Abstract

Pearl millet is an underutilized grain crop commonly used as whole flour for traditional food preparation and hence confined to traditional consumers and to people of lower economic strata. In this study two commercially available pearl millet varieties (Kalukombu & MRB) obtained from the local market were milled into whole flour, semi refined flour & bran rich fraction. These milling fractions were evaluated for nutrients, antinutrients and mineral bioaccessibility. The bran rich fraction, a by product of flour milling contained significantly (P ≤ 0.05) higher ash content (3.3 & 3.5 g/100 g in K & MRB respectively). Minerals like phosphorus, calcium and antinutrients like oxalates, phytates, were found mainly distributed in the bran fraction. The nutrient content of semi-refined flour was comparable to whole flour except for the fat content (1.3%). Due to partial separation of the bran fraction, semi refined flour was low in antinutrients which improved its mineral bioaccessibility making it nutritionally superior.

Keywords: Pearl millet, Whole flour, Semi refined flour, Bran rich fraction, Antinutrients, Mineral bioaccessibility

Introduction

Pearl millet is one of the most important drought-tolerant crops, grown in India and Africa. In developing countries, millet is a multipurpose crop, used for food, feed, construction materials and fuel in the rain fed areas. It is comparable and even superior in some of the nutritional characteristics to major cereals, with respect to its energy value, protein, fat and minerals content (Abdalla et al. 1998). The use of pearl millet for human consumption is limited due to non-availability in convenience form. The millet is mostly used as whole flour for traditional food preparation and hence confined to traditional consumers and to people of lower economic strata. The flour prepared out of pearl millet is coarse and has a grey to yellow colour which imparts bitter taste (Olatungi et al. 1982). This is one reason for its poor acceptability by rice/wheat eaters. It also contains tough fibrous seed coat which is rich in antinutrients like phytic acid, tannins and oxalates that form complexes with dietary minerals, such as calcium, zinc and iron leading to a marked reduction in its bioavailability and make them biologically unavailable to human organism (Arora et al. 2003). As a result, the products prepared from whole flour have low consumer appeal. Alternately, whole flour could be refined to overcome these advantages and improve overall acceptability and nutritional quality (Desikachar 1975). Refined flours for the traditional food could be blended with other cereals and grain legumes for preparation of composite flours suitable of baking nutritious foods and other non-conventional recipes (Chavan and Kadam 1998). In general, products prepared out of refined flour are superior from those prepared out of whole flour due to reduced visibility of bran spec and for a softer, smoother and more consistent texture.

The purpose of this study was to promote utility of pearl millet by the use of traditional milling. Two commercially available pearl millet varieties (Kalukombu & MRB) obtained from the local market and milled into whole flour, semi refined flour & bran rich fraction. The milled fractions were evaluated for nutrients, antinutrients and mineral bioaccessibility.

Materials and methods

Two pearl millet varieties—Kalukombu and MRB were procured from a local market of Mysore for the study. The grains were cleaned manually to remove dust, broken seeds and other extraneous materials. The processing of the sample was carried in 2 replicates.

Description of milling fractions

Pearl millet milling fractions were produced by pulverizing the grains in a plate mill to obtain whole flour (WF). A part of the whole flour was further sieved through a 44 mesh sieve (BSS). The ‘+’ fraction was termed as the bran rich fraction (BRF) and the ‘−’ fraction was termed as semi-refined flour (SRF). The semi refined flour contained endosperm and finely ground bran, while the bran rich fraction consisted mostly of bran and large fragments of central endosperm that resisted sieving. These milling fractions were kept in air tight polythene bags and stored in a cool and dry place until further use.

Nutrient composition of the processed pearl millet flours

Moisture, crude protein (Kjeldhal, Nx6.25), fat (Soxhlet, solvent extraction) and ash contents were estimated by the AOAC Standard methods of analysis (2005).

Determination of minerals

Mineral analysis was carried out on samples digested with hydrochloric acid. Total iron was analysed by colorimetric method using αα bipyridyyl method (AOAC 2005). Total phosphorus was analysed colorimetrically using Taussky and Shorr method (1953). Total calcium was analysed by Raghuramulu et al. method (1983).

