Abstract

Objective:

The amount and consistency of the applied forces to the tooth are important factors in tooth movements; therefore, the aim of this study was to compare the initial force and the force loss of three brands of elastics in 24 hours.

Materials and Methods:

In this in-vitro study sixty non-latex elastics (3/16 medium) from three companies (Forestadent, Dentaurum and Ortho Technology) were randomly selected. Two static tests were performed, the first in a dry environment to evaluate the initial force and the other performed in a wet environment (artificial saliva) to evaluate the force loss in 24 hours. The Universal testing machine measured the forces after stretching the elastics to three times the lumen diameter. Data were analyzed by repeated measures ANOVA, One-way ANOVA, Tukey-HSD, Paired samples test, and one sample test.

Results:

The difference between the brands was significant (p=0.002). Force loss was observed in all samples; 4–7.5% force loss occurred after one hour and 19–38% force loss occurred after 24 hours. The average initial force of Forestadent and Ortho Technology was significantly higher than marketed forces (p<0.001), but the initial force of Dentaurum elastics was similar to the marketed force.

Conclusion:

The force loss over 24 hours time period was Forestadent>Dentaurum>Ortho-Technology. According to the initial force and force loss percentage it is suggested to replace the non-latex elastics several times a day.

Keywords: Dentistry, Latex, Rubber, Orthodontic Appliances

INTRODUCTION

Elastics have been used in orthodontics for more than a century [1]. Orthodontic elastics are cheap and can be easily replaced by the patient [2]. Natural latex is an isoprene polymer made of high-weighted molecules and small amounts of protein and fatty acids [3]. Natural latex is non-allergic, but has low mechanical properties; therefore, processing is needed to reinforce it. During processing ammonia is added and it produces an allergen protein. Vulcanization is another process in which chemical agents such as accelerators and anti-oxidants are added that are also allergens [4]. ADA reported that approximately 0.12–6% of the people and 6.2% of the dentists are allergic to latex [5]. Skin contact with latex in allergic people can lead to dermatitis and mucosal contact with orthodontic elastics can lead to systemic reactions such as anaphylactic shock [6]. In the early 90’s a synthetic product called non-latex elastics were generated for allergic patients. Latex and non-latex elastics have different behavior in clinical use, therefore the mechanical properties (initial force and force loss) of non-latex elastics need to be evaluated experimentally. Russell et al. compared the properties of latex and non-latex elastics and reported that the mechanical features of elastics differ according to the material and the production company [6]. Kersey et al. evaluated the initial force and 24 hours force loss in four brands of non-latex elastics and stated that in similar traction forces, the initial force produced in the different brands were significantly different. In addition, all the elastics lost 50% of their initial force after 24 hours of dynamic testing [7].

Aljhani et al. performed static and dynamic tests on latex and non-latex elastics and stated that there was no significant difference between the groups in static tests, but the difference was significant in dynamic tests [8]. Lopez et al. carried out an in vitro study evaluating the force loss in latex and non-latex. Their results showed that moist environments show higher force loss than dry environments and non-latex elastics had a higher force loss [9]. Clinicians should be aware of the force magnitude generated by the elastics and how this force declines during time.

This study aims to evaluate the primary traction force and force loss of three brands of non-latex elastics during 0.5, 1, 3, 6 and 24 hours maintenance in wet and dry environments.

MATERIALS AND METHODS

The non-latex elastics used in this in-vitro experimental study were 3/16-inch medium Dentaurum (Dentaurum, Ispringen, Germany) with 4.5-oz (128g) force, Ortho Technology (Ortho Technology, Florida, USA) with 4.5-oz (128g) force and Forestadent (Forestadent, Pforzheim, Germany) with 4-oz (113g) force. Each group had 20 samples of the latest products and was kept in a dark and cool place. The Universal testing machine (Walter+Bai AG, Lohningen, Switzerland) was used for force measurement with 200 Newton load cell capacity and stated accuracy 0.01 Newton.

Two cylindrical stainless steel pieces of 1.5 mm diameter and 1 cm length were designed to hold the elastics in the Universal testing machine. Twenty holding devices were made of stainless steel wires with 1.5 mm diameter to keep the samples in artificial saliva and to keep them stretched at three times the lumen diameter.

