fe-S metabolism-associated SufE |

| ZMO1136 | cytc | Cytochrome c peroxidase |

| ZMO1221 | other | Hypothetical protein |

| ZMO1252 | cytc | Cytochrome c biogenesis factor-like protein |

| ZMO1253 | cytc | Cytochrome c biogenesis protein |

| ZMO1255 | cytc | Cytochrome c assembly protein |

| ZMO1389 | cytc | Cytochrome c biogenesis protein transmembrane region |

| ZMO1391 | mem | Diacylglycerol kinase catalytic region |

| ZMO1404 | reg | RNA polymerase, sigma-24 subunit, ECF subfamily |

| ZMO1429 | eff | RND efflux system, outer membrane lipoprotein, NodT family |

| ZMO1430 | eff | Efflux transporter, RND family, MFP subunit |

| ZMO1431 | eff | Hypothetical protein |

| ZMO1432 | eff | Fusaric acid resistance protein conserved region |

| ZMO1490 | mem | Hypothetical protein |

| ZMO1520 | other | Hypothetical protein |

| ZMO1541 | other | Ferrous iron transport protein B |

| ZMO1590 | mem | ABC transporter related protein |

| ZMO1659 | other | ATP-dependent metalloprotease FtsH |

| ZMO1715 | mem | Biopolymer transport protein ExbD/TolR |

| ZMO1722 | glt | S-(hydroxymethyl)glutathione dehydrogenase/class III alcohol dehydrogenase |

| ZMO1723 | glt | Hypothetical protein |

| ZMO1874 | glt | BolA family protein |

| ZMO1875 | glt | Hypothetical protein |

Systematic gene names, their functional class, and annotation are listed. Functional classes are auxo (auxotroph), cytc (cytochrome c), eff (efflux), glt (glutathione related), mem (membrane), other (other), and reg (regulator). Annotations were obtained from RefSeq ( http://www.ncbi.nlm.nih.gov/RefSeq/).

The 44 putative tolerance genes included 8 auxotrophs, 5 genes involved in cytochrome c biogenesis or cytochrome c-containing proteins, 4 efflux pump-related genes, 6glutathione-related genes, 8 genes related to membranes or the cell wall, 3 regulators, and 10 other genes (Table I). The variety of predicted gene functions suggests that the cellular response to growth in hydrolysate is complex and that hydrolysate tolerance is a multigenic trait. This is consistent with the fact that plant hydrolysates are complex mixtures containing a variety of chemical classes (e.g., weak organic acids, furans, aldehydes, and phenolics) that likely affect cell physiology by different mechanisms of action.

To confirm the pooled fitness results, 25 transposon mutants were selected from our set of 44 tolerance genes for detailed follow-up studies (Supplementary Table 6). This group of strains represents examples from each of the seven functional classes we identified. Each mutant was re-streaked to a single colony isolate and their transposon insertion sites were verified by PCR and DNA sequencing. We then used our transposon stability assay to check whether the insertion was stable or mixed. Nine of the twenty-five mutants had mixed transposon insertions and were not studied further. Four of these nine mixed mutants were in a single operon encoding an efflux pump (ZMO1429-ZMO1432). Of the remaining 16 stable mutants, we confirmed negative fitness defects for 13 of them, when grown in batch 1 or batch 2 miscanthus hydrolysate (e.g., see Supplementary Figure 9). In addition, we complemented three mutants (ZMO0100::TN5, ZMO1722::TN5, and ZMO0759::TN5) by expression of the corresponding wild-type gene on a plasmid, demonstrating that the observed phenotype is due to a single gene defect (Supplementary Figure 10). In sum, these data demonstrate that our pooled fitness assay can be used to identify bona fide hydrolysate tolerance genes that are critical for growth in plant hydrolysate.

To further understand the specific function of each putative tolerance gene, we examined the fitness pattern for these 44 genes in each of the 37 components (colored red) known to be present in miscanthus and switchgrass hydrolysates (Figure 3B). Broadly, most of the tolerance genes had fitness defects in many of the individual hydrolysate components, which makes it difficult to infer a specific detoxification function for any particular tolerance gene. Some of the tolerance genes might respond to or detoxify a class of compounds, such as aldehydes, so this could explain the lack of a one-to-one relationship between gene fitness and hydrolysate component. While more detailed follow-up studies will be required to determine the specific biochemical functions of these tolerance genes, we find that hydrolysate tolerance genes with related functions cluster together on our fitness data heatmap (X axis, Figure 3B). For example, one cluster contains four auxotrophs that are part of the sulfate assimilation pathway (cysCHIJ encoded by ZMO0003, ZMO0007, ZMO0008, and ZMO0009), and a second cluster contains cytochrome c peroxidase (CCP) (ZMO1136) and two genes that are involved in cytochrome c biogenesis (ZMO1389 and ZMO1252). Many of these fitness clusters contain genes that are predicted to form operons, which are also consistent with their shared function (ZMO0100-ZMO0101, ZMO0007-ZMO0009, ZMO1874-ZMO1875, ZMO0200-ZMO0201, ZMO1429-ZMO1432).

Five hydrolysate tolerance genes (ZMO0760, ZMO0100, ZMO0101, ZMO1722, and ZMO1723) did not exhibit a fitness defect in any of the 37 inhibitors we tested. These hydrolysate-specific mutants might be affected by some unknown component of hydrolysate or only by a combination of inhibitors. To test the latter possibility, we made two synthetic hydrolysate mixtures based on the composition of miscanthus batch 1; one contained the 10 most abundant inhibitors (SYN-10; furfural, acetic acid, formic acid, levulinic acid, succinic acid, 5-HMF, 2-furoic acid, vanillin, vanillic acid, and syringaldehyde), and the second contained the full set of 37 inhibitors and four sugars: glucose, xylose, arabinose, and cellobiose (SYN-37). The composition of SYN-10 and SYN-37 was verified using GC/MS and LC-RID and closely matched the values for batch 1 hydrolysate (Supplementary Table 1).

Fitness profiling of synthetic hydrolysate mixtures in Z. mobilis and S. cerevisiae

We first examined the effect of SYN-10 and SYN-37 on the growth of Z. mobilis and found that both mixtures were less potent than the batch 1 and batch 2 hydrolysates and inhibited growth in a similar manner (Supplementary Figure 11A, P<10−5, analysis of variance (ANOVA)). This suggests that our synthetic mixtures are missing critical inhibitory components. To further understand this difference, we performed pooled fitness assays in the presence of SYN-10 or SYN-37 (Supplementary Figure 12A; Figure 4A). The fitness profiles of SYN-10 and SYN-37 were very similar (R2=0.807, Supplementary Figure 12B), consistent with their similar growth effects on Z. mobilis. However, a plot of average fitness in SYN-37 versus average fitness in hydrolysate shows that nine genes are outliers (fitnesshydrolysate <−1 and fitnessSYN-37>−1/3, enclosed by dashed black lines in Figure 4A). Of the 9 genes, 5 are important for growth in hydrolysate but not in any of the 37 components (ZMO0760, ZMO1722, ZMO1723, ZMO0100, and ZMO0101, all fitnesscomponents>−1, leftmost cluster in Figure 3B). In addition, a heatmap of the 44 tolerance genes shows that SYN-10 and SYN-37 are more alike each other than hydrolysate (Figure 4B). In sum, our synthetic mixtures do not fully recapitulate the growth and fitness effects of real hydrolysate and the presence of outliers indicates that there are unidentified hydrolysate components that contribute to its overall toxicity.

