Abstract

Introduction

Floor layers have high rates of musculoskeletal disorders yet few studies have examined their work exposures. This study used observational methods to describe physical exposures within floor laying tasks.

Methods

We analyzed 45 videos from 32 floor layers using Multimedia-Video Task Analysis software to determine the time in task, forces, postures, and repetitive hand movements for installation of four common flooring materials. We used the WISHA checklists to define exposure thresholds.

Results

Most workers (91%) met the caution threshold for one or more exposures. Workers showed high exposures in multiple body parts with variability in exposures across tasks and for different materials. Prolonged exposures were seen for kneeling, poor neck and low back postures, and intermittent but frequent hand grip forces.

Conclusions

Floor layers experience prolonged awkward postures and high force physical exposures in multiple body parts, which probably contribute to their high rates of musculoskeletal disorders.

Keywords: musculoskeletal disorders, observational assessment, construction trades

1. Introduction

Work-related musculoskeletal disorders (WRMSD) are a leading cause of injury and disability in the United States (U.S. Bureau of Labor and Statistics, 2009). Between 2003 and 2007, flooring contractors had the highest average WRMSD rate of 87.3/10,000 of employed workers involving days away from work compared to all other construction groups and far above the private industry rate of 42.0/10,000 workers (Centers for Disease Control and Prevention, 2009). The past literature pertaining to floor layer injuries has primarily focused on the knee (Kivimäki et al., 1992; Village et al., 1993); kneeling and squatting postures, common in floor laying tasks, has been associated with knee osteoarthritis, meniscal tears, and knee bursitis (Coggon et al., 2000; Kivimäki et al., 1992; Yuan et al., 2011). With greater use of interventions and changes in work practices and policies, WRMSD have decreased in all industries over the past 10 years, although construction declines have lagged behind all other industries (Spector et al., 2011).

In construction, the levels of physical exposures experienced during work tasks differ depending on the trade examined due to the highly variable schedules of workers and their job tasks. Floor layers perform more similar work tasks than many trades with each job requiring the same steps to install the material. General work tasks involve the preparation of floor surface, installation of materials, and finishing of floors with transition or base materials. However, the physical demands may differ between workers depending upon the amount of time spent in the general tasks as well as the material installed on the floor (Jensen et al., 2000b). Few studies have completed time studies of floor layers work tasks (Bhattacharya et al., 1985; Jensen et al., 2010a; Kivimäki et al., 1992; Thun et al., 1987) and all of these studies focused solely on exposures of the knee to install flooring material.

Floor layers spend long periods of time in awkward postures and with contact stress on the knee while kneeling and squatting to install materials (Ditchen et. al., 2010; Jensen et al., 2000a; Manninen et al., 2002; Reid et al., 2010; Rytter et al., 2009b; Seidler et al., 2008). These workers also handle heavy loads, manipulate tools and materials during installation, and complete tasks involving hand repetition and force simultaneously, such as transporting materials and removing old flooring. The combination of repetitive manipulation, lifting heavy loads, and exerting high levels of force with awkward postures of the upper body, low back and lower extremity may increase the risk for WRMSDs in body parts other than the knee (Hartmann and Fleischer, 2005; Holmström and Engholm, 2003). It is important to assess physical exposures for all body parts within job tasks of floor layers across materials to understand the potential increased risks for WRMSDs in workers of this trade. Examining differences in exposures within material may shed light on opportunities for developing interventions.

The purpose of this study was to explore the duration of time and intensity levels of observed physical exposures within floor laying tasks. Physical exposures were examined between different types of material and within different body parts (low back, knee, neck, shoulder, and wrist). Measured physical exposures for floor layers were compared to suggested threshold for exposures associated with increased risk for WRMSDs. The goal of the analysis was to determine whether the daily physical exposures of floor layers exceeded acceptable thresholds of exposures.

Material and Methods

2.1 Source data

We analyzed exposure data collected for the Predicting Carpal Tunnel Syndrome (PrediCTS) study, a prospective study of 1107 newly-hired workers from several work types (construction trade, service, technical, and hospital workers) in St. Louis, USA. All participants of the PrediCTS study provided written consent with study approval by the Institutional Review Board for Washington University School of Medicine. Exposure data came from worksite visits conducted with floor layers between 2007 and 2009. Thirty-eight floor layers participated in one or more worksite visits for a total of 54 visits. Each visit included a brief worker interview and videotape of job tasks performed by the worker on the day of the visit. All videos were reviewed for clarity of the picture, full body views of the worker, and at least 10 minutes of footage of job tasks. A minimum of 5 minutes of continuous work was needed for assessment of each non-cyclic job task, defined as activity with no repetitive pattern or 10 cycles of work activities for cyclic job tasks involving movements in the same pattern within the total footage recorded (Bao et al., 2006a). These criteria yielded 45 videos for analysis from worksite visits of 32 individual floor layers with some workers contributing more than one video from repeated worksite visits.

During worksite visits, technicians conducted brief interviews to learn about regularly performed job tasks, to obtain worker's daily time estimates for job tasks, and worker's ratings of perceived effort for job tasks using the modified Borg-CR 10 scales (Borg, 1990). Workers were asked to estimate the average daily time spent in the three general job tasks of preparation, installation, and finishing of flooring materials. The technician discussed the steps required for each job task for each of four material types (Vinyl Composite Tile (VCT), Ceramic Tile, Hardwood, or Carpet) so workers could give informed estimates of daily time spent in each task (Jensen et al., 2000b). Self-reported time estimates in pre-defined tasks have been used in several previous studies and have shown good reliability when compared to direct observation and diaries of daily tasks (Jensen, 2000b; Kallio, 2000; Unge, 2005). A full list of the steps to job task completion and detailed definitions are available in Appendix A. The technician obtained a list of tools, equipment, and materials commonly used at work and weighed these items on a scale. In addition, the technician measured the worker's maximum grip strength and asked for the worker's perceived rating of effort in activities on the Borg CR10 scale. All of this information (measured weights, Borg ratings, maximum grip) was used to help the technician have a better understanding of the effort required for different tasks when assigning force ratings on the observed video samples. Use of this additional information has been shown by other researchers to improve reliability of force ratings (Bao et al.,2010; Koppelaar and Wells, 2005; McGorry et al., 2010). Video recordings from a single camera, typically for several cycles of work tasks recorded from multiple angles, were obtained from each worker on the day of the visit.

