Abstract

The use of bone grafts is the standard to treat skeletal fractures, or to replace and regenerate lost bone, as demonstrated by the large number of bone graft procedures performed worldwide. The most common of these is the autograft, however, its use can lead to complications such as pain, infection, scarring, blood loss, and donor-site morbidity. The alternative is allografts, but they lack the osteoactive capacity of autografts and carry the risk of carrying infectious agents or immune rejection. Other approaches, such as the bone graft substitutes, have focused on improving the efficacy of bone grafts or other scaffolds by incorporating bone progenitor cells and growth factors to stimulate cells. An ideal bone graft or scaffold should be made of biomaterials that imitate the structure and properties of natural bone ECM, include osteoprogenitor cells and provide all the necessary environmental cues found in natural bone. However, creating living tissue constructs that are structurally, functionally and mechanically comparable to the natural bone has been a challenge so far. This focus of this review is on the evolution of these scaffolds as bone graft substitutes in the process of recreating the bone tissue microenvironment, including biochemical and biophysical cues.

Keywords: Bone Tissue Engineering, Bone Graft, Scaffold, Biomaterials, Biophysical Stimulation, Biochemical Stimulation, Bone, Mesenchymal Stem Cells, Osteoblasts

1. INTRODUCTION

Bone grafts are used for augmenting or stimulating the formation of new bone in cases such as the healing of skeletal fractures or between two bones across a diseased joint, to replace and regenerate lost bone as a result of trauma, infection, or disease, or improve the bone healing response and regeneration of bone tissue around surgically implanted devices, such as artificial joints replacements or plates and screws used to hold bone alignment. The high incidence of these conditions is evidenced by the 2.2 million bone grafts used in orthopedic procedures annually worldwide.1 The three main types of bone grafts are the autografs, allografts and bone graft substitutes.2 The tissue regeneration capacity of these bone grafts is measured in terms of their osteogenic, osteoconductive and osteoinductive potential.3 The osteogenic potential of a bone graft is given by cells involved in bone formation, such as mesenchymal stem cells (MSCs), osteoblasts, and osteocytes. The term osteoconductive refers to the scaffold or matrix which stimulates bone cells to grow on its surface. Osteoinductive capacity of a bone graft is perhaps the most important property in bone healing as it refers to the stimulation of MSCs to differentiate into preosteoblasts to begin the bone-forming process. The most common of these bone grafts is the autograft, which is the transplanting of bone tissue from one site to another in the same patient. It is usually transplanted from the iliac crest, but it can also be from the distal femur or the proximal tibia. This type is considered the standard in bone grafts since it contains both osteogenic cells and an osteoconductive mineralized extracellular matrix where these can grow and proliferate. However, its use is limited by complications such as pain, infection, scarring, blood loss, and donor-site morbidity.4-6 Another alternative is the allograft, which is bone tissue from cadavers or living donors. Their benefits over autographs include the elimination of donor site morbidity and issues related to their limited supply. However, they lack the osteogenic capacity of autografts and carry the risk of infectious agents or immune rejection.7,8 Although both types of bone grafts have been widely used, their limitations have prompted the search for other alternatives, which are referred to bone graft substitutes.9 This type of bone graft is based on the concept of bone tissue engineering, which focused on improving their osteogenic, osteoconductive and osteoinductive potential by incorporating bone progenitor cells and growth factors to stimulate cells into a scaffold made of various natural or synthetic materials or their combination, which mimic the bone microenvironment. This review focuses on the current state of development of these biomimetic scaffolds, and the alternatives and design criteria for their application in bone regeneration applications.

2. BONE PROPERTIES

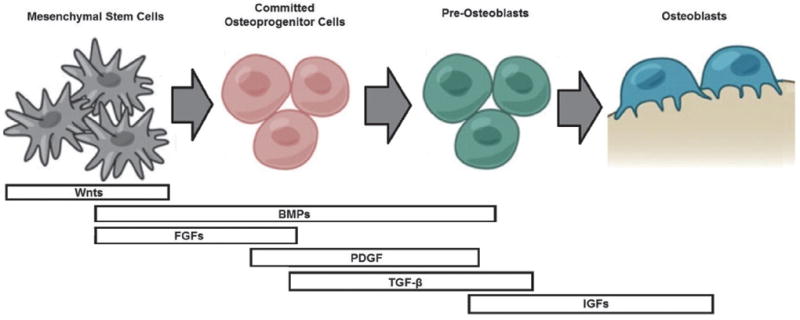

To design bone biomimetic scaffolds involves building a proper representation of bone, which requires understanding bone biology and physiology. Bone can be seen as an open cell composite material composed of osteogenic cells extracellular matrix (ECM) proteins, growth factors, mineral calcium in the form of calcium hydroxyapatite, and a complex vascular system. The cells that make up the bone represent about 10% of the total volume and include osteoprogenitor cells of mesenchymal origin, i.e., osteoblasts and osteocytes and bone-resorptive cells of hematopoietic origin, i.e., osteoclasts. Pre-osteoblasts are bone progenitor cells located in the periosteum, endosteum, and Haversian canals that derive from MSCs and which are stimulated through growth factors (e.g., bone morphogenetic proteins (BMPs), transforming growth factor-β (TGF-β), fibroblast growth factor (FGF), insulin-derived growth factor (IGF), platelet-derived growth factor (PDGF), and interleukins) into migrating to a specific site, to proliferate and differentiate into osteoblasts. Osteoblast differentiation occurs in three stages: (1) cell proliferation, (2) matrix maturation, and (3) matrix mineralization. During the proliferation stage ECM proteins are expressed and secreted by osteoblasts forming the non-mineralized bone matrix or osteoid. This is followed by the crosslinking of the proteins of the osteoid during matrix maturation, forming a structure that is stronger and more stable. Crosslinked collagen type I fibrils, the main component of the osteoid, become templates onto which the inorganic minerals are deposited forming the mineralized bone matrix. At the end of this stage, osteoblasts can either: become embedded in the bone as osteocytes, transform into inactive osteoblasts and become bone-lining cells, or undergo programmed cell death (i.e., apoptosis).10 The osteocytes embedded in bone matrix are the most abundant cell type of bone forming networks connected to each other via long cytoplasmic extensions that occupy tiny canals called canaliculi. Through this network, that is thought to include osteoclasts, they function as strain and stress sensors, signals that are very important for maintaining bone structure.11 Osteoclasts are large, multinucleated cells that attach to bone matrix through a brush border and solubilize its mineral content via acidification. This process is tightly regulated via the paracrine co-regulation between osteoclasts and osteoblasts in a process called bone remodeling. The main recognized functions of bone remodeling include preservation of bone mechanical strength by replacing older, microdamaged bone, with newer, healthier bone and calcium and phosphate homeostasis. The cortical bone turnover rate is smaller than in trabecular bone, but adequate to maintain biomechanical strength of the tissue. The rate of trabecular bone turnover is higher, more than required for maintenance of the mechanical strength of cortical bone, indicating that is more important for mineral metabolism. This process can also respond to changes in the functional demands of the mechanical loading.12

The ECM proteins self-assemble and are composed mainly of collagens, and non-collagenous proteins, which include glycoproteins, proteoglycans and growth factors. The collagens form 90% of the total weight of ECM proteins, which mainly contain collagen type I (97%), with smaller amounts of type III, V, XI and XIII. The non-collagenous proteins form the additional 10% of the bone mass.13, 14 The glycoproteins include alkaline phosphatase (ALP), osteopontin (OPN), bone sialoprotein (BSP), and osteocalcin (OCN), which modulate the mineralization process and osteonectin that modulates collagen fibril diameter. In addition, there are proteins containing the RGD integrin–binding domain, which include thrombospondins, fibronectin, vitronectin, and fibrillin 1 and 2.15 The proteoglycans constitute about 10% of the non-collagenous proteins and provide resistance to compressive forces. This property stems primarily from the glycosaminoglycan portion of proteoglycans, which are long-chain polysaccharides whose chemical properties are determined by the types of sugars in the chain. Another property of proteoglycans is their capacity to bind growth factors for future use. For instance growth factors can be stored in the bone ECM by binding to the proteoglycans decorin, biglycan or perlecan, or membrane-bound proteoglycans such as syndecan or betaglycan, which may act as co-receptors for these growth factors.16

Bone is a reservoir for calcium in the body, containing 99% of the body’s calcium. Bone mineral is mostly (85%) in the form of hydroxyapatite (HA, Ca10(PO4)6(OH)2), with calcium carbonate (10%), calcium fluoride (2–3%) and magnesium fluoride (2–3%). Natural hydroxyapatite contains carbonate ions as replacement groups in phosphate and hydroxyl sites of the hydroxyapatite structure. These crystals are about 20 nm in their largest dimension. Bone strength and stiffness is higher along its longitudinal axis.17 This is due to collagen and mineral crystals being usually oriented in this direction, with the mineral providing stiffness, and the collagen fibrils providing fracture toughness to the bone.18