Invitro accessibility of minerals

Invitro Fe availability was determined by the method of Luten et al. (1996). Dialyzable iron: Free form of iron in the dialysate which reacts with α α bipyridyl to yield color was determined by AOAC method (2005). Dialyzable calcium present in the dialysate was precipitated as oxalates and is titrated against standard potassium permanganate (Raghuramulu et al. 1983).

Antinutrients

Oxalates were extracted with HCl, precipitated as calcium oxalates from the deproteinized extracts and are estimated by subsequent titration with potassium permanganate (Baker 1952). Phytic acid was extracted & determined according to Thompson & Erdman method (Thompson and Erdman 1982).

Statistical analysis

Data were analysed by (Analysis of Variance) ANOVA using SPSS 16.0 software. Values were calculated per 100 g of flour. All analysis was carried in 2 replicates. The results were presented as means ± SD of 6 determinations. The means were separated using tukey’s test. Level of significance was set at P < 0.05. Correlation coefficients between mineral bioaccessibility and antinutrient content of pearl millet were also determined.

Results and discussion

Effect of milling on proximate composition

The proximate composition of the pearl millet milling fractions is presented in Table 1. Whole flour had a moisture content was about 10%, which was well below the maximum moisture content limit (13%) intended for human consumption as recommended by FAO/WHO (1995). There were no significant differences in the moisture content of the milling fractions. The mean protein content of K & MRB was 9.3% & 10.2% respectively, which was lower than the reported value (Fasasi 2009). Milling showed no significant effect on the protein content for both varieties. The fat content of K & MRB was 4.8% & 5.4% respectively. The concentration of fat was significantly (P < 0.05) higher in the bran rich fraction of K variety (7%) than that of MRB variety seeds (4.9%). Ash represents the non-combustible fraction of the sample, i.e. minerals. The% total ash content of MRB and K was 1.5% and 2.0% respectively. The bran rich fraction retained significantly (P < 0.05) higher ash content (3.3% in K & 3.5% in MRB). Semi-refining caused a significant (P < 0.05) decrease in the ash content. The carbohydrate content ranged from 71 to 75% for K variety and 73–74% for MRB, while the energy values were 375 & 382 Kcal for K & MRB.

Table 1.

Effect of milling on the proximate composition of pearl millet varieties (g%) (n = 6)

| Variety | Processing | Moisture | Proteins | Fat | Ash | *Cho % | Energy (Kcal) |

|---|---|---|---|---|---|---|---|

| Kalukombu | WF | 10.1ab ± 1.80 | 9.3a ± 1.15 | 4.8a ± 0.64 | 2.0b ± 0.35 | 74 | 375 |

| SRF | 10.8a ± 0.31 | 8.5a ± 0.65 | 4.5a ± 0.40 | 1.3a ± 0.13 | 75 | 374 | |

| BRF | 10.2b ± 0.34 | 8.6a ± 0.62 | 7.0b ± 0.71 | 3.3c ± 0.34 | 71 | 381 | |

| MRB | WF | 9.6a ± 0.82 | 10.2a ± 0.38 | 5.4b ± 0.22 | 1.5b ± 0.06 | 73 | 382 |

| SRF | 9.5a ± 0.72 | 10.2a ± 0.39 | 5.0a ± 0.09 | 1.3a ± 0.16 | 74 | 382 | |

| BRF | 9.5a ± 0.30 | 8.5b ± 0.38 | 4.9a ± 0.20 | 3.5c ± 0.07 | 73 | 370 |

Means followed by different letters in the same column significantly differ (P ≤ 0.05),

* Calculated by difference, Cho Carbohydrates; WF Whole flour; SRF Semi Refined Flour; BRF Bran Rich Fraction