The artificial saliva consisted of 1.3 g/L potassium chloride, 0.1 g/L sodium chloride, 0.05 g/L magnesium chloride, 0.1 g/L calcium chloride, 2.5 × 10−5 g/L sodium fluoride, 0.035 g/L potassium dehydrogenate phosphate (KH2PO4), and 0.162 g/L ZnSO4 with a PH of 7.

In this study, two methods were performed:

Measuring the traction force after stretching the elastic to 14.3 mm (3 times the lumen diameter) in a dry environment and room temperature (25° C)

Evaluating the amount of force loss in artificial saliva using 14.3 mm traction in 0.5, 1, 3, 6 and 24 hours

In the dry test, elastics were stretched from 5 mm to 14.3 mm by the Universal testing machine with 25 mm/min speed and the generated forces were immediately recorded. The stretched elastics were then transported to the artificial saliva container using the holders. The artificial saliva was kept at 37° C to stimulate human body temperature. A heating machine maintained the temperature during the test. In both tests, the performer was blind regarding the type of elastic. Each sample remained in the artificial saliva for 30 minutes and then restored to the Universal testing machine in the same length and the traction force was evaluated again.

After this, the samples were put inside artificial saliva again. This process was repeated every 0.5, 1, 3, 6, and 24 hours for each sample, resulting in a total 60 tractions in the dry environment to evaluate the initial force and 300 tractions in saliva to evaluate force changes.

Statistical Analysis

The Kolmogorov-Smirnov test was performed and it resulted in normal data distribution. Data were analyzed by repeated measure ANOVA, Tukey HSD, Paired-Samples T-Test, One-way ANOVA and One-Samples T-Test. Repeated measure ANOVA test was used to compare the effects of time intervals and different brands (Dentaurum, Forestadent, and Ortho Technology).

The significance level was set at p<0.05. Calculations were performed with the SPSS software for Windows, version 17 (SPSS, Chicago, Il, USA).

RESULTS

Sixty non-latex elastics (3/16 inch, Medium) were evaluated in this study. The initial force was measured in a dry environment and force loss was measured in artificial saliva at 0.5, 1, 3, 6 and 24 hours after the first stretching.

Means, standard deviations and range of force values generated by each group of elastics when stretched to three times their internal diameter are shown in Table 1. The repeated measures ANOVA test showed that there was a significant difference between the forces of the three types of elastics regarding the time of measurement (p<0.001, df=2.33, F=1149).

Table 1.

Comparison of Initial Forces and Force Loss Over Time of Non-Latex Elastics Between Three Manufacturers

| Brand | 0 Hour Mean±SD (Range) g | 30 min Mean±SD (Range) g | 1 Hour Mean±SD (Range) g | 3 Hours Mean±SD (Range) g | 6 Hours Mean±SD (Range) g | 24 Hours Mean±SD (Range) g |

Repeated Measures ANOVA

|

|---|---|---|---|---|---|---|---|

| P Valued | |||||||

| Forestadent N=20 | 139.03±6.6 (128–156) | 138.58±5.8 (128–152) | 128.59±6.8 (117–147) | 126.27±7.07 (112–140) | 119.52±6.3 (103–131) | 86.27±9.9 (68–110) | P<0.001 df=5 F=938.5 |

| Ortho Technology N=20 | 134.25±5.6 (123–141) | 132.76±5.6 (119–140) | 128.95±7.1 (115–137) | 123.66±6.7 (105–132) | 119.87±5.9 (105–129) | 108.49±5.5 (96–119) | P<0.001 df=5 F=301.1 |

| Dentaurum N=20 | 127.90±12.7 (119–179) | 125.24±12.6 (115–175) | 120.56±11.9. (109–166) | 113.17±11.8 (102–159) | 104.85±10.2 (94–143) | 100.18±12.1 (82–140) | P<0.001 df=5 F=194.8 |

| One Way ANOVA | P<0.001 | P<0.001 | P=0.006 | P<0.001 | P<0.001 | P<0.001 | |

| P Value | 27.84 | 211.71 | 25.64 | 212.19 | 224.24 | 227.34 | |

| df | |||||||

| F |

Different brands also showed significant differences (p=0.002, df=2, F=7.09). The Tukey HSD test showed that there was no significant difference between Forestadent and Ortho Technology (p=0.81), but the difference between Forestadent and Dentaurum (p=0.01) and between Ortho Technology and Dentaurum (p=0.002) was significant. The paired T-test showed that there was a significant difference between the different times of measurement regardless of the elastic brand (p<0.001).

