Abstract

Tahin helva is one of Turkish traditional confectionary foods. Sesame paste, sugar syrup and soapwort extract were used for tahin helva’s production. The purpose of this study was to solve the oil separation problem occurred in tahin helva by using food additives permitted as an emulsifier for tahin helva in the Turkish and EU Codex. Sorbitan tristearate (STS), sorbitan monopalmitate (SMP) and their combinations (STS:SMP, 1:1) were added to tahin helva, then helva samples were stored at the storage temperatures of 20 °C, 30 °C, and 40 °C. The emulsifiers did not have any effect on physical, chemical and sensory properties of tahin helva except on its oil content, whereas storage temperature and storage time had effects on those properties of helva. STS:SMP combination was found to be statistically more effective than SMP and STS formulations in preventing oil separation. Penetration force of tahin helva has increased by increasing the storage temperature and storage time. It was found that there was a decrease in −a colour value of helva through the storage time at 20 °C and 30 °C, while there was an increase in that value at 40 °C. The highest change in the moisture content of all helva samples through storage was observed at the storage temperature of 20 °C. Sensory scores for appearance, texture and flavour characteristics of helva have decreased significantly during the storage period.

Keyword: Tahin Helva, Oil separation, Emulsifier, Sorbitan ester

Introduction

Foods through the world present different tastes to consumers according to climatic conditions, economic reasons, traditional habits in social life and cultural diversity of the nations. Turkish eating culture has a various food varieties and it is originated from Middle Asia. There are lots of traditional foods consumed through regional scale in Turkey (Tan 2004). Tahin helva is one of the Turkish traditional confectionary foods and it is produced at industrial scale in Turkey. The history of tahin helva has not been known completely, but it is said that this product has been produced since BC 3000. Tahin helva is also the most popular food in the Mediterranean and Middle East Countries such as Greece, Iran, Iraq, Jordan, and Saudi Arabia (Ozdemir et al. 2006).

The main ingredients of tahin helva are sesame paste (tahin), sugar syrup and Saponaria officinalis (soapwort) extract and they are mixed at different levels for the production. Tahin helva is then produced as a result of using a special mixing technique of these ingredients. Besides the main ingredients, nuts, walnuts, pistachio, cacao powder, and dried fruits may be added to enhance the flavour of tahin helva (Anon 2004). It was suggested to consume this product due to its high energy and nutritional value especially for sportsman, workers, teens, and pregnant women (Ceyhun Sezgin and Artik 2010, Var et al. 2004, Var et al. 2007). Turkish Food Codex describes the minimum limits for the chemical composition of tahin helva as; 27.50% for sesame oil, 52% for tahin, 11% for protein, 47% for total sugar (sucrose), and 97% for dry matter (Anon 2008).

Helva has a porous non-crystalline sugar melt particles surrounded by a precipitated protein layer originating from tahin. The sesame oil was found as a free fluid, filling in the spaces between sugar and protein particles. Therefore, tahin helva has got oil separation problem. It occurs by starting of the removing of the sesame oil from the product. The oil separation problem in tahin helva begins immediately after production and continues increasingly during storage of the product. This problem causes; 1) contamination of package material with oil, 2) changes on the colour of the helva negatively, and 3) changes in the texture of helva from a stringy and oily tender structure to a tough one. These changes affect the purchasing decision of the consumer, negatively due to the product looks stale and in low quality. It is also stated that the reason for this problem in tahin helva is due to the filling of spaces between protein and sugar particles with sesame oil physically in the non-emulsified form (Ereifej et al. 2005).

Although the helva producers have been using different food additives or their combinations sold under several commercial names in order to solve the oil separation problem, it is observed that the problem has not been completely solved yet. In addition, it was also determined that these additives did not contain the ones permitted to be used in this type of product. There are many studies on chemical and microbiological properties of tahin helva (Abu-Jdayil et al. 2002; Abu-Jdayil 2004; Alpaslan and Hayta 2002; Arslan et al. 2005; Ceyhun Sezgin and Artik 2010; Kahraman et al. 2010; Var et al. 2004, 2007; Yigit et al. 2007) and on other similar confectionery products (Itagi and Singh 2011; Itagi et al. 2011; Muresan et al. 2010). However, the studies on oil separation problem in tahin helva are very limited (Ereifej et al. 2005). The purposes of this present study were to solve the oil separation problem of tahin helva by using permitted food additives as emulsifiers and to evaluate the effects of the food additives on physical, chemical and sensory characteristics of tahin helva during storage at different temperatures.

Materials and methods

Materials

Traditionally prepared plain type tahin helva samples were used as the material in this study. The helva samples were produced in a tahin helva manufacturer (Tatlan Food Company, Canakkale, Turkey) by using its sugar solution, tahin and Saponaria officinalis extract. Sorbitan monostearate (E491), sorbitan tristearate (E492), sorbitan monolaurate (E493), sorbitan monooleate (E494) and sorbitan monopalmitate (E495) were used to reduce oil separation and all were food grade. All chemicals were analytical reagents (Merck, Darmstadt, Germany).