Figure 4.

Synthetic hydrolysate mixtures do not fully explain the fitness profile of real hydrolysate. Two synthetic hydrolysate mixtures containing either 37 components (SYN-37) or the 10 most abundant components (SYN-10) were made based on the composition of miscanthus batch 1 (Supplementary Table 1). Data for SYN-10 are shown in Supplementary Figure 12. (A) Scatterplot of Z. mobilis gene fitness data in SYN-37 (average of 4 experiments) versus in hydrolysate (average of 37 experiments). The 44 Z. mobilis tolerance genes are color coded by category. Nine outlier genes (defined by two dashed black lines) have more negative gene fitness values in hydrolysate than in SYN-37, and are listed in a black box and color coded by category. (B) Heatmap of gene fitness data for the 44 Z. mobilis tolerance genes. Genes were clustered by Euclidean distance with complete linkage using all non-averaged fitness data. Fitness values are colored according to the color bar. The baseline conditions are rich media (ZRMG) and rich media supplemented with DMSO (DMSO). (C) Scatterplot of S. cerevisiae gene fitness data in SYN-37 (average of 6 experiments) versus in batch 1 miscanthus hydrolysate (average of 6 experiments). In all, 99 putative tolerance genes are color coded according to their function as indicated on the graph legend. Twenty of these genes are outliers (defined by two dashed black lines) and have more negative fitness values in hydrolysate than in SYN-37. Outlier genes are listed in a black box and color coded according to the legend. (D) Heatmap of gene fitness data for the 99 S. cerevisiae tolerance genes. Genes were clustered as in (B). Fitness values are colored according to the color bar. Two baseline conditions are shown: YPD is the rich media used for S. cerevisiae growth (n=3) and ZRMG is the rich media used for Z. mobilis growth that was also used to prepare the SYN-10 and SYN-37 synthetic hydrolysate mixtures (n=2, see Materials and methods).

To determine whether synthetic mixtures can recapitulate the fitness profile of plant hydrolysates in other organisms, we chose Saccharomyces cerevisiae, for which a genome-wide collection of DNA-barcoded deletion strains is available (Giaever et al, 2002). First, we profiled the S. cerevisiae homozygous deletion library (as a pool) in the presence of batch 1 hydrolysate. To identify the putative tolerance genes in S. cerevisiae, we searched for mutants with a significant fitness defect in rich media (YPD) supplemented with hydrolysate, but not in the rich media baseline condition. Using the same selection criterion as for Z. mobilis (fitnesshydrolysate <−1 and fitnesshydrolysate<fitnessrich −1), we identified 99 yeast hydrolysate tolerance genes. As in Z. mobilis, the S. cerevisiae tolerance genes represent a variety of functional categories and pathways, including 12 regulatory genes, 12 amino-acid biosynthesis genes, 4 pentose phosphate pathway genes, 15 membrane/secretion-related genes, and 5 oxidant-induced cell-cycle arrest (OCA) genes (Table II; Supplementary Figure 13; Supplementary Dataset 3). The overlap withthe Z. mobilis tolerance genes was just two genes involved in amino-acid biosynthesis (see Discussion).

Table 2. Table of 99 S. cerevisiae hydrolysate tolerance genes identified in this study.

