Abstract

Background: Friction between archwires and brackets is assuming greater importance for finishing with increased use of sliding mechanics in orthodontics as friction impedes the desired tooth movement. The following study is conducted to compare and evaluate the effect of ligation on friction in sliding mechanics using 0.022" slot bracket in dry condition. Materials & Methods: In the study 48 combinations of brackets, archwires and different ligation techniques were tested in order to provide best combination that offers less friction during sliding mechanics. Instron- 4467 machine was used to evaluate static and kinetic friction force values and the results were subjected to Statistical Analysis and Anova test. Results: The results of the study showed that 0.022" metal brackets, Stainless steel wires and Slick modules provided the optimum frictional resistance to sliding mechanics. It is observed that frictional forces of 0.019" x 0.025" were higher when compared with 0.016" x 0.022" Stainless steel archwire due to the increase in dimension. Self-ligating brackets offered least friction followed by mini twin, variable force, regular stainless steel, ceramic with metal insert bracket and ceramic brackets. The stainless steel ligature offered less resistance than slick and grey modules, and TMA wires recorded maximum friction. Conclusion: The stainless steel archwire of 0.019" x 0.025" dimension are preferred during sliding mechanics, these archwires with variable force brackets ligated with Slick Modules offer decreased friction and is cost effective combination which can be utilized during sliding mechanics. How to cite the article: Vinay K, Venkatesh MJ, Nayak RS, Pasha A, Rajesh M, Kumar P. A comparative study to evaluate the effects of ligation methods on friction in sliding mechanics using 0.022" slot brackets in dry state: An In-vitro study. J Int Oral Health 2014;6(2):76-83.

Key words: : Brackets, friction, kinetic friction, slick modules, static friction

Introduction

Friction is defined as the resisting force tangential to the common boundaries between two or more bodies, when under the action of an external force; one body moves or tends to move relative to the surface of the other. 1

Binding may occur when point contacts are formed between bracket, archwire and or ligatures producing a force couple that resists sliding. This force may prevent tooth movement and may also result in damage to the surface of the orthodontic appliance resulting in notching. 2

Proffit (2000) reported that 50% of the force necessary to initiate tooth movement is required to overcome the retarding force generated between brackets, arch wire and ligatures. 3

For better understanding of friction it is important to know the role of various factors in the origin of friction. Many studies have been conducted on orthodontic arch wires and bracket and the following factors influencing friction have been identified. 4 They can be classified as Physical factors like archwire, ligation, material, and appliance design. 5 Thus the aim of the study was 1) To understand the unknown frictional resistance offered by different methods of ligation. 2) To choose the right method of ligation and also overcome the resistance by suitably modifying the force applied to bring about desired tooth movement.

Materials and Methods

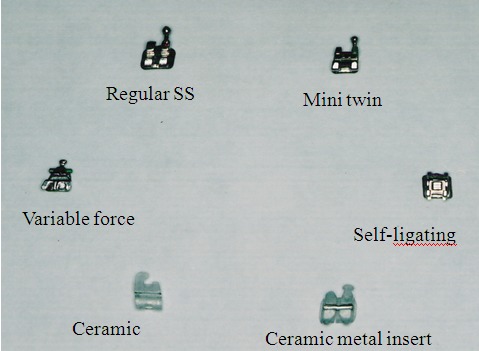

Pre-adjusted edgewise brackets (0.022" slot) of the following bracket types like regular Stainless Steel (GAC), Mini Twin (Ortho Organizers), Ceramic (3M), Ceramic brackets with Metal inserts (3M), Self-Ligation (Damon SL), and Variable force (Ortho Organizers) ( Figure 1 ) and different arch wires used in study are Stainless steel

Figure 1: Different bracket types used in the study.

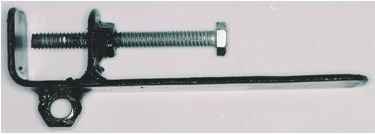

and TMA of 0.016" x 0.022" and 0.019" x 0.025" dimensions. Different ligation method s like Stainless steel, regular grey modules, New Slick modules (TP), and Selfligating brackets were used. A custom made jig was constructed to record the resistance to movement. The jig consists of a screw type of locking mechanism to secure the arch wire to the jig as shown in Figure 2 .

Figure 2: Custom made Jig.

Sample size consisted of 48 combinations of brackets, archwires and ligating methods in dry state.

