Abstract

Quality problems occurring during or after sea transportation of bananas in refrigerated containers are mainly caused by insufficient cooling and non-optimal atmospheric conditions, but also by the heat generated by respiration activity. Tools to measure and evaluate these effects can largely help to reduce losses along the banana supply chain. The presented green life model provides a tool to predict the effect of deviating temperature, relative humidity, and CO2 and O2 gas concentrations on the storage stability of bananas. A second thermal model allows evaluation of the cooling efficiency, the effect of changes in packaging and stowage and the amount of respiration heat from the measured temperature curves. Spontaneous ripening causes higher respiration heat and CO2 production rate. The resulting risk for creation of hot spots increases in positions in which the respiration heat exceeds the available cooling capacity. In case studies on the transport of bananas from Costa Rica to Europe, we validated the models and showed how they can be applied to generate automated warning messages for containers with reduced banana green life or with temperature problems and also for remote monitoring of the ripening process inside the container.

Keywords: green life, fruit logistics, hot spot, banana ripening, container transport

1. Introduction

Bananas are one of the most important products in world agricultural trade. Although a high share of the world production is consumed locally in countries such as Brazil and India, the share of exported bananas summed up to 16.4 million tonnes in 2012 [1]. More than three-quarters of export bananas are grown in Latin America (13 million tonnes), and about one-quarter of the world exports are shipped to the European Union (4.5 million tonnes). The supply chain for bananas is currently undergoing important changes.

Although palletized bananas have been mainly transported on dedicated vessels in the past, the mode of transportation is now shifting to containers on third-party vessels. This mode allows a more flexible reaction to fluctuating market volumes. However, on the other hand, transportation through third-party vessels in rented containers can cause more quality-related problems, if inadequate care is taken to maintain optimal transport conditions. Because the owners no longer have direct access to the fruit during transportation, remote monitoring of transport conditions and quality changes becomes an important issue.

In the following, we present a case study on the transport of ‘Cavendish’ bananas from Costa Rica to North Europe by the company Dole Fresh Fruit as an example of the quality supervision of tropical fruits. Bananas are harvested ‘green’ approximately 14 weeks after emergence of the inflorescence. Bananas (18 kg) are packed into one box. Inside the box, the bananas are protected by a polyethylene bag to prevent dehydration. The bag either can have some small holes to allow penetration of a controlled atmosphere (CA) into the box, provided by the ship, or can be completely closed to generate a higher CO2 concentration and lower O2 concentration by respiration of the fruit.

Forty-eight boxes are stacked on each pallet (eight tiers of six), and 20 palletloads are stowed in each container. Transportation to the port takes about 4 h. Cooling starts after connecting the container to mains power in the port terminal, but it might be interrupted for a few hours during loading to the vessel. During the two weeks of transport to Europe, the bananas are cooled down from approximately 25°C to 14°C.

The port handling in Antwerp, Belgium, can take up to 4 days until the palletloads are stripped from the container and stored in a high bay warehouse. The palletloads are taken from the warehouse on the same or the following days and are forwarded by trucks to customers in northern Europe.

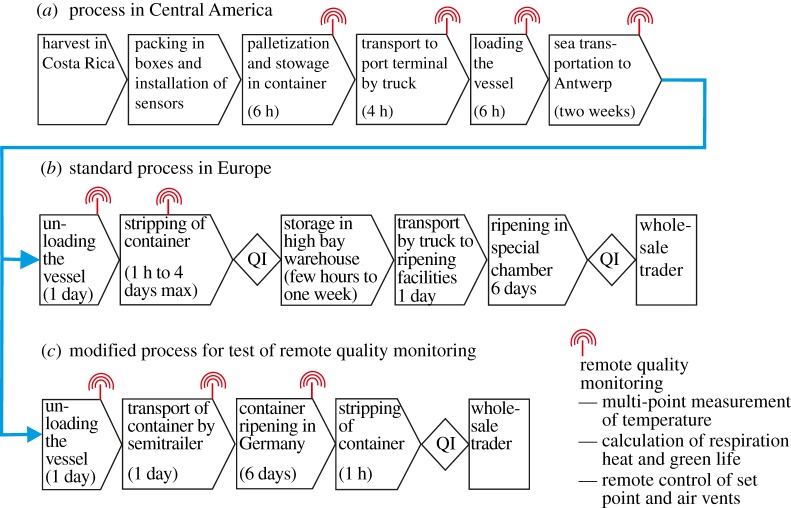

In our case study, we bypassed the warehouse handling and directly transported a test container by truck to the ripening facilities of Dole in Stelle, Germany. The ripening process was initiated by a technical ethylene gas treatment over 24 h. Cooling was continued over 5 days until the desired ripening degree with obvious yellowing but still dominant green colour was achieved. Figure 1 shows the structure of the cold chain for bananas as applied in our field tests.

Figure 1.

Simplified structure of the cold chain for bananas, from harvest to ripening by ethylene treatment, with typical duration of steps. (a) Process in Central America. (b) Standard process in Europe. (c) Modified chain for a test of our prototype system for remote quality monitoring. Steps with remote monitoring are marked. QI, points of manual/visual quality inspection. (Online version in colour.)

Bananas put high demands on the cooling equipment because of their high respiration activity. If premature ripening occurs, then the bananas can generate more heat than the cooling unit is able to remove, leading to creation of a hot spot. Furthermore, bananas are very sensitive to ethylene. The ethylene emission of one palletload in a poor-quality state can initiate spontaneous ripening of the full containerload. Quality problems become obvious at two inspection points along the transport and processing chain:

1. Before moving to the high bay warehouse, each pallet undergoes a visual inspection. The colour is checked though the ventilation holes of the boxes. If a certain number of boxes with signs of yellowing is detected, then the pallet has to be taken out of the normal process. Part of these so-called turners can be related to pathogen infections. However, most of the turners seem to appear randomly.

2. Sample boxes from different pallets are taken for further inspection after ripening. The boxes are opened, and the colour stage of individual bananas is evaluated. If the boxes of one pallet show large deviations in their colour stage, then the pallet will not be accepted by the customers.

Although the banana chain has already achieved a high standard and losses at these inspection points are only in the range of a few per cent, there is still high economical potential for further reduction in losses. Improved management of the supply chain requires more accurate and timelier information about changes in quality. An estimation of green life, giving the number of days until an unwanted spontaneous ripening will be triggered, can be considered as basic information for warehouse management. Information should be available in real time by remote access to the container during transportation. New remote monitoring systems, such as the prototype of our ‘intelligent container’ [2], will enable optimization of chain processes in several ways:

1. If a quality problem is detected before the vessel's arrival in Europe, then the farm can be informed. Besides searching for obvious problems such as careless stowage of the container, they can adjust the harvest age. Reducing the harvest age by one week extends the green life by 3–5 days [3], but at a cost of reducing the weight by 10%. If a quality loss is detected only after arrival, then two more ships carrying containers with similar quality problems will already be on their way to Europe.

2. If it can be foreseen that a number of containers will arrive in a poor quality state, then there is more time to organize replacements. This is especially crucial if the boxes were branded for a certain customer.

3. A prediction or at least a rating of green life enables a first-expired-first-out (FEFO) management. Containers with low green life can be prioritized for port handling. Palletloads which are at risk for spontaneous ripening can be sent immediately to nearby ripening rooms, whereas pallets with long green life can be held back for remote customers or intermediate storage.

Standard container tracking systems only provide a means for detection of power failures, technical problems and wrong adjustment of the cooling set point. Measurements of the cooling unit's supply air temperature tell very little about quality changes inside the palletloads. The development of a remote quality monitoring system for bananas requires the identification of adequate measurement principles and models to estimate the green life as well as provision of a means to measure the core temperature in different palletloads.

In the following section, we describe laboratory experiments that were carried out to determine factors influencing banana green life and present a model describing its dependency on temperature, humidity and atmosphere. In §3, we analyse temperature curves recorded in various field tests offshore and ashore and show how an automated warning system can detect a lack of cooling air, increased respiration activity and the resulting risk of hot spots based on core temperature measurements.

During our field tests, we found that it is too short-sighted to focus only on the detection of current cooling problems. General, long-term improvements in packaging and pallet stowage can make an important contribution to improving cooling conditions. The temperature measurement and modelling system proved to be a useful tool, to compare and evaluate modifications of banana box packaging and pallet stowage schemes. Packaging development and monitoring technologies have to go hand in hand to improve the food chain. By combining different modifications, we showed that it is possible to improve the cooling effect by almost 50% (§3c).