| Class | ORF | Gene |

|---|---|---|

| AA biosynthesis | YDR127W | ARO1 |

| AA biosynthesis | YGL148W | ARO2 |

| AA biosynthesis | YPR060C | ARO7 |

| AA biosynthesis | YAL012W | CYS3 |

| AA biosynthesis | YJL101C | GSH1 |

| AA biosynthesis | YDR158W | HOM2 |

| AA biosynthesis | YER052C | HOM3 |

| AA biosynthesis | YJR139C | HOM6 |

| AA biosynthesis | YER086W | ILV1 |

| AA biosynthesis | YCR053W | THR4 |

| AA biosynthesis | YKL211C | TRP3 |

| AA biosynthesis | YGL026C | TRP5 |

| Membrane | YBR036C | CSG2 |

| Membrane | YLR436C | ECM30 |

| Membrane | YMR202W | ERG2 |

| Membrane | YGL012W | ERG4 |

| Membrane | YMR015C | ERG5 |

| Membrane | YPL057C | SUR1 |

| Membrane | YBR058C-A | TSC3 |

| OCA | YNL099C | OCA1 |

| OCA | YNL056W | OCA2 |

| OCA | YCR095C | OCA4 |

| OCA | YHL029C | OCA5 |

| OCA | YDR067C | OCA6 |

| Other | YLR338W | OPI9 |

| Other | YDR136C | VPS61 |

| Other | YLR261C | VPS63 |

| Other | YNL148C | ALF1 |

| Other | YML035C | AMD1 |

| Other | YGL105W | ARC1 |

| Other | YHR013C | ARD1 |

| Other | YBR068C | BAP2 |

| Other | YPL161C | BEM4 |

| Other | YFL023W | BUD27 |

| Other | YFR036W | CDC26 |

| Other | YPL241C | CIN2 |

| Other | YGR092W | DBF2 |

| Other | YFL001W | DEG1 |

| Other | YMR126C | DLT1 |

| Other | YDL172C | Dubious |

| Other | YJL120W | Dubious |

| Other | YDR048C | Dubious |

| Other | YML122C | Dubious |

| Other | YDR008C | Dubious |

| Other | YDL050C | Dubious |

| Other | YDR125C | ECM18 |

| Other | YGL168W | HUR1 |

| Other | YJL082W | IML2 |

| Other | YOL081W | IRA2 |

| Other | YOR322C | LDB19 |

| Other | YDL051W | LHP1 |

| Other | YDR378C | LSM6 |

| Other | YNL147W | LSM7 |

| Other | YBR255W | MTC4 |

| Other | YDL040C | NAT1 |

| Other | YOR209C | NPT1 |

| Other | YDR360W | OPI7 |

| Other | YDL173W | PAR32 |

| Other | YHR071W | PCL5 |

| Other | YGR240C | PFK1 |

| Other | YGR233C | PHO81 |

| Other | YPR153W | Putative protein |

| Other | YDR529C | QCR7 |

| Other | YMR283C | RIT1 |

| Other | YJR063W | RPA12 |

| Other | YOL138C | RTC1 |

| Other | YGL100W | SEH1 |

| Other | YOR035C | SHE4 |

| Other | YNL032W | SIW14 |

| Other | YCR033W | SNT1 |

| Other | YMR304W | UBP15 |

| Other | YKR020W | VPS51 |

| Other | YNL246W | VPS75 |

| Other | YML097C | VPS9 |

| Other | YNL107W | YAF9 |

| PPP | YJL121C | RPE1 |

| PPP | YLR354C | TAL1 |

| PPP | YPR074C | TKL1 |

| PPP | YNL241C | ZWF1 |

| Regulatory | YPL202C | AFT2 |

| Regulatory | YDR173C | ARG82 |

| Regulatory | YIR023W | DAL81 |

| Regulatory | YOL051W | GAL11 |

| Regulatory | YGR163W | GTR2 |

| Regulatory | YOL012C | HTZ1 |

| Regulatory | YDR162C | NBP2 |

| Regulatory | YDR195W | REF2 |

| Regulatory | YDR028C | REG1 |

| Regulatory | YDL020C | RPN4 |

| Regulatory | YHR178W | STB5 |

| Regulatory | YML007W | YAP1 |

| Secretion | YGL054C | ERV14 |

| Secretion | YML121W | GTR1 |

| Secretion | YOR070C | GYP1 |

| Secretion | YDR137W | RGP1 |

| Secretion | YLR039C | RIC1 |

| Secretion | YMR183C | SSO2 |

| Secretion | YOL018C | TLG2 |

| Secretion | YLR262C | YPT6 |

Functional class (Class), systematic gene name (ORF), and gene name (Gene) are listed. The six broad functional classes are AA biosynthesis (amino-acid biosynthesis), membrane, secretion, OCA (Oxidant-induced Cell-cycle Arrest), PPP (pentose phosphate pathway), and regulatory. These classes are based on GO annotations obtained from the Saccharomyces Genome Database ( http://www.yeastgenome.org). See Supplementary Dataset 2 for detailed annotations.

We then examined the effects of SYN-10 and SYN-37 on S. cerevisiae growth. In contrast to Z. mobilis, we found the primary effect of either synthetic or genuine hydrolysates was an increase in the length of lag phase rather than a reduction in growth rate. SYN-10 and SYN-37 increased the length of lag phase less than batch 1 or batch 2 hydrolysate did (Supplementary Figure 11B; P<10−15, ANOVA). To examine this difference in detail, we profiled the S. cerevisiae mutant pool in SYN-10 and SYN-37 (Figure 4C; Supplementary Figure 12C). The fitness profiles of SYN-10 and SYN-37 are highly similar (Figure 4D; Supplementary Figure 12D, R2=0.860) consistent with their similar effects on lag phase length. Similarly to Z. mobilis, a plot of average fitness in SYN-37 versus average fitness in batch 1 hydrolysate uncovered 20 outliers among our set of 99 tolerance genes (fitnesshydrolysate <−1 and fitnessSYN-37>−1/3) that have significant fitness defects in real hydrolysate but not in SYN-37 (listed on plot in Figure 4C).

Taken together, our results demonstrate that in both bacteria and yeast, synthetic hydrolysate mixtures of up to 37 compounds do not fully recapitulate the fitness effects of real hydrolysate, strongly suggesting that we are missing critical inhibitors from our synthetic mixtures. Consistent with our fitness data, there are many unidentified peaks in our hydrolysate GC/MS chromatograms. Prioritizing which peaks to study further using analytical chemistry is difficult without additional knowledge regarding the potential contribution of each peak to overall hydrolysate toxicity. To address this problem, we used chemogenomic profiling of our 37 known hydrolysate components and a computational model to search for key missing inhibitors.

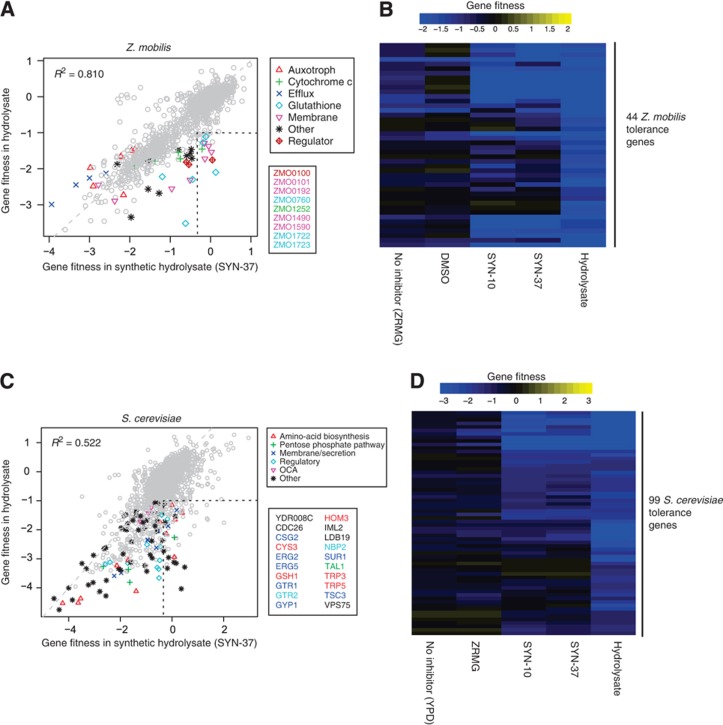

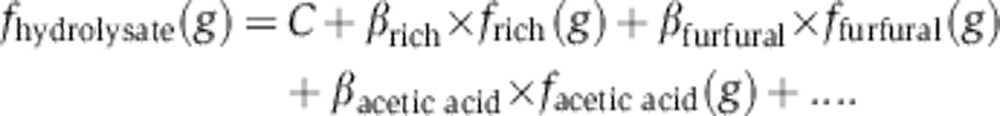

Modeling Z. mobilis hydrolysate fitness and identification of methylglyoxal as a previously unknown hydrolysate component

Using the Z. mobilis fitness data for the 37 compounds, we first modeled average gene fitness in hydrolysate as a linear combination of its fitness in each component. Our model included fitness in the baseline condition (rich media) and in the 16 (of 37 tested) components that significantly improved the fit. The full linear model, including the list of components, can be found in Supplementary Table 7. Our model (Model-16) correlates well with fitness in hydrolysate (R2=0.880, Figure 5A). This is as good a fit as we obtained with experimental fitness data from SYN-37 (R2=0.810, Figure 4A). To test for possible synergistic effects of inhibitors, we also tested a model that included non-linear interactions. We identified three significant pairs (see Materials and methods): formic acid × levulinic acid (P<10−13), furfural × 4-hydroxyphenylacetic acid (P<10−15), and furfural × vanillin (P<10−5). Adding these terms to our linear model makes relatively little difference overall (adjusted R2 rises from 0.880 to 0.893). Unlike previous growth and fermentation studies that have documented synergistic inhibitor combinations (Zaldivar and Ingram, 1999; Zaldivar et al, 1999; Oliva et al, 2004), our modeling suggests that fitness effects of hydrolysate are primarily additive (see Discussion).

