Abstract

Objectives

The purpose of this study was to evaluate in situ the occurrence of corrosion in the soldering point areas between the wire, silver brazing and band in Haas expanders.

Material and Methods

Thirty-four 7-12-year-old patients who needed maxillary expansion with a Haas expander were randomly assigned to two groups of 17 individuals each, according to the oral hygiene protocol adopted during the orthodontic treatment: Group I (control), toothbrushing with a fluoride dentifrice and Group II (experimental), toothbrushing with the same dentifrice plus 0.12% chlorhexidine gluconate (Periogard®) mouthrinses twice a week. The appliances were removed after approximately 4 months. Fragments of the appliances containing a metallic band with a soldered wire were sectioned at random for examination by stereomicroscopy, scanning electron microscopy (SEM) and energy dispersive x-ray spectroscopy (EDS). Data were analyzed statistically by Fisher's test at 5% significance level.

Results

The analysis by optical microscopy revealed areas with color change suggestive of corrosion in the soldering point areas joining the band and the wire in all specimens of both groups, with no statistically significant difference between the groups (p=1). The peaks of chemical elements (Ni, Fe, Cr, O, C and P) revealed by EDS were also similar in both groups.

Conclusion:

Color changes and peaks of chemical elements suggestive of corrosion were observed in the soldering point areas between the wire, silver brazing and band in both control and experimental groups, which indicate that the 0.12% chlorhexidine gluconate mouthrinses did not influence the occurrence of corrosion in situ.

Keywords: Orthodontics, Corrosion, Maxillary expansion, Chlorhexidine

INTRODUCTION

The oral environment is particularly favorable to metal biodegradation due to its chemical, thermal, microbiological and enzymatic conditions19. When in contact with saliva and acid/basic foods at different temperatures, the metal components of orthodontic appliances may undergo corrosion2.

In addition, the orthodontic treatment, especially with fixed appliances, causes specific alterations in the oral cavity, including decrease of pH, increase of dental biofilm accumulation26 and elevation of the salivary microbial levels6,27, which are favorable conditions to the occurrence of corrosion. Corrosion of orthodontic appliances may have serious clinical implications that range from loss of dimension of the appliance's components, which results in application of lower force to the teeth, up to possible failure of the appliance due to tension corrosion2. In the corrosive process, the released metallic ions may get in contact with cells and tissues in the contiguous environment or pervade throughout the body. Absorption of toxic products released during corrosion of metallic orthodontic components by body tissues is undesirable11,14,28.

In dentistry, corrosion may manifest as biological, functional and esthetic effects, the biological being the most significant10,14,18. The released metallic ions may cause damage or sensitization due to the toxicity17,21.

Corrosion in orthodontic appliances has been extensively investigated by analysis of ion release both in vitro 2,4,17 and in vivo 1,13,20. Considering that fixed orthodontic appliances may act as retention niches for microorganisms23,25 and are susceptible to corrosion, the development of in situ studies evaluating corrosion from a clinical standpoint is of paramount importance.

This study evaluated in situ the corrosion of the metallic components of Haas expanders by stereomicroscopy, scanning electron microscopy (SEM) and energy dispersive x-ray spectroscopy (EDS).

MATERIAL AND METHODS

Thirty-four patients of both sexes (14 male and 20 female) aged 6 to 12 years (mean age = 9 years and 7 months) from the Orthodontic Clinic of the Ribeirão Preto Dental School, University of São Paulo, Brazil, who needed maxillary expansion with a Haas expander for correction of posterior crossbite were enrolled in this study. The children were randomly assigned to two groups of 17 individuals each (Groups I and II).

Patients who were using antimicrobial mouthwashes, presented any systemic disease and/or had used antibiotics within the previous 3 months were excluded from the trial. This research project was approved by the local Ethics in Research Committee (process number 2006.1.391.58.9) and written informed consent was obtained from the parents or guardians.