A sensor system is useful not only for monitoring the transport, but also for controlling subsequent processing steps. Currently, the ripening process is monitored by visual quality inspection and checking of temperature thresholds of four wired temperature probes. Our intelligent container prototype enables assessment of the progress of the ripening process by calculation of the respiration activity based on the thermal model and thereby provides valuable information if visual inspection is not feasible, e.g. when the bananas are still stowed inside a container or are on board a vessel. Our three field tests demonstrated the feasibility of remote monitoring and control of the ripening process inside a transport container (§3f). This will not only save costs ashore, but also save time by starting the ripening offshore a few days before the vessel's arrival.

Further sensor principles that can be used to receive a more detailed picture of processes inside the container, such as humidity, air flow, CO2 and ethylene gas sensors, will be briefly discussed in §3g. Section 4 closes with conclusions.

2. Green life modelling for bananas after harvest

Biological modelling of green life has to accomplish the following tasks. As a first step, a method has to be established to measure the current maturity stage of a fruit. Second, we have to evaluate how accurate a green life prediction can be in regard to variances we found in several laboratory experiments. During the third step, the influence of temperature, humidity and atmosphere on the green life is quantified. Finally, we have to consider the mutual influence of pallets inside one container by gas exchange, although we could not quantify this effect.

(a). Measurement parameters for banana ripening

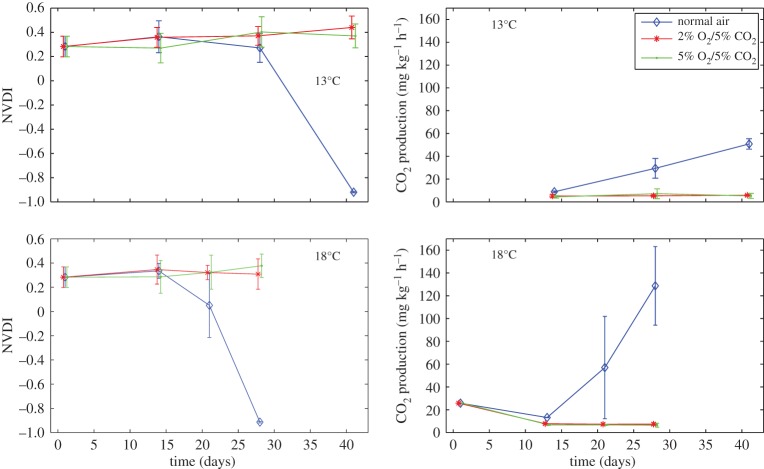

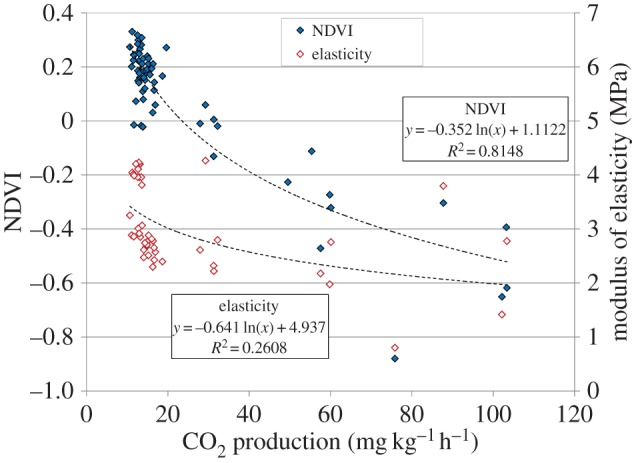

The change from the green life, also called pre-climacteric, to the climacteric ripening phase of banana fruits begins with autocatalytic ethylene production. Furthermore, the ripening phase is characterized by increased respiration, loss of chlorophyll, starch conversion to sugars, softening and production of aromatic compounds. To define the end of green life, we tested several non-destructive measuring methods. The normalized difference vegetation index (NDVI) was measured with a spectrometer (pigment analyser; Control in applied Physiology (CP) GbR, Falkensee, Germany). The NDVI indicates chlorophyll content in plant material [4,5] and is calculated by the relation between the red and infrared share of reflected light intensity I (I780 nm−I660 nm)/(I780 nm+I660 nm). CO2 production was determined in a closed system fitted with infrared sensors (FYA600; Ahlborn, Holzkirchen, Germany). Elasticity was measured with a texture analyser (TA.XT.plus; Stable Microsystems, Godalming, UK). Using CO2 production as the reference, because the increase appears simultaneously with the ethylene increase [6,7], the parameter NDVI seemed to be the most appropriate criterion for determining the end of green life for laboratory experiments. The decrease in the NDVI was well correlated with the increase in CO2 production (figure 2). As the limit value, NDVI<0 was defined for ripening fruits after the end of green life, which corresponds to ripening stage 2 of the commercially used colour scale from 1 to 7.

Figure 2.

Relationship between NDVI, modulus of elasticity and CO2 production of ripening bananas without ethylene treatment at 18°C storage temperature. (Online version in colour.)

However, for supervision of transport in a closed container, the measurement of the NDVI is less suitable, because, with optical methods, the ripening assessment could be realized only for individual fruits; on the other hand, testing for increased concentrations of ethylene or CO2 enables monitoring of the container as a whole for a—wanted or unwanted—start of banana ripening.

(b). Prediction of average green life

The target of a green life model is to predict how much the maximum storage period is shortened by deviations from the optimal temperature and atmospheric conditions. However, as a natural product, bananas are subject to biological variations. After defining the experimental set-up, we first evaluated the amount of these variations. In the second step, we evaluated the average period of time after which ripening starts without an external trigger.

(i). Experimental procedure for banana storage

Banana fruits harvested in Costa Rica and transported to Germany by Dole Fresh Fruit were used in order to investigate the effect of environmental conditions on the green life period. The effects of temperature, humidity and O2 and CO2 concentration were studied in a series of experiments with fruits from different shipments. The bunch age at harvest was chosen according to the common requirement for commercialization of between 12 and 15 weeks but was uniform in each shipment. The transport temperatures in the boxes were recorded during the shipment and following truck transport. After arrival at the laboratory, the individual fruits were separated from the hands, and the fruit stem end was wrapped in stretchable plastic film. To study the effects of humidity and atmosphere (O2 and CO2 concentration), the banana fruits were stored either in glass jars (three fruits per jar) with specific opening cross sections to regulate the atmosphere or in storage containers with CA. The last CA storage experiment in spring 2013 was carried out with green ‘Cavendish’ bananas from Colombia (Fyffes Company), which were bought wholesale and stored as clusters of about five fruits. Storage conditions were

— a temperature range between 12°C and 30°C with high humidity (98%) and normal air for green life evaluation and a temperature range between 5°C and 11°C for observation of chilling injury which causes subepidermal discoloration of the fruit peel. We rated the externally visible greyish-brown areas;

— relative humidity between 50% and 98% at storage temperatures of 15°C and 18°C; and

— elevated CO2 concentration (up to 5%) and low O2 concentration (down to 2%) at temperatures of 13°C, 15°C and 18°C.

The effect of fruit position in the bunch was considered by separating the physiologically older fruits at the top of the bunch (hands 1 and 2) and the younger fruits at the bottom (hands 6 and 7).

Besides NDVI measurements twice a week for the determination of the end of green life, for fruits which had been stored in low temperature less than or equal to 11°C a visual rating of peel browning symptoms was done.

(ii). Variation of green banana storability

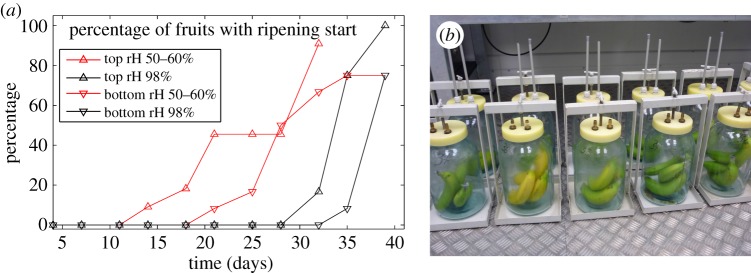

The green life period of the banana fruits varied clearly between the samples of 12 single banana fruits stored in four glass jars in the same environment. As an example, figure 3 shows the period from the ripening start of the first fruit of a sample to the ripening start of the last fruit, which sometimes took up to two weeks.