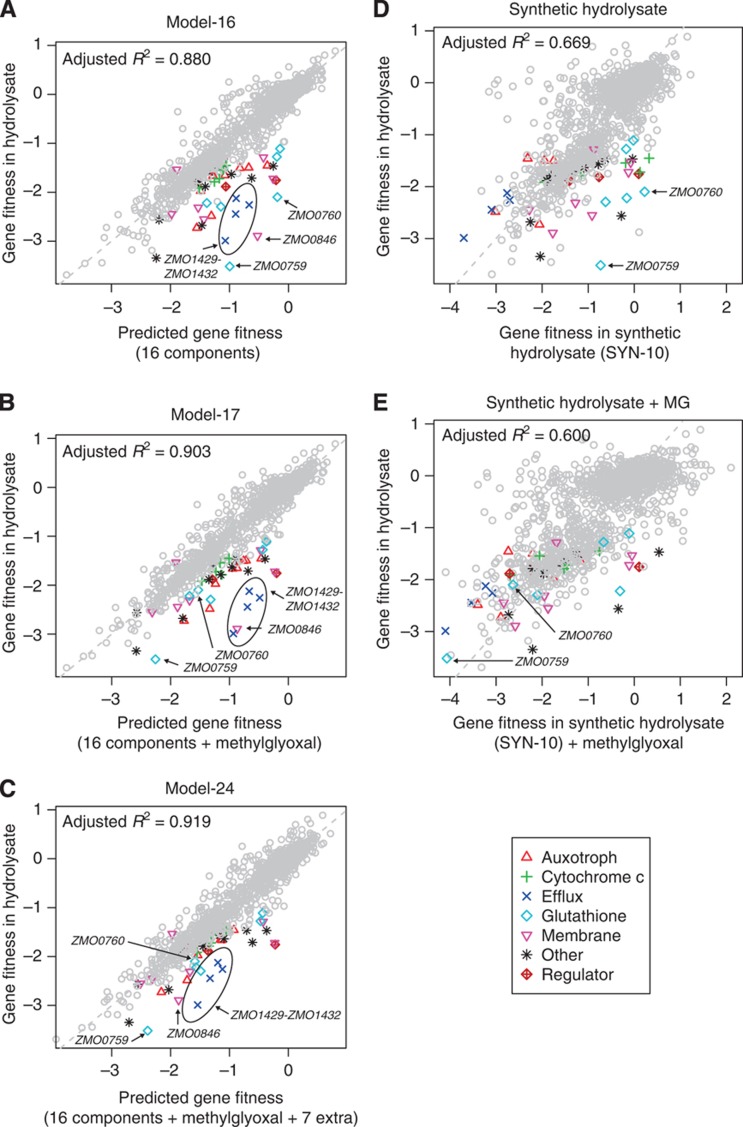

Figure 5.

Linear model of hydrolysate fitness based on fitness profiles of chemical components and identification of a new component, methylglyoxal. (A) Scatterplot of actual and predicted gene fitness in Z. mobilis. The model is a linear combination of fitness in rich media and in 16 inhibitors (Model-16). Arrows indicate three outlier genes, ZMO0759, ZMO0760, and ZMO0846. Four additional outlier genes, ZMO1429-ZMO1432, are enclosed by an ellipse. (B) Scatterplot of actual and predicted gene fitness in hydrolysate using a 17-component model that includes methylglyoxal fitness data (Model-17). (C) Scatterplot of actual and predicted gene fitness in hydrolysate using a 24-component model that includes methylglyoxal (MG) and 7 additional significant conditions (Model-24). (D) Plot of average gene fitness (n=4) for a10-component synthetic hydrolysate mixture (SYN-10) versus average gene fitness in hydrolysate (n=37). Arrows indicate two outlier genes, ZMO0759 and ZMO0760, which encode the GloAB detoxification system. Mutants in these genes are sensitive to hydrolysate but not to SYN-10. (E) In SYN-10 with methylglyoxal added (n=2), ZMO0759 and ZMO0760 are now important for fitness, which suggests that methylglyoxal stress contributes to hydrolysate toxicity. In all panels, the 44 Z. mobilis tolerance genes are color coded according to their function as indicated on the graph legend.

Our linear model does not fully explain the fitness profile of real hydrolysates. There are still several outliers where the fitness defect of the mutant predicted by our model is not as severe as observed in the real hydrolysate (Figure 5A). Two of these outliers (ZMO0760-ZMO0759) form an operon that encodes a putative GloAB glutathione-dependent enzyme system, which is required for detoxification of methylglyoxal (or other 2-oxoaldehydes) in a wide variety of organisms (Ozyamak et al, 2010). Typically, methylglyoxal is formed during unbalanced metabolism (Freedberg et al, 1971), which suggests that growth on hydrolysate leads to a methylglyoxal stress that is detoxified by the GloAB system. However, the Z. mobilis genome appears to lack a methyglyoxal synthase gene; thus, it is not clear why Z. mobilis needs a GloAB enzyme system or whether significant amounts of methyglyoxal can be formed intracellularly during unbalanced metabolism. The other outliers in our model encode a predicted efflux pump of unknown function (ZMO1429-ZMO1432) and a sodium/hydrogen exchanger (ZMO0846) (Figure 5A). ZMO0846 is a member of the KefB superfamily and may play a role in pH regulation. The presence of these outliers together with gloAB strongly suggests that we are missing critical hydrolysate components.

To investigate this, we obtained fitness profiles in methylglyoxal and a number of additional compounds and stress conditions that might result from hydrolysate exposure or from unbalanced metabolism (Supplementary Table 5). For example, furfural is known to induce the formation of reactive oxygen species (ROS) (Allen et al, 2010), so we tested two types of oxidative stress (hydrogen peroxide and sodium hypochlorite). Glycolaldehyde was recently reported to be a new component of hydrolysate, so we added this to our list of conditions (Jayakody et al, 2011). In total, we performed Z. mobilis pooled fitness assays in 11 additional conditions, including salt stress (KCl, NaCl), oxidative stress (hydrogen peroxide, sodium hypochlorite), glycerol, acetaldehyde, methylglyoxal, glycolaldehyde, and organic acids (acetic, formic, levulinic) at pH 6 to match the pH of our hydrolysate. The fitness data for these additional conditions are included in Figure 2 and 3B and Supplementary Dataset 1. Adding methylglyoxal to the regression significantly improved the fit (adjusted R2=0.903, P<10−15, ANOVA) and explained the two outliers in the GloAB system (Model-17 in Figure 5B and Supplementary Table 7). Adding all of the extra components, but removing insignificant ones, further improved the adjusted R2 to 0.919 (Model-24 in Figure 5C and Supplementary Table 7). In Model-24, the biggest improved prediction was for ZMO0846, which tends to be sensitive to organic acids at pH 6 but not in our unbuffered organic acid experiments (Figure 3B), consistent with its predicted role in pH regulation.