The paired T-test showed that there was no significant difference between the mean initial force and the force after 0.5 hours of stretching in Forestadent elastics (p=0.18), but comparing the initial force with the remaining forces at other times, the differences were significant (p<0.001). Ortho Technology elastics showed significant difference between the forces at different times (p<0.001). Dentaurum elastics showed the same properties as Ortho Technology. The One-way ANOVA test compared the force loss of the three brands at each of the specific times, which showed significant differences (Table 1).

The Tukey HSD test was performed afterwards and its results are shown in Table 2. The One samples test showed that the mean forces measured in Forestadent elastics were significantly different from the manufacturers statement (p<0.001).

Table 2.

Comparison of Different Elastics in Different Times

| Time (hour) | Tukey HSD/ P Value | |||||

|---|---|---|---|---|---|---|

|

|

|

|||||

| Brand | 0 | 0.5 | 1 | 3 | 6 | 24 |

| Forestadent-OrthoTechnology | 0.21* | 0.09* | 0.99* | 0.62* | 0.98* | <0.001 |

| Forestadent-Dentaurum | 0.001 | <0.001 | 0.017 | <0.001 | <0.001 | <0.001 |

| Dentaurum-OrthoTechnology | 0.071* | 0.023 | 0.012 | <0.001 | <0.001 | 0.022 |

No Significant difference

The same results were obtained from Ortho Technology elastics except at the 1-hour measurement (p1h =0.55).

The forces stated by Dentaurum (128 g) were not significantly different at the time 0 and 0.5 hour (pt0=0.97, pt0.5h=0.34), but the difference with the 1-hour (p=0.01), 3, 6 and 24-hours (p<0.001) measurement was significant.

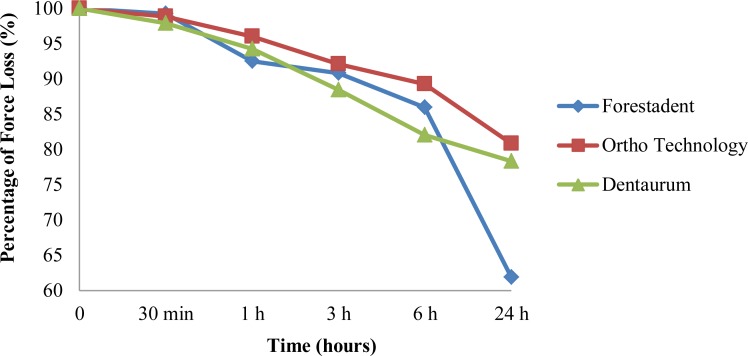

Dentaurum elastics showed the highest force loss after 0.5, 3 and 6 hours, but after 24 hours Forestadent elastics showed a very high force loss. Ortho Technology elastics had the least force loss. Until the first 6 hrs, the mean force produced by Forestadent and Ortho Technology elastics was not significantly different, but after 24 hrs, Forestadent elastics showed significant force loss compared with the other two elastics. The percentage of elastic force loss is showed in figure 1.

Fig 1.

The percentage of initial force loss over time for non-latex elastics

DISCUSSION

Different environments have various effects on elastic properties and the oral cavity can plastize these polymers.

Paulich stated that the force loss of elastics is related to the experimental environments [10]. Ash and Nikolai suggested that a higher force relaxation is observed in 37°c water compared to the same temperature air [11]. Lopez et al. confirmed these findings [9]. On the contrary, Bales et al. reported no difference between the forces generated by elastics in dry and wet environments [12]. Therefore, there is no consensus on the optimal environment for experimenting orthodontic elastics. The initial force in this study was measured in a dry environment in room temperature because the elastics are normally kept in room temperature. The second experiment was performed in artificial saliva (37°c and PH= 7). The oral environment cannot be exactly simulated because it is affected by various foods, repetitious opening closing, temperature and difference PH over the day. Reviewing the data showed that in all three products, the elastics from the same package generated a variety of forces. Other studies have also confirmed this finding [6-9, 13]. This finding does not have any clinical importance, because the force variation is in the acceptable range for moving the teeth (100–250g) [14,15].