Methods

Selection of emulsifiers and their concentrations

According to Turkish Food Codex (Anon 2008) sorbitan monostearate, sorbitan tristearate, sorbitan monolaurate, sorbitan monooleate and sorbitan monopalmitate are permitted emulsifiers to be used in tahin helva at a maximum concentration of 5 g/kg (0.5%), alone or in combination. These emulsifiers were evaluated for their suitability to this food product by taking their Hydrophilic Lipophilic Balance (HLB) values into consideration. HLB values for sorbitan monolaurate, sorbitan monopalmitate, sorbitan monostearate, sorbitan monooleate and sorbitan tristearate are 8.6, 6.7, 4.7, 4.3 and 2.1, respectively (Hepworth 2006). Tahin helva is a W/O (Water in Oil) emulsion type product because of its oil and moisture contents. Therefore, sorbitan monolaurate was eliminated from this study due to its more hydrophilic character (HLB:8.6) than others. Sorbitan monostearate was also not selected for this study. Because it has both higher HLB value than sorbitan monooleate and lower esterification degree than sorbitan tristearate. So, sorbitan monopalmitate, sorbitan monooleate and sorbitan tristearate were selected for preliminary experiments. In the preliminary experiments, these selected emulsifiers were added to tahin helva as alone and with sorbitan tristearate:sorbitan monopalmitate combination (STS:SMP, 1:1) at the concentrations of 2 g/kg, 3.5 g/kg and 5 g/kg. So, 12 different helva samples and a control sample having no emulsifier were produced and stored at 40 °C for four weeks. The oil separation levels of the samples were checked during the storage. At the end of the storage, ranking test was applied by ten trained panellists to the samples for sensory evaluation in order to determine consumer overall preferences. Through the preliminary experiments, it was found that the preventive effect of sorbitan monooleate on oil separation problem was too low in all concentrations according to the others. So, it was decided for sorbitan monooleate not to include to this study. It was also not determined any significant difference between the concentration levels of the emulsifiers according to the results of sensory evaluation. Therefore, it was decided to add sorbitan tristearate (STS), sorbitan monopalmitate (SMP), and sorbitan tristearate:sorbitan monopalmitate combination (STS:SMP, 1:1) at the concentrations of 0.35%, 0.35%, and 0.2%, respectively to tahin by taking the helva production cost into consideration.

Production of tahin helva

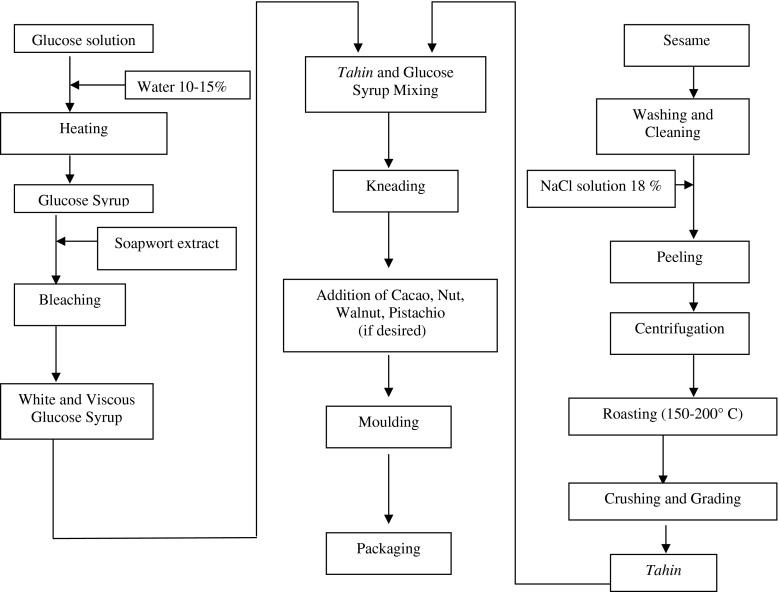

Tahin helva was produced by following the traditional production steps of the tahin helva manufacturer. These steps were observed during the production in the manufacturer and they are shown on Fig. 1. Through the production line, no changes were made except adding the food additives. They were directly added to tahin and then the tahin was mixed with a hand blender to obtain a homogenous mixture. The production was duplicated and its quantity was 10 kg for each formulation. A control sample having no emulsifier was also produced. After the bulk production of tahin helva, the product was moulded perpendicularly into small weights as 250 g and then packaged in plastic moulds. The samples were taken from these small packages as a cubic weighing almost 100 g and then put into a petri dish. The Petri dish contains filter paper and metal grids for allowing the leaked oil to remove from the sample completely during storage. Then, a beaker having suitable diameter for taking the cubic sample into itself was placed invertedly into the petri dish for avoiding moisture loss of the sample. The samples were later stored at the storage temperatures of 20 °C, 30 °C and 40 °C for 36 days to determine the effects of the emulsifiers, the storage temperature and the storage time on the oil separation level in tahin helva and also to evaluate physical, chemical and sensory properties of tahin helva.

Fig. 1.

The production steps for tahin helva (observation through the production in the helva manufacturer)

Colour measurement

Colour parameters were measured by CIE LAB Colour System. L* for lightness, −a for greenness, and +b for yellowness values of helva samples were determined on the surface of tahin helva by using Minolta Chroma Meter CR-400 model colorimeter (Minolta Ltd., Japan) during storage. The instrument was standardized with white tile of CIE Lab colour scale. Colour measurements were repeated three times at different surfaces for each helva sample and colour measurements were duplicated.

Texture measurement

The texture of helva sample was evaluated by determining penetration force. Texture analyzer, TA.XTPlus (Stable Micro Systems Ltd., U.K.) with P3 probe was used. The penetration test was carried out on 15 × 15 × 15 mm of helva sample at 20 °C. Test parameters were; 5 mm for the penetration distance and 2 mm/s for the test speed. The penetration force was automatically recorded and calculated by the TA 32 software program from the penetration force vs. time diagram in the unit of gram force (gf). Five measurements were made for each helva sample.

Moisture content

Moisture content of helva samples was determined by using vacuum drying method for confectionery products (AOAC International 2000).

Oil separation

The oil separation from the helva samples can be expressed as the decrease in the oil content of the samples during storage. Therefore, the oil content of helva samples through the storage was determined by using soxhlet extraction method (AOAC International 2000).