Our modeling results suggested that methylglyoxal might be present in our plant hydrolysates. We reanalyzed our batch 2 hydrolysate sample using a modified derivatization protocol and detected 41.4 μg/ml (0.56 mM) methylglyoxal (see Materials and methods). To our knowledge, methylglyoxal has not been previously reported in dilute-acid plant hydrolysates; however, the formation of methylglyoxal from glucose degradation has been detected in a model buffer system, and after supercritical water treatment of cellulose derived from red cedar (Thornalley et al, 1999; Nakata et al, 2006). To examine the impact of methylglyoxal in the context of hydrolysate, we measured the genome-wide fitness profile of SYN-10 alone or with 0.56 mM methylglyoxal added and compared it with the fitness profile of genuine hydrolysate. Although SYN-10 with methylglyoxal had a poorer fit to fitness in hydrolysate than SYN-10 did (R2=0.600 versus 0.669), the addition of methylglyoxal recapitulated the fitness defects of the gloAB operon (ZMO0759 and ZMO0760, compare arrows in Figure 5D and E). This suggests that ZMO0759 and ZMO0760 are important for growth in real hydrolysate because they are directly involved in methylglyoxal detoxification. Finally, we tested the effect of 0.56 mM methylglyoxal on the growth of wild-type Z. mobilis and found that addition of this hydrolysate-relevant concentration resulted in a small, but significant growth defect (Supplementary Figure 18, unpaired t-test, P<10−5). In sum, we used our modeling, fitness, and growth experiments to identify methylglyoxal as a previously unknown component of hydrolysate and to demonstrate that it contributes to overall hydrolysate toxicity in Z. mobilis.

Rational engineering of Z. mobilis for improved fermentation performance

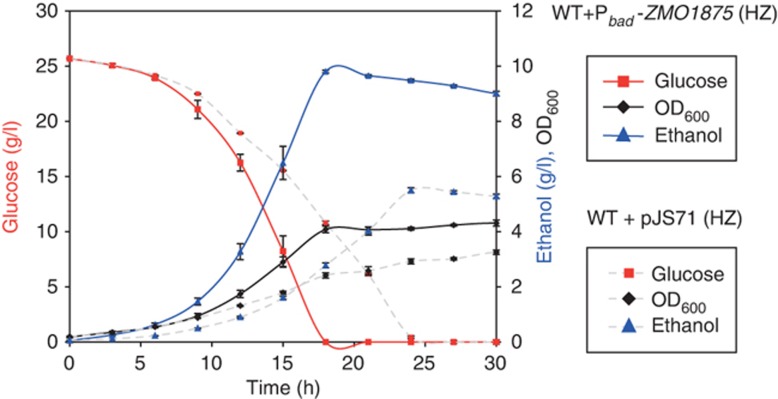

We hypothesized that overexpression of putative tolerance genes in Z. mobilis might improve its growth and ethanol production in hydrolysate. To test this idea, we systematically overexpressed 21 tolerance genes (Supplementary Table 6), which were selected because they represented examples of the various functional classes we identified. These genes were overexpressed using an arabinose inducible Pbad promoter and a broad host plasmid system that we developed for this purpose (Supplementary Figure 14). Each tolerance gene was tagged with an N-terminal FLAG tag (DDDDYDK) that allowed us to examine relative protein levels by western blot. We first screened our overexpression strains for the correct molecular weight proteins and lack of significant protein degradation (Supplementary Figure 15). Based on these data, and on our prior verification of their negative fitness phenotypes, we selected 10 transposon mutant strains for complementation studies (Supplementary Table 6). For these experiments, we asked whether each Pbad expression construct was sufficient to complement the fitness defect of the corresponding transposon mutant (e.g., see Supplementary Figure 10). Based on the complementation data, we then selected four strains for detailed fermentation studies to measure ethanol productivity in the presence of miscanthus batch hydrolysate (WT+Pbad-ZMO1722, WT+Pbad-ZMO1875, WT+Pbad-ZMO0760, and WT+Pbad-ZMO0100). Small-scale aerobic batch fermentations were performed to determine specific ethanol productivity (g/l/h/OD600). We found that overexpression of ZMO1875 improved hydrolysate tolerance and increased specific ethanol productivity 2.4-fold (0.38 versus 0.16 g/l/h/OD600), whereas overexpression of ZMO1722, ZMO0760, and ZMO0100 had no significant effect on growth or ethanol production (Figure 6; Supplementary Figure 16). Glucose is fully consumed in both the wild-type and overexpression strains, yet the wild-type strain makes both less biomass and less ethanol. This suggests that the improvements in ethanol productivity in the ZMO1875 overexpression strain are due to a metabolic shift resulting in the production of less byproducts (Amin et al, 1983; Yang et al, 2009b).

Figure 6.

Overexpression of ZMO1875 improves ethanol productivity in the presence of miscanthus hydrolysate. Batch fermentation profile of the Z. mobilis wild-type+Pbad-ZMO1875 overexpression strain grown in rich media supplemented with 8% (v/v) batch 2 miscanthus hydrolysate (HZ). A control fermentation (WT+pJS71, colored symbols over dotted grey lines) is also shown for comparison (data taken from Figure 1B). Data shown are the average of four replicates and error bars indicate standard deviation.

Discussion

Deconstructing a complex chemical stress using chemogenomic profiling

In this study, we present a combined experimental and computational approach to address two challenges: (1) to understand how a complex chemical stress affects the growth and fermentation of Z. mobilis and S. cerevisiae and (2) to rationally engineer Z. mobilis for increased ethanol production in plant hydrolysate. Using chemogenomic profiling, we identified hydrolysate tolerance genes in Z. mobilis and S. cerevisiae and we used this information to rationally improve the fermentation performance of Z. mobilis in miscanthus hydrolysate. By modeling the Z. mobilis hydrolysate fitness data and then examining outliers in the regression, we identified methylglyoxal as an unknown component of miscanthus hydrolysate that contributes to its toxicity. Although we have focused on miscanthus and switchgrass hydrolysates prepared using dilute acid at high temperature, our experimental approach is generally applicable to any plant hydrolysate regardless of method of pretreatment and hydrolysis.

To our knowledge, this study is the first use of chemogenomic profiling to deconstruct the biological response to a highly complex chemical mixture. Previous large-scale studies in yeast have used fitness profiling to understand the mechanism of action of single compounds (Jansen et al, 2009; Cokol et al, 2011). Similarly, most previous studies of hydrolysate inhibitors in bacteria and yeast have focused on single compounds or simple binary mixtures (Palmqvist et al, 1999; Zaldivar and Ingram, 1999; Zaldivar et al, 1999, 2000; Klinke et al, 2003; Oliva et al, 2004). Only a few studies have looked at more complex inhibitor mixtures or at mixtures of hydrolysate fractions (Clark and Mackie, 1984; Koppram et al, 2012). Here, we examined synthetic mixtures of up to 37 inhibitors (SYN-37), greatly extending previous work, and determined that for Z. mobilis SYN-37 is a reasonable proxy (R2=0.810) for a dilute-acid miscanthus hydrolysate. Although not tested, addition of methylglyoxal to the SYN-37 mixture might further improve this correlation. Our Model-17 results (adjusted R2=0.903) suggest that it may be possible to recapitulate the biological effects of hydrolysate with a mixture of only 17 compounds. Thus, our work provides a good starting point for developing new synthetic hydrolysate mixtures that mimic the real material and for enabling the rational engineering of hydrolysate tolerance.