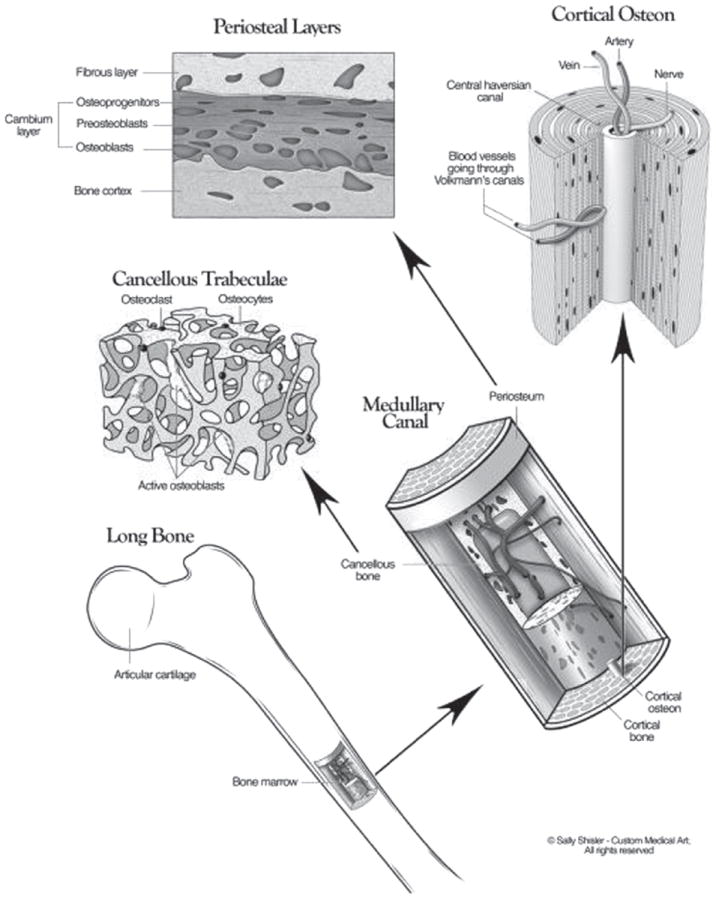

At the histological level, there are two main structural types in bone, the cortical bone which forms a dense outer shell and the cancellous or trabecular bone which forms the porous inner core. Both of these are classified based on their porosity, structure and metabolic activity, which modulate their function and physiology (Fig. 1). Cortical bone is highly dense and consists of a hierarchical structure, each with in a different size scale,12 see Table I. These range from the solid material (> 3 mm), to the cylindrically organized osteons (10–500 μm), lamellae (3–20 μm), and the collagen-mineral composite (60–600 nm).19 The osteons give cortical bone its strength and include the central Haversian canal which is composed of blood vessels interconnected with vessels on the surface of the bone through perforating canals (Fig. 1). The lamellae are layers of bone generally 3–7 mm in thickness, which are arranged concentrically around the central Haversian canal in osteonal bone. The primary function of cortical bone is to provide torsion and bending resistance and compressive strength. In contrast, cancellous bone is highly porous, consisting of an interconnected network of trabeculae which is usually filled with marrow. Its hierarchical structure ranges from the solid material (> 3 mm), to the trabeculae (75–200 μm), lamellae (1–20 μm), and the collagen-mineral composite (60–600 nm).18 The porous trabeculae provide a high surface area which allows for nutrient diffusion and exposure to circulating growth factors. This access allows cancellous bone tissue to be metabolically active and can be remodeled more frequently than that of cortical bone.20 In contrast to the regular, cylindrically shaped lamellae in cortical bone, in cancellous bone lamellae consist of irregular, semicircular shapes, which allows for deformation and absorption of loads.21

Figure 1.

The three-dimensional structure of bone, which includes the cortical and a cancellous/trabecular component. Reprinted with permission from [12], D. Buck II and G. Dumanian, Plast Reconstr Surg. 129, 1314 (2012). © 2012, American Society of Plastic Surgeon.

Table I.

Structural and mechanical properties of cortical and trabecular bone.

| Bone type—Loading | Porosity* (%) |

Density (g/cm3) |

Volume fraction¶ (mm3/mm3) |

Surface/bone volume¶ (mm2/mm3) |

Young’s modulus¥ (GPa) |

Tensile strength¥ (MPa) |

Compressive strength¥ (MPa) |

|---|---|---|---|---|---|---|---|

| Cortical—Longitudinal | 5–10 | 1.99† | 0.85–0.95 | 2.5 | 17–20¥ | 79–151¥ | 131–224¥ |

| Cortical—Transverse | 6–13¥ | 51–56¥ | 106–133¥ | ||||

| Cancellous—Longitudinal | 75–90 | 0.05–1.0‡ | 0.05–0.60 | 20 | 20§ | 2–5 | |

| Cancellous—Transverse | 14.7§ |

Bone is considered an anisotropic material because its mechanical properties vary with anatomical location and the loading direction. For instance, there is great variability in Young’s modulus of elasticity, tensile and compressive strengths between the longitudinal and transverse loadings.20 In contrast, cancellous bone does not show a consistent mechanical strength and varies both longitudinally and from one bone to another. As a result, cancellous bone exhibits much broader mechanical properties compared to those of cortical bone. The trabeculae of cancellous bone follow the lines of stress and can be realigned by changes in the direction of stress.

3. THE EVOLUTION OF BONE GRAFT SUBSTITUTES

The evolution of bone implant devices has resulted with an increase in knowledge about the microenvironment where the replacement will occur, which results in changes in requirements and properties of the biomaterials used. This evolution can be measured by defining three different generations as defined by Hench.22 As pointed by Navarro et al.23 these generations are not chronological but technological, since there is currently active research and development for each. First generation bone graft substitutes require the biomaterial to match the physical properties of the tissue to be replaced, while maintaining inertness with the tissue microenvironment. These include metals such as stainless steel, titanium, and alloys; ceramics such as alumina and zirconia; and polymers such as silicone rubber, polypropylene, and polymethylmethacrylate. A common occurrence for all these biomaterials is the formation of fibrous tissue at the biomaterial-tissue interface that would eventually encapsulate the graft subsequently leading to aseptic loosening. This occurs as a non-specific immune response to a material that cannot be phagocytosed, in which an inflammatory response persists until the foreign body becomes encapsulated by fibrotic connective tissue, shielding it from the immune system and isolating it from the surrounding tissues.24

To avoid this non-specific immune response, second generation bone graft substitutes were developed with bioactive interfaces which would elicit a specific biological response (i.e., osteoconduction) to avoid the formation of this fibrous layer and improve osseointegration. The overall strategy is to modify first generation biomaterials with coatings that are bioactive or biodegradable. This bioactivity is provided by a surface chemistry that would either allow mineralization through the heterogeneous nucleation and crystallization of HA, or cover the biomaterial surface with bioactive ceramics such as HA, β-tricalcium phosphate (β-TCP), or bioactive glass. A second type of second generation bone graft substitutes is made biodegradable with the aim that the rate of degradation matches the healing rate of the injured bone tissue. These biomaterials are based on the use of synthetic or natural polymers that can provide a controlled chemical breakdown under physiological conditions into inert products that can be resorbed by the body. Examples of the synthetic polymers include polylactide, poly(ε-caprolactone), and polyglicolide; and chitosan and hyaluronic acid for natural ones.23 The mechanical and osteoconductive properties of these polymers can be improved by forming composites with bioactive ceramics. Another alternative to improve the polymers is to chemically modify them through the conjugation of osteoinductive biomolecules.

Third generation bone graft substitutes try to get closer to the autograft standard by using biomaterials capable of inducing specific cellular responses at the molecular level, by integrating the bioactivity and biodegradability of second generation devices. This type of bone graft is based on the concept of bone tissue engineering, which focused on creating a device that enhances bone repair and regeneration by incorporating bone progenitor cells and growth factors to stimulate cells into a scaffold made of various natural or synthetic biomaterials or their combination and with sufficient vascularization to allow access to nutrients to support this process.25 This process of bone regeneration is osteoconductive in which MSCs are recruited and stimulated to differentiate into pre-osteoblast and depends on the microenvironment. This is similar to what happens during new bone formation or immediately after skeletal injury or biomaterial implantation, being particularly active during the first week post-trauma. In contrast, bone repair involves a basic inflammatory response, where fibrous tissue is formed, and does not depend on the osteoinductive potential of the microenvironment.26