Sensory evaluation

Sensory evaluation was conducted with ten panellists (7 females and 3 males, ages ranged from 25 to 42 years old) by using a five-point scale scoring test in the aspects of appearance, texture and flavour characteristics of tahin helva (Demirag and Altug 1999) during storage. Panellists were consisted of academic staff and graduate students in the Department of Food Engineering at Canakkale Onsekiz Mart University. The panellists had 50 h of experience in sensory evaluation. Four samples were evaluated in each sensory panel session and each session was duplicated.

Statistical analysis

Statistical analyses were applied to the data by using Variance Analysis of Repeated Measurements to determine statistically significant differences (p < 0.05) between the factors of type of emulsifier, storage time and storage temperature and their interactions. Tukey Honestly Significant Differences (HSD) test was used for multiple comparisons. The statistical analyses were conducted by using the software packages of SPSS (Statistical Package for the Social Sciences, SPSS for Windows, release 15.0.6, USA) and SAS (Statistical Analysis System, SAS, version 9.1.3, SAS Institute Inc., NC, USA). Duplicate independent helva productions were carried out. Two parallel independent samples were taken for each analysis from each production. So, the values were expressed as mean±standard error of four independent measurements (n = 4).

Results and discussion

Colour

It was found that the changes on the colour parameter of lightness (L*) for tahin helva during the storage were not significant (p > 0.05). This shows that type of emulsifier, the storage time and the storage temperature did not have any significant effect on L* colour value of tahin helva. It was observed that the effects of the selected emulsifiers on the colour parameters of −a and +b for tahin helva were not significant (p = 0.942 and p = 0.924 for −a and +b, respectively). However, a significant interaction between storage time and storage temperature was determined for both −a and +b values of tahin helva (p = 0.001). This means that the storage temperature has a significant effect on the colour values of −a and +b for tahin helva depending on the storage time. The changes in these Hunter colour values for tahin helva during the storage at different temperatures are shown in Table 1.

Table 1.

Changes in quality characteristics of helva samples during storage at different temperatures

| Storage Temperature (°C) | Storage time (days) | ||||

|---|---|---|---|---|---|

| 0 | 6 | 12 | 24 | 36 | |

| Colour −a value | |||||

| 20 | 1.87 ± 0.07Aa | 1.91 ± 0.08Aa | 1.67 ± 0.07Aab | 1.71 ± 0.07Aab | 1.46 ± 0.05Ab |

| 30 | 1.97 ± 0.08Aa | 1.70 ± 0.09Abc | 1.76 ± 0.10Abc | 1.60 ± 0.09Ac | |

| 40 | 1.86 ± 0.09Aab | 1.72 ± 0.10Ab | 1.95 ± 0.08Aab | 2.00 ± 0.16Ba | |

| Colour +b value | |||||

| 20 | 19.59 ± 0.17Ab | 20.35 ± 0.20Aa | 19.66 ± 0.31Ab | 19.96 ± 0.14Bab | 19.39 ± 0.14Cb |

| 30 | 20.59 ± 0.16Aa | 20.14 ± 0.24Aab | 20.69 ± 0.17Aa | 20.11 ± 0.21Bab | |

| 40 | 20.79 ± 0.17Aac | 20.15 ± 0.38Aab | 21.18 ± 0.29Acd | 21.72 ± 0.44Ad | |

| Texture sensory scores | |||||

| 20 | 3.88 ± 0.04Aa | 4.07 ± 0.06Aa | 3.23 ± 0.23Ab | 2.87 ± 0.16Ac | 3.33 ± 0.06Ab |

| 30 | 3.97 ± 0.07Aa | 3.75 ± 0.11Ba | 3.53 ± 0.11Ba | 2.86 ± 0.11Bb | |

| 40 | 4.11 ± 0.09Aa | 3.45 ± 0.19ABb | 3.45 ± 0.14Bb | 3.52 ± 0.11Ab | |

The results are expressed as mean±standard error of four independent measurements (n = 4). Different capital letters within a column and different small letters within a row show significant difference for each characteristic (p < 0.05).

There is a general decrease in the colour value of −a for tahin helva through the storage time at the storage temperatures of 20 °C and 30 °C (Table 1). It was noticed that this decrease has continued until 12 days of storage and then an increase in −a value has begun for the storage temperature of 40 °C. These changes in −a values of tahin helva samples were found to be significant after the storage time of 36 days, 12 days and 12 days at the storage temperatures of 20 °C, 30 °C and 40 °C, respectively (p < 0.05). The colour value of −a is a positive function of the storage temperature under each storage time. The effect of the storage temperature on the colour value of +b for helva samples (Table 1) was found to be significant after the storage time of 24 days (p < 0.05). No significant differences were observed in the colour values of +b for helva samples stored at 30 °C and 40 °C in the storage time of 24 days, whereas significant differences were observed in between the colour values of +b of helva samples in the storage time of 36 days for each temperature. The highest +b value observed in helva samples stored at 40 °C in the storage time of 36 days.