For construction of the Haas expanders, the permanent first molars were banded and the metallic bands were silver welded (Dental Morelli, Sorocaba, SP, Brazil) to 0.9 mm stainless steel orthodontic wires (Dentaurum, Ispringen, Germany). The active component was an 11 mm expanding screw (Dental Morelli, Sorocaba, SP, Brazil). The bands were cemented with zinc phosphate cement (LS cement; Vigodent S/A Indústria e Comércio, Rio de Janeiro, RJ, Brazil) and the orthodontic wires were fixed to the primary canines or molars with light-cured composite resin (TPH; 3M/ESPE, St. Paul, MN, USA).

After correction of the posterior crossbite, which lasted 20 days on average, the orthodontic appliance was maintained for additional 3 months in the mouth as a retention period. During the time of use of the appliances, the patients were submitted to different oral hygiene protocols. The patients of Group I were instructed to brush their teeth with a fluoride dentifrice 3 times a day and not to use any antimicrobial mouthrinse solution. For patients of Group II, in addition to toothbrushing with a fluoride dentifrice, 1-minute mouthrinses with 10 mL of a 0.12% chlorhexidine gluconate solution (Periogard®; Colgate-Palmolive Company, New York, NY, USA) were prescribed twice a week (Tuesdays and Fridays). On Tuesdays, mouthrinsing was performed at the Dental School under the researcher's supervision, while on Fridays mouthrinsing was performed at the child's home under parental supervision.

After removal from the mouth, the fixed appliances of both groups were cut with a sterile pair of pliers (Orthopli 021; Dentaurum, Pforzheim, Germany) on either the right or the left side, according to a table of random numbers, in order to obtain a fragment containing a sample of the wire/silver brazing/band region. The fragments were placed in a 300-mm desiccator (Vidrolabor, Paulínia, SP, Brazil) containing silica gel as an indicator of humidity for further analysis of the corrosive process. After desiccation, the specimens were examined with an optical stereomicroscope (Leica L2; Wetzlar, Germany) coupled to a digital camera (Sony Cyber Shot 3.3 mega pixels DSC-575, Tokyo, Japan) at x40 magnification to obtain images of the soldering point areas (silver brazing/band, silver brazing/wire and wire/silver brazing/band), as suggested by Wichelhaus, et al.30 (2004). The images were analyzed with respect to the presence of areas with color change due to oxidation, suggestive of corrosion. This type of qualitative analysis has been described in several studies9,21,30 and allowed delimiting the areas to be examined by SEM and EDS. Data referring to the presence (+) or absence (-) of color change suggestive of in situ corrosion in both groups were compared by Fisher's test using the SAS (Statistical Analysis System, Institute Inc., Cary, NC, USA) statistical software package at 5% significance level.

The specimens were then processed for analysis by SEM and EDS. The analysis was undertaken with a scanning electron microscope (EVO 50 EP; Carl Zeiss SMT AG, Germany) operating at 20 kV coupled to an energy dispersive x-ray spectrometer (IXRF Systems Inc., Houston, TX, USA), which allows analyzing the predetermined area at x60 to 194 magnification with four-quadrant electron-backscatter detectors (QBSD) using a pre-determined depth of penetration of the electron beam. This analysis was performed to identify the peaks of the following chemical elements: nickel (Ni), iron (Fe), chromium (Cr), oxygen (O), carbon (C) and phosphorus (P) in the region delimited in the fragments of the appliances of Groups I and II. Graphs of the peaks of these chemical elements were obtained using the EDX/2004 software.