The osteoprogenitor cells, growth factors and vascularization are all natural components of the bone tissue microenvironment, making the scaffold the only element of this formulation which requires fabrication. This entails defining the necessary design parameters for achieving the cell function leading to bone regrowth, which include cell attachment, proliferation, and differentiation. These design parameters should lead to specific scaffold properties, which include biocompatibility, porosity, micro and nano-scale structure, degradation rate, mechanical strength, and growth factor delivery, all of which dictate the biomaterial to be used or developed.27 Defining specific design parameters requires knowledge of MSC activity in osteogenesis, including the progression of cellular events and the sensitivity of cells to biochemical and mechanical stimuli. Biocompatibility is related to a scaffold biomaterial which does not elicit undesirable local or systemic responses in the eventual host and is thus a property of the material itself.28 Scaffold geometry affects cell adhesion, proliferation and distribution by affecting the access to cell recruitment, vascularization, nutrients and oxygen. This is related to the pore size and interconnectivity, which directly affect the scaffold porosity. Pore structure and overall porosity seem to be able to modulate osteogenesis since osteogenic cells have been shown to respond to particular pore dimensions. For instance, bone growth in canines where the pore diameters range 15–50 mm is fibrovascular, 50–150 mm is osteoid, and 150–500 mm is mineralized.29 It can be seen why a highly porous scaffold facilitates cell seeding and migration, while smaller pores allow tissue ingrowth. High porosity in excess of 90% is chosen in many scaffold designs since it allows for adequate diffusion of nutrients during tissue culture and provides sufficient surface area for cell–biomaterial interactions. Since the mechanical strength provided by the scaffold decreases with porosity, this value should always be balanced with the mechanical needs of the particular tissue that is going to be replaced. Another important aspect of pore structure is pore interconnectivity, since interconnected pores enhance the diffusion rates to and from the center of the scaffold and facilitates vascularization, thus improving oxygen and nutrient supply and waste removal. Microscale pores allow cell migration, vascular distribution, and diffusion of nutrients and oxygen providing osteoconductivity. In contrast, nanostructured biomaterials significantly enhance cell functions leading to improved osteoinductivity and osseointegrativity, since osteogenic cells interact with nano-scale minerals and proteins.30 It has been shown that these nano-topographies affect adsorbed protein conformation giving access to motifs that can allow binding by osteogenic cells through integrins, a widely expressed family of transmembrane adhesion receptors, consisting of α and β heterodimers, which bind to specific amino acid sequences, such as the RGD cell binding domain.31 The rate of degradation of the scaffold must be tuned so that it provides the necessary structural support until the newly grown bone has sufficient mechanical strength to replace this supporting function.32 If this condition is not met, the scaffold could fracture after being submitted to a mechanical load before the bone healing process is complete. Growth factors such as platelet-derived growth factors (PDGF), bone morphogenetic proteins (BMP), insulin-like growth factors (IGF), and transforming growth factor-β (TGF-β) increase the osteoinductive and osteoconductive potential of osteoprogenitor and osteoblast functions to enhance bone growth by encouraging MSCs to migrate into the scaffold, proliferate, differentiate, and begin ECM production.33 These can be delivered by methods such as bolus injection, surface adsorbed protein release, osmotic pumps, and controlled release from biodegradable scaffolds. Challenges found by these methods include loss of their bioactivity because of a short half-life, limited control over dose administration, and non-targeted delivery. Among the delivery methods, controlled release from biodegradable scaffolds has proven the most effective.

4. MATERIALS

4.1. Natural Polymers

Bone tissue engineering has focused on the creation of 3D scaffolds that can mimic the ECM, support the formation of new bone, while degrading as new bone is produced. Natural polymers have attractive properties for the construction of 3D scaffolds, such as biocompatibility and biodegradability. Importantly, control of porosity, charge, and mechanical strength can be controlled by changing polymer concentrations, polymerization conditions, or by introducing various functional groups.34 Bioactivity can also be controlled by the addition of chemicals, proteins, peptides, and cells.35 The most commonly studied natural polymers for the purpose of bone engineering are collagen/gelatin, chitosan, silk, alginate, hyaluronic acid, and peptides.36, 37 Here we discuss recent studies where these natural polymers are studied as 3D scaffolds for bone regeneration, and are modified in different manners in order to improve their osteogenic capabilities.

4.1.1. Collagen

As a primary component of bone, collagen (and gelatin) is an ideal candidate for the design of 3D scaffolds.38 It is inherently biocompatible and biodegradable, and stimulates proliferation and differentiation of cells as extracellular matrix.39 However, it has poor mechanical properties.40 In the following studies, collagen was used as a base for 3D scaffolds and modified with the addition of polymers and other biomolecules in order to improve osteoinductivity.

In one study,41 the authors combine the mechanical properties of a 3D macrochanneled poly-ε-caprolactone (PCL) scaffold, fabricated via the robotic dispensing technique, with the bioactive properties of collagen. A MSC loaded collagen hydrogel collagen was inserted onto the macrochanneled scaffold. The authors studied the effect of growing these cell-seeded scaffolds in a perfusion bioreactor, to test how osteogenesis was affected by the continuous supply of fresh media and shear stress. The collagen/PCL scaffolds had a statistically significant increase in cell proliferation when grown in the perfusion chamber when compared to cells grown in static conditions. The activity of alkaline phosphatase (ALP), an early osteogenic marker, was also significantly upregulated at 14 days in cells grown in the perfusion chamber. The expression of the osteogenic genes OPN, OCN, and BSP was also significantly upregulated when cells were grown in the perfusion chamber. Results clearly indicate that cell proliferation and differentiation are enhanced by the effects of the perfusion chamber. The authors tested if the shear stress provided to the cells in scaffold by the perfusion chamber could cause upregulation of genes associated with mechanotransduction, a process by which physical forces are converted into biochemical signals that are essential for the formation of bone.42 This hypothesis was supported by the very substantial increase of the c-fos and COX-2 genes in cells grown in the perfusion chamber, factors that have been shown to respond rapidly to mechanical stress.43

Collagen hydrogels have also been used to test the ability of MSCs from different sources to undergo osteogenic differentiation.44 In this study, a scaffold composed of 90% type 1 collagen, which gives bone its tensile strength,45 and 10% type 3 collagen. In recent years, bone marrow MSCs (BM-MSC) have shown great potential for tissue engineering purposes. They are relatively easy to isolate, retain their multipotency even after several passages, and can be induced to differentiate into bone.46 However, there is a very low amount that can be harvested from bone marrow, they have limited proliferation, and high senescence.47 It has recently been reported that MSCs can be isolated from the Wharton’s Jelly found in the umbilical cord (UC-MSC), and they are more abundant, more easily expanded and more resistant to cryogenic storage.48 The adhesion, migration into scaffold, growth, spreading, osteogenic differentiation, ECM degradation and synthesis of BM-MSCs versus UC-MSCs was compared. The tested collagen scaffold showed excellent cytocompatibility with both cell types and could maintain high proliferation and viability. When stimulated with osteogenic induction medium, both cell types showed comparable osteogenic gene expression, migration and scaffold colonization, and ability to contract the collagen scaffold. It is very interesting to note that UC-MSCs were much more capable of producing an ECM. They showed at least 10-fold higher expression of the ECM marker genes collagen I, collagen III, collagen IV, and laminin than BM-MSCs. Since the production of ECM is an integral component of bone regeneration, UC-MSCs could have a significant impact on bone tissue engineering, and its osteogenic potential should be investigated in additional scaffold compositions.

Several studies have been conducted where other materials are incorporated into collagen in order to enhance mechanical properties and enhanced bone-matrix interface strength. In one such study,49 a CaO–P2O5–SiO2 bioactive glass (BA) was added to a collagen solution to prepare composite scaffolds, in the presence or absence of phosphatidylserine (PS). At higher PS ratios, the porosity (%) of the scaffold increased and compressive strength (MPa) decreased. The scaffold chosen for in vivo and in vitro studies had a COL-PS/BA ratio (w/w) of 35:65. This scaffold had a porosity of 75.40% and a compressive strength of 1.5469 MPa. As a control, a scaffold composed of COL-BG was used. Rat MSCs were used for in vitro studies. Attachment and proliferation of MSCs was higher in the COL-BG-PS than in the COL-PA scaffolds at all time-points tested. When cultured in osteogenic media, ALP activity was significantly higher in COL-BG-PS constructs after day 7, and mineralization was significantly increased in cells grown in the COL-BG-PS scaffolds at day 21. Expression of ALP, OC, and OPN were obviously higher in MSCs in contact with the COL-BG-PS composite. For in vivo studies, a rat femur defect model was used. Three groups were analyzed: COL-BG-PS/MSC, COL-BG/MSC, and cell free COL-BG-PS. MSCs were cultured in osteoinductive media prior to seeding into the scaffold. At 6 weeks post-surgery, the femurs of the rats in the COL-BG-PS/MSC group showed the greatest amount of healing, followed by the COL-BG/MSC group. The least amount of healing was observed in the cell free COL-BG-PS group. The data obtained from this work suggests that the addition of PS into other types of scaffolds could enhance their osteogenic potential. In another study, the hydraulic permeability (k) of a collagen-based scaffold is manipulated in order to improve mechanical properties, cell–scaffold interactions, oxygen flow and nutrient diffusion.50 Permeability is the ability of porous structures to transfer fluids through their interstices under applied pressure, and this can be controlled through pore size, number, orientation, distribution and interconnectivity.51 Collagen scaffolds were prepared and exposed to plastic compression using different static stresses in order to control permeability. Results showed that increasing compression reduces k. It was also found that a decrease in k correlates with an increase of the modulus and permeability of collagen gels. The authors then went on to test the effect of k on MSC proliferation, differentiation and mineralization. When compared to non-compressed gels, compressed gels showed higher proliferation, ALP staining, and mineralization, but no significant difference was found between the different compressed gels. These findings suggest that decreasing k provides a good matrix for cell proliferation and osteodifferentiation, but the influence of k on osteoinduction and osteoconduction has not been fully defined. Another study examines the effect of varying gelatin (G) and chitoolisaccharide (COS) ratio on scaffold pore size, and the effect of pore size on osteogenic differentiation.52 Scaffolds at G/COS mixing ratios of 100:0, 70:30 and 50:50 were fabricated by freeze-drying and glutaraldehyde cross-linking. Gelatin (100:0) scaffolds had the largest pore size and most homogenous distributions and higher compressive moduli than scaffolds prepared at 70:30 and 50:50 ratios. MSCs were seeded into the scaffolds and allowed to proliferate and differentiate in osteogenic media. ALP activity and calcium content was found to be highest for the G:COS 70:30 formulation. This scaffold was then chosen for in vivo subcutaneous implantation studies. This scaffold was pre-cultured with MSCs in osteogenic media and then implanted using a cell free scaffold as a control. Calcium was deposited on the surface of scaffolds pre-cultured with MSC at 8 weeks post-implantation. No calcium deposition was observed in control scaffolds. This study shows that the tested formulation supports ectopic calcium deposition, however, the effect of pore size was not evaluated at this stage. The same group also tested the effect of adding magnesium calcium phosphate (MCP) onto gelatin scaffolds in order to find optimal pore size and mechanical properties for osteoinduction.53 MCP was added to the gelatin solution at 25, 50, 75, and 90 wt%. Porosity was not significantly affected with the addition of MCP, however, the compression moduli (MPa) and amount of magnesium released into cell culture media increased with higher percentages of MCP in the formulation. MSCs were seeded onto the gelatin sponges and tested for proliferation, osteocalcin content, and ALP activity. An increase in MCP content correlated with an increased proliferation, ALP activity, and osteocalcin content. It remains to be determined whether these effects are due to the change in mechanical properties conferred by addition of MCP, or if the amount of magnesium released in the media could have an important impact on these effects.54