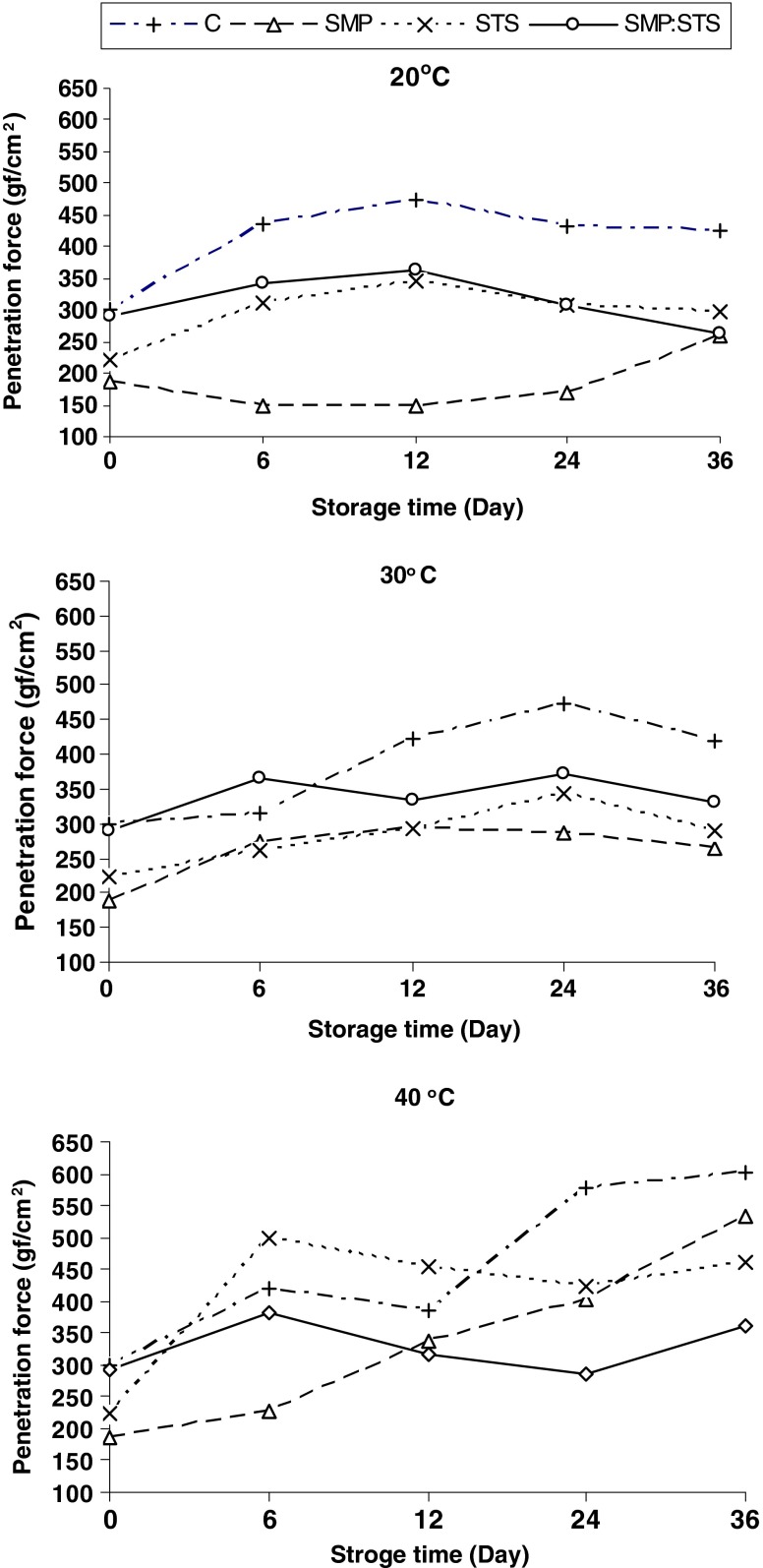

Texture

The changes on textural characteristics of tahin helva samples during storage were determined by measuring the penetration force to describe the hardness of helva. These changes are graphically shown on Fig. 2 for each selected storage temperature.

Fig. 2.

Changes in penetration force of helva samples at different temperatures. (C: helva samples without food additive; SMP: helva samples added sorbitan monopalmitate; STS: helva samples added sorbitan tristearate; SMP:STS: helva samples added Sorbitan monopalmitate:sorbitan tristearate). Each value is a mean of four independent measurements (n = 4)

There is an increase in the penetration force of tahin helva samples through the storage at each storage temperature. The penetration force for tahin helva was not significantly affected by addition of the emulsifier (p = 0.236), whereas the storage time (p = 0.001) and the storage temperature (p = 0.009) affected individually to this textural parameter significantly. In the aspect of the storage time, the increase in the penetration force was found significant in the first 6 days of the storage (p < 0.05). The penetration force of the samples stored at 40 °C was found higher and significantly different than the values obtained at the storage temperatures of 20 °C and 30 °C (p < 0.05). The highest value of penetration force was also observed at 40 °C (Fig. 2). The reasons for this significant difference are; more oil separation from tahin helva samples and slower increase in moisture content of the samples stored at 40 °C than the samples stored at 20 °C and 30 °C.