RESULTS

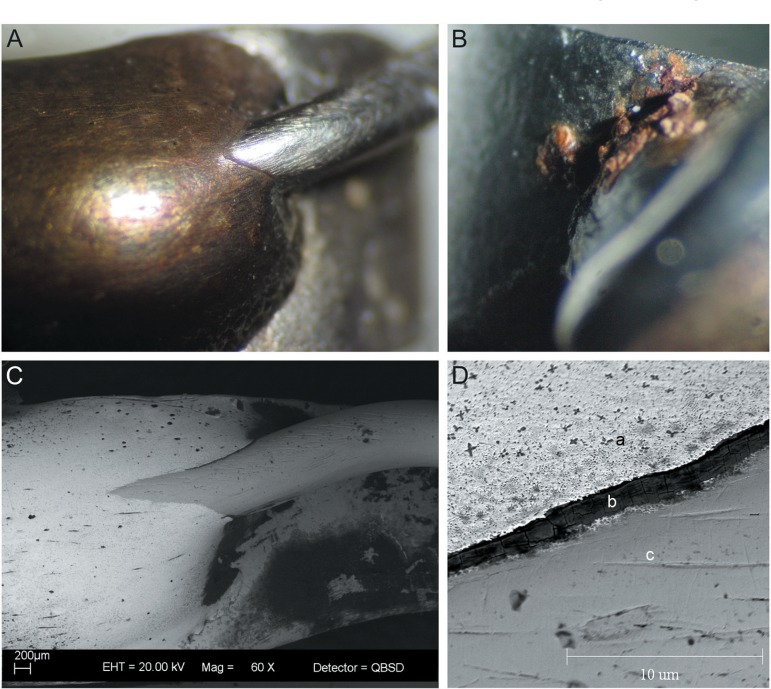

The analysis of the images obtained under optical stereomicroscopy revealed areas of color change suggestive of corrosion in the soldering point areas (wire/silver brazing/band region) in all specimens of both groups (Figure 1A and B), with no statistically significant difference (p=1).

Figure 1.

A: Stereomicroscopic analysis of a representative Group I specimen showing color change in the band/silver brazing/wire joint. ×20 magnification. B: Close-up view of A showing color change suggestive of corrosion at the band/ silver brazing/wire joint. ×40 magnification. C: Scanning electron microscopy (SEM) micrograph showing the band/silver brazing/wire joint to be analyzed by energy dispersive x-ray spectroscopy (EDS). ×60 magnification. D: Areas of Ag solder (a), material-to-material interface (b) and orthodontic wire (c) analyzed by EDS with four-quadrant electron backscatter detectors QBSD detectors

The regions suggestive of corrosion were submitted to SEM examination (Figure 1C) with EDS analysis (Figure 1D). Graphs representative of the qualitative readings of the specimens of Groups I and II are presented in Figures 2 and 3.

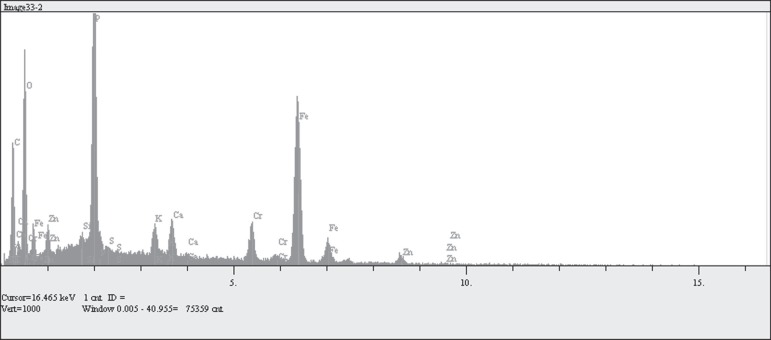

Figure 2.

Quantitative energy dispersive x-ray spectroscopy (EDS) reading representative of areas of color change suggestive of corrosion in the soldered region in contact with the band and the wire in a Group I specimen (control)

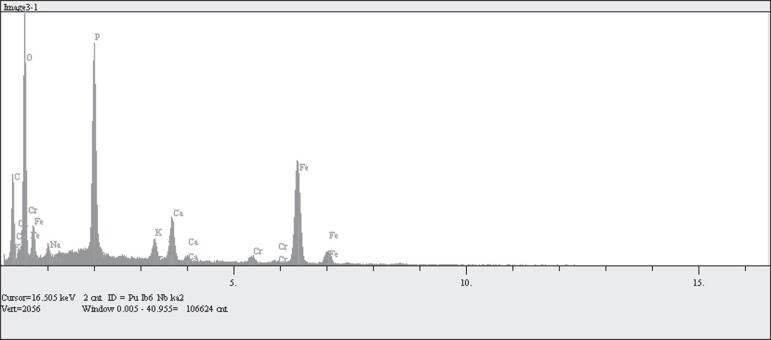

Figure 3.