Forestadent and Ortho Technology elastics generated significantly higher forces than the marketed force, when stretched 3 times the lumen diameter in a dry environment (p<0.001). But the Dentaurum elastics generated forces that did not have significant differences with the marketed force (p=0.97). Studies carried out by Russell et al., Lopez et al. and Aljhani et al. confirmed these findings [6,8,9]. Kersey et al. reported that forces generated by non-latex elastics were lower than the marketed force [13]. This difference could be due to the different brands of elastics that were used. The force loss evaluation showed that after 1-hour the amount of force loss was 4–7.5% and after 24-hours it was 19–38%. Kersey et al. reported 31% force loss after 24-hours in the static test and 47% in the dynamic test [13]. After 24-hours, Russell et al. reported 20–43% force loss that is similar to our results [6]. The amount of 1-hour force loss reported by Russell et al. was 15–20% and 10–12% was reported by Aljhani et al., which are very higher than our study (4–7.5%) [6,8].

Lopez et al. measured the amount of 24-hours force loss of non-latex elastics kept in distilled water, which was 10–21% and lower than our results [9]. These differences may be related to the various elastic brands used and the different experimental environments.

One might ask how much force loss is clinically significant? There is no clear answer, but Baty et al. suggested that a 10% force change is clinically significant when using elastomeric chains, [16]. In the present study, all elastics had greater than 10% force loss after six hours. This study evaluated the force loss using a static test similar to the majority of studies [2, 9, 12, 17–19]. Other studies evaluated the force loss dynamically [6–8, 13]. The results for a dynamic test are different from a static one and are closer to the real elastic use in clinic. Kersey et al. stated that repetitious stretching of elastics causes a higher force loss than the static testing at the beginning of the test, but after 1-hour, the force loss was similar in both tests [13]. Aljhani et al. declared that there was no significant difference between different latex elastics or even non-latex elastics in the static testing, but the dynamic test showed differences between the elastics. They also concluded that the highest force loss in the static test was in the first half hour and it was after ten cycles in the dynamic test [8].

Elastic replacement time is important. Some authors suggest replacing elastics every 8 hours [7, 13].

Various factors can affect elastics inside the oral cavity; for example, the oral PH significantly affects the rate of force loss. PH levels above neutral increase the force-decay rate [20].Clinical decisions should not be made only by considering in vitro experiences. We suggest further studies evaluating the force loss of latex and non-latex elastics in intra-oral conditions.

CONCLUSION

Dentaurum elastics were significantly different from Ortho-Technology and Forestadent regarding force loss. There was no significant difference between Ortho Technology and Forestadent elastics.

The initial force generated by Forestadent and Ortho Technology elastics was significantly higher than the marketed force. But the initial force of Dentaurum elastics had no significant difference with the marketed force.

Dentaurum elastics showed the highest force loss after 0.5, 3 and 6 hours, but after 24 hours Forestadent elastics showed very high force loss. Ortho Technology elastics had the least force loss.

The force loss over the 1 hour time period was 4% −7.5% and after 24 hours it was 19%–38%.

It is suggested to change non-latex elastics at regular intervals during 24 hours.

Acknowledgments

This study was supported by Isfahan University of Medical Sciences Research Grant #386401. The manuscript was based on a thesis submitted to the postgraduate School of Dentistry, Isfahan University of Medical Sciences in partial fulfillment of the Master of Science degree.

REFERENCES

- 1.Case CS. Original use and misuse of the intermaxillary force, and its relation to occipital and other anchorage forces in orthodontia. Dental Cosmos. 1904 May;:345–62. [Google Scholar]

- 2.Wang T, Zhou G, Tan X, Dong Y. Evaluation of force degradation characteristics of orthodontic latex elastics in vitro and in vivo. Angle Orthod. 2007 Jul 4;77(4):688–93. doi: 10.2319/022306-76. [DOI] [PubMed] [Google Scholar]

- 3.Billmeyer FW. Textbook of polymer science. New York: Wiley & Sons; 1984. [Google Scholar]

- 4.Cronin E. Contact dermatitis. Edinburg, UK: Churchill Livingstone; 1980. [Google Scholar]