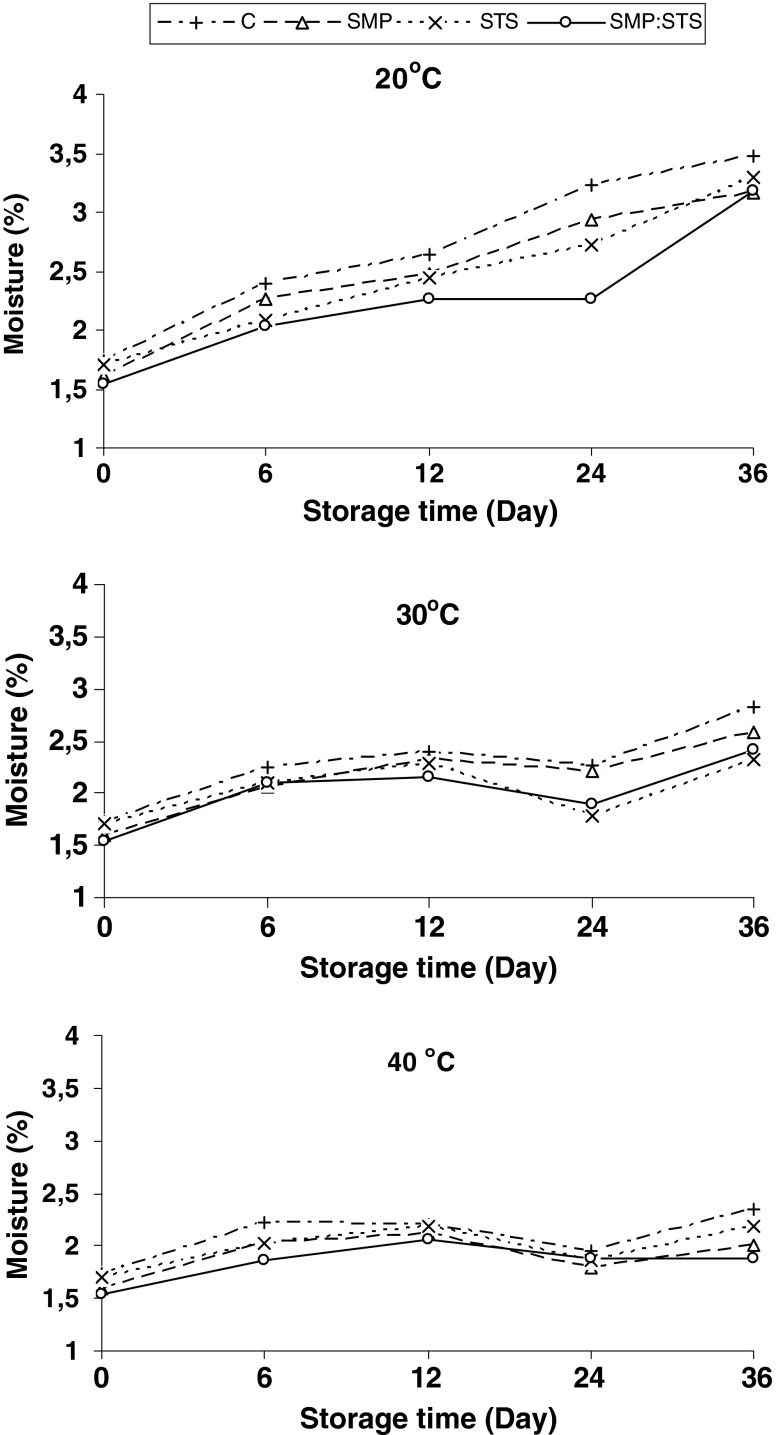

Moisture

The effect of the emulsifiers on moisture content of tahin helva samples during storage was not significant (p = 0.254), whereas a significant interaction was observed in between the storage time and the temperature for the moisture content of the samples (p = 0.001). The effect of the storage temperature on the moisture content depends on the storage time. It was also obtained that the moisture content of the samples was affected by storage time individually and both the storage time and storage temperature until and after 12 days of storage, respectively. Figure 3 shows the changes in moisture content of helva samples during storage at the temperatures of 20 °C, 30 °C and 40 °C.

Fig. 3.

Changes in moisture content of helva samples at different temperatures (C: helva samples without food additive; SMP: helva samples added sorbitan monopalmitate; STS: helva samples added sorbitan tristearate; SMP:STS: helva samples added Sorbitan monopalmitate:sorbitan tristearate). Each value is a mean of four independent measurements (n = 4)

The moisture contents of helva samples added emulsifiers increased during storage at all selected temperatures (Fig. 3). In addition, helva samples stored at 20 °C became moister than the others. The reason for this might be due to very slow water vapour circulation in the air and much more moisture absorption by helva surface at this temperature than the others. It is emphasized that confectionary products having high sugar content tend to get moisture during storage because of their hydroscopic structure. The moisture content for this type of products is very important because of being indicator of freshness. Tahin helva is given as a good example to these products and it is determined that the moisture content has got a very important effect on its durability and consumability (Mohos 2010; Edwards 2000).

