Abstract

Instant wheat porridge (Dalia) mix based on precooked broken wheat, sugar, skim milk powder and flavouring agents was developed using response surface methodology and central composite rotatable design. Stability of instant wheat porridge (Dalia) mix packed in polypropylene (PP) and metallised polyester (MP) pouches was evaluated. Instant porridge (Dalia) mix remained stable for 9 and 12 m respectively in PP and MP pouches under ambient temperature (15–34 °C) conditions. Deterioration in instant porridge mix during storage was mainly caused by autoxidation of lipids, browning due to maillard reaction and development of off-flavour.

Keywords: Packaging material, Lipid oxidation, Shelf life, Sensory evaluation

Introduction

During combat operations or when deployed in inaccessible mountainous terrains where regular supply of fresh foods becomes almost impossible, troops have to survive mainly on processed ready-to-eat or convenience foods. In India, many dehydrated convenience foods based on cereals, pulses, vegetables and spices have been developed as operational pack rations for the Armed Forces (Uma Devi et al. 2008; Yadav and Sharma 2008; Semwal et al. 2001; Patki and Arya 1997; Jayaraman et al. 1991; Vidyasagar et al. 1991). Since the troops have to carry their own ration, it has to be light in weight with long shelf-life, providing adequate calories and nutrients besides being suitable to troop’s palate. Previously, freeze dried wheat porridge had been developed requiring 5 min for reconstitution (Vijay Rao et al. 1994). Despite providing considerable convenience, this product did not receive acceptance from Armed Forces because of high processing cost of freeze drying and shorter shelf-life of product (9 m). A minimum shelf-life of 1 year under all weather conditions is an essential requirement laid down by the Indian Armed Forces for all operational pack rations. In order to meet the requirements of Indian Armed Forces, instant wheat porridge (Dalia) mix which can be reconstituted by putting in boiling water for 4–5 min has been developed. The present paper describes the results of a study conducted on the development and storage stability of the same.

Materials and methods

Broken wheat, skim milk powder, white free flowing sugar, cashewnuts, hydrogenated fat and cardamom were procured from the local market.