Collagen scaffolds have also been used as a method for delivery of factors that induce osteogenic differentiation. In one study, bone morphogenetic protein-4 (BMP4) was spatially immobilized in a collagen-poly(lactic-co-glycolic acid) (PLGA) hybrid scaffold.55 BMP4 has been shown to induce osteogenic differentiation of osteoblasts promote bone formation.56 MSCs were loaded into collagen-PLGA scaffolds, with or without BMP-4, and cultured in osteoinductive media prior to implantation into the dorsa of athymic nude mice. Four weeks after implantation, scaffolds were removed and analyzed. Only the scaffold with immobilized BMP-4 showed positive staining of deposited calcium. The expression levels of several osteogenic markers were analyzed by RT-PCR. Type 1 collagen, OPN, and OCN were showed a significant increase in expression as compared to the control. However, there was no difference in ALP expression; however, this may be that ALP expression increased prior to analysis of the removed implants. Another group studied the effect of adding basic fibroblast growth factor bFGF into collagen hydrogels,57 which has been shown to enhance bone formation in organ culture models.58 Various amounts of bFGF were incorporated into the hydrogel matrix. Release profiles of bFGF from hydrogels were monitored, and it was found that they could liberate up to 76.3% of the original amount in the hydrogel. Proliferation of MSCs in hydrogels containing a broad range of bFGF concentrations (0, 5, 50, and 500 ng per 500 mL hydrogel sample) was examined. Proliferation peaked at the 5 ng concentration but declined at higher concentrations. This concentration was used for the remainder of the experiments. At 7 days, there was no difference in ALP expression between the bFGF-containing hydrogels and the control, but at day 14 there was a statistically significant increase. Expression of osteogenesis related genes (type 1 collagen, OPN, BSP, and OCN) was measured at 3 different time points, and the presence of bFGF increased the expression of these markers in at least one of the time points tested. It would be interesting to evaluate if controlling the release of bFGF from low to high could allow for an early low release to increase proliferation and a later high release to induce differentiation. In another study, a collagen-based silicified matrix was loaded with stromal cell-derived factor-1 (SDF-1),59 which is a chemokine-receptor ligand that is involved in mobilization and homing of stem cells to injured tissues.60 The silicified collagen scaffold (SCS), was first compared to collagen scaffold (CS) in terms of mechanical properties. The tangent modulus values (KPa) from 0–5% strain were 0.80 ± 0.21 for CS and 599.8 ± 166.0 for SCS. The modulus of resilience values (KPa) were 0.18 ± 0.06 for CS and 165.3 ± 4.0 for SCS. In vitro analyses showed there was no difference in cell viability when MSCs or endothelial progenitor cells EPCs were in contact with CS or SCS. The formation of extracellular bone nodules in differentiated MSCs was significantly higher in SCS than in CS, and the formation of capillary-like tubes by EPCs was much higher in SCS than in CS. These results indicate that the presence of silica in collagen hydrogels increases its osteogenic and angiogenic potential. The release kinetics of the SDF-1 from SCS hydrogels was analyzed, and it was found that at high concentrations, up to 80% release could be obtained at 30 days. In vitro cell homing experiments were conducted with MSCs and EPCs using a transwell migration assay, using SDF-1 concentrations that corresponded to the ones used in the release assay. Both MSCs and EPCs showed higher migration with higher SDF-1 concentrations. For in vivo experiments, the ability to promote osteogenesis was compared between SCS loaded with MSCs (cell-seeding approach) and cell-free SDF-1 containing SCS (cell-homing approach). Scaffolds were implanted into subcutaneous pockets of Balb/c mice. Implants were studied after removal, and it was found that ectopic bone formation was similar in both scaffolds. However, ectopic bone formation in scaffolds loaded with SCF-1 showed a statistically significant increase in capillary formation. The results indicate that cell-homing strategies such as this one must be further explored, as it reduces the complications of cell seeding and increases angiogenesis, a requirement for the formation of healthy bone.

4.1.2. Chitosan

Chitosan is an excellent natural polymer to consider as a material for the construction of 3D scaffolds for bone tissue engineering. It is biodegradable, biocompatible, has antibacterial, wound healing, and bioadhesive properties.61 Here we describe several studies where the osteogenic properties of chitosan 3D scaffolds are modified through the addition of other polymers, cells, and bone-inducing factors.

Chitosan and poly(butylene succinate) (CH-PBS) scaffolds were constructed and seeded with human MSCs in order to test their ability to induce osteogenesis.62 The material was found to have 59% porosity, 144.9 mm pore size, and 60.9% interconnectivity. MSC viability increased for 21 days in the scaffold, and ALP activity also increased for 21 days after MSCs were exposed to osteogenic induction. The ability of the MSC-seeded scaffolds to repair a cranial critical-sized bone defect in mouse was also examined. The cell-scaffold constructs were cultured in osteogenic-induced medium for two weeks prior to implantation. Cell-free scaffolds were used as a control. The crania were observed 8 weeks after implantation. Bone formation was analyzed using μCT. The results evidently showed an elevated rate of bone formation in the cell-seeded scaffold, evidencing the importance of the existence of stem cells near the area where bone formation is needed. In another study, human bone marrow-derived stem cells (hBMSC) were encapsulated in hydrogels at chitosan/collagen ratios of 100/0, 65/35, 25/75, and 0/100 wt%.63 Beta-glycerophosphate (β-GP) was added to hydrogels, as it has been shown to be an osteogenic supplement when added to cultures of hBMSC, and has also been used as a catalyst to sol–gel transitions in chitosan hydrogels.64 The effect of collagen addition to chitosan on matrix mechanical properties was assessed. Stress-strain profiles (0–8% strain) showed that all collagen materials were approximately 3 times stiffer than pure chitosan, which has a modulus of 6.3 kPa. When evaluating cell proliferation, DNA content dropped by about half over 12 days in pure chitosan materials while it increased twofold in materials containing collagen. For these reasons, only collagen-containing materials were examined as to their effect on osteogenic gene expression. hBM-SCs were encapsulated in chitosan-collagen and collagen hydrogels and exposed to osteogenic medium. Hydrogels with a chitosan/collagen ratio of 65/35 had the highest levels of osterix expression, bone sialoprotein expression, and ALP activity. These osteogenic markers started to decrease at lower chitosan concentrations. These results suggest that the presence of collagen was highly beneficial for the osteogenic capabilities of the 3D scaffold, although it remains to be determined if this was caused by the change in mechanical properties, or the intrinsic biological properties of collagen. In a subsequent study, the authors studied the effect of glyoxal crosslinking on chitosan/collagen hydrogels.65 Glyoxal was used in order to provide stability to the hydrogels. The effect of crosslinking on gel compaction and stiffness was examined in 50:50 chitosan/collagen hydrogels. Crosslinking caused decreased gel compaction. Rheological measurements indicated a six-fold increase as shown from the storage modulus when gels were crosslinked, but no change in the loss modulus, indicating increased matrix stiffness. DNA content, ALP activity, calcium deposition, and osteogenic gene expression was evaluated for hBMSCs embedded in hydrogels with and without crosslinkers and cultured in osteogenic media. Crosslinking inhibited cell proliferation, and decreased ALP activity at day 9 after induction and had no effect on calcium deposition. Osterix expression was higher in non-crosslinked gels on day 9, but higher on crosslinked gels at day 21. Crosslinking inhibited bone sialoprotein expression at all days tested, but had no effect on the expression of type-1 collagen. These results suggest that the mechanical changes conferred to the hydrogel upon crosslinking are not beneficial to the induction of bone formation. Another group prepared porous 3D-scaffolds based on chitosan (CHI), chitosan/silk fibroin (CHI/SF) and chitosan/silk fibroin/hydroxyapatite (CHI/SF/HA).66 SF/HA scaffolds has been previously reported to be unsuitable for bone tissue engineering, due to insufficient formability and inflexibility.67 The characteristics imparted by the nature of the chitosan polymer could improve these characteristics. Porosity of the scaffolds was measured by liquid displacement. The CHI scaffolds have a porosity of 94.2 ± 0.9%, which was statistically higher than the one presented by CHI/SF/HA scaffolds, which had a porosity of 89.7 ± 2.6%. The CHI/SF scaffold had a porosity of 91.6 ± 1.2%, which was not significantly different from other materials. SaOs-2 cells were used to measure viability and differentiation. At day 21, there was a statistically significant increase in cell proliferation and in ALP activity in the CHI/SF/HA scaffolds as compared to CHI and CHI/SF. It is unclear whether it is the presence of HA or the changes in porosity that help promote osteogenesis.