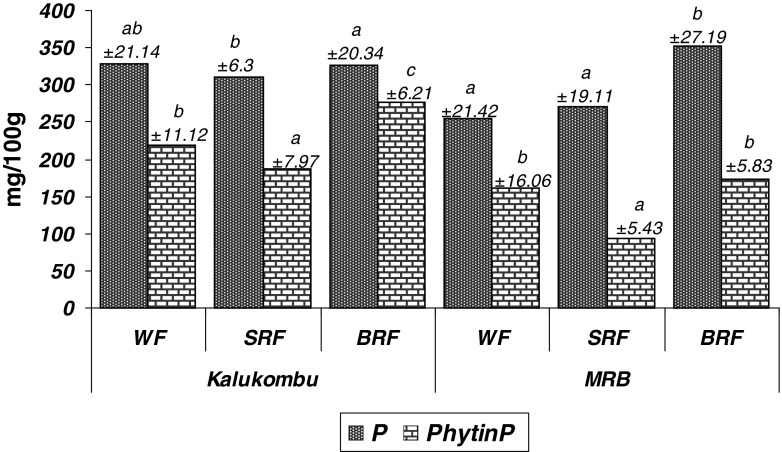

Total and phytin phosphorus content

Total and Phytin phosphorus content of pearl millet milling fractions are presented in Fig. 1. Total phosphorus content was significantly (P < 0.05) higher in K variety grains (327.8 mg%) compared to MRB (255.7 mg%). Milling had little effect on the total phosphorus content of K variety grains, whilst for MRB, the bran rich fraction (352.5 mg%) retained a significant (P < 0.05) amount of phosphorus. The phytin P content of K variety was 219.4 mg% & 160.6 mg% for MRB. The whole flour of both varieties contained about 65% of phytin P which was reduced to around 60 & 35% (K & MRB respectively) upon partial removal of bran to obtain semi refined flour. The bran rich fraction of both the varieties had a significant (P < 0.05) amount of phytin phosphorus (277.8 & 173.9 mg% for K & MRB respectively). Our results correlate well with an earlier report on pearl millet as well as wheat, stating that debranning to obtain refined flours considerably reduced the phytate content, signifying the distribution of phytate in the outer layers (Guansheng et al. 2005; Pawar and Machewad 2006).

Fig. 1.

Total and phytin phosphorus content of pearl millet-milled fractions (n = 6). WF Whole flour; SRF Semi refined flour; BRF Bran rich fraction, different superscripts on each bars are significantly (P < 0.05) different, values followed by ± on the bars are Standard deviation of the mean values respectively

