Abstract

A novel electron beam focusing scheme for medical X-ray sources is described in this paper. Most vacuum based medical X-ray sources today employ a tungsten filament operated in temperature limited regime, with electrostatic focusing tabs for limited range beam optics. This paper presents the electron beam optics designed for the first distributed X-ray source in the world for Computed Tomography (CT) applications. This distributed source includes 32 electron beamlets in a common vacuum chamber, with 32 circular dispenser cathodes operated in space charge limited regime, where the initial circular beam is transformed into an elliptical beam before being collected at the anode. The electron beam optics designed and validated here are at the heart of the first Inverse Geometry CT system, with potential benefits in terms of improved image quality and dramatic X-ray dose reduction for the patient.

INTRODUCTION

This section briefly presents X-ray generating schemes used for imaging applications, electron emitter and focusing techniques—with emphasis towards commercial, medical vacuum based X-ray sources, and introduces the novel beam optics proposed for the distributed/multispot X-ray source for Computed Tomography (CT) applications.

X-ray sources today

Even before the discovery of electrons by Thompson in 1897,1 one of the most impactful applications of the negatively charged particle orbiting the nucleus in an atom was demonstrated by Röntgen two years earlier,2 by generating X-rays in a vacuum tube between two biased electrodes. Later it was understood that the cathode emitted electrons, which were accelerated by an electric potential, and that the fast electrons generated photons (X-rays) upon hitting the anode by a process called bremsstrahlung. This method of X-ray generation remains even today the most frequently used in medical imaging, tumor treatment, sterilization of food, industrial defectoscopy, homeland security, just to name a few of the many present applications. As an example, the X-ray vacuum tube is at the heart of the multibillion dollar CT industry that has a dramatic, positive daily impact on the well-being of patients worldwide. A typical CT machine has an X-ray tube that rotates on a gantry around the patient at very high speeds—around 0.5 s per revolution, allowing 3D image reconstruction by collecting a large number of 2D snapshots during full rotation. By 2015, it is estimated that the world will have about 60 000 CT scanners.3 Only in US, there are about 70 × 106 CT scans/exams per year.4 X-rays can be produced also by rapidly changing the direction of high energy electrons in a synchrotron, using undulators, wigglers, or dipole magnets. The synchrotron radiation was discovered by a group of scientists at General Electric in 1947, using a 70 MeV machine.5 Since then, synchrotrons with ever increasing electron energies made possible the routine production of soft and hard X-rays, opening entirely new research directions in material science, biology, chemistry, medicine, etc. One of the preferred methods of generating quasi monochromatic, coherent X-rays is the Thomson scattering (or Inverse Compton scattering) of fast electrons with a counter-propagating infrared laser beam.6

In this paper, we will focus on using highly energetic electron beams, on the order of ∼80 kV, to bombard a high Z material anode (tungsten, for example) to generate X-rays for a game changing electron gun embodiment meant to enable a novel CT scanner architecture. This radically different X-ray source, a multispot/distributed source, will have tens of independently controlled electron beamlets in the same vacuum envelope, producing tens of X-ray beamlets for a CT scanner geometry called IGCT—Inverse Geometry CT. The “Inverse Geometry” name comes from the fact that here the system includes a large, distributed X-ray source with tens of beamlets, and a small radiation detector. The typical CT architecture includes a large area detector and one point source for X-ray generation. The IGCT system may have advantages in cost compared to traditional CT since X-ray detectors are more expensive to manufacture than X-ray sources. Other potential advantages of IGCT enabled by the novel source presented in this work will be listed in Subsection 1C2.

Electron emitter options for X-ray based vacuum electronics

There are several physical processes which can be used to produce electrons for vacuum electronics based X-ray sources. By far, the most used electron emission method is the thermionic emission—in the hundreds of thousands of X-ray tubes produced yearly worldwide. The classic example of this process is the electron emission from a metal filament heated by an electric current in a vacuum tube. The electrons in the heated metal gain enough energy to overcome the potential-energy barrier or the work function of the metal, and they flow from the surface of the metal toward a positively biased electrode. Research in thermionic emitters focuses on finding materials with low work function, high temperature stability, and immunity to contaminants present in vacuum systems. Electron emitter cathodes made of pure refractory metals have the advantage of ruggedness, resistance to contaminants, and relative low cost. Their main disadvantage is that they need to be heated to very high temperatures and the emitted electron current density may not be sufficient in certain applications. Running at elevated temperatures also shortens the lifetime of such emitters—typically through evaporation.

The first successful effort to reduce the work function of a thermionic emitter was done by Langmuir and Rogers,7 who added a few percent of thorium oxide to the tungsten, increasing the emitted current density several thousand times compared to the same temperature pure tungsten. Thoria originally was added to the tungsten to control the growth of the grains in the tungsten. Later, it was understood that the thorium (reduced from the ThO2) migrated to the surface of the tungsten, forming a monolayer with a much lower work function. This is the working principle of an entire class of thermionic emitters, the dispenser cathodes.8 In these emitters, a low work function alkali-earth element is stored usually in the form of oxide in a reservoir, in a porous tungsten matrix. By indirectly heating the cathode, the oxide is reduced and the alkali-earth element is migrating to the surface of the emitter, forming a monolayer with low work function. These monolayers are prone to contamination and can be easily destroyed by back-streaming positive ion bombardment. For this reason, high vacuum is required where dispenser cathodes operate; most of the microwave tubes—klystrons, travelling wave tubes, gyrotrons, or inductive output tubes—have dispenser cathodes as electron emitters. These types of cathodes cannot be used in current commercial sealed medical X-ray tubes (built without active pumping); the reason is that even with the most evolved cleaning and seasoning processes, during normal operation in the sealed X-ray tube, the highly energetic electrons striking the anode will produce substantial outgassing, raising the pressure inside the vacuum envelope by several orders of magnitude. There have been limited efforts to introduce dispenser cathodes in medical imaging X-ray sources with active pumping, although with a single cathode in a source that was stationary (not rotating on a gantry).9 The work presented here illustrates opportunities for using tens of dispenser cathodes in a single vacuum chamber rotating on a CT gantry for medical imaging applications, the first of its kind in the world.

