Abstract

Due to its origin from renewable resources, its biodegradability, and recently, its industrial implementation at low costs, poly(lactide) (PLA) is considered as one of the most promising ecological, bio-sourced and biodegradable plastic materials to potentially and increasingly replace traditional petroleum derived polymers in many commodity and engineering applications. Beside its relatively high rigidity [high tensile strength and modulus compared with many common thermoplastics such as poly(ethylene terephthalate) (PET), high impact poly(styrene) (HIPS) and poly(propylene) (PP)], PLA suffers from an inherent brittleness, which can limit its applications especially where mechanical toughness such as plastic deformation at high impact rates or elongation is required. Therefore, the curve plotting stiffness vs. impact resistance and ductility must be shifted to higher values for PLA-based materials, while being preferably fully bio-based and biodegradable upon the application. This review aims to establish a state of the art focused on the recent progresses and preferably economically viable strategies developed in the literature for significantly improve the mechanical performances of PLA. A particular attention is given to plasticization as well as to impact resistance modification of PLA in the case of (reactive) blending PLA-based systems.

Keywords: poly(lactide), (reactive) compounding, mechanical properties, impact resistance, toughening

Introduction

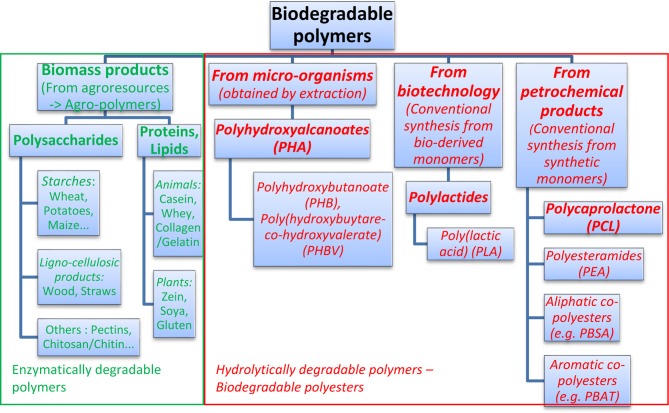

Over the past decade, there has been a significant research interest on compostable and/or biodegradable polymers in order to alleviate solid waste disposal problems related with petro-based plastics (Lim et al., 2008). These biodegradable polymeric materials are increasingly used today in packaging, agricultural, medical, pharmaceutical, and other areas (Rabetafika et al., 2006; Vroman and Tighzert, 2009). Two main classes of biodegradable polymers can be distinguished (Vroman and Tighzert, 2009) (Figure 1):

Figure 1.

Classification of the most known biodegradable polymers.

– Natural and synthetic biodegradable polymers produced from feedstocks derived from biological or renewable resources available in large quantities;

– Synthetic biodegradable polymers produced from feedstocks derived from non-renewable petroleum resources.

Aliphatic polyesters represent a large part of biodegradable polymers. They are considered as hydrolytically degradable polymers due to the presence in their backbone of hydrolytically sensitive chemical bonds, that is, ester moieties (Li, 1999; Nair and Laurencin, 2007). There are two routes generally used to chemically develop biodegradable polyesters; step (condensation) polymerization and ring-opening polymerization (ROP) (Nair and Laurencin, 2007). Due to the absence of any by-products released during condensation process, ROP is thereby the most used pathway to prepare biodegradable polyesters. Among them, the most extensively investigated polymers are the poly(α-hydroxyacid)s, which include poly(glycolic acid) and the stereoisomeric copolymers of poly(lactic acid). Due to the commercial and low cost production of high molecular weight polymers using ROP, poly(lactide) (PLA) is one of the most studied candidates (Lim et al., 2008). Indeed, this polymer represents one of the stiffest organic materials with a Young's modulus of ca. 3 GPa, together with good optical and thermal properties [melting temperature (Tm) of ca. 170°C and a glass transition temperature (Tg) of ca. 60°C]. In addition, PLA is directly derived from renewable resources, making it environmentally sustainable in terms of depletion of petroleum resources and CO2-release. Due to these attributes, PLA holds tremendous promises as an alternative to the ubiquitous petroleum-based materials as shown in Table 1. For instance, compared with the general purpose polystyrene (GPPS), PLA has not only comparable tensile strength and modulus, but also exhibits very similar inherent brittleness (see Table 1). However, despite its numerous advantages such as good optical, physical, mechanical properties (high flexural and tensile moduli and strengths), the inherent brittleness significantly impedes its applications in many fields when a high level of mechanical strength is required.

Table 1.

PLA mechanical properties compared to those of most common polymers used in commodity applications [Copyright ©(2011) Wiley and Sons; used with permission from Liu and Zhang (2011)].

| PLA | PET | PS | HIPS | PP | |

|---|---|---|---|---|---|

| Tg (°C) | 55–65 | 75 | 105 | – | 10 |

| Tensile strength at break (MPa) | 53 | 54 | 45 | 23 | 31 |

| Tensile modulus (GPa) | 3.4 | 2.8 | 2.9 | 2.1 | 0.9 |

| Elongation at break (%) | 6 | 130 | 7 | 45 | 120 |

| Notched Izod impact strength (J/m) | 13 | 59 | 27 | 123 | 27 (i-PP) |

| Gardner impact (J) | 0.06 | 0.32 | 0.51 | 11.30 | 0.79 |

| Cost ($/lb)a | 1–1.5 | 0.70–0.72 | 0.99–1.01 | 1.01–1.03 | 1.15–1.17 |

PET, Poly(ethylene terephthalate); PS, Polystyrene; HIPS, High-impact polystyrene; PP, Polypropylene; i-PP, Isotactic polypropylene homopolymer.

Cost cited from “Plastic News”, March 31, 2011 except PLA resin.

The mechanical resistance of a material is its ability to withstand the application of a sudden load without failure by dissipation of energy of the impact blow. There are two general failure modes, namely brittle fracture and ductile fracture. While brittle fracture, usually resulting of highly concentrated crazing, is characterized by a relatively low energy dissipation and a short nearly linear dependence of load–deformation before fracture, a ductile fracture is characterized by a high energy dissipation and a large-scale deformation (plastic yielding and plastic flow) (Bucknall, 1978; White, 1984; Argon and Cohen, 1990; Perkins, 1999). A brittle-ductile transition is accordingly defined as the point at which the fracture energy increases significantly with a mode of failure passing from brittle fracture to ductile fracture. The importance of this transition zone depends mainly on the strain nature and rate, the temperature gradient, and the specimen geometry (Perkins, 1999). For instance, the same material can exhibit higher brittleness at low temperatures and/or high testing speeds. Mechanical resistance of polymers may be evaluated in terms of the energy absorbed by the specimen during testing by various methods including (Pearson Raymond, 2000):

– Tensile testing: The area under the stress strain curve is often used to quantify toughness. However, different stress-strain curve shapes indicating different mechanical behaviors and responses to the impact loading may dissipate the same impact energy.

– Impact testing: The energy required to break the sample which is usually entailed by a hammer is measured. The related impact strength is expressed in terms of the difference between the potential energy of the striker before and after the impact. It is generally obtained by dividing the energy required to break the sample by the sample width or cross-sectional area. For impact testing, three different tests are typically performed such as Izod (ASTM D256 where samples are clamped as a cantilever), Charpy (ASTM D6110 unclamped samples are supported at both ends) and Dynstat (DIN 53453 where samples are unclamped at the lower end), which can be done in either a notched or un-notched state.

– Falling weight tests where a projectile propelled onto the specimen or dropped on it under the force of gravity is used to measure the impact energy. Gardner impact tester is a well-known example of this type of instrument which offers the advantage over impact testing method that the fracture shape can be also analyzed.

Typically, like conventional brittle thermoplastics, the reason for brittleness of PLA is strain and stress localizations at its use temperature, which is usually below its glass transition and brittle to ductile transition temperature. Under mechanical loading PLA deforms involving highly localized crazing mechanism. As at room temperature its yield stress is superior to the critical stress value for crack formation and propagation, catastrophic damage and break can most likely occur at low deformation and in the elastic zone. The strain-localization can be suppressed namely by compounding the brittle polymer with various softening and toughening agents including plasticizers and rubbery polymers or impact modifiers. However, the most preferred way is to blend PLA with rubbery polymers in order achieve a good toughness-stiffness balance without largely scarifying its glass transition temperature. Like many tough polymer blends, PLA blends can undergo one or a combination of the most known toughening mechanisms, namely multiple crazing, shear yielding, cavitation and debonding (Petchwattana et al., 2012). The mechanical energy is therefore transferred to the plastic flow and dissipated through a large volume fraction of material. The energy dissipation mechanisms retard or stop crack initiation and propagation through the polymer, and ultimately result in a material with improved toughness. There are several factors that can influence the amount of toughening, mainly related to the matrix polymer (Kramer, 1983), the rubber phase (type, particle size, concentration, strength and morphology), and the rubber-matrix interfacial interaction. For instance, the correlations between the deformation morphologies (mainly under tensile and impact testing) and the resulting mechanical properties reveal that the blend compatibility and related morphologies are important factors to influence the toughening mechanisms. The toughening mechanisms can be analyzed through several aspects, including stress whitening, matrix ligament thickness, microstructure evolution under testing, and morphology features of the fracture surface of the impacted sample. For instance, when the matrix ligament thickness is below the critical value, the blends deform to a large extent because of shear yield initiated by stress concentrations and interfacial de-bonding. This may result in the formation of fibers in both tensile and impact samples and the dissipation of a large amount of energy (Han and Huang, 2011).

Many strategies, namely the incorporation of a variety of soft polymers or rubbers, addition of rigid fillers and fibers, and modification of crystalline morphology, have been developed in the literature during the last decades in order to enhance the general toughness of PLA, while maintaining its stiffness-toughness balance acceptable (Anderson et al., 2008; Liu and Zhang, 2011). An optimal toughness balance can be obtained with 10–30% of toughening agents, even if little improvement can be seen by the addition of 5–10% of the latter (Mascia and Xanthos, 1992; Anderson et al., 2008; Liu and Zhang, 2011). In this regard, blending represents an economically viable approach such as plasticization, (reactive) compounding with a variety of flexible/soft polymers or rubbers and the addition of rigid fillers. In this report, an update on the strategies recently developed in the literature to significantly and effectively improve PLA's mechanical properties, will be discussed on its toughening and impact resistance properties.

Approaches for the improvement of PLA's mechanical properties by modifying its inherent crystalline structure

The impact strength of semicrystalline polymers usually varies inversely with the percent crystallinity (Mercier et al., 1965). It is likely that crystallites act as stress concentrators, causing the stress acting on a small volume of the material to be much greater than the average stress applied to the whole sample. As a result, the material breaks at a stress that is less than the expected critical value. Also, crystallites are seen to reduce multiple crazing and shear yielding (Pecorini and Hertzberg, 1993), both energy-dissipative mechanisms of polymer matrices. The size and number of these crystalline structures have a profound influence on impact resistance. It is generally agreed that impact resistance and the brittle to ductile transition temperature are inversely related to spherulite size and morphology which can be tuned by controlling the cooling and drawing rates via thermal and mechanical treatments, respectively (Hammer et al., 1959; Ohlberg et al., 1959; Barish, 1962). This part of the study concerns the PLA matrix itself. In this regard we will report the main approaches that tune up the relationships “physical treatments—crystalline structure—mechanical properties” in order to improve the mechanical properties of PLA-based materials.

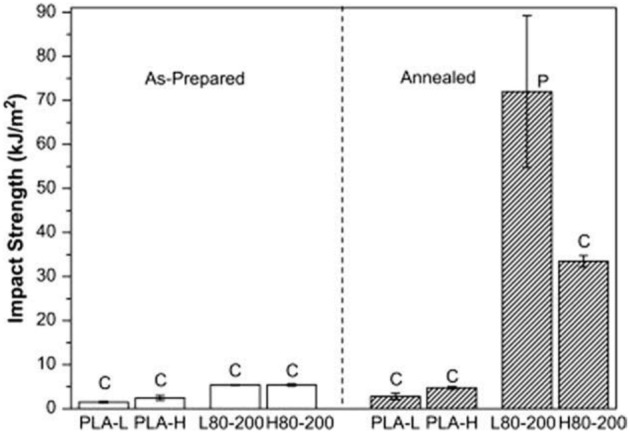

Thermal treatments—annealing

The effect of annealing treatment on thermal, mechanical and fracture behavior of PLA was investigated. Most of the studies demonstrated that the increase of PLA crystallinity usually leads to; an improvement of its overall mechanical and heat resistance behaviors (Perego et al., 1996; Park et al., 2006; Yu et al., 2008; Nascimento et al., 2010). For instance, (Perego et al., 1996) evidenced that annealed PLA possess higher heat resistance, elastic moduli (tensional and flexural), Izod impact strength. Park et al. (2006) and Nascimento et al. (2010). Annealed PLA under different conditions to obtain several microstructures with varying spherulite size and density. They demonstrated that heat resistance is dramatically improved as crystallinity. Furthermore, the quasi-static fracture toughness of PLA decreases with increase of crystallinity corresponding to decrease of amorphous region; on the other hand, the impact fracture toughness tends to increase with crystallinity. The crack growth behaviors of the PLA specimens having different crystallinity exhibited that under quasi-static loading, disappearance of multiple crazes in the crack-tip region results in the decrease of the fracture toughness with crystallinity. On the contrary, under impact loading, the increase of the fracture toughness with crystallinity is considered to be related to the increase of fibril formation. Finally, for the amorphous PLA, the static toughness was higher than the impact one; mainly owing to extensive multiple craze formation at the static rate. On the contrary, for the crystallized PLA, the impact toughness became larger than the static one due to formation of fibril structure at the impact rate (Gamez-Perez, 2010). Gamez-Perez (2010) applied annealing treatment on two commercial grades of PLA from NatureWorks® (2002D and 4032D) of comparable average molecular weights (Mw) of 212 and 207 kDa, respectively, but they exhibited different optical purities, that is, d-lactic monomer contents of 4.25 and 2%, respectively (Natureworks®, 2005, 2006; Li and Huneault, 2007; Xiao et al., 2009; Carrasco et al., 2010). Annealing the sheets was performed using an oven at 60°C for 20 min, followed by a rapid quenching. The nomenclature employed was “PLA-X” and “PLA-XT” for extruded and thermally treated films, respectively. “X” is set as 96 and 98 for PLAs for a content of 95.75 and 98% l-lactic monomer, respectively. From Table 2, it results that the heating at temperatures close to the glass transition temperature (Tg) with the subsequent quenching treatment produces a “de-aging effect,” with an increase of the free-volume of polymeric chains, as highlighted by the decrease of the Tg. The increase in the system potential energy was also shown by the disappearance of the endothermic peak at Tg. As a consequence, annealing promotes a brittle-to-ductile change in the fracture behavior of PLA with a decrease of the tensile strength and stiffness and yield stress, regardless the d-lactic isomer content. A shear yielding with a localized neck formation thereby appeared. The fracture parameters, assessed by the EWF method used to characterize the fracture toughness of PLA showed a great enhancement of the toughness after the annealing and quenching treatments. Regarding the influence of the D-lactic isomer content in PLA films, when they were in a glassy stage, no remarkable differences were noticed out in the mechanical properties and fracture behavior. Only when the films were in a de-aged form, the differences in the stiffness of both PLA grades had been revealed. The optical purity, the elastic modulus and the tensile strength were high. However, the deformation to break was still low, only passing from 17% (PLA-98) to 24% (PLA-96).