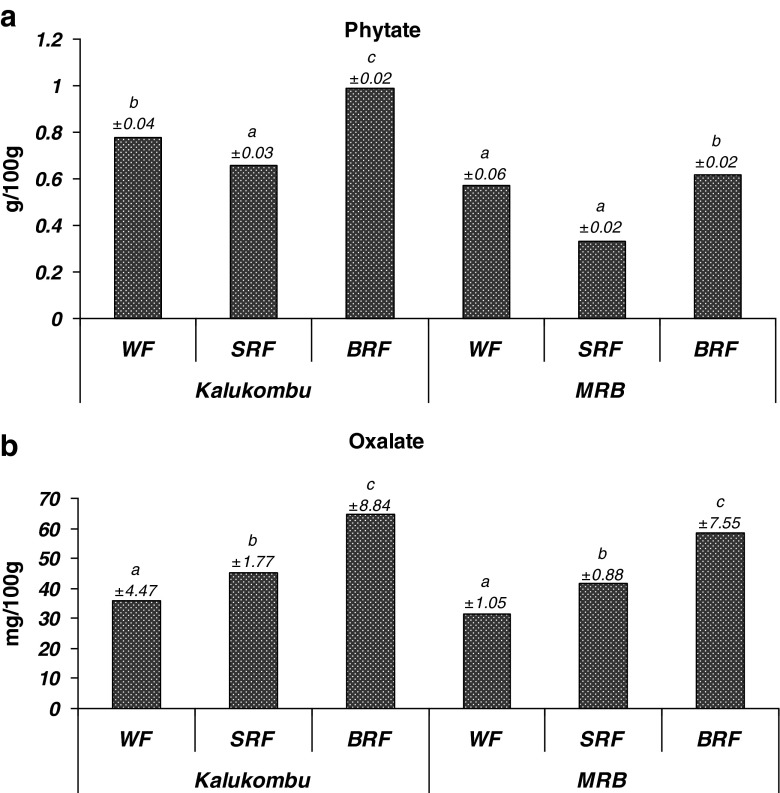

Phytate and oxalate content

The values of phytic acid content were calculated assuming 28.20% of phosphorus in the molecule. The calculated Phytic acid content of the milling fractions of K variety ranged from 0.66 to 0.99 g% while, for MRB it ranged from 0.33 to 0.62 g% (Fig. 2). Phytic acid content was significantly (P < 0.05) lower in the semi refined flour while, bran rich fraction retained significant (P < 0.05) amounts. Oxalate content of K variety grains ranged from 36 to 64.8 mg%, whereas, for MRB it ranged from 31.6 to 58.4 mg%. Results obtained were in accordance with reported literature (Lestienne et al. 2005; Abdalla et al. 1998; Fasset 1973). Similar amounts of oxalates were found to occur widely in many vegetables and fruits which do not pose a nutritional problem (Honow and Hesse 2002). The total oxalate content was significantly (P < 0.05) higher in the bran rich fraction followed by semi refined flour and whole flour for both varieties.

Fig. 2.

(A&B) Phytate & oxalate content of milled fractions of pearl millet-milled fractions (n = 6). WF Whole flour; SRF Semi refined flour; BRF Bran rich fraction, different superscripts on each bars are significantly (P < 0.05) different, values followed by ± on the bars are Standard deviation of the mean values respectively

Total & bioaccessible iron and calcium content

Table 2 represents data on total & bioaccessible iron and calcium content of the milled fractions. There were no significant differences between the total iron content of pearl millet varieties—K & MRB (5.0 & 6.4 mg/100 g respectively). Milling fractions like semi refined flour and bran rich fraction had significantly (P ≤ 0.05) lower total iron content. Iron bioaccessibility of the whole flour for K & MRB was 3% and 7% respectively after gastro-intestinal digestion stimulation. The bioaccessibility of iron was significantly (P ≤ 0.05) higher semi refined flour followed by whole flour and least bran rich fraction. The total calcium content was 40 mg% in MRB and 41.3 mg% in K variety. The bran rich fraction contained significantly higher (P < 0.05) calcium levels (55.2 mg% for K & 77.2 mg% for MRB) followed by semi refined flour (45.5 mg% in K variety and 47.7 mg% in MRB). Calcium invitro accessibility of the milling fractions ranged from 28% to 73% for K variety while, MRB had 20 to 87%. Calcium bioaccessibility was significantly (P < 0.05) higher in whole flour followed by semi refined flour and bran rich fraction in both varieties.

Table 2.

Total & invitro bioaccessible iron and calcium content of pearl millet milling fractions

| Kalukombu | MRB | |||||||

|---|---|---|---|---|---|---|---|---|

| Milled fractions | Iron (mg%) | Calcium (mg%) | Iron (mg%) | Calcium (mg%) | ||||

| Total | Bioaccessibility | Total | Bioaccessibility | Total | Bioaccessibility | Total | Bioaccessibility | |

| WF | 5.0c ± 0.24 | 0.16a ± 0.03 (3) | 41.3a ± 4.08 | 30.1b ± 0.37 (73) | 6.4b ± 0.80 | 0.44b ± 0.07 (7) | 40.0a ± 4.45 | 34.6c ± 2.41 (87) |

| SRF | 4.1b ± 0.47 | 0.20b ± 0.05 (5) | 45.5 b ± 1.89 | 22.4a ± 3.64 (50) | 5.8b ± 0.45 | 0.48b ± 0.05 (8) | 47.7b ± 5.20 | 26.1b ± 2.47 (55) |

| BRF | 3.1a ± 0.00 | 0.16a ± 0.01 (5) | 55.2c ± 1.34 | 20.8a ± 1.12 (38) | 4.7a ± 0.70 | 0.20a ± 0.01 (4) | 77.2c ± 7.24 | 15.7a ± 1.11 (20) |

Means followed by different letters in the same column significantly differ (P < 0.05), WF Whole flour; SRF Semi Refined Flour; BRF Bran Rich Fraction. The values in parenthesis are% bioaccessibility of iron/calcium content

Comparison of phytate:iron, oxalate:calcium and calcium:phytate molar ratios with recommended critical values (CV) for these ratios

Table 3 depicts the molar ratios of phytate/iron of the milling fractions, which were 13–24 in K variety and 9–11 in MRB grains. These ratios were higher than the recommended critical value(1). Oxalate/Calcium molar ratios for the milling fractions ranged from 0.28 to 0.31 in K and 0.24 to 0.27 in MRB variety while, the molar ratios of Calcium:Phytate ranged from 0.88 to 1.03 in K variety and 0.88 to 2.42 in MRB. The molar ratios of oxalate/calcium & Calcium/Phytate of all the milling fractions were well below the recommended critical values of 1 & 6.1 respectively.