Processing of broken wheat

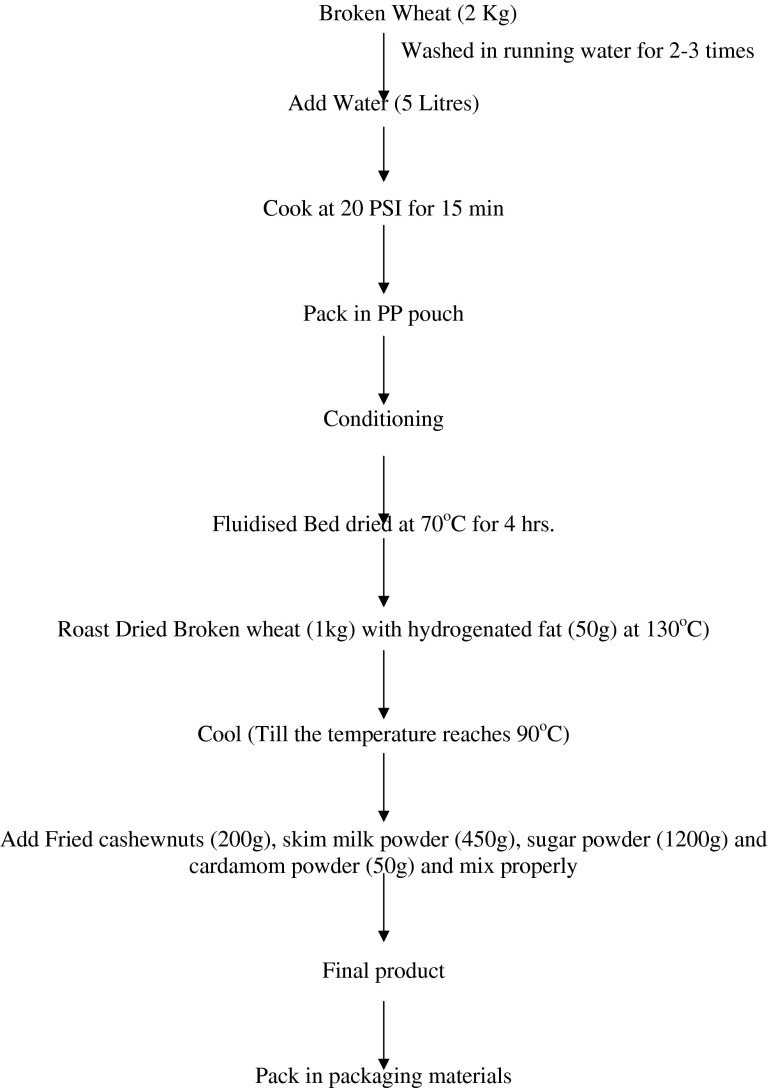

Good quality broken wheat was washed 2–3 times in running tap water to remove impurities. Broken wheat (2 kg) was cooked in 5 l water under steam pressure (20 PSI) for 15 min in an autoclave. Cooked broken wheat was spread in aluminium trays (80 × 40 cm) and frozen in a blast freezer (Cryo Scientific Chennai, India) by keeping at −20 °C for 4 h and then allowed to thaw at room temperature followed by subsequent drying in a fluidized bed dryer (Chemech, Chennai, India) at 70 °C for 4–5 h. The final moisture content of dehydrated broken wheat was maintained at approximately 6%.

Experimental design

The central composite rotatable design (CCRD) was used for optimizing the levels of variable ingredients for the preparation of instant wheat porridge mix Mullen and Ennis (1979). The variables optimized for instant wheat porridge mix were, sugar powder (X1),milk powder (X2) and water required for reconstitution (X3) based on weight of dehydrated broken wheat whereas consistency, taste and overall acceptability scores (OAA) were taken as responses during the experiments. The coded and actual levels used for independent variables have been given in Table 1. The levels of variables were selected based on the preliminary experiments. Twenty different experiments were carried out with eight factorial points, 6 axial points and six replicates of centre using the statistical software package design expert 6.0.9, Statease Inc., Minneapolis, USA. Experimental runs were randomized in order to minimize the effect of unexpected variability in the observed responses. The following second order polynomial equation was fitted to the data to obtain regression equations for consistency, taste and overall acceptability.

|

Where Y = independent variable; X1: sugar; X2: milk powder; X3: water and β represents the coefficients indicating the relative importance of their X value.

Table 1.

Experimental design matrix for instant wheat porridge mix at various levels

| Exp. No. | Variable levels (coded) | Variable levels (used) (Based on 100 g of dehydrated broken wheat) | Responses | ||||||

|---|---|---|---|---|---|---|---|---|---|

| X1 | X 2 | X3 | Sugar (g), X1 | Milk Powder (g), X 2 | Water for reconstitution (ml),X3 | Consistency | Taste | OAA | |