Table 2.

Effect of some (thermo)mechanical treatments and processing on the thermal and mechanical properties of PLA.

| Material | Tg(°C) | Tm(°C) | ΔHcc(J/g) | ΔHm(J/g) | Xc(%) | Yield stress σ y (MPa) | Young's modulus E (GPa) | Elongation at break εb (%) | Charpy (KJ/m2) | Izod impact (KJ/m2) | References |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PLA-96 | 60 | 148 | – | 1 | 1 | 56.2 ± 0.7 | 4.0 ± 0.2 | 24 ± 5 | Gamez-Perez, 2010 | ||

| PLA-98 | 61 | 164 | 29 | 31 | 2 | 58.4 ± 0.5 | 4.3 ± 0.1 | 17 ± 4 | |||

| PLA-96T | 56 | 148 | – | 1 | 1 | 47.3 ± 1.1 | 3.3 ± 0.2 | 456 ± 100 | |||

| PLA-98T | 57 | 165 | 31 | 34 | 3 | 53.4 ± 0.6 | 3.5 ± 0.3 | 422 ± 50 | |||

| Un-oriented | 47.0 | 3.65 | 1.5 | 12.5 | 1.6 | Grijpma et al., 2002 | |||||

| Oriented (λ = 2.5) | 73.3 | 4.49 | 48.2 | 35.9 | 5.9 | ||||||

| Oriented (λ = 3.4) | 66.3 | 3.74 | 21.8 | No break | 52.0 | ||||||

| PLA-I | 65.6 ± 1.3 | 3.7 ± 0.1 | 4.0 ± 0.8 | Carrasco et al., 2010 | |||||||

| PLA-EI | 65.2 ± 0.9 | 3.9 ± 0.1 | 5.4 ± 0.6 | ||||||||

| PLA-IA | 75.4 ± 0.9 | 4.1 ± 0.1 | 2.5 ± 0.2 | ||||||||

| PLA-EIA | 77.0 ± 1.1 | 4.1 ± 0.1 | 3.3 ± 0.3 |

I, Injected; IA, Injected then Annealed; EI, Extruded then Annealed; EIA, Extruded then Injected then Annealed.

Thermomechanical treatments—self-reinforcing polymeric materials procedures (SRPMs)—alignment and orientation procedures

Although polymeric composites are referred to as multi-phase or hetero-composites, self-reinforced polymeric materials (SRPMs) are referred to as single-phase or homo-composites because the same polymer forms both the reinforcing and the matrix phases. The basic concept of self-reinforcement is to create a one-, two- or three-dimensional alignment (1D, 2D, or 3D alignment, respectively) within the matrix to fulfill the role of matrix reinforcement. As a result, the generated structure has to possess a higher stiffness and strength than the matrix as well as to be “well-bonded” to the matrix polymer. Consequently, the stress can be transferred from the “weak” matrix to the “strong” reinforcing structure, according to the “working principle” of all composites. The reinforcing structure can be produced during one (in situ) or more processing steps (ex situ) (Kmetty et al., 2010). A driving force for SRPMs is the possibility of manufacturing lightweight parts and structures because the density of SRPMs is well-below those of traditional filled polymers, where the “heavier” reinforcements incorporated in the polymeric matrix are of, e.g., glass fibers (density: 2.5–2.9 g.cm−3), carbon fibers (density:1.7–1.9 g.cm−3), basalt fibers (density: 2.7–3.0 g.cm−3), aramid fibers (density: 1.38–1.44 g.cm−3) and/or fillers like talc (density: 2.7–2.8 g.cm−3), chalk (density: 1.1–2.5 g.cm−3) and silica (density: 2.1–2.6 g.cm−3) (Kmetty et al., 2010). Furthermore, the ease of recycling SRPMs must be emphasized when reprocessing via re-melting is targeted. The concepts used to produce SRPMs can be also adapted to biodegradable polymers for improving their property profiles. Reinforcing a PLA matrix by embedding PLA fibers enables to respond the demands for high strength and stiffness required for many applications. The development of high-stiffness and high-strength polymeric fibers is essential to imparting superior mechanical properties for the resulting PLA SRCs (Matabola et al., 2009). The mechanical properties of fibers can be increased via molecular orientation during spinning and drawing (Alcock et al., 2006). The most commonly used methods to produce PLA fibers are melt-spinning and electro-spinning (Mäkelä et al., 2002; Tsuji et al., 2006; Li and Yao, 2008). Significantly improved interfacial bonding can be achieved in materials where both matrix and reinforcing elements have the same chemical structure (Törmälä, 1992). For example, SRCs consisting of oriented PLA fibers surrounded by a PLA matrix have improved strength and rigidity compared to non-reinforced PLA (Tormala et al., 1988; Majola et al., 1992; Wright-Charlesworth et al., 2005).

To control the impact performances, molecular orientation of amorphous poly(D,L-lactide) (PDLLA) chains was carried out through injection moulding techniques at T < Tg or by non-conventional shear controlled orientation by injection moulding (SCORIM) process in which the melt is cooled under oscillating shear conditions. The latter allowed getting oriented PLA-based materials, leading to the elaboration of degradable devices with much improved mechanical properties compared to non-oriented materials (Grijpma et al., 2002). The brittle fracture mechanism of PDLLA via crazing changed from a fragile to a ductile energy dissipation mechanism upon orientation. Consequently, a significant increase in impact strength was obtained. In comparison to the brittle tensile behavior of un-oriented PDLLA, a much more ductile behavior was observed. This increase in toughness was not accompanied by a decrease in tensile strength and stiffness, as it is generally in the case of plasticization and rubber modification. Due to orientation of the polymer chains in the direction of testing, fibrillation took place during the fracture process. Growing cracks got stopped in the anisotropic structure, and catastrophic failure could be postponed. The mechanical data are summarized in Table 2. However, in the perpendicular direction to the orientation, mechanical properties are much poorer and must be taken into account. The effects of operative SCORIM parameters were also investigated. The correlations between processing, morphology and mechanical properties of SCORIM-moulded PLLA were established and compared with conventional injection moulded CIM PLLA (Ghosh et al., 2008). The level of molecular orientation was assessed indirectly by hot recoverable strain HR test. The fracture surface-morphology assessed by optical microscopy and SEM technique showed that, at low mould temperature, the level of molecular orientation increased with shearing time. The SCORIM processing changed the typical heterogeneous skin–core morphology of CIM into a near homogeneous oriented structure. The extent of core-fibrillation increased with shearing time. Under the three-point flexural test, the higher oriented PLLA exhibited dual fractures where the crack initiation started in the skin and transferred to oriented core fraction without decreasing the modulus. At high mould temperatures, the orientation increased steadily with shearing time. However, the level of molecular orientation was lower than the corresponding low mould temperature conditions. The orientation of core-fraction increased steadily with shearing time. Depending on the level of molecular orientation, the SCORIM-processed PLLA products showed four distinct types of fracture surfaces under three-point flexural test: (i) the un-oriented core failed through crazing; (ii) the sub-skins failed either in smooth, rough or fibrillated fracture surfaces depending on the level of molecular orientation; (iii) the less oriented core failed with fibrillation through pronounced plastic deformation; and (iv) the highly oriented skins failed with smooth surface. All the SCORIM-processed PLLA exhibited higher toughness and higher maximum stress compared with conventional injection-moulded PLLA (Table 2). The overall increments in maximum stress and toughness were of 134% and 641%, respectively. The increase in maximum stress and toughness were higher in low mould temperatures (30°C) in contrast to high mould temperature temperatures (50°C). Unlike the traditional blending technique, the increments in mechanical performances were achieved without sacrificing the stiffness. The mechanical behavior namely toughness and maximum stress of PLLA processed by SCORIM could be tailored by controlling the melt stage, the in-mould shearing time and the cooling conditions. In another study (Bigg, 2005), biaxial orientation of PLLAs chains by extrusion induced a 5–10-fold increase in elongation and enhanced tensile strength at break, tensile toughness and tensile modulus (Table 2). The mechanical processing of PLA (injection and extrusion/injection) as well as annealing of processed materials were studied in order to analyse the variation of its chemical structure, thermal degradation and mechanical properties (Carrasco et al., 2010). Processing of PLA yielded a decrease of its molecular weight and melt-viscosity due to chain hydrolysis. PLA crystal structure was significantly recovered after annealing. The authors also confirmed by proton NMR techniques that the chemical composition of PLA did change after processing, and the proportion of methyl groups from PLA matrix increased, more likely indicating the presence of a different molecular environment. The mechanical behavior was altered as well (Table 2). After annealing, the samples showed an increase in Young's modulus (5–11%) and in yield strength (15–18%), which had been explained by the higher degree of crystallinity of annealed materials, with its subsequent decrease in chains mobility. Extruded/injected materials showed a significant increase in elongation at break (32–35% higher), compared to injected materials. It is ascribed to the presence of low molecular-weight chains at high contents, due to hydrolysis reactions in reprocessed materials.

In general, the modification of chain orientation and crystallinity for PLA-based materials can improve its ductility and impact resistance to some extent. Some processing techniques may contribute efficiently to toughening PLA, without compromising its tensile properties. Orientation of chains by injection moulding and especially injection moulding with macroscopic oscillating shear force resulted, for instance, in an enhancement of tensile, Izod and Charpy impact in the orientation direction. In order to increase the crystallinity of PLA blends and therefore tune its mechanical properties, some routes may be considered (Battegazzore et al., 2011):

– By chain orientation under stress;

– By applying thermal treatments (quenching and/or annealing);

– By minimizing the amount of the other lactide and mesolactide in the lactide used as the major monomer. The crystallinity and crystallization rate of PLA decrease as the purity decreases. The crystallization half-time was found to increase by roughly 40% for every 1 wt.% increase in the mesolactide content of the polymerization mixture (Kolstad, 1996). In addition, it is known that a co-monomer content higher of 7 wt% with polymeric chains leads to an amorphous polylactide.;

– By playing with the moulding conditions, in particular moulding temperature and cooling time. Even at high L-lactide content, PLA crystallization is typically too slow to develop significant crystallinity unless it is induced by strain like processes used to manufacture bottles. In processes such as injection moulding, where the orientation is limited and the cooling rate is high, it is much more difficult to develop significant crystallinity and therefore formulation or process changes are required.;

– By adding nucleating agent.

Nevertheless, these techniques are not very industrially considered because they require increasing the processing time. In addition, studied alone, their influences are usually marginal and the resulting increase of toughness properties is insufficient [but sometimes quite enough because excellent stiffness-toughness balance was achieved in some cases (Gamez-Perez, 2010)] to satisfy the requirement of most applications. However, the combination of these factors with others such as compounding strategies (that will be discussed further) may bring more added-values in terms of the enhancement of PLA's mechanical properties and constitute more prospective routes to improve them.