Quantitative energy dispersive x-ray spectroscopy (EDS) reading representative of areas of color change suggestive of corrosion in the soldered region in contact with the band and the wire in a Group II specimen (Periogard® mouthrinse)

In both groups, the soldered areas in contact with the band and the wire presented Fe, Cr, O, C and P peaks. Expressive Ni peaks were not observed in either of the groups.

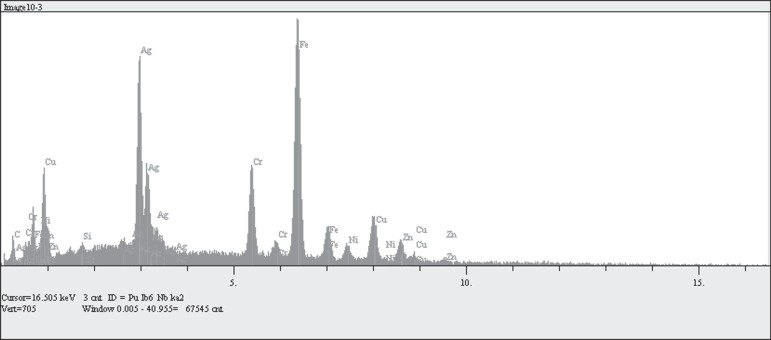

Figure 4 illustrates the reading obtained in a non-assayed region of an orthodontic wire of a Haas expander. No area of corrosion was visible under optical stereomicroscopy, demonstrating how the peaks of chemical elements behave in this situation.

Figure 4.

Quantitative reading of the composition of the stainless steel wire showing absence of corrosion

DISCUSSION

Several studies have currently evaluate the resistance to corrosion of orthodontic wires and brackets in an attempt to find materials with greater compatibility with the oral environment4,5,21,24,28. However, most studies are in vitro experiments that are performed with artificial saliva and methodologies that simulate the oral conditions, reaching results that cannot be extrapolated to the clinical situation. The present investigation was designed as a randomized clinical trial because it is the "golden standard" of studies that evaluate the clinical efficacy of materials and treatment techniques12.

Soldering is still the prevailing joining technique in the dental laboratory, although problems arise from the susceptibility to corrosion and the low strength of soldered joints. In the flame soldering technique, the wire elements are heated directly, so that the temperature of the wire mostly rises to levels exceeding the fusing temperature of the solder. Under these conditions, intergranular corrosion occurs due to the change in the composition of grain contours deriving from phase precipitations, concentration of impurities or elementary Cr depletion close to the areas of grain contours2.

The results of the present study showed the occurrence of failure in the flame-soldered joints between the stainless steel wires occurred during the construction of the Haas expanders. These findings are in agreement with those of Heidemann, et al.16 (2002) who evaluated in vitro different soldering techniques produced by various dental technicians and observed incomplete filling of the soldering gap, porosities resulting from the production process, local structural changes due to overheating and deficient alloying at the solder margin.

The EDS analysis qualifies chemically the composition of a certain material, being a complementary method to evaluate the presence of corrosion11,15,21,28. Under ideal conditions, Fe and Cr peaks in the soldered joint should be high and similar. Graphs with high Fe peaks and medium Cr peaks and presence of O suggest the occurrence of corrosion due to formation of Fe2O3 or hydrated ferric oxide (Fe2O3 x H2O), indicating rust5,22. The presence of P with high Fe peaks and medium Cr peaks suggests the occurrence of a process corrosive by formation of iron phosphate (FePO4)29. In the present study, peaks of these elements were observed in the soldered joints in all specimens of both groups.