Ligation

The elastic modules compared were the regular grey modules and the new Slick modules incorporating metafasix technology. 5 The stainless steel ligatures were initially fully tightened and then unwound to allow little play between both spans of ligature and the arch wire. 6

Procedure

The testing was performed on an Instron-4467 machine ( Figure 3 ) with a cross head speed of 20 mm/min over an 8 mm stretch of the archwire. The jig was mounted on the lower cross head of the machine. The arch wire was aligned parallel with the vertical framework of the Instron machine as shown in Figure 2 . A 30 kg load cell was placed on the upper crosshead and readings were recorded. The bracket was pulled in a vertical direction by a loop of 0.5 mm stainless steel wire.

Figure 3: Instron -4467 Universal Testing Machine.

Static and Kinetic frictional forces were recorded as displayed on the electronic monitor and tabulated. 7

Statistical Analysis:

The frictional resistance (static and kinetic) were recorded and tabulated as Tables 1 to 4 . The variables in each table are subjected to Anova.

Table 1: Static and kinetic frictional forces for various brackets and ligation methods using 0.016”x 0.022”stainless steel wire.

| Bracket | Friction | SS Ligature (gms) | Grey Modules (gms) | Slick Modules (gms) | Self Ligating (gms) |

| Mini Twin | Static | 18.4 | 58.9 | 37.4 | - |

| Kinetic | 13.2 | 49.4 | 31.9 | - | |

| Ceramic | Static | 46.4 | 98.7 | 69.9 | - |

| Kinetic | 38.9 | 87.2 | 61.2 | - | |

| Ceramic Metal Insert | Static | 87.8 | 91.4 | 87.4 | - |

| Kinetic | 79.6 | 81.2 | 78.3 | - | |

| Regular SS | Static | 24.5 | 72.1 | 64.1 | - |

| Kinetic | 19.2 | 65.8 | 58.9 | - | |

| Variable Force | Static | 16.2 | 41.3 | 40.1 | - |

| Kinetic | 11.8 | 36.8 | 33.4 | - | |

| Self-Ligating | Static | - | - | - | 13.1 |

| Kinetic | - | - | - | 9.6 |

Table 4: Static and kinetic frictional forces for various brackets and ligation methods using 0.019" x 0.025"stainless steel wire depicted using Anova test.

| Source of Variation | SS | df | MS | F | P-value | F crit |

| Between Brackets | 32445.23 | 5 | 6489.0469 | 274.361 | 2.364E-20 | 2.6207 |

| Between Modules | 59138.23 | 3 | 19712.744 | 833.468 | 2.188E-24 | 3.0088 |

| Interaction | 20856.55 | 15 | 1390.4368 | 58.7886 | 3.151E-15 | 2.1077 |

Null Hypotheses:

H 0I : There is no significant interaction effect between brackets and modules.

H 0Tr : There is no significant difference among brackets.

H 0B : There is no significant difference among modules.

Alternate Hypotheses:

H 1I : There is a significant interaction effect between brackets and modules.

H 1Tr : There is a significant difference among brackets.

H 1B : There is a significant difference among modules.

Level of Significance: α = 0.05

Critical region:

The probability values (P-value) for each of the hypotheses is compared with the level of significance. The decision criterion is to reject H 0 if P < 0.05. Otherwise we accept H 0 .

Results

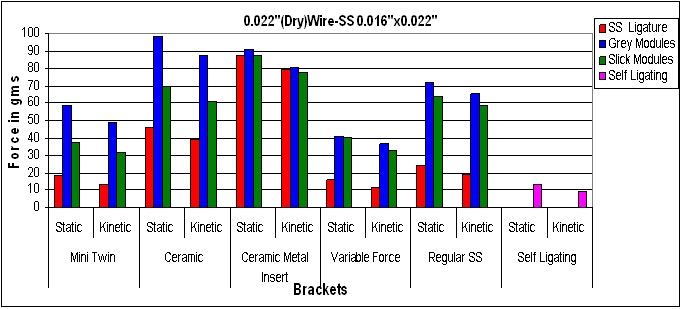

Table 1 and Graph 2 showed that static and kinetic friction values for using 0.016"x 0.022" Stainless steel wire were highest in ceramic brackets with grey modules where as self ligating showed the least values. Among the ligation techniques, grey modules showed the highest friction values and stainless steel ligatures showed the least friction. It can be inferred from Table 2 that since the P value is <0.05, there is a significant difference among the brackets with respect to frictional forces. With respect to module the P values is < 0.05 which again indicates a significant difference among the modules in frictional forces. The Pvalue for Interaction effect being < 0.05 indicates that there is a significant interaction effect between brackets and