- 5.The dental team and latex hypersensitivity ADA Council on Scientific Affairs. J Am Dent Assoc. 1999 Feb;130(2):257–64. doi: 10.14219/jada.archive.1999.0177. [DOI] [PubMed] [Google Scholar]

- 6.Russell KA, Milne AD, Khanna RA, Lee JM. In vitro assessment of the mechanical properties of latex and non-latex orthodontic elastics. Am J Orthod Dentofacial Orthop. 2001 Jul 17;120(1):36–44. doi: 10.1067/mod.2001.114642. [DOI] [PubMed] [Google Scholar]

- 7.Kersey ML, Glover KE, Heo G, Raboud D, Major PW. A comparison of dynamic and static testing of latex and nonlatex orthodontic elastics. Angle Orthod. 2003 Apr;73(2):181–6. doi: 10.1043/0003-3219(2003)73<181:ACODAS>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 8.Aljhani AS, Aldrees AM. The effect of static and dynamic testing on orthodontic latex and non-latex elastics. Orthodontic Waves. 2010 May 26;69(3):117–22. [Google Scholar]

- 9.Lopez N, Vicente A, Bravo LA, Calvo JL, Canteras M. In vitro study of force decay of latex and non-latex orthodontic elastics. Eur J Orthod. 2012 Apr;34(2):202–7. doi: 10.1093/ejo/cjq188. [DOI] [PubMed] [Google Scholar]

- 10.Paulich F. Measuring of orthodontic forces. Am J Orthod Oral Surg. 1939 Sep;25(9):817–49. [Google Scholar]

- 11.Ash JL, Nikolai RJ. Relaxation of orthodontic elastomeric chains and modules in vitro and in vivo. J Dent Res. 1978 May-Jun;57(5–6):685–90. doi: 10.1177/00220345780570050301. [DOI] [PubMed] [Google Scholar]

- 12.Bales TR, Chaconas SJ, Caputo AA. Force-extension characteristics of orthodontic elastics. Am J Orthod. 1977 Sep 1;72(3):296–302. doi: 10.1016/0002-9416(77)90215-9. [DOI] [PubMed] [Google Scholar]

- 13.Kersey ML, Glover K, Heo G, Raboud D, Major PW. An in vitro comparison of 4 brands of nonlatex orthodontic elastics. Am J Orthod Dentofacial Orthop. 2003 Apr 16;123(4):401–7. doi: 10.1067/mod.2003.22. [DOI] [PubMed] [Google Scholar]

- 14.Storey EE, Smith R. Force in orthodontics and its relation to tooth movement. Aust J Dent. 1952;56(1):11–8. [Google Scholar]

- 15.Reitan K. Some factors determining the evaluation of forces in orthodontics. Am J Orthod. 1957;43(1):32–45. [Google Scholar]

- 16.Baty DL, Volz JE, von Fraunhofer JA. Force delivery properties of colored elastomeric modules. Am J Orthod Dentofacial Orthop. 1994 Jul 1;106(1):40–6. doi: 10.1016/S0889-5406(94)70019-2. [DOI] [PubMed] [Google Scholar]

- 17.Kanchana P, Godfrey K. Calibration of force extension and force degradation characteristics of orthodontic latex elastics. Am J Orthod Dentofacial Orthop. 2000 Sep 13;118(3):280–7. doi: 10.1067/mod.2000.104493. [DOI] [PubMed] [Google Scholar]

- 18.Fernandes DJ, Fernandes GM, Artese F, Elias CN, Mendes AM. Force extension relaxation of medium force orthodontic latex elastics. Angle Orthod. 2011 Sep;81(5):812–9. doi: 10.2319/120810-709.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Raji SH, Alavi Sh, Yasini M. In Vitro Evaluation of Extension Force and Comparison of Force Degradation in Three Brands of Orthodontic Latex Elastics. Shiraz Univ Dent J. 2009 Jan;10(1):7–15. [Google Scholar]

- 20.Ferriter JP, Meyers CE, Jr, Lorton L. The effect of hydrogen ion concentration on the force-degradation rate of orthodontic polyurethane chain elastics. Am J Orthod Dentofacial Orthop. 1990 Nov 1;98(5):404–10. doi: 10.1016/S0889-5406(05)81648-8. [DOI] [PubMed] [Google Scholar]