Because our high-throughput fitness protocols were developed for aerobic conditions, most of the experiments in this study were performed in the presence of oxygen. However, we recognize that most industrial biofuel fermentations will likely be microaerobic or anaerobic; therefore, we performed anaerobic hydrolysate experiments in Z. mobilis to determine whether the tolerance genes we identified in this study can be used to engineer tolerance under these growth conditions. Using the same criterion for identifying aerobic tolerance genes (fitnesshydrolysate <−1 and fitnesshydrolysate<fitnessrich −1), we identified 11 genes that are important for growth in anaerobic hydrolysate (Supplementary Figure 17). Four of these genes were found in our aerobic studies (ZMO0100-ZMO0101, ZMO0759, and ZMO1490). In addition to these four genes, we identified seven new anaerobic tolerance genes (ZMO1015, ZMO1016, ZMO1017, ZMO1018, ZMO1355, ZMO1548, and ZMO1556), which provide a basis for future engineering of anaerobic hydrolysate tolerance. These results emphasize the need to match laboratory hydrolysate tolerance studies with the specific growth and environmental conditions of an industrial-scale cellulosic biofuel process. However, our approach for dissecting a complex chemical stress is general, and by collecting fitness data for the 37 components under anaerobic conditions, it should be possible to model anaerobic hydrolysate stress.

Mechanisms of hydrolysate tolerance in Z. mobilis and S. cerevisiae

In both Z. mobilis and S. cerevisiae, we identified severalbroad categories of gene functions required for hydrolysate tolerance. We also identified many genes of unknown function, or unrelated to any previously known tolerance mechanism, demonstrating that our experimental approach is a rich source of new knowledge for understanding the biological response to a complex chemical stress. Of the 44 tolerance genes we identified in Z. mobilis, only 1 (ZMO1432) has previously been reported in the patent WO 2012/082711 A1 (Caimi and Hitz, 2012). In this patent, they identified a point mutation in ZMO1432 after evolving Z. mobilis for improved fermentation performance in hydrolysate. ZMO1432 is part of a four gene operon (ZMO1429-ZMO1432) that encodes a predicted efflux pump. In our study, we identified transposon insertions in all four of these genes as sensitive to hydrolysate, which suggests that efflux of inhibitory compounds is an important mechanism for hydrolysate tolerance. Upregulation of efflux pump genes has recently been reported in a transcriptome study of E. coli growth in corn stover hydrolysate (Schwalbach et al, 2012). In S. cerevisiae, only 9 of 99 tolerance genes that we identified were previously reported in single inhibitor or hydrolysate tolerance studies (BAP2, ERG2, GTR2, LSM6, RPN4, TAL1, TKL1, YAP1, and ZWF1) (Jeppsson et al, 2003; Gorsich et al, 2006; Kawahata et al, 2006; Ma and Liu, 2010; Sundström et al, 2010; Liu, 2011; Pereira et al, 2011; Sanda et al, 2011; Gao and Xia, 2012; Hueso et al, 2012). Broadly, there is little overlap in the genes we identified with previous tolerance studies in Z. mobilis, E. coli, and S. cerevisiae (Petersson et al, 2006; Almeida et al, 2007; Miller et al, 2009b, 2010; Yang et al, 2010a, 2010b; Parawira and Tekere, 2011; Drobna et al, 2012), which likely reflects the underlying genetic complexity of tolerance, the different experimental protocols used for tolerance gene identification, and the different plant feedstocks and methods used for hydrolysate preparation. However, despite these differences, we did identify genes in two pathways (oxidative stress response and amino-acid biosynthesis) that overlap with previous studies, which suggest a fundamental role for these pathways in hydrolysate tolerance in bacteria and yeast (Miller et al, 2009a; Allen et al, 2010; Warner et al, 2010). In addition, our work in Z. mobilis has uncovered genes involved in sulfate assimilation and iron-sulfur (Fe-S) cluster assembly and repair that represent new potential gene targets for strain engineering.

Oxidative stress response

In both Z. mobilis and S. cerevisiae, we identified tolerance genes involved in oxidative stress response, which suggests that growth in hydrolysate induces the intracellular formation of ROS, which includes hydrogen peroxide, superoxide anion, and hydroxyl radicals. Although not tested, these ROS are not likely to be present in our plant hydrolysates due to their chemical instability. Furfural, which is an abundant component of plant hydrolysates, can induce the formation of ROS in S. cerevisiae, and provides a direct link between oxidative stress and hydrolysate toxicity (Allen et al, 2010). In our Z. mobilis gene fitness data, we identified CCP (ZMO1136), and a number of genes involved in cytochrome c biogenesis (ZMO1252, ZMO1253, ZMO1255, and ZMO1389) that are important for growth in hydrolysate. CCP converts hydrogen peroxide to water (Mishra and Imlay, 2012), and likely has a direct role in hydrolysate tolerance by reducing the levels of this ROS. Consistent with previous studies of Z. mobilis CCP (Charoensuk et al, 2011), we find that mutants in ZMO1136 are sensitive to hydrogen peroxide (average fitness in rich media=0.003, average fitness in hydrogen peroxide=−3.82, Supplementary Dataset 1). Previous work in E. coli identified three genes involved in peroxide detoxification (ahpC, tpx, and bcp) that were important for growth in corn stover hydrolysate (Warner et al, 2010). In our S. cerevisiae hydrolysate fitness data, we identified YAP1, which is a known regulator of the oxidative stress response, including the response to peroxides (Veal et al, 2003; Drobna et al, 2012), and previously found to be important for growth in 5-HMF, an abundant component of hydrolysate (Ma and Liu, 2010). We also identified two transcriptional targets (GSH1 and CYS3) of the YAP1 regulator (Nisamedtinov et al, 2011), further implicating the YAP1 pathway. In addition, we identified five OCA genes (OCA1, OCA2, OCA4, OCA5, and OCA6) that are important for growth in hydrolysate, which are involved in the repair of lipids after oxidative damage (Alic et al, 2001). Together, our data suggest that in both bacteria and yeast, growth in hydrolysate leads to the formation of intracellular peroxides and that peroxide detoxification is an important mechanism of hydrolysate tolerance.

Amino-acid biosynthesis

We also implicated amino-acid biosynthesis as a mechanism of hydrolysate tolerance in both Z. mobilis and S. cerevisiae. We found that both homoserine dehydrogenase (ZMO0483 or HOM6), which is required for methionine biosynthesis, and glutamine amidotransferase (ZMO0201 or TRP3), which is required for tryptophan biosynthesis, are important for growth in hydrolysate. In addition, we identified four tolerance genes involved in sulfate assimilation, which also suggests a role for cysteine biosynthesis in hydrolysate tolerance; although this pathway may play other roles in hydrolysate tolerance (see next section). Our work is consistent with previous studies in E. coli which found that addition of cysteine and methionine to the growth media helped alleviate furfural, acetic acid, and hydrolysate toxicity (Roe et al, 2002; Miller et al, 2009a; Nieves et al, 2011; Sandoval et al, 2011). In E. coli, reduction of furfural depletes NADPH, which limits sulfate assimilation by the NADPH-dependent enzyme sulfite reductase encoded by cysIJ. Acetate appears to block methionine biosynthesis downstream of homocysteine, which leads to accumulation of this toxic intermediate (Roe et al, 2002). Our studies also suggest that addition of methionine and cysteine might improve hydrolysate tolerance; however, our fitness experiments were conducted in rich media (ZRMG or YPD), which should have high levels of these amino acids, in contrast to previous studies that were conducted in minimal media (Nieves et al, 2011). It is not clear why we identified amino-acid biosynthesis genes in our rich media growth conditions, but the overlap with previous studies strongly suggests a fundamental role for amino-acid biosynthesis in hydrolysate tolerance in both bacteria and yeast.