Figure 3.

Percentage of fruits (n=12) with beginning ripening (yellowing) after storage at 18°C in different humidity conditions and bunch position top/bottom (a) in glass jars in a cooling chamber (b).

Also between fruits of different shipments green life under uniform storage conditions varied greatly (table 1). The ripening parameters elasticity and NDVI measured at the beginning of the test partially reflected these variations in storability, e.g. the fruits with the longest green life at 18°C of 44 days in addition to the 14 days of container transportation (April 2011) showed a high NDVI and a high modulus of elasticity compared with the fruits which arrived in January 2011. One reason for this long storability of the fruits in April 2012 might be the low average transport temperature of 14.2°C. Fruits with a short green life lost weight faster than fruits with a long green life. In addition, differences in transport atmosphere (CO2 and O2 concentration), which unfortunately were not documented, had an influence on storability after transport.

Table 1.

Green life period and fruit properties of bananas from different shipments.

| experiment start | June 2011 | August 2011 | January 2012 | February 2012 | March 2012 | April 2012 | March 2013 | |

|---|---|---|---|---|---|---|---|---|

| bunch age at harvest (weeks) | 14 | 12 | 13 | 13 | 13 | 13 | — | |

| average cooling time to 15°C at transport start (h) | 38 | — | 75 | 50 | 58 | 40 | — | |

| average transport temperature (°C) | 15 | — | 15 | 14.5 | 15 | 14.2 | — | |

| green life (days) 18°Cb | 20±2 | 11±8 | 28±3 | 34±3 | 39±14 | 44±9 | 21 | |

| daily weight loss (%) 18°C | — | — | 0.13 | 0.09 | 0.05 | 0.03 | 0.1 | |

| NDVI | 0.45±0.1a | 0.30±0.1a | 0.21±0.1 | 0.18±0.2 | 0.5±0.1 | 0.31±0.1 | 0.28±0.1 | |

| modulus of elasticity (MPa) | — | 4.6±0.6 | 3.7±0.4 | 4.3±0.3 | 4.4±0.4 | 5.7±0.6 | 3.4±0.4 |

aScale of the spectrometer (pigment analyser) changed after August 2011 because of revision of the device.

bFourteen days of transport from Costa Rica to Germany have to be added to calculate total green life.

Besides the transport environment and maturity at harvest [3], the cultivation conditions also have an impact on the post-harvest green life period of ‘Cavendish’ bananas. Bugaud et al. [8] found 8–9 days shorter green life of fruits harvested in the wet season in summer than in the dry season in winter, but there was no correlation with the physiological age of fruits at harvest or with the recorded climatic parameters. They assumed that the reason for reduced green life of fruits grown during the wet season is the higher incidence of Sigatoka, a fungal disease which provokes necrotic lesions on the leaves. The green life-reducing effect of Sigatoka disease has also been shown by Castelan et al. [9]. Furthermore, we assume that climatic conditions in winter and spring (2012) had a positive influence on the green life after harvest of the bananas for these experiments compared with the bananas harvested in summer (2011).

(iii). Effect of temperature, humidity and atmosphere on green life period

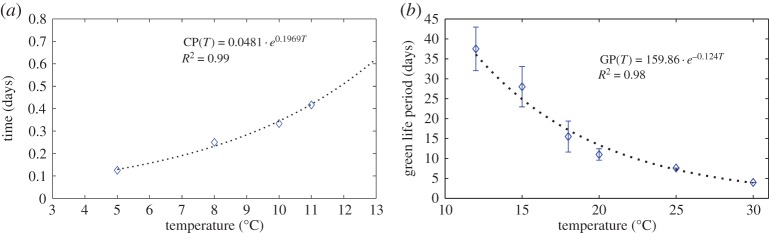

As the variation in banana green life differed between the banana samples the effects of temperature, humidity and atmosphere are presented separately and could not be integrated into one model involving all environmental factors. We found an exponential function for the relationship between storage temperature T and the average green life period GP for the temperature range between 12°C and 30°C (GP(T)=159.86·e−0.124T) in normal air. At an optimal storage temperature of 13–14°C the green life period lasts about 30 days after the shipment with GP(13°C)=31.9 days. Per 10°C temperature increase, the green life is reduced by a factor of Q10=3.46. Green life decreases to one week at a storage temperature of 25°C.

A similar green life period was found by Bugaud et al. [8] with 42–50 days for bananas from different production sites when we include the transport time of 14 days for our tests. After a few hours exposure of the green banana fruits to low temperature, the peel colour was affected by slight chilling injury symptoms CP before or after yellowing. This relationship between temperature and time needed to induce chilling symptoms CP was also exponential CP(T)=0.0481·e0.1969T (figure 4).

Figure 4.

Time–temperature relationship for (a) the time required for appearance of peel browning at 5–12°C and (b) the green life period (12–30°C) of green bananas harvested in June 2011. (Online version in colour.)

For banana storage, high relative humidity of 90–95% is recommended [10]. Experiments in spring 2012 showed that the average green life period of fruits stored in low relative humidity (50–60%) was about one week shorter than after storage under 98% humidity (table 2). George et al. [11] supposed that water stress induces ethylene production, which causes earlier climacteric respiration rise.

Table 2.

Green life of bananas harvested in spring 2012 and stored under different relative humidity (RH) and CO2 concentration.

| experiment start |

February 2012 (effect of RH) |

March 2012 (effect of elevated CO2) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| humidity atmosphere |

RH 50–60% normal air |

RH 80% normal air |

RH 98%<2% CO2 |

RH 98%<2% CO2 |

RH 98% 5% CO2 |

|||||

| bunch position | top | bottom | top | bottom | top | bottom | top | bottom | top | bottom |

| 15°C | 42±4 | 44±5 | 37±5 | 46±8 | 48±2 | 50±0 | 57±1 | 58±5 | 61±2 | 62±9 |

| 18°C | 23±7 | 29±7 | 28±4 | 30±9 | 32±2 | 36±2 | 30±4 | 48±14 | 49±17 | 51±14 |

The fruits of the tests in 2012 for the effect of humidity and elevated CO2 concentration showed overall much better storability than the fruits of the temperature experiments in 2011 (tables 1 and 2). Elevated CO2 concentration (5%) in the storage vessels led to an increase in average green life of 4 days at 15°C and 11 days at 18°C compared with storage under an atmosphere with low CO2 concentration of less than 2%. Some tests showed prolonged green life for the less mature fruits from lower banana bunch positions compared with the fruits at the top of bunches (table 2), but this effect of bunch position was not consistent in several experiments over the year.

A high CO2 concentration of 5% and additionally a low O2 concentration of 2% or 5% significantly delayed ripening of green pre-climacteric fruit at temperatures of 13°C, 15°C and 18°C. Fruits stored in these CA conditions did not show increased respiration and chlorophyll loss at 18°C up to four weeks and at 13°C up to six weeks and thus showed prolonged green life compared with normal air storage of two weeks (figure 5). We could not prolong the experiment because of slight mould occurrence on the fruits.

Figure 5.

NDVI and CO2 production of fruits in normal air after storage under a controlled atmosphere at temperatures of 13°C and 18°C. (Online version in colour.)

These results support recommendations of O2 and CO2 concentrations for green banana storage in a range of 2–5% [12,13]. Nevertheless, a decrease of O2 down to 2% before ethylene treatment can result in inferior banana aroma owing to inhibited volatile ester formation [14]. After CA storage under 3% O2, the difference from normal air-stored bananas could not be perceived by the consumers after ripening [15]. An understanding of the mode of action of increased CO2 and decreased O2 on the metabolism of bananas after harvest is still incomplete. Besides an effect on ethylene action and synthesis, modified atmospheres (MAs) can also cause an increased level of ethanol in fruit tissue, and this might delay ripening [16].

The ripening inhibition effect of CA conditions depends on the ripeness stage of the fruits. We carried out a CA experiment with fruits at slightly advanced ripeness stage 2–3 with comparatively low NDVI (0.13±0.2) and low modulus of elasticity (2.9±0.4) when the experiment started. Low O2 and elevated CO2 concentration (2%/5%) delayed the onset of climacteric respiration and yellowing, e.g. at 18°C up to two weeks and at 13°C and 15°C up to five weeks. Probably, the ethylene synthesis by the fruits had progressed too much, especially at the high temperature of 18°C, so that the ripening process could not be delayed in the same manner as with green fruits at stage 2.