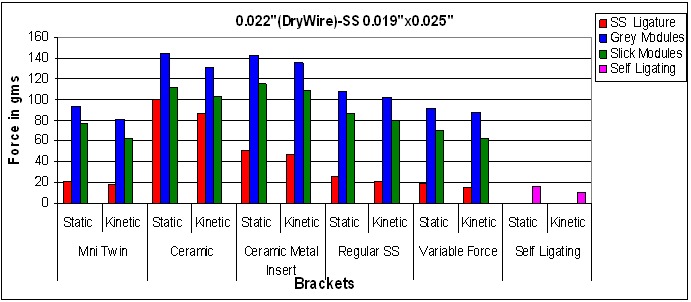

Graph 2: Bar graph representing Static and kinetic frictional forces for various brackets and ligation methods using 0.019" x 0.025" Stainless steel wire.

Table 2: Static and kinetic frictional forces for various brackets and ligation methods using 0.016”x 0.022”stainless steel wire depicted using Anova test.

| Source of Variation | SS | Df | MS | F | P-value | F crit |

| Between Brackets | 18409.8 | 5 | 3681.956 | 206.13 | 6.77E-19 | 2.6207 |

| Between Modules | 20880.1 | 3 | 6960.019 | 389.65 | 1.75E-20 | 3.0088 |

| Interaction | 11097.2 | 15 | 739.8146 | 41.418 | 1.73E-13 | 2.1077 |

modules when used with 0.016" x 0.022" stainless steel wire.

Table 3 and Graph 2 showed that static and kinetic friction values 0.019" x 0.025" Stainless steel wire were highest in ceramic bracket with grey modules where as self ligating showed the least values. Among the ligation techniques grey modules showed the highest friction values and stainless steel showed the least friction.

Table 3: Static and kinetic frictional forces for various brackets and ligation methods on 0.019”x 0.025”stainless steel wire.

| Bracket | Friction | SS Ligature (gms) | Grey Modules (gms) | Slick Modules (gms) | Self Ligating (gms) |

| Mini Twin | Static | 20.9 | 93.8 | 77.4 | - |

| Kinetic | 18.1 | 80.4 | 63.2 | - | |

| Ceramic | Static | 99.1 | 144.6 | 110.9 | - |

| Kinetic | 86.4 | 130.1 | 103.7 | - | |

| Ceramic Metal Insert | Static | 50.9 | 141.8 | 114.5 | - |

| Kinetic | 47.4 | 135.6 | 109.2 | - | |

| Regular SS | Static | 26.5 | 108.3 | 86 | - |

| Kinetic | 20.9 | 101.9 | 79.2 | - | |

| Variable Force | Static | 18.6 | 91.4 | 70.5 | - |

| Kinetic | 15.1 | 88.1 | 63.1 | - | |

| Self-Ligating | Static | - | - | - | 17.1 |

| Kinetic | - | - | - | 10.2 |

It can be inferred from Table 4 that since the P value is <0.05, there is a significant difference among the brackets with respect to frictional forces. With respect to module the P values is < 0.05 which again indicates a significant difference among the modules in frictional forces. The Pvalue for Interaction effect being < 0.05 indicates that there is a significant interaction effect between brackets and modules when used with 0.019" x 0.025" stainless steel wire.

Table 5 and Graph 3 showed that static and kinetic friction values for 0.016" x 0.022" TMA wire were highest in ceramic bracket with grey modules where as self ligating showed the least values. Among the ligation techniques grey modules showed the highest friction values and stainless steel showed the least friction.

Table 5: Static and kinetic frictional forces for various brackets and ligation methods using 0.016" x 0.022" TMA wire.

| Bracket | Friction | SS Ligature (gms) | Grey Modules (gms) | Slick Modules (gms) | Self Ligating (gms) |