The deterioration of orthodontic appliances has been a matter of concern in orthodontic research due to the potential adverse biological reactions associated mainly to Ni release3,7. In the present in situ study, the EDS analysis did not reveal Ni peaks in the soldered joints of any of the Haas expanders worn for approximately 4 months. Although no increase in the Ni levels were observed, which would indicate a corrosive process, the presence of corrosion was detected on examination of the images under optical microscopy. Intergranular corrosion was most likely the cause5. This situation is further aggravated if one considers two other conditions that may contribute to potentialize corrosion: the mouth is an aggressive oral environment to the various types of sensitized alloys and crevice corrosion is intensified where gaps and/or cracks develop16.

In addition to intergranular and crevice corrosion, the stainless steel becomes susceptible to the corrosive process, since the alloy has its structure altered and the passivation film cannot be reestablished. This permits the occurrence of different types of corrosion: fatigue corrosion, which occurs frequently in orthodontic wires submitted to long intraoral periods under load8; microbiological corrosion, which causes color change in the presence of microorganisms due to action of sulfur or reduction of sulfates to hydrogen sulfide and formation of insoluble dark sulfites, in addition to pitting (corrosive attack that occurs in points or small areas) and deposits that may occur in the presence of microorganisms5; and galvanic corrosion, which is the deterioration of an alloy by transference of electrons due to difference of potential between two materials in the presence of a common electrolyte.

The C peaks observed in the EDS analysis were greater in Group I, possibly due to the greater accumulation of bacterial biofilm. The P peaks were very expressive in all specimens, possibly originating from the saliva and/or the zinc phosphate cement used for cementation of the orthodontic bands. The presence of Ag peaks in the graphs of soldered joints distant from material-to-material interface only suggests the presence of the metal used as a soldering material.

Although the methodology of the present study does not allow determining accurately which factors caused corrosion, alterations occurred in the wire/silver brazing/band joints, since a dark line suggestive of corrosion was observed on the alloy by optical microscopy and SEM, though without significant difference between the groups.

CONCLUSIONS

Under the conditions evaluated in this randomized clinical study, it may be concluded that there were color change and peaks of chemical elements suggestive of corrosion in all specimens of both groups in the soldering point areas between the wire, silver brazing and bands of the Haas expanders, with no difference between the groups. These results suggest that the use of chlorhexidine mouthrinses did not influence the occurrence of corrosion in situ.

ACKNOWLEDGEMENTS

This study was supported by a grant-in-aid from FAPESP (Fundação de Amparo à Pesquisa do Estado de São Paulo - Process number 2006/52612-6) and a research postgraduate scholarship granted by CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior). The authors are indebted to the Department of Chemistry of the School of Philosophy, Sciences and Literature of Ribeirão Preto, University of São Paulo, Brazil, for specimen preparation and analyses by SEM and EDS.

REFERENCE

- 1.Ağaoğlu G, Arun T, Izgi B, Yarat A. Nickel and chromium levels in the saliva and serum of patients with fixed orthodontic appliances. Angle Orthod. 2001;71:375–379. doi: 10.1043/0003-3219(2001)071<0375:NACLIT>2.0.CO;2. Erratum in: Angle Orthod. 2002;72:377. [DOI] [PubMed] [Google Scholar]

- 2.Barrett RD, Bishara SE, Quinn JK. Biodegradation of orthodontic appliances. Part I. Biodegradation of nickel and chromium in vitro. Am J Orthod Dentofacial Orthop. 1993;103:8–14. doi: 10.1016/0889-5406(93)70098-9. [DOI] [PubMed] [Google Scholar]

- 3.Bass JK, Fine H, Cisneros GJ. Nickel hypersensitivity in the orthodontic patient. Am J Orthod Dentofacial Orthop. 1993;103:280–285. doi: 10.1016/0889-5406(93)70009-D. [DOI] [PubMed] [Google Scholar]

- 4.Costa MT, Lenza MA, Gosch CS, Costa I, Ribeiro-Dias F. In vitro evaluation of corrosion and cytotoxicity of orthodontic brackets. J Dent Res. 2007;86:441–445. doi: 10.1177/154405910708600510. [DOI] [PubMed] [Google Scholar]