Chitosan has also been used as an injectable biomaterial. Bi et al.68 produced an injectable composite of tricalcium phosphate (TCP), chitosan, and platelet rich plasma (PRP).69 A TCP-chitosan composite (TC) was used as control. PRP contains a number of growth factors (i.e., PGDF, TGF-β, IGF, bFGF, and VEGF), which have often been shown to have an important role in bone tissue engineering applications. The composites were fabricated into cylinders for mechanical testing. It was found that the compressive strength (MPa) of both composites increased over time (~9–16 over 7 days), but there was no difference between them. MSCs were seeded onto TCP and TC scaffolds and cell proliferation was measured over 7 days, showing that the amount of cells on PTC was significantly higher than on TC at every time point tested. MSCs grown in plates in osteogenic media (OM) were used as a positive control for osteo-differentiation analysis of the materials being tested. ALP activity was tested at 7 and 14 days. At 7 days, ALP activity was higher in PTC than TC, and PTC and OM had comparable levels. At day 14, ALP activity was significantly higher in PTC than TC and even OM. RT-PCR analysis was used to study the expression of osteogenesis-related genes. Runx-2, type-1 collagen, and osteonectin expression in TCP was comparable to that in OM. Hardly any expression was observed on TC. TCP and TC materials were tested in vivo for their capacity to repair osseous defects in goat tibiae; untreated animals were used as a control. Through radiological examination, it was very evident at 16 weeks that bone had been repaired much more effectively in TCP than in TC. Almost no new bone was formed in the blank group. This work shows a promising system where MSCs do not need to be conditioned in osteogenic medium in order to produce robust bone growth. Another study investigated the use of 3D porous chitosan–alginate (CA) scaffolds for critical size calvarial defect repair in Sprague–Dawley rats.70 The material had a porosity of 97%, with an average pore size of 100 μM. MSCs grown on the CA scaffolds in vitro were able to promote cell attachment. For in vivo tests, the CA scaffold was modified either with MSCs, bone marrow aspirate (BM), or BMP-2. An empty defect was used as a control. Through micro-CT analysis, percent defect reduction at 4 and 16 weeks were only significantly higher for CA-BMP-2 scaffolds as compared to controls. At 16 weeks, mineralization was studied by Von Kossa staining, showing a significant increase in mineralization as compared to controls was found for the CA-BM and CA-BMP-2 scaffolds. At 16 weeks, osteocalcin staining showed significantly higher intensity for CA-BMP-2 as compared to control, and OPN staining showed significantly higher expression for CA-BM and CA-BMP-2 as compared to controls. This study, along with many others, suggests that the addition of proteins and other factors tends to improve osteoactivity of most scaffolds.

Another group studied porous chitosan alone and in combination with insulin-like growth factor-1 (IGF-1) and bone morphogenetic protein-2 (BMP-2) for their effectiveness in bone healing.71 The scaffold had a porosity of 85 ± 2%, with pore sizes between 20–900 μM. Pore size and distribution changed when the scaffold was loaded with growth factors, to 27–350 μm and 35–480 μm for chitosan + IGF-1 and chitosan + BMP-2 samples, respectively. Materials were tested in vivo for the treatment of critical size bone defects. In the control group, the bone defect was treated with bare chitosan scaffold, another group was treated with the chitosan- IGF-1 scaffold, and another group was treated with the chitosan BMP-2 scaffold. Radiographs were taken postoperatively for 15–90 days. The scaffolds with IGF-1 and BMP-2 significantly improved bone formation, but the effect was higher with IGF-1. It remains to be elucidated if these improved outcomes are due to changes in the porosity of the materials or the presence of growth factors.

Chitosan-based scaffolds have also been used to immobilize peptides that can contribute to bone formation. In this study, the addition of the RGD peptide into chitosan/hydroxyapatite scaffolds (C/H) was assessed as a means of promoting osteogenesis by improving cell adhesion onto the scaffold.72 The porosity of the C/H scaffold was calculated to be 88.4%. Pores had an average width of 400 μM. Porosity was not tested after addition of RGD peptide. C/H scaffolds were loaded with two concentrations of RGD peptide, 50 mg/L and 100 mg/L. All materials were cytocompatible with MSCs. The effect of MSC adhesion onto C/S-RGD versus C/S scaffolds was tested. At higher concentrations of RGD there was a tendency for higher cell adhesion, but results were not statistically significant. The effect of RGD on MSC differentiation was tested by ALP activity. MSCs were cultured in the different scaffolds with osteogenic medium for 14 days. ALP activity was 103.1% higher in C/H-RGD scaffolds versus C/H scaffolds (0.00197 ± 0.00031 U/L/ng vs. 0.00097 ± 0.00025 U/L/ng, respectively). These findings suggest that providing a cell attachment site is highly beneficial to the differentiation process, and is a strategy that should be explored in composites of other materials.