Sulfate assimilation

Our fitness data in Z. mobilis also suggest that growth in hydrolysate induces ROS that lead to an increased demand for cysteine biosynthesis and for sulfide. We identified four Z. mobilis auxotrophs in the sulfate assimilation pathway (ZMO0003, ZMO0007, ZMO0008, and ZMO0009) encoding CysC, CysH, CysI, and CysJ, respectively, which are needed for de novo cysteine biosynthesis and are important for growth in hydrolysate. In Salmonella typhimurium, the CysB regulon is induced by oxidants, such as hydrogen peroxide or menadione, and cysCIJ mutants have reduced levels of glutathione and induce an oxidative stress response (Turnbull and Surette, 2010). Similarly, growth of Z. mobilis in hydrolysate may lead to reduced levels of glutathione, which is formed from glutamate and cysteine; thus, this might explain the increased demand for cysteine. In addition, the sulfate assimilation pathway also functions to provide sulfur for assembly of Fe-S clusters; thus, it is likely that this pathway has multiple roles in hydrolysate tolerance.

Fe-S clusters

Fe-S clusters are essential enzyme prosthetic groups that can be damaged by ROS (Djaman, 2004). A number of pathways exist in E. coli for the repair of Fe-S clusters that have been damaged by oxidative stress (Yang, 2002; Djaman, 2004; Bitoun et al, 2008). We identified four tolerance genes in Z. mobilis (ZMO0429, ZMO1067, ZMO1874, and ZMO1875) that provide a causal link between growth in hydrolysate, oxidative stress, and Fe-S clusters. In Z. mobilis, ZMO0429 and ZMO1067 encode predicted Fe-S assembly proteins, and ZMO1874 encodes a predicted BolA family member, which has also been linked to Fe-S cluster assembly (Li and Outten, 2012); however, ZMO1875 has no predicted function. The fitness profiles of ZMO1067::TN5, ZMO1874::TN5, and ZMO1875::TN5 are similar and cluster together (Figure 3B), suggesting a shared function in Fe-S cluster repair and hydrolysate tolerance.

BolA family members have recently been shown to interact with GrxD family monothiol glutaredoxins in both E. coli and S. cerevisiae (Huynen et al, 2005; Koch and Nybroe, 2006; Rouhier et al, 2010; Shakamuri et al, 2012). These complexes directly bind Fe-S clusters, and are thought to function in both Fe-S cluster assembly and regulation of new Fe-S cluster synthesis (Kumanovics et al, 2008; Cameron et al, 2011; Shakamuri et al, 2012; Willems et al, 2012). Consistent with this role, ZMO1874 is in the same operon with a predicted monothiol glutaredoxin (ZMO1873) and an Fe-S containing enzyme quinolinate synthetase (ZMO1871), which is involved in NAD biosynthesis. The ZMO1874-ZMO1873 complex may function to assemble Fe-S clusters in the quinolinate synthetase enzyme, or regulate its activity.

ZMO1875 encodes a gene of unknown function (DUF1476), which, in this study, was used to improve ethanol productivity in the presence of hydrolysate. One recent study identified a DUF1476 protein that functions as an inhibitory subunit of the FoF1 ATP synthase complex (Morales-Rios et al, 2010). It is not clear how inhibiting ATP synthase would improve hydrolysate tolerance, and ATP synthase is not consistently detrimental to fitness in hydrolysate. Instead, we propose that ZMO1875 functions together with BolA-GrxD like complexes in Z. mobilis (ZMO1874-ZMO1873) to assemble Fe-S clusters in the enzyme quinolinate synthetase or to regulate the de novo biosynthesis of new Fe-S clusters, to replace those that have been damaged by ROS. This is the first example, to our knowledge, of targeting Fe-S cluster pathways for engineering improved hydrolysate tolerance.

Synergistic effects of inhibitors

Previous studies have explored synergistic interactions between hydrolysate inhibitors, based on effects on growth and fermentation (Palmqvist et al, 1999; Zaldivar and Ingram, 1999; Zaldivar et al, 1999, 2000). Some combinations of compounds inhibit growth or ethanol production more than one would expect from the activity of the compounds individually. The mechanisms behind this synergistic inhibition of growth are not well understood. More broadly, synergistic inhibition on growth appears to be common but not predominant—a recent study found that 38 of 200 pairs of antifungal drugs synergistically inhibited the growth of S. cerevisiae (Cokol et al, 2011).

Here, we focused on a related but different question: do inhibitors have synergistic effects on a mutant's growth relative to wild type? We found that gene fitness on hydrolysate can be modeled as a linear combination of gene fitness on the individual compounds. Furthermore, although some genes were important for fitness in plant hydrolysate without being important for fitness on any of the known components, these genes were not important for fitness in synthetic hydrolysate mixtures, which suggests that they are important for resisting unidentified components. Similarly, we did not identify any genes with much lower fitness in the defined mixtures SYN-10 or SYN-37 than in any of their components (the biggest reductions in fitness, relative to the minimum on the components, were –1.1 and –0.6, respectively). Finally, we considered adding interaction terms of the form X × Y to our regression. These would be necessary if combining inhibitors converts some mutants’ mild phenotypes into severe ones. Although we found interaction terms that were statistically significant, adding them did not lead to a notable improvement in the fit of the model.

Implications for rational engineering of hydrolysate tolerance

The success of our linear model for predicting hydrolysate fitness suggests that we can separately engineer tolerance to individual components, and then combine these improvements into a single strain. The successful evolution of a S. cerevisiae strain for improved fermentation in spruce hydrolysate by adaptation to a cocktail of 12 inhibitors is consistent with our hypothesis that the biological response to hydrolysate can be understood as the combination of responses to the individual compounds (Koppram et al, 2012). A combinatorial engineering approach has already proved successful for improving tolerance to a binary mixture of inhibitors (Sommer et al, 2010). In their study, they identified three genes, recA, orfX, and udpE that conferred resistance to either 2-furoic acid or syringaldehyde. When these three genes were co-expressed, the combination conferred tolerance to the mixture of both compounds. Based on these results and our data, we believe that a strain engineered for improved tolerance to the main chemical classes found in hydrolysate, such as weak organic acids, phenolics, aldehydes, and furans, might be sufficient to confer tolerance to the full, complex chemical mixture present in real plant hydrolysates. For example, two well-known tolerance mechanisms, furfural reduction and laccase detoxification of phenolics (Parawira and Tekere, 2011) could be combined into a single strain for further improvements in hydrolysate tolerance. In addition, based on our work, this strain could be further engineered by modifying pathways for peroxide detoxification and Fe-S cluster repair. It is possible that complex epistatic relationships exist between tolerance gene pathways, making combinatorial engineering more difficult (Sandoval et al, 2012); however, to a first approximation our linear fitness model and previous work (Wood et al, 2012) argues against this possibility.