Approaches to incorporating soft components into PLA matrix via compounding/blending

Blending polymers is as old as the polymer industry itself. Interestingly, using blending approach, PLA can be readily impact-modified, plasticized, filled, chemically modified and reactive blended and processed like many of other conventional polymers. There are two main ways to improving the ductility and the toughness of PLA materials namely through plasticization or incorporation of soft/rubbery polymers. Plasticization makes possible to achieve improved processing behaviors for polymeric materials, while providing better flexibility in the end-use product. As far as blending is concerned, blending PLA with immiscible polymers produces a new type of polymeric materials with different properties, in which each polymeric partner provide its own feature. Because of their impact-absorbing ability when well-dispersed with the convenient particle size distribution, rubbers should act as stress concentrators at many sites throughout the material. Therefore, they impart great ductility and impact strength to the material, resulting from dissipative micromechanisms initiated by the rubber particles. All of these phenomena are dependent on the deformation, toughening and fracture mechanisms, namely crazing, shear yielding, cavitation, or debonding as mostly reported in the literature (Kambour, 1973; Michler, 1989; Wu, 1990; Könczöl et al., 1992; Ikeda, 1993; Dompas et al., 1994; Lu et al., 1997; O'Connell and McKenna, 2002; Narisawa and Yee, 2006; Bucknall, 2007; Seelig and Van Der Giessen, 2009):

1. Crazing mechanism can be initiated in a material when the stress or hydrostatic tension is locally concentrated at a defect which can be a notch, voids, in-homogeneities or rubber particles. Therefore, interpenetrating micro-voids and highly drawn elongated micro-fibrils called tufts (usually a fraction of 1 μm in length, depending on the molecular weight of a polymer, several nanometers in diameter, and confined to a small volume of the material), are formed giving rise to macroscopic highly localized zones of plastic dilatational deformation (Kramer and Berger, 1990). Under sufficient mechanical loading, the local stress exceeds a critical value. Thus, the micro-fibrils elongate until breaking and cause the micro-voids growth and coalescence turning into micro-cracks. Crazing mechanism is dilatational in nature and consumes the predominant part of fracture energy in the case of many thermoplastics. Accordingly, crazing is to some extent a precursor to macroscopically brittle failure and is view as a damaging mechanism in the case of brittle polymers when the craze evolution into a micro-crack cannot be arrested. However, when blended with the brittle matrix, the rubbery impact modifier particles have two separate effects but equally important features as a response to load application. They first concentrate locally the stress where craze initiation takes place. The crazes then grow perpendicularly to the maximum applied stress direction. In a second step, the surrounding rubber particles play the role of “craze terminators,” preventing the generation of micro-cracks. The result is that a large number of small crazes are formed, in contrast with the small number of large crazes (micro-cracks) within the same polymer matrix in the absence of rubber particles. This multiple crazing that occurs throughout a comparatively large volume of rubbery-modified material explains the high energy absorption in fracture tests and the extensive stress whitening that accompanies deformation and failure (Perkins, 1999). Some matrices tend to craze because of low entanglement density while high molecular weight is needed to stabilize crazes.

– Shear yielding mechanism is highly localized plastic deformation characterized by appearance of oriented shear bands under uniaxial tension at 45°C to the direction of the applied stress. Shear yielding occurs approximately at constant volume while initiation of shear bands is affected by the hydrostatic tension (mean stress). In ductile polymers, shear-yielding is usually the major energy absorbing mechanism. There are also few polymers such as acrylonitrile butadiene styrene (ABS) and rubber-toughened PMMA that exhibit both shear yielding and crazing mechanisms. When the craze initiation stress of the matrix is lower than the yield stress, a polymer will tend to craze; if the yield stress is lower than the craze initiation stress, the matrix will fail by shear-yielding. Mixed crazing and shear yielding tends to occur when the craze initiation stress and the yield stress are comparable or when interactions occur between crazes and shear bands.

– Cavitation is void-expansion, which can occur in the matrix (generally coupling with crazing) or initiate inside the rubber particles, which is generally characterized by viewing stress-whitening zones. The essential conditions for void growth is an energy balance between the strain energy relieved by cavitation and the surface energy associated with the generation of a new surface. Cavitation is a precursor to other toughening mechanisms, thereby relieving the hydrostatic strain energy and initiating shear yielding of the matrix. It is assumed that internal rubber cavitation is an instantaneous process, which cannot occur for very small particles (less than 200 nm). In other words, rubber-cavitation mechanism is favored by increasing the particle size within rubber toughening materials or by decreasing the crosslinking density (which can suppress cavitation).

– De-bonding is the energy-dissipation due to the interfacial failure. The interface between the phases influences the final blends properties by efficient stress transfer between the two phases. However, interfacial de-bonding can be thought of as a secondary toughening mechanism being more important as a trigger for other induced mechanisms like shear yielding. Accordingly, low interfacial adhesion easily results in premature interfacial failure and hence rapid and catastrophic crack propagation, whereas very strong adhesion is unfavorable for de-bonding and also delays the occurrence of matrix yielding, involving the matrix-particle interface as an important factor that we need to control for optimum energy dissipation.

Toughening mechanisms and competition between both modes of fracture are mainly governed by a variety of factors such as mode of loading, environment, processing conditions, composition and behavior of the matrix, relaxation behavior of the dispersed phase, rubber content, blend morphology, rubber-matrix adhesion, etc. Being a suitable processing technique, reactive extrusion for instance, represents a unique tool to manufacture biodegradable polymers upon different types of reactive modification in a cost-effective polymer processing (Michaeli et al., 1993; Mani et al., 1999). This technique enhances the commercial viability and cost-competitiveness of polymer materials, in order to carry out not only melt blending, but also chemical reactions including polymerization, grafting, compatibilization, branching, functionalization… (Michaeli et al., 1993; Mani et al., 1999). The in situ chemical modification of PLA by reactive extrusion has proven to be an effective promising way to elaborate tougher PLA-based materials with improved stiffness-toughness balance compared to neat PLA as it will be detailed later. Here, the forthcoming paragraphs will report the recent investigations on simple plasticization of PLA and blending PLA with rubbery/soft materials.

Compounding with plasticizers—miscible to partially miscible blends

Plasticization is widely used to improve the polymers processability and/or other properties according to specific applications. Plasticizers can act by altering the intermolecular interactions among the host polymer chains to other interactions between the macromolecules and the plasticizer. This promotes conformational changes, resulting in increased mobility of plasticized chains. The Standard ISO427 (1988) define a plasticizer as being as a low or negligible volatility component, which is once incorporated to a plastic material, lowers its softening interval temperature, facilitates its processability and increases its flexibility and ductility. Its behavior can be explained by decreasing the viscosity of the molten plasticized polymer, the glass transition temperature and the elastic modulus of the plasticized materials. The evolution of the elongation at break can be also related to the ductility of a polymer and give information about the plasticization extent of polymers.

To be suitable with PLA, a plasticizer should fulfill the following characteristics (Liu and Zhang, 2011):

– To have an optimum molecular weight and loading level to be miscible with the polymer matrix. Miscibility of plasticizers in a polymer matrix is evaluated by solubility parameters (δ) and magnitude of interaction parameters (χT) (Pillin et al., 2006);

– Significantly lower the Tg of PLA and thus enhance tensile toughness;

– Preferably bio-sourced and biodegradable;

– Non-volatile;

– Non-toxic;

– Exhibit minimal even more negligible leaching/migration phase separation from the polymer matrix during ageing.

Many classes of plasticizers were reported by Liu and Zhang and will be discussed in the forthcoming part as follows (Liu and Zhang, 2011):

– Monomeric or small molecule plasticizers;

– Oligomeric and polymeric plasticizers;

– Mixed plasticizers.

In the review, a special emphasis is made on the impact behavior of plasticized PLA, because it has not received enough attention in the literature.

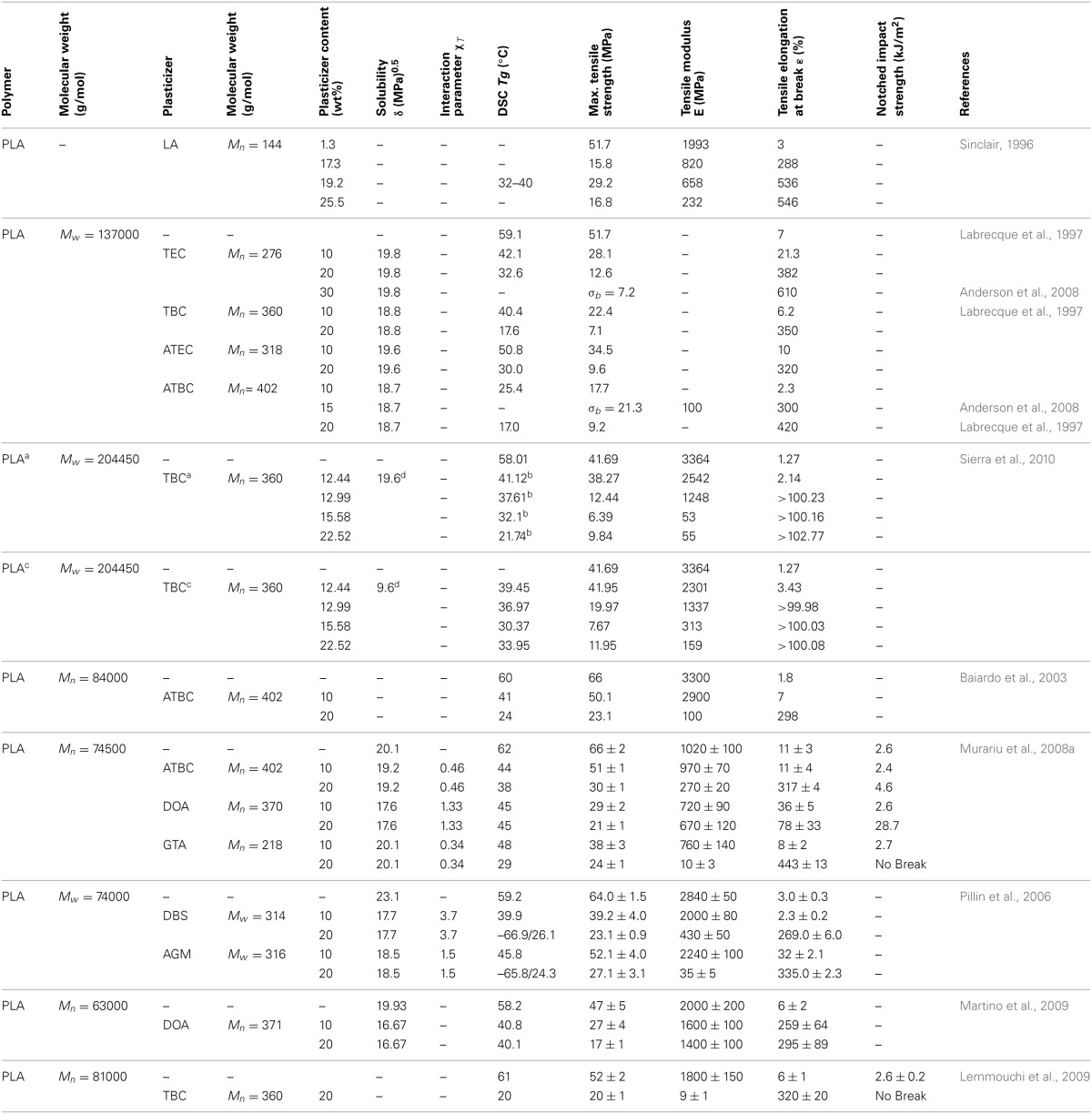

Monomeric or small molecule plasticizers

Many small molecules/monomeric plasticizers have been studied in order to evaluate their plasticization efficiency and their influence on the overall physical properties of PLA (Table 3). The optimal plasticizer content has to take into account the molecular weight, solubility δ and interaction parameters χT. For instance, most of the studies showed that between 10 and 20 wt.% of plasticizer content in PLA, all studied citrate esters (TEC, TBC, ATEC, ATBC) results in a higher elongation and lower Tg for the as-plasticized PLA materials compared to neat PLA.

Table 3.

Plasticization effects on PLA with some monomeric plasticizers [Copyright ©(2011) Wiley and Sons; used with permission from Liu and Zhang (2011)].

aMaterial aged for 10 days.

bMaterial aged for 20 days.

cMaterial aged for 24 days.

d(Ljungberg and Wesslén, 2003).

LA, Lactide; TEC, Triethyl citrate; TBC, Tributyl citrate; ATEC, Acetyl triethyl citrate; ATBC, Acethyl tributyl citrate; DOA, Dioctyl adipate (Bis(2-ethyldhexyl) adipate); GTA, Glycerin triacetate (Triacetin); DBS, Dibutyl sebacate; AGM, Acetyl glycerol mono–laurate; σb, Tensile strength at break.

Among the monomeric or small molecule plasticizers studied in the literature, lactide monomer (LA) possesses the best plasticization efficiency for PLA. However, due to its low molecular weight compared to the others, lactide tends to migrate toward the PLA surface. Therefore, the toughness of plasticized PLA tends to be reduced with time (Jacobsen and Fritz, 1999). LA can also volatilize during melt processing because of its low boiling point (~120°C). In terms of good stiffness-toughness balance, Dioctyl adipate (DOA) seems to be the most efficient one by significantly enhancing elongation with a slight depression of tensile modulus (Martino et al., 2009). The plasticizing efficiency of ATBC was higher compared to the others citrate-based plasticizers. Generally, the miscibility of plasticizers with a polymer decreases with increasing molecular weight of the plasticizers. Small molecule plasticizers are usually more efficient than larger ones in order to lower the host polymer's Tg because the mixing entropy is higher in the case of low Mw plasticizers. However, because of their low boiling point, small molecule plasticizers usually evaporate during melt processing (Labrecque et al., 1997; Ljungberg and Wesslén, 2003; Ljungberg et al., 2003; Martino et al., 2009) and have also a strong tendency to migrate toward the surface of the polymeric material (Ljungberg and Wesslén, 2003; Ljungberg et al., 2003, 2005; Martino et al., 2006). The driving force of the migration is ascribed to the enhanced crystallization ability of plasticized samples. Consequently, the ability of PLA to accommodate the plasticizer in the amorphous PLA phase diminishes (Ljungberg and Wesslén, 2002; Ljungberg et al., 2003, 2005; Martino et al., 2006; Pillin et al., 2006). In addition to the loss of the material toughness (plasticized PLA regains part of the brittleness of neat PLA); the plasticizer migration can, for example, contaminate the food or beverage in contact with plasticized PLA in food packaging applications. All monomeric plasticizers should be added in the range of 5–25% (depending on the plasticizer itself) in order to reduce the migration to the maximum, to maintain the optimum balance between tensile modulus, strength and elongation at break and reduce significantly the glass transition temperature of the host polymer. However, monomeric plasticizers cannot fulfill these requirements due to their high tendency to migrate and evaporate. In this regard, researches had been more widely focused on oligomeric and polymeric plasticizers.