Table 3.

Comparison of phytate:iron, oxalate:calcium and calcium:phytate molar ratios with recommended critical values (CV) for these ratios

| Processing | Kalukombu | MRB-351 | ||||

|---|---|---|---|---|---|---|

| [Phy] [Fe] | [Ox][Ca]* | [Ca][Phy]** | [Phy] [Fe] | [Ox][Ca]* | [Ca][Phy]** | |

| WF | 13.1 | 0.28 | 0.88 | 9.7 | 0.26 | 0.88 |

| SRF | 13.8 | 0.31 | 1.03 | 4.8 | 0.27 | 2.45 |

| BRF | 24.8 | 0.37 | 0.93 | 11.0 | 0.24 | 2.01 |

*Recommended critical value for [Ox][Ca] is 1.0

** Recommended critical value for [Ca][Phy] is 6.1

WF whole flour; SRF semi refined flour; BRF bran rich fraction

Correlation coefficients for the association of iron & calcium bioaccessibility with antinutrients of pearl millet

Correlation coefficient among mineral bioaccessibility and antinutrient level was calculated (Table 4). Iron accessibility was found to be negatively and significantly (P < 0.05) correlated with phytate and oxalate content in both varieties. On the other hand, a positive correlation was observed between calcium bioaccessibility, phytate and oxalate content in both varieties. It could be inferred that iron rather than calcium was more affected by the presence of phytate and oxalate.

Table 4.

Association of iron & calcium bioaccessibility with antinutrients in two pearl millet varieties

| Bioavailable Mineral | Antinutrients | Correlation coefficient |

|---|---|---|

| Kalukombu | ||

| Bioaccessible Iron | Phytate | −0.501** |

| Bioaccessible Iron | Oxalate | −0.389** |

| Bioaccessible Calcium | Phytate | 0.670** |

| Bioaccessible Calcium | oxalate | 0.854** |

| MRB | ||

| Bioaccessible Iron | Phytate | −0.550* |

| Bioaccessible Iron | Oxalate | −0.752** |

| Bioaccessible Calcium | Phytate | 0.469* |

| Bioaccessible Calcium | oxalate | 0.948* |

*Correlation is significant at 0.05 level (2-tailed)

** Correlation is significant at 0.01 level (2-tailed)

Conclusion

Pearl millet flour is gaining popularity since it is gluten free. This flour can be used in breads or baked products to reduce gluten content or lower the carbohydrate content. The major constrain for its wide utilization and acceptability is non-availability of products in convenience form. The millet flour is mostly used for traditional food preparation and consequently confined to traditional consumers and to people of lower economic strata. Hence, an attempt was made to bring in variety by milling pearl millet (Kalukombu and MRB varieties) into whole flour, semi refined flour and bran rich fraction and analysed for nutrients, antinutrients and bioaccessible mineral content. The bran rich fraction showed a higher concentration of fat & ash content. Minerals like calcium, phosphorus and antinutrients like phytate was high in the bran rich fraction. Semi refining considerably reduced the phytate content, indicating its distribution in the outer layers. The bioaccessibility of minerals like iron and calcium (invitro) also improved after semi refining the flour.

The process of refining whole flours removes the bran as well as the germ which contains oils and other nutrients such as vitamin B and E. The highly processed refined flour (white flour) which is chemically bleached lacks in fibre rich parts of the grain such as the bran layer and germ (embryo). Semi refining of pearl millet flour attempted in this study resulted in flour with some desirable nutritional qualities of both whole and refined flour. The use of semi refined flour for better quality of the product and utilizing bran as a functional ingredient can be instrumental in popularizing pearl millet.