- 5.Darabara MS, Bourithis LI, Zinelis S, Papadimitriou GD. Metallurgical characterization, galvanic corrosion, and ionic release of orthodontic brackets coupled with Ni-Ti archwires. J Biomed Mater Res B Appl Biomater. 2007;81:126–134. doi: 10.1002/jbm.b.30645. [DOI] [PubMed] [Google Scholar]

- 6.Derks A, Frenken J, Bronkhorst E, Kuijpers-Jagtman AM, Katsaros C. Effect of chlorhexidine varnish application on mutans streptococci counts in orthodontic patients. Am J Orthod Dentofacial Orthop. 2008;133:435–439. doi: 10.1016/j.ajodo.2007.10.024. [DOI] [PubMed] [Google Scholar]

- 7.Dunlap CL, Vincent SK, Barker BF. Allergic reaction to orthodontic wire: report of case. J Am Dent Assoc. 1989;118:449–450. doi: 10.14219/jada.archive.1989.0174. [DOI] [PubMed] [Google Scholar]

- 8.Eliades T, Athanasiou AE. In vivo aging of orthodontic alloys: implications for corrosion potential, nickel release, and biocompatibility. Angle Orthod. 2002;72:222–237. doi: 10.1043/0003-3219(2002)072<0222:IVAOOA>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 9.Eliades T, Eliades G, Athanasiou AE, Bradley TG. Surface characterization of retrieved NiTi orthodontic archwires. Eur J Orthod. 2000;22:317–326. doi: 10.1093/ejo/22.3.317. [DOI] [PubMed] [Google Scholar]

- 10.Eliades T, Eliades G, Watts DC. Intraoral aging of the inner headgear component: a potential biocompatibility concern? Am J Orthod Dentofacial Orthop. 2001;119:300–306. doi: 10.1067/mod.2001.111402. [DOI] [PubMed] [Google Scholar]

- 11.Eliades T, Zinelis S, Papadopoulos MA, Eliades G, Athanasiou AE. Nickel content of as-received and retrieved NiTi and stainless steel archwires: assessing the nickel release hypothesis. Angle Orthod. 2004;74:151–154. doi: 10.1043/0003-3219(2004)074<0151:NCOAAR>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 12.Fletcher RH, Fletcher SW, Wagner EH. Clinical epidemiology: the essentials. 4th edition. Baltimore: Lippincott Williams & Wilkins; 2005. [Google Scholar]

- 13.Fors R, Persson M. Nickel in dental plaque and saliva in patients with and without orthodontic appliances. Eur J Orthod. 2006;28:292–297. doi: 10.1093/ejo/cji091. [DOI] [PubMed] [Google Scholar]

- 14.Geis-Gerstorfer J. In vitro corrosion measurements of dental alloys. J Dent. 1994;22:247–251. doi: 10.1016/0300-5712(94)90124-4. [DOI] [PubMed] [Google Scholar]

- 15.Gioka C, Bourauel C, Zinelis S, Eliades T, Silikas N, Eliades G. Titanium orthodontic brackets: structure, composition, hardness and ionic release. Dent Mater. 2004;20:693–700. doi: 10.1016/j.dental.2004.02.008. [DOI] [PubMed] [Google Scholar]

- 16.Heidemann J, Witt E, Feeg M, Werz R, Pieger K. Orthodontic soldering techniques: aspects of quality assurance in the dental laboratory. J Orofac Orthop. 2002;63:325–338. doi: 10.1007/s00056-002-0019-3. [DOI] [PubMed] [Google Scholar]

- 17.Iijima M, Endo K, Yuasa T, Ohno H, Hayashi K, Kakizaki M, et al. Galvanic corrosion behavior of orthodontic archwire alloys coupled to bracket alloys. Angle Orthod. 2006;76:705–711. doi: 10.1043/0003-3219(2006)076[0705:GCBOOA]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 18.Kao CT, Ding SJ, He H, Chou MY, Huang TH. Cytotoxicity of orthodontic wire corroded in fluoride solution in vitro. Angle Orthod. 2007;77:349–354. doi: 10.2319/0003-3219(2007)077[0349:COOWCI]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 19.Kedici SP, Aksüt AA, Kílíçarslan MA, Bayramoğlu G, Gökdemir K. Corrosion behaviour of dental metals and alloys in different media. J Oral Rehabil. 1998;25:800–808. doi: 10.1046/j.1365-2842.1998.00305.x. [DOI] [PubMed] [Google Scholar]