Oligomeric and polymeric plasticizers

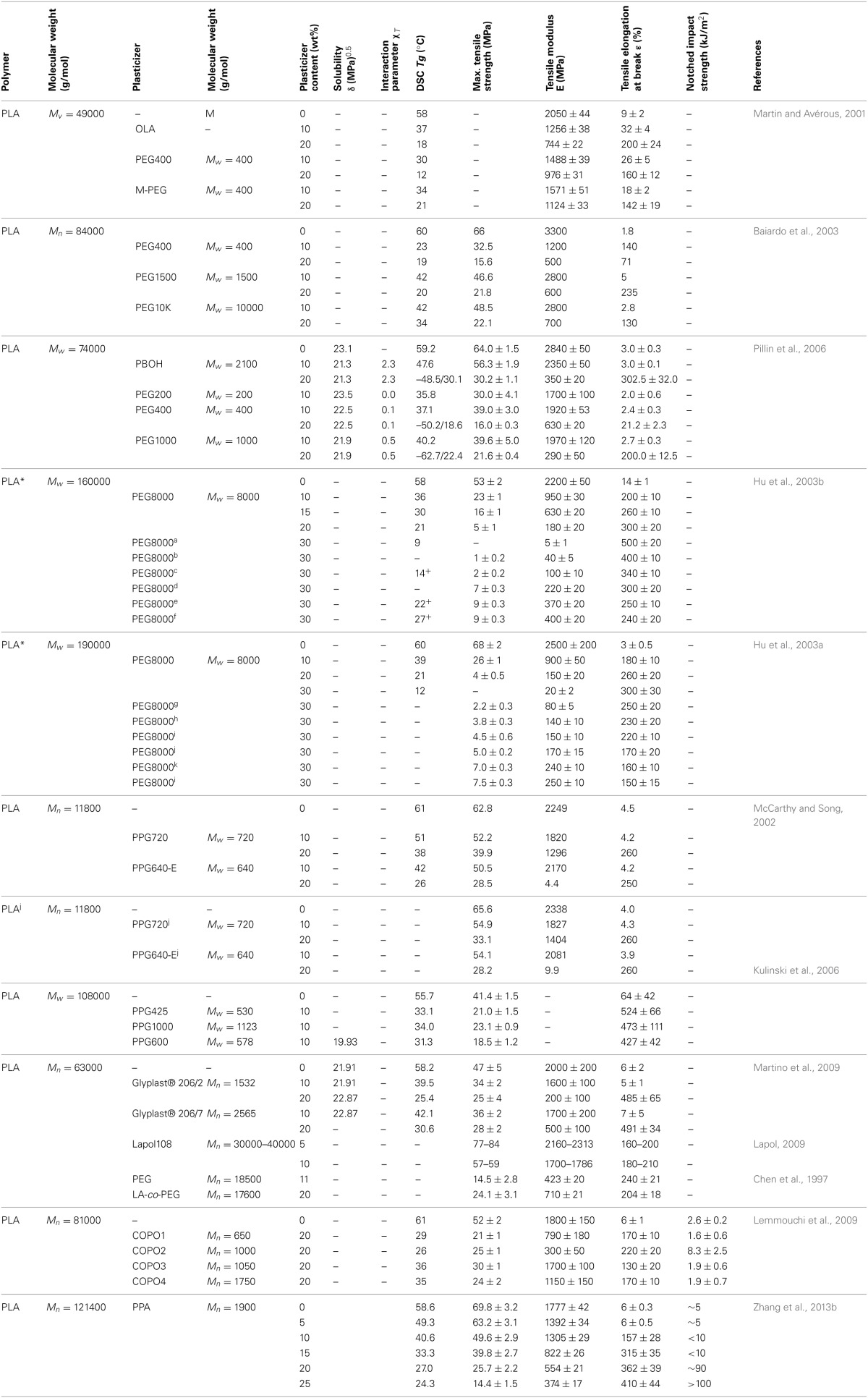

The common way to reduce plasticizers' migration and evaporation is to increase their molecular weight in such a way to retain their miscibility with the polymer matrix at the same time. In this respect, many researchers have investigated the effect of some oligomeric and polymeric molecules as plasticizers for PLA (Table 4).

Table 4.

Table molecular weight and solubility parameters (δ) of some oligomeric and polymeric plasticizers and their Plasticization effects on PLA [Copyright © (2011) Wiley and Sons; used with permission from Liu and Zhang (2011)].

An update of the Table 4 has been made by Kfoury et al. in the frame of this review.

*with low stereoregularity, +Tg measured from E” in DMA

aaging for 6 h.

baging for 30 h.

caging for 120 h.

daging for 500 h.

eaging for 1800 h.

faging for 2 h.

gaging for 10 h.

haging for 24 h.

iaging for 120 h.

jaging for 720 h.

kaging for 3000 h.

LA, lactide; OLA, oligomeric lactic acid; PEG, poly(ethylene glycol), the subsequent number represents its nominal molecular weight; M-PEG, poly(ethylene glycol) monolaurate; PBOH, poly(1,3-butanediol); PPG, poly(propylene glycol), the subsequent number represents its nominal molecular weight; PPG-E, epoxy capped poly(propylene glycol); GlyplastVR 206/2 and GlyplastVR 206/7, two kinds of commercial polymeric adipates with molecular weight of 1532 and 2565 g/mol, respectively; COPO1 and COPO2, two kinds of AB-type block copolymers of DLLA and either PEG350 monomethyl ether or PEG750 monomethyl ether, that is, PDLLA-b-PEG350 (10/4, molar ratio of D,L-LA monomer to PEG350 used in the feed) and PDLLA-b-PEG750 (10/4, molar ratio of D,L-LA monomer to PEG750 used in the feed); COPO3, ABA-type block copolymer of PDLLA and PEG400, that is, PDLLA-b- PEG400-b-PDLLA (10/2, molar ratio of D,L-LA monomer to PEG400 used in the feed); COPO4, 3-star-(PEG-b-PDLLA) block copolymer (10/1.3, molar ratio of D,L-LA monomer to 3-star-PEG used in the feed); COPO5, 4-star-(PEG-b-PDLLA) block copolymer (10/1, molar ratio of D,L-LA monomer to 4-star-PEG used in the feed); PPA, Poly(1,2-propylene glycol adipate).

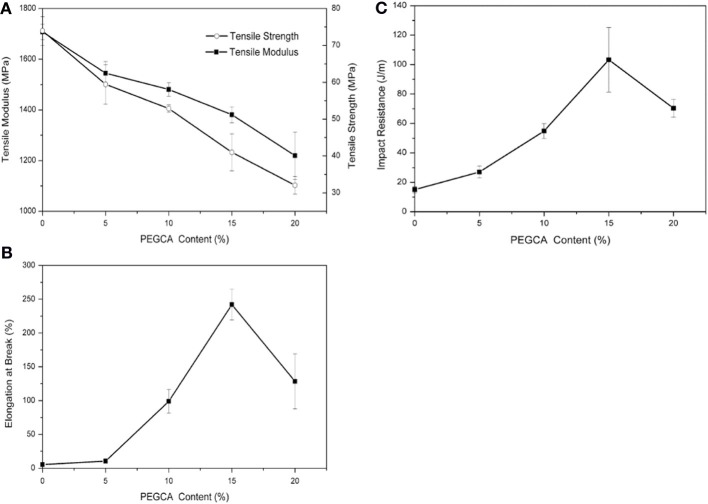

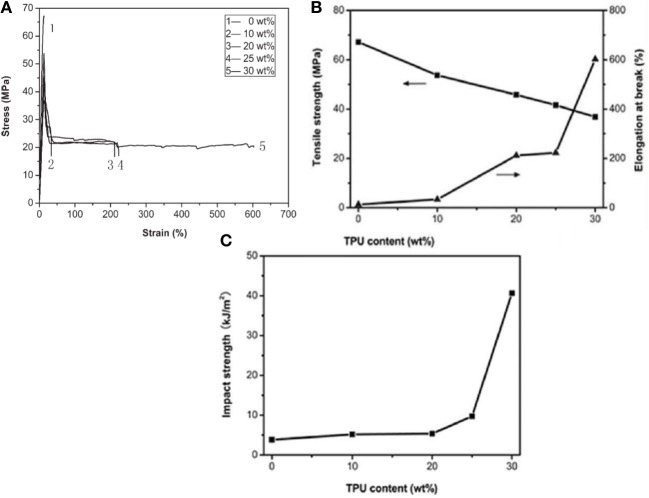

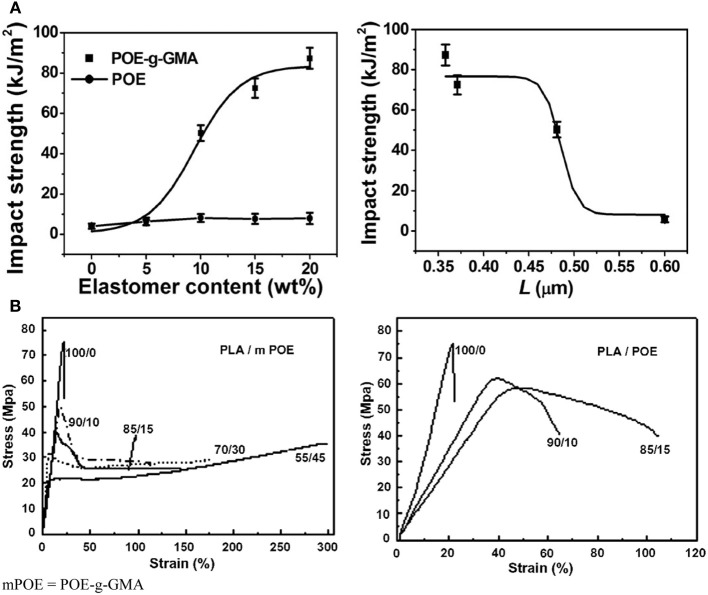

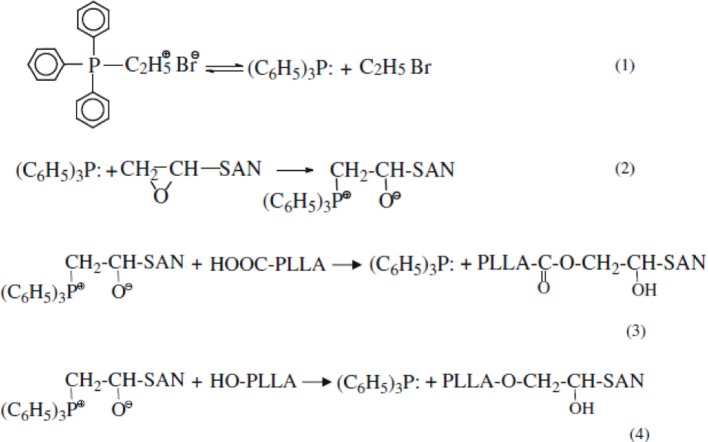

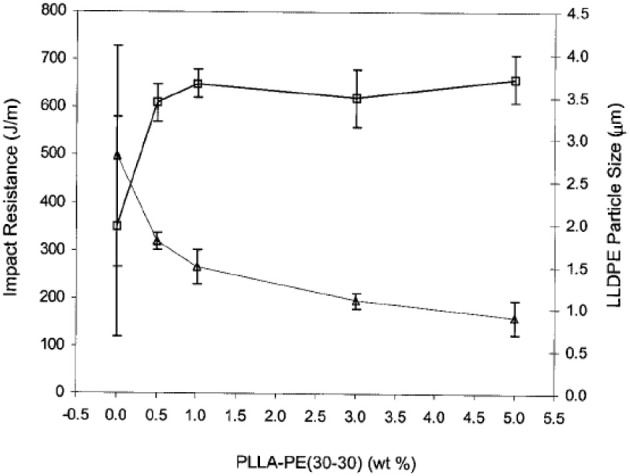

For 20 wt% plasticizer content, ABA-type block copolymer of PDLLA and PEG400, that is, PDLLA-b- PEG400-b-PDLLA (10/2, molar ratio of D,L-LA monomer to PEG400 used in the feed) (COPO3) and poly(propylene glycol) (PPG720) provide a good stiffness-toughness balance. PPGs 425, 600 and 1000, Glyplast® 206/2 and Glyplast® 206/7 have a better plasticizing efficiency compared to the others. Adipates-based plasticizers are miscible with PLA until a critical concentration reached in function of the molar mass of adipate. A remarkable increase in elongation was achieved when the concentration of plasticizer reached 10 wt%, whereas the decreases in elastic modulus and tensile stress were noted for all the plasticizers investigated. Very recently, it has been shown that PLA can be efficiently plasticized and toughened by melt-blending with poly (1,2-propylene glycol adipate) (PPA) (Zhang et al., 2013b). Thermal and dynamic mechanical analysis revealed that PPA was partially miscible with PLA. In addition, morphological investigation of PLA/PPA blends showed that PPA was compatible with PLA. As a result, with the increase of PPA content (5–25 wt%), the blends showed a decrease in the tensile strength and the Young's modulus (Table 4); but the elongation at break and the impact strength dramatically increased due to the plastic deformation. The Izod notched impact strength reached 90 J/m when the PPA amount was of 20 wt%, and even exceeded 100 J/m when PPA amount was of 25 wt%. The plasticization effect of PPA was also highlighted by the lowering of dynamic storage modulus and viscosity in the melt stage of the blends compared with neat PLA. In another recent study, Gui et al. have successfully toughened PLA by melt-blending with poly(ethylene glycol-co-citric acid) (PEGCA) (Gui et al., 2013). The addition of PEGCA to PLA lowered the viscosity and the glass transition temperature of the resulting material. PEGCA was partially miscible in PLA and the blends exhibited a phase-separated morphology. The ductility and toughness of PLA were significantly improved in the presence of PEGCA. Whereas the impact resistance (Figure 2C) and the elongation at break (Figure 2B) of the blends were remarkably higher than those of neat PLA, the tensile and flexural strength and modulus of the blends (Figure 2A) monotonically dropped with increasing PEGCA content.