2.2 Video Analysis

Video footage was analyzed using the Multimedia-Video Task Analysis (MVTA) software system (Ergonomics Analysis and Design Research Consortium, 2003; Yen and Radwin, 1995). MVTA is observation analysis software that allows for time studies of visually discernable activities on video samples. All segments of video were coded for estimated force to determine the proportion of time spent in forceful exposures. Randomly selected frames were coded for posture within each job task. Definitions and thresholds of force and postures are shown in Table 1. Each video was reviewed several times to code multiple parameters: 1) duration of time working in tasks, 2) forces of the body (lift/carry or push/pull) and power grip/pinch forces for the right and left hands separately, 3) postures for eight body parts (neck flexion/extension, low back flexion and rotation, right and left wrist flexion/extension, right and left shoulder elevation, right and left knee flexion/extension), and 4) hand/wrist repetition for right/left hands simultaneously.

Table I. Exposure cut points and definitions.

| Exposure | Cut Point | Definition from the Literature | Literature |

|---|---|---|---|

|

| |||

| Force | |||

| Power Grip | ≥10 lbs | Conspicuous force applied to an object ≥10 lb to hold or manipulate an unsupported object. Grip postures must include contact of the palm and have all fingers grasp the object | Bao et al., 2006b; Stetson, 1991; Washington State Ergonomic Checklist 2009 |

| Pinch Grip | ≥2 lbs | Conspicuous force applied to an object with fingertips in 3 point pinch or lateral pinch position ≥2 lb to hold or manipulate. Pinch grip uses fewer than 5 fingers and may include the pads, tips, or radial side of fingers and thumb. The palm cannot be included | Bao et al., 2006b; Stetson, 1991; Washington State Ergonomic Checklist 2009 |

| Lift/Carry | ≥10 lbs | The weight of an unsupported object lifted or carried, relative to gravity in a vertical plane, in order to transport it with one or both hands; weighing greater ≥10lbs. Lifting between 11 and 22 lbs of force has shown a positive relationship with knee osteoarthritis. | Coggon et al., 2000 |

| Push/Pull | Whole body | Body part contact with a surface or object by a worker to move it in a horizontal direction. Using force through multiple proximal body parts or using the weight of the body to help push or pull the object. | Bao et al., 2006b |

| Posture | |||

|

| |||

| Neck | Away from neutral (flexion or extension) | Away from neutral (flexion or extension) (Based on van Wely) | van Wely, 1979 |

| Shoulder | ≥90° elevation | Severe shoulder flexion or abduction over 90° is predictive of severe shoulder disorders; working or repeatedly raising the hands above head or the elbows above shoulder level. | Punnett et al., 2001; Leclerc et al., 2004; Washington State Ergonomic Checklist 2009 |

| Wrist | ≥45° extension or flexion | ≥ 30 extension increases intracarpal pressure and risk for CTS. Pressure in the carpal tunnel also increases with flexion, which can cause damage to the median nerve. | Gelberman et al., 1981 Rempel, 1995 |

| Low back | ≥30° and ≥90° flexion ≥20° lateral flexion or rotation |

Cases of back disorder have been associated with mild flexion (neutral-45 degrees), severe flexion (≥45 degrees), and any lateral bending or twisting in any direction. Working with back bent more than 30 degrees. | Punnett et al., 1991; Washington State Ergonomic Checklist 2009 |

| Knee | Knee flexion of at least 90° (Kneeling, kneeling with heel sit, squat) | Kneeling and squatting have been associated with knee disorders. | Jensen, et al., 2000; Jensen, 2005; Washington State Ergonomic Checklist 2009 |

Note: the Washington State Ergonomic Checklist 2009 was based on the duration of time spent working at the defined intensity level. A caution rating required exposure of two or more hours per day. A hazard rating required exposure of four or more hours per day.

Posture category thresholds were based on joint angles considered to increase the risk of WRMSDs (see Table 1) A pre-determined number of randomly selected still frames were coded for posture based on the number of steps needed to complete the job task: 75 frames were sampled for each body part posture for samples with one step, 80 frames for samples with two steps, 90 frames for 3 steps and 100 frames for four or more steps (Bao et al., 2006b). Random sampling reduced the time required for coding while still capturing the variability of postures within tasks. To reduce inaccuracies of coding postures, criteria followed recommendations by past research: viewing angles with parallax (defined as a viewing angle that is not aligned with the axis of joint rotation (Lau and Armstrong, 2011; Paul and Douwes, 1993), and frames with blurry images or obstructed views were assigned a “null” code. Two technicians independently coded posture to evaluate inter-rater reliability of values and determined the consistent interpretation of definitions of posture categories; technicians achieved an Intraclass Correlation Coefficient (ICC) of 0.7-0.9 for eight body parts during a pilot study of 30-80 randomly sampled frames per body part.

Repetition was defined as repeating the same motion or movement with the wrist or hands with little or no variation every few seconds (Washington State Department of Labor and Industries, 2000). Video segments of at least one minute duration for each step to a job task were selected and assigned a repetition rating using the Hand Activity Level (HAL) (value range: 0 to 10) (Jones et al., 2010; Latko et al., 1997). The HAL rating was based upon the speed of active movement of a body part and frequency of breaks during the movement; static muscular efforts that showed no visible movement were excluded. Repetition coding was completed by joint consensus with two technicians. Video segments of one-minute length were randomly sampled within videos of each material.

2.34 Evaluating Hazardous Exposure Levels

The Washington State Department of Labor and Industries (WISHA) Caution and Hazards Checklist provided thresholds of physical exposures across multiple body parts so a worker's daily exposure risk may be assessed (Washington State Department of Labor and Industries, 2000). The tool was developed in Washington State in the late 1990's as part of a regulatory effort to control exposures to musculoskeletal risks in the work place (Silverstein 2007) and has been used extensively by employers and researchers to identify levels of risk within jobs (Eppes, 2004; Washington State Ergonomic Checklist, 2009). The WISHA checklists are one of the few measures that account for musculoskeletal hazards across all regions of the body. The caution and hazard levels are determined by the duration of time spent working at a defined intensity level; a caution rating requires exposure of two hours or more and a hazardous rating requires exposures above four hours.