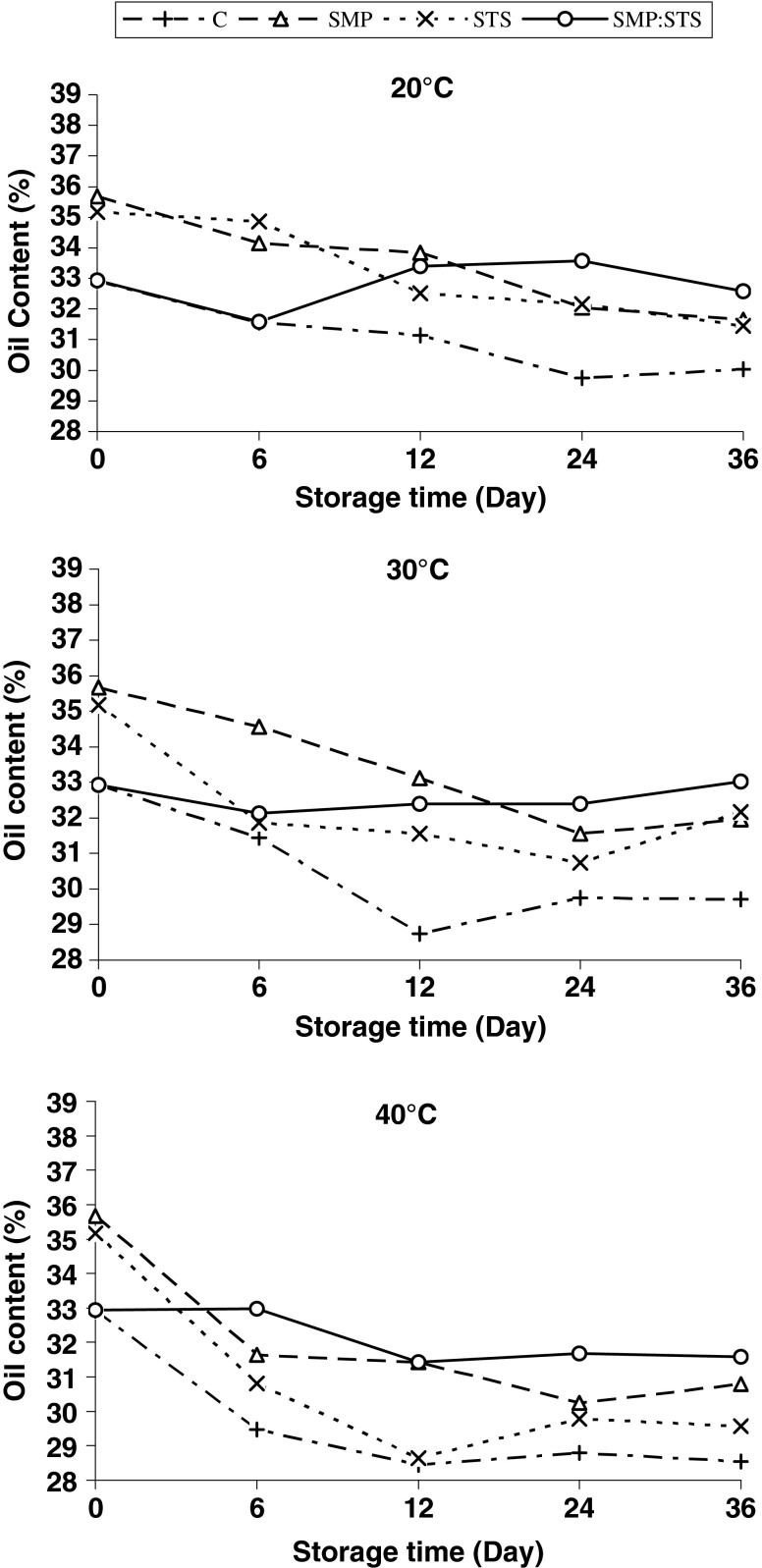

Oil separation

The effects of the selected emulsifiers on the oil separation from tahin helva samples stored at selected storage temperatures were evaluated by determining the changes in the oil content of the samples. The changes of oil content of helva samples during their storage are shown in Fig. 4.

Fig. 4.

Changes in oil content of helva samples at different temperatures (C: helva samples without food additive; SMP: helva samples added sorbitan monopalmitate; STS: helva samples added sorbitan tristearate; SMP:STS: helva samples added Sorbitan monopalmitate:sorbitan tristearate). Each value is a mean of four independent measurements (n = 4)

In Fig. 4, it can be seen that there was a general decrease in oil content of helva samples except the samples added SMP:STS combination during storage for all the storage temperatures. However, the rate of this decrease shows a slowing tendency through the storage. This means that the oil separation from helva samples has stopped after a time during storage. The decreases in the oil content of helva samples added SMP:STS during the storage were not significant for all storage temperatures. This indicates that oil separation problem in helva samples, in which sorbitan tristearate:sorbitan monopalmitate combination (STS:SMP, 1:1) was added at the concentration of 0.2%, occurs at the least ratio compared to the other helva samples. It was determined that all the factors; the selected emulsifiers, the storage time and the storage temperatures interacted significantly on oil separation from the helva samples (p = 0.007). Decreases in oil contents of control and helva samples, in which sorbitan monopalmitate (SMP) and sobitan tristearate (STS) were added, were found to be significant after the 24 days of the storage at 20 °C (p < 0.05). The changes in oil contents of these helva samples were not significantly different until 24th days of the storage. No significant differences were observed between in the oil contents of SMP:STS added samples through storage time (p > 0.05). At the storage temperature of 30 °C, the changes in the oil contents of control, SMP and STS added samples were found to be significant after 6th, 12th and 24th days of the storage, respectively (p < 0.05). Any significant differences between the oil contents of SMP:STS added samples were not observed during the storage at this temperature (p > 0.05). The changes in the oil contents of all samples except SMP:STS added ones were found to be significant after 6 days of the storage at the temperature of 40 °C (p < 0.05). These results indicate that sorbitan tristearate:sorbitan monopalmitate emulsifiers combination (STS:SMP, 1:1) at the concentration of 0.2% was very effective in preventing oil separation from helva samples during the storage for all the selected storage temperatures.

Uluöz et al. (1975) showed that oil leaked out from tahin helva at the ratio of 8.5% of its weight and they emphasized that addition of magnesium stearate and licorice extract (24%) at the concentration of 1% and 0.25% might be suitable for solving oil separation problem in tahin helva, respectively. However, they stated that comprehensive researches were required on solving this problem. Ereifej et al. (2005) investigated the effects of various food ingredients such as palm oil, soy protein isolate, gelatine, lecithin, gum arabic, pectin, and ground sugar on oil separation in tahin helva. They stated that ground sugar, gum arabic and pectin decreased the oil leaked out from tahin helva, however this decreasing was not important practically. It was demonstrated that the addition of palm oil in the concentrations of 1% and 2.5% into tahin helva at 25 °C prevented the oil separation from tahin helva, whereas soy protein isolate, gelatine and lecithin were not effective. The effects of particle dimension and storage temperature on oil emulsion stability of tahin were investigated by Ciftci et al. (2007). It was found that oil emulsion stability was increased by the decreasing of particle dimension in tahin stored at 20 °C. Hence, oil emulsion stability became independent from particle dimension of tahin at 30 °C and above temperatures. The researchers have determined the emulsion stability of tahin depended on both storage temperature and particle dimension, hence they stated that storage temperature was more effective on emulsion stability than particle dimension. Eissa and Zohair (2006) investigated the changes of some quality characteristics in modified helva with dried mushroom (oyster mushroom, Pleurotus sajor-caju) during storage at 25 °C for 6 months. It was found that colour value of a and browning index of helva increased depending on the increasing mushroom concentration (from 10 g/kg to 120 g/kg) in tahin helva. The researchers stated that the addition of dried mushroom prevented oil separation in helva. In a study by Damir (1984), utilization of sunflower seed to produce tahin and helva was investigated. In the study, no differences were observed between sunflower and sesame helva samples in terms of textural and flavour characteristics. However, sunflower helva had distinctly dark colour than sesame helva. Oil separation in sunflower helva was followed during storage at room temperature for 90 days. The researcher also emphasized that the addition of glycerol monostearate had a pronounced stabilizing action resulting in reducing oil separation from 11.8% to 6.25%.