| Mini Twin | Static | 87.1 | 219.9 | 96.9 | - |

| Kinetic | 75.9 | 182.4 | 72.3 | - | |

| Ceramic | Static | 302.6 | 435.3 | 355.6 | - |

| Kinetic | 287.1 | 414.2 | 327.3 | - | |

| Ceramic Metal Insert | Static | 271.4 | 390.1 | 198.5 | - |

| Kinetic | 222.3 | 378.2 | 189.4 | - | |

| Regular SS | Static | 150.5 | 226.5 | 120.3 | - |

| Kinetic | 142.1 | 201.6 | 99.4 | - | |

| Variable Force | Static | 114.7 | 201.4 | 108.5 | - |

| Kinetic | 103.2 | 193.6 | 102.5 | - | |

| Self-Ligating | Static | - | - | - | 40.2 |

| Kinetic | - | - | - | 36.9 |

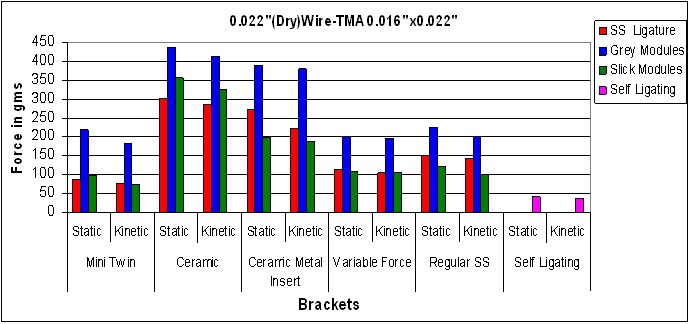

Graph 3: Bar graph representing Static and kinetic frictional forces for various brackets and ligation methods using 0.016" x 0.022" TMA wire.

It can be inferred from Table 6 that since the P value is <0.05, there is a significant difference among the brackets with respect to frictional forces. With respect to module the P values is < 0.05 which again indicates a significant difference among the modules in frictional forces. The Pvalue for Interaction effect being < 0.05 indicates that there is a significant interaction effect between brackets and modules when used with 0.016" x 0.022" TMA wire.

Table 6: Static and kinetic frictional forces for various brackets and ligation methods using 0.016" x 0.022" TMA wire depicted using Anova test.

| Source of Variation | SS | df | MS | F | P-value | F crit |

| Between Brackets | 327263 | 5 | 65452.601 | 411.987 | 1.943E-22 | 2.62065 |

| Between Modules | 324475.7 | 3 | 108158.56 | 680.796 | 2.415E-23 | 3.00879 |

| Interaction | 162967.7 | 15 | 10864.516 | 68.3859 | 5.489E-16 | 2.10768 |

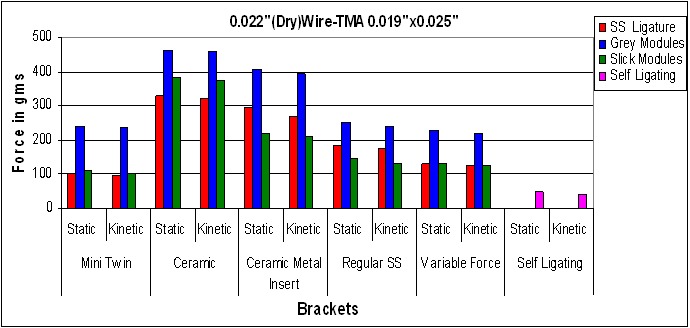

Table 7 and Graph 4 showed that static and kinetic friction values for 0.019" x 0.025" TMA wire were highest in ceramic bracket with grey modules where as self ligating showed the least values. Among the ligation techniques grey modules showed the highest friction values and

Table 7: Static and kinetic frictional forces for various brackets and ligation methods using 0.019" x 0.025" TMA wire.

| Bracket | Friction | SS Ligature (gms) | Grey Modules (gms) | Slick Modules (gms) | Self Ligating (gms) |

| Mini Twin | Static | 101.6 | 240.4 | 110.2 | - |

| Kinetic | 97.2 | 235.6 | 101.5 | - | |

| Ceramic | Static | 329.3 | 465.4 | 381.7 | - |

| Kinetic | 320.1 | 460.2 | 374.4 | - | |

| Ceramic Metal Insert | Static | 296.7 | 405.6 | 220.5 | - |

| Kinetic | 270.1 | 396.2 | 210.6 | - | |

| Regular SS | Static | 180.9 | 250.1 | 147.5 | - |

| Kinetic | 173.5 | 241.6 | 130.9 | - | |

| Variable Force | Static | 131.6 | 226.5 | 130.2 | - |

| Kinetic | 127.8 | 220.6 | 124.5 | - | |

| Self-Ligating | Static | - | - | - | 46.9 |

| Kinetic | - | - | - | 39.2 |

Graph 4: Bar graph representing Static and kinetic frictional forces for various brackets and ligation methods using 0.016" x 0.022" TMA wire.

stainless steel showed the least friction.