Figure 2.

(A) Tensile modulus, tensile strength, (B) elongation at break, and (C) of neat PLA and PLA/PEGCA blends (Gui et al., 2013, original copyright with kind permission from Springer Science and Business Media).

Hassouna et al. investigated new plasticization ways based on low molecular bio-plasticizers to improve the ductility of PLA. Grafting reactions between anhydride-grafted-PLA (MA-g-PLA) copolymer with hydroxyl-functionalized citrate plasticizer, i.e., tributyl citrate (TbC) (Hassouna et al., 2012), and poly(ethylene glycol) (Hassouna et al., 2011) were carried out through reactive extrusion. All plasticizers drastically decreased the Tg of PLA due to the mobility gained by the polymer chains within the plasticized blends. Regardless the nature of the plasticizer, the elastic modulus and yield stress decrease, while the ultimate strain increases for plasticized PLA. Very recently, we have investigated a novel and efficient pathway to chemically modify PLA in the presence of “reactive” polyethylene glycol (PEG) derivatives via reactive extrusion (Kfoury et al. Tunable and durable toughening of polylactide materials via reactive extrusion. Submitted). In this purpose, polyethylene glycol methyl ether methacrylate (MAPEG) and polyethylene glycol methyl ether acrylate (AcrylPEG) were melt-mixed and extruded with PLA in the absence and in the presence of a free-radical di-tertiary alkyl peroxide, 2,5-dimethyl-2,5-di-(tert-butylperoxy)hexane (Luperox101 or L101). Molecular characterization revealed that in the case of PLA/MAPEG/L101 blends (79.5/20/0.5 wt/wt/wt), about 20% of the initially introduced MAPEG can be grafted onto PLA chains. The remaining fraction (80%) of the plasticizer was a mixture of unreacted/monomeric and “homo-oligomerized” MAPEG. As a result, an efficient plasticization effect was evidenced by a significant lowering of the glass transition temperature (Tg) and storage modulus E' as well as by a drastic increase of the tensile elongation at break of approximately 70 times as compared to neat PLA. More interestingly, in the case of PLA/AcrylPEG/L101 (79.5/20/0.5 wt/wt/wt), up to 65% of the initially introduced AcrylPEG reacted and was grafted onto the PLA chains. The remaining non-grafted AcrylPEG completely homo-oligomerized. As a result, an efficient toughening effect of the resulting materials was reached. This was especially marked by a drastic enhancement of the impact strength, ~36 times, and a significant improvement of the elongation at break, ~63 times.

Lapol®108 is a renewable bioplasticizer of PLA that can be processed using standard processes such as injection moulding, extrusion coating, thermoforming, and cast films (http://www.lapol.net/). It promotes toughness and flexibility without sacrificing modulus, while minimizing the reduction of glass transition temperature. For the lowest plasticizer content (5–10 wt%), the bioplasticizer Lapol®108 seems to be the most convenient one to maintain a good stiffness-toughness balance among this list of investigated plasticizers (Table 4). Interestingly, the new Lapol® HDT additive used for increasing the heat deflection temperature of PLA is now available at pilot-production. For many high-performance applications, using PLA requires a high temperature resistance to deformation and deflection, i.e., a heat deflection temperature higher than 100°C. Compounding 20 wt.% of Lapol® HDT with PLA 3001D, 4032D, or 7000D can increase the heat deflection temperature of unannealed PLA from 55°C to about 160°C. This capability greatly expands the potential uses and applications to PLA. This increased heat-performance is achieved without adding inorganic fillers or other additives, although these additions may further enhance some other properties. Table 5 shows typical flexural properties data for a blend of 20% Lapol® HDT in PLA compared to commercially available neat and annealed PLA.

Table 5.

Comparison of flexural properties of Lapol® HDT blends vs. PLA (unannealed and annealed) (From http://www.lapol.net/).

| Flexural properties | Modulus (MPA) | HDTb (°C) |

|---|---|---|

| PLA | 3300 | 55 |

| Annealed PLAa | 3800 | 155 |

| 20% Lapol HDT in PLA | 3800 | 165 |

PLA was annealed for 10 min at 110°C.

Heat deflection temperature is measured using a thermomechanical analyzer using a load of 0.2–0.3 N.

PLA-based blends containing Lapol® HDT exhibit similar or higher flexural modulus than commercially available PLA (annealed and unannealed). Lapol® HDT may be compounded with an impact modifier to tailor the properties of PLA for specific applications.

Globally, these studies show that oligomeric and polymeric plasticizers are in general less efficient than monomeric ones in order to improve the elongation and reduce the glass transition temperature of resulting blend. However, they have more tendencies to give better stiffness-toughness balance for PLA material compared to small molecule plasticizers. Based on their complementary advantages, the combination of small molecule plasticizers with polymeric or oligomeric ones was also attempted in the literature.

Mixed plasticizers

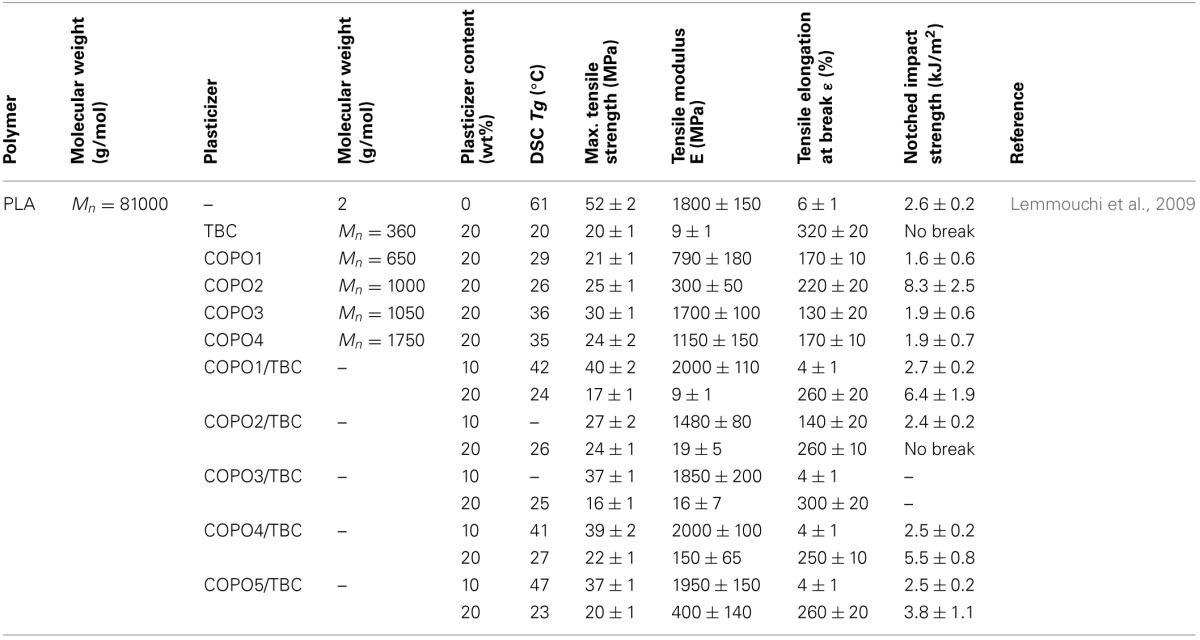

These mixed plasticizers combine an oligomeric or polymeric plasticizer with a small molecule plasticizer. Therefore, they should lead to a medium level of depression in Tg and more balanced mechanical properties (elongation, modulus and strength) than the individual plasticizers. Some plasticizer combinations were studied. They are reported in Table 6.

Table 6.

Summary of effects of some mixed plasticizers on mechanical properties of PLA [Copyright © (2011) Wiley and Sons; used with permission from Liu and Zhang (2011)].

TBC, tributyl citrate; COPO1 and COPO2, two kinds of AB-type diblock copolymers of PDLLA and either PEG350 monomethyl ether or PEG750 monomethyl ether, that is, PDLLA-b-PEG350 (10/4, molar ratio of D,L-LA monomer to PEG used in the feed) and PDLLA-b-PEG750 (10/4, D,L-LA monomer to PEG molar ratio used in the feed); COPO3, ABA-type triblock copolymer of DLLA and PEG400, that is, PDLLA-b-PEG400-b-PDLLA (10/2, molar ratio of D,L-LA monomer to PEG used in the feed); COPO4, 3-star-(PEG-b-PDLLA) block copolymer (10/1.3, molar ratio of D,L-LA monomer to PEG used in the feed); COPO5, 4-star-(PEG-b-PDLLA) block copolymer (10/1, molar ratio of D,L-LA monomer to PEG used in the feed).

In general, one can conclude on the behaviors of the plasticizers in PLA and their effect on the properties of the polymer as follows:

– The addition of 10–20% of plasticizers may be a successful way to remarkably reduce Tg and improve PLA flexibility/ductility/tensile elongation at the same time.

– Substantial reductions in tensile strength and modulus are unfortunately unavoidable.

– An excessive incorporation of plasticizer leads to the saturation of the plasticizer in the amorphous phase of PLA, resulting in a migration or phase separation depending on the plasticizer nature.

– Small molecule or monomeric plasticizers are more efficient in order to improve PLA flexibility/ductility/tensile elongation and decrease its Tg, but less efficient on tensile strength and modulus than oligomeric and polymeric plasticizers.

– The higher the molecular weight of the plasticizer, the lower the critical saturation concentration, at which phase separation begin to occur.

– Lower molecular weight PEGs exhibit good miscibility with PLA and result in more efficient reduction of Tg. This can lead to drastic improvement in ductility and/or impact resistance of PLA at low concentrations.

– After ageing for 1 month, the mechanical properties of the plasticized PLA did not change remarkably. This result indicated that PPG and PPG-E could prevent the physical ageing and the embrittlement of PLA.

– Whilst increasing the molecular weight of the plasticizer can slow down migration rate and thus improve morphological stability of PLA materials during storage, it also decreases its solubility and plasticizing efficiency. Additionally, high-molecular weight plasticizers are keen to phase-separation because of low saturation concentrations of plasticizers.

Compounding with flexible/soft polymers—partially miscible to immiscible blends—ways of compatibilization

The term “blending” refers to the simple mixing of polymeric materials in the molten state. During the last three decades, polymer blends have become a very important part of the commercialization of polymers because one can tailor blend compositions to meet specific end-use requirements (Baker et al., 2001). Melt-blending polymers is a much more economical and convenient methodology at the industrial scale rather than synthesizing new polymers to achieve the properties unattainable with existing polymers. However, most polymer pairs are immiscible, which can lead to phase-separated materials. The latter has often three inherent problems if the morphology and the interfaces of the blend are not well-controlled: (1) poor dispersion of one polymer phase in the other one; (2) weak interfacial adhesion between the two phases; and (3) instability of immiscible polymer blends (Baker et al., 2001). However, immiscible polymer blends are much more interesting for commercial development because immiscibility allows maintaining the good features of each polymeric component of the blend. One of the most important challenges is thereby to develop compatibilization techniques that allow controlling both the morphology and the interfaces of phase-separated blends. In general, compatibilization in physical blends is tuned by the physical interactions (hydrogen bonds, Van der Waals interactions etc.) between the blend components.

PLA has been blended with various polymers for different purposes, namely for improving its stiffness-toughness balance. A variety of biodegradable and non-biodegradable soft polymers have been used as toughness modifiers for PLA. Recently, it has been shown that new impact modifiers can efficiently strengthen/toughen brittle/stiff PLA, due to their core-shell polymeric structure (a block copolymer). They form a soft or elastomeric block having high compatibility and miscibility with the toughening polymer, and surrounded with a rigid block copolymer, usually having a high compatibility and/or miscibility with the matrix polymer. When the softer component forms a second phase within the stiffer continuous phase, it may act as a stress concentrator, which enables ductile yield and prevents brittle failure (Babcock et al., 2008). At the same time, the core is “locked in” by slight crosslinking and grafting with its shell to avoid phase-separation during blending. Moreover, the adhesion between the two phases, core-shell polymer and polymer matrix, depends strongly on the degree of miscibility of the shell polymer with the matrix, that is, whether they are completely miscible, partially miscible, or immiscible. However, a partial miscibility between core-shell modifiers and polymeric matrix is often necessary to obtain blends of desired impact properties. From the literature, multiple crazing initiated from the dispersed rubber phase is recognized to be one of the main mechanisms, which increases the toughness of glassy materials like polylactide-based materials (Ikeda, 1993; Bucknall, 2007; Mahajan and Hartmaier, 2012). Some authors have preferred to blend PLA with biodegradable flexible/soft polymers in order to preserve the overall biodegradability of resulting blends. Some of these blends are in this regard, finding short-term applications, namely packaging and mulch films for agriculture.