Sensory evaluation

Plain type of tahin helva has got smooth and homogenous surface and slightly sticky, oily, fibrous, crunchy and fragile texture, when it is produced, in the aspects of such sensory characteristics as appearance and texture, respectively. Helva has also got rich yellowish colour due to its high sesame oil content. However, this product begins to loose these sensory quality characteristics through the storage. In the present study, it was observed that helva had got a tough appearance and a dull colour after a period of storage and there were increases in textural properties of stickiness and fragility, whereas there was a decrease in the property of oiliness. According to the statistical results of sensory evaluation for tahin helva samples, it was found that the selected emulsifiers did not have any effect on the sensory characteristics of appearance (p = 0.756), texture (p = 0.203) and flavour (p = 0.953) of tahin helva. On the other hand, it was observed that there was a significant interaction between the storage temperature and time in the aspect of the texture of helva (p = 0.00). This means that the storage temperature significantly affected the texture of tahin helva depending on the storage time (Table 1).

Depending on the storage time, a general decrease in sensory textural scores of helva samples was also observed during storage period (Table 1). While the decreases in the texture scores of helva samples were found significant after 12 days of storage (p < 0.05) for 20 °C and 40 °C, a decrease was found to be significant after 36 days of the storage at the temperature of 30 °C. As a result, helva samples stored at 30 °C were found more stabile regarding sensory textural properties than helva samples stored at 20 °C and 40 °C.

It was also determined that the effects of both the storage time (p = 0.001) and the storage temperature (p = 0.001) were individually significant on appearance of tahin helva, while only the storage time significantly affected the flavour of helva (p = 0.001) (Table 2).

Table 2.

Appearance and flavour sensory mean scores of helva samples for both storage time and temperatures

| Appearance sensory scores | Flavour sensory scores | ||

|---|---|---|---|

| Storage time (day) | 0 | 4.31 ± 0.11A | 4.16 ± 0.10A |

| 6 | 4.39 ± 0.04A | 4.12 ± 0.05A | |

| 12 | 3.82 ± 0.18B | 3.58 ± 0.06B | |

| 24 | 3.83 ± 0.06B | 3.31 ± 0.15C | |

| 36 | 3.64 ± 0.04B | 3.13 ± 0.14C | |

| Storage temperature (°C) | 20 | 3.77 ± 0.08B | 3.63 ± 0.06A |

| 30 | 4.09 ± 0.07A | 3.66 ± 0.08A | |

| 40 | 4.13 ± 0.06A | 3.70 ± 0.08A |

The results are expressed as mean ± standard error of four independent measurements (n = 4). Different capital letters within a column show significant difference for both storage time and temperatures (p < 0.05)

There was a general decrease in the sensory scores of appearance and flavour of helva samples during storage (Table 2). It was determined that the decreases in the appearance and flavour scores of helva samples were found significant after 12 days of storage (p < 0.05). No significant differences were observed between the appearance scores of helva samples stored at 30 °C and 40 °C in the aspect of storage temperature and the lowest appearance mean score (3.77) was found in helva samples stored at 20 °C.

Conclusion

Sorbitan tristerate:sorbitan monopalmitate: (STS:SMP, 1:1) combination at the concentration of 2 g/kg helva was obtained statistically more effective formulation than the other formulations used in this study on solving oil separation problem in tahin helva through the storage at the temperatures of 20 °C, 30 °C and 40 °C. The emulsifiers did not have any effect on the selected quality characteristics of the samples except in oil separation. Storage temperature and storage time were found more effective on physical, chemical and sensory properties of tahin helva than the emulsifiers. Thereby, the storage temperature and the storage time are important factors which should be considered in producing tahin helva in high quality. Further researches are needed to state the effects of different storage conditions, packaging materials and other food additives on tahin helva quality.

Acknowledgments

This research was funded by Scientific Research Fund of Canakkale Onsekiz Mart University (project no 2007/87). The Authors would like to thank to Tatlan Company which provided raw material and the manufacturing of tahin helva. The Authors also thank to the panel members for their judges and participation in sensory evaluation.

Footnotes

Practical applications

The oil separation problem is really considered as a very important problem in the aspects of both helva manufacturers and consumers in Turkey and also in other countries where this product is preferred to consume. Although the helva producers have been using different food additives or their combinations sold under several commercial names in order to reduce the oil separation level, it is observed that the problem has not been completely solved yet. There are many studies on chemical and microbiological properties of tahin helva and on its compounds. However, the studies on oil separation problem in tahin helva are very limited. So, we think that the results of this study will be used as a scientific source in the future studies and by confectionary manufacturers to improve quality of tahin helva.