| 1 | −1 | −1 | −1 | 110 | 40 | 290 | 7.0 | 7.1 | 7.1 |

| 2 | 1 | −1 | −1 | 130 | 40 | 290 | 7.1 | 7.0 | 6.9 |

| 3 | −1 | 1 | −1 | 110 | 50 | 290 | 6.5 | 6.5 | 6.5 |

| 4 | 1 | 1 | −1 | 130 | 50 | 290 | 6.9 | 7.0 | 7.0 |

| 5 | −1 | −1 | 1 | 110 | 40 | 310 | 7.4 | 7.4 | 7.4 |

| 6 | 1 | −1 | 1 | 130 | 40 | 310 | 7.5 | 7.3 | 7.3 |

| 7 | −1 | 1 | 1 | 110 | 50 | 310 | 7.3 | 7.4 | 7.3 |

| 8 | 1 | 1 | 1 | 130 | 50 | 310 | 7.7 | 7.7 | 7.8 |

| 9 | −1.68 | 0 | 0 | 104 | 45 | 300 | 6.9 | 6.9 | 6.8 |

| 10 | 1.68 | 0 | 0 | 137 | 45 | 300 | 7.2 | 7.1 | 7.2 |

| 11 | 0 | −1.68 | 0 | 120 | 37 | 300 | 7.5 | 7.4 | 7.4 |

| 12 | 0 | 1.68 | 0 | 120 | 53 | 300 | 7.2 | 7.3 | 7.3 |

| 13 | 0 | 0 | −1.68 | 120 | 45 | 283 | 6.8 | 6.9 | 6.8 |

| 14 | 0 | 0 | 1.68 | 120 | 45 | 317 | 7.8 | 7.8 | 7.8 |

| 15 | 0 | 0 | 0 | 120 | 45 | 300 | 8.4 | 8.5 | 8.4 |

| 16 | 0 | 0 | 0 | 120 | 45 | 300 | 8.6 | 8.5 | 8.6 |

| 17 | 0 | 0 | 0 | 120 | 45 | 300 | 8.5 | 8.6 | 8.5 |

| 18 | 0 | 0 | 0 | 120 | 45 | 300 | 8.4 | 8.4 | 8.4 |

| 19 | 0 | 0 | 0 | 120 | 45 | 300 | 8.5 | 8.5 | 8.5 |

| 20 | 0 | 0 | 0 | 120 | 45 | 300 | 8.4 | 8.6 | 8.5 |

Preparation of instant wheat porridge mix

The different formulations obtained (Table 1) were weighed separately while the content of fried cashew nut (shallow fried in hydrogenated fat at 180 °C in an aluminium frying pan to light brown colour) and depodded cardamom powder was kept constant for all the runs based on dehydrated broken wheat by weight. Dehydrated broken wheat was roasted in an aluminium frying pan with hydrogenated fat. The temperature was allowed to rise to 130 °C and maintained for about 3 min. The roasted material was allowed to cool down to 90 °C and then mixed with powdered sugar, skim milk powder, cardamom powder and fried cashewnuts in an electric blender for 3 min and packed for optimization of the product as per the flow diagram (Fig. 1).

Fig. 1.

Flow diagram for the preparation of instant wheat porridge mix

Reconstitution of instant wheat porridge mix

One hundred grams each of all the combinations obtained (Table 1) were mixed in hot water for reconstitution. The reconstituted wheat porridge were evaluated by a panel of 15 trained judges through grading for consistency, taste and overall acceptability on a 9 point hedonic scale where 9 was considered as excellent in all respects and 1 for highly disliked samples as described by Larmond (1977).

Storage and evaluation

Instant wheat porridge (Dalia) mix prepared using optimized levels of ingredients were packed in polypropylene (PP, 75 μ) and metallised polyester (MP, 90 μ) pouches (10 cm × 10 cm), heat sealed and stored under ambient temperature (15–34 °C) conditions for further studies.

Analysis

Moisture, protein, fat, total ash and total sugars were determined using standard AOAC (1990) methods. Changes in instant wheat porridge during storage were monitored through peroxide value (PV) and free fatty acids (FFA) estimations as per AOCS (1990) methods, while thiobarbituric acid value (TBA) was determined according to the method of Tarledgis et al. (1960) initially and after at 3 months interval. For measuring the browning intensity, 5 g sample in volumetric flask was made up to 100 ml using 70% ethanol and shaken well for 2 h, filtered and optical density measured at 420 nm. Mineral content was determined using Atomic Absorption Spectrophotometer (Vario 6, Analytika Jena, Germany) after wet digestion as per the method of Semwal et al. (1995). Fatty acid composition of fat extracted from instant wheat porridge was determined using standard AOCS (1990) methods with the help of Gas Liquid Chromatograph (Chemito, HR 1000, Chennai, India) on a 10% diethylene glycol-succinate column (DEGS, 8 × 1/8″) with nitrogen as carrier gas and flame ionization detector. During analysis, the column temperature was maintained at 190 °C while the injector and detector temperatures were kept at 230 °C.