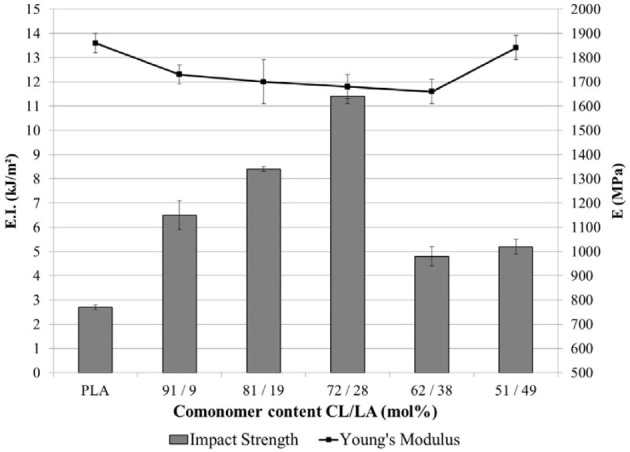

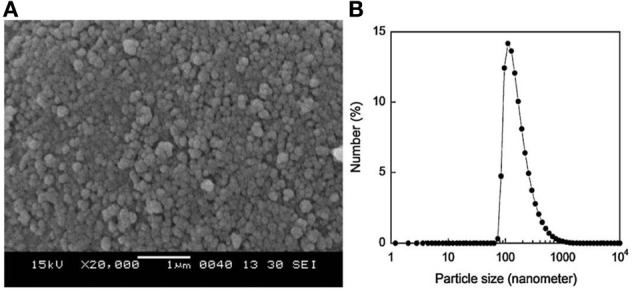

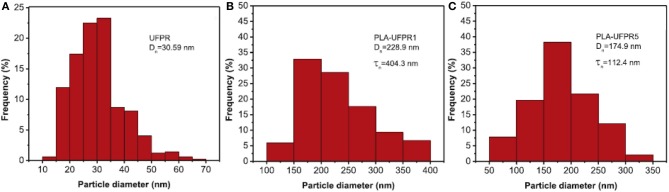

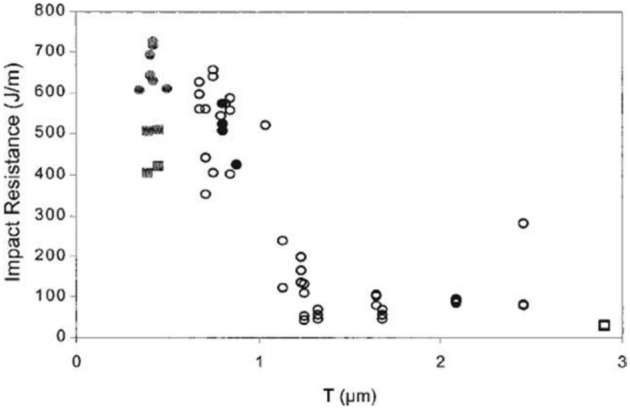

Flexible/soft (ε-caprolactone)-based copolymers

As obtained by ring-opening polymerization of e-caprolactone, poly(e-caprolactone) (PCL) is a biodegradable and flexible/soft polyester with a melting temperature of 60°C and a glass transition temperature of −60°C. Due to the low glass transition temperature, PCL-based materials were considered as interesting impact modifiers. PCL and PLA blends have been extensively investigated over the past years. For instance, Broz et al. investigated the tensile properties of blends made of P(D,L-LA) and PCL at different content in PCL (Broz et al., 2003). Whilst the strain-at-failure decreases monotonically for PCL contents from 0.6 wt%, the modulus and tensile strength increased almost linearly with composition. This was more likely ascribed to some strengthening of the blend interface in this regime. However, DSC and NMR results suggested that PCL was able to crystallize to a certain extent within PCL/P(D,L-LA) blends, indicating that phase-separation was more pronounced under these conditions. However, as shown here, the simple melt blending of PLA and PCL usually results in a marginal toughness improvement because of their poor miscibility (López-Rodríguez et al., 2006). This can be more likely explained by the fact that PCL can readily crystallize within PLA/PCL blends, leading to the more pronounced phase-separation. Accordingly, the simple melt blending of PLA and PCL usually leads to a marginal improvement in toughness because of their immiscibility (López-Rodríguez et al., 2006; Vilay et al., 2009). In this regard, some of us have designed bio-sourced and hydrolytically degradable random copolyesters based on poly(ε-caprolactone) as a soft core component. (Co)polymerization of CL with other lactones affords an elegant way to modulate the thermal and mechanical properties of resulting PCL-based materials. The most interesting feature was that the overall crystallinity of these (co)polyesters decreased with the comonomer content, yielding rubbery-like materials at ambient temperature. When dispersed into glassy materials like PLA, it is well-known that rubbery microdomains can readily absorb the impact energy. In a first study (Odent et al., 2012), 10 wt.% of amorphous poly(ε-caprolactone-co-δ-valerolactone) (P[CL-co-VL]) random aliphatic copolyesters were thereby synthesized and investigated as biodegradable impact modifiers for commercial PLA using a microcompounder. The use of a high molar mass copolyester (Mn = ca. 60,000 g/mol) with a molar composition of 45/55 mol% (CL/VL) resulted in the optimal improvement in notched Izod impact strength for compression-moulded (vs. injection-moulded) PLA materials (7 kJ/m2) compared to 2.5 kJ/m2 for PLA. According to the author, this improvement in toughness is also related to the mean size (0.7 μm) and size distribution of the dispersed copolymer micro-domains throughout the PLA matrix. In a similar study (Odent et al., 2013b), the random biocopolyester was synthetized and used as impact modifier is poly(ε-caprolactone-co-d,l-lactide) (P[CL-co-LA]). By varying the comonomer content, a phase inversion was noticed. A control of the affinity between PCL-based impact modifiers and PLA matrix gives access to a mixture of spherical microdomains with similar range of optimum particles diameter (i.e., 0.9 μm) and nanosized oblong structures, involving a combination of shear yielding and multiple crazing mechanisms. As a result, PLA blended with 10 wt.% of the CL/LA composition 72/28 mol.% displayed a maximum impact strength of about 11.4 kJ/m2 (Figure 3). The mean size of the rubbery micro-domains was 0.9 μm in this case.

Figure 3.

Influence of the LA comonomer content of copolyester on the notched Izod impact strength and Young's modulus of PLA-based materials containing 10 wt.% of P[CL-co-LA]. [Reprinted from Odent et al. (2013b) with permission from Elseiver].

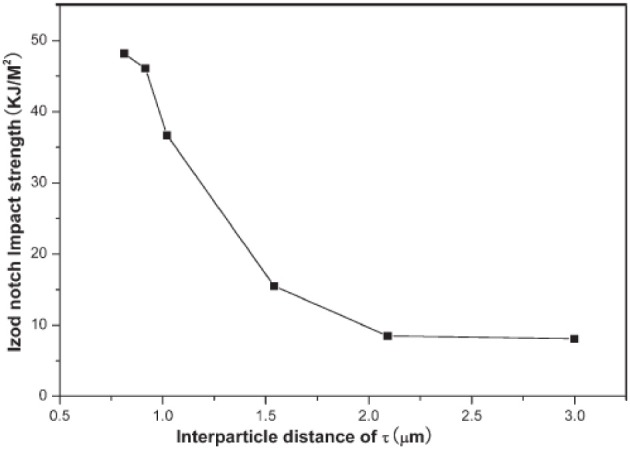

In the case of brittle polymers, spherical microdomains act as stress reservoirs and initiate crazing upon the microdomains size, i.e., larger microdomains size than 0.5 μm are required to nucleate crazing mechanism and enhance fracture energy absorption (Donald and Kramer, 1982; Van Der Wal and Gaymans, 1999). Accordingly, an optimum particle size range (ca. 0.7–0.9 μm) for PLA toughening was identified by correlating dispersed microdomains size with notched Izod impact strength (Gramlich et al., 2010; Liu et al., 2011). Wu and al. correlated rubber particle diameter with chain structure parameter of the matrix and claimed that the optimum particle size for toughening decreased as the matrix becomes less brittle (Wu, 1990). Kowalczyk et al. reported that rubbery poly[1,4-cis-isoprene] microdomains within PLA-based materials initiated crazing at the early stages of deformation, immediately followed by the cavitation phenomena inside rubbery microdomains. This latter promotes further shear yielding for PLA matrix (Kowalczyk and Piorkowska, 2012). More recently, some of us have elaborated ultratough PLA-based materials by synergistically adding PLA, rubber-like poly(ε-caprolactone-co-D,L-lactide) copolyester and silica nanoparticles using extrusion techniques (Odent et al., 2013a). A peculiar alteration for the phase-morphology of the rubbery phase within PLA matrix was achieved by co-adding copolyester and silica nanoparticles into PLA matrix. It resulted that regularly obtained spherical nodules convert into almost continuous features after adding nanoparticles in the PLA-based melt-blend. In the latter, an enhancement of 15-fold impact strength was obtained by comparison to unfilled PLA.

The use of small molecule reactive additives during compounding has been demonstrated to be an effective way to improve the compatibility between PLA and PCL. Wang et al. (1998) investigated the tri-phenyl phosphate (TPP) as a catalyst or coupling agent for the preparation of PLA and PCL blends. The addition of 2 phr TPP to PLA/PCL (80/20, w/w) blend during processing resulted in a higher elongation (127 vs. 28%) and tensile modulus (1.0 GPa vs. 0.6 GPa) compared to the binary TPP-free blend. The balance between degradation of molecular weight and the formation of copolymer was believed to govern the final mechanical properties of the blends. Reaction time and molecular weight of PCL used were found to have remarkable effects on mechanical properties of the blends. Higher molecular weight PCL (Mn = 80,000 g/mol) and medium reaction time (15 min) promoted the largest improvement of the ductility. In another study, di-cumyl peroxide (DCP) was used to promote reactive compatibilization of the PLA/PCL blends (Semba et al., 2006). The results showed again that the addition of DCP increased the ductility of the final material. Further addition of DCP beyond the optimum amount had an opposite effect on elongation. AFM observation revealed that the diameter of the dispersed PCL domains decreased with increasing DCP content. The addition of 0.3 phr DCP to the optimum ration PLA/PCL = 70/30 resulted in (1) an impact strength of 2.5 times more than that of neat PLA, (2) an improved blend compatibility, (3) an improved ultimate tensile strain (4) a yield point and ductile behavior under tensile test, and (5) mechanical properties comparable to those of HIPS and ABS. In contrast, the addition of DCP to PLA alone did not alter mechanical properties. It was suggested that DCP caused crosslinking of PLA with PCL and therefore improved interfacial adhesion. Depending on feeding procedure, addition of DCP via the splitting feeding method resulted in a higher reverse Izod impact strength than feeding at once through the main hopper (Semba et al., 2007). Lysine tri-isocyanate (LTI) as a reactive compatibilizer improved the compatibility of PLA and PCL, resulting in the reduction of size of PCL spherulites (Takayama and Todo, 2006; Takayama et al., 2006). Impact fracture toughness markedly improved by increasing LTI content, which was attributed to the strengthening structure of the blend as a consequence of crosslinking reactions. The compatibilizing effect of LTI was compared with four other reactive processing agents on the PLA/PCL (80/20, w/w) blends (Harada et al., 2008). The addition of 0.5 phr of each reactive agent resulted in an increase in the un-notched Charpy impact strength in the order of LTI > LDI (lysine diisocyanate) > Duranate TPA-100 [1,3.5-tris(6-isocyanatohexyl)- 1,3,5-triazinane-2,4,6-trione] > Duranate 24A-100 [1,3,5-tris(6-isocyanatohexyl)biuret] > Epiclon 725 (trimethylolpropane triglycidyl ether). It was assumed that the reaction of isocyanates group with both terminal hydroxyl and carboxylic groups of polyesters accounted for improved compatibility at the PLA/PCL interfaces and therefore the enhancement in the physical properties.

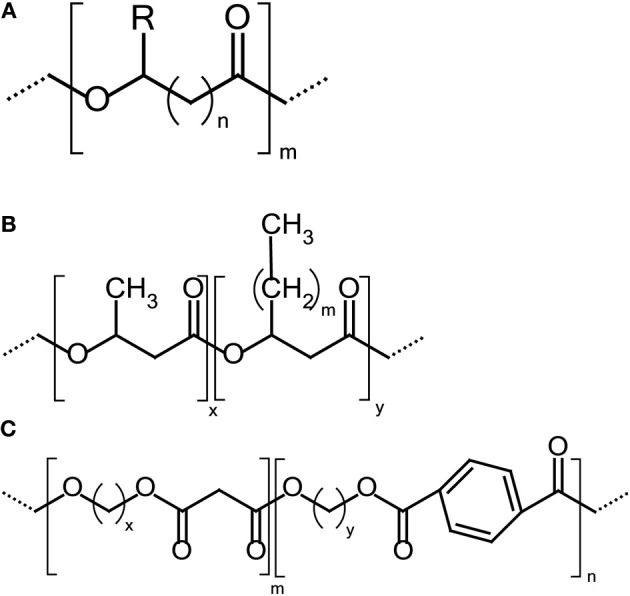

Polyhydroxyalkanoates (PHAs) and their copolyesters

Polyhydroxyalkanoates (PHAs) are biodegradable polyesters produced by bacterial fermentation of sugar or lipids (Steinbüchel and Valentin, 1995; Zinn et al., 2001; Poirier, 2002; Noda et al., 2005) when nutrient shortage is present. Since the range of monomers available is impressive within this family, the mechanical properties of PHAs can range from stiff thermoplastics to elastomers dependent on their pendent alkyl chain length (Scheme 1A). However, only one grade, i.e., Nodax™, was industrially implemented by Procter and Gamble Co., which correspond to copolymers of 3-hydroxybutyrate with a small amount of 3-hydroxyalkanoate as co-monomer (Scheme 1B) (Noda et al., 2004, 2005).

Scheme 1.