Field emission is another method used in electron generation. This effect was described first by Lilienfeld,10 who observed a few milliamperes of electron current emitted by a sharp, cold cathode in a high-voltage X-ray tube. The use of field emission is motivated to eliminate the high temperatures associated with the operation of the thermionic emitters. Field emitters are researched extensively up to present days for X-ray tube applications; Carbon Nano Tubes (CNT)11 were proposed as cold electron emitters for X-ray sources. As current research efforts will bring more understanding regarding field emitter behavior—emission current density vs. lifetime trade-offs, degradation mechanisms, and methods to mitigate them, sensitivity to vacuum contaminants, cold cathodes may become one day the technology of choice for electron generation in X-ray sources. Especially, distributed X-ray sources, with many emitters in one vacuum chamber, could benefit from the room temperature operation and compactness of field emitters.

Electrons generated with the photoelectric effect are used mainly in RF guns, in the accelerator physics community.12 These electron sources are capable of generating very high beam intensities with very low emittance, resulting in high brightness beams, necessary for Free Electron Laser (FEL) based light sources. The longitudinal and transverse beam characteristics can be manipulated by properly shaping the laser beam which illuminates the photocathode, usually a high quantum efficiency material; this type of materials is usually prone to environmental contamination. For this reason, photocathodes need to operate in extremely high vacuum, today not feasible in medical imaging X-ray sources employed commercially. However, photocathodes have been also employed for X-ray generation in academic research, with recent efforts focused around Inverse Compton Scattering schemes.13

Electron beam focusing

Electron beam focusing schemes in vacuum tubes

In order to extract the electrons from the emitter and shape the beam, it is necessary to use a properly tailored electric field, produced by a set of biased electrodes. The emitter and electrode assembly is called an electron gun. The electron gun with a thermionic emitter can operate either in temperature limited or space charge limited mode. In the first case, the amount of electrons extracted from the emitter is controlled by the emitter temperature; in the latter mode of operation, it is assumed that there are more electrons available for extraction than the electric field produced by the electrodes in the gun can extract. The limitation comes from the effect of electric repulsion of the particles with like charges. This space charge limit was established independently by Child14 and Langmuir.15 The maximum extractable current at a given extractor voltage can be written as

| (1) |

where P is the electron gun perveance and U is the extractor voltage.

This relationship communicates two important facts. In order to have a fast control of the extracted electron current in an electron gun, it is desirable to have an extractor electrode, which can apply a rapidly controlled/varied voltage. If the gun operates in temperature limited mode, the beam intensity emitted can be controlled at a much slower rate, due to the thermal inertia of the emitter. The other important conclusion of Eq. 1 is that for a given perveance gun, one need to apply sufficiently high extraction voltage to obtain a high current beam.

Usually, after the electrons leave the electron gun, they are further accelerated by additional electric fields before they are used in specific applications. In order to compensate for the space charge effects which would make the extracted beam divergent, Pierce16 deduced analytically an electrode shape which modifies the electric field around the emitter to exactly compensate for this repulsion. Most of the further electron gun designs are based on this theoretical result.

In order to reduce the negative effects of the space charge in gun designs for high power microwave tubes, one could use emitters which produce a sheet beam or multiple round beams. A sheet beam has a cross section in the form of an ellipse with a large aspect ratio. In this way, the repulsive force due to the space charge can be decreased.

Sheet beams can be generated either directly, with a rectangular or elliptical electron gun with convergence in one dimension and very little focusing in the other dimension, or by utilizing a conventional circular electron gun followed by a beam aspect ratio transformation element. Designing a rectangular or high aspect ratio elliptical electron gun is computationally challenging, because of the need for compensating the edge-focusing effect; additionally, the lack of axisymmetry poses difficulties in manufacturing. To avoid such complications, Basten et al.17 proposed the transformation of a round electron beam into an elliptical beam using a pair of quadrupole magnets. The use of quadrupole magnets has the added benefit of allowing changes in the aspect ratio of the ellipse externally to the vacuum envelope, by adjusting the strength and separation of the two quadrupole magnets. Because the electron beams considered for high-power microwave generation are intense, it is challenging to employ quadrupole lenses due to relatively large diameter of the beam which may expand significantly in a short axial distance. To avoid this difficulty, Humphries et al.18 proposed to use a magnetic solenoid with elliptical apertures for the circular-to-elliptical transformation. This asymmetric solenoid creates unequal forces in the two transverse directions but also couples the two transverse motions.

Scheitrum19 described the design and construction of a W-band sheet beam klystron using a cylindrical cathode with a cylindrical cut perpendicular to the beam direction. A racetrack shaped focus electrode produced focusing in the vertical plane and only a small amount of convergence in the horizontal plane. In this way, it was possible to obtain a sheet beam with a 12:1 aspect ratio.