Microbial profile of the instant wheat porridge mix samples was determined using the petri plate method as described by APHA (1992) for standard plate count on agar, coliform count on violet red bile agar, faecal coliform on Escherichia coli agar and, yeast and mold counts on the potato dextrose agar. Presence of pathogens viz. coliform, salmonella and staphylococcus aureus was also determined using APHA (1992) methods.

Initially and after regular interval of 3 m, sensory quality of instant wheat porridge was also evaluated as described earlier.

Statistical analysis

Experiments were performed using a 2-way factorial design consisting of storage time and packaging materials as treatments. All the experiments were performed in triplicate and Analyses of Variance were calculated using Statistica Software Version 7.0 of Stat Soft Incorporation, Tulsa OK, USA as per the methods of Snedecor and Cochran (1968).

Results and discussion

Instant wheat porridge mix (Dalia) mix has been developed using RSM. The 20 experimental combinations of central composite rotatable design with three independent variables and three responses studied are given in Table 2. Since attributes like consistency, taste and overall acceptability directly effect on the quality of product these are taken as responses (Yadav et al. 2007; Yadav and Sharma 2008). All main, linear, quadratic and interactive effects were calculated for each model (Table 2). The adequacy of the models was tested using F-ratio and co-efficient of determination (R2). The ANOVA for full second order regression model for different responses (Table 2) showed that the co-efficient of determination R2 was more than 80% and lack of fit (LoF) was insignificant indicating the fitness of polynomial models used for describing the effect of independent variables on the responses (Henika 1982). Therefore, all three responses were selected for further interpretation. The effect of different variables on responses could be predicted by following multiple regression equations (in terms of coded factors).

|

Table 2.

Co-efficients of second order polynomial regression models for the various parameters

| Co-efficient constant | Consistency | Taste | Overall acceptability |

|---|---|---|---|

| Intercept | |||

| β0 | 8.47 | 8.52 | 8.48 |

| Linear | |||

| β1 | 0.011* | 0.069* | 0.10* |

| β2 | −0.081* | −0.027 | −0.020 |

| β3 | 0.30* | 0.027* | 0.29* |

| Quadratic | |||

| β11 | −0.50* | −0.53* | −0.52* |

| β22 | −0.39* | −0.41* | −0.40* |

| β33 | −0.41* | −0.41* | −0.41* |

| Interactive | |||

| β12 | 0.075* | 0.13* | 0.16* |

| β13 | 0.007 | −0.025 | 0.013 |

| β23 | 0.10* | 0.13* | 0.11* |

| R2 | 0.99 | 0.99 | 0.99 |

| F-value | 239.53 | 274.41 | 274.43 |

| Mean | 7.58 | 7.59 | 7.58 |

| SD | 0.063 | 0.060 | 0.060 |

| CV% | 0.83 | 0.79 | 0.79 |

| LoF | Not Significant | Not significant | Not significant |

*significant (p ≤ 0.05)