All the tested environmental factors temperature, humidity and atmosphere have an important impact on the green life period of harvested banana fruits. Under stable storage conditions (14°C, humidity in the polyethylene bags of more than 95% and CO2/O2 concentrations of 5%) the average green life of our tested fruits exceeded one month and so premature ripening should not occur during a three-week transport time. However, in these laboratory investigations, we did not consider ethylene effects, which might have an important effect on fruit ripening during transport in a container as discussed in the following section.

We found a high variation of green life between fruits transported in different containers at almost similar temperature conditions. But even within the same container there is a variation between ±2 and ±14 days. Therefore, the physiological produce status determined with additional parameters other than elasticity, respiration and NDVI should be taken into consideration at the beginning of the transport for an exact prediction of green life.

(c). Mutual influence on ripening by autocatalytic ethylene effects

Banana fruits are very sensitive to ethylene. The response depends on fruit maturity, exposure time and temperature. At 15°C, ripening of green ‘Cavendish’ bananas is initiated in air with 0.1 ppm ethylene for 2 days. At 20°C with 0.1 ppm ethylene, fruit ripening is initiated already after 20 h [17]. The start of ripening is accompanied by an increase in ethylene production from 0.15 μl kg−1 h−1 to 5 μl kg−1 h−1 at 15°C [12], thus leading to an autocatalytic effect as the following example calculation shows: one 18 kg box of yellow bananas produces within 2.2 days sufficient ethylene to increase the concentration in the whole container with a free air volume of 47.4 m3 to a critical threshold of 0.1 ppm, if the air flaps are closed, and no ethylene is released to the ambient.

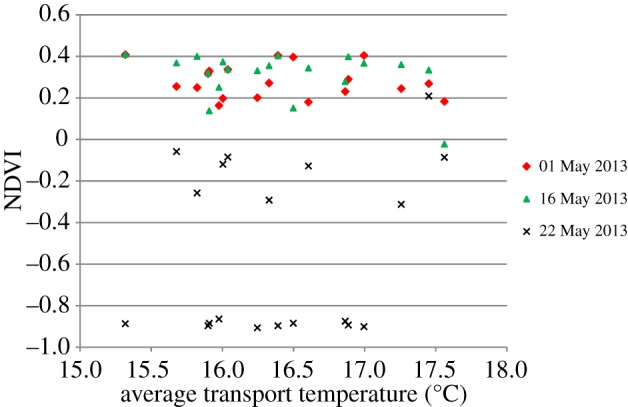

Temperature has a small effect on ethylene production of green bananas in the range of 0.1–0.3 μl kg−1 h−1 [12]. Elevated CO2 concentration and low O2 concentration under CA or MA conditions lead to a lower production rate and also lower sensitivity [18]. The ethylene production of single fruits can increase owing to mechanical stress or fungal infections. The autocatalytic effect has to be considered for the whole containerload and not individually for single boxes, because the polyethylene packaging is semi-permeable to ethylene gas. The autocatalytic ethylene synthesis process dominates the effect of moderate temperature differences between the palletloads during transport. During the laboratory experiments, we could verify the influence of deviations in the environmental conditions on the green life, if the fruits were stored in different jars. But, we could not find any correlation between moderate variations in average transport temperature (15.3–17.5°C; figure 6), and bunch position (bottom/top) with the remaining green life at the end of a two-week transport in the same container. Therefore, in the case of moderate temperature deviations, green life prediction is feasible only for a container as a whole and not for individual palletloads. The observation that only single fruits or hands turned yellow in a box at the end of the transport might be due to the fact that there was insufficient time to initiate ripening of the neighbouring fruits.

Figure 6.

NDVI change of banana fruits during three weeks after arrival in Germany (1 May 2013) at 18°C storage temperature with average container transport temperatures in a range of 15.3–17.5°C without ethylene treatment. (Online version in colour.)

Although knowing the average temperature is sufficient to calculate the green life in most cases, local temperature deviations have to be measured in order to detect hot spots. The much higher temperature in a hot spot leads to short green life, and thus strong temperature deviations cause different ripening behaviour of the fruit in one container. Palletloads with a hot spot should be separated as soon as possible in order to avoid accelerated ripening of the neighbouring fruits.

If the feedback loop of the autocatalytic process is interrupted, then green life is prolonged. Ketsa et al. [19] showed that the storage life of green bananas in cardboard boxes under an MA at 14°C can be extended to 100 days by adding 1-MCP, which inhibits ethylene action, compared with 40 days under an MA without 1-MCP treatment. On the other hand, the onset of the feedback process is hard to predict, because the process is triggered by small changes in the initial conditions of the fruits after the harvest. At present, no instrument to predict spontaneous ripening is available, so we are only able to measure the effects by higher heat generation and higher CO2 and ethylene concentrations and to assess risks such as deficient cooling.

More detailed data on the effect of ethylene in closed containers are currently not available, mainly because, currently, there is no mobile ethylene sensor system available that enables measurement of concentration changes during sea transportation.

3. Measurement and modelling of temperature dynamics

The choice of sensors for automated quality monitoring during transportation inside a closed container is very limited. Some methods require mechanical handling and are destructive, such as measurement of sugar content (Brix value) [20]. Others methods require that a measurement device is attached to a single fruit, such as for optical parameters (NDVI, hue–angle for peel colour [7]) or firmness, and thereby fail to provide a representative value for the whole box or palletload. Sensors can either be dedicated to measure an average value for the whole containerload, for example by measurement of gas concentrations, or they can be installed in separate boxes or palletloads to detect spatial deviations. For the latter applications, the choice of sensors is additionally limited by size, energy supply and cost considerations to standard sensors such as temperature and humidity. As a first step for planning of a monitoring system, we therefore ask: how much information can be retrieved from temperature curves measured at multiple points inside the container?

Three tests for sea transportation and several tests ashore were carried out between 2011 and 2013 in our prototype ‘intelligent container’. The container was equipped with a new Thermoking magnum plus cooling unit with a nominal cooling capacity of 16.6 kW at 21.1°C and a fan capacity of 5480 m3 h−1 at 50 Hz power supply in an empty container [21]. Temperature measurements were taken by a set of 20 wireless sensors and additional iButton [22] data loggers. Technical details of the wireless sensor network and remote access by telematics are described in a separate article [2]. Additional temperature records were available from earlier tests with three containers with an age of 2, 3 and 12 years [23].

Quality changes are related to pulp temperature. But, continuous measurements of pulp temperature are not feasible, because the banana would be injured by the probe, and therefore react differently from other fruits. Alternatively, we measured the air temperature in the centre of the box. Random samples showed that the pulp temperature is between 0.2°C and 0.5°C higher than the air temperature.

The boxes are stacked eight tiers high on each pallet. The cooling air is supplied from the floor (tier 1) and eventually warms up along its way through the palletload. The top tier (number 8) is additionally cooled by the flow of the return air. The highest temperatures were found in the centre of the palletloads between tiers 5 and 7.

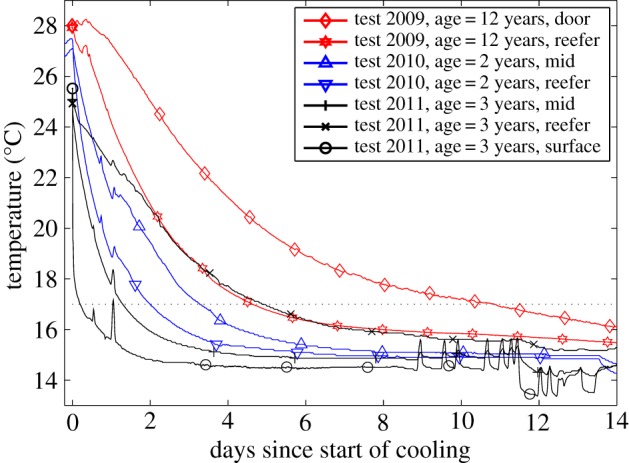

Figure 7 shows some sample cooling curves during sea transportation in three different containers. From the curves, we can learn the following:

— the speed of the cooling process depends largely on the quality and age of the cooling equipment. The 12 year old container required more than double the time to cool down to 17°C. In the worst case, even after two weeks of cooling, the temperature was 2.2°C above the set point of 13.9°C. Especially if the supply chain depends on containers rented from third-party companies, then the quality of the equipment has to be checked;

— there is no preferred location for the hottest point inside the container. During the three tests, it was found at the door end, the machinery end or in between;

— newer equipment cools faster, but local deviations in cooling performance are still present; and

— sensors on the surface of the palletloads react very rapidly to changes in the supply air temperature. They can be used to verify the distribution of air flow in the container, but the pulp temperature cannot be directly deduced from them.