4.1.3. Silk

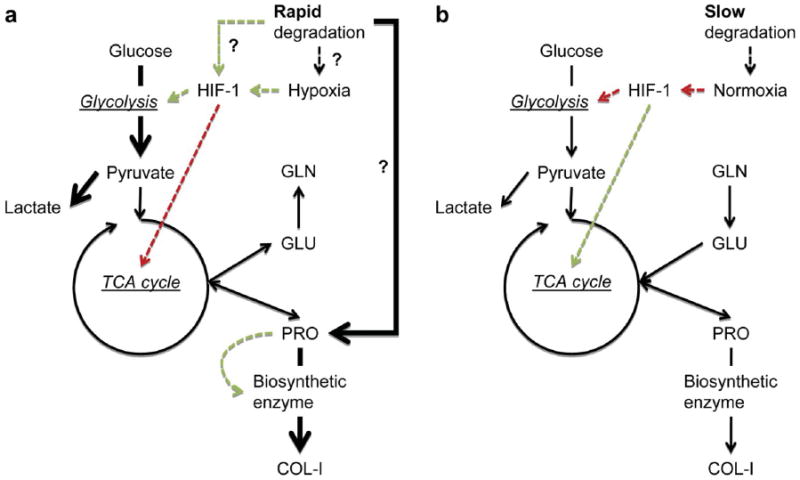

Silk fibroin is a natural polymer that has also been extensively used for tissue engineering applications.73 This material has impressive mechanical properties, and has environmental stability, biocompatibility, controlled proteolytic biodegradability, and morphologic flexibility. In one study, CaP/silk powders were incorporated into silk scaffolds to improve porous structure and distribution of CaP powders in the composite scaffolds.74 The scaffolds tested contained pure silk, or silk with 5% or 10% CaP. The pure silk and silk composite scaffolds were prepared using a freeze-drying method. The addition of CaP did not affect the compressive strength of the material (all tested were ~70 KPa) or the compressive modulus (~250 MPa for all materials tested). All scaffolds tested supported BMSC proliferation to comparable levels. However, ALP activity was significantly higher in CaP/silk scaffolds at days 7 and 14. The expression of the osteogenic markers ALP, type 1 collagen, and osteocalcin was also significantly increased in CaP/scaffolds at day 7 and 14 as compared to pure silk scaffolds. In vivo bone formation was assessed in a calvarial defect model by micro-CT. Groups studied were silk scaffold, CaP/scaffold, silk scaffold + MSC, and CaP/scaffold + MSC. Defect areas were collected after 4 weeks. When bone formation was measured, it was clear that the addition of CaP into the scaffold significantly increased bone volume in the area. These results suggest that the presence of CaP in the scaffold was sufficient to enhance osteogenesis, as it did not have any effect on the scaffold’s mechanical properties. In another study, different amounts of HA were embedded in silk sponges at volume fractions of 0%, 1.6%, 3.1% and 4.6% to enhance the osteoconductive activity and mechanical properties of the scaffolds.75 hMSCs were cultured on the scaffolds for up to 10 weeks, when they were subsequently analyzed. At increasing HA concentrations, there was an increase in the scaffold equilibrium compressive Young’s modulus. The moduli of scaffolds containing 0%, 1.6%, 3.1%, and 4.6% HA were 121 ± 49, 140 ± 70, 201 ± 90, and 251 ± 117 kPa, respectively, at day 0. By 5 weeks, the moduli of scaffolds containing 0%, 1.6%, 3.1%, and 4.6% HA reached 340 ± 99, 594 ± 234, 865 ± 347, and 1005 ± 381 kPa, respectively. There was no difference in cell proliferation between cells seeded in the various scaffolds. Micro-CT imaging was used to measure bone fracture, fracture volume, connectivity density, trabecular number, and trabecular spacing. Decellularized bovine trabecular bone was used for comparison. It was found that these values of these parameters approached the values for bovine trabecular bone in scaffolds with 3.1% and 4.6% HA. Calcium content was studied in all scaffolds at up to 10 weeks, there was an increase over time but there were no differences between groups. These studies demonstrate a system where even if there is no improvement in cell proliferation or calcium deposition with the addition of HA, the presence of certain amounts of HA can lead to the formation of tissue grafts with excellent enhancement of trabecular structure, increased connectivity and superior mechanical properties. Another group studied silk sponge matrices reinforced with silk microparticles to generate protein–protein composite scaffolds with desirable mechanical properties for in vitro osteogenic tissue formation.76 Three different scaffold compositions were tested: Non-reinforced scaffolds (1:0), scaffolds reinforced with a 1:1 mass ratio of silk in solution to silk microparticles (1:1), and scaffolds reinforced with a 1:3 mass ratio of silk in solution to silk microparticles (1:2). Adding silk microparticles increased the compressive modulus from 0.28 ± 0.13 MPa to 1.03 ± 0.45 and 1.93 ± 0.88 MPa for the 1:1 and 1:2 scaffolds, respectively. The reinforced scaffolds showed an increase in yield stress from 22.6 ± 6.3 kPa to 50.4 ± 28.6 and 154.9 ± 77.5 kPa for the 1:1 and 1:2 scaffolds, respectively. The equilibrium modulus also showed a significant increase: 67.19 ± 36.13 kPa for the untreated scaffold, 320.95 ± 145.09 kPa for the 1:1 scaffold and 981.43 ± 311.92 kPa for the 1:2 scaffold. hMSC cells were seeded into the different scaffolds and cultured in osteogenic medium, and analyzed at 3 and 6 weeks. Analysis of osteogenic markers by RT-PCR revealed that type 1 collagen, ALP, and OPN had a significant increase in expression as compared to control at 6 weeks on the 1:2 scaffold. Bone sialoprotein expression was significantly increased at 6 weeks on both the 1:1 and 1:2 scaffolds. Biochemical analysis of the scaffolds at 3 and 6 weeks revealed that there were no significant differences in ALP activity or soluble collagen levels. However, there was a significant increase in calcium deposition in the 1:1 and 1:2 scaffolds at 6 weeks as compared to the 1:0 scaffold. Micro-CT analysis was done to measure bone volume in the scaffolds after 6 weeks in culture. Bone volume fraction for 1:0, 1:1, and 1:2 was 0.0077, 0.0709, and 0.0667, respectively. These results show that improving the mechanical properties of the scaffolds, even though they did not reach the mechanical properties of trabecular bone, improved almost all osteogenesis parameters tested. In another work, the relationship between scaffold degradability and osteogenesis was examined.77 3D porous silk fibroin scaffolds were prepared with two different degradation rates. The water-based scaffold was synthesized as the rapidly degrading scaffold (control), and a slower-degrading scaffold was obtained by the addition of hexafluoroisopropanol (HFIP) to induce insolubility in aqueous media (HFIP scaffold). Degradation studies were done, the control scaffold lost more than 90% of its mass at day 7, and the HFIP scaffold’s mass remained nearly the same at 7 days. Various biochemical assays were performed on both scaffolds after seeding with MSCs and culturing for 16 or 56 days. At 56 days, DNA content in the control scaffolds was around 6-fold lower than for HFIP scaffolds. There was no significant difference in ALP activity between the two scaffolds. However, calcium content/DNA ant total collagen/DNA showed a dramatic increase in the rapidly degrading scaffold when compared to the slowly degrading scaffold. RT-PCR was used to measure the expression of osteogenesis-related genes. There was no significant difference in expression of ALP, BSP, Col1a1, or OP between control and HFIP scaffolds. However at day 56, HIF-1 expression was significantly higher in the control than the HFIP scaffold. Studies in transgenic mice have shown that HIF-1 is a critical component of bone regeneration.78 Markers of metabolic activity, such as glucose consumption rate and lactate synthesis rate were significantly higher in the slowly degrading scaffold. An understanding of the interplay between cellular metabolism and scaffold degradability should aid in the more rational design of scaffolds for bone regeneration needs both in vitro and in vivo (Fig. 2).

Figure 2.

Illustration of cellular metabolism-scaffold degradation model describing bone remodeling with fluxes representing expected pathways leading to the formation of new bone. (a) Model for rapidly degrading scaffold, and (b) model for slow degrading scaffolds. Solid arrows: metabolic flux. Dashed arrows: signal transduction. Colors: red and inhibition; green and activation. Reprinted with permission from [77], S.-H. Park, et al., Biomaterials 31, 6162 (2010). © 2010, Elsevier.

Another study systematically compared 4 different silk scaffolds as to their architecture and biomechanics to develop a greater understanding of the scaffold characteristics that could best induce bone formation.79 Factors taken into account were solvent (aqueous vs. HFIP), pore size (250–500 μm vs. 500–1000 μm), and structure (lamellar vs. spherical pores). The resulting scaffolds were Aq-250 with the smaller pore size; Aq-500 with the larger pore size; Aq-Lam with the lamellar-shaped pores, and HFIP with pores ranging from 400–600 μM. These scaffolds were tested as to their bone tissue outcomes and compared to decellularized trabecular bone. In this study, adipose stem cells (ASCs) were used to seed the scaffolds, and cultured in osteogenic medium for up to 14 days. Morphometric parameters of the aqueous based solvents were obtained by micro-CT. Aq-250 scaffolds had a porosity of 86.62%, an interconnectivity of 90.97%, an average pore size of 139.74 μM, and a trabeculae thickness of 59.98 μM. Aq-500 scaffolds had a porosity of 75.95%, an interconnectivity of 97.83%, an average pore size of 254.32 μM, and a trabeculae thickness of 56.51 μM. Aq-Lam scaffolds had a porosity of 64.25%, an interconnectivity of 63.25%, an average pore size of 126.24 μM, and a trabeculae thickness of 63.13 μM. Morphometric parameters were not reported for HFIP scaffolds. Cell seeding efficiency was around 80% for all scaffolds tested, and the Aq-Lam scaffold had the least amount of cells per scaffold. The equilibrium modulus was superior in Aq-Lam and HFIP scaffolds. Calcium change, bone volume and ALP activity were not significantly different in any of the scaffolds tested. Although all materials tested showed similar osteogenic properties, it shows that adipose-derived stem cells are a feasible source of bone progenitor cells. Another study was conducted to evaluate the ability of fibroin scaffolds combined with human stem cells, such as dental pulp stem cells (hDPSCs) and amniotic fluid stem cells (hAFSCs) to repair critical-size cranial bone defects.80 These scaffolds had an 85% porosity and pore diameters ranging from 10–250 μM, and a compressive modulus of 25.69 ± 1.61 kPa. hDPSCs and hAFSCs were seeded onto the scaffolds and grown in osteogenic media for 10 days before implantation into the cranial critical size defect. Groups tested consisted of scaffolds without cells, scaffold + hDPSCs, scaffold + hAFSCs, and empty defect. Thirty days after surgery, radiograph images showed that scaffolds without cells were able to slightly repair the area, but this effect was more pronounced when either kind of stem cell was present. Hematoxylin/eosin staining showed that there was vascularization present in all scaffolds tested, however, hASFCs seemed to have a greater potential for bone regeneration because it was the only scaffold tested that showed bone in scaffold areas distant to the dura matter. This study gives additional evidence that silk fibroin scaffolds can be engineered to enhance bone formation, and that stem cells from various sources can be used to optimize bone formation in these scaffolds.

One research group reported the effects of different concentrations of silk fibroin protein on 3D scaffold pore microstructure, and its effects on bone formation when cultured with hBMSCs transfected with BMP-7.81 Untransfected cells were included in the study as a control. At 1% wt silk protein, scaffolds had a porosity of 94% and a pore size ranging from 250–300 μM. At 2% wt protein, porosity was 87% and pore size from 200–250 μM. At 3.5% wt silk protein, scaffolds had a porosity of 80% and a pore size ranging from 150–200 μM. At 2% wt protein, porosity was 71% and pore size from 80–150 μM. MSCs proliferated on all scaffolds, but at day 14 there was a significant decrease in the 5% scaffold. ALP activity was shown to increase in all groups, but there was significantly higher expression in the 3.5% scaffold. After 2 weeks in osteogenic medium, expression of osteogenic markers in transfected and untransfected MSCs in the various scaffolds was analyzed by RT-PCR. ALP, Col1, and OCN had similar levels of expression in all scaffolds tested when they were transfected with BMP-7, except in the 5% scaffold, where there was a significant decrease in marker expression. MSCs that were not transfected showed similar levels of expression to cells cultured in undifferentiated medium. This study indicates that decreased scaffold porosity is detrimental for the promotion of bone formation, and that the presence of BMP-7 greatly enhances the cells capabilities to express osteogenic phenotypes.