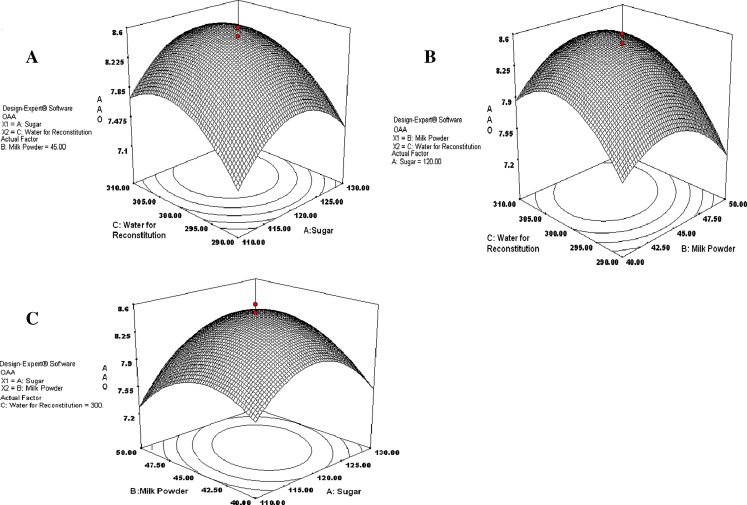

Table 2 revealed that all the variables had a siginificant positive effect (p ≤ 0.05) on all the responses except milk powder which had negative effect (p ≤ 0.05) on consistency and showed no significant effect on other responses. At the quadartic level all the varialbes had significant negative effect (p ≤ 0.05) on all the responses studied. At interactive level though sugar and water for reconstitution showed positve effect (p ≤ 0.05) but milk powder had little significant effect on all the responses. The response surface for OAA in relation to sugar, milk powder and water for reconstitution have been shown in Fig. 2 (a), (b) and (c). With the increase level of sugar, milk powder and water for reconstitution, OAA goes on increasing upto certain limit and then declined. The same trend follows in the case of consistency and taste of the wheat porridge mix.

Fig. 2.

a Effect of water for reconstitution and sugar, b effect of water for reconstitution and milk powder and c effect of milk powder and sugar on the overall acceptability of instant wheat porridge

For the optimization of sugar, milk powder and water for reconstitution, all the three responses i.e. consistency, taste and overall acceptability were selected because these responses had direct effect on the quality of instant wheat porridge mix. These responses were used for numerical optimization of the variables and the criterion used along with predicted and actual values of the responses have been presented in Table 3. By using the given criterion (Table 3) the solution obtained was: dehydrated broken wheat (100 g), sugar (121 g), skim milk powder (44 g), fried cashewnuts (20 g), cardamom powder (5 g) and water for reconstitution (303 ml). Instant wheat porridge mix was prepared based on solution obtained and responses were measured. The measured responses were very much close to the predicted ones, reconfirming the adequacy of the models. Therefore, the optimized set of condition was recommended for the preparation of instant wheat porridge mix.

Table 3.

Constraints criteria for optimization, solution along with predicted and actual response values

| Variables | Goal | Lower limit | Upper limit | Predicted value | Actual value |

|---|---|---|---|---|---|

| Sugar powder | In range | 110 | 130 | – | – |

| Milk powder | In range | 40 | 50 | – | – |

| Water for reconstitution | In range | 290 | 310 | – | – |

| Consistency | Maximize | 6.5 | 8.6 | 8.49 | 8.50 ± 0.1 |

| Taste | Maximize | 6.5 | 8.6 | 8.57 | 8.56 ± 0.2 |

| Overall acceptability | Maximize | 6.5 | 8.6 | 8.59 | 8.54 ± 0.2 |

Freshly prepared instant wheat porridge (Dalia) mix had moisture, 2.26%; total protein, 12.5%; total soluble sugars, 39.0% and fat, 16.60%. There were no significant changes in these values except moisture, during storage. The calorific value calculated from the above composition was found to be 435 Kcal/100 g. Instant porridge mix could be reconstituted within 4–5 min irrespective of the length of storage.

The role of packaging materials on the storage stability of instant porridge mix under ambient temperature (15–34 °C) conditions was investigated on the basis of changes in peroxide value (PV), free fatty acid value (FFA), thiobarbituric acid value (TBA), browning index and overall acceptability. It may be observed that the rates of autoxidation as measured by changes in PV and TBA values were significantly (p ≤ 0.01) higher in samples packed in PP as compared to those in MP pouches (Table 4). The peroxide value of wheat porridge mix packed in PP increased from 7.12 to 29.16 meqO2/kg fat as compared to 7.12 to 18.62 meqO2/kg for those packed in MP at the end of 12 m storage. The TBA values after 12 m of storage increased from 0.05 to 0.116 and 0.089 mg malonaldehyde/kg in PP and MP packed samples respectively. FFA in instant porridge mix increased during storage irrespective of the packaging materials used. The increases were considerably higher in PP packed samples than those in MP. After 12 months of storage, the FFA value in PP packed samples was 2.11 compared to 1.28 as% oleic acid in MP packed ones. Hydrolysis of lipids during storage is normally brought about by the naturally occurring lipases (Clayton and Morrison 1972). However, during thermal processing employed for cooking and roasting, lipase activity was destroyed and therefore the formation of free fatty acids in stored wheat porridge mix must have resulted from the decomposition of hydroperoxide. Previously, Thakur and Arya (1990) have also reported an increase in FFA in the processed cereal products from the decomposition of hydroperoxide rather than that from lipids. In the present study, the samples having higher peroxide and TBA values were invariably found to have higher FFA suggesting the involvement of lipid autoxidation for an increase in FFA.