Figure 7.

Temperature course during cooling in containers of different age. Two sensors in the centre of the boxes in tier 5 or 6 were selected from the dataset of each test representing the positions with the slowest and the fastest temperature decline. (Online version in colour.)

In the following, we look in detail at the causes of local temperature deviations inside the container. There are several reasons why it is not feasible to make a quantitative evaluation by direct comparison of the curves: the boxes have different initial temperatures; the set point also varies and might be changed several times during transport. A direct fit with a single exponential decline function also fails.

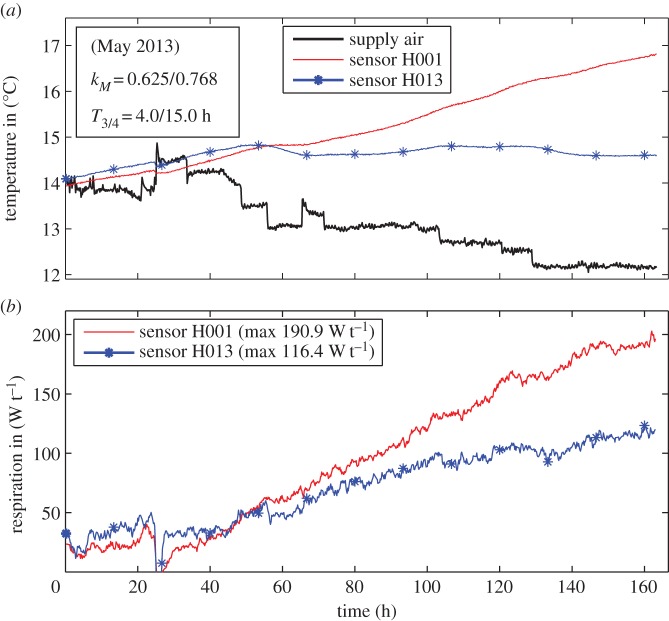

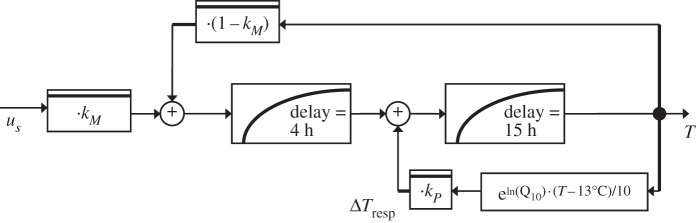

Furthermore, the course of temperature changes can only be understood if not only heat removal by the unit is considered, but also the heat generated by respiration. We found that the model presented in figure 8 provides a good fit for curves measured offshore as well as for tests ashore, in which we were only allowed to modify the set point between 13°C and 16°C.

Figure 8.

Dynamic temperature model for air temperature in the centre of the boxes [24]. kP, proportional factor for heat generation by respiration; kM, input gain factor to describe cooling efficiency.

The model predicts the air temperature T in the centre of a box as a function of air supply temperature uS and two box-dependent parameters kM and kP. The temperature dependency of the respiration activity is described by a Q10 model. Q10=3 is the factor by which the activity is increased for a temperature change of 10°C. A proportional factor kP summarizes the influence of atmosphere and current ripening state of the bananas in one box. The time behaviour is modelled by a series of two delay elements. Because the thermal mass is identical for all boxes, the time constants were set to fixed values of 4 and 15 h. Differences in the efficiency of cooling were modelled by a variable input gain kM. Details of the model can be found in [24]. kP depends only on the maturity state of the fruit and varies only a little for one containerload of fruits with the same origin, except for the case of premature ripening in part of the boxes. kM depends mainly on box design, but also shows a variation inside one pallet- or containerload owing to local effects such gaps, chimneys and blocking by neighbouring boxes.

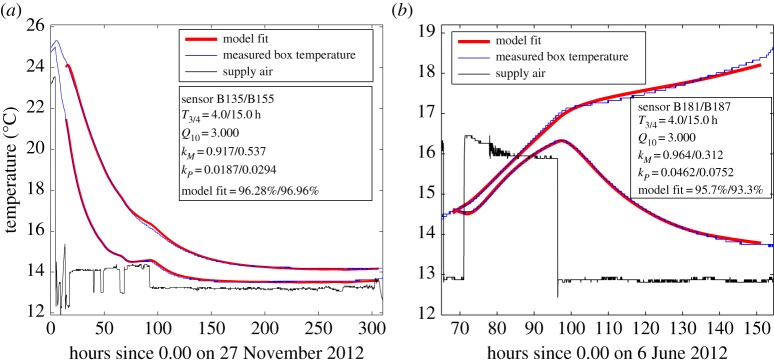

Figure 9 shows sample temperature curves recorded in our prototype container during sea transport and a simulated set-up ashore. The parameter kM for local cooling efficiency varied between 0.312 and 0.964 with higher values standing for fast cooling. In all cases, a satisfying fit between model and measured values was achieved.

Figure 9.

Comparison of measured temperatures with model fit. (a) Offshore and (b) ashore. (Online version in colour.)

During the preparations for the test ashore, four palletloads were stored in the warehouse of the ripening facilities for 2 days and thereby mistakenly exposed to ethylene. Their respiration rate increased by 68%. The air flow at the side of one of these pallets was inhibited by pressing it close to the container wall. The rate of cooling was 43% less than the average value. The coincidence of these two factors led to a situation in which more heat was produced by respiration than could be removed by cooling. Figure 9b shows a typical temperature curve for such a hot spot.

(a). Contributors to thermal balance

Temperature-related problems are mainly caused by an imbalance between generated and removed heat. In order to analyse such situations and to predict related risks, we developed a method to separate these two contributing factors from the measured temperature curves.

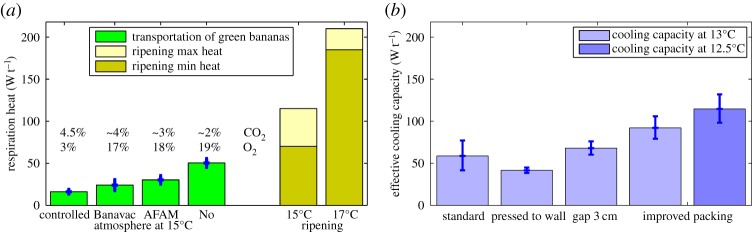

In the first step, the two model parameters kP and kM are estimated by use of the Matlab system identification toolbox. The temperature change ΔTresp caused by respiration activity can be directly calculated by the Q10 dependency to the current box temperature T. The generated heat that caused this temperature change can be calculated as Presp=CB·ΔTresp in the unit of watts per tonne with CB=930.5 Ws K−1 t−1. The factor CB includes the thermal capacity of bananas of 3350 J K−1 kg−1 and a conversion from hours to seconds. Figure 10a shows calculated values for different atmospheric conditions. The CA is achieved by connecting the container to a nitrogen supply provided by a generator on the vessel. An MA can be achieved either by packing the bananas in a particular thickness of polyethylene (Banavac [25]), leading to increased CO2 in the bag, or by an automated fresh air vent control of the container. With a CA, the respiration activity can be reduced to 16 W per tonne at a reference temperature of 15°C, in a similar range given by Stewart et al. [26], who found for green bananas a respiration reduction of 60% under 3% O2 and 3.5% CO2 compared with normal air at 15°C.

Figure 10.

(a) Respiration heat for different atmospheric conditions. (b) Heat removal for different packing conditions. Values are related to a box temperature of 15°C and an air supply temperature of 13°C, unless stated otherwise. (Online version in colour.)

If the bananas start ripening, either spontaneously or under control, the heat production increases dramatically. At a temperature of 15°C, the respiration activity can increase by a factor of 7 compared with green bananas under CA conditions. The generated heat can increase to more than 200 W per tonne, if the cooling unit fails to maintain a temperature of 15°C. Ripening chambers ashore are therefore equipped with more powerful cooling units and fans. The technical challenges are high to provide sufficient cooling with the limited resources of a transport container.