4.1.4. Alginate

Alginate is also an attractive polymer for 3D scaffolds for tissue regeneration. It is soluble in water, and forms a gel at room temperature in the presence of divalent cations, allowing for the formation of 3D gels. In one study, A macroporous alginate scaffold was fabricated and mineral-coated using a biomimetic approach.82 The nucleation of HA was achieved by incubating the scaffold in modified simulated body fluids for up to four weeks. Mineralization of the scaffold was determined by a change in mass, which increased steadily from weeks 1–4. Energy dispersive X-ray spectroscopy revealed a Ca/P ratio of 1.61, when the Ca/P ratio of pure hydroxyapatite (HAP) is 1.67. Viability experiments demonstrated that the HAP coatings support attachment and proliferation of hMSCs. Cell number was significantly higher in the coated scaffolds at all time-points tested. This work shows that a simple scaffold modification, such as immersion in simulated biological fluids, can change the topography and environment of a scaffold in order to improve the osteogenic outcome of the scaffold. In another study, human umbilical cord mesenchymal stem cells (hUCMSCs) were encapsulated in three types of alginate-based microbeads.83 The three types of microbeads tested were: alginate microbeads (AM), oxidized alginate microbeads (OAM), and oxidized alginatefibrin microbeads (OAFM). Alginate was oxidized to increase its biodegradability. Fibrin was added to decrease biodegradability. Encapsulated hUCMSCs were grown for up to 21 days. Cells in OAFMs always showed the highest viability at all-time points tested, and cells grown in AM always had the lowest viability at all-time points tested. Although all materials were tested for viability measurements, only the cells in OAFMs were tested for the expression of osteogenic markers and ALP activity. ALP gene expression peaked at day 7, Runx-2 expression peaked at day 14, and OC and collagen I peaked at day 21, as compared to cells that were not grown in the differentiation media. ALP activity steadily increased over time when cells were grown in the OAFMs. Although this study supports that OAFM is a suitable candidate for bone regeneration, it does not address whether the presence of fibrin, thus degradability of the scaffold, truly has a role in enhancing osteogenesis. In another study, a 3D matrix of calcium phosphate cement (CPC) combined with alginate was tested for potential usefulness for drug delivery and tissue engineering of bone.84 Fiber diameter decreased as the ratio of CPC powder to alginate liquid increased from 1.5 to 2.0, and the needle gauge increased from 23 to 27 G. This allowed for the formation of low (13.6%), medium (34%) and high (53.7%) porosity scaffolds. MSCs actively populated and permeated into the porous network with time of culture and showed a significantly more favorable proliferation on scaffolds with relatively high porosity levels. ALP activity was also significantly higher in the high porosity scaffolds. An in vivo pilot study of the CPC–alginate scaffolds with high porosity was implanted into rat calvarium. Examination after 6 weeks revealed the formation of new bone tissue within the scaffold, closing the defect almost completely. This study illustrates that subtle changes in physical properties, such as porosity, can be adjusted to obtain more satisfactory results.

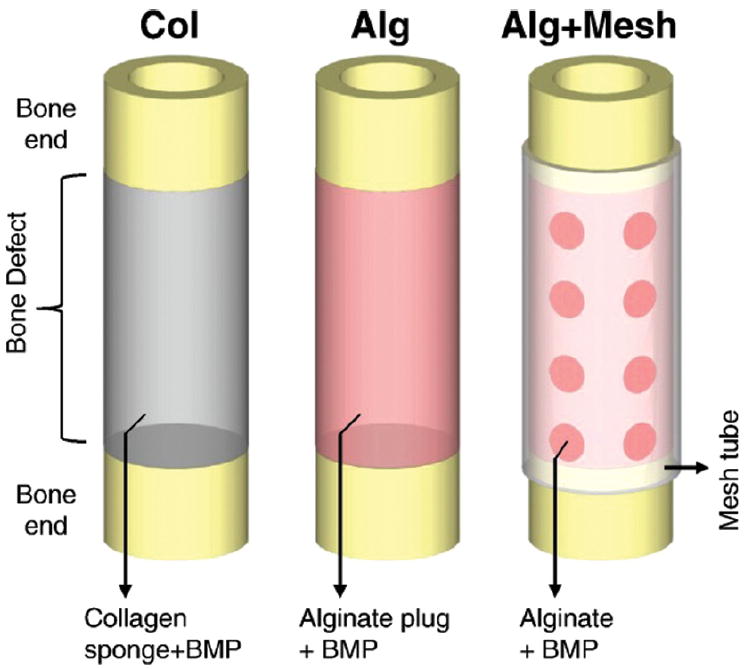

Alginate scaffolds have also been used in combination with proteins and peptides to enhance osteogenesis. One such study aimed to determine if the delivery of human bone marrow stromal cells (HBMSC) seeded onto VEGF/BMP-2 releasing composite alginate scaffolds could enhance the bone regenerative capability in a critical sized femur defect.85 Release kinetics were fine-tuned so VEGF would be released rapidly and BMP-2 would have a later release. This was achieved by using alginate fibers as a carrier for VEGF, and PDLLA was used as a carrier for BMP-2. Cumulative release experiments confirmed that VEGF release occurred earlier than BMP-2 release, and it was confirmed that the proteins remained active after release. Prior to implantation, scaffolds were seeded with or without HBMSCs. Three groups were examined: control alginate/PDLLA scaffold group, alginate-VEGF165/PDLLA-BMP-2 scaffold group, and alginate- VEGF/PDLLA-BMP-2 scaffolds seeded with HBMSC. 28 days after implantation, the bone defect was examined in each of the groups by micro-CT. There was a statistically significant increase in bone volume in alginate-VEGF/PDLLA-BMP-2 and alginate VEGF/PDLLA-BMP-2 + HBMSC scaffolds. There was no difference in bone surface to bone volume and trabeculae thickness between groups tested. Bone volume to total volume and trabecular number was only significantly increased in alginate VEGF/PDLLA-BMP-2 + HBMSC scaffolds. There was a significant decrease in trabecular spacing only in alginate VEGF/PDLLA-BMP-2 + HBMSC scaffolds. These data show that adding cells to alginate VEGF/PDLLA-BMP-2 scaffold resulted in better bone regeneration, but it is not clear if the coordinated release of proteins from the scaffold had any effect on this outcome. Another group also used alginate as a scaffold to induce spatiotemporal release kinetics of growth factors.86 This was accomplished by encapsulating the bone defect in a nanofiber mesh tube and an RGD-functionalized BMP-containing alginate hydrogel was injected inside the tube (Fig. 3). To test this material, three groups were used in this study. Collagen sponge + 5 μg rhBMP-2 (COL), Alginate plug + 5 μg rhBMP-2 (ALG), and Alginate + Nanofiber mesh tube + 5 μg rhBMP-2 (ALG + MESH). Scaffolds were placed in rat femoral segmental defects and evaluated by micro-CT. Two Volumes of Interest (VOI) were established: Central VOI, which was defined as the cylindrical volume that captured the central defect region, and Total VOI, which included entire volume of mineralization, in and around the defect. At 12 weeks, central bone volume (central and total VOI) was significantly higher in ALG and ALG + MESH groups. Bone Volume Accumulation (central and total VOI) was only significantly higher in the ALG + MESH group. Mean density was significantly lower in the ALG + MESH group, and there was no difference in connectivity density between the groups. The biomechanical properties of the regenerated femurs were measured at 12 weeks. Maximum torque, torsional stiffness, and work to failure were significantly increased only in the ALG + MESH set. There was no difference in failure angle between groups. The collective data from this study suggests constraining bone formation within the defect region, in this case by means of a mesh tube, improves bone formation in rat femoral segmental defects. Another group developed a nanoscale calcium sulfate (nCS)/alginate (nCS/A) injectable paste.87 The nCS/A ratios tested were 85:15 (nCS/15%A), 90:10 (nCS/10%A), or 95:5 (nCS/5%A). The injectability force (N) and flexural strength (MPa) significantly increased in an alginate concentration-dependent matter. The nCS/10%A paste was chosen for the remaining studies becaused it supported increased cell viability. The paste was loaded with bone morphogenetic protein 2 (BMP2) gene-modified rat mesenchymal stem cells (MSCs) and effect on bone and blood vessel growth was studied. The injectable paste was studied in rat critical-sized calvarial defects. Groups tested included: no treatment (blank), nCS/10%A, nCS/10%A + untransfected MSCs (nCS/10%A + M), and nCS/10%A + MSCs transfected with BMP-2 (nCS/10%A + M/B2). 7 weeks after implantation, X-ray was used to measure bone formation. The groups treated with nCS/10%A + M/B2 paste showed a significant increase in bone density and bone area measurement when compared to other groups. Very importantly, the nCS/10%A + M/B2 material significantly enhanced the production of blood vessels. The induction of angiogenesis is a significant accomplishment, as it is a requisite for the formation and maintenance of healthy bone.

Figure 3.

Schematic representations of the three protein delivery strategies: Collagen sponge-rhMBP-2, Alginate-BMP-2 and Alginate-rhBMP-2. Reprinted with permission from [86], Y. M. Kolambkar, et al., Bone 49, 485 (2011). © 2011, Elsevier.