Acknowledgement

The first author expresses sincere thanks to CSIR- New Delhi for the award of Senior Research Fellowship

References

- Abdalla AA, El Tinay AH, Mohamed BE, Abdalla AH. Proximate composition, starch, phytate and mineral contents of 10 pearl millet genotypes. Food Chem. 1998;63(2):243–246. doi: 10.1016/S0308-8146(97)00228-8. [DOI] [Google Scholar]

- Official methods of analysis. 18. Washington DC: Association of Official Analytical Chemists; 2005. [Google Scholar]

- Arora P, Sehgal S, Kawatra A. Content and HCl-extractability of minerals as affected by acid treatment of pearl millet. Food Chem. 2003;80(1):141–144. doi: 10.1016/S0308-8146(02)00379-5. [DOI] [Google Scholar]

- Baker CJL. The determination of oxalates in fresh plant materials. Analyst. 1952;77:340–344. doi: 10.1039/an9527700340. [DOI] [Google Scholar]

- Chavan JK, Kadam SS. Nutritional enrichment of bakery products by supplementation with non-wheat flours. Crit Rev Food Sci and Nutr. 1998;33:189–226. doi: 10.1080/10408399309527620. [DOI] [PubMed] [Google Scholar]

- Desikachar . Sorghum and millets: Chemistry and technology. St Paul: American association of Cereal Chemists; 1975. [Google Scholar]

- FAO/WHO (1995) Codex alimentarius: Cereals, pulses, legumes and derived products and vegetable proteins. Codex Alimentarius Commission. Vol.7. Food and Agriculture Organization of the United Nations. Rome 27–29

- Fasasi OS. Proximate, antinutritional factors and functional properties of processed pearl millet (Pennisetum glaucum) Journal of Food Technol. 2009;7(3):92–97. [Google Scholar]

- Fasset DW (1973) Oxalates, In Toxicants occurring naturally in foods. National Research Council. Washington DC 346–362

- Guansheng M, Jin Y, Piao J, Kok F, Guusje B, Jacobsen E. Phytate, calcium, iron and zinc content and their molar ratios in foods commonly consumed in China. J Agric Food Chem. 2005;53:1285–1290. doi: 10.1021/jf052051r. [DOI] [PubMed] [Google Scholar]

- Honow R, Hesse A. Comparison of extraction methods for the determination of soluble and total oxalate in food by HPCL-enzyme-reactor. Food Chem. 2002;78:511–521. doi: 10.1016/S0308-8146(02)00212-1. [DOI] [Google Scholar]

- Lestienne I, Besancon P, Caporicco B, Lullien-Pellerin V, Treche S. Iron and zinc in vitro availability in pearl millet flours (Pennisetum glaucum) with varying phytate, tannin and fibre contents. J Agric Food Chem. 2005;53:3240–3247. doi: 10.1021/jf0480593. [DOI] [PubMed] [Google Scholar]

- Luten J, Crews H, Flynn A, Van Dael P, Kastenmayer P, Hurrell R, Deelstra H, Shen Li-Hua, Fairweather-Tait S, Hickson K, Farre R, Schlemmer U, Frohlich W. Interlaboratory trial on the determination of the in vitro iron dialysability from food. J Sci Food Agric. 1996;72(4):415–424. doi: 10.1002/(SICI)1097-0010(199612)72:4<415::AID-JSFA675>3.0.CO;2-X. [DOI] [Google Scholar]

- Olatungi O, Akinrele IA, Erwards CC, Loleoso OA. Sorghum and millets processing and uses in Nigeria. Cereal Foods World. 1982;27:277–280. [Google Scholar]

- Pawar VD, Machewad GM. Changes in availability of iron in barely during malting. J Food Sci Technol. 2006;43(1):28–29. [Google Scholar]

- Raghuramulu N, Nair M, Kalyansundaram S. A manual for laboratory techniques, Jami-Osmania, Hyderabad. India: National Institute of Nutrition, Indian Council for Medical Research; 1983. [Google Scholar]

- Taussky HH, Shorr E. A micro colorimetric method for determination of inorganic phosphorus. J Biol Chem. 1953;202:675–685. [PubMed] [Google Scholar]

- Thompson DB, Erdman JW. Phytic acid determination in soybeans. J Food Sci. 1982;47:513–517. doi: 10.1111/j.1365-2621.1982.tb10114.x. [DOI] [Google Scholar]