- 20.Kerosuo M, Moe G, Hensten-Pettersen A. Salivary nickel and chromium in subjects with different types of fixed appliances. Am J Orthod Dentofacial Orthop. 1997;111:595–598. doi: 10.1016/s0889-5406(97)70310-x. [DOI] [PubMed] [Google Scholar]

- 21.Kim H, Johnson JW. Corrosion of stainless steel, nickeltitanium, coated nickel-titanium and titanium orthodontic wires. Angle Orthod. 1999;69:39–44. doi: 10.1043/0003-3219(1999)069<0039:COSSNT>2.3.CO;2. [DOI] [PubMed] [Google Scholar]

- 22.Kusy RP, Ambrose WW, La Vanier LA, Newman JG, Whitley JQ. Analyses of rampant corrosion in stainless-steel retainers of orthodontic patients. J Biomed Mater Res. 2002;62:106–118. doi: 10.1002/jbm.10226. [DOI] [PubMed] [Google Scholar]

- 23.Lessa FC, Enoki C, Ito IY, Faria G, Matsumoto MA, Nelson-Filho P. In-vivo evaluation of the bacterial contamination and disinfection of acrylic baseplates of removable orthodontic appliances. Am J Orthod Dentofacial Orthop. 2007;131:705–e17.: doi: 10.1016/j.ajodo.2006.09.042. [DOI] [PubMed] [Google Scholar]

- 24.Lin MC, Lin SC, Lee TH, Huang HH. Surface analysis and corrosion resistance of different stainless steel orthodontic brackets in artificial saliva. Angle Orthod. 2006;76:322–329. doi: 10.1043/0003-3219(2006)076[0322:SAACRO]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 25.Magno AF, Enoki C, Ito IY, Matsumoto MA, Faria G, Nelson- P., Filho In-vivo evaluation of the contamination of Super Slick elastomeric rings by Streptococcus mutans in orthodontic patients. Am J Orthod Dentofacial Orthop. 2008;133:S104–S109. doi: 10.1016/j.ajodo.2006.04.054. [DOI] [PubMed] [Google Scholar]

- 26.Naranjo AA, Triviño ML, Jaramillo A, Betancourth M, Botero JE. Changes in the subgingival microbiota and periodontal parameters before and 3 months after bracket placement. Am J Orthod Dentofacial Orthop. 2006;130:275–e22.: doi: 10.1016/j.ajodo.2005.10.022. [DOI] [PubMed] [Google Scholar]

- 27.Rosenbloom RG, Tinanoff N. Salivary Streptococcus mutans levels in patients before, during, and after orthodontic treatment. Am J Orthod Dentofacial Orthop. 1991;100:35–37. doi: 10.1016/0889-5406(91)70046-Y. [DOI] [PubMed] [Google Scholar]

- 28.Siargos B, Bradley TG, Darabara M, Papadimitriou G, Zinelis S. Galvanic corrosion of metal injection molded (MIM) and conventional brackets with nickel-titanium and copper-nickeltitanium archwires. Angle Orthod. 2007;77:355–360. doi: 10.2319/0003-3219(2007)077[0355:GCOMIM]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 29.Vinnichenko MV, Pham MT, Chevolleau T, Poperenko LV, Maitz MF. In situ ellipsometric investigation of stainless steel corrosion behavior in buffered solutions with amino acids. Appl Surf Sci. 2003;207:176–182. [Google Scholar]

- 30.Wichelhaus A, Brauchle G, Mertmann M, Sander FG. Corrosion of orthodontic pliers using different sterilization procedures. J Orofac Orthop. 2004;65:501–511. doi: 10.1007/s00056-004-0417-9. [DOI] [PubMed] [Google Scholar]