The calculation of heat removed by cooling is not as straightforward as that of the respiration heat because it depends on the box and supply air temperature as well as on the dynamic behaviour of the two delay elements in the model. We considered the data from the sea transportation test in 2011 in a 3 year old container without any modifications in packaging and stowage as the reference set-up. The average kM value of 16 sensors in tier 5 of nine pallets was estimated to be 0.524±0.151. The change in temperature caused by the local cooling effect ΔTcool can be calculated by subtracting ΔTresp from the total temperature change ΔT. In order to compare and summarize the three experiments, we had to compensate for the effect of deviating set points. Therefore, the data from the experiments were recalculated for reference conditions (uS=13°C) by model simulation with the previously identified kM and kP values. ΔT was read from the curve for the point of time when T arrives at 15°C. Multiplication by CB resulted in an average effective cooling capacity of 58.7 W per tonne at 15°C.

If airflow is blocked, local cooling is hindered. In a test ashore in January 2012, we deliberately pressed four pallets to the side wall of the container, resulting in a poor kM value for the boxes beside the wall of 0.322±0.032, or in terms of power 41.6 W per tonne. The remaining gap at the other side of the container led to a better cooling with 68 W per tonne.

(b). Improvements in packaging and stowage

Although the nominal cooling capacity of our container is specified as 16.6 kW, the actual removed heat is only about 58.7 W per tonne or 1 kW for a full container load of 17.6 tonnes of bananas. Owing to the dense packing of bananas, the static pressure increases clearly, and only a small proportion of the air flow actually arrives at the fruits. The high sensitivity of bananas towards chilling injuries (figure 4) prohibits lowering the set point below 13°C to increase the heat transfer. But, the large disproportion between nominal and efficient cooling capacity leads to the assumption that better cooling is possible by improved packaging and stowage.

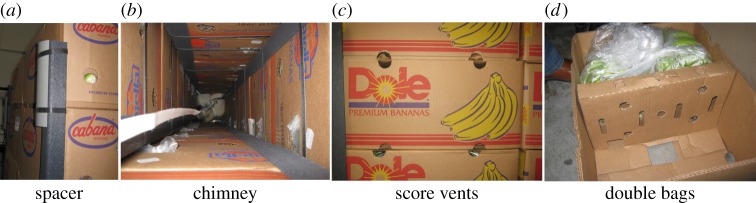

As a first measure to avoid the negative effect of closed gaps, we installed spacers between pallets and the wall in the subsequent tests in 2012 (figure 11a). Because the pallet size does not ideally match the container's interior dimensions, an empty ‘lost’ space of approximately 0.25 m2 cannot be avoided, which is normally left over at the door end. In order to make best use of this space, we arranged four pallets each in a pin-wheel [27], forming a chimney of 0.22×0.22 m width in the centre (figure 11b). The top of each of the five chimneys was closed with a foam block. The chimneys enhanced the air flow between the pallets. In mid-2012, Dole changed the box design. The new so-called score vent boxes had eight additional ventilation holes with a diameter of 3.5 cm at the four edges (score lines) of the long side of the box (figure 11c). Because we had only one test with both types of boxes in the same container, we can give only a rough estimation of the advantage of the new box design to improve the cooling by approximately 15%.

Figure 11.

Modifications in packaging and stowage. (a) Spacer; (b) chimney after removing foam block. (c) Score vents and (d) double bags.

During the last two sea transportation tests in November 2012 and April 2013, we also modified the packing of bananas inside the boxes. The bananas were packed in two polyethylene bags, separated by a cardboard spacer with a diameter of 4.5 cm (figure 11d). This new channel provided a much better vertical air flow through the boxes. The kM value was improved by 13.7% compared with single bags to 0.781±0.098 or 92.1 W per tonne (figure 10b). However, the improved cooling has to be paid for by a loss of packing capacity of about 4%. In total, the combination of all four measures led to an improvement of more than 50% compared with the reference test from 2011.

(c). Approach for an automated warning system

A logistics company, handling 1000 or more consignments per day, can devote only limited time to a single container. Visual inspection of temperature curves is hardly feasible. The preferred solution consists of a traffic light indicator per container, showing whether the container is in the proper state (green), needs detailed inspection or rescheduling of the transport planning (yellow) or will probably not arrive at the customer in an acceptable quality state (red).

The above-described modelling of heat transfer enables the retrieval of more detailed information from measured temperature curves in the box centre than a simple threshold checking does. The parameters kM and kP can be estimated by curve fitting of the measured temperature curve with the model given in figure 8 with the help of system identification techniques. In our last sea transportation test, we were able to show that the mathematical estimation process can be directly handled by the container. The identification by the Matlab toolbox was replaced by a JAVA program. The code implements an incremental form of the algorithm and can therefore efficiently run on an embedded system. Only a few matrix operations are necessary to update the estimation after arrival of each new temperature measurement. If the new measurements lead to a significant change in the estimated model parameters, then the container automatically sends an update message over the external communication system. Full temperature records are transmitted only on request or if a severe problem occurs. The data volume and costs for satellite communication can thereby be reduced to a few messages.

The accuracy of the estimation increases with the number of measurements. A simulation with recorded data showed that 10% accuracy is reached for kM after 4 days and for kP after 7.5 days after the vessel's departure. Information about cooling problems and suspicious respiration activity can be made available one week ahead of arrival in Europe.

A high kP value indicates a higher biological activity and finally the beginning of spontaneous ripening. A low kM value indicated a deficient cooling of a palletload, which is most likely caused by poor stowage. The coincidence of both factors leads to a high risk for a hot spot, in which the emitted ethylene can finally trigger ripening in the whole containerload. The generated and removed heat per tonne can be calculated according to §3a.

A high variation in maturity of bananas inside one container can also be detected by the variance of the kP value. This can lead to an uneven quality after ripening, and such containers should be handled separately

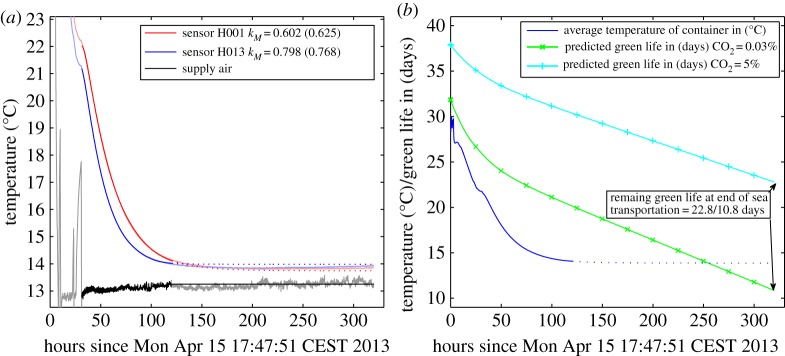

(d). Combination of thermal and biological model

If no critical states or risks for spontaneous ripening are detected, as described in §3c, the measurements can be used to prioritize containers on the basis of the remaining green life. The temperature curve is taken as input for the green life model. The loss of green life per time unit is calculated as a function of current temperature based on the equation given in §2b(iii) and stepwise subtracted from the initial green life value of freshly harvested bananas. In the example in figure 12b, the model calculation results in a remaining green life of 22.8 days under an MA with CO2=5% and 10.5 days under a normal atmosphere at the end of the sea transport.

Figure 12.

Example for green life calculation. (a) Prediction of temperature by a thermal model for two sensors (H001 and H013). Light colours, measured values; bold lines, range for identification; dotted lines, prediction by thermal model. (b) Gradual decline of green life during transport.

Although the main purpose of our model is to calculate cooling and respiration as separate factors, the model can also be used to predict the ‘missing’ part of the temperature curve several days before arrival in Europe. The kM and kP values for two example sensors H001 and H013 in figure 12a were identified based on the temperature measurements of the first 5 days of transport (bold lines). The sensors were placed in tier 7 of two different palletloads. At this point of time, the estimated kM values deviate slightly from the final values given in brackets. The temperature curves for the remaining 8 days were simulated based on the model in figure 8, and the assumption that the supply air temperature uS remains on the last measured value.

As shown in §2b(ii), the resulting green life value can only be taken as the average for the whole containerload, owing to the influence of biological variance and other unknown factors. Because of the mutual influence of the bananas inside one container by the exchange of ethylene, we recommend the use of average values for kM and kP for green life prediction. For individual boxes, a standard deviation of typically ±5 days has to be taken into account.

(e). Remote monitoring of container ripening

After triggering the ripening process by exposing the pallets to a high concentration of ethylene over 24 h, the conversion from starch to sugar starts with a gradual increase of respiration heat over the next 5 days.

The advancement of the ripening process can be evaluated by two means: by opening of sample boxes and repeated visual inspection and by analysis of temperature curves in the closed container. Although the first approach cannot be applied for a closed container, the second one is supported by detailed spatial temperature measurements and the thermal model.

An upward curvature indicates the start of the ripening process with increasing respiration activity. For a constant set point value, this can be directly deduced from the temperature curve. But if the set point is modified to compensate for higher heat production, mathematical tools are required to quantify the respiration of single boxes.

Because the respiration heat is no longer only a function of current temperature, but also of time, the model has to be adapted. The contribution of the respiration heat to temperature changes ΔTresp is considered as a further unknown state variable of the dynamic system. If the pallets are still in the same position inside the container as during the transport, the parameter kM can be set to the value which was identified from the transport temperature curve. With the measured system input uS and output T, the unknown state can be estimated by the Kalman filter [28]. Figure 13 shows an example for temperature curves measured during ripening after our last test in 2013 and the calculated ripening heat.

Figure 13.

(a) Example of a temperature course during ripening for two example sensors. (b) Calculated respiration heat. (Online version in colour.)

As long as a temperature of 15°C is maintained, the generated heat stays between 70 and 115 W per tonne. At a set point of 13°C, the cooling unit can remove 92.1 W per tonne, if all four described measures are applied to enhance the air flow. Additionally, the set point can be lowered to 12.5°C during the last 2 days of ripening, when the heat generation is at the highest. This is possible because bananas are less sensitive towards chilling injuries after the ripening process has fully started. By this measure, the heat removal could be increased to 114.6 W per tonne, which is sufficient to keep the process fully controllable. Furthermore, it is possible to select only those containers with high kM values for direct ripening. Containers for which a low cooling efficiency had been detected during transport should be stripped, and ripening should take place in dedicated chambers ashore.

During our third test for container ripening in May 2013, with all four measures to improve the airflow applied, 80% of the boxes had an end temperature below 16°C after ripening. After 60 h, the temperature of H013 in figure 13 stabilized at 14.7°C, but the produced respiration heat continued increasing owing to the progress of ripening. The warmest box (H001) with a kM value far below the container average had an end temperature of 16.8°C. Although temperature control was no longer possible for a few boxes, they did not show quality deviations.

The feasibility of container ripening could be verified during three tests with eight pallets each. Only during the first test, without modifications of the packing inside the boxes, did the bananas have to be removed from the container one day earlier than planned, because the temperature increased above 17°C in some pallets, and cooling was no longer possible. During the last two tests, a good and even quality was achieved after 6 days of ripening. But, the high temperatures measured in some boxes during our last test indicate that there is still a small risk that the process can run out of control. Therefore, further tests are required before container ripening can be applied in daily business.

(f). Additional sensors

As mentioned above, the choice of sensors which can be applied additionally inside a closed container is limited for practical reasons. The sensors must not damage the fruit and sensors for wireless multi-point measurement have to comply with cost and energy restrictions. Basically only temperature, humidity and air flow sensors are suitable for wireless applications.

A miniaturized thermal flow sensor was integrated onto a standard wireless sensor node platform [29] and tested in our container. The micro-fabricated sensor [30] has no moving parts and very low power consumption. The sensor works on the principle of voltage difference between two thermopiles. The heat dissipation profile of a heater element, mounted between the thermopiles, is disturbed when air passes over the sensor membrane.

Although too low humidity can cause weight loss and premature ripening (§2(b)iii), such problems are seldom reported in practical transport business. Humidity sensors are therefore less important for monitoring banana transportation. The humidity inside the boxes was always above the recommended threshold of RH=85% [31] for Banavac packing as well as for perforated bags for MA or CA transports. The humidity increased up to RH=99% until the end of the transport.

Gas sensors are less suitable for multi-point or wireless measurement owing to costs and energy consumption. The latter is caused by the required heating of the sensor element to 200°C or 300°C, except for optical CO2 sensors. Furthermore, gases such as CO2, O2 and ethylene intermix quickly inside the container owing to the high air exchange rate of 100 circulations per hour. Because gas production rates can only be measured in a closed volume, the air vents have to be closed during measurement. This needs the presence of a remote interface and an air vent control system which are available in modern reefers.

The rate of CO2 production is an important indicator for the physiological state of the bananas and for the onset of unwanted spontaneous ripening. In laboratory experiments, we measured CO2 rates between 12 and 18 mg kg−1 h−1 for green bananas in a temperature range between 14°C and 18°C in normal air and up to 180 mg kg−1 h−1 during ripening at 18°C. During sea transportation under an MA, we measured a rate of only 4.5 mg kg−1 h−1.

Ethylene has a large impact on autocatalytic reactions, as shown in §2c. But, currently there is no mobile device that provides the requisite high resolution of less than 0.1 ppm. Although we showed that it is possible to detect such low concentrations with a compact and mobile device in laboratory experiments [32], we could not finally handle all the technical problems of installing the device in our intelligent container for measurement during sea transportation.

4. Summary and outlook

Losses in the banana transport chain can be reduced by extending the green life by optimized transport conditions and by provision of tools for remote monitoring and prediction of green life changes. The implementation of new management processes, which are based on the actual—measured or predicted—quality, has to go hand in hand with general improvements in the chain processes.

Green bananas in the pre-climacteric phase, indicated by the optical indicator NDVI>0, proved to be a very stable product. The importance of adequate cooling and of modified (MA) or CA conditions was verified during our laboratory experiments. MA with increased CO2=5% extended the green life by one week. CA with additionally decreased O2=2% led to an extension of more than two weeks compared with normal air storage. Lowering the temperature by 2°C extends the green life by 28% (figure 5; normal air). However, temperatures below 13°C have to be avoided because of the risk of chilling injuries.

The efficiency of cooling can be greatly improved by better packaging and stowage. For the standard packing, only 10% of the available cooling capacity actually affects the fruit inside the boxes. We showed that the air flow and therefore the cooling capacity could be improved by up to 50% through changes in packaging and stowage pattern.

Besides these static measures to improve the transport process, losses can be further reduced by better online monitoring of potential risk factors and by green life prediction. The presented thermal model detects boxes for which the relation between generated and removed heat is in danger of running out of balance. It thereby allows early prediction of a potential hot spot. Although the risk for hot spots can be predicted for individual pallets or boxes, the prediction of remaining green life is only possible as an average for the whole container owing to the mutual influence by ethylene exchange. The high standard deviation of typically ±5 days makes the green life calculation far from being an exact prediction.

The accuracy of the green life prediction can be improved if the autocatalytic process by ethylene exchange is better understood and quantified. Therefore, there is a high demand for a mobile high-resolution ethylene sensor that can be installed in sea containers, both for test applications and for permanent installation. Differences in the predicted green life can be used to prioritize containers for unloading in the discharge port or to implement quality-based warehouse management strategies such as FEFO. The goal of such strategies is to increase the number of containers that arrive at the ripening rooms before their green life ends, by swapping routes for subsequent transports. The option to implement FEFO-based warehouse management is only one of the advantages of a remote quality monitoring system.

New chain concepts such as door-to-door delivery of containers directly to customers are enabled by better supervision. Customer complaints can be largely reduced by an early detection of quality problems by remote monitoring of pallet core temperature. Container ripening only becomes feasible if adequate tools are provided to monitor the progress of the ripening process remotely.

Although the commercial advantage of these applications of remote quality supervision has not been quantified yet, they have a high potential to improve transport processes and reduce losses in the banana chain.

Acknowledgements

Further information about the project can be found at http://www.intelligentcontainer.com. We thank Ingersoll Rand Climate Control Technologies for provision of cooling equipment, and Dole Fresh Fruit Europe for provision of test facilities.

Funding statement

The research project ‘Intelligent Container’ was supported by the Federal Ministry of Education and Research, Germany, under reference no. 01IA10001.

References

- 1.Food and Agriculture Organization of the United Nations. 2013. Commodity markets monitoring and outlook: banana—world imports and exports. Rome, Italy, FAO; See http://www.fao.org/economic/est/est-commodities/bananas/banana-exports/en/. [Google Scholar]

- 2.Jedermann R, Pötsch T, Lloyd C. 2014. Communication techniques and challenges for wireless food quality monitoring. Phil. Trans. R. Soc. A 372, 20130304 ( 10.1098/rsta.2013.0304) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Turner DW. 1997. Bananas and plantains. In Postharvest physiology and storage of tropical and subtropical fruits (ed. Mitra SK.), pp. 47–83. New York, NY: CAB International. [Google Scholar]

- 4.Kuckenberg J, Tartachnyk I, Noga G. 2008. Evaluation of fluorescence and remission techniques for monitoring changes in peel chlorophyll and internal fruit characteristics in sunlit and shaded sides of apple fruit during shelf-life. Postharvest Biol. Technol. 48, 231–241. ( 10.1016/j.postharvbio.2007.10.013) [DOI] [Google Scholar]

- 5.Zude M. 2003. Comparison of indices and multivariate models to non-destructively predict the fruit chlorophyll by means of visible spectrometry in apple fruit. Anal. Chim. Acta 481, 119–126. ( 10.1016/s0003-2670(03)00070-9) [DOI] [Google Scholar]

- 6.Dominguez M, Vendrell M. 1994. Effect of ethylene treatment on ethylene production, EFE activity and ACC levels in peel and pulp of banana fruit. Postharvest Biol. Technol. 4, 167–177. ( 10.1016/0925-5214(94)90018-3) [DOI] [Google Scholar]

- 7.Golding JB, Shearer D, Wyllie SG, McGlasson WB. 1998. Application of 1-MCP and propylene to identify ethylene-dependent ripening processes in mature banana fruit. Postharvest Biol. Technol. 14, 87–98. ( 10.1016/s0925-5214(98)00032-5) [DOI] [Google Scholar]

- 8.Bugaud C, Daribo MO, Dubois C. 2007. Climatic conditions affect the texture and colour of Cavendish bananas (Grande Naine cultivar). Sci. Hort. 113, 238–243. ( 10.1016/j.scienta.2007.03.013) [DOI] [Google Scholar]

- 9.Castelan FP, Abadie C, Hubert O, Chilin-Charles Y, de Bellaire LD, Chillet M. 2013. Relation between the severity of Sigatoka disease and banana quality characterized by pomological traits and fruit green life. Crop Protect. 50, 61–65. ( 10.1016/j.cropro.2013.02.019) [DOI] [Google Scholar]

- 10.Cantwell MI. 2002. Summary table of optimal handling conditions for fresh produce. In Postharvest technology of horticultural crops (ed. Kader A.), 3rd edn. Oakland, CA: University of California. [Google Scholar]

- 11.George JB, Marriott J, Palmer JM, Karikari SK. 1982. Sensitivity to water-stress and ethylene of stored plantain fruits. J. Exp. Bot. 33, 1194–1201. ( 10.1093/jxb/33.6.1194) [DOI] [Google Scholar]

- 12.Kader A. 1996. Banana. Recommendations for maintaining postharvest quality. See http://postharvest.ucdavis.edu/PFfruits/Banana.

- 13.Yahia EM, Singh SP. 2009. Tropical fruits. In Modified and controlled atmospheres for the storage, transportation and packaging of horticultural commodities (ed. Yahia EM.), p. 589 Boca Raton, FL: CRC Press. [Google Scholar]

- 14.Imahori Y, Yamamoto K, Tanaka H, Bai JH. 2013. Residual effects of low oxygen storage of mature green fruit on ripening processes and ester biosynthesis during ripening in bananas. Postharvest Biol. Technol. 77, 19–27. ( 10.1016/j.postharvbio.2012.11.004) [DOI] [Google Scholar]

- 15.Madrid M, Lopez-Lee F. 1998. Differences in ripening characteristics of controlled atmosphere or air-stored bananas. Acta Hort. (ISHS) 464, 357–362. [Google Scholar]

- 16.Yi C, Jiang YM, Sun J, Luo YB, Jiang WB, Macnish A. 2006. Effects of short-term N2 treatment on ripening of banana fruit. J. Hort. Sci. Biotechnol. 81, 1025–1028. [Google Scholar]

- 17.Inaba A, Nakamura R. 1988. Numerical expression for estimating the minimum ethylene exposure time necessary to induce ripening in banana fruit. J. Am. Soc. Hort. Sci. 113, 561–564. [Google Scholar]

- 18.Beaudry RM. 1999. Effect of O2 and CO2 partial pressure on selected phenomena affecting fruit and vegetable quality. Postharvest Biol. Technol. 15, 293–303. ( 10.1016/s0925-5214(98)00092-1) [DOI] [Google Scholar]

- 19.Ketsa S, Wisutiamonkul A, van Doorn WG. 2013. Apparent synergism between the positive effects of 1-MCP and modified atmosphere on storage life of banana fruit. Postharvest Biol. Technol. 85, 173–178. ( 10.1016/j.postharvbio.2013.05.009) [DOI] [Google Scholar]

- 20.Mustaffa R, Osman A, Yusof S, Mohamed S. 1998. Physico-chemical changes in Cavendish banana (Musa cavendishii L var Montel) at different positions within a bunch during development and maturation. J. Sci. Food Agriculture 78, 201–207. ( 10.1002/(sici)1097-0010(199810)78:2%3C201::aid-jsfa106%3E3.0.co;2-k) [DOI] [Google Scholar]

- 21.Ingersoll Rand Climate Control Technologies. 2008. TK 60275-4-MM magnum + maintenance manual. Ingersoll Rand Climate Control Technologies. See http://arcticstore.co.uk/files/Termo_King_Magnum_manual.pdf

- 22.Maxim Integrated. 2013. DS1922L/DS1922T: iButton temperature loggers with 8KB data-log memory. See http://datasheets.maximintegrated.com/en/ds/DS1922L-DS1922T.pdf

- 23.Jedermann R, Becker M, Görg C, Lang W. 2011. Testing network protocols and signal attenuation in packed food transports. Int. J. Sensor Networks 9, 170–181. ( 10.1504/IJSNET.2011.040238) [DOI] [Google Scholar]

- 24.Jedermann R, Geyer M, Praeger U, Lang W. 2013. Sea transport of bananas in containers: parameter identification for a temperature model. J. Food Eng. 115, 330–338. ( 10.1016/j.jfoodeng.2012.10.039) [DOI] [Google Scholar]

- 25.Snowdon AL. 2010. Carriage of bananas (Musa spp.) in refrigerated ships and containers: preshipment and shipboard factors influencing cargo out-turn condition. Acta Hort. (ISHS) 879, 375–383. [Google Scholar]

- 26.Stewart OJ, Raghavan GSV, Golden KD, Gariepy Y. 2005. MA storage of Cavendish bananas using silicone membrane and diffusion channel systems. Postharvest Biol. Technol. 35, 309–317. ( 10.1016/j.postharvbio.2004.10.003) [DOI] [Google Scholar]

- 27.Hui KC, Vigneault C, Sotocinal SA, de Castro LR, Raghavan GV. 2008. Effects of loading and air bag bracing patterns on correlated relative air distribution inside refrigerated semi-trailers transporting fresh horticultural produce. Can. Biosyst. Eng. 50, 27–35. [Google Scholar]

- 28.Welch G, Bishop G. 2006. An introduction to the Kalman filter. See http://www.cs.unc.edu/~welch/kalman/kalmanIntro.html.

- 29.Lloyd C, Issa S, Lang W, Jedermann R. 2013. Empirical airflow pattern determination of refrigerated banana containers using thermal flow sensors. In Fifth Int. Workshop Cold Chain Management, Bonn, Germany, 10–11 June 2013, Bonn, Germany: University of Bonn. [Google Scholar]

- 30.Sosna C, Walter T, Lang W. 2011. Response time of thermal flow sensors with air as fluid. Sensors Actuators A, Phys. 172, 15–20. ( 10.1016/j.sna.2011.02.023) [DOI] [Google Scholar]

- 31.Scharnow R. 1986. Codiertes Handbuch der Güter des Seetransports. Rostock, Germany: Deutfracht/Seereederei. [Google Scholar]

- 32.Janssen S, Schmitt K, Blanke M, Bauersfeld ML, Wöllenstein J, Lang W. 2014. Ethylene detection in fruit supply chains. Phil. Trans. R. Soc. A 372, 20130311 ( 10.1098/rsta.2013.0311) [DOI] [PMC free article] [PubMed] [Google Scholar]