2.4 Data Analysis

The data were summarized to determine the time in job task (prep, install, finish) for each material by averaging the time spent in tasks for all videos analyzed, separately by material. The average proportion of time spent using significant forceful exertions was computed for each type of force for each material and calculations of coefficient of variation showed the variability within tasks. To determine the proportion of time spent in poor postures, it was assumed that the proportions of randomly selected frames with extreme postures observed reflected the proportion of postures (Bao et al., 2006b). The amount of time spent in poor postures was averaged for each job task by videos for each material.

To determine whether the frequency and intensity of exposures for each worker would reach the daily hazard threshold level of concern for developing musculoskeletal disorders, the average daily time and intensity of exposures summarized for each of the main job tasks (prep, install, and finish) were weighted by the worker's estimated time spent in each job task from the worksite visit interview. Time weighted averages for the job tasks reflected exposures in a full working day for individual workers; the number of hours with high physical exposures were compared to the WISHA daily exposure levels to determine a caution or hazard level.

MVTA and Microsoft Excel and Access software were used to process the video data and perform summary results. Summary results were computed using IBM SPSS version 19 (SPSS, 2010).

3. Results

The 32 floor layers were predominantly Caucasian, right-handed males as shown in Table II. The following results show the time in tasks for floor layers that were new to the trade with an average tenure of 1.4 years with 7.9 average daily work hours (range 7.5-9.0 hours). Table III shows the distribution of video time by material and job tasks for the 45 video samples; individual video length average was 13:20 minutes (range 8:00-19:52 minutes). Five percent (31.6 minutes) of the total video time was unable to be coded, or “null,” indicating good quality videos were available for analysis. The proportion of time spent in job tasks showed that twice as much time was spent in install and finish job tasks compared to prep tasks which is similar to the worker estimated times obtained from the worksite interviews.

Table II. Characteristics of floor layers.

| n | Mean | SDa | Median | Min | Max | |

|---|---|---|---|---|---|---|

| Age in years | 32 | 27.8 | 7.3 | 26.0 | 19 | 45 |

| BMI | 32 | 29.0 | 5.6 | 27.6 | 22.9 | 45.7 |

| Time in Trade (years) | 32 | 1.37 | 1.0 | 1.0 | 0 | 3 |

| Grip Strengthc | ||||||

| Right | 32 | 114.6 | 21.8 | 115.3 | 76.0 | 160.3 |

| Left | 32 | 111.8 | 21.3 | 116.7 | 53.6 | 157 |

| Gender | n | % | ||||

| Males | 32 | (100%) | ||||

| Females | 0 | 0 | ||||

| Race | ||||||

| Caucasians | 30 | (94%) | ||||

| Othersb | 2 | (6%) | ||||

| Handedness | ||||||

| Right handed | 30 | (94%) | ||||

| Left handed | 2 | (6%) |

Standard Deviation

Others – Black, Asian, Native American, other

Average of three trials on a Jamar dynamometer

Table III. Video time analyzed across material and within job task.

| Coded Video Minutes by Job Task | |||||||

|---|---|---|---|---|---|---|---|

|

| |||||||

| Material | # videos | Not Coded (minutes) | Coded (minutes) | Total (minutes) | Prep minutes (%) | Install minutes (%) | Finish minutes (%) |

| VCT | 7 | 1.5 | 82.9 | 84.4 | 36.2 (43) | 21.6 (26) | 25.2 (30) |

| Ceramic | 18 | 14.8 | 231.1 | 245.9 | 28.9 (13) | 79.0 (34) | 123.3 (53) |

| Wood | 12 | 10.6 | 148.3 | 158.9 | 11.7 (8) | 84.6 (57) | 52.1 (35) |

| Carpet | 8 | 4.7 | 92.2 | 96.9 | 16.3 (18) | 52.4 (57) | 23.5 (25) |

| Total | 45 | 31.6 | 554.5 | 586.1 | 93.1 (17) | 237.6 (43) | 224.1 (40) |

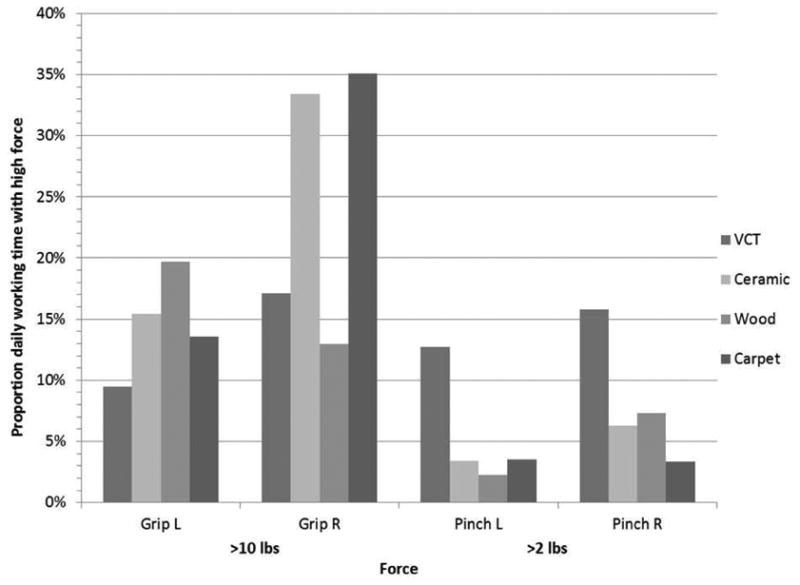

3.1 Force

The maximum daily exposure time with force as defined in Table 1 was 38% for power hand grip, 20% for finger pinch, 16% for lift and 25% for push/pull. The average coefficient of variation (COV) of force exposures by tasks and materials was 66% (median 62%) with a maximum value of 234% showing the variation in exposure in video samples between workers. The average daily working time with high hand force levels among all workers and within each material is shown in Figure 1. Overall, carpet and ceramic materials exhibited the greatest average daily time in forceful grip bilaterally (right 35%, and 33% respectively) with lower portions of daily time for VCT and wood (right 17% and 13%). VCT (right 16%, left 13%) showed the largest proportions of daily time spent using a pinch force during work activities. Within specific job tasks, power grip occurred more often during prep and install of all materials as observed to operate nailers, use floor scrapers, and transport heavy loads. Pinch was common for install and finish job tasks of VCT material primarily to push tiles into place and to manipulate and trim base cove. The use of back forces was most common for push/pull forces in handling carpet (19% bilaterally) and lifting for ceramic and wood (right hands: 9% and 6%).