It can be inferred from Table 8 that since the P value is < 0.05, there is a significant difference among the brackets with respect to frictional forces. With respect to module the P values is < 0.05 which again indicates a significant difference among the modules in frictional forces. The Pvalue for Interaction effect being < 0.05 indicates that there is a significant interaction effect between brackets and modules when used with 0.019" x 0.025" TMA wire.

Table 8: Static and kinetic frictional forces for various brackets and ligation methods using 0.019" x 0.025" stainless steel wire depicted using Anova test.

| Source of Variation | SS | df | MS | F | P-value | F crit |

| Between Brackets | 189058 | 4 | 47264.55 | 1217.6 | 1.43E-23 | 2.8661 |

| Between Modules | 213860 | 3 | 71286.65 | 1836.44 | 1.42E-24 | 3.0984 |

| Interaction | 84007.1 | 12 | 7000.588 | 180.345 | 1.19E-17 | 2.2776 |

Discussion

As an orthodontist friction inhibits treatment progress and increases forces for retraction of teeth. Finding the best combination of archwires, brackets and ligation methods reduces the overall treatment time and force for retraction.

Variable force brackets provide a variety of patterns of ligation favoring either for sliding mechanics or torque expression. Here ligation pattern for siding mechanics has been used where two wings of the brackets are ligated (0.016" x 0.022" stainless steel in 0.022" slot). Results show

that self-ligating brackets offered least friction followed by variable force brackets. It has previously been reported that self-ligating brackets produce less friction in sliding mechanics as investigated by Vittorio Caccifesta et al.8 The following brackets showed increasing order of friction: Mini twin, Regular stainless steel, ceramic with metal insert brackets and ceramic brackets ( Table 1 )( Graph 1 ).

Graph 1: Bar graph representing Static and kinetic frictional forces for various brackets and ligation methods using 0.016" x 0.022" Stainless steel wire.

Table 2 gives the results of Table 1 data subjected to ANOVA test. Table 2 indicates that there is significant difference among the brackets. There is a significant difference among the modules and also a significant interaction effect between brackets and modules as indicated by the P value.

It is observed that frictional forces of 0.019" x 0.025" were higher when compared with 0.016" x 0.022" Stainless steel archwire due to the increase in dimension which is in accordance with Janet L. Vaughan et al. 9 Self-ligating brackets again had the least friction followed by the variable force brackets. Then this followed by the Mini twin, regular stainless steel, ceramic with metal insert bracket and ceramic brackets. Stainless steel ligatures offer less resistance followed by slick modules and grey modules ( Table 3 ) ( Graph 2 ).

Table 4 gives the results of Table 3 data subjected to ANOVA test. Table 4 indicates that there is a significant difference among the brackets. There is a significant difference among the ligatures and also there is a significant interaction effect between brackets and modules as indicated by the P value.

It is observed that there is a large increase in the frictional forces in 0.016" x 0.022" TMA wire when compared to

stainless steel archwire as also was observed by Clarie Nishio et al. 10 Again self-ligating brackets offered least friction followed by mini twin, variable force brackets, regular stainless steel brackets, ceramic with metal insert brackets and ceramic brackets. Stainless steel ligatures offer less friction than slick modules and grey modules ( Table 5 ) ( Graph 3 ).

Table 6 gives the results of Table 5 data subjected to ANOVA test. Table 6 indicates that there is a significant difference among the brackets. There is a significant difference among the ligatures and also a significant interaction effect between brackets and modules as indicated by the P value.

It is observed that there is an increase in frictional forces in 0.019" x 0.025" TMA wire when compared with 0.016" x 0.022" TMA archwire. Self-ligating brackets offered least friction followed by mini twin, variable force, regular stainless steel, ceramic with metal insert bracket and

ceramic brackets. The stainless steel ligature offered less resistance than slick and grey modules ( Table 7 ) ( Graph 4 ).

Table 8 gives the results of Table 7 data subjected to ANOVA test. ( Table 8 ) indicates there is a significant difference among the brackets. There is a significant difference among the ligatures and also there is significant interaction effect among the brackets and modules as indicated by P value. 5

It is observed that in 0.022" bracket slot the self-ligating bracket offered least friction with stainless steel archwires.

Due to the high cost factor of self-ligating brackets, the next alternative is variable force brackets using stainless steel ligatures which also offered less friction. Manipulation and placement of stainless steel ligature is a limitation when compared to ligation using slick modules as it

consumes more chairside time.

Conclusion

The following conclusions are drawn from the present study:

The effect of ligation in sliding mechanics is an important contributory factor in sliding mechanics.

Wider brackets such as regular Stainless steel brackets offered more friction compared to narrower brackets such as Mini twin.