References

- Abu-Jdayil B. Flow properties of sweetened sesame paste (halawa tehineh) Eur Food Res Technol. 2004;219:265–272. doi: 10.1007/s00217-004-0959-5. [DOI] [Google Scholar]

- Abu-Jdayil B, Al-Malah K, Soud H. Rheological characterization of milled sesame (tehineh) Food Hydrocolloids. 2002;16(1):55–61. doi: 10.1016/S0268-005X(01)00040-6. [DOI] [Google Scholar]

- Alpaslan M, Hayta M. Rheological and sensory properties of pekmez (grape molasses) tahin (sesame paste) blends. J Food Eng. 2002;54:89–93. doi: 10.1016/S0260-8774(01)00197-2. [DOI] [Google Scholar]

- Anon (2004) 5th Development plan. (in Turkish) Turkey Prime Ministry State Planning Organization.

- Anon (2008) Communiqué on tahin helva Turkish Food Codex (in Turkish) Communiqué No: 2008/6 Turkish Official Newspaper 05.03.2008–26807.

- Official methods of analysis of AOAC International. 17. Gaithersburg: AOAC International; 2000. [Google Scholar]

- Arslan E, Yener ME, Esin A. Rheological characterization of tahin/pekmez (sesame paste/concentrated grape juice) blends. J Food Eng. 2005;69:167–172. doi: 10.1016/j.jfoodeng.2004.08.010. [DOI] [Google Scholar]

- Ceyhun Sezgin AE, Artik N. Determination of saponin content in Turkish tahini halvah by using HPLC. Adv J Food Sci Technol. 2010;2(2):109–115. [Google Scholar]

- Ciftci DK, Kaya S, Kahyaoglu T, Kapucu S. Colloidal stability and rheological properties of sesame paste. J Food Eng. 2007;87(3):428–435. doi: 10.1016/j.jfoodeng.2007.12.026. [DOI] [Google Scholar]

- Damir AA. Utilization of sunflower seeds in tahina and halawa processing. Food Chem. 1984;14(2):83–92. doi: 10.1016/0308-8146(84)90047-5. [DOI] [Google Scholar]

- Demirag K, Altug T (1999) Formulation and quality evaluation of reduced sugar tahini halvah. Proc Int Congr Improved Traditional Foods for the Next Century 28–29 October Valencia, Spain 222–226.

- Edwards WP. Sugar glasses in the chemistry of boiled sweets. The science of sugar confectionery. UK: Royal Society of Chemistry; 2000. pp. 85–91. [Google Scholar]

- Eissa H, Zohair A. Quality and safety of halawa modified with mushroom. J Sci Food Agric. 2006;86:2551–2559. doi: 10.1002/jsfa.2645. [DOI] [Google Scholar]

- Ereifej KI, Rababah TM, Al-Rababah MA. Quality attributes of halva by utilzation of proteins, non-hydrogeneted palm oil, emulsifiers, gum arabic, sucrose, and calcium chloride. Int J Food Prop. 2005;8:415–422. doi: 10.1080/10942910500267323. [DOI] [Google Scholar]

- Hepworth P. Non-ionic surfactants. In: Farn RJ, editor. Chemistry and technology of surfactants. Oxford: Blackwell; 2006. pp. 133–151. [Google Scholar]

- Itagi HBN, Singh V (2011) Preparation, nutritional composition, functional properties and antioxidant activities of multigrain composite mixes. J Food Sci Technol. doi:10.1007/s13197-011-0267-6 [DOI] [PMC free article] [PubMed]

- Itagi HBN, Singh V, Indiramma AR, Parakash M (2011) Shelf stable multigrain halwa mixes: preparation of halwa, their textural and sensory studies. J Food Sci Technol. doi:10.1007/s13197-011-0423-z [DOI] [PMC free article] [PubMed]

- Kahraman T, Issa G, Ozmen G, Buyukunal S. Microbiological and chemical quality of tahini halva. Br Food J. 2010;112(6):608–616. doi: 10.1108/00070701011052691. [DOI] [Google Scholar]

- Mohos FA. Water activity shelf life and storage. Confectionery and chocolate engineering. Principles and applications. Singapore: Wiley-Blackwell; 2010. pp. 525–548. [Google Scholar]

- Muresan V, Muste S, Racolta E, Semenıuc CA, Man S, Bırou A, Chırcu C. Determination of peroxide value in sunflower halva using a spectrophotometric method. Bull UASVM Agric. 2010;67(2):334–339. [Google Scholar]

- Ozdemir F, Golukcu M, Erbas M. Influence of different microwave seed roasting processes on the changes in quality and fatty acid composition of tehina (Sesame butter) oil. Akdeniz Univ J Fac Agric. 2006;19(2):207–216. [Google Scholar]

- Tan E (2004) Project of Turkish traditional food (in Turkish). Proc Traditional Food Symp 23–24 September Van, Turkey 128–133.

- Uluöz M, Yigit V, Gözlü S (1975) Researhes on increasing the oil stability in tahin helva (in Turkish). The Scientific and Technological Research Council of Turkey Unit of Nutrition and Food Technology. Projects Report No: 9.

- Var I, Gok F, Kabak B (2004) Microbiological quality of tahin helva. Proc Traditional Food Symp 23–24 September Van, Turkey 215–219.

- Var I, Kabak B, Gok F. Survey of aflatoxin B1 in helva, a traditional Turkish food, by TLC. Food Control. 2007;18:59–62. doi: 10.1016/j.foodcont.2005.08.008. [DOI] [Google Scholar]

- Yigit A, Sahan Y, Irkin R, Korukluoglu M (2007) Chemical and microbiological properties of tahin helvas sold Bursa-Turkey. Proc Turkey 9th Food Cong The Association of Food Technology Bolu, Turkey 33.