(A) General chemical structure of PHAs polyesters where R=hydrogen or hydrocarbon chains of up to C15 in length; x = 1 to 3. (B) The general structure of PHA copolyesters. (C) Chemical structure of poly(butylene adipate-co-terephthalate) (PBAT).

In this regard, Noda et al. (2004) melt-blended PLA with a poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) copolymer, i.e., NodaxH6, containing 5 mol% of 3-hydroxyhexanoate (3-HH) unit. The PLA/NodaxH6 (90/10, w/w) blend exhibited a tensile toughness of 10 times more than that of neat PLA and an elongation superior to 100%. When NodaxH6 content was less than 20 wt % in the blends, its crystallization was largely restricted and thereby NodaxH6 was dispersed as rubbery amorphous droplets within PLA, suggesting that the material was toughened by craze-initiation. Furthermore, it was interesting that the inclusion of these small amounts of PHA did not compromise the optical clarity of PLA itself.

Schreck and Hillmyer investigated the impact toughness of blends of PLLA with a NodaxH6 containing 7 mol.% of 3-HH (Schreck and Hillmyer, 2007). The PLLA/NodaxH6 (85/15, w/w) blend demonstrated a twofold increase in notched Izod impact strength (44 J/m) compared with that of PLLA (22 J/m). Ma et al. toughened PLA by melt-compounding with fully bio-based and bio-compostable poy(β-hydroxybutyrate-co-β-hydroxyvalerate) (PLA/PHBV) with high β-hydroxyvalerate content (40 mol%) (Ma et al., 2013). The blends displayed two separate glass transition temperatures and two separate phases, indicating that the PLA and PHBV were immiscible. The toughness and the ductility of PLA can be effectively improved by incorporation of 10–30 wt% of the PHBV as evidenced by a significant increase in the elongation at break and the impact toughness (Table 8). The local deformation mechanism revealed that fibrillation, partial interfacial de-bonding, cavitation and matrix yielding were involved in the toughening mechanism of the PLA/PHBV blends under impact and tensile testing conditions.

Table 8.

Mechanical properties of different PLA blends with biodegradable flexible/soft polymers.

| Formulation (wt.%) | Et (MPa) | σy (MPa) | εb(%) | NIIE (KJ/m2) | |||

|---|---|---|---|---|---|---|---|

| PLA/PHBV (Ma et al., 2013) | U-NIIE (KJ/m2) | Ef(GPa) | σf (MPa) | ||||

| 100/0 | 68 | 4 | 2.5 | 16 | 3.5 | 109 | |

| 95/5 | 62 | 5 | 2.7 | 15 | 3.4 | 96 | |

| 90/10 | 53 | 220 | 3.1 | 23 | 3.0 | 85 | |

| 80/20 | 42 | 230 | 11 | 150n.f. | 2.5 | 66 | |

| 70/30 | 35 | 260 | 10 | 127n.f. | 2.0 | 51 | |

| 50/50 | 15 | 15 | 6 | 41 | 1.2 | 21 | |

| 0/100 | 9 | 12 | 48 | 45n.f. | 0.5 | 11 | |

| PLA/PBAT (Jiang et al., 2006) | |||||||

| 100/0 | 3400 | 63 | 3.7 | 2.6 | |||

| 95/5 | – | – | ~115 | – | |||

| 80/20 | 2600 | 47 | >200 | 4.4 | |||

| PLA/PEBA (Han et al., 2013) | |||||||

| 100/0 | 1170 ± 42 | 60.0 ± 1.1 | 6.7 ± 0.4 | 4.5 ± 0.6 | |||

| 95/5 | 1151 ± 75 | 49.3 ± 1.2 | 13.7 ± 0.8 | 7.1 ± 0.3 | |||

| 90/10 | 1156 ± 44 | 46.8 ± 0.4 | 283 ± 18 | 7.4 ± 0.4 | |||

| 85/15 | 1062 ± 48 | 42.5 ± 0.9 | 313 ± 2 | 9.1 ± 0.4 | |||

| 80/20 | 1011 ± 41 | 42.4 ± 1.0 | 346 ± 18 | 39.3 ± 2.2 | |||

| 70/30 | 911 ± 54 | 36.8 ± 0.6 | 335 ± 5 | 60.5 ± 1.0 | |||

| PLA/PAE (Zhang et al., 2009b) | Es (MPa) | TgPAE (°C) | TgPLA (°C) | ||||

| 100/0 | 1814 | 46.8 | 5.1 | 2460 | 79.48 | ||

| 95/5 | 1517 | 48.1 | 161.5 | 2116 | –47.31 | 77.85 | |

| 90/10 | 1633 | 40.9 | 194.6 | 2017 | –53.87 | 75.97 | |

| 80/20 | 1240 | 23.7 | 184.6 | 1442 | –57.89 | 74.47 | |

| 70/30 | 1050 | 24.6 | 367.2 | 1395 | –60.26 | 73.84 | |

| PLA/NR (Bitinis et al., 2011) | |||||||

| Pristine PLA | 2900 ± 100 | 63.1 ± 1.1 | 3.3 ± 0.4 | ||||

| Processed PLA | 3100 ± 40 | 58.0 ± 1.5 | 5.3 ± 0.7 | ||||

| 95/5 | 2500 ± 60 | 50.4 ± 1.6 | 48 ± 22 | ||||

| 90/10 | 2000 ± 50 | 40.1 ± 1.5 | 200 ± 14 | ||||

| 80/20 | 1800 ± 80 | 24.9 ± 0.9 | 73 ± 45 | ||||

| PLA/GMS (Ge et al., 2013) | |||||||

| 100/0 | 1777 ± 42 | 69.8 ± 3.2 | 5.7 ± 0.3 | 4.7 ± 0.2 | |||

| 95/5 | 1570 ± 44 | 44.8 ± 1.3 | 4.5 ± 0.5 | 8.1 ± 0.4 | |||

| 90/10 | 1200 ± 12 | 41.9 ± 4.6 | 7.6 ± 2.4 | 8.5 ± 0.5 | |||

| 85/15 | 1270 ± 36 | 39.7 ± 1.0 | 11 ± 5.0 | 15.5 ± 0.3 | |||

| 80/20 | 1210 ± 17 | 35.1 ± 2.1 | 9.5 ± 6.5 | 36.7 ± 0.3 | |||

| 75/25 | 1190 ± 24 | 32.4 ± 1.8 | 11 ± 3.1 | 46.1 ± 2.9 | |||

| 70/30 | 695 ± 38 | 29.9 ± 2.6 | 45 ± 15.8 | 48.2 ± 4.6 | |||

Et, Tensile modulus; σy, Tensile yield stress; εb, Tensile elongation at break; NIE, Notched Izod Impact Energy; U-NIIE, Un-Notched Izod Impact Energy; Ef, Flexural modulus; σf, Flexural stress; Es, Storage modulus; Tg, Glass transition temperature by DMA; n.f., Not (completely) fractured.

Biodegradable poly(butylene adipate) (PBA), poly(butylene succinate) (PBS), and poly(butylene adipate-co-butylene terephthalate) (PBAT)

Poly(butylene adipate-co-terephthalate) (PBAT) is a fully biodegradable aliphatic–aromatic copolyester (Scheme 1C), which is commercially available under the trade name of EcoflexVR (BASF Co.).

PBAT has similar thermal properties to those of LDPE, but exhibits higher mechanical properties, more particularly higher flexibility and ductility (elongation > 700%). Even though PLA/PBAT blend are immiscible, PBAT could be dispersed in PLA with an average particle size of about 0.3–0.4 μm without use of compatibilizers in co-rotating twin-screw extruder (Jiang et al., 2006). The mechanical properties of the different PLA/PBAT blends are reported in Table 8. It was demonstrated that the de-bonding-induced shear yield was responsible for the remarkable high extensibility of the blends. Because of weak interfacial adhesion in the blends, impact toughness was slightly improved. Interestingly, the PLA/PBAT blends are now being commercially produced by BASF Co. under the trademark EcovioVR for film and extruded foam applications.