Stainless steel archwires offered less friction when compared to TMA archwires.

Self-ligating brackets followed by variable force brackets, Mini twin brackets, regular stainless steel brackets, ceramic with metal insert brackets and ceramic brackets offered more friction in increasing order.

Among the commonly employed brackets, mini twin 0.022" slot offered relatively less friction.

The self-ligating brackets offered least friction, while ceramic brackets recorded maximum friction.

Among ligation methods, self-ligation offered least friction followed by stainless steel ligatures, slick modules and grey modules.

When compared to self-ligating brackets, variable force brackets offered a cost effective choice and provide comparable frictional force values when combined with slick modules and stainless steel archwires making this "the preferable choice" in sliding mechanics where frictional forces are in acceptable ranges.

Footnotes

Source of Support: Nil

Conflict of Interest: None

Contributor Information

K Vinay, Department of Orthodontics & Dento-facial Orthopaedics, M R Ambedkar Dental College & Hospital, Bangalore, Karnataka, India.

M J Venkatesh, Department of Orthodontics & Dento-facial Orthopaedics, M R Ambedkar Dental College & Hospital, Bangalore, Karnataka, India.

Rabindra S Nayak, Department of Orthodontics & Dento-facial Orthopaedics, M R Ambedkar Dental College & Hospital, Bangalore, Karnataka, India.

Azam Pasha, Department of Orthodontics & Dento-facial Orthopaedics, M R Ambedkar Dental College & Hospital, Bangalore, Karnataka, India.

M Rajesh, Department of Orthodontics & Dento-facial Orthopaedics, M R Ambedkar Dental College & Hospital, Bangalore, Karnataka, India.

Pradeep Kumar, Department of Orthodontics & Dento-facial Orthopaedics, M R Ambedkar Dental College & Hospital, Bangalore, Karnataka, India.

References

- 1.L Mitchell. An introduction to orthodontics, 2nd ed. Oxford:Oxford University Press. 2001:183–183. [Google Scholar]

- 2.RP Kusy, J Whitley, MJ Prewitt. Comparison of the frictional coefficients for selected archwire bracket slot combinations in the dry and wet states. Angle Orthod. 1991;61:293–310. doi: 10.1043/0003-3219(1991)061<0293:COTFCF>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 3.WR Profitt. Contemporary orthodontics, 2nd edn. St. Louis:CV Mosby. 2000 [Google Scholar]

- 4.M Tselepis, P Brockhurst, VC West. The dynamic frictional resistance between orthodontic brackets and archwires. Am J Orthod Dentofacial Orthop. 1994;106:131–138. doi: 10.1016/s0889-5406(94)70030-3. [DOI] [PubMed] [Google Scholar]

- 5.M Hain, A Dhopatkar, P Rock. The effect of Ligation method on friction in sliding mechanics. Am J Orthod Dentofacial Orthop. 2003;123:416–422. doi: 10.1067/mod.2003.14. [DOI] [PubMed] [Google Scholar]

- 6.HM Omana, RN Moore, MD Bagby. Frictional properties of metals and ceramic brackets. J Clin Orthod. 1992;116:425–432. [PubMed] [Google Scholar]

- 7.K Kuroe, T Tajiri, T Nakayama, C Nagakubo, S Kubota, T Matsuda, I Gakuji. Frictional forces with frictionfree edgewise bracket. J Clin Orthod. 1994;117:347–351. [PubMed] [Google Scholar]

- 8.V Cacciafesta, MF Sfondrini, A Scribante, C Klersy, F Auricchio. Evaluation of friction of conventional and metal insert ceramic brackets in various brackets archwire combinations. Am J Orthod Dentofacial Orthop. 2003;124:403–409. doi: 10.1016/s0889-5406(03)00501-8. [DOI] [PubMed] [Google Scholar]

- 9.JL Vaughan, Jr Duncanson MG, RS Nanda, GF Currier. Relative kinetic frictional forces between sintered Stainless steel brackets and orthodontic wires. Am J Orthod Dentofacial Orthop. 1995;110:20–27. doi: 10.1016/s0889-5406(95)70153-2. [DOI] [PubMed] [Google Scholar]

- 10.C Nishio, AF da Motta, CN Elias, JN Mucha. In vitro evaluation of frictional forces between archwire and ceramic brackets. Am J Orthod Dentofacial Orthop. 2004;125:56–64. doi: 10.1016/j.ajodo.2003.01.005. [DOI] [PubMed] [Google Scholar]