One study used alginate-based scaffolds to study the effects of co-culturing osteoblast-related SaOS-2 cells and osteoclast-like RAW 264.7 cells.88 These cells were embedded into beads composed of a Na-alginate-based hydrogel matrix, with (HG:S) or without (HG) the addition of silica, which was used as an inorganic matrix. The advantage of the co-incubation conditions applied here is that under straightforward conditions soluble mediators released from one cell line can diffuse to a compartmentalized second cell line where they can cause a differential response. The mechanical stability of HG and HG:S was tested. The Martens hardness was of 0.548 ± 0.039 GPa for HG and 0.742 ± 0.027 GPa for HG:S. The reduced elastic modulus was of 20.336 ± 0.812 GPa for HG and 22.826 ± 0.579 GPa for HG:S. The expression of OPG was used as a functional indicator of SaOS-2 cells and TRAP as a functional indicator of RAW 264.7 cells. RANKL was used as a reference gene for SaOs-2 cells and TRAF-4 for RAW 264.7 cells. Cellular viability and gene expression analysis was measured in four groups: SaOs-2: HG, SaOs-2 + RAW: HG, SaOs-2: HG:S, and SaOs-2 + RAW: HG:S. Cellular viability was measured for 48 hours and no changes were observed between groups. Expression of OPG/RANKL was significantly higher in the two groups that contained silica in the hydrogel, but highest in the SaOs-2 + RAW: HG:S group, demonstrating SaOS-2 functionality. The expression of TRAP/TRAF-4 was significantly lower only in the SaOs-2 + RAW: HG:S group, suggesting that the presence of silica and SaOS-2 cells somehow have a combined suppressive effect on the activity of RAW cells. Although these groups were not tested individually to assess bone formation, these results clearly suggest that there was cross-talk between the osteoblast-and osteoclast-like cell lines.

4.1.5. Hyaluronic Acid

Hyaluronic acid (HAc) has also demonstrated potential as bone scaffold material. It is naturally occurring, hydrophilic, nonimmunogenic, and has also been found in the cytoplasm of osteoprogenitor cells.89 This natural polymer has been used in combination with other materials, factors, and drugs to enhance its osteogenic potential. In one study, a photo-cured HAc hydrogel containing an osteogenesis-inducing drug, Simvastatin (SIM), was designed.90 SIM has been found to induce osteodifferentiation of human adipose-derived stromal cells. Hydrogel viscoelastic properties were tuned through 2-aminoethyl methacrylate substitution (HAc-AEMA). Three different HAc-AEMA scaffolds were studied: HAc with 20% (wt/wt) AEMA (HAc-AEMA-20), 30% AEMA (HAc-AEMA-30), and 40% AEMA (HAc-AEMA-40). Rheological measurements showed that the elastic storage of the hydrogel increased with increasing AEMA concentration (from 40–80 Pa). Pore size increased with increasing AEMA concentration, but sizes were not reported. MC3T3 fibroblasts were seeded into the hydrogels to test for cytocompatibility, it was found that the material was cytocompatible and that there were no differences in viability between groups. After SIM was loaded into the hydrogel, release kinetic experiments showed that it could sustain release for up to 14 days. HAc-AEMA-40 hydrogel was chosen for the remaining experiments. Loading of 1 mg SIM into HAc-AEMA-40 significantly increased fibroblast proliferation and mineralization at all time-points tested. The presence of SIM also upregulated the expression of OCN and OPN at all time-points tested. The effectiveness of this system was then tested in vivo with and without SIM. Hydrogels were implanted in parietal bone defects in rabbits. Cone beam computed tomography was used to assess healing of the bone defect for up to 9 weeks. Healing was only slightly superior at 9 weeks in the SIM containing hydrogel. These results show that substitution with AEMA can improve viscoelastic properties and the addition of SIM into the hydrogel shows improved osteogenesis in vitro, although the results were not as notable in vivo. In another study, the ability of a HAc-based, cell-adhesive hydrogel that could direct initial attachment and subsequent differentiation of human MSCs into pre-osteoblasts without osteogenic supplements was assessed.91 This was accomplished by using a novel HAc hydrogel system, referred to as the doubly crosslinked networks (DXNs), comprised of densely crosslinked HAc hydrogel particles (HGPs) physically embedded in or covalently connected to a loosely crosslinked secondary network that is also HAc-based. A HAc-based hydrogel particle system was produced with (gHGP) or without (bHGP) immobilized gelatin. Gelatin was added to impart cell adhesive properties to the hydrogel. Both gHGPs and bHGPs had an average particle size of 5–6 μM. There was no statistically significant difference in the compression moduli of either HGP (24.6 ± 1.6 kPa and 21.3 ± 0.6 kPa for bHGP and gHGP, respectively). hMSCs were seeded on both hydrogels and cultured for up to 28 days. Cell viability did not change between materials tested. Cells cultured on bHGP control remained rounded and stationary; however, cells grown on gHGP formed branched intracellular networks and had migrated inside the gel. Histochemical analysis revealed that cells grown on gHGP had osteogenic markers, and cells grown in bHGP had adipogenic markers. These results suggest that osteogenic differentiation without osteogenic supplements was achieved by the ability of gHGP to foster the attachment of MSCs.

HAc scaffolds have also been used to enhance osteogenesis via the delivery of growth factors. In one study, HAc hydrogel scaffold systems with tunable degradation properties were developed for the controlled delivery of osteoinductive and angiogenic growth factors (BMP-2 and VEGF).92 Hydrogels were designed to degrade at fast, intermediate, and slow rates by varying crosslinking parameters. There was relatively little difference between scaffolds for BMP-2 and VEGF release kinetics. The three hydrogel groups were either loaded or not loaded with BMP-2 and surgically implanted into a rat calvarial defect model, and regeneration was measured for up to six weeks by micro-CT. The presence of BMP-2 had an overwhelming effect on mineralization increase, but there was no difference between low, intermediate, and fast-degrading scaffolds. Co-delivery with VEGF was tested on the fast degrading scaffolds. There was not a significant increase in mineralization when only VEGF was present in the scaffold, but when BMP-2 and VEGF were co-delivered, mineralization was significantly higher than BMP-2 by itself. These data indicate that osteoinductive and angiogenic factors can have a synergistic effect on bone mineralization. In another study, an injectable HAc hydrogel was obtained through aldehyde modification of HAc by the incorporation of an amino-glycerol side chain via amidation reaction and selective oxidation of the pendent group.93 Controlled release of active bone morphogenetic protein-2 (BMP-2) from the hydrogel was achieved. Human dermal fibroblasts were seeded onto the gels in the presence or absence of rhBMP-2. Viability was measured for up to three days and there were no changes between groups. In vivo evaluation of this gel as a BMP-2 carrier was performed by injecting gels over the rat calvarium. Bone formation was measured after 8 weeks by peripheral Quantitative Computerized Tomography and histology. There was a correlation between amount of BMP-2 loaded (0, 5 and 150 μg) within the gel and newly formed bone volume. The 150 μg BMP-2 loaded hydrogel produced significantly higher amounts of bone. In addition, histological examination showed newly formed bone with a high expression of OCN, OPN and with angiogenic bone marrow when higher BMP-2 concentration was employed. This system shows great potential, as it induces high mineralization and induces angiogenesis. Another study also shows the potential of combining a hyaluronic acid based system with the presence of BMP-2.94 Hyaluronan-based hydrogels formulated to include heparin (Heprasil™) were compared to similar gels without heparin (Glycosil™) for their ability to deliver bioactive BMP-2 in vitro and in vivo. Heparin has been used for many years to stabilize susceptible growth factors such as BMP-2.95 An examination of BMP-2 release kinetics from both hydrogels showed that more BMP-2 is retained and less is released in the heparin containing gels. For in vivo experiments, the ability of both BMP-2 loaded hydrogels to form bone in a rat ectopic model was assessed. The bone-forming capacity of Glycosil/BMP-2 or Heprasil/BMP-2 hydrogels were quantitatively assessed by micro-CT bone volume measurements. There was negligible bone formation in the control, Glycosil, or Heprasil hydrogels. However, there was bone formation in both Glycosil/BMP-2 and Heprasil/BMP-2 hydrogels, with approximately a 1.5 fold increase in Glycosil/BMP-2 as compared to Heprasil/BMP-2. Non-Heprasil loaded hydrogels resulted in a more efficacious outcome in vivo, emphasizing the therapeutic importance of an increased release of BMP-2.

Another study evaluated whether covalent grafting of an integrin-specific ligand into an HAc hydrogel could improve cell attachment and further enhance the osteogenic potential of rhBMP-2.96 Hydrazide-thiol HAc (HAc-hy-SH) and aldehyde-derivatized HAc (HAc-al) were prepared from hyaluronic acid. HAc-al and HAc-hy-SH were mixed together at equal ratios to form the hydrogel. A fibronectin (FN) fragment containing an integrin-binding domain of full-length FN was engineered and incorporated into the hydrogel (HAc-FN). The mechanical properties of the hydrogels were analyzed by rheological testing. The elastic moduli for HAc before and after swelling were 2520 ± 30 Pa and 405 ± 78 Pa, respectively. These values for HAc-FN were 2600 ± 30 Pa and 325 ± 31 Pa before and after swelling, respectively. There was no cytotoxicity of either hydrogel towards MSCs after 48 hours of incubation. The percent of adhered cells was statistically higher in HAc-FN than in HAc. For in vivo experiments, a rat ectopic bone model was selected. HAc and HAc-FN hydrogels were prepared with or without rhBMP-2, and hydrogels were implanted subcutaneously. After seven weeks, quantitative analysis of the bone volume normalized to the total tissue volume (BV/TV) by micro-CT revealed there was significantly higher for BV/TV in the HA-FN loaded with rhBMP-2 than in the HA hydrogels loaded with rhBMP-2. There was no bone formation in either of the hydrogels in the absence of BMP-2. Histological measurements show the delivery of rhBMP-2 through HA-FN resulted in morphologically more homogenous bone tissue with better organization of collagen fibers. This work suggests that HA hydrogel with an integrin ligand enhances the osteogenic potential of rh-BMP-2.

4.1.6. Peptide Hydrogels