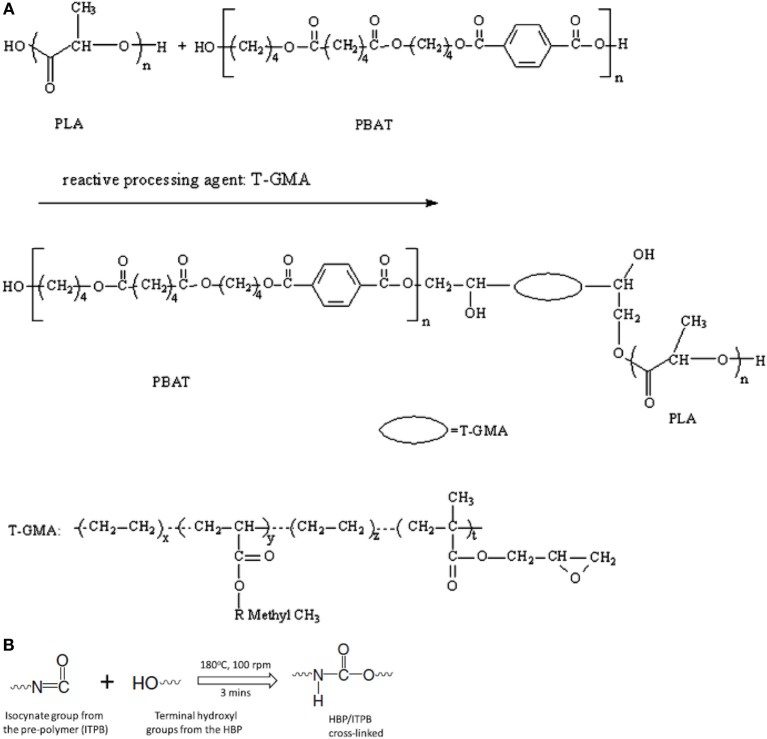

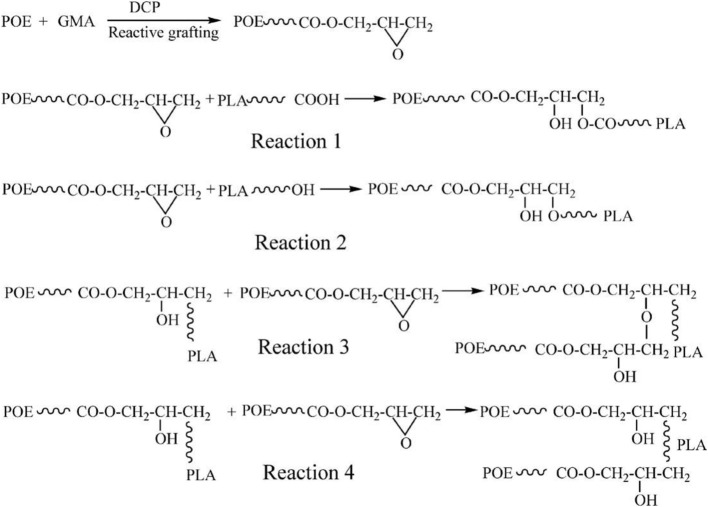

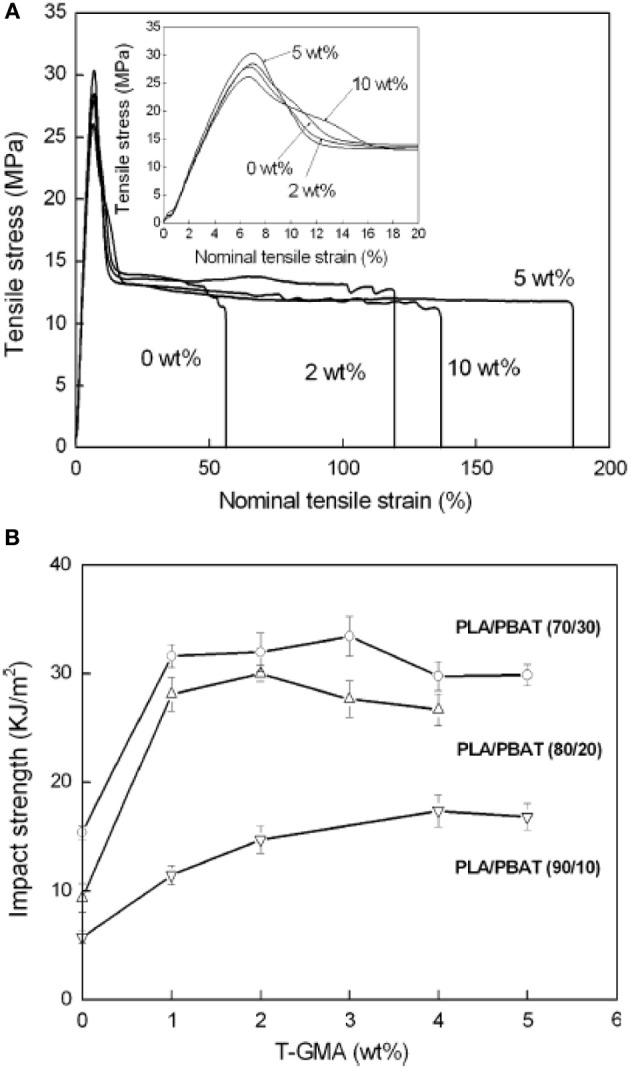

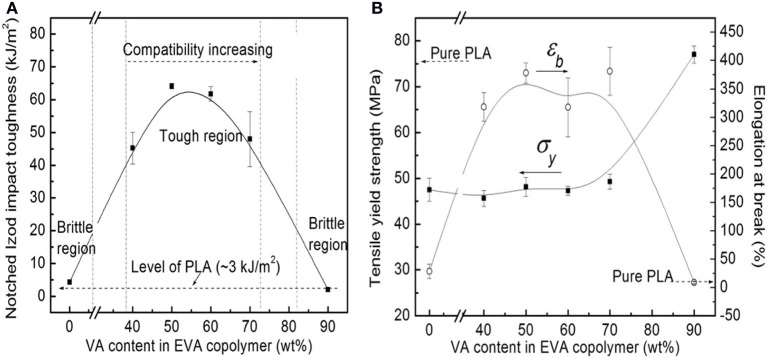

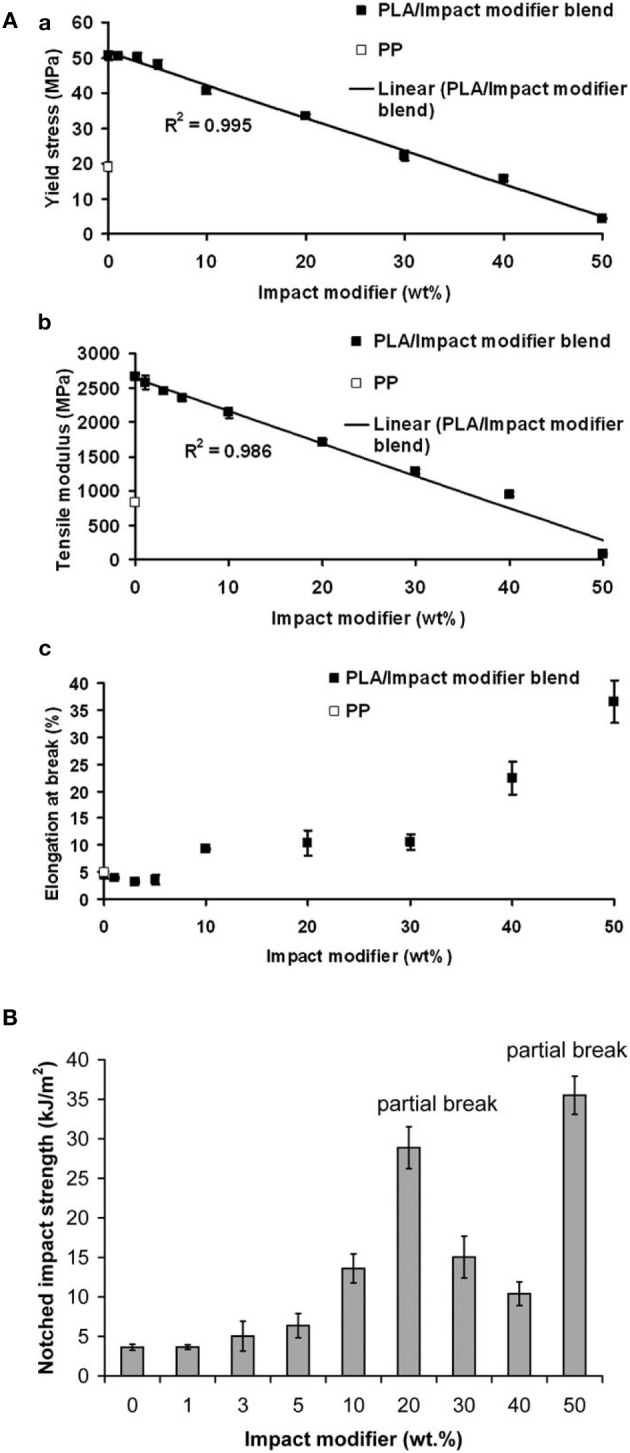

To improve the compatibility of PLA/PBAT blends, a random terpolymer of ethylene, acrylate ester, and glycidyl methacrylate (referred as “T-GMA”) was investigated as a reactive compatibilizer in melt compounding (Zhang et al., 2009a). Regardless the PLA/PBAT blends composition (70/30, 80/20 or 90/10 wt/wt), the increase of T-GMA content up to 5 wt% resulted in a great improvement of tensile nominal strain at break (Figure 4A) and the notched impact strength (Figure 4B) to reach more than 150% and 30 kJ/m2, respectively, approximately two times that of the uncompatibilized binary blends. These results were correlated to the good miscibility and interfacial adhesion between PLA and PBAT, leading to a shear yielding mechanism when increasing the T-GMA content. The authors attributed the better interfacial adhesion to the in situ reactive compatibilization phenomena (Scheme 2A).

Figure 4.

(A) Stress–strain curves of PLA/PBAT (90/10 wt%) blend in the presence of T-GMA. The inset gives details of stress–strain of the blends in the neighborhood of yield points. (B) Effect of T-GMA concentration in the PLA/PBAT blends (PLA/PBAT = 90/10, 80/20, 70/30 wt%) on impact strength. [Zhang et al. (2009a) original copyright with kind permission from Springer Science and Business Media].

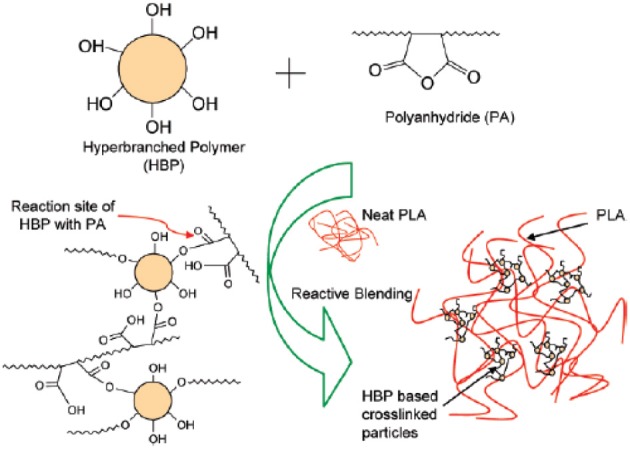

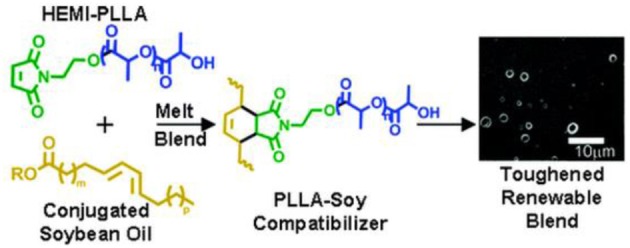

Scheme 2.

(A) Predicted reaction of PLA, PBAT, and T-GMA [Zhang et al. (2009a), original copyright with kind permission from Springer Science and Business Media]. (B) Schematic showing the proposed in-situ crosslinking of the terminal hydroxyl groups from HBP or PLA with isocyanate groups from the ITPB during reactive blending in extruder at 180°C [Nyambo et al. (2012), original copyright with kind permission from Springer Science and Business Media].

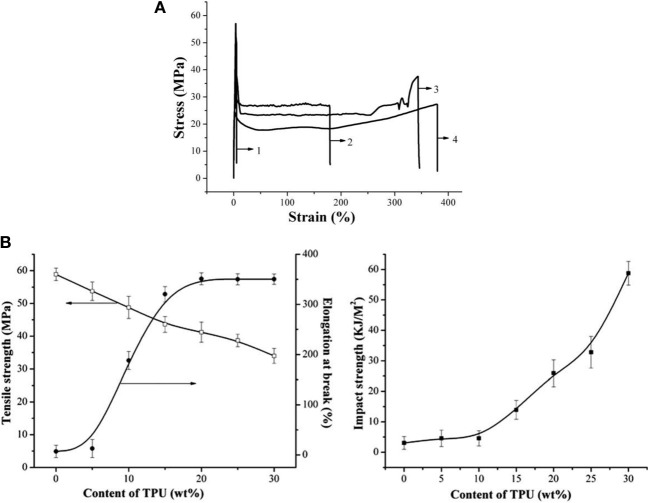

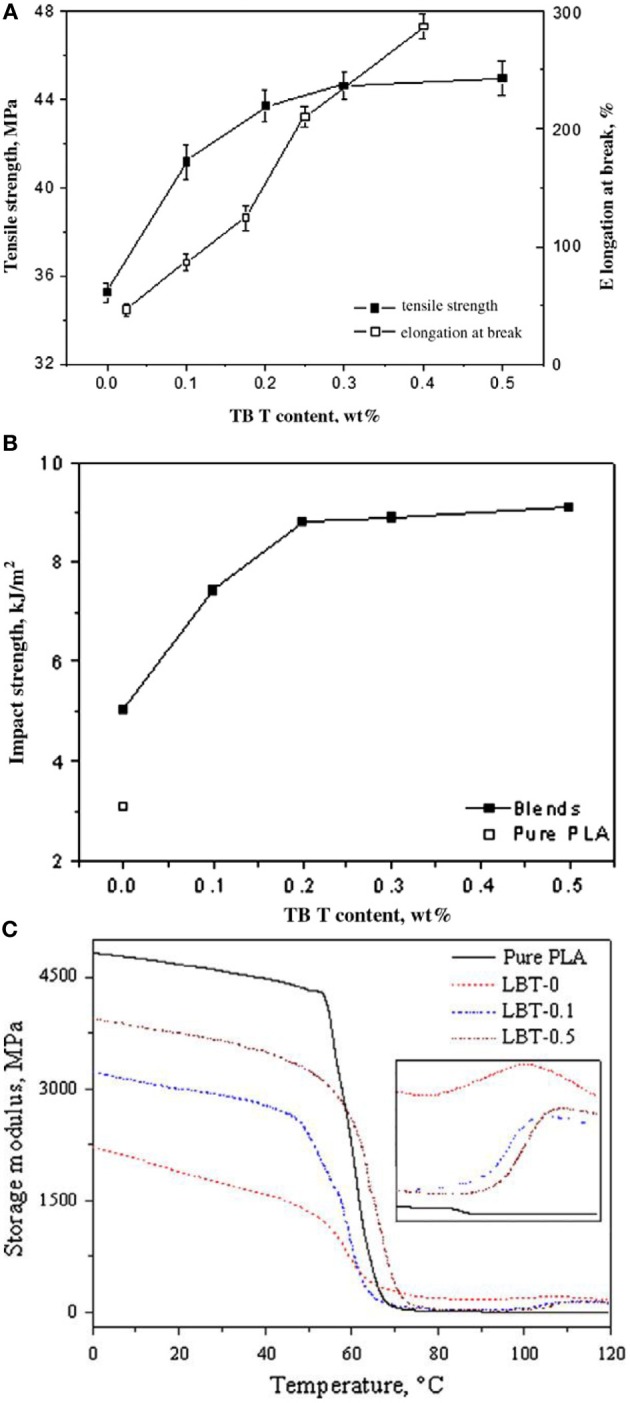

Lin et al. (2012) compatibilized the biodegradable blends poly(lactic acid) (PLA)/poly(butylene adipate-co-terephthalate) (PBAT) by in situ transesterification using various amounts of tetrabutyl titanate (TBT) as catalyst. The incorporation of 0.5% of TBT into PLA/PBAT blends not only improved their overall mechanical properties as well as gave values of tensile strength, elongation at break and impact strength of 45 MPa, 298% and 9 kJ/m2 (Figures 5A,B), respectively. It was also demonstrated that the storage modulus of the blends and glass transition temperature (Figure 5C) were enhanced compared to the binary blends free of TBT. The SEM micrographs demonstrated that the compatibility between PLA and PBAT was improved via transesterification during reactive melt-extrusion. The interfacial de-bonding and the yielding deformation were the most important mechanisms to improve toughness.

Figure 5.

(A) Effect of TBT concentrations on the tensile strength and elongation at break. (B) Variation of impact strength of PLA/PBAT blends with TBT concentration. (C) Temperature dependence of storage modulus of pure PLA and its blends [Reprinted from Lin et al. (2012) with permission from Elseiver].

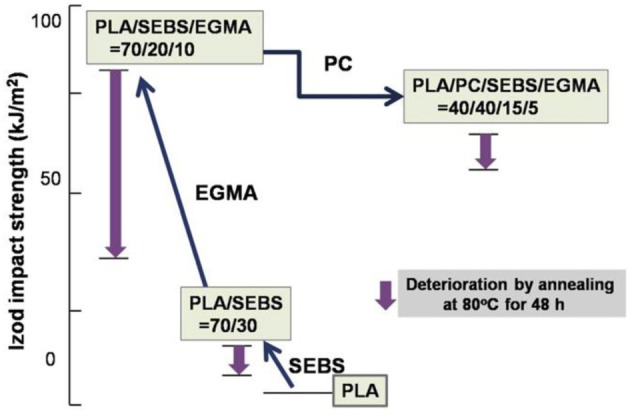

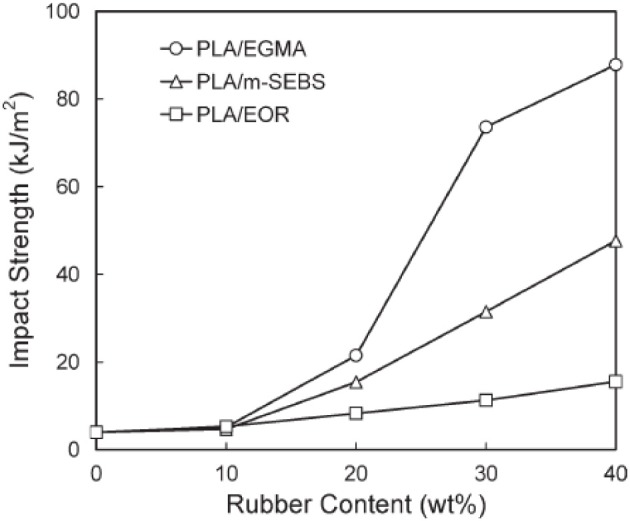

Poly(butylene succinate)s (PBS) and their copolyesters