Table 4.

Changes in moisture content (%), peroxide value (PV, meq O2/kg fat), free fatty acid value (FFA,% oleic acid), thiobarbituric acid value (TBA, mg MA/kg sample), browning index (OD at 420 nm) and overall acceptability score (OAA) of instant wheat porridge mix packed in Polypropylene (PP) and Metallised Polyester (MP) pouches and stored under ambient temperature (15–34 °C) conditions

| Storage Period (months) | Moisture* | PV* | FFA* | TBA* | Browning* | OAA** | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PP | MP | PP | MP | PP | MP | PP | MP | PP | MP | PP | MP | |

| 0 | 2.26a ± 0.01 | 2.26a ± 0.01 | 7.12a ± 0.12 | 7.12a ± 0.11 | 0.74a ± 0.01 | 0.74a ± 0.01 | 0.050a ± 0.02 | 0.050a ± 0.01 | 0.030a ± 0.001 | 0.030a ± 0.001 | 8.5a ± 0.13 | 8.5a ± 0.14 |

| 3 | 2.93b ± 0.02 | 2.61bx ± 0.01 | 11.43b ± 0.20 | 9.86bx ± 0.18 | 0.96b ± 0.01 | 0.89bx ± 0.01 | 0.074b ± 0.02 | 0.062bx ± 0.02 | 0.035b ± 0.001 | 0.032bx ± 0.002 | 7.4b ± 0.23 | 8.0bx ± 0.21 |

| 6 | 3.88c ± 0.02 | 3.01cx ± 0.02 | 19.32c ± 0.25 | 12.56cx ± 0.21 | 1.35c ± 0.02 | 0.98cx ± 0.02 | 0.081c ± 0.02 | 0.070cx ± 0.02 | 0.040c ± 0.002 | 0.035cx ± 0.002 | 7.2c ± 0.34 | 7.7cx ± 0.32 |

| 9 | 4.21d ± 0.03 | 3.28dx ± 0.02 | 24.45d ± 0.21 | 15.68dx ± 0.25 | 1.98d ± 0.02 | 1.12dx ± 0.03 | 0.094d ± 0.01 | 0.079dx ± 0.03 | 0.048d ± 0.003 | 0.037dx ± 0.002 | 7.0d ± 0.28 | 7.5dx ± 0.28 |

| 12 | 4.46e ± 0.03 | 3.51ex ± 0.03 | 29.16e ± 0.21 | 18.62ex ± 0.23 | 2.11e ± 0.02 | 1.28ex ± 0.03 | 0.116e ± 0.03 | 0.089ex ± 0.03 | 0.058e ± 0.003 | 0.041ex ± 0.002 | 6.2e ± 0.20 | 7.3ex ± 0.25 |

* mean ± SD (n = 3)

** mean ± SD (n = 15)

a–e : values within the same column with different superscripts differ significantly (p ≤ 0.01)

x: significantly different from their corresponding PP packed samples (p ≤ 0.01)

The changes in browning in porridge mix were measured as optical density of the alcoholic extract at 420 nm during storage in PP and MP pouches and the results have been represented in Table 4. The samples stored in PP pouches exhibited significally (p ≤ 0.01) higher browning indices (0.058) as compared to those packed in MP (0.041) at the end of 12 m storage. Visibly, the samples packed in both the packaging materials were not significantly different in colour either initially or after storage. However, when the samples were reconstituted there were considerable differences in colour intensity of the reconstituted porridge mixes, packed in PP especially after 9 m of storage; while the samples packed in MP pouches retained the original creamish colour even after 12 m storage under ambient temperature conditions. This may be due to the formation of intermediate browning compounds in PP stored samples which on heating with water during reconstitution may have formed melanoidins leading to brown colour. Previously also, at low water activities formation of intermediate browning compounds has been observed which on heating led to excessive browning colour.