Employing multiple emitters and merging these beamlets serves a similar purpose of addressing the space charge challenges. When the beam has low velocity and the space charge is the most effective, the individual beamlets have low currents; they are merged after acceleration, when the negative effect of the space charge is reduced.

Electron guns can contain several electrodes, which control and shape the beam. One can also use magnets to focus and shape the electron beam, without changing its energy. The most used electron guns in commercial, medical X-ray tubes have only electrostatic focusing tabs.

Electron beam focusing in commercial, medical X-ray sources

A typical, state of the art electron gun used in X-ray sources (in temperature limited regime) for medical imaging applications is illustrated in Figure 1. Electron emitters are W filaments; this electron gun has two W (tungsten) filaments running at about 2500 °C, to produce a smaller and a larger X-ray focal spot on the anode, as desired (the footprint of the electron beam hitting the anode is observed as an X-ray focal spot). Image resolution is correlated to the size of X-ray focal spot—smaller and larger image resolutions are enabled here by having large and small focal spots. The simple beam optics employed typically does not allow for producing a wide span of focal spot sizes with only one electron emitter. Simple focusing tabs surrounding the W filaments are responsible for ensuring the desired beam optics. The initial beams emitted by the W filaments are longitudinal, like the eventual focal spot on the anode.

Figure 1.

Typical electron gun for CT X-ray sources. The two longitudinal W filaments are visible. Around the W filaments, the gun has simple electrostatic focusing tabs. This electron gun has two filaments—a smaller and a larger one—to be able to change the focal spot, and therefore the image resolution (smaller focal spot means improved image resolution—when this is needed).

There have been recently proposed commercial X-ray tubes for CT scanners with more sophisticated focusing schemes. The Straton X-ray tube developed by Siemens20 employs a quadrupole magnet to change the width of the electron beam focal spot on target and two dipole magnets to adjust the position of the focal spot in two mutually perpendicular directions. The iMRC X-ray tube made by Phillips21 utilizes two quadrupole magnets, allowing the independent adjustment of the focal spot length and width, as well as two dipole magnets for position adjustment.

Since typical CT scanners employ one X-ray source rotating very fast around the patient, the concept of using a distributed X-ray source or multispot source with novel beam optics—one vacuum chamber with tens of X-ray beamlets—is a dramatic change in the 40 year evolution of computed tomography applications. Potential opportunities enabled by this new X-ray source are lower radiation dose to the patient, improved image quality (improved resolution, reducing image artifacts) and a horizon towards a lower cost CT system compared to state-of-the art.22 This new electron gun will run in space charge mode to allow very fast rise time in the beam current (∼1 μs), would use a circular-to-elliptical electron beam transformation, and would produce larger or smaller focal spots on the anode from the same emitter (no need to have emitters of different sizes to produce focal spots of different sizes, as shown in Figure 1).The final embodiment of the multispot X-ray source designed and built at GE Global Research includes 32 identical and separate electron guns/electron beamlets.

Thermal versus optical focal spots in commercial medical X-ray sources

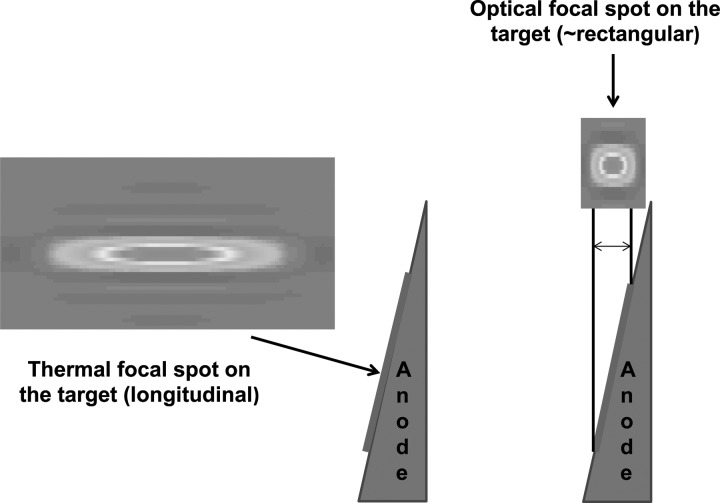

Finally, Figure 2 illustrates the difference between the thermal focal spot on the anode (the electron beam footprint on the anode), to what is being called the optical focal spot, as a measure of image resolution in medical imaging applications. If one looks perpendicular to the anode, the thermal focal spot is visible, on the order of 1 × 10 mm—a longitudinal spot with width and length. The optical focal spot, on the order of 1 × 1 mm for CT applications is visible at a different angle, from the object to be imaged (Figure 2) and is the critical metric in medical imaging. The width of the focal spot does not change when going from thermal to optical spots—and is therefore an important dimension that needs to be within specifications; the length of the spot will be adjusted within the optical focal spot as a function of the anode angle. In certain medical applications, the X-ray tube will be rotated so that the length of the optical focal spot is reduced as needed—but the tube needs to deliver the required focal spot width, as there is no other method to compensate for a larger than needed width.

Figure 2.

Difference between thermal focal spot (left hand side) and optical focal spot (right hand side) in X-ray tubes. The red line on the anode is the footprint of the electron beam.

COMPUTATIONAL DESIGN OF THE ELECTRON BEAM OPTICS

Beam optics design has been performed using Opera 3D software,23 which is a three-dimensional finite element analysis tool. Since the ultimate distributed source embodiment has 32 beamlets in a small footprint vacuum chamber that would need to rotate on a CT gantry around the patient, compact focusing schemes need to be employed. This is the reason why electrostatic focusing, and not magnetic focusing, has been chosen for this application. Typical CT applications use hundreds of mA electron beams, so the focusing scheme here needs to accommodate this requirement. Dispenser cathodes have been chosen as electron emitters, since they meet the emission and lifetime metrics. In simulations, emission was implemented using the Langmuir-Fry model,24 with simulated cathode (1.9 eV work function, and an emission constant of 120).

In this design, there are three electrodes used for beam control and focusing, as shown in Figure 3. A mesh grid is used to control the beam emission current. The mesh grid is placed at close distance from the cathode, 250 μm, therefore significantly reducing the switch voltage required for beam current control (for this application, using a mesh grid as opposed to an aperture electrode increases the field at the same voltage by 7 times). The electric field on the cathode created by the mesh grid has a very small ripple, ∼0.4%. When the mesh grid is biased at a positive voltage, the electron beam will be extracted from the emitter. The higher the voltage, the higher is the emission. On the other hand, when a negative voltage is added on the mesh grid, the emission is suppressed. The downside of using a mesh grid is its power handling capability. To minimize the heating due to electrons collected by the mesh grid, one has several methods to be potentially employed: minimize the beam extraction voltage by placing the mesh grid as close as possible to the cathode—while keeping the electric field uniformity on the cathode, choose a mesh grid with high transparency and reduce the duty cycle for the beam ON. Due to added complexity, the shadow grid solution utilized for microwave vacuum tubes was not favored for this electron gun concept. Another drawback of the mesh is its emittance growth. Because the mesh itself is a non-linear optical system, after the beam passes the mesh, the beam emittance grows. In the current design, in order to minimize this emittance growth, a second electrode was placed behind the mesh. This second electrode is called ECE, Emittance Compensating Electrode. When the voltage of this electrode is set at a right value such that the electric fields on both sides of the mesh are roughly equal, the beam emittance growth is minimized. The beam shaping and focusing is done by a combined function provided by the second and third electrode. The third electrode, called FP—Focusing Plate, has a rectangular opening to transform the beam from circular shape into elliptical shape, as required by CT imaging applications. The voltage at the second electrode and third electrode are carefully selected to reach the desired focal spot size and shape on the target.

Figure 3.

Beam focusing scheme designed for the X-ray distributed source (Opera 3D modeling): ECE = Emittance Compensating Electrode, FP = focusing plate. Various angles have been considered for the target.

EXPERIMENTAL SETUP AND ELECTRON GUN ASSEMBLY

The electron gun was designed, built, and assembled using the output of the Opera 3D simulation effort. The focusing and extraction schemes were the ones illustrated in Figure 3. Dispenser cathodes from Semicon Associates,25 with a circular emitting area, 3.5 mm diameter, were utilized in this work. Cathodes were typically operated at about 1100 °C, heating accomplished by using ∼7.5 V and 1.25 A (∼10 W heating power). As previously mentioned, the first focusing electrode, the ECE, has a circular opening, while the second focusing electrode, the FP, has a rectangular opening, to transform the emitted circular beam to an elliptic beam, as shown in Figure 4a. Since the final embodiment of the distributed X-ray source will include 32 emitters/electron beams on two rows, each row containing 16 electron beams, the choice was made to adopt a modular electron gun design, with each separate electron gun having four dispenser cathodes (4 × 1 gun)—as depicted in Figures 4a, 4b. Therefore a row of 16 emitters will include four electron guns, each with four dispenser cathodes.

Figure 4.

Front view of the 4 × 1 electron gun (a) and side view of the electron gun (b).

Electron gun materials were chosen so that mechanical, electrical, and vacuum properties were appropriate for the application. Spacers between mesh grid, ECE, and FP were made from alumina; ECE and FP were made from vacuum grade stainless steel. Mesh grid was made from molybdenum, by HeatWave Labs.26 The entire electron gun structure was placed in a Macor base plate (the white block on Figure 4b—right hand side). During operation, the electron gun will reach about 350 °C at thermal equilibrium, when all four cathodes are at 1100 °C. This gun was operated at about 10−7 Torr. Typically, ECE and FP have been biased using two different voltage power supplies operated in the DC mode; electron beam control was ensured using pulsed voltages on the grid plate, with the pulse width on the order of tens of us and rise time below 1 μs. Various types of anodes have been utilized to characterize the beam optics performance of this electron gun. The experiments described here utilized planar W plates as anodes, placed at 25 mm from the electron gun; anode and electron gun were parallel – electron beam strikes the anode at 90°. The anode was biased using high voltage power supplies typically used in CT applications, with 40–140 kV capability. Electron beam focusing on the anode has been characterized by measuring the X-ray focal spot on the anode; the measurement has been performed using the pinhole method27—traditionally used to characterize beam focusing for medical X-ray tubes, with a CCD camera able to capture the X-ray emission from the anode that occurs when the electron beam impacts the W anode.

It should be mentioned that other methods for measuring the beam profile may be employed in experiments. A common tool to measure the electron beam profile and position in an electron synchrotron or LINAC is the insertable optical transition radiation (OTR) viewer. Backward scattered OTR is produced on a thin (few microns) metal foil. The radiation is detected with optical video camera. Spatial resolution on the order of 10 μm and linear response as a function of current density are the main advantages of this method.28 A different diagnostic system was used by Russel et al.29 to experimentally characterize their elliptical aperture focusing solenoid which transforms a circular beam to an elliptical one. It consists of a circular 0.001-in. thick stainless steel foil followed by a circular 0.1-mm thick YAG:Ce scintillator crystal. The steel foil stops the electron beam, generating a pulse of Bremsstrahlung X-rays. In turn, the X-rays are imaged by the scintillator crystal, and a telescope focuses this image into an electronically gated, intensified CCD camera. The optical resolution of this diagnostic (camera plus telescope) is approximately 30 μm, however, the total resolution is around 0.1 mm due to the X-ray scattering in the stainless steel foil and scintillator crystal.

Zhou et al.30 used a 10–15 μm of P-43 phosphor (Gd2O2S:Tb) on an indium tin oxide (ITO) coated glass disk to test their elliptical electron gun. In order to prevent damage to the screen from overheating, the beam must be pulsed. The cathode of the electron gun was pulsed with both 100 ns pulses at 10 Hz and 1 μm pulses at 1 Hz.

EXPERIMENTAL CHARACTERIZATION OF THE BEAM OPTICS

Various experiments were conducted to characterize the beam optics designed for the multisource/X-ray distributed source. For the initial experiments, a 4 × 1 electron gun with four dispenser cathodes, as shown in Figure 4a, was tested in a commercially available vacuum chamber. Emission curves for dispenser cathodes were generated. The emission curves were generated in pulse mode, with emitter at ground and the grid voltage positively biased. ECE, FP, and the anode/target were grounded. Figure 5 shows a comparison between experimental and simulation data for emitted current—with excellent correlation simulation vs. experiments.

Figure 5.

Experimental and simulation emission data for the dispenser cathode in the electron gun (data obtained in pulse mode, 5 μs pulses).

In X-ray medical imaging applications, the output of the X-ray source is critical; therefore one should try to minimize current loses on the beam path, from the cathode to the anode/target. The biggest source of current loss for the electron gun described here is the mesh grid. As suggested by the manufacturer, the optical transparency of the mesh grid is about 80%—therefore one would expect about 20% current loss in the mesh grid. Simulations confirmed this fact, at various ECE voltages. However, experimental data revealed a strong dependency of the mesh grid current loss as a function of ECE voltage, as shown in Figure 6.

Figure 6.

Fraction of the total emitted current intercepted by the mesh grid, as a function of ECE voltage. Focusing voltage has been fixed at 100 V, anode voltage 80 kV, 130 V on the grid, emitted current was about 400 mA.

If geometric considerations and simulation results predicted about 20% current loss in the mesh grid, experiments show that at low ECE voltage indeed the current loss is close to this value (∼18% here), but the loss decreases significantly towards high ECE voltages—loss reduced to 12% at 6 kV ECE. The ECE field penetration in the space between cathode and grid strongly accelerates electrons, and the loss in the grid seems considerably reduced. Since experiments showed less than 1% current loss in ECE and FP, the electron gun designed here will send 80 to ∼88% of the emitted electrons to the anode.

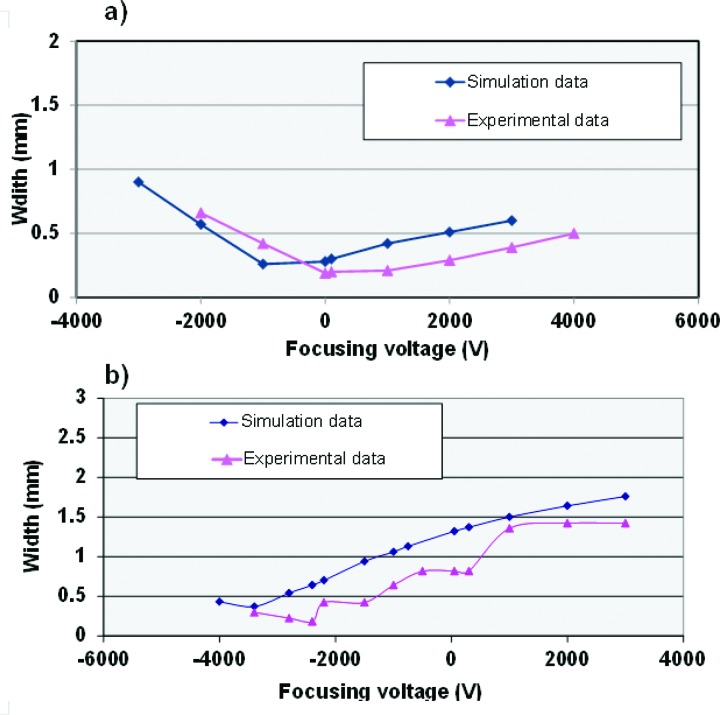

As image resolution in medical imaging is directly impacted by the focal spot/focusing of the electron beam on the anode, in depth characterization of focal spot size at various parameters—beam current, ECE, FP voltages, etc.—has been performed. As examples, Figures 7a, 7b show focal spot width experiments vs. simulations at 30 mA and 360 mA emitted currents, respectively. As previously mentioned and illustrated in Figure 2, the optical focal spot width determining the image resolution is given by the electron beam spot width, while the optical focal spot length is given by the length of the electron beam spot and by the angle of the anode. While by adjusting the target angle, one could account for longer/shorter electron beam spot, the width of the focal spot cannot be adjusted this way—it becomes a critical metric for beam focusing. Figures 7a, 7b show that qualitatively the simulation is relatively close in terms of prediction to experiments. While the experimental trends are excellently predicted by simulations, there are differences in the absolute values.

Figure 7.

Focal spot width (FWHM) for 30 mA emitted current (a) and 360mA emitted current (b), as a function of FP voltage, at constant anode voltage, 80 kV. ECE was 3 kV for 30 mA, and 6 kV for 360 mA.

Beam compression is defined here as the ratio of two areas: The electron emitting area and the total area of the optical focal spot (where optical focal spot is illustrated in Figure 2). The area of the optical spot is typically calculated as Width (at 50 %/FWHM) × Length (at 20 %). The beam compression for the 360 mA case at the optimum experimental size is 6.3, while the simulated beam compression at the same focusing parameters is 7.3; the correlation is good. Typical usage for electron beams in CT medical imaging ranges around hundreds of mA. Therefore, focusing parameters and performance in this range is the most relevant. For 30 mA, experimental beam compression is 30, while the simulated beam compression is 29. At low mA, below the expected usage for this gun, the beam compression is very high.

One of the particular beam optics requirements for the electron gun presented here, that separates it from other applications, is the focusing “robustness” requirement—the ability to keep the beam focused at large variations in current, while all focusing and anode voltages are maintained constant. The final X-ray source with this electron gun will have two rows of 16 emitters; in every row the emitters are separated by 25 mm. For simplicity, as a qualitative way of introducing the focusing “robustness requirement,” Figure 8 shows one row of 5 emitters, and an object to be imaged (e.g., can be the cross section of the human body). The X-ray beam produced by the electron emitter 3 has to travel the most through the object to be imaged—therefore it needs to have more photons, compared to the X-ray beams 2 and 4. Additionally, X-ray beams 1 and 5 would need to have less photons to travel through less material in the object, compared to X-ray beams 2 and 4. Obviously, one could use over the entire row the X-ray beam of maximum number of photons (like beam 3)—image quality will be insured. However, in order to significantly minimize X-ray dose to human subjects, the modulated X-ray beam intensity in Figure 8 is to be used here. Since X-ray photons are created by electrons hitting the anode, also the electron beam intensities 1, 2, 3, 4, and 5 in Figure 8 will be modulated as shown. Due to this source extreme complexity—a total of 32 emitters on two rows with 16 emitters per row, each with heating needs, mesh grid, ECE and FP connections—the preferred solution was to use individual mesh grid control for every cathode (get individual grid voltage and beam current for every emitter), but common ECE and FP voltages (DC). This way, the construction and control of this novel source are greatly simplified. If one needs the electron beam modulation as shown in Figure 8, various beam intensities would need to have consistent focusing at the same ECE, FP, and anode voltages. Figures 9a, 9b, 9c illustrate the excellent beam focusing robustness of the beam optics designed here.

Figure 8.

Qualitative representation of beam modulation needs for a row of 5 emitters for imaging of an object. Red arrows depict the modulation needed in the electron and X-ray beams for every cathode, in order to ensure minimum X-ray dose for the patient/object. The complete distributed X-ray source here will actually have 16 emitters in row—but the same modulation, with high beams in the middle, and lower beams towards the edges is needed for optimum dose distribution.

Figure 9.

Experimental characterization of beam focusing robustness: Optimizing focusing parameters at total emitted current of 460 mA—highlighted on every plot (80 kV on anode, 6 kV ECE, −3.3 kV FP), and evaluating the focal spot when the current is varied from 160 to 760 mA. Plot (a) is focal spot width (FWHM), plot (b) is the focal spot length (measured at 20%), and plot c) is the beam compression ratio.

For example, Figure 9a shows that by going from 460 to 760 mA, a 65% increase in current, the focal spot width increases from 0.34 to 0.37, less than 10% increase. At the other end of the spectrum, reducing the current almost by a factor of three to 160 mA has a small effect on the focal spot width: about 10% decrease from 0.34 to 0.3. It should be mentioned that while the focal spot width stays almost constant at 50%, FWHM evaluation (Figure 9a), when the current increases, the focal spot width measured at 20% increases (data not shown here). Therefore the beam optics relaxes the constraints on the tail of the beam (20% measurement), while maintaining FWHM quasi-constant. For the compression ratio, if at 460 mA the measured value is 3.7, at 760 mA becomes 3.2, a 15% decrease in beam compression ratio for 65% increase in the beam current. Therefore, the space charge term remains fairly constant despite the fact the beam current varies dramatically here.31 As expected, beam compression becomes higher towards much smaller currents—however this will not affect the performance of this gun for medical imaging applications (we want to avoid dramatic defocusing primarily).

DISCUSSION AND CONCLUSIONS

This paper presents the beam optics design and characterization of a novel electron beam focusing scheme for medical imaging applications. This focusing scheme represents a major departure from typical vacuum based X-ray sources commercially employed for healthcare applications. The main novelty elements are: use a dispenser cathode emitter in space charge regime, as opposed to a W based emitter used in temperature limited regime; use a flat emitter—dispenser cathode, instead of a W coil (the flat emitter may be improving the beam quality); instead of simple tabs for focusing, use several focusing electrodes and a mesh grid for beam extraction and control; propose a compact, modular multi-beam approach, where typical medical X-ray sources today have one electron beam; transform a circular electron beam in an elliptical beam at the anode, where most CT X-ray sources today use a rectangular emitter and a rectangular beam that will be collected by the anode. Due to extreme space constraints (need to have a compact vacuum chamber with 32 electron beamlets, with the electron gun—anode distance being 25 mm), electrostatic focusing has been implemented here as opposed to magnetic focusing.

First, simulations were able to correctly predict the emission properties of the electron emitters chosen for the current application. Experiments confirmed focusing trends first predicted by the 3D simulations, at low current (tens of mA) and high currents (hundreds of mA). There are differences in the absolute values of focal spot size, between experiments and simulations. Potential causes can include finite vacuum conditions (the electron beam does not propagate in a perfect vacuum; ions will be created that may alter the focusing physics), more complex initial conditions for electron emission at the cathode surface as opposed to the simple model used in simulations, and the lack of magnetic focusing components in the 3D electromagnetic software. The fact that background gas ionization can provide electron beam focusing has been proposed previously as a technique for X-ray sources.32

One finding not predicted by simulations has been the sensitivity of the mesh grid collected current as a function of ECE voltage. While the optical transparency of the mesh grid used here was about 80%, at 6 kV on the ECE, only roughly 10% of the incident beam is being collected by the mesh grid. This finding has practical implications, since the beam power dumped in the grid is being cut almost in half at 6 kV ECE, reducing the grid heating (grid heating can cause deformation, which might subsequently trigger beam quality degradation). A potential cause of the discrepancy between simulations and experiments here may be the complex geometry of the mesh grid; wire to wire spacing in the mesh grid is about 280 μm, wire width roughly 30 μm, while other dimensions in the electron gun simulations are much larger: Emitter diameter 3.5 mm, electron gun—anode spacing 25 mm. More optimized meshing in simulations around the grid area may be able to capture the beam dynamics discovered experimentally at high ECE voltages, with significantly reduced beam loss in the mesh grid. Shadow grid may be used in other electron beam applications—microwave tubes; the added complexity of shadow grids for a distributed X-ray source that can have tens of individual beamlets determined the use of the gridding solution shown here. Additionally, potential paths towards utilizing in the future CNT emitters for distributed X-ray sources33, 34 makes the choice of shadow grids even less attractive (one cannot simply apply a shadow grid on a CNT emitter in diode configurations for obvious practical reasons).

Unique medical imaging requirements for focusing robustness—maintain electron beam focusing at the same focusing voltages, when the beam current is significantly changed—has been successfully demonstrated here. A single set of focusing voltages has been shown to ensure proper beam optics from 160 to 760 mA. The focusing performance demonstrated in this paper opens the possibility towards a “universal” electron focusing scheme for vacuum electronics based X-ray medical applications. In mammography X-ray enabled workflows, typical focal spot widths are on the order of ∼0.3 mm at tens of mA, while in computed tomography applications, a focal spot width on the order of 1 mm at hundreds of mA is desired (focal spot length is typically considered in conjunction with the angle of the anode). Today, typical mammography and CT X-ray sources have different focusing schemes and different size emitters. Data shown here prove that this novel electron gun can meet the electron beam focusing metrics for two very different applications—mammography and CT, which save lives every day in healthcare facilities around the world, by allowing the early detection of tumors.

Finally, Figure 10 shows the final embodiment of the X-ray distributed source for CT applications developed at GE Global Research. The compact source contains 32 cathodes in a common vacuum chamber (eight 4 × 1 electron guns as illustrated in Figure 4). This source uses an ion pump and a getter pump (SAES) to maintain a good vacuum, 10−7 Torr, while rotated at high speeds (1 s per revolution) on the CT gantry. The electron beam optics described here has enabled the most powerful distributed X-ray source demonstrated in the world up to date,35 the first of its kind in the range of beam currents validated here. Potential dramatic benefits such as improved temporal resolution, improved image quality, and radiation dose reduction for the patient may enable one day improved healthcare outcomes in hospital facilities worldwide.

Figure 10.

The final embodiment of the distributed source designed and built at GE Global Research. Four anode blocks are placed in between the two electron gun rows.

ACKNOWLEDGMENTS

This work was partially funded through NIH support NIBIB Grant Nos. R01 EB006837 and R01 EB006837. The authors would like to thank Dr. Norbert Pelc (Stanford University) for his critical support throughout this project.

Paper VI3 1, Bull. Am. Phys. Soc. 58, 362 (2013).

References

- Thomson J. J., Philos. Mag. 44, 293 (1897). 10.1080/14786449708621070 [DOI] [Google Scholar]

- Röntgen Sber W. C., Physik.-Med. Ges. Würzburg 9, 132–141 (1895). [Google Scholar]

- See http://www.prweb.com/releases/computed_tomography/CT_scanners/prweb8075828.htm for the number of CT scanners world wide.

- See http://www.scientificamerican.com/article.cfm?id=how-much-ct-scans-increase-risk-cancer for the number of CT scans in US per year.

- Elder F. R., Gurewitsch A. M., Langmuir R. V., and Pollock H. C., Phys. Rev. 71, 829–830 (1947). 10.1103/PhysRev.71.829.5 [DOI] [Google Scholar]

- Sprangle P., Ting A., Esarey E., and Fisher A., J. App. Phys. 72, 5032 (1992). 10.1063/1.352031 [DOI] [Google Scholar]

- Langmuir I. and Rogers W., Phys. Rev. 4, 544 (1914). [Google Scholar]

- Cronin J. L., “ Modern dispenser cathodes—Review,” IEEE Proc. 128(I), 1 (1981). [Google Scholar]

- Oudkerk M., Coronary Radiology (Springer, 2004), p. 137. [Google Scholar]

- Lilienfeld J. E., Am. J. Roentgenol. 9, 192 (1922). [Google Scholar]

- de Jonge N. and Bonard J.-M., Phil. Trans. R. Soc. Lond. A 362, 2239–2266 (2004). 10.1098/rsta.2004.1438 [DOI] [PubMed] [Google Scholar]

- Hernandez-Garcia C., Siggins T., Benson S., Bullard D., Dylla H. F., Jordan K., Murray C., Neil G. R., Shinn M., and Walker R., “ A high average current DC GaAs photocathode gun for ERLs and FELs,” in Proceedings of 2005 Particle Accelerator Conference, Knoxville, Tennessee: (2005), p. 3117.

- Graves W. S., Kärtner F. X., Moncton D. E., and Piot P., “ Intense superradiant x rays from a compact source using a nanocathode array and emittance exchange,” Phys. Rev. Lett. 108, 263904 (2012). 10.1103/PhysRevLett.108.263904 [DOI] [PubMed] [Google Scholar]

- Child C. D., Phys. Rev. 32, 492 (1911). [Google Scholar]

- Langmuir I., Phys. Rev. 2, 450 (1913); 10.1103/PhysRev.2.450 [DOI] [Google Scholar]; Langmuir I., Phys. Rev. 21, 419 (1923). 10.1103/PhysRev.21.419 [DOI] [Google Scholar]

- Pierce J. R., J. App. Phys. 11, 548 (1940). 10.1063/1.1712815 [DOI] [Google Scholar]

- Basten M. A., Booske J. H., and Anderson J., “ Magnetic quadrupole formation of elliptical sheet beams for high-power microwave devices,” IEEE Trans. Plasma Sci. 22(5), 960 (1994). 10.1109/27.338313 [DOI] [Google Scholar]

- Humphries S., Russell S., Carlsten B., Earley L., and Ferguson P., “ Circular-to-planar transformations of high-perveance electron beams by asymmetric solenoid lenses,” Phys. Rev. Spec. Top.: Accel. Beams 7, 060401 (2004). [Google Scholar]

- Scheitrum G., “ Design and construction of a W-band sheet beam klystron,” in SLAC-PUB-11688, Contributed to 7th Workshop on High Energy Density and High Power RF, Kalamata, Greece, 2005, pp. 1–5.

- Schardt P., Deuringer J., Freudenberger J., Hell E., Knüpfer W., Mattern D., and Schild M., “ New x-ray tube performance in computed tomography by introducing the rotating envelope tube technology,” Med. Phys. 31, 2699 (2004). 10.1118/1.1783552 [DOI] [PubMed] [Google Scholar]

- Hauttmann S., Maring W., and Holzapfel S., U.S. patent 7,839,979 (2010).

- Wang G., Yu H., and De Man B., “ An outlook on X-ray CT research and development,” Med. Phys. 35(3), 1051 (2008). 10.1118/1.2836950 [DOI] [PubMed] [Google Scholar]

- See http://operafea.com/ for details about FEA Opera software.

- Schutt P., Skocic A., and Weiland T., “ Computer simulations of inductive output tubes,” Eur. Part. Accel. Conf. 2, 1233–1235 (1998). [Google Scholar]

- See http://www.semiconassociates.com/ for details about the dispenser cathodes used in this work.

- See http://www.cathode.com/ for details about the manufacturer of the mesh grids used in this work.

- Bushberg J. T., Seibert J. A., E. M.Leidholdt, Jr., and Boone J. M., The Essential Physics of Medical Imaging, 2nd ed. (Lippinncott Williams & Wilkins, 2002), p. 111. [Google Scholar]

- Yang B. X., Rotela E., Arnold N., Stein S. J., Berg W., and Sharma S., “ Design and performance of a compact imaging system for the APS LINAC bunch compressor,” in Proceedings of the 2001 Particle Accelerator Conference, Chicago: (2001), p. 2335.

- Russel S., Wang Z.-F., Haynes W., Wheat R., Carlsten B., Earley L., Humphries S., and Ferguson P., “ First observation of elliptical sheet beam formation with an asymmetric solenoid lens,” Phys. Rev. Spec. Top.: Accel. Beams 8, 080401 (2005). [Google Scholar]

- Zhou J., Bemis T., Chen C., and Lawrence M., “ Beam imaging of a high brightness elliptic electron gun,” AIP Conf. Proc. 1299, 528 (2010). 10.1063/1.3520379 [DOI] [Google Scholar]

- Resiser M., Theory and Design of Charged Particle Beams (John Wiley & Sons, Inc., 1994), p. 222. [Google Scholar]

- Martin J. C., “Flash X-ray tube with gas focusing of beam,” U.S. patent 3,344,298 (1967).

- Smith D. J., Bui P., Michael J. D., Aceto S. C., Marquard K., and Brewer J. E., “ Stable, high current density carbon nanotube field emission devices,” in 26th International Vacuum Nanoelectronics Conference (IVNC) - IEEE Catalog Number: ISBN: CFP13VAC-POD, Roanoke, 2013, p. 15.

- Yang G., Rajaram R., Cao G., Sultana S., Liu Z., Lalush D., Lu J., and Zhou O., “ Stationary digital breast tomosynthesis system with a multi-beam field emission x-ray source array,” Proc. SPIE 6913, 69131A (2008). 10.1117/12.770622 [DOI] [Google Scholar]

- Baek J., Pelc N. J., De Man B., Uribe J., Harrison D., Reynolds J., Neculaes B., Inzinna L., and Caiafa A., “ Initial results with a multisource inverse-geometry CT system,” Proc. SPIE 8313, 83131A (2012). 10.1117/12.912207 [DOI] [Google Scholar]