Conclusions

In this study, we have shown that chemogenomic profiling and modeling can be used to deconstruct a complex chemical stress and that this information can be used to rationally engineer a strain for improved fermentation in plant hydrolysate. More broadly, our approach can be used to model other complex stresses, such as the array of environmental stresses (including product toxicity) encountered by microbes inside an industrial bioreactor (Gibson et al, 2007, 2008). Understanding how the production host deals with this complex environmental stress has significant implications for improving the yield and productivity of any industrial-scale fermentation process.

Materials and methods

Strains, media, plasmids, and primers

Bacterial strains, primers, and plasmids used in this study are listed in Supplementary Table 6. Zymomonas mobilis strain ZM4 obtained from ATCC (ATCC 31821) was the parent strain for our studies. E. coli strains TOP10 (Invitrogen), NEB 5-alpha (New England Biolabs), and WM3064 (W. Metcalf, University of Illinois at Urbana-Champaign) were used as needed. Z. mobilis was cultured in ZRMG, Zymomonas Rich Medium Glucose (25 g/l glucose, 10 g/l yeast extract, and 2 g/l KH2PO4) or ZMMG, Zymomonas Minimal Medium Glucose (Goodman et al, 1982), and grown aerobically at 30°C. Anaerobic growth was performed in sealed Hungate tubes after degassing media with nitrogen or on ZRMG agar plates in an anaerobic chamber (Coy Lab Products). For Z. mobilis, plates or liquid media were supplemented with 100 μg/ml kanamycin, chloramphenicol, or spectinomycin as necessary. E. coli strains were grown in Luria-Bertani (LB) broth at 37°C, supplemented with 30 μg/ml kanamycin, 20 μg/ml chloramphenicol, or 50 μg/ml spectinomycin as needed. The S. cerevisiae homozygous barcoded deletion mutant collection (Giaever et al, 2002) was a gift of Ron Davis (Stanford Genome Technology Center). Yeast strains were grown aerobically at 30°C in Difco Yeast Extract Peptone Dextrose (YPD) media.

Preparation and analysis of plant hydrolysates

A dilute-acid pretreatment method was used to release fermentable sugars from plant biomass. M. giganteus (miscanthus) and P. virgatum (switchgrass) were grown in Illinois at four different field sites: Brownstown (BTN), Fairfield (FRF), Havana (HAV), and Orr (ORR). ‘Batch’ hydrolysates were prepared from a mixed miscanthus sample that was derived from several field sites (Batch February 2009, EBI South 2006 Season, obtained from UIUC). After harvesting, samples were air dried, processed with a SM 2000 cutting mill and a 2-mm sieve (Retsch, Haan, Germany), and then finally ground to pass a 120-μm sieve screen using a SR 200 rotor beater mill (Retsch). Pretreatment and hydrolysis were performed in an Ethos Z microwave (Milestone Inc., Shelton, CT) equipped with six closed reaction vessels (each 100 ml in volume). In brief, each vessel contained 5 g ground miscanthus and 45 g of 1% (w/w) sulfuric acid. The temperature was increased in 4 min to 180°C (in 4.5 min to 200°C for batch 1 and batch 2) and held for 2 min. The mixture was cooled in an ice bath to 95°C,the vessels were opened and the contents rapidly transferred into a beaker and the mixture was further cooled to room temperature. The supernatant was collected after centrifugation (5000 × g) and adjusted to pH 6.0 with KOH. Samples were filter sterilized, 10 ml aliquots were flash frozen in a dry-ice ethanol bath, and stored at −80°C, protected from light. Since the stability of compounds present in hydrolysate is unknown, hydrolysate aliquots used in pool and growth experiments were thawed and used only once.

The supernatant was analyzed for soluble carbohydrates, organic acids and furans using an Agilent 1200 series liquid chromatography system (Agilent Technologies, Santa Clara, CA) equipped with a refractive index detector and a diode-array detector. Samples were injected onto an Aminex HPX-87H column (Bio-Rad, Hercules, CA) and compounds were eluted at 50°C and a flow rate of 0.6 ml/min by a mobile phase consisting of 0.005 M sulfuric acid. For detection and quantification of methylglyoxal, 1 ml of the hydrolysate was mixed with 0.5 ml of a solution of 1% orthophenylenediamine in 0.5 M sodium phosphate (pH 6.5). The mixture was incubated at room temperature in the dark for 16 h and then 5 μl was injected onto a Zorbax SB-C18 Rapid Resolution column (Agilent Technologies) and eluted at 40°C by a gradient of solvent A (0.1% (v/v) formic acid) and solvent B (acetonitrile containing 0.1% (v/v) formic acid). The gradient program was: 5–50% B in 10 min, 50–90% B in 4 min, 90–5% B in 1 min, then 3 min isocratic elution. Detection was at 312 nm. A standard of methylglyoxal (40% solution, Sigma-Aldrich, St. Louis, MO) was derivatized in the same way and used to confirm the retention time and UV spectra. GC/MS was used for analysis of phenolic compounds: to 1 ml of neutralized hydrolysate, 30 μl of 72% sulfuric acid and 20 μl of internal standard (iso-propylphenol, 1 mg/ml in 0.1% sodium hydroxide) were added. This mixture was vigorously mixed three times each with 0.5 ml of ethyl acetate. After phase separation, the upper ethyl acetate layer was removed and collected. All ethyl acetate phases were combined and dried over sodium sulfate. An aliquot of the combined dried ethyl acetate phase (100 μl) was incubated with 50 μl of N,O-bis(trimethylsilyl)trifluoroacetamide containing 1% trimethylchlorosilane (Sigma-Aldrich) at 70°C for 30 min. In all, 1 μl was injected in splitless mode onto a VF5-MS capillary column (Varian, Palo Alto, CA). An Agilent 7890A gas chromatograph coupled to an Agilent 5975C single quadrupole mass spectrometer with the following settings was used: injector temperature 280°C, carrier gas: helium at 1 ml/min, temperature program: 3 min isocratic 75°C, 5°C/min to 150°C, 0.5°C/min to 160°C, 2°C/min to 190°C, 5°C/min to 240°C, 70°C/min to 325°C, 3 min isocratic, ions were detected by electron impact ionization (70 eV) in full scan mode m/z 35–500. Compounds were identified by matching their mass spectra with NIST database entries and by comparing their retention times with commercially available standards (Sigma-Aldrich). Peak areas were quantified using selected extracted ions for the compounds in internal standard calibration mode (m/z 193 for iso-propylphenol). We quantified 37 inhibitors and 4 sugars for each plant hydrolysate sample (Supplementary Table 1). Only batch 2 hydrolysate was analyzed for methylglyoxal.

Preparation and analysis of synthetic hydrolysate mixtures (SYN-37 and SYN-10)