Fatty acid and mineral compositions of wheat porridge mix have been given in Table 5. The changes in fatty acid composition were not appreciable except a slight decrease in the concentration of linoleic acid and corresponding increase in the concentration of saturated fatty acids. Calcium was found to be present in large concentrations mostly due to the use of skim milk powder in wheat porridge mix. However, iron, zinc and copper contents were quite low. During storage practically no changes in any of the minerals were observed (Table 5).

Table 5.

Fatty acid (%) and mineral composition (mg/100 g) of instant wheat porridge mix (n = 3)

| Initial | 12 Months | ||

|---|---|---|---|

| PP | MP | ||

| Myristic (C14:0) | 1.44 ± 0.03 | 1.83 ± 0.05 | 1.95 ± 0.08 |

| Palmitic (C16::0) | 30.89 ± 0.12 | 30.97 ± 0.16 | 30.92 ± 0.11 |

| Stearic (C18::0) | 5.12 ± 0.04 | 5.57 ± 0.08 | 5.33 ± 0.08 |

| Oleic (C18:1) | 49.88 ± 0.41 | 50.21 ± 0.57 | 50.16 ± 0.31 |

| Linoleic (C18:2) | 12.67 ± 0.10 | 11.42 ± 0.14 | 11.64 ± 0.09 |

| Calcium | 288 ± 18.1 | 284 ± 20.2 | NA |

| Iron | 4.7 ± 0.021 | 4.8 ± 0.019 | NA |

| Sodium | 192.6 ± 10.2 | 189.2 ± 8.8 | NA |

| Potassium | 395.7 ± 26 | 386.9 ± 19 | NA |

| Zinc | 2.5 ± 0.10 | 2.8 ± 0.11 | NA |

| Copper | 0.32 ± 0.01 | 0.36 ± 0.01 | NA |

NA not analysed

PP polypropylene; MP metallised polyester

There was practically no change in the microbiological status of instant porridge mix during the entire storage period. The total plate counts of freshly prepared instant porridge mix ranged between 100 and 150 colonies/g and those of 12 months stored samples was 200–400 colonies/g. Yeast and mold counts in fresh and stored samples were below 100 colonies/g. Samples stored in PP and MP did not differ significantly in total plate and, yeast and mold counts upto 12 m of storage. All the samples were free from salmonella, S.aureus and E.coli.

Changes in overall acceptability score of the reconstituted wheat porridge (Dalia) samples stored under ambient temperature conditions in PP and MP pouches have been depicted in Table 4. Initially, the instant porridge mix had an overall acceptability score of 8.5 on a 9 point hedonic scale and therefore, a score of 7.0 was taken as limit for acceptability during the storage experiments. As is evident, packaging material played a major role in determining the shelf-life of instant porridge mix during storage. The changes in overall accept ability score was lesser in MP stored samples as compared to those stored in PP pouches. The chemical changes also revealed a similar trend (Table 4). Instant porridge mix stored in MP remained stable during the entire 12 m storage period under ambient temperature (15–34 °C) conditions. On the other hand, instant dalia mix, when packed in PP pouches had shelf-life of only 9 m under ambient temperature conditions.

Autoxidation of lipids and development of browning was found to be the major cause of sensory changes in instant wheat porridge mix during storage. Consequently, deterioration in instant porridge mix and its shelf-life are expected to be governed by the availability of oxygen in the pack, which in turn, will be governed by the oxygen permeability of the packaging material. The MP having relatively low oxygen permeability (<100 ml/M2/24 h) exhibited longer shelf-life (12 m) while, on other hand, PP having relatively higher oxygen permeability (>3800 ml/M2/24 h) could protect the contents upto 9 m.