Figure 1.

The average daily working time spent interacting with significant forces for grip and pinch across materials calculated using time weighted averages of daily working time for workers.

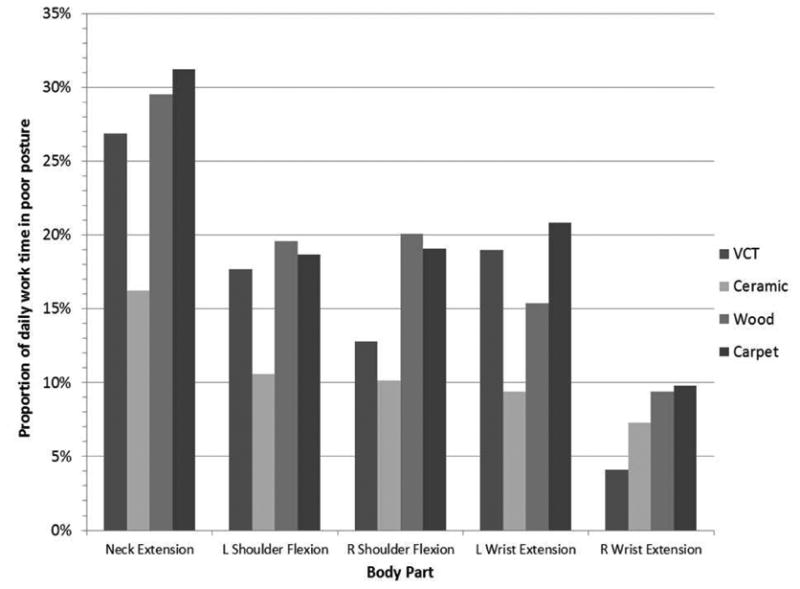

3.2 Posture

The proportions of frames not able to be coded, or “null,” for each body part, was 11% or less for the low back and lower extremity, 18-35% for the upper extremity and 35-46% for the neck, with similar values across all materials and for right and left sides. These null codes reduced the overall sample of posture frames. The weighted averages daily working time in poor postures of the upper extremity is shown in Figure 2.

Figure 2.

Comparison of weighted averages of daily working time spent in all poor postures of the upper extremity for each material.

Postures of the upper extremity were most common for shoulder flexion of more than 90 degrees (from a standing or kneeling position) and extension of the left wrist of more than 45 degrees in all materials except ceramic. These postures occurred most often during the install task of all materials. Workers often leaned on the left hand and wrist as a support on the floor while the right hand operated a tool or handled material. Wrist flexion occurred for only brief periods, accounting for a small amount of time (0%-1%).

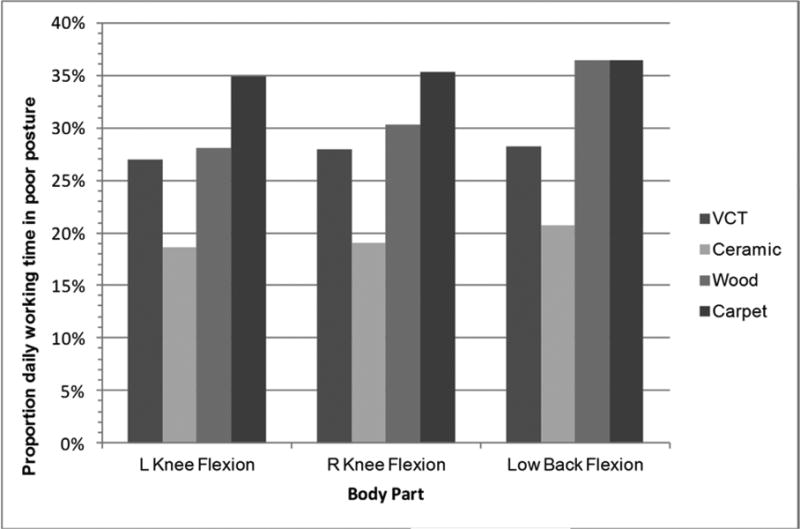

Install and finish tasks were performed while kneeling or in an all-fours posture with both knees and hands on the floor. From the all-fours position, neck extension postures were quite common, although the neck was often not captured in the video frame so this accounted for a large number of missing codes of neck posture. Poor low back postures were most common to install wood (36%) and carpet (36%) materials and poor knee postures for the same materials: carpet (kneeling on left and right 35%) and wood (kneeling left 30%, right 27%) (See Figure 3).

Figure 3.

Comparison of weighted averages of daily working time spent in all poor postures of the low back and knee postures for each material.

3.3 Repetition

The highest ratings of repetition with values of 5.0 (on a 0-10 point scale) were assigned to two steps in job tasks for prep (repair and mix) and install (troweling) (see Table IV). These steps with the highest repetition ratings were present in the right hand with much lower levels for the left hand. A review of all video samples showed some activities had repeated body movements but the movement did not occur within a one minute time frame, and therefore were not considered repetitive activities.

Table IV. Hand Repetition.

| Job Task | Step | Material | Video samples | HAL* Right hand Mean (SD) | HAL* Left hand Mean (SD) |

|---|---|---|---|---|---|

| Prep | Demolition | VCT, Carpet | 3 | 3.3 (2.5) | 2.6 (1.5) |

| Repair | VCT | 1 | 5.0 (0) | 1.0 (0) | |

| Mix | Ceramic, Wood | 4 | 5.3 (1.5) | 3.0 (3.2) | |

| Install | Trowel | VCT, Ceramic, Carpet | 6 | 5.1 (0.8) | 2.2 (2.2) |

| Cut/Lay | VCT, Ceramic, Carpet, Wood | 9 | 3.0 (0.7) | 2.8 (0.8) | |

| Finish | Sponge/Buff | Ceramic, Wood | 5 | 3.2 (1.6) | 1.4 (0.5) |

| Carpet Tack | Carpet | 2 | 3.0 (0) | 1.0 (0) |

HAL- Hand Activity Level Scale (0=none, 10= highest rating). (Latko et al., 1997)

3.4 Observed Exposure Levels Compared to Recognized Hazard Levels

The time weighted average daily durations of intense exposure levels for force and posture for the 32 workers were compared to threshold levels suggested by the WISHA Checklist (Washington State Department of Labor and Industries, 2000). For each worker, the estimated time in task was weighted by the exposure (proportion of exposure per task) and summated to a daily time for each exposure per worker. The average proportion of time in exposures from the video analysis that were used in these computations was presented in Appendix B. Overall, 30 (94%) of the workers met a caution or hazard level rating of daily exposure for at least one force or posture exposure while working (see Table V). Most workers had poor postures of the low back, neck, and knee that worked in VCT, carpet and wood materials. Workers (69%) in ceramic were exposed to poor low back and knee postures for slightly less time (1.5-1.9 hours) than the 2-hour caution threshold. Six workers (19%) met caution or hazard levels for one or more exposures in both force and posture categories.

Table V. Workers who met a WISHA caution or hazard level.

| Caution Level ≥2 hours | Hazard Level ≥4 hours | |||||

|---|---|---|---|---|---|---|

|

| ||||||

| Category | VCT (n=5) | Ceramic (n=13) | Wood (n=9) | Carpet (n=5) | All materials (n=32) | Carpet (n=5) |

|

| ||||||

| Posture Intensity | n | n | n | n | n (%) | n (%) |

| Low back bent > 30° | 5 | 1 | 8 | 4 | 18 (56) | 1 (20) |

| R Knee bent | 5 | 1 | 8 | 5 | 19 (59) | 0 |

| L Knee bent | 4 | 1 | 6 | 5 | 16 (50) | 0 |

| Neck bent* | 4 | 0 | 7 | 5 | 16 (50) | 0 |

| R Shoulder | 0 | 0 | 2 | 1 | 3 (9) | 0 |

| L Shoulder | 0 | 0 | 2 | 1 | 3 (9) | 0 |

| L wrist ≥45° extension | 0 | 0 | 0 | 2 | 2 (6) | 0 |

| Force Intensity | ||||||

|

| ||||||

| R grip ≥ 10 lbs | 0 | 13 | 0 | 5 | 18 (56) | 0 |

| L grip ≥ 10 lbs | 0 | 1 | 0 | 0 | 1 (3) | 0 |

| R pinch ≥ 2 lbs | 0 | 0 | 0 | 0 | 0 (0) | 0 |

| L pinch ≥ 2 lbs | 0 | 0 | 0 | 0 | 0 (0) | 0 |

Neck bent into extension

Note: R- right; L- left; WISHA-(Washington State Department of Labor and Industries, 2000)

Hand grip was the most common force exposure, and low back and knee the most common poor postures. Most workers (n=19, 59%) showed one or more awkward postures during daily working tasks. Install of ceramic and carpet materials produced high exposure levels with caution ratings for right hand grip. Left wrist postures of risk were common during install of carpet material and approached the 2-hour caution level during install of VCT and wood materials. No workers met the WISHA caution threshold for 2 hours or more of exposure to hand repetition.

4. Discussion

The results show that floor layers encounter high levels of physical exposures in multiple body parts although there seems to be some difference in exposure levels depending upon the type of material. Hand forces for gripping tools to install ceramic and carpet were common while pinch forces were used to handle VCT tile during installation. In addition to poor postures of the knee and low back in floor laying tasks, poor upper extremity postures for shoulder flexion, and wrist extension occurred up to 20% of the work day. Repetitive motions were present in only a few steps of tasks such as in troweling or mixing mortar, but these tasks occurred for short episodes rather than prolonged periods of time. Less common tasks such as pack and knee kick showed high levels of force and postures. These floor layers primarily installed floors on commercial builds which infrequently included stretch-in carpet and therefore use of a knee kicker, though knee kicking has been shown to be a very high exposure in other studies (Bhattacharya et al., 1985).

Assessment of exposures at the worker level showed that most workers met the caution threshold level of exposures on the WISHA checklist (Washington State Department of Labor and Industries, 2000). The most common physical exposure was poor posture of the low back (>30 degrees flexion) and knee (squatting or kneeling) occurring for 2 or more hours per day. The other most common exposure was forceful hand grip, met by 56% of the workers. The average time spent in poor knee postures (56%) was similar to the reported daily exposures by Jensen and colleagues of 41% obtained by reviews of one-day continuous video recordings of 4 floor layers (2010a) and the study of tile layers (64%) using directly measured exposures (Ditchen et. al., 2010). These long periods of time in poor postures likely contribute to the high number of low back and knee claims previously reported in the literature (Hartmann and Fleischer, 2005; Holmström and Engholm, 2003; Jensen et al., 2000a; Kivimäki et al., 1992; Punnett et al., 1991). The all-fours position (kneeling with hands on the floor) with low back flexion and kneeling is commonly used to perform many tasks at the floor level. Jensen and colleagues have spent more than 10 years conducting studies with floor layers and through their work they have demonstrated an association between osteoarthritis and other knee disorders to squatting and kneeling postures (Jensen, 2005, 2000a; Rytter et al., 2009a, 2009b, 2008). Their recent work has explored interventions that allow work to be performed from an upright position such as using a stand-up trowel to spread adhesive and floor leveler (Jensen et al., 2010b; Jensen and Friche, 2008, 2007). Upright postures relieve stress on the knee and correct low back flexion and may improve awkward postures of the upper extremity.

Exposures of the upper extremities have not been the typical focus among floor layers. The study results showed poor postures of the shoulder and wrist are relatively common, occurring between 10-35% of the workday. Poor shoulder postures were commonly seen and yielded caution level categories according to WISHA for wood and carpet workers. However, many of these shoulder postures did not occur against gravity as floor layers usually worked on their knees with the arms handling material in front of them. Another novel finding of the study was the long periods of time spent working with the non-dominant hand in an extended wrist posture, which commonly occurred during install of materials. Workers supported their upper body on their non-dominant hand while in a tripod position so the dominant hand could be free to manipulate a tool or material. Interventions that provide upper body support at the floor level or working in an upright posture may relieve stress on the wrist, and allow the shoulders to work in a more natural posture.

Reported exposure differences between the four main flooring types suggest that some variability in exposures is related to material type. The job tasks and materials identified as having high levels of physical exposures should be considered for areas of ergonomic interventions for floor layers. Workers may benefit from installing a variety of materials rather than being restricted to a single type. However, installing all materials showed high exposures to the low back from the forward bent working posture. Upper body supports, rolling stools, and scooters are used to varying degrees to reduce the weight of the upper body on the low back. Stand up devices to spread adhesive and mortar eliminate some time spent in forward flexion. For wood and ceramic materials, adapted work practices and improved tool design such as modified handles to limit gripping while placing pieces of material or using tools to assist with installing materials may reduce grip forces. Poor shoulder postures to install wood may be due to operating the mallet with a manual nailer that may be reduced or eliminated with a pneumatic nailer. For VCT material, the high levels of pinching to hold and manipulate material most often occurred while finishing the job; interventions that educate workers on using sharp tools to cut the vinyl, a heat source to improve the flexibility to bend the vinyl for trimming, and assistive devices to eliminate pinching of the material may help reduce the high levels of pinch force. Due to the variability of physical exposures shown within a single job title, understanding the job tasks floor layers perform is critical in order to develop proper interventions to prevent injury.

There were several important limitations in this study that should be considered when interpreting the results. The selection of subjects for worksite visits from our longitudinal cohort study of carpal tunnel syndrome may have produced a non-representative sample or too brief of video samples to provide representative exposures. We reviewed all video for clarity of views, and used random sampling to select a large number of frames to code postures, following procedures that have been previously described (Bao, 2006b) for use in field studies. The time spent in poor postures likely varies between subjects; computing an average exposure reduces the variation and will over or underestimate exposure time for individual workers in a construction trade characterized by variable work situations. Data collection that produced the most valid estimate of exposures for individual workers for postures of the knee, low back, and upper extremity would require direct instrumentation of dozens of workers during many work days each. Several researchers have shown excellent reliability within and between observers (0.92 and 0.88) using similar observational methods to code posture and force (Koppelaar and Wells, 2005) but the agreement of the results when compared to direct measurement methods has been more variable, usually with modest correlations (r=0.49 or less) (Bao, 2010; Koppelaar and Wells, 2005). Assignment of postures from still frames may have contributed some misclassification of exposures, although our technicians showed good inter-rater reliability results when coding the same videos independently. The purpose of this study was to provide better and more complete information than currently exists about the exposures incurred by workers in a trade at high risk of MSD so although exposure misclassification is present in this data - measuring its extent would require a resource intensive study. There are no studies with which to compare our results on forceful exertions in floor layers. Using self-reported time estimates of daily work tasks may have over or under estimated the actual exposure levels for comparison to daily exposure thresholds. Another limitation was the relatively short tenure of the workers included in the study. Newer workers may have different proportions of time for different exposures that may change with experience in the trade. There was limited or no data available to document exposure to vibration and temperatures, which may also affect the musculoskeletal system.

The strengths of this study were using a detailed exposure analysis of videos from many floor layers and ability to explore several different exposures across multiple tasks and material types. The relatively large number of worker samples spanned the most common work materials used by floor layers giving us the opportunity to compare and contrast exposure levels in specific work groups of the floor laying industry. Furthermore, selecting videos in a systematic way and ensuring that comparisons of self-reported working time in each job task and analyzed time were similar helped to reduce selection bias in the sample. Using recently published literature on coding schemes, video analysis reliability, and selecting suitable video segments to reduce uncodable frames supported the accuracy of the results. By using a task based approach to analyze physical exposures with video observation allowed analysis of exposures across different materials within many multi-step job tasks performed by floor layers. These results offer the most complete picture to date of the exposures incurred in this high risk construction trade.

5. Conclusion

Floor layers have a high risk of many types and levels of physical exposures in their work tasks and these occur during the installation phase of all types of materials. Although exposures to the knee have been thoroughly reviewed previously, this research showed that poor postures of the low back, shoulders, and wrists, as well as forceful grip, are common. Working with different materials shows some differences in exposures such as forceful grip to install wood and ceramic, and awkward shoulder and wrist postures to install wood or carpet. These results can be used to guide the development of tools and work methods to reduce exposures in floor laying tasks.

Supplementary Material

Most (91%) floor layers met caution risk levels of physical exposures daily

Prolonged awkward postures and high force exposures occurred in multiple body parts

Besides kneeling, poor neck and low back postures are common in floor layers

Upper extremity exposures occur from 10-30% of the work day

Hand, wrist, and shoulder exposure levels differ by the type of material installed

Acknowledgments

We would also like to acknowledge the floor layer participants in the worksite assessments who provided the data for this study.

Role of the funding source: This study was supported by research funding from the Centers for Disease Control / National Institute of Occupational Safety and Health (R01 OH008017-01 and NIOSH U60 OH009762) and from the National Center for Research Resources (NCRR), a component of the National Institutes of Health (NIH), and NIH Roadmap for Medical Research (UL1 RR024992). These funds were used by the research team in order to design the study, and to perform the data analysis and interpretation, and to prepare this manuscript. The study sponsors had no specific involvement in this manuscript.

Footnotes

Disclosure Statement: No authors in this study have actual or potential conflict of interest including any financial, personal or other relationships with other people or organizations within three (3) years of beginning the work submitted that could inappropriately influence this work.

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final citable form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- Bao A, Howard N, Spielholz P, Silverstein B. Inter-observer reliability of forceful exertion analysis based on video-recordings. Ergonomics. 2010;53(9):1129–1139. doi: 10.1080/00140139.2010.507879. [DOI] [PubMed] [Google Scholar]

- Bao S, Silverstein B, Spielholz P, Howard N. The Washington state SHARP approach to exposure assessment. In: Marras WS, Karwowski W, editors. Fundamentals and Assessment Tools for Occupational Ergonomics. Taylor & Francis Group; Boca Raton, FL: 2006b. pp. 1–22. [Google Scholar]

- Bao S, Spielholz P, Howard N, Silverstein B. Quantifying repetitive hand activity for epidemiological research on musculoskeletal disorders - Part I: individual exposure assessment. Ergonomics. 2006a;49(4):361–380. doi: 10.1080/00140130500520214. [DOI] [PubMed] [Google Scholar]

- Bhattacharya A, Mueller M, Putz-Anderson V. Traumatogenic factors affecting the knees of carpet installers. Appl Ergon. 1985;16:243–250. doi: 10.1016/0003-6870(85)90087-0. [DOI] [PubMed] [Google Scholar]

- Borg GA. Psychophysical scaling with applications in physical work and the perception of exertion. Scand J Work Environ Health. 1990;16(Suppl):55–58. doi: 10.5271/sjweh.1815. [DOI] [PubMed] [Google Scholar]

- Centers for Disease Control and Prevention. Average rate of occupational musculoskeletal disorders involving days away from work, Construction sectors, Private Industry, 2003 – 2007. National Institute for Occupational Safety and Health, Division of Surveillance, Hazard Evaluations & Field Studies Worker Health eChartbook. 2009 Retrieved January 30, 2012, from: http://wwwn.cdc.gov/niosh-survapps/echartbook/Chart.aspx?id=1310&cat=577.

- Coggon D, Croft P, Kellingray S, Barret D, McLaren M, Cooper C. Occupational physical activities and osteoarthritis of the knee. Arthritis Rheum. 2000;43(7):1443–1449. doi: 10.1002/1529-0131(200007)43:7<1443::AID-ANR5>3.0.CO;2-1. [DOI] [PubMed] [Google Scholar]

- Ditchen D, Ellegast R, Rehme G. Institute of Occupational Health of the German Social Accident Insurance; Alte Heerstr. 111, 53757 Sankt Augustin: 2010. GonKatast: A measure of land to professional knee loads. IFA Report. Retrieved from: http://www.dguv.de/ifa/de/pub/rep/reports2009_2010/ifa0110/index.jsp. [Google Scholar]

- Eppes S. Washington State Ergonomic Tool: predictive validity in the waste industry. Texas A&M University; 2004. [Google Scholar]

- Ergonomics Analysis and Design Research Consortium. User's Manual for Multimedia Video Task Analysis™ (MVTA™) Wisconsin Alumni Research Foundation (WARF); Wisconsin: 2003. [Google Scholar]

- Gelberman RH, Hergenroeder PT, Hargens AR, Lundborg GN, Akeson WH. The carpal tunnel syndrome. A study of carpal canal pressures. J Bone Joint Surg Am. 1981;63(3):380–383. [PubMed] [Google Scholar]

- Hartmann B, Fleischer AG. Physical load exposure at construction sites. Scand J Work Environ Health. 2005;31(Suppl 2):88–95. [PubMed] [Google Scholar]

- Holmström E, Engholm G. Musculoskeletal disorders in relation to age and occupation in Swedish construction workers. Am J Ind Med. 2003;44(4):377–384. doi: 10.1002/ajim.10281. [DOI] [PubMed] [Google Scholar]

- Jensen LK. Knee-straining work activities, self-reported knee disorders and radiographically determined knee osteoarthritis. Scand J Work Environ Health. 2005;31(Suppl 2):68–74. [PubMed] [Google Scholar]

- Jensen LK, Eenberg W, Mikkelsen S. Validity of self-reporting and video-recording for measuring knee-straining work postures. Ergonomics. 2000b;43(3):310–316. doi: 10.1080/001401300184422. [DOI] [PubMed] [Google Scholar]

- Jensen LK, Friche C. Implementation of new working methods in the floor-laying trade: long-term effects on knee load and knee complaints. Am J Ind Med. 2010b;53(6):615–627. doi: 10.1002/ajim.20808. [DOI] [PubMed] [Google Scholar]

- Jensen LK, Friche C. Effects of training to implement new working methods to reduce knee strain in floor layers. A two-year follow-up. Occup Environ Med. 2008;65(1):20–27. doi: 10.1136/oem.2006.028803. [DOI] [PubMed] [Google Scholar]

- Jensen LK, Friche C. Effects of training to implement new tools and working methods to reduce knee load in floor layers. Appl Ergon. 2007;38:655–665. doi: 10.1016/j.apergo.2006.03.008. [DOI] [PubMed] [Google Scholar]

- Jensen LK, Mikkelsen S, Loft IP, Eenberg W. Work-related knee disorders in floor layers and carpenters. J Occup Environ Med. 2000a;42(8):835–842. doi: 10.1097/00043764-200008000-00015. [DOI] [PubMed] [Google Scholar]

- Jensen LK, Rytter S, Bonde JP. Exposure assessment of kneeling work activities among floor layers. Appl Ergon. 2010a;41(2):319–325. doi: 10.1016/j.apergo.2009.08.004. [DOI] [PubMed] [Google Scholar]

- Jones T, Kumar S. Comparison of ergonomic risk assessment output in four sawmill jobs. Int J Occup Saf Ergon. 2010;16(1):105–11. doi: 10.1080/10803548.2010.11076834. [DOI] [PubMed] [Google Scholar]

- Koppelaar E, Wells R. Comparison of measurement methods for quantifying hand force. Ergonomics. 2005;48(8):983–1007. doi: 10.1080/00140130500120841. [DOI] [PubMed] [Google Scholar]

- Kilbom A, Persson J. Work technique and its consequences for musculoskeletal disorders. Ergonomics. 1987;30(2):273–279. doi: 10.1080/00140138708969706. [DOI] [PubMed] [Google Scholar]

- Kivimäki J, Riihimäki H, Hänninen K. Knee disorders in carpet and floor layers and painters. Scand J Work Environ Health. 1992;18(5):310–316. [PubMed] [Google Scholar]

- Latko W, Armstrong TJ, Foulke JA, Herrin GD, Rabourn RA, Ulin SS. Development and evaluation of an observational method for assessing repetition in hand tasks. Am Ind Hyg Assoc J. 1997;58(4):278–285. doi: 10.1080/15428119791012793. [DOI] [PubMed] [Google Scholar]

- Lau MH, Armstrong TJ. The effect of viewing angle on wrist posture estimation from photographic images using novice raters. Appl Ergon. 2011;42(5):634–643. doi: 10.1016/j.apergo.2010.08.008. [DOI] [PubMed] [Google Scholar]

- Leclerc A, Chastang JF, Niedhammer I, Landre MF, Roquelaure Y. Incidence of shoulder pain in repetitive work. J Occup Environ Med. 2004;61(1):39–44. [PMC free article] [PubMed] [Google Scholar]

- Manninen P, Heliövaara M, Riihimäki H, Suoma-lainen O. Physical workload and the risk of severe knee osteoarthritis. Scand J Work Environ Health. 2002;28(1):25–32. doi: 10.5271/sjweh.643. [DOI] [PubMed] [Google Scholar]

- McGorry RW, Lin JH, Dempsey PG, Casey JS. Accuracy of the Borg CR10 scale for estimating grip forces associated with hand tool tasks. J Occup Environ Hyg. 2010;7(5):298–306. doi: 10.1080/15459621003711360. [DOI] [PubMed] [Google Scholar]

- Paul JA, Douwes M. Two-dimensional photographic posture recording and description: a validity study. Appl Ergon. 1993;24(2):83–90. doi: 10.1016/0003-6870(93)90079-o. [DOI] [PubMed] [Google Scholar]

- Punnett L, Fine LJ, Keyserling WM, Herrin GD, Chaffin DB. Shoulder disorders and postural stress in automobile assembly work. Scand J Work Environ Health. 2000;26(4):283–291. doi: 10.5271/sjweh.544. [DOI] [PubMed] [Google Scholar]

- Punnett L, Fine LJ, Keyserling WM, Herrin GD, Chaffin DB. Back disorders and nonneutral trunk postures of automobile assembly workers. Scand J Work Environ Health. 1991;17(5):337–346. doi: 10.5271/sjweh.1700. [DOI] [PubMed] [Google Scholar]

- Reid CR, Bush PM, Cummings NH, McMullin DL, Durrani SK. A review of occupational knee disorders. J Occup Rehabil. 2010;20(4):489–501. doi: 10.1007/s10926-010-9242-8. [DOI] [PubMed] [Google Scholar]

- Rytter S, Egund N, Jensen LK, Bonde JP. Occupational kneeling and radiographic tibiofemoral and patellofemoral osteoarthritis. J Occup Med Toxicol. 2009a;4:19. doi: 10.1186/1745-6673-4-19. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rytter S, Jensen LK, Bonde JP. Clinical knee findings in floor layers with focus on meniscal status. BMC Musculoskelet Disord. 2008;9:144. doi: 10.1186/1471-2474-9-144. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rytter S, Jensen LK, Bonde JP, Jurik AG, Egund N. Occupational kneeling and meniscal tears: a magnetic resonance imaging study in floor layers. J Rheumatol. 2009b;36(7):1512–1519. doi: 10.3899/jrheum.081150. [DOI] [PubMed] [Google Scholar]

- Seidler A, Bolm-Audorff U, Abolmaali N, Elsner G, knee osteoarthritis study group The role of cumulative physical work load in symptomatic knee osteoarthritis – a case-control study in Germany. J Occup Med Toxicol. 2008;3:14. doi: 10.1186/1745-6673-3-14. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Silverstein M. Ergonomics and regulatory politics: The Washington State cases. Am J Ind Med. 2007;50(5):391–401. doi: 10.1002/ajim.20437. [DOI] [PubMed] [Google Scholar]

- Spector JT, Adams D, Silverstein B. Burden of work-related knee disorders in Washington State, 1999 to 2007. J Occup Environ Med. 2011;53(5):537–47. doi: 10.1097/JOM.0b013e31821576ff. [DOI] [PMC free article] [PubMed] [Google Scholar]

- SPSS Base 19.0. SPSS Inc.; Chicago, IL: 2010. [Google Scholar]

- Stetson DS, Keyserling WM, Silverstein BA, Leonard JA. Observational analysis of the hand and wrist: A Pilot study. Appl Occup Environ Hyg. 1991;6(11):927–937. doi: 10.1080/1047322X.1991.10387994. [DOI] [Google Scholar]

- Thun M, Tanaka S, Smith AB, Halperin WE, Lee ST, Luggen ME, Hess EV. Morbidity from repetitive knee trauma in carpet and floor layers. Br J Ind Med. 1987;44(9):611–620. doi: 10.1136/oem.44.9.611. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Unge J, Hansson GA, Ohlsson K, Nordander C, Axmon A, Winkel J, Skerfving S. Validity of self-assessed reports of occurrence and duration of occupational tasks. Ergonomics. 2005;48(1):12–24. doi: 10.1080/00140130412331293364. [DOI] [PubMed] [Google Scholar]

- U.S. Bureau of Labor and Statistics, U.S. Department of Labor. Nonfatal occupational injuries and illnesses requiring days away from work, 2009. USDL report number: 10-1546. 2009 Retrieved January 30, 2012, from: http://www.bls.gov/news.release/osh2.nr0.htm.

- Village J, Morrison JB, Leyland A. Biomechanical comparison of carpet-stretching devices. Ergonomics. 1993;36(8):899–909. doi: 10.1080/00140139308967955. [DOI] [PubMed] [Google Scholar]

- Washington State Department of Labor and Industries. Evaluation tools. 2000 Retrieved January 30, 2012, from: http://www.lni.wa.gov/Safety/Topics/Ergonomics/ServicesResources/Tools/default.asp.

- Washington State Ergonomic Checklist. Retrieved October 24, 2013, from: http://www.ttl.fi/en/ergonomics/methods/workload_exposure_methods/table_and_methods/Documents/WashingtonStateErgonomicchecklist.pdf.

- Yen TY, Radwin RG. A video-based system for acquiring biomechanical data synchronized with arbitrary events and activities. IEEE Trans Biomed Eng. 1995;42(9):944–948. doi: 10.1109/10.412663. [DOI] [PubMed] [Google Scholar]

- Yuan L, Buchholz B, Dale AM. Knee disorders among carpenters in the St. Louis area. The Open Occupational Health and Safety Journal. 2011;3(Suppl 1-M4):31–38. doi: 10.2174/1876216601103010031. http://benthamscience.com/open/toohsj/articles/V003/SI0008TOOHSJ/31TOOHSJ.pdf. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.