Conclusion

It is evident that highly acceptable instant wheat porridge (Dalia) mix, capable of reconstitution in 4–5 min by putting in boiling water can be prepared by fluidized bed drying of frozen cooked broken wheat and blending the dehydrated product with sugar, milk powder, cashewnuts and flavouring agent. Major spoilage in instant wheat porridge mix during storage is caused by autoxidation of lipids and non-enzymatic browning reactions, resulting in development of off-flavour and brown discolouration in the stored porridge mix samples.

References

- Official methods of analysis. 15. Washington: Association of Official Analytical Chemists; 1990. [Google Scholar]

- Official methods and recommended practices. 4. Champaign: American Oil Chemist’s Society; 1990. [Google Scholar]

- APHA (1992) Compendium of methods for the microbiological examination of food, 2nd edn. In: Speck ML (ed) American Public Health Association, Washington DC

- Clayton TA, Morrison WR. Changes in flour lipids during storage of wheat flour. J Sci Food Agric. 1972;23:721–724. doi: 10.1002/jsfa.2740230607. [DOI] [PubMed] [Google Scholar]

- Henika RG. Use of response surface methodology in sensory evaluation. Food Technol. 1982;36(11):96–101. [Google Scholar]

- Jayaraman KS, Gopinathan VK, Dasgupta DK, Babu Rao N. Development of ready-to-eat quick cooking dehydrated vegetable curry mix (avial) containing yoghurt and coconut. Indian Food Packer. 1991;45:5–12. [Google Scholar]

- Larmond E (1977) Laboratory methods for sensory evaluation of foods. Canada Dept of Agric, Ottawa, p 1637

- Mullen K, Ennis DM. Rotatable designs in product development. Food Technol. 1979;33(7):74–80. [Google Scholar]

- Patki PE, Arya SS. Studies on storage stability of instant kichadi mix. Indian Food Packer. 1997;51:77–80. [Google Scholar]

- Semwal AD, Narasimhamurthy MC, Arya SS. Metal contents in some of the processed foods and their effect on the storage stability of precooked dehydrated flaked Bengalgram dhal. J Food Sci Technol. 1995;32:386–390. [Google Scholar]

- Semwal AD, Sharma GK, Patki PE, Padmashree A, Arya SS. Studies on development and storage stability of instant vegetable pulav mix. J Food Sci Technol. 2001;38:231–234. [Google Scholar]

- Snedecor GW, Cochran WG. Statistical methods. 6. New Delhi: Oxford and IBH Pub Co; 1968. [Google Scholar]

- Tarledgis BG, Watts BM, Younathan ME, Dugon LR. A distillation method for the qualitative determination of malonaldehyde in rancid food. J Am Oil Chem soc. 1960;37:44–47. doi: 10.1007/BF02630824. [DOI] [Google Scholar]

- Thakur BR, Arya SS. Packaging requirement and stability of fried snacks (trisnacks) J Food Sci Technol. 1990;27:76–81. [Google Scholar]

- Devi U, Sharma GK, Semwal AD. Development of instant peas curry mix and its quality evaluation. J Food Sci Technol. 2008;45:152–156. [Google Scholar]

- Vidyasagar K, Premavalli KS, Arya SS. Effect of oils and packaging materials on the stability of instant nutrocereal mix. Indian Food Packer. 1991;45:24–32. [Google Scholar]

- Vijay Rio D, Radhakrishna K, Jayathilakan K, Vasundhara TS, Bhagirathi B, Gopala Rao KR, Srihari KA, Siddalingaswamy M. Manufacture of freeze-dried breakfast and dessert foods. J Food Sci Technol. 1994;31:40–43. [Google Scholar]

- Yadav DN, Sharma GK. Optimisation of soy fortified instant upma mix ingredients using response surface methodology. J Food Sci Technol. 2008;45:56–60. [Google Scholar]

- Yadav DN, Sharma GK, Bawa AS. Optimisation of soy-fortified instant sooji halwa mix using response surface methodology. J Food Sci Technol. 2007;44:297